Page 1

HP 1410 Switch Series Getting Started Guide

HP 1410-24-R Switch (JD986B)

HP 1410-24G-R Switch (JG708A)

Part number:

5998-4635

Document version: 5W100-20130808

Page 2

Legal and notice information

© Copyright 2013 Hewlett-Packard Development Company, L.P.

No part of this documentation may be reproduced or transmitted in any form or by any means without

prior written consent of Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or

use of this material.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained

herein.

Page 3

i

Contents

Product Overview ························································································································································· 1

Preparing for installation ············································································································································· 2

Safety recommendations ·················································································································································· 2

Safety symbols ·························································································································································· 2

General safety recommendations ··························································································································· 2

Electrical safety ························································································································································· 3

Examining the installation site ········································································································································· 3

Temperature/humidity ············································································································································· 3

Cleanness ·································································································································································· 3

ESD prevention ························································································································································· 4

EMI ············································································································································································· 4

Lightning protection ·················································································································································· 5

Installation preparation checklist ····································································································································· 5

Installing the switch ······················································································································································ 7

Mounting the switch in a 19-inch rack with mounting brackets ··················································································· 7

Mounting the switch on a workbench ····························································································································· 8

Connecting cables ···························································································································································· 9

Connecting network cable ······································································································································ 9

Connecting the AC power cord ······························································································································ 9

Verifying the installation ················································································································································ 10

Troubleshooting ·························································································································································· 11

Appendix A Chassis views and technical specifications ························································································ 12

Chassis views ································································································································································· 12

1410-24-R switch ··························································································································································· 13

Front panel ····························································································································································· 13

Rear panel ······························································································································································ 13

1410-24G-R switch ························································································································································ 13

Front panel ····························································································································································· 13

Rear panel ······························································································································································ 14

Technical specifications ················································································································································· 14

Appendix B LEDs ························································································································································ 15

Power LED ······························································································································································ 15

Ethernet copper port LEDs ···································································································································· 15

Support and other resources ····································································································································· 16

Contacting HP ································································································································································ 16

Subscription service ·············································································································································· 16

Related information ························································································································································ 16

Documents ······························································································································································ 16

Websites ································································································································································· 16

Index ··········································································································································································· 88H17

Page 4

1

Product Overview

HP 1410 series switches are unmanaged Fast Ethernet and Gigabit Ethernet switches designed for small

businesses looking for entry-level, low-cost networking solutions with a lifetime warranty. The HP 1410

switch series consists of nine models with flexible mounting options that allow customers to choose the

best switch to meet their network switching needs. All models have QoS support and IEEE 802.3x flow

control features to provide outstanding data efficiency. Simplified plug-and-play operation is enabled by

features like Auto-MDIX and auto-speed negotiation. HP has innovated and combined the latest

advances in silicon technology to provide some of the most power-efficient switches: 1410-16, 1410-24

and 1410-24G-R models are the industry's first IEEE 802.3az compliant unmanaged Fast Ethernet

switches. The available green features, along with the HP lifetime warranty, make the HP 1410 switch

series ideal for customers seeking low-cost and reliable networking solutions.

The HP 1410 Switch Series includes the models in Table 1.

Table 1 HP 1410 Switch Series models

Product code HP description Alias

J9559A HP 1410-8G Switch 1410-8G

J9560A HP 1410-16G Switch 1410-16G

J9561A HP 1410-24G Switch 1410-24G

JD986B HP 1410-24G-R Switch 1410-24G-R

J9661A HP 1410-8 Switch 1410-8

J9662A HP 1410-16 Switch 1410-16

J9663A HP 1410-24 Switch 1410-24

JG708A HP 1410-24-R Switch 1410-24-R

J9664A HP 1410-24-2G Switch 1410-24-2G

This Getting Started Guide covers HP 1410-24-R and 1410-24G-R switches. These models are 24-port

unmanaged Fast Ethernet and Gigabit Ethernet switches with full rackwidth and internal power supply.

Please contact HP local sales for the product availability.

Page 5

2

Preparing for installation

Safety recommendations

W

ARNING!

Before installation and operation, read all of the safety instructions in the

Compliance and Safety Guid

e

supplied with your device.

Safety symbols

When reading this document, note the following symbols:

WARNING means an alert that calls attention to important information that if not understood or

followed can result in personal injury.

CAUTION means an alert that calls attention to important information that if not understood or

followed can result in data loss, data corruption, or damage to hardware or software.

General safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the following safety

recommendations before installation. Note that the recommendations do not cover every possible

hazardous condition.

• Do not place the switch on an unstable case or desk. The switch might be severely damaged in case

of a fall.

• Make sure the ground is dry and flat and anti-slip measures are in place.

• Keep the chassis and installation tools away from walk areas.

• Keep the chassis clean and dust-free.

• Do not place the switch near water or place it in a damp environment. Prevent water or moisture

from entering the switch chassis.

• To prevent condensation, unpack the switch at least half an hour after you move the switch from a

location below 0°C (32°F) to the equipment room. Power on the switch at least 2 hours after you

move the switch from a location below 0°C (32°F) to the equipment room.

• Ensure proper ventilation of the equipment room, and keep the air inlet and outlet vents of the switch

free of obstruction.

• Make sure the operating voltage is in the required range.

• Use a screw driver to fasten screws.

Page 6

3

Electrical safety

• Carefully examine your work area for possible hazards, like moist floors, ungrounded power

extension cables, or missing safety grounds.

• Locate the emergency power-off switch in the room before installation. Shut off the power

immediately if an accident occurs.

• Unplug all the external cables (including power cables) before moving the chassis.

• Do not work alone when you operate the switch with the switch powered on.

• Always check that the power has been disconnected when you perform operations that require the

switch to be powered off.

Examining the installation site

The HP 1410 switches must be used indoors. To ensure correct operation and a long lifespan for your

switch, the installation site must meet the requirements in this section.

Temperature/humidity

Maintain appropriate temperature and humidity in the equipment room.

• Lasting high relative humidity can cause poor insulation, electric creepage, mechanical property

change of materials, or metal corrosion.

• Lasting low relative humidity can cause washer contraction and ESD, and can cause problems

including loose captive screws and circuit failure.

• High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the switch.

Maintain temperature and humidity in the equipment room, as described in Table 2.

Table 2 Temperature/

humidity requirements in the equipment room

Temperature Relative humidity

0°C to 45°C (32°F to 113°F) 5% to 95%, noncondensing

Cleanness

Dust buildup on the chassis might result in electrostatic adsorption. Electrostatic adsorption causes poor

contact of metal components or contact points, especially when indoor relative humidity is low. In the

worst case, electrostatic adsorption can cause communication failure.

To ensure correct operation, the equipment room must meet the dust concentration requirements listed

in Table 3.

Page 7

4

Table 3 Dust concentration limit in the equipment room

Substance Concentration limit (particles/m³)

Dust ≤ 3 × 104 (no visible dust on the tabletop over three days)

NOTE:

Dust diameter ≥ 5 μm

The equipment room must also meet strict limits on salts, acids, and sulfides, as shown in Table 4, to

eliminate corrosion and premature aging of components.

Table 4 Harmful gas limits in the equipment room

Gas Maximum concentration (mg/m³)

SO2 0.2

H2S 0.006

NH3 0.05

Cl2 0.01

ESD prevention

To prevent electrostatic discharge (ESD), follow these guidelines:

• Ground the switch correctly.

• Take dust-proof measures for the equipment room.

• Maintain the humidity and temperature at a proper level.

• Always wear an ESD-preventive wrist strap. Make sure the wrist strap makes skin contact and is well

grounded.

NOTE:

The ESD-preventive wrist strap is not provided with the switch. Order it yourself.

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application

system, adversely affect the switch in the following conduction patterns:

• Capacitance coupling

• Inductance coupling

• Electromagnetic wave radiation

• Common impedance (including the grounding system) coupling

• Cables (power cords, signal cables, and output cables)

To prevent EMI:

• If the AC power supply system is a TN system, use a single-phase three-wire power receptacle with

protection earth (PE) to filter interference from the power grid.

Page 8

5

• Keep the switch far away from radio transmitting stations, radar stations, and high-frequency

devices.

• Use electromagnetic shielding, for example, shielded interface cables, when necessary.

• Route interface cables indoors.

Lightning protection

To better protect the switch from lightning, follow these guidelines:

• Make sure the grounding cable of the chassis is well grounded.

• Make sure the grounding terminal of the AC power receptacle is well grounded.

Installation preparation checklist

Table 5 Installation preparation checklist

Item Requirements Result

Installation

site

Ventilation

• There is a minimum clearance of 10 cm (3.9 in) around

the inlet and outlet vents for heat dissipation of the switch

chassis.

• A ventilation system is available at the installation site.

Temperature 0°C to 45°C (32°F to 113°F)

Relative humidity 5% to 95% (noncondensing)

Cleanness

• Dust concentration ≤ 3 × 104 particles/m3

• No dust on desk within three days.

ESD prevention

• The equipment and rack are well grounded.

• The equipment room is dust-proof.

• The humidity and temperature are at a proper level.

• Wear an ESD-preventive wrist strap. Make sure the wrist

strap makes good skin contact and is well grounded.

EMI prevention

• Take effective measures to protect the power system from

the power grid system.

• Separate the protection ground of the switch from the

grounding device or lightning protection grounding

device as far as possible.

• Keep the switch far away from radio stations and radar

and high-frequency devices working in high current.

• Use electromagnetic shielding when necessary.

Lightning

protection

• The grounding cable of the chassis is well grounded.

• The grounding terminal of the AC power receptacle is

well grounded.

Electricity safety

• Equip a UPS.

• In case of emergency during operation, switch off the

external power switch.

Page 9

6

Item Requirements Result

Rack-mounting

requirements

• Install the switch in an open rack if possible. If you install

the switch in a closed cabinet, make sure that the cabinet

is equipped with a good ventilation system.

• The rack is sturdy enough to support the weight of the

switch and installation accessories.

• The size of the rack is appropriate for the switch.

• The front and rear of the rack are at least 0.8 m (31.50 in)

away from walls or other devices.

Safety

precautions

• The switch is far away from any moist area and heat source.

• You have located the emergency power switch in the equipment room.

Accessories Accessories shipped with the switch

Reference

• Documents shipped with the switch.

• Online documents.

Page 10

7

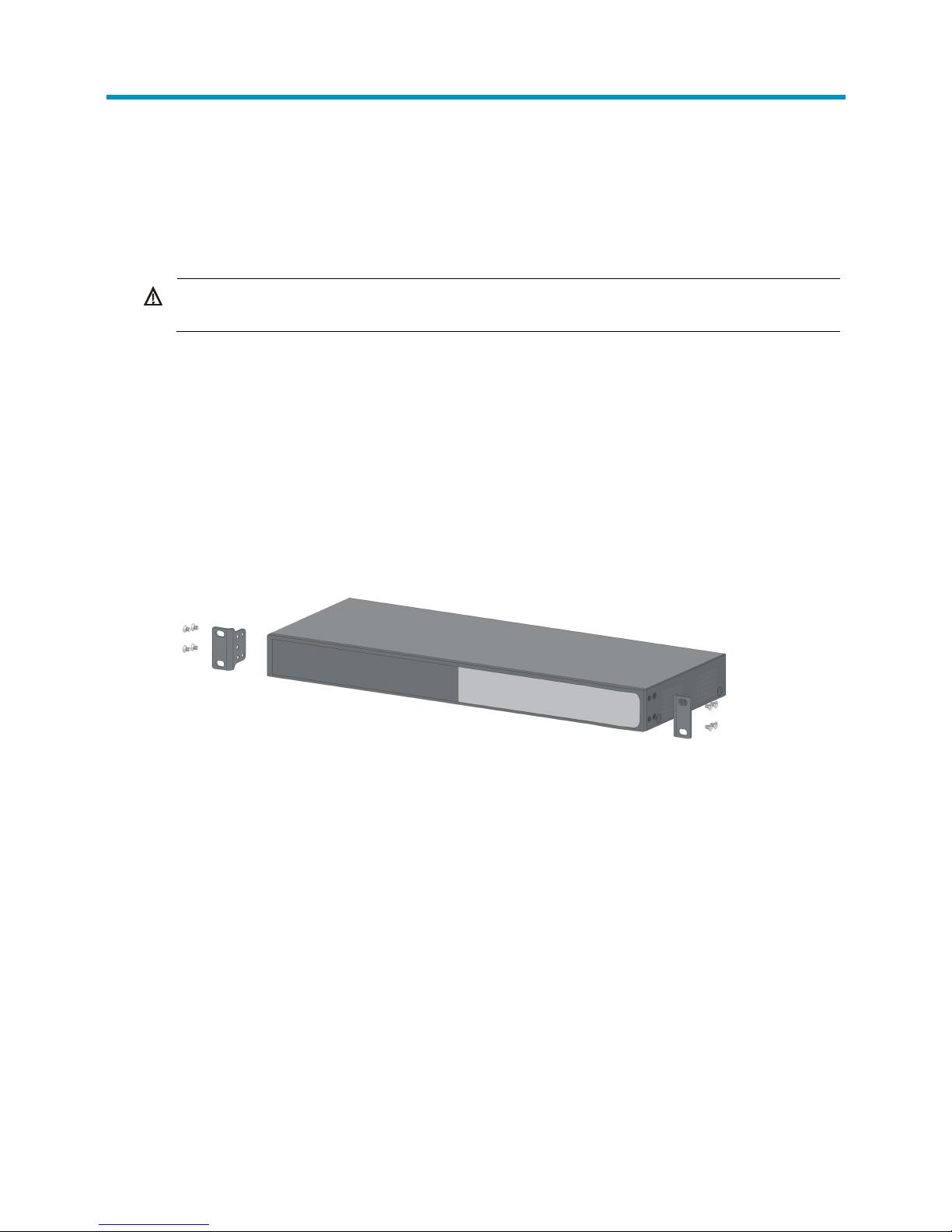

Installing the switch

The HP 1410 switch can be installed in a 19-inch rack or on a workbench. The installation procedures for

the HP 1410-24-R switch and the HP 1410-24G-R switch are the same. The following installation

procedure uses the HP 1410-24-R switch as an example.

W

ARNING!

Before installing or moving the switch, remove the power cord.

Mounting the switch in a 19-inch rack with

mounting brackets

To install the switch with mounting brackets:

1. Wear an ESD-preventive wrist strap, and make sure the rack is securely grounded and is stable.

2. Attach the mounting brackets on the sides of the front panel with screws.

Figure 1 Installing the mounting brackets to the HP 1410-24-R switch

3. Place the switch on a holder in the rack, and push in the switch along the guide rails until the oval

holes in the brackets align with the mounting holes in the rack posts.

4. Attach the mounting brackets to the rack posts with screws.

Page 11

8

Figure 2 Mounting the HP 1410-24-R switch in the rack

NOTE:

The mounting brackets are used only for attaching the switch instead of bearing the switch weight. A

holder on the rack is used to hold (bear the weight of) the switch.

Mounting the switch on a workbench

IMPORTANT:

• Ensure good ventilation and 10 cm (3.9 in) of clearance around the chassis for heat dissipation.

• Avoid placing heavy objects on the switch.

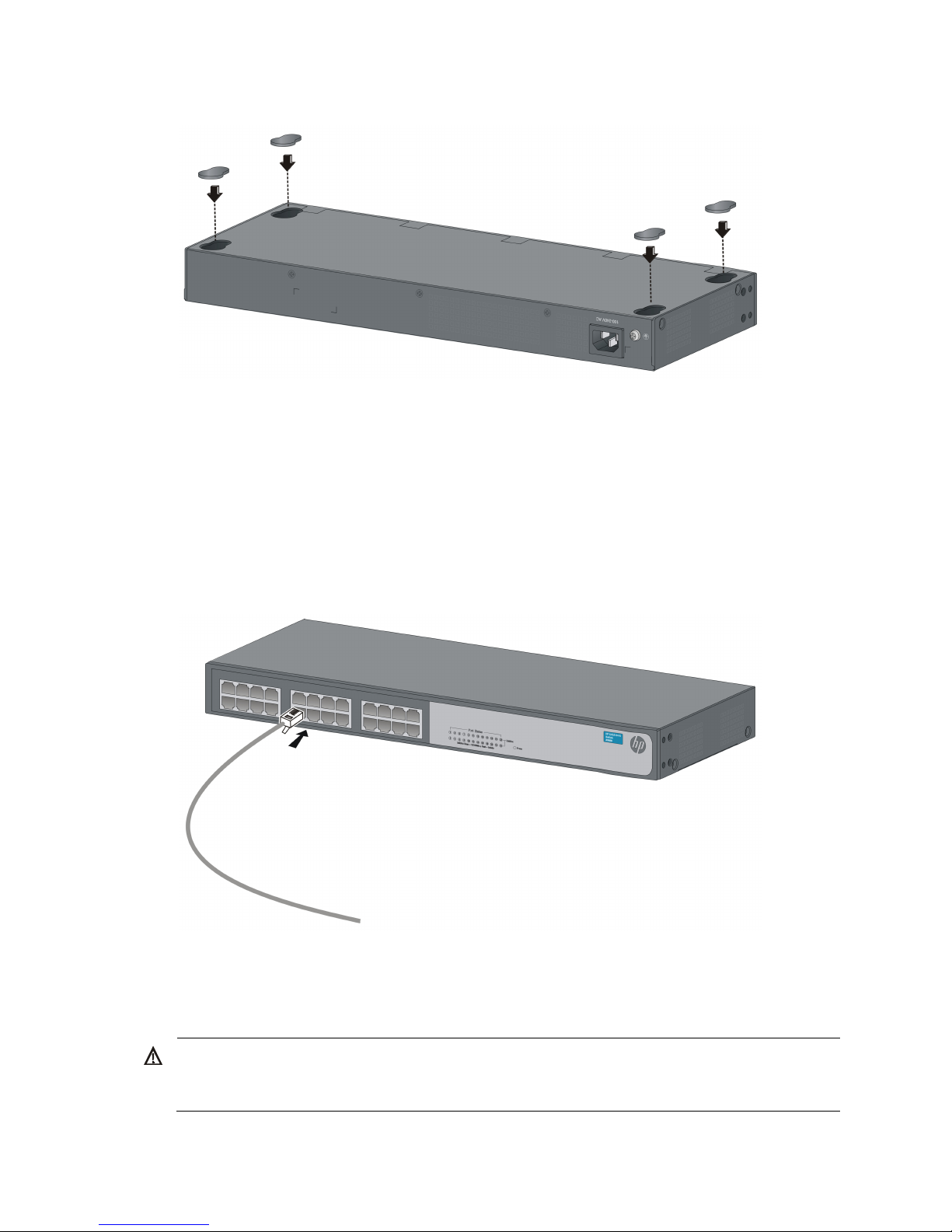

To mount the switch on a workbench:

1. Make sure the workbench is securely grounded and is stable.

2. Place the switch upside down, and clean the round holes on the bottom of the chassis with a dry

cloth.

3. Attach the rubber feet to the four round holes on the bottom of the chassis.

4. Place the switch with right side up on the workbench.

Page 12

9

Figure 3 Attaching rubber feet

Connecting cables

Connecting network cable

Use crossover cables or straight-through cables to connect a PC or other network devices to the Ethernet

port of the switch.

Figure 4 Connecting network cable

Connecting the AC power cord

W

ARNING!

Make sure the grounding cable is securely connected and the switch is well grounded before connectin

g

the AC power cord.

Page 13

10

1. Make sure the correct power source is used.

2. Connect one end of the AC power cord to the AC-input power receptacle on the switch.

3. Connect the other end of the AC power cord to the AC power outlet.

4. Check the Power LED.

If it is ON, it means the power connection is correct.

Verifying the installation

After you complete the installation, verify that:

• There is enough space for heat dissipation around the switch, and the rack or workbench is stable.

• The grounding cable is securely connected.

• The correct power source is used.

• All the interface cables are cabled indoors.

Page 14

11

Troubleshooting

This chapter lists issues and solutions while using and managing the switch. If you encounter an issue that

is not listed and you cannot solve it, contact HP Technical Support.

Table 6 Troubleshooting

Symptom Troubleshooting method

Power LED off

1. Verify that the correct power source is used and the power cords

are correctly connected.

2. Verify that the power source side provides power supply correctly.

LAN interface LED off

1. Verify that the network cable is correctly connected to the network

port of the switch.

2. Plug the two ends of a network cable into two network ports of the

switch. If the port LEDs are on, it indicates that the network cable is

operating correctly. Otherwise, replace the network cable.

Page 15

12

Appendix A Chassis views and technical

specifications

Chassis views

The HP1410 Switch Series includes the models in Table 7. For availability information about the models,

contact HP sales.

Table 7 HP 1410 Switch Series models

Product code HP description Alias

JD986B HP 1410-24-R Switch 1410-24-R

JG708A HP 1410-24G-R Switch 1410-24G-R

IMPORTANT:

For regulatory identification purposes, the HP 1410 Switch Series products are assigned Regulatory

Model Numbers (RMN). The Regulatory Model Numbers for these products are listed below. These

regulatory numbers should not be confused with the marketing names HP 1410, or product numbers

J

D986B and JG708A

Table 8 Regulatory Model Numbers in the HP 1410 Switch Series

Product code RMN HP description

JD986B HNGZA-HA0006 HP 1410-24-R Switch

JG708A HNGZA-HA0007 HP 1410-24G-R Switch

NOTE:

The figures in this document are for illustration only.

Page 16

13

1410-24-R switch

Front panel

Figure 5 1410-24-R front panel

(1) 10/100Base-TX port (2) Port LED (3) Power LED (Power)

Rear panel

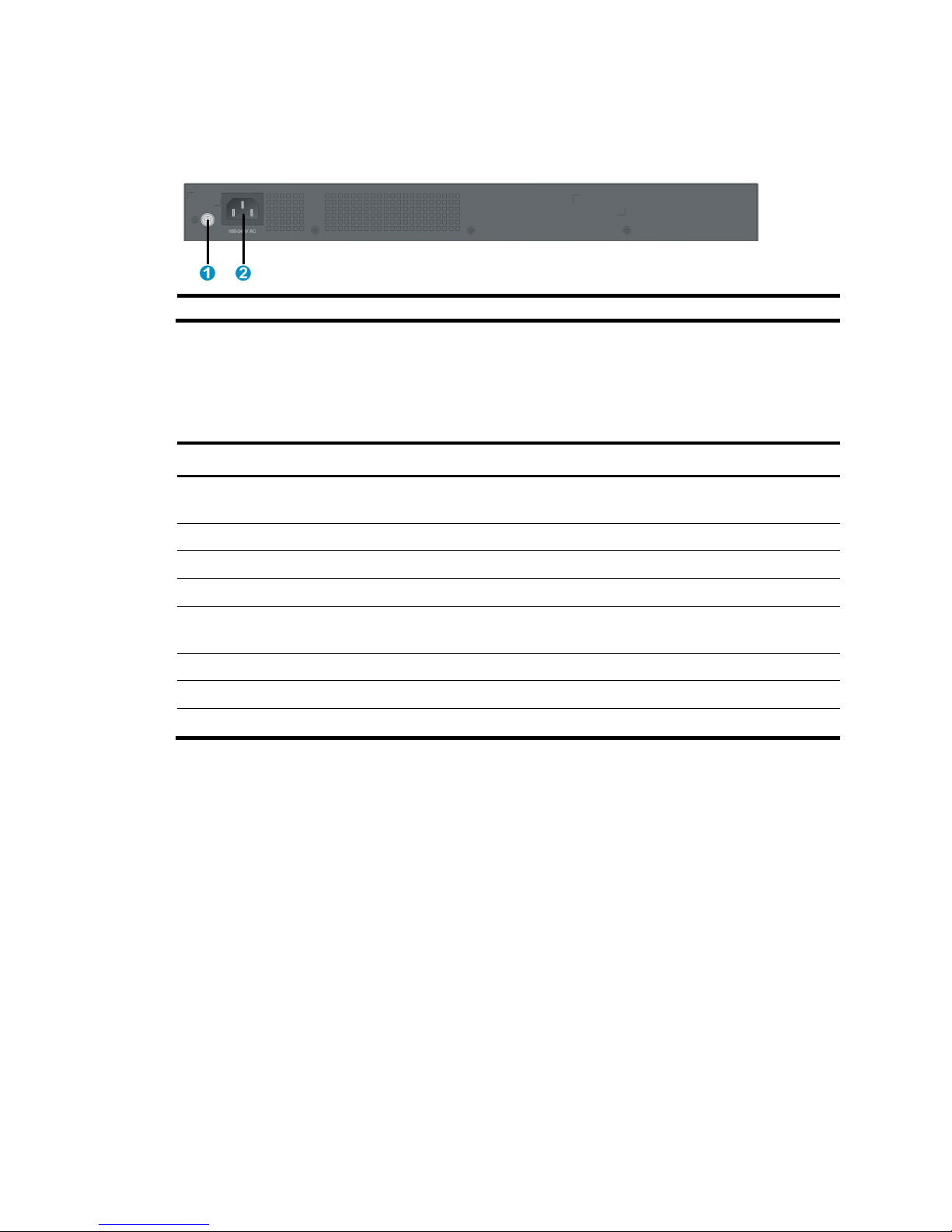

Figure 6 1410-24-R rear panel

(1) Grounding screw (2) AC-input power receptacle

1410-24G-R switch

Front panel

Figure 7 1410-24G-R front panel

(1) 10/100/1000Base-T port (2) Port LED (3) Power LED (Power)

Page 17

14

Rear panel

Figure 8 1410-24G-R rear panel

(1) Grounding screw (2) AC-input power receptacle

Technical specifications

Table 9 Technical specifications

Item 1410-24-R 1410-24G-R

Dimensions (H × W × D)

44 × 440 × 173 mm (1.73 × 17.32

× 6.81 in)

44 × 440 × 173 mm (1.73 × 17.32 ×

6.81 in)

Weight ≤ 2.5 kg (5.51 lb) ≤ 3 kg (6.61 lb)

Ethernet port 24 × 10/100Base-TX ports 24 × 10/100/1000Base-T ports

Input AC voltage Rated voltage range: 100 VAC to 240 VAC @ 50 Hz or 60 Hz

Power consumption (full

configuration)

< 6 W < 16 W

Operating temperature 0°C to 40°C (32°F to 104°F)

Relative humidity 5% to 95%, noncondensing

Cooling system No fans for heat ventilation

Page 18

15

Appendix B LEDs

The LEDs on the front panel show the operation status of the switch.

Power LED

Table 10 Power LED description

LED Status Description

Power

Steady green The switch is operating correctly.

Flashing green The system is performing power-on self-test (POST).

Off The switch is powered off or the power supply has failed.

Ethernet copper port LEDs

Table 11 Ethernet copper port LEDs

LED Status Description

Link/Act

10/100BASE-TX port

Steady green The port is operating at 10/100 Mbps.

Flashing green

The port is sending or receiving data at

10/100 Mbps.

Off No link is present on the port.

10/100/1000BASE-T

port

Steady green The port is operating at 1000 Mbps.

Flashing green

The port is sending or receiving data at 1000

Mbps.

Steady yellow The port is operating at 10/100 Mbps.

Flashing yellow

The port is sending or receiving data at

10/100 Mbps.

Off No link is present on the port.

Page 19

16

Support and other resources

Contacting HP

For worldwide technical support information, see the HP support website:

http://www.hp.com/support

Before contacting HP, collect the following information:

• Product model names and numbers

• Technical support registration number (if applicable)

• Product serial numbers

• Error messages

• Operating system type and revision level

• Detailed questions

Subscription service

HP recommends that you register your product at the Subscriber's Choice for Business website:

http://www.hp.com/go/wwalerts

After registering, you will receive email notification of product enhancements, new driver versions,

firmware updates, and other product resources.

Related information

Documents

To find related documents, browse to the Manuals page of the HP Business Support Center website:

http://www.hp.com/support/manuals

• For related documentation, navigate to the Networking section, and select a networking category.

• For a complete list of acronyms and their definitions, see HP FlexNetwork Technology Acronyms.

Websites

• HP.com http://www.hp.com

• HP Networking http://www.hp.com/go/networking

• HP manuals http://www.hp.com/support/manuals

• HP download drivers and software http://www.hp.com/support/downloads

• HP software depot http://www.software.hp.com

• HP Education http://www.hp.com/learn

Page 20

17

Index

A

AC

power cord connection, 9

Appendix A (Chassis views and technical

specifications), 12

Appendix B (LEDs), 15

C

cable

network cable connection, 9

checklist (pre-installation), 5

cleanness (installation site), 3

connecting

AC power cord, 9

network cables, 9

D

dust (installation site), 3

E

electricity

AC power cord connection, 9

electromagnetic interference. Use EMI

electrostatic discharge. Use ESD

EMI prevention, 4

ESD prevention, 4

safety recommendations, 3

EMI prevention, 4

environment

installation site, 3

site cleanness, 3

site dust concentration, 3

site gas saturation, 3

site humidity, 3

site temperature, 3

ESD prevention, 4

examining installation site, 3

G

gas (installation site), 3

grounding

EMI prevention, 4

ESD prevention, 4

lightning protection, 5

H

hardware

rack switch mount, 7

switch installation, 7

workbench switch mount, 8

hardware management/maintenance

chassis technical specifications, 12

chassis views, 12

LEDs, 15

humidity

installation site requirements, 3

I

installing

checklist, 5

EMI prevention, 4

ESD prevention, 4

installation verification, 10

lightning protection, 5

site cleanness, 3

site examination, 3

site humidity, 3

site temperature, 3

switch, 7

L

lightning

protection, 5

M

mounting

rack switch mount, 7

workbench switch mount, 8

N

network cable connection, 9

network management

chassis technical specifications, 12

chassis views, 12

Page 21

18

LEDs, 15

P

power supply

AC power cord connection, 9

preparing for installation, 2

preventing

EMI prevention, 4

ESD prevention, 4

procedure

connecting AC power cord, 9

connecting network cables, 9

installing switch, 7

mounting switch in rack, 7

mounting switch on workbench, 8

verifying installation, 10

R

rack switch mount, 7

S

safety

caution and warning symbols, 2

electrical safety recommendations, 3

EMI prevention, 4

ESD prevention, 4

general recommendations, 2

installation site cleanness, 3

installation site dust concentration, 3

installation site gas saturation, 3

installation site humidity, 3

installation site temperature, 3

lightning protection, 5

site

cleanness, 3

dust concentration, 3

examination, 3

gas saturation, 3

humidity, 3

temperature, 3

switch

AC power cord connection, 9

installation, 7

installation verification, 10

network cable connection, 9

rack switch mount, 7

workbench switch mount, 8

T

temperature

installation site requirements, 3

V

verifying installation, 10

W

workbench switch mount, 8

Loading...

Loading...