HP StorageWorks 2/64, StorageWorks Core Switch 2/64, StorageWorks SAN Director 2/128 Installation Manual

Page 1

HP StorageWorks

Core Switch 2/64 and

SAN Director 2/128

installation guide

Part number: AA–RVUSC–TE

Third edition: January 2005

Page 2

Legal and notice information

© Copyright 2004–2005 Hewlett-Packard Development Company, L.P.

Hewlett-Packard Company makes no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be liable for errors contained herein or

for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

This document contains proprietary information, which is protected by copyright. No part of this document may be photocopied,

reproduced, or translated into another language without the prior written consent of Hewlett-Packard. The information is provided

“as is” without warranty of any kind and is subject to change without notice. The only warranties for HP products and services are

set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as

constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Compaq Computer Corporation is a wholly-owned subsidiary of Hewlett-Packard Company.

Microsoft,

UNIX is a registered trademark of The Open Group.

Printed in the U.S.A.

Windows, and Windows NT are U.S. registered trademarks of Microsoft Corporation.

Core Switch 2/64 and SAN Director 2/128 installation guide

Page 3

Contents

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Document conventions and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rack stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Getting help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

HP technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

HP storage web site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HP authorized reseller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contents

1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Core Switch 2/64 and SAN Director 2/128 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Upgrading ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Key features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hardware components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

High availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optional management features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Interoperability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Network manageability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Management summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Managing the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Optional hardware kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Installing and configuring the switch . . . . . . . . . . . . . . . . . . . . . . 25

Unpacking and verifying carton contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Selecting an operating location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cooling requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing the switch as a stand-alone unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Removing the chassis door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing the switch on a flat surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing the switch in a rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pre-installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Items required for installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Important rack mount guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Core Switch 2/64 and SAN Director 2/128 installation guide 3

Page 4

Installing the switch in specified racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Attaching the rack mount shelf brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Attaching the retainer nuts—for rails with square holes . . . . . . . . . . . . . . . . . . . . . . . . 37

Attaching the clip nuts—for rails with round holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Attaching the upper rack mount bracket assemblies to the chassis. . . . . . . . . . . . . . . . . 38

Finalizing the rack mount procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Sliding the switch into the rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Securing the chassis to the rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Reinstalling the chassis door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Powering on the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Establishing a serial connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Manage cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

PID format summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Mixed fabric environment with different switch platforms . . . . . . . . . . . . . . . . . . . . . . . . . 51

Configuration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Core Switch 2/64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

SAN Director 2/128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Initial configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Core Switch 2/64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

SAN Director 2/128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Setting up a configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Configure IP addresses for CP cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Configure IP address for the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Establish an Ethernet connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Customize a switch name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Specify status policies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Set the Domain ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Connect to the fabric and configure fabric parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Enable software licenses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Back up the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3 Operating the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Interpreting LED activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

16-port cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

CP cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Blower assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

WWN card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Diagnostics and troubleshooting overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Obtaining chassis and component status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Interpreting POST and boot results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

POST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Boot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Troubleshooting the switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Contents4

Page 5

4 Installing FRUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Replacing the chassis door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Replacing the cable management tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Replacing the cable guides (pillars). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Replacing a 16-port card and filler panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Preliminary steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Replacing a 16-port card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Removing the existing16-port card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Removing a filler panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Installing a 16-port card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Installing a filler panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replacing a CP card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Identifying a failed CP Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Recording critical switch information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Removing a CP card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Installing a CP card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Verifying operation of the new CP card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Replacing a power supply and filler panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Replacing a power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Replacing a blower assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

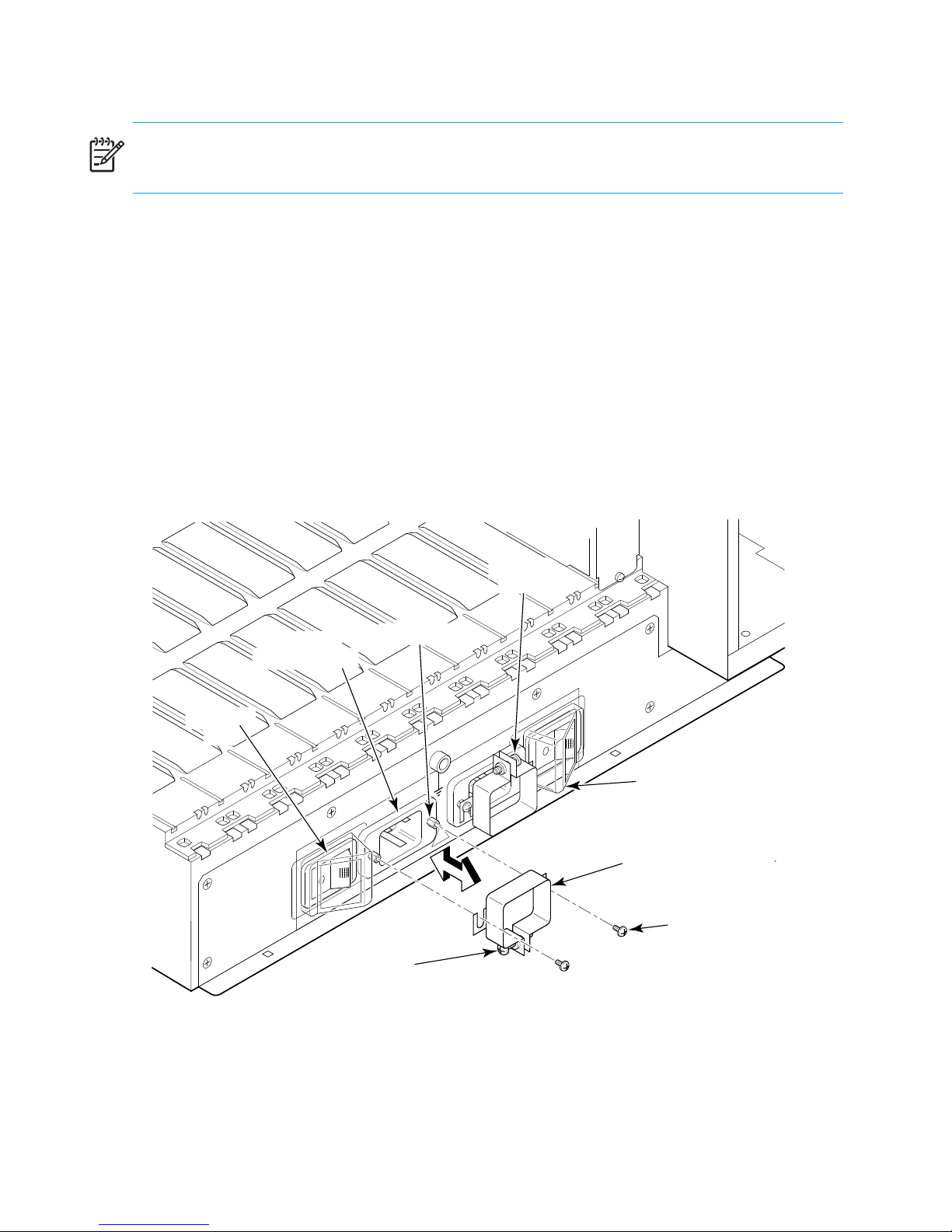

Replacing the WWN bezel and card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Identifying a failed WWN card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Replacing a WWN card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Installing a WWN card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Replacing the WWN bezel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

5 Setting up and installing modems . . . . . . . . . . . . . . . . . . . . . . . 123

Using high-availability connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Connecting modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Setting up a remote modem system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Verifying the modem connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

6 Running routine operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Backing up system configuration settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Restoring the system configuration settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Upgrading firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Verifying optional software licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Enabling licensed features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

A Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

System architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

System size and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

System FRU weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Facility requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Power cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Core Switch 2/64 and SAN Director 2/128 installation guide 5

Page 6

Fibre Channel port specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

CP card specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Memory specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Battery specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Terminal serial port specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Modem serial port specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

B Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Grounding methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

C Regulatory compliance notices . . . . . . . . . . . . . . . . . . . . . . . . . 149

FCC EMC statement (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

EMC statement (Canada) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

EMC statement (European Union) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Germany noise declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

VCCI EMC statement (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Power cord statement (Japan). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

RRL EMC statement (Korea) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Battery replacement notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figures

1 Core Switch 2/64 and SAN Director 2/128 (port side). . . . . . . . . . . . . . . . . . . . . . . . . 16

2 Core Switch 2/64 and SAN Director 2/128 (nonport side) . . . . . . . . . . . . . . . . . . . . . . 17

3 Carton contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Sequence for detaching the chassis door from the hinges . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Installing the left and right rack mount shelf brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Installing the retainer nuts on the rails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7 Attaching the left and right flat upper rack mount brackets . . . . . . . . . . . . . . . . . . . . . . . 39

8 Attaching L-shaped brackets to rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9 Attaching the upper rack mount bracket to the L-shaped brackets. . . . . . . . . . . . . . . . . . . 41

10 Securing the chassis port side to rack rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11 ON/OFF switch for a 16-port card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

12 AC panel and power cord retainers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

13 Cable guide (pillar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

14 Effective cable management (Director 2/128 shown). . . . . . . . . . . . . . . . . . . . . . . . . . . 50

15 Front of 16-port card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

16 Front of CP card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

17 Power supply LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

18 Blower assembly LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

19 WWN bezel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

20 Upper door hinge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Contents6

Page 7

21 Cable management tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

22 16-port card removal and replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

23 Removing and replacing a filler panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

24 Card guides inside each card slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

25 CP card removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

26 Power supply removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

27 Blower assembly removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

28 WWN bezel and card removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

29 Two modems attached for high availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

30 Remote modem setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Tables

1 Document conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Management options for Core Switch 2/64 and SAN Director 2/128 . . . . . . . . . . . . . . 21

3 Core Switch 2/64 and SAN Director 2/128 orderable hardware. . . . . . . . . . . . . . . . . . 22

4 Carton contents checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 Core Switch 2/64 default parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6 Director 2/128 default parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7 16-port card LED patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8 CP card LED patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9 Power supply LED patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10 Blower assembly LED patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11 Data stored on the WWN card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12 Messages that can indicate WWN card failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

13 WWN bezel LED patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

14 Environmental status and maintenance commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

15 Troubleshooting the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

16 Data stored on the WWN card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

17 Messages that might indicate a WWN card failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

18 Terminal emulator configuration settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

19 Core Switch 2/64 and SAN Director 2/128 system specifications . . . . . . . . . . . . . . . . 135

20 System size and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

21 FRU weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

22 Power specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

23 Power cord types (international). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

24 Terminal serial port pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

25 Modem serial port pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Core Switch 2/64 and SAN Director 2/128 installation guide 7

Page 8

Contents8

Page 9

About this guide

This installation guide provides information to help you:

• Set up and configure the HP StorageWorks Core Switch 2/64 (Core Switch 2/64) and HP

StorageWorks SAN Director 2/128 (SAN Director 2/128)

• Maintain and operate the switches

• Contact technical support for additional assistance

Intended audience

This guide is intended for system administrators and technicians who are experienced with the

following:

• HP StorageWorks Fibre Channel Storage Area Network (SAN) switches

• Fabric Operating System

Related documentation

Documentation, including white papers and best practices documents, is available on the HP

website:

http://www.hp.com/country/us/eng/prodserv/storage.html

To access current Fabric OS related documents:

1. Locate the Networked storage section of the web page.

2. Under Networked storage, go to the By type subsection.

3. Click SAN infrastructure.

The SAN infrastructure page displays.

4. Locate the Fibre Channel Switches section.

5. Locate the B-Series Fabric subsection, and then go to the Enterprise Class subsection.

6. To access version documents (such as this document), select SAN Director 2/128 & SAN

Director 2/128 power pack or Core Switch 2/64 & Core Switch 2/64 power pack.

The switch overview page displays.

7. Go to the Product Information section, located on the right side of the web page.

Core Switch 2/64 and SAN Director 2/128 installation guide 9

Page 10

8. Click Technical documents.

9. Follow the onscreen instructions to download the applicable documents.

Document conventions and symbols

Table 1 Document conventions

Convention Element

Medium blue text: Figure 1 Cross-reference links

Bold Menu items, buttons, keys, tabs, and user input in a graphical

interface

Italics Text emphasis

Monospace font Command-line user input, commands, code, device instances,

file and directory names, and system responses (output and

messages)

Monospace, italic font Command-line and code variables

Medium blue, underlined sans serif

font text (http://www.hp.com

)

Web site addresses

WARNING! Indicates that failure to follow directions could result in bodily harm or death.

CAUTION: Indicates that failure to follow directions could result in damage to equipment or

data.

IMPORTANT: Provides clarifying information or specific instructions.

!

NOTE: Provides additional information.

About this guide10

Page 11

TIP: Provides helpful hints and shortcuts.

Rack stability

WARNING! To reduce the risk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that the full weight of the rack rests on the leveling jacks.

• Install stabilizing feet on the rack.

• In multiple-rack installations, secure racks together.

• Extend only one rack component at a time. Racks may become unstable if more than one

component is extended.

Getting help

If you still have a question after reading this guide, contact an HP authorized service provider

or access our web site at

HP technical support

Telephone numbers for worldwide technical support are listed on the following HP web site:

http://www.hp.com/support/

NOTE: For continuous quality improvement, calls may be recorded or monitored.

Be sure to have the following information available before calling:

• Technical support registration number (if applicable)

• Product serial numbers

• Product model names and numbers

• Applicable error messages

http://www.hp.com

.

. From this web site, select the country of origin.

Core Switch 2/64 and SAN Director 2/128 installation guide 11

Page 12

• Operating system type and revision level

• Detailed, specific questions

HP storage web site

The HP storage web site has the latest information on this product, as well as the latest drivers:

http://www.hp.com/country/us/eng/prodserv/storage.html

appropriate product or solution.

HP authorized reseller

For the name of your nearest HP authorized reseller:

• In the United States, call 1-800-345-1518

• In Canada, call 1-800-263-5868

. From this web site, select the

• Elsewhere, see the HP web site for locations and telephone numbers:

http://www.hp.com

.

About this guide12

Page 13

1Overview

This chapter provides the following topics:

• Core Switch 2/64 and SAN Director 2/128 models, page 13

• Upgrading ports, page 14

• Key features, page 14

• Hardware components, page 15

• High availability, page 18

• Reliability, page 18

• Serviceability, page 19

• Management summary, page 20

• Optional hardware kits, page 22

Core Switch 2/64 and SAN Director 2/128

models

The Core Switch 2/64 and SAN Director 2/128 include the following configurations:

• Basic models— Ship with 32 ports installed and include Advanced Zoning and Advanced

Web Tools as standard software components.

• Power Pack models—Ship with 32 ports installed and include Zoning and Advanced Web

Tools as standard software components. These models also include licenses for all optional

management tools:

•Fabric Watch

• Advanced Performance Monitoring

•ISL Trunking

• Extended Fabric

•Remote Switch

13Core Switch 2/64 and SAN Director 2/128 installation guide

Page 14

Upgrading ports

The Core Switch 2/64 and SAN Director 2/128 are available with 32 ports (0 through 31)

installed and activated. To install additional ports, contact your HP representative to purchase

a 16-port Upgrade module. Then, see the following sections for instructions on installing the

16-port card module:

• Removing a filler panel, page 94

• Installing a 16-port card, page 95.

Key features

The Core Switch 2/64 and SAN Director 2/128 represent the next generation of advanced

Fibre Channel Director models used to interconnect storage devices, hosts, and servers

intelligently in a Storage Area Network (SAN). HP StorageWorks director-class switches deliver

performance, scalability, flexibility, functionality, reliability, and availability.

Key features include the following:

• 64 ports in a single chassis for the Core Switch 2/64.

• 128 ports in a single chassis for the SAN Director 2/128.

• High-availability platform for mission-critical SAN-designed applications.

• Dual, redundant Control Processors (CP) provide high availability and enable nondisruptive

software upgrades.

• Nonblocking architecture enables all ports to operate at full 2 Gb speed simultaneously.

• Universal ports self-configure as E-ports, F-ports, or FL-ports.

• Small form-factor pluggable (SFP) optical transceivers support any combination of short

wavelength (SWL), long wavelength (LWL), and extended long wavelength (ELWL) optical

media on a single switch module (the 16-port card).

• Forward and backward compatibility with HP StorageWorks switches.

• High availability redundant design, extensive diagnostics, and system monitoring

capabilities integrated with Fabric OS management tools deliver unprecedented reliability,

availability, and serviceability (RAS).

• Support for 1- and 2-Gb/s autosensing Fibre Channel ports (trunking technology groups up

to four ports together to create high-performance 8 Gb/s ISL trunks between switches).

Overview14

Page 15

Hardware components

The Core Switch 2/64 and SAN Director 2/128 feature a modular and scalable

mechanical construction that allows a wide range of flexibility in switch installation, fabric

design, and maintenance.

The modular chassis consists of the following:

• Two slots for control processor (CP) cards (slots 5 and 6):

• A single active CP card can control all ports in the chassis.

• The standby CP card assumes control of the switch if the active CP fails.

• Modular hot-swappable field replaceable units (FRUs):

• Up to eight I/O cards

•Two CP cards

• Small form-factor pluggable (SFP) optical transceivers

• Three blower assemblies

• Four power supplies

• Cables

• Support for mounting the chassis with the port side facing the air-intake aisle if adequate

cooling is provided

• Easy cable management using a cable management tray and cable guides (pillars)

• Constant intake and FAN temperature monitoring

• World Wide Name (WWN) card on the nonport side, to maintain chassis-specific

information such as WWNs, IP addresses, and summary status information of each card

(16-port and CP) and power supply through LEDs

Figure 1 shows the port side of the Core Switch 2/64 and the SAN Director 2/128.

15Core Switch 2/64 and SAN Director 2/128 installation guide

Page 16

Exhaust

Vent

1 2 3 4 5 6 7 8 9 10

Power

Supply

Filler

Panel

ON/OFF Switch

(in "ON" position)

ON/OFF Switch

(in "OFF" position)

CP Card

16-Port

Card

Grounding

Strap

Connector

scale:

3/16" = 1"

AC Power

Switch

!

15

15

d

d

14

14

c

c

13

13

b

b

12

12

a

a

11

11

d

d

10

10

c

c

9

9

b

b

8

8

a

a

7

7

d

d

6

6

c

c

5

5

b

b

4

4

a

a

3

3

d

d

2

2

c

c

1

1

b

b

0

0

a

a

15

15

d

d

14

14

c

c

13

13

b

b

12

12

a

a

11

11

d

d

10

10

c

c

9

9

b

b

8

8

a

a

7

7

d

d

6

6

c

c

5

5

b

b

4

4

a

a

3

3

d

d

2

2

c

c

1

1

b

b

0

0

a

a

POWER SUPPLY 1&3 POWER SUPPLY 2&4

200-240 VAC 12A 50-60 Hz

!

!

IOIOIRS -232

IOIOIRS -232

Link

Link

10/100Mb/s

10/100Mb/s

ActiveCP

ActiveCP

200-240 VAC 12A 50-60 Hz

!

!

!

AC Power

Connector

!

!

15

15

d

14

14

c

13

13

b

12

12

a

11

11

d

10

10

c

9

9

b

8

8

a

7

7

d

6

6

c

5

5

b

4

4

a

3

3

d

2

2

c

1

1

b

0

0

a

AC Power

Connector

d

c

b

a

d

c

b

a

d

c

b

a

d

c

b

a

AC Power

(for Power Supply1&3) (for Power Supply2&4)

POWER SUPPLY 4

POWER SUPPLY 3

!

!

POWER SUPPLY 2

!

!

POWER SUPPLY 1

Switch

Card

Slot

Filler

Panel

Power

Supply

#2

Power

Supply

#1

Cable

Management

Tray

2.001

Figure 1 Core Switch 2/64 and SAN Director 2/128 (port side)

NOTE: Card slots are numbered 1 through 10 (left to right). Slots 1–4 and 7–10

accommodate the 16-port cards, and slots 5-6 accommodate the CP cards.

Overview16

Page 17

Figure 2 shows the nonport side of the Core Switch 2/64 and SAN Director 2/128.

Port Card and

CP Card LEDs

WWN

Bezel

Power Supply

LEDs

10 pwr4

987654321

pwr3

pwr2

pwr1

Blower

Power

LED

Blower

Fault

LED

Blower

Handle

Blower

Assembly

#3

scale:

Blower

3/16" = 1"

Assembly #1

Figure 2 Core Switch 2/64 and SAN Director 2/128 (nonport side)

Blower

Assembly #2

2.006

17Core Switch 2/64 and SAN Director 2/128 installation guide

Page 18

High availability

The following features contribute to the Core Switch 2/64 and SAN Director 2/128

high-availability design:

• Redundant, hot-swappable components

• Redundant power and cooling subsystems

• Enhanced data integrity on all data paths

• Fabric Shortest Path First (FSPF) rerouting around failed links

• Integration with SNMP managers

• Automatic control processor failover

• Nondisruptive hot software code loads and activation

• Easy configuration, save, and restore

The high-availability software architecture of the Core Switch 2/64 and the SAN

Director 2/128 provides a common framework for all applications that reside on the system,

allowing global and local states to be maintained enough to manage any component failure.

High-availability elements consist of the High Availability Manager, the heartbeat, the

fault/health framework, the replicated database, initialization, and software upgrade.

The High Availability Manager controls access to the standby control processor, facilitates

software upgrades, prevents extraneous switchover activity, closes and flushes streams as

needed, provides flow control and message buffering, and supports a centralized active and

standby state.

Reliability

The Core Switch 2/64 and the SAN Director 2/128 use the following error detection and

correction mechanisms to ensure the reliability of all data inside the chassis:

• Power-on self test (POST)

• Error Detection and Fault Isolation (EDFI), such as cyclic redundancy checking (CRC), parity

checking, checksum, and illegal address checking

Overview18

Page 19

• Dual control processors that enable hot, nondisruptive fast firmware upgrades

Each control processor contains two serial ports and one Ethernet port. Offline control

processor diagnostics and remote diagnostics simplify troubleshooting. The standby control

processor continuously runs diagnostics to ensure it is operational, should a failover be

necessary.

2

• I

C monitoring and control, used between Integrated Circuits (IC) to monitor how they are

working

Serviceability

The Core Switch 2/64 and the SAN Director 2/128 provide the following features to enhance

and ensure serviceability:

• Modular design with hot-swappable components

• Redundant flash memory that stores two firmware images per control processor

• Extensive diagnostics and status reporting, along with a serial port to support an external,

country-specific modem for remote diagnostics and status monitoring

• Nonvolatile random-access memory (NVRAM), containing the HP serial number,

manufacturer’s serial number, revision information, and part number information

• Background health-check daemon

• Memory scrubber, self test, and bus ping to determine if a bus is not functioning

• Watchdog timers

• Status LEDs

• Predictive diagnostics analysis through Fabric Watch

• SNMP integration with higher-layer managers

Optional management features

Refer to the HP StorageWorks release notes for the Fabric OS running on your switch to get a

complete list of management and optional software features enabled on the switch.

Interoperability

Fabric OS v4.x interoperates with HP StorageWorks switches running Fabric OS version 2.6 or

later.

19Core Switch 2/64 and SAN Director 2/128 installation guide

Page 20

Security

Secure telnet access is available using Secure Shell (SSH), a network security protocol for

secure remote login and other secure network services over an insecure network.

Advanced Web Tools management is available via a secure browser using Secure Sockets

Layer (SSL). The SSL security protocol provides data encryption, server authentication, message

integrity, and optional client authentication for a TCP/IP connection. Because SSL is built into

all major browsers and web servers, installing a digital certificate turns on the SSL capabilities.

Network manageability

The Core Switch 2/64 and SAN Director 2/128 are each managed as a single element and

appear as a single element to a Network Management System (NMS). The switch responds to

its own IP address and appears as a separate entity to the telnet protocol and SNMP.

The management interfaces include blade assemblies as intermediate components between

switches and ports. In addition, all management interfaces, such as telnet, Advanced Web

Tools, the Fabric Access Layer API, and Management Server, support a port N within blade M

naming scheme.

When SNMP devices send SNMP messages to a management console running SAN

management software, the information is stored in a management information base (MIB).

Fabric OS v4.x supports the latest Fibre Alliance Fibre Channel Management (FCMGMT) and

Storage Management Initiative (SMI) MIBs, which allow common information necessary for

management software to provide information to a SAN administrator.

NOTE: For additional MIB information, refer to the HP StorageWorks MIB reference guide for

the Fabric OS version running on your switch.

Management summary

The Core Switch 2/64 and the SAN Director 2/128 can be managed in-band using Fibre

Channel protocol or out-of-band by connecting to the Ethernet port. The management functions

allow you to monitor fabric topology, port status, physical status, and performance statistics.

The Core Switch 2/64 and the SAN Director 2/128 are compatible with the following

management interfaces:

• Command Line Interface (CLI) through a telnet connection

• Advanced Web Tools, an integrated GUI

• SNMP applications

Overview20

Page 21

Managing the switch

You can use the management functions built into the Core Switch 2/64 and the SAN

Director 2/128 to monitor the fabric topology, port status, physical status, and other

information to aid in performance analysis and system debugging.

You can manage the Core Switch 2/64 and the SAN Director 2/128 using any of the

management options listed in Table 2. For information about inband support, contact the

switch provider.

The Core Switch 2/64 and the SAN Director 2/128 include the Fabric OS and are

compatible with HP StorageWorks 1-Gb and 2-Gb SAN switches.

NOTE: For information about upgrading the Fabric OS, refer to the HP StorageWorks

procedures user guide for the Fabric OS version you want to use on your switch.

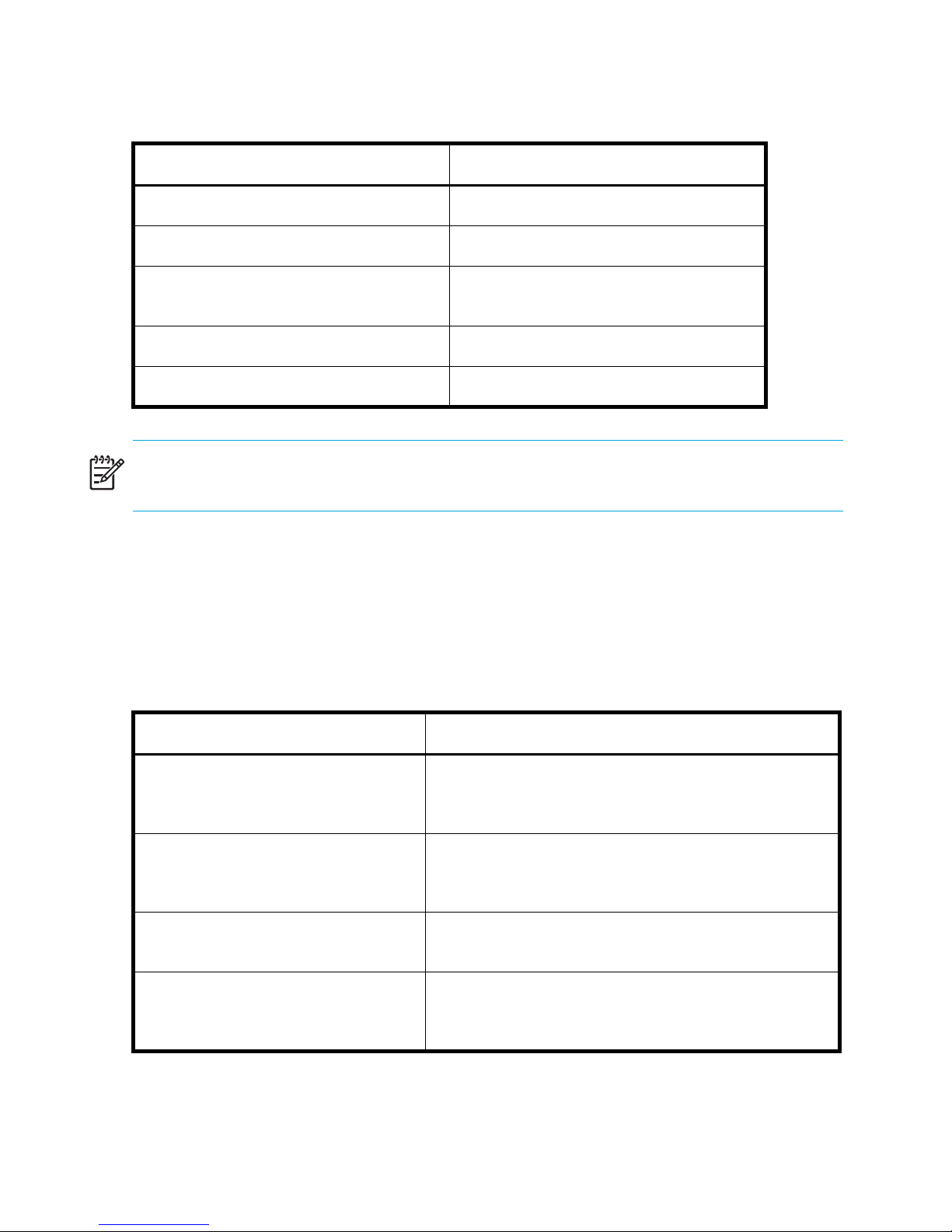

Table 2 Management options for Core Switch 2/64 and SAN Director 2/128

Management tool Out-of-band

.

support

Command line interface

For Ethernet, up to two admin sessions and four user sessions at the same

time. For details, refer to the HP StorageWorks procedures user guide

the HP StorageWorks command reference guide for the Fabric OS version

running on your switch. Sectelnet and Secure Shell clients are both

supported.

Fabric Manager

Fabric Manager v4.4.x or later required. For information refer to the HP

StorageWorks Fabric Manager user guide.

Advanced Web Tools

For information refer to the HP StorageWorks Advanced Web Tools user

guide for the Fabric OS version running on your switch.

Standard SNMP applications

For information refer to the HP StorageWorks MIB reference guide for the

Fabric OS version running on your switch.

Management server

and

Ethernet or serial

connection

Ethernet

Ethernet

Ethernet

Ethernet

For information about MS, refer to the

guide

and the

OS version running on your switch.

HP StorageWorks command reference guide

HP StorageWorks procedures user

for the Fabric

21Core Switch 2/64 and SAN Director 2/128 installation guide

Page 22

NOTE: To ensure efficiency and interoperability, HP recommends upgrading switches to the

latest firmware version. Go to

http://www .hp.com

Optional hardware kits

Table 3 lists the Core Switch 2/64 and SAN Director 2/128 optional hardware kits.

Table 3 Core Switch 2/64 and SAN Director 2/128 orderable hardware

Accessory Part number

Short wavelength SFP A6515A* or 300834-B21**

Long wavelength SFP, 10 km A6516A* or 300835-B21**

Long wavelength SFP, 35 km 300386-B21**

2m LC-to -LC Fibre Channel (fc) cable C7524A*

2m LC-to-LC multi-mode fc cable 221692-B21**

to obtain the latest firmware.

16m LC- to-LC fc cable C7525A*

5m LC-to-LC multi-mode fc cable 221692-B22**

50m LC-to-LC fc cable C7526A*

15m LC-to-LC multi-mode fc cable 221692-B23**

200m LC-to-LC fc cable C7527A*

30m LC-to-LC multi-mode fc cable 221692-B26**

50m LC-to-LC multi-mode fc cable 221692-B27**

2m LC-to-SC fc cable C7529A*

2m LC-to-SC multi-mode fc cable 221691-B21**

16m LC-to-SC fc cable C7530A*

5m LC-to-SC multi-mode fc cable 221691-B21**

15m LC-to-SC multi-mode fc cable 221691-B23**

Overview22

Page 23

Table 3 Core Switch 2/64 and SAN Director 2/128 orderable hardware (continued)

Accessory Part number

30m LC-to-SC multi-mode fc cable 221691-B26**

50m LC-to-SC multi-mode fc cable 221691-B27**

SC female to SC female adapter kit C7534A*

2m LC male to SC male adapter kit C7540A*

* premerger HP part number

** premerger Compaq part number

23Core Switch 2/64 and SAN Director 2/128 installation guide

Page 24

Overview24

Page 25

2 Installing and configuring the switch

This chapter provides the following topics:

• Unpacking and verifying carton contents, page 26

• Installation overview, page 28

• Powering on the switch, page 43

• Establishing a serial connection, page 45

• Manage cables, page 47

• PID format summary, page 51

• Configuration overview, page 52

• Initial configuration parameters, page 53

• Setting up a configuration, page 55

25Core Switch 2/64 and SAN Director 2/128 installation guide

Page 26

Unpacking and verifying carton contents

Unpack and verify Core Switch 2/64 and SAN Director 2/128 shipping carton contents. See

Figure 3 and Table 4.

1

2

4

3

Figure 3 Carton contents

NOTE: SFP transceivers can be ordered separately from your authorized HP representative.

The Core Switch 2/64 and SAN Director 2/128 support SWL, LWL, and ELWL transceivers.

See Table 3, ”Core Switch 2/64 and SAN Director 2/128 orderable hardware” on page 22

for information about optional hardware kits.

Installing and configuring the switch26

SHR-2506B

Page 27

Table 4 Carton contents checklist

Item Summary

1

2

Chassis, includes the following:

• Two CP cards

• Two 16-port cards

• Two power supplies

• Three blower assemblies

• One WWN card

• One cable management tray

Accessory Kit, includes the following

• One HP StorageWorks software CD; one set of HP StorageWorks product

documentation, including the Core Switch 2/64 and SAN Director 2/128 installation

guide (this document), Safety Guides, and User License and Warranty

• ESD grounding strap, sixteen cable guides, and two power cord retainers

• RS-232 serial cable with an RJ-45 adapter

• Two AC power cords, appropriate to country where switch is installed

In addition, there are two PDU power cords and two pigtail power cords (not shown).

(See ”Power requirements” on page 29 for information about PDUs.)

27Core Switch 2/64 and SAN Director 2/128 installation guide

Page 28

Table 4 Carton contents checklist (continued)

Item Summary

3

4

14U Rack Mount Kit Rails, includes the following:

• Left rack mount shelf bracket, (1); Right rack mount shelf bracket (1)

• Left upper rack mount bracket assembly includes: Left upper rack mount bracket (flat);

left upper rack mount bracket (L-shaped); screw (torque to 32 inch-pounds)

• Right upper rack mount bracket assembly includes: right upper rack mount bracket

(flat); right upper rack mount bracket (L-shaped); screw (torque to 32 inch-pounds)

• M5 Tinnermans (0590-2318) and M5 Torx screws (0515-0671) are required rack

mount kit hardware.

14U Rack Mount Kit hardware:

• #10-32 x 5/16 Phillips flathead screws (8); #10-32 x 5/16 Phillips panhead screws

with washers (4)

• For use with an HP 42U rack (or racks with square holes): #10-32 x 5/16 retainer nuts;

#1/4-20 x 0.500 Phillips panhead screws with glue (16); 0.375-inch square washers

(16)

• For use with rack with round holes: #10-32 clip nut (package of 20, only 4 required);

#1/4-20 x 1/2 inch Phillips panhead screws with lockhead washers (16)

Installation overview

You can install the Core Switch 2/64 or SAN Director2/128 in one of the following ways:

• As a stand-alone unit on a stable table or lab workbench

• In a rack using the 14U Rack Mount Kit supplied with the switch

Selecting an operating location

Verify that the switch location meets the following requirements:

• Adequate supply circuit, line fusing, and wire size, as specified by the electrical rating on

the switch nameplate.

• Air flow of at least 350 cubic feet per minute, available in the immediate vicinity of the

Core Switch 2/64 or SAN Director 2/128.

• If you are installing the switch in an HP rack:

Installing and configuring the switch28

Page 29

• All equipment installed in the rack should have a reliable branch circuit ground

connection, and should not rely on a connection to a branch circuit, such as a power

strip.

• The rack should be balanced, and the installed equipment should be within the rack’s

weight limits. Ensure that the rack is mechanically secured to insure stability in the event

of an earthquake.

Cooling requirements

Install the switch so that air intake and exhaust for all components in the rack is flowing in the

same direction.

NOTE: To ensure adequate cooling, install the chassis with the port side facing the aisle into

which exhaust air is released (usually called the service aisle). This prevents the fans from

pulling in heated exhaust air.

Power requirements

Two AC power cords connect to the switch. The AC power source must meet these

requirements:

NOTE: Installing each power cord using two separate sources ensures power supply

redundancy.

• 200 to 240 VAC, 50–60 Hertz

• Protected by a circuit breaker in accordance with local electrical codes

• Supply circuit, line fusing, and wire size that are adequate according to the electrical rating

on the chassis nameplate

• Grounded AC outlets installed by a licensed electrician and compatible with the power

cords

The switch includes a universal power supply capable of functioning worldwide without voltage

jumpers or switches. The power supply is auto ranging in terms of accommodating input

voltages and line frequencies.

HP recommends connecting two optional Power Distribution Units (PDUs) to the switch for

power redundancy. The recommended PDU is E7671A. HP recommends that you do not

connect the switch to the wall, because it would require two dedicated wall outlets. Using the

PDU, you can connect more devices to a power source.

29Core Switch 2/64 and SAN Director 2/128 installation guide

Page 30

Two jumper cables (C19-C20) are provided to connect from the switch to the PDU. The

recommended power cords to connect from the PDU to the wall are E7803A, E7805A,

E7806A, E7808A, and E7809A.

Installing the switch as a stand-alone unit

The following items are required for this setup:

• Core Switch 2/64 or SAN Director 2/128

• AC power cords and cables supplied with the switch

Removing the chassis door

CAUTION: You must remove the chassis door before lifting the chassis off the pallet.

(See Figure 4 for an illustration of the complete chassis door removal sequence.)

1. Open the door to a 90° angle.

2. Push the spring-loaded lever on the upper hinge up and into the notch in the hinge.

3. Push the spring-loaded lever on the lower hinge down and into the notch in the hinge, while

supporting the door to prevent it from falling.

1 2 3

SHR-2508A

Figure 4 Sequence for detaching the chassis door from the hinges

Installing and configuring the switch30

Page 31

NOTE: Put the chassis door aside. You will need to reinstall it after moving the switch off the

pallet.

4. Position the pallet so that the bottom of the chassis is level with the installation surface.

5. If the chassis is on a pallet jack or lift, stabilize the pallet jack or lift to prevent it from

moving during the transfer.

WARNING! A fully populated chassis weighs approximately 250 lbs (113 kg) and requires a

minimum of two people to safely slide it from one surface to another.

Installing the switch on a flat surface

Use these steps to install the switch on a flat surface.

NOTE: The switch must be placed on a stable, flat surface, with the blower side of the chassis

having access to cool air. Orient the switch so that the port side faces the service aisle.

1. Remove the switch chassis door, if you have not already done so. See ”Removing the

chassis door” on page 30.

2. Place the switch on a flat, sturdy surface like a table or lab bench.

3. Connect the two power cables to the power supply inlets on the switch.

NOTE: HP recommends powering the switch using two separate power sources to ensure

redundancy.

4. Connect the two power cables to corresponding power outlets. Make sure that the power

cables are routed so that they are not exposed to stress.

5. Turn on power to the switch.

The switch automatically runs a Power On Self Test (POST).

NOTE: Do not connect the switch to the network until the IP address is set correctly.

6. Reinstall the chassis door as described in the section ”Reinstalling the chassis door” on

page 42.

31Core Switch 2/64 and SAN Director 2/128 installation guide

Page 32

Installing the switch in a rack

These sections contain specific information about installing the Core Switch 2/64 or the SAN

Director 2/128 in an HP 10,000 series or HP System/e rack.

WARNING! For safety reasons, when installing this product in an equipment rack, you must

consider rack stability against tipping. Please refer to the user manual provided with the

equipment rack to determine rack stability; the manual is available through the HP web site:

http://www.hp.com/racksolutions/prodinfo/racks/index.html

If the necessary stability is not achieved through the placement of additional equipment or

ballast, the equipment rack must be anchored to the building structure before operation.

Pre-installation checklist

Review the following checklist before installing the switch.

• Prepare a site plan.

• Verify that required technical personnel (two technicians) are available and scheduled for

the installation.

.

• Obtain the required fiber-optic cables (multimode or single-mode). Verify cable length and

required connectors.

• If applicable, obtain the necessary remote workstations or Simple Network Management

Protocol (SNMP) workstations. Workstations are customer-supplied and connected through

a corporate or dedicated LAN.

• Verify that the front panel air temperature does not exceed 40°C (104°F) during operation.

• Verify that all equipment installed in the rack has a reliable branch circuit ground

connection, and does not rely on a connection to a branch circuit, such as a power strip.

• Verify that the rack is balanced.

• Check that the rack is mechanically secured to insure stability in the event of an

earthquake.

Installing and configuring the switch32

Page 33

Items required for installation

Locate the following items before beginning the installation procedure:

• Lift device—A fully populated switch weighs approximately 250 lbs. A minimum of two

people and a hydraulic or assisted lift are required to move the switch from the pallet to its

operating location.

• Two power outlets—Identify one power outlet for each of the two power cords. Installing

the power cords at two separate sources ensures power supply redundancy.

• Torque driver—Required to secure the 14U Rack Mount Kit hardware to the rack rails.

• Fiber optic protective plugs—For safety and port transceiver protection, fiber optic

protective plugs must be inserted in all Core Switch 2/64 and SAN Director 2/128 ports

without Fiber optic cables attached. The switch ships with protective plugs installed in all

ports.

• Standard flat-tip and cross-tip Phillips screwdrivers—Required to remove, replace, adjust or

tighten various FRUs, chassis, or rack components.

• Electrostatic discharge (ESD) grounding strap—Required when working in and around the

switch card cage. Use the ESD strap supplied with the switch.

• Maintenance terminal (desktop or notebook computer)—Required to configure switch

network addresses and acquire event log information through the serial port. Computer

requirements include:

•Microsoft

Millennium Edition

• RS-232 serial communication software (for example, ProComm Plus or HyperTerminal)

• HP-supported racks—HP 10,000 series and HP System/e rack.

® Windows® 98, Windows NT® 4.0, Windows 2000, or Windows

® operating system installed

33Core Switch 2/64 and SAN Director 2/128 installation guide

Page 34

Important rack mount guidelines

Review the following rack mount guidelines before proceeding with the installation.

WARNING! A fully populated Core Switch 2/64 or SAN Director 2/128 weighs

approximately 250 lbs and requires a minimum of two people and a hydraulic or assisted lift

to install it.

Before installing, verify that the additional weight of the chassis does not exceed the rack’s

weight limits or unbalance the rack, especially when some of the cards or power supplies are

partially extended out of the chassis.

• Check that a minimum distance of 28.25 inches is between the front and back rails.

• Verify that the additional weight of the chassis does not exceed the rack’s weight limits.

• Check that all equipment installed in the rack is grounded through a reliable branch circuit

connection. Do not rely on a secondary connection to a branch circuit, such as a power

strip.

• Verify that the rack has enough space. The Core Switch 2/64 and SAN Director 2/128

are 14U, or 24.11 inches high.

• Verify that the rack is stable.

• M5 Tinnermans (0590-2318) and M5 Torx screws (0515-0671) are required pieces of

rack mount kit hardware.

• Verify that all other equipment installed in the rack is connected to a reliable ground

connection; do not rely on connections to a branch circuit, such as a power strip.

• Plan for cable management before installing the chassis. Cables can be managed in a

variety of ways, such as by routing cables below the chassis, to either side of the chassis, or

through cable channels on the sides of the rack.

• Verify that the switch has access to a minimum airflow of 350 cubic feet per minute.

• Ensure adequate cooling by installing the chassis with the port side facing the aisle into

which exhaust air is released (usually called the service aisle). This prevents the fans from

pulling in heated exhaust air.

Installing and configuring the switch34

Page 35

Installing the switch in specified racks

Use the following procedure to install the Core Switch 2/64 or the SAN Director 2/128 in an

HP 10,000 series or HP System/e rack using the 14U Rack Mount Kit supplied with the switch.

Allow approximately 45 minutes to complete this procedure.

NOTE: These instructions describe how to install the switch in the bottom area of the rack

(section closest to the floor). You may need to orient 14U Rack Mount Kit hardware based on

your particular rack’s configuration.

Attaching the rack mount shelf brackets

Use these steps to install the rack mount shelf brackets.

CAUTION: You can install up to two Core Switch 2/64 or SAN Director 2/128 switches. HP

supports up to two switches in the racks specified for each switch.

1. If you have not already done so, remove the chassis door. See ”Removing the chassis door”

on page 30.

2. Locate the left and right rack mount shelf brackets. Refer to Figure 3 and Table 4 to identify

the hardware.

3. Loosen the adjusting screws on the left and right rack mount shelf brackets, and adjust the

length of the brackets according to the depth of the rack. See Figure 5.

4. Locate the small, round marker holes on the rack rails. Each marker hole delineates the

beginning of one rail unit, or U. Leave 1U of space free at the bottom of the rack.

5. Count up five square holes from the 1U location. Align the left rack mount shelf brackets

with the fifth square hole.

6. Attach the rack mount shelf brackets:

a. For rails with round holes, position the left and right rack mount shelf brackets with

notched portion toward exhaust aisle (see Figure 5) and attach to rack rails, using six

1/4-20 x 0.500-inch (1.27 cm) screws with lock washers per bracket (two on the

notched end and four on the other end).

b. For rails with square holes, attach the left rack mount shelf bracket to the rack rails using

six 1/4-20 x 0.500-inch screws and six square washers. See Figure 5.

CAUTION: All 14U Rack Mount Kit hardware and screws are supplied with the switch. Use

the exact screws specified in the procedure. Using longer screws may damage the chassis.

35Core Switch 2/64 and SAN Director 2/128 installation guide

Page 36

2

1

3

4

SHR-2509A

1 Left rack mount shelf bracket

2 Adjusting screws

3 Right rack mount shelf bracket

4 1/4-20 x .500-inch screws and

washers (6)

Figure 5 Installing the left and right rack mount shelf brackets

7. Tighten the screws to a torque of 80-inch pounds.

8. Repeat step 5 through step 7 to install the right rack mount shelf bracket.

NOTE: When finished securing the rack mount shelf brackets, remember to tighten the

adjustment screws you loosened in step 3, and torque to 32 inch-pounds.

Installing and configuring the switch36

Page 37

Attaching the retainer nuts—for rails with square holes

If you are installing the 14U Rack Mount Kit in rails with square holes (like the 10,000 series

42U rack), attach retainer nuts to vertical rails on service side of the rack as follows.

1. First, count up 41 square holes from the 1U location.

2. Attach the four retainer nuts to the two rails at the front of the rack (service aisle side). See

Figure Figure 6.

1 Upper retainer

1

2 Lower retainer

3 1U location

nuts, installed in

hole #41

nuts, installed in

hole #9

2

3

Figure 6 Installing the retainer nuts on the rails

37Core Switch 2/64 and SAN Director 2/128 installation guide

Page 38

Attaching the clip nuts—for rails with round holes

If you are installing the 14U Rack Mount Kit in rails with round holes, use the instructions in this

section. Attach the clip nuts to the vertical rails on the service side of the rack as follows.

1. Count up 41 round holes from the 1U location.

2. Attach the four clip nuts to the two rails at the front of the rack (service aisle side). See

Figure 6.

NOTE: Cables can be routed down through the cable management tray or through the holes

in the sides of the chassis. If the cables will be routed down through the cable management

tray, allow adequate space below the chassis for cable management.

Attaching the upper rack mount bracket assemblies to the chassis

Use these steps to attach the upper rack mount brackets to the chassis. The upper rack mount

bracket assemblies consist of the following:

• One right flat upper rack mount bracket attached to an L-shaped bracket

• One left flat upper rack mount bracket attached to an L-shaped bracket

NOTE: To compete this procedure, you must first detach the L-shaped brackets from the upper

rack mount bracket assemblies.

1. Use a Phillips head screwdriver to remove the screws securing the left and right upper rack

mount brackets to the L-shaped brackets. Detach the L-shaped brackets from the assembly

and put them aside.

NOTE: You reinstall the L-shaped brackets to the rack rails in step 5.

2. Save the screws for attaching the bracket assemblies to the chassis (see step 1 in the section

”Securing the chassis to the rails” on page 41).

3. Use four #10-32 x 5/16 inch screws to secure the right and left flat upper rack mount

brackets to the chassis. See Figure 7.

NOTE: Orient the slotted holes in the brackets toward the blower side of the chassis (see

Figure 7 for orientation).

Installing and configuring the switch38

Page 39

3

2

1

4

SHR-2511A

1 Left flat upper rack mount bracket

2 #10-32 x 5/16 inch screws (4)

Figure 7 Attaching the left and right flat upper rack mount brackets

4. Tighten the screws and torque to 32 inch-pounds.

5. Attach the two L-shaped brackets to the rack rails farthest from the service aisle. See

Figure 8.

• For rails with square holes:

Attach the two L-shaped brackets to the rack rails with two of the #1/4-20 x 1/2 inch

Phillips panhead screws and two square washers per bracket. Tighten the screws to a

torque of 80 inch-pounds.

• For rails with round holes:

Attach the two L-shaped brackets to the rack rails using two of the #1/4-20 x 1/2 inch

Phillips panhead screws per bracket. Tighten the screws to a torque of 80 inch-pounds.

6. Route any cables or cords through the rack or along any other route that will be difficult to

reach after the chassis is installed. Leave enough cable allowance to plug and unplug

cables from switch.

3 Detached L-shaped brackets (1 of 2)

4 Right flat upper rack mount bracket

39Core Switch 2/64 and SAN Director 2/128 installation guide

Page 40

1

2

3

1 Two L-shaped brackets

2 Aligning top screw in hole #37

3 1/4-20 x 1/2 inch Phillips

panhead screws and

square washers

Figure 8 Attaching L-shaped brackets to rails

Finalizing the rack mount procedure

This section tells you how to slide the switch into the rack and secure the chassis to the

rack rails.

Sliding the switch into the rack

1. Before lifting the chassis into the rack, determine an easy access route for cables or cords.

Make sure that cables do not get pinned under the weight of the chassis.

2. Position the lift device next to the switch.

3. Position one technician at the front of the chassis, and the second technician at the rear of

the chassis. Carefully move the chassis onto the lift device.

SHR-2512A

Installing and configuring the switch40

Page 41

4. Use the lift device to raise the chassis until the bottom of the chassis is level with the

shelf-like surfaces of the rack mount shelf brackets.

5. Slide the chassis onto the two rack mount shelf brackets.

Securing the chassis to the rails

1. Attach the two flat upper rack mount brackets (that you installed on the chassis earlier) to

the two L-shaped brackets installed onto the rack rails. Use the two screws set aside in

step 1 of ”Attaching the upper rack mount bracket assemblies to the chassis” on page 38.

See Figure 9.

Figure 9 Attaching the upper rack mount bracket to the L-shaped brackets

2. Tighten screws, and torque to 32 inch-pounds.

SHR-2513A

41Core Switch 2/64 and SAN Director 2/128 installation guide

Page 42

3. Secure the chassis port side to the rack rails using two #10-32 x 5/8 inch screws on each

side.

SHR-2514A

Figure 10 Securing the chassis port side to rack rails

4. Tighten the screws, and torque to 32 inch-pounds. See Figure 10 for screw locations.

Reinstalling the chassis door

1. Verify that the spring-loaded pins on both door hinges are retracted (push levers into

notches).

2. Align the door hinges with the chassis portion of the hinges.

3. Push the levers out of the notches to release the pins.

Installing and configuring the switch42

Page 43

Powering on the switch

NOTE: If you plan to use a modem with the Core Switch 2/64 or a SAN Director 2/128, you

need to connect it prior to powering on the switch. To install a modem, refer to ”Setting up and

installing modems” on page 123.

1. Verify that the ON/OFF switches for each 16-port card and CP card are in the ON

position (see Figure 11).

Port Card

ON/OFF Switch

(in "OFF" position)

Power LED

Status LED

Port Speed LED

(16x)

Port Status LED

(16x)

scale: 5/16" = 1"

ON/OFF Switch

in "ON" position

!

15

d

14

c

13

b

12

a

11

d

10

c

9

b

8

a

7

d

6

c

5

b

4

a

3

d

2

c

1

b

0

a

!

Fibre Channel

Port (16x)

Ejector

(2x)

Figure 11 ON/OFF switch for a 16-port card

2.017

43Core Switch 2/64 and SAN Director 2/128 installation guide

Page 44

NOTE: The ON/OFF switches for CP cards are identical to the ON/OFF switches on the

16-port cards (see Figure 11).

2. Verify that the AC switch covers are installed over the AC switches.

These clear plastic covers fit over the AC switches with their edges tucked underneath the

outlet covers, preventing the AC switches from being powered on or off accidentally (see

Figure 12).

3. Connect the AC power cord retainers to the chassis:

a. Orient a retainer against the AC panel as shown in Figure 12.

b. Place the retainer tabs under the two jack screws on either side of the power receptacle

and tighten the screws.

4. Repeat step 3 for the other retainer (note that the power cord retainers are oriented in the

same direction as the power receptacles).

Clamping

Screw

Jack

AC Power

Screw (2x)

Receptacle (2x)

AC Switch

(2x)

P

1&3

LY

RSUPP

E

W

O

P

200-240 VAC 12A 50-60 Hz

!

200-240 VA

Clamping

Screw

Figure 12 AC panel and power cord retainers

O

W

RSUPPL

E

C1

Y

2A

2&4

50-60 Hz

AC Switch Cover (2x)

Power Cord

Retainer (2x)

Retainer

Attaching

Screw (2x)

scale: 5/16" = 1"

POWER S

2.014

Installing and configuring the switch44

Page 45

5. Loosen the clamping screw on each retainer, insert the power cords through the retainers

into the power receptacles on the Core Switch 2/64 or the SAN Director 2/128, and

tighten the clamping screws.

The power cords are designed with left bends, so each should route to opposite sides of the

chassis.

6. Ensure that the power cord has a minimum service loop of 6 inches available at the

connection to the switch and is routed so that it is not exposed to stress.

7. Connect the power cords to a power source with voltage of 200 to 240 VAC, 50 to 60 Hz.

8. Position AC power switches to position 1.

The AC power switches light up green when switched on and power is supplied.

NOTE: The switch automatically performs a power-on self-test (POST) by default each time it is

powered on. POST takes approximately 10 minutes and is complete when indicator light

activity returns to its standard state. For information about LED patterns, see ”Interpreting LED

activity” on page 64).

CAUTION: To prevent a potential IP address conflict, do not connect the Core Switch 2/64 or

the SAN Director 2/128 to the network until the IP addresses are configured. See ”Core

Switch 2/64” on page 53 for additional information.

Establishing a serial connection

The initial communication to a Core Switch 2/64 or a SAN Director 2/128 switch requires a

serial connection. Follow these steps to establish a serial connection and log in to the switch:

1. Verify that the switch is powered on and that POST is complete by verifying that all power

LED indicators on the 16-port cards and CP cards are displaying a steady green light.

2. Use the serial cable provided with the switch to connect the console port on the active CP

card to a computer workstation.

The console port is the second serial port from the top of the CP card; the active CP card is

indicated by an illuminated (blue) LED (see ”CP cards” on page 68). The Active CP LED in

the standby CP card should be off (not illuminated).

45Core Switch 2/64 and SAN Director 2/128 installation guide

Page 46

NOTE: The console port is intended primarily for use during the initial setting of the IP

address and for service purposes. If necessary, the adapter on the serial cable can be removed

to allow for an RJ45 serial connection.

3. Access the switch using a terminal emulator application (such as HyperTerminal on

Windows 95, Windows 2000, or Windows NT, or TERM in a UNIX

®

environment).

NOTE: Both the Core Switch 2/64 and the SAN Director 2/128 support up to two telnet

sessions with administrative privileges at the same time.

4. Disable any serial communication programs running on the workstation (such as

synchronization programs).

5. Open the terminal emulator application and configure as follows:

•Bits per second: 9600

•Databits: 8

•Parity: None

•Stop bits: 1