HP ProCurve J8161A, ProCurve 600, J8169A, ProCurve 610, J8168A Installation And Getting Started Manual

Page 1

Installation and

Getting Started Guide

HP ProCurve

600/610 External

Power Supplies

www.hp.com/go/hpprocurve

PoE

Power over Ethernet Devices

Page 2

Page 3

HP ProCurve 600/610

External Power Supplies

Installation and Getting Started Guide

Page 4

© Copyright 2004 Hewlett-Packard Development Company, L.P. The information contained herein is subject

to change without notice.

This document contains proprietary information, which is

protected by copyright. No part of this document may be

photocopied, reproduced, or translated into another

language without the prior written consent of HewlettPackard.

Publication Number

5990-8800

August 2004

Applicable Products

HP ProCurve 600 Redundant and

External Power Supply (J8168A)

HP ProCurve 610 External Power Supply (J8169A)

Disclaimer

HEWLETT-PACKARD COMPANY MAKES NO WARRANTY

OF ANY KIND WITH REGARD TO THIS MATERIAL,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. Hewlett-Packard shall not

be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing,

performance, or use of this material.

The only warranties for HP products and services are set

forth in the express warranty statements accompanying

such products and services. Nothing herein should be

construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions

contained herein.

Hewlett-Packard assumes no responsibility for the use or

reliability of its software on equipment that is not furnished

by Hewlett-Packard.

Warranty

See the Customer Support/Warranty booklet included with

the product.

A copy of the specific warranty terms applicable to your

Hewlett-Packard products and replacement parts can be

obtained from your HP Sales and Service Office or

authorized dealer.

Hewlett-Packard Company

8000 Foothills Boulevard, m/s 5552

Roseville, California 95747-5552

http://www.hp.com/go/hpprocurve

Safety

Before installing and operating these products, please

read the “Installation Precautions” in chapter 2,

“Installing and Connecting the HP 600/610 External

Power Supplies”, and the safety statements in appendix C, “Safety and Regulatory Statements”.

Page 5

Contents

1 Introducing the HP ProCurve 600/610 External Power

Supplies

Front of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

EPS Ports on the HP 610 EPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Back of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

RPS Ports on the HP 600 RPS/EPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

EPS Ports on the HP 600 RPS/EPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Port Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Internal Power Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

EPS Backup Power Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

RPS Port Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

EPS Port Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

EPS Backup Power Port Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Supported Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2 Installing and Connecting the HP 600/610 External Power

Supplies

Included Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation Precautions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

1. Prepare the Installation Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2. Mount the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Rack or Cabinet Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Horizontal Surface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3. Connect to Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Connecting RPS Ports to Switches . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Connecting EPS Ports to Switches . . . . . . . . . . . . . . . . . . . . . . . . 2-10

i

Page 6

4. HP 610 EPS Only: Connect the EPS Backup Power Ports . . . . . . . 2-11

5. Connect to AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

6. Verify Correct Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

LED Behavior: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Recommended Connection Topologies . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

RPS Connections on the HP 600 RPS/EPS . . . . . . . . . . . . . . . . . . . . . . 2-16

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

EPS Connections on the HP 600 RPS/EPS . . . . . . . . . . . . . . . . . . . . . . 2-17

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

EPS Connections on the HP 610 EPS . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

EPS Backup Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Limitations (Calculating required number of HP 610 EPS units) 2-23

Status Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Fault Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

UPS Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

3 Troubleshooting

Basic Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diagnosing with the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Testing the Unit by Resetting It . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Checking the Unit’s LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Testing Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

HP Customer Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

ii

Page 7

A Specifications

Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Acoustic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

EMC Compliance (Class A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

B Connectors and Cables

HP 600 RPS/EPS Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

HP 610 EPS Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Connector Pin-Outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

EPS Cable for HP PoE Switch Connections . . . . . . . . . . . . . . . . . . . . B-2

Connector Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

RPS Cable for HP ProCurve Switch Connections . . . . . . . . . . . . . . . . B-3

Connector Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

EPS Backup Power Cable for HP 610 EPS Connections . . . . . . . . . . B-4

Connector Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Pin Assignments (10-pin Connector) . . . . . . . . . . . . . . . . . . . . . . B-4

C Safety and EMC Regulatory Statements

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

EMC Regulatory Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Index

iii

Page 8

— This page is intentionally unused. —

Page 9

Introducing the HP ProCurve 600/610 External

1

Introducing the HP ProCurve 600/

610 External Power Supplies

Power Supplies

The HP ProCurve 600 Redundant and External Power Supply is a dual-mode

power supply that can supply backup power to so equipped HP ProCurve

switches and additional power for Power over Ethernet (PoE) capable

switches.

The HP ProCurve 610 External Power Supply can supply additional power for

PoE capable switches and backup power to other HP ProCurve 610 units.

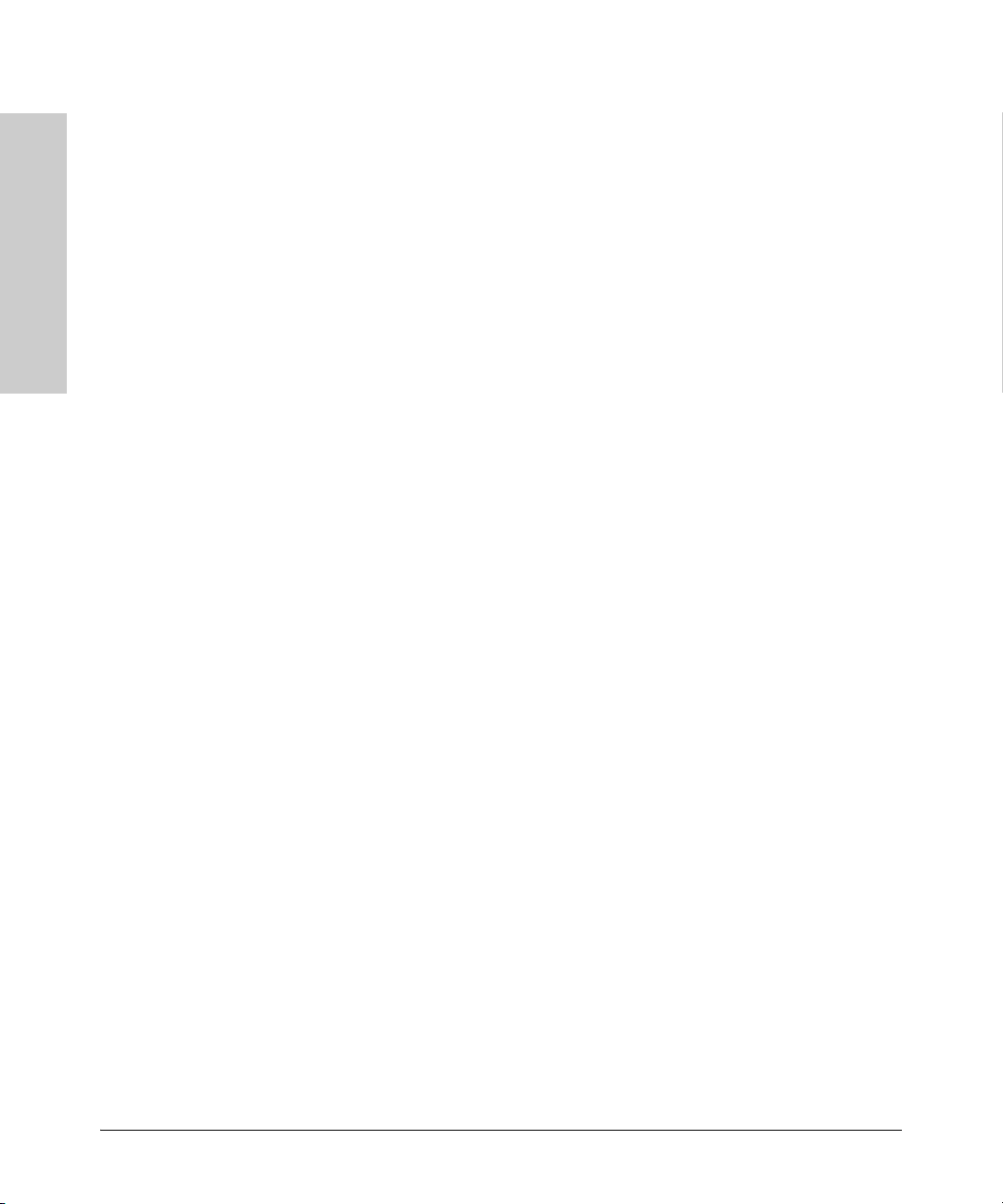

EPS PortStatus

E1

E2

Device Connected

Power

Fault

Power

Fault

Fan/Temp

Status

Fan/TempStatus flash = Temperature too high

Fan/TempStatus + Fault flash = Fan failure

HP ProCurve

610 EPS

J8169A

Internal Power Status

Fan/Temp Status

Fan/TempStatus flash = Temperature too high

Fan/TempStatus + Fault flash = Fan failure

Power Status

EPS Backup Power Ports Status

Out Ready

In Ready

HP ProCurve 600 Redundant and External Power Supply (J8168A)

Device Connected

Power Status

R6 R5

RPS Port Status

R4 R3

R1

R2

HP ProCurve 610 External Power Supply (J8169A)

EPS Ports PairA

EPS A1

(

408 W total for PoE applications

)

Device

A1

A2

Connected

EPS A2 EPS B1

Power

Status

EPS Ports: 50 V

8.3 A max per port pair.

EPS Ports PairB

(

408 W total for PoE applications

B1

EPS B2

)

Device

B2

Connected

Power

Status

Throughout this manual, these units will be abbreviated as the HP 600 RPS/

EPS and HP 610 EPS.

The HP 600 RPS/EPS has six redundant power supply (RPS) ports supporting

backup power to six supported HP ProCurve switches. The HP 600 RPS/EPS

also has two external power supply (EPS) ports that provide PoE power for

up to two HP PoE switches.

The HP 610 EPS has four EPS ports that provide PoE power for up to four HP

PoE switches. The HP 610 EPS also has two backup ports for supporting

backup power to other HP 610 EPS units connected in a group. There are two

supported topologies, a string (daisy-chain) and a ring (closed-loop).

1-1

Page 10

Introducing the HP ProCurve 600/610 External Power Supplies

610 External Power Supplies

Introducing the HP ProCurve 600/

This chapter describes your HP 600 RPS/EPS and HP 610 EPS including:

■ front of the unit (page 1-3)

■ back of the unit (page 1-6)

■ RPS port operation (page 1-8)

■ EPS port operation (page 1-8)

■ backup power port operation (page 1-9)

■ supported switches (page 1-10)

1-2

Page 11

Power

and Fault

LEDs

Front of the Unit

EPS port LEDs

Introducing the HP ProCurve 600/610 External Power Supplies

Front of the Unit

RPS port LEDs

HP 600 RPS/EPS

Introducing the HP ProCurve 600/

610 External Power Supplies

Fan/Temp

Power

Status

Fan/TempStatus flash = Temperature too high

Fault

Fan/TempStatus + Fault flash = Fan failure

Fan/Temp

Status LED

Power

and Fault

LEDs

HP ProCurve

610 EPS

J8169A

Power

Fan/TempStatus flash = Temperature too high

Fault

Fan/TempStatus + Fault flash = Fan failure

Fan/Temp

Status LED

Device Connected

Power Status

EPS Backup Power port LEDs

Internal Power Status

Fan/Temp Status

EPS Backup Power Ports Status

In Ready

Internal Power

Status LED

EPS PortStatus

E1

E2

Power Status

Out Ready

R6 R5

Device Connected

Power Status

Device Connected

EPS Ports PairA

EPS A1

EPS Pair A

RPS Port Status

R4 R3

R1

R2

Power Status

EPS port LEDs

(

408 W total for PoE applications

)

Device

A1

A2

Connected

EPS A2 EPS B1

Power

Status

EPS Ports: 50 V

8.3 A max per port pair.

Power Status

Device Connected

EPS Ports PairB

(

408 W total for PoE applications

B1

EPS B2

HP 610 EPS

)

Device

B2

Connected

Power

Status

EPS Pair B

EPS Ports on the HP 610 EPS

The HP 610 EPS has four external power supply ports. You can connect one

to four HP PoE capable switches to provide PoE power as a primary or backup

source. Power is equally shared between the EPS ports in pair A (that is, port

A1 and A2) and between the EPS ports in pair B (port B1 and B2); one port in

each pair supplies maximum power (408 W) if the other port is not used.

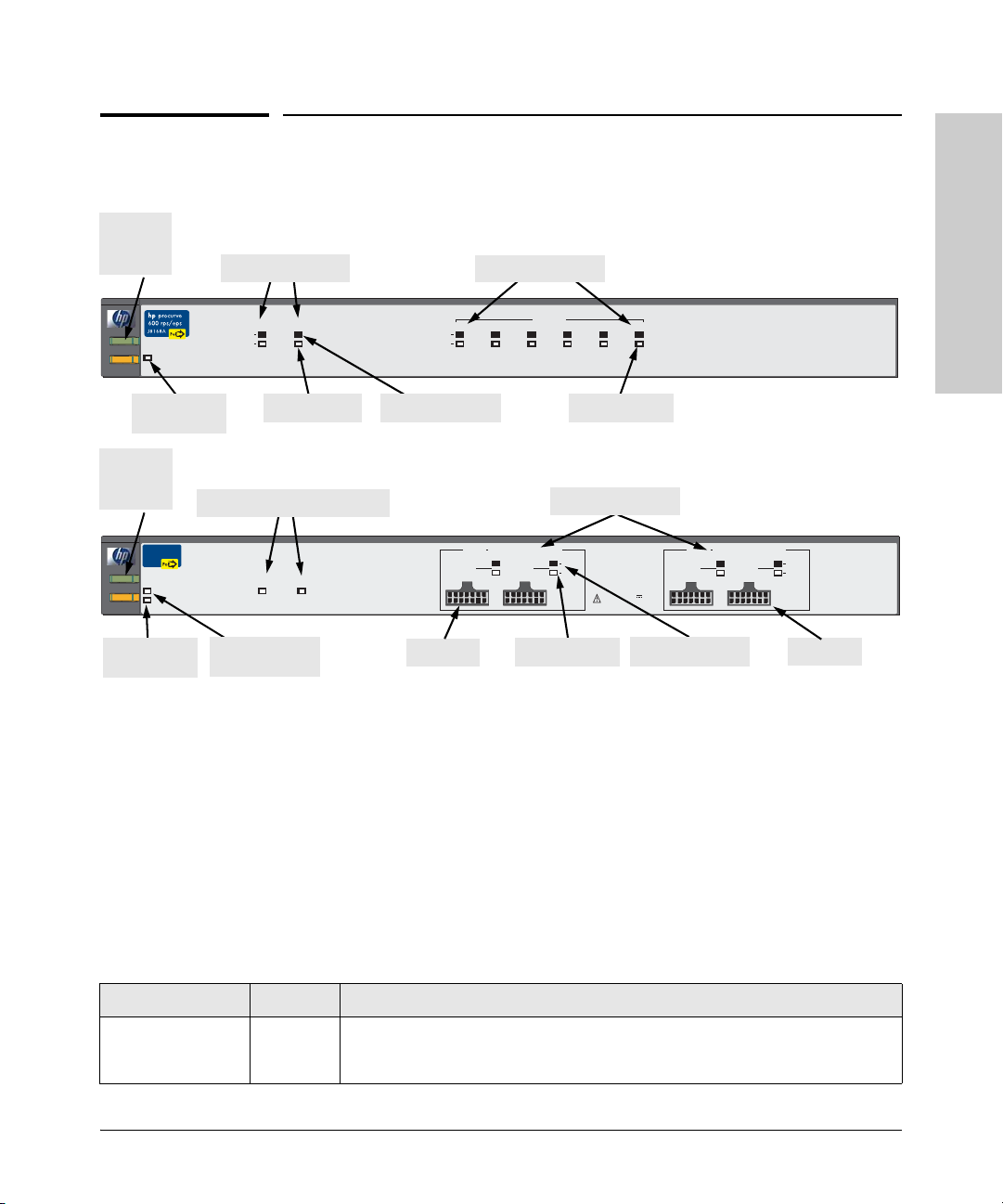

LEDs

Table 1-1. HP 600 RPS/EPS and HP 610 EPS LEDs

LED State Meaning

Power

(green)

On The unit is powered on.

Off The unit is NOT powered on.

1-3

Page 12

Introducing the HP ProCurve 600/610 External Power Supplies

Front of the Unit

Table 1-1. HP 600 RPS/EPS and HP 610 EPS LEDs (Continued)

LED State Meaning

Fault

(orange)

610 External Power Supplies

Introducing the HP ProCurve 600/

Internal Power

Status (green)

(also on back panel

of the HP 610 EPS)

Fan/Temp Status

(green)

Port Status (also on back panel of the HP 600 RPS/EPS)

Device Connected

(green – over-laid

with the port

number)

Power Status

(green)

Off The normal state; indicates that there are no fault conditions on the unit.

Blinking*†A fault has occurred on the unit, one of the ports, or the fan. The Status LED for the

component with the fault will blink simultaneously.

On On briefly after the unit is powered on or reset, at the beginning of unit self test. If

this LED is on for a prolonged time, the unit has encountered a fatal hardware

failure, or has failed its self test. See chapter 3, “Troubleshooting” for more

information.

On The HP 610 EPS unit’s internal power supply is operating normally.

Blinking* The HP 610 EPS unit’s internal power supply has failed and the unit is being

powered by another HP 610 EPS. The unit Fault LED will be blinking simultaneously.

On The cooling fans are operating normally.

Blinking* One of these conditions exists:

• A cooling fan has failed. The unit Fault LED will be blinking simultaneously.

• There is an over temperature condition in the unit. The unit Fault LED is off.

On There is a valid connection to a device. For xl PoE Modules, the EPS Device

Connected LED is only on if the module is receiving power from the 5300 switch

chassis.

Off There is no device connected to the port.

On The unit is supplying power to a connected device.

Off One of these conditions exists:

• There is no connected device.

• A connected RPS device does not require power.

• A connected EPS device has not successfully communicated for EPS power.

Blinking* One of these conditions exists:

• On the HP 600 RPS/EPS, RPS power is not available to the connected device

because a higher priority port is using it.

• When the LED is blinking simultaneously with the Fault LED, there is a fault

condition on the port.

* The blinking behavior is an on/off cycle once every 1.6 seconds, approximately.

†

Specific fault conditions can be viewed by checking switch log files.

1-4

Page 13

Introducing the HP ProCurve 600/610 External Power Supplies

Front of the Unit

Table 1-1. HP 600 RPS/EPS and HP 610 EPS LEDs (Continued)

LED State Meaning

EPS Backup Power Status (on front and back panels of the HP 610 EPS only)

In Ready

(green)

Out Ready

(green)

* The blinking behavior is an on/off cycle once every 1.6 seconds, approximately.

On Backup power is available from another HP 610 EPS in the backup power group.

Off Backup power is not available. One of these conditions exists:

• There is not adequate reserve power in the other units to support this device.

• The backup power cable is not properly connected.

• One or more of the backup power cables are faulty.

On Backup power is available for other HP 610 EPS units in the backup power group.

Off Backup power is not available for other HP 610 EPS units. The unit’s internal power

supply has failed and the unit is being powered by another HP 610 EPS. The unit’s

Internal Power Status and Fault LEDs will be blinking simultaneously.

Introducing the HP ProCurve 600/

610 External Power Supplies

1-5

Page 14

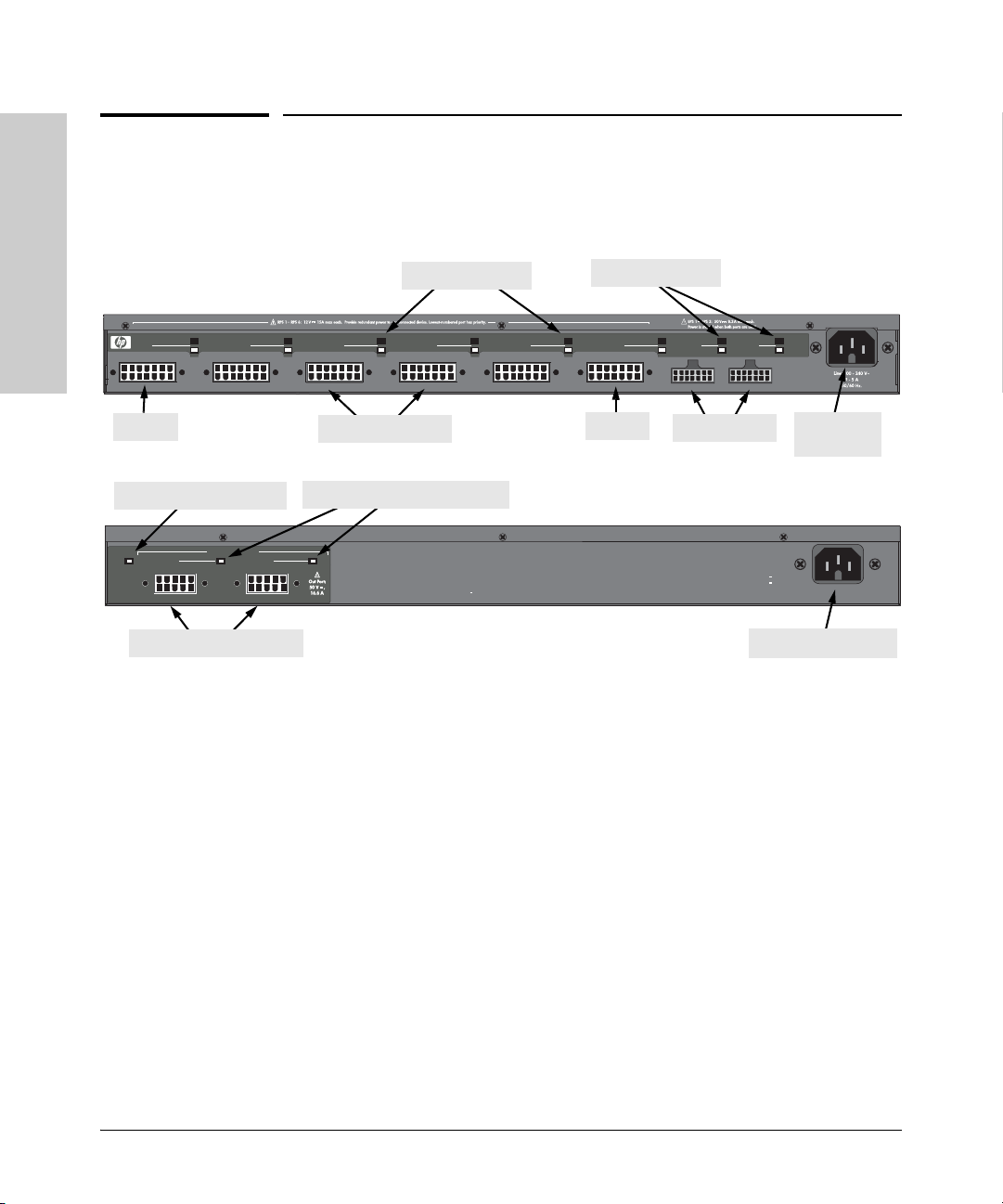

Introducing the HP ProCurve 600/610 External Power Supplies

Back of the Unit

Back of the Unit

Device Connected

RPS 1

610 External Power Supplies

Power Status

Introducing the HP ProCurve 600/

RPS 1

Internal Power Status LED

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power ports

RPS 2

EPS Backup Power Ports

EPS Backup Power Ports

Ready

Ready

RPS port LEDs

EPS port LEDs

HP 600 RPS/EPS

R2

R3R1

RPS 3

R4

RPS 4

RPS ports

R5

RPS 5

RPS 6

R6

RPS 6

E1

EPS 1

EPS ports

EPS Backup Power port LEDs

Ready

Out

Out

Ready

Multiple power sources disconnect both t he AC cord and EPS Bac kup power cables to completely remove power from the unit.

Device

E2

Connected

EPS 2

Power

Status

AC power

connector

HP 610 EPS

Hz

Line: 50/60

240 V~

110

11 6 A

AC power connector

RPS Ports on the HP 600 RPS/EPS

The HP 600 RPS/EPS has six redundant power supply ports. You can connect

up to six HP ProCurve switch units, but backup power can be supplied to only

one unit based on port priority. Port 1 has the highest priority and port 6 the

lowest. A switch connected to port 1 always receives power before any other

port. Likewise, port 2 receives power before ports 3 to 6, port 3 receives power

before ports 4 to 6, and so on down to port 6, which only receives power when

no other port is receiving power.

1-6

EPS Ports on the HP 600 RPS/EPS

The HP 600 RPS/EPS has two external power supply ports. You can connect

one or two HP PoE capable switches to provide PoE power as a primary or

backup source. Power is equally shared between the two EPS ports (204 W

each); one port supplies maximum power (408 W) if the other port is not used.

Page 15

Introducing the HP ProCurve 600/610 External Power Supplies

Back of the Unit

Port Status LEDs

The RPS and EPS port status LEDs on the HP 600 RPS/EPS back panel are a

duplication of those on the front panel. Similarly, the backup power port status

LEDs on the HP 610 EPS back panel are a duplication of those on the front

panel. For a description of these LEDs, see Table 1-1 on page 1-3.

Internal Power Status LED

The Internal Power Status LED on the HP 610 EPS back panel is a duplication

of the one on the front panel. For a description of this LED, see Table 1-1 on

page 1-3.

EPS Backup Power Ports

The HP 610 EPS has two backup power ports that allow up to five EPS units

to be connected together and thereby provide backup power to a failed unit.

However, note that the power load on the remaining active units must be

limited so that there is still enough reserve power to support a failed unit. The

simplest way is to have one unit in the group that has no direct PoE load on

it. Sample topologies are shown at the end of chapter 2 in this book.

Power Connector

Introducing the HP ProCurve 600/

610 External Power Supplies

The HP 600 RPS/EPS and HP 610 EPS do not have a power switch; they are

powered on when connected to an active AC power source. The HP 600 RPS/

EPS automatically adjusts to any voltage between 100--240 volts and either 50

or 60 Hz, and the HP 610 EPS between 110--240 volts and either 50 or 60 Hz.

There are no voltage range settings required.

In addition, the HP 610 EPS may be powered on when receiving power

through a backup power port even when not connected to an active AC power

source.

Caution The power cords supplied for the HP 600 RPS/EPS may be of a lower amperage

rating than those supplied for the HP 610 EPS. For safe operation, only use

the AC power cord that is supplied with the HP 610 EPS.

1-7

Page 16

Introducing the HP ProCurve 600/610 External Power Supplies

RPS Port Operation

610 External Power Supplies

Introducing the HP ProCurve 600/

RPS Port Operation

The HP 600 RPS/EPS can be connected to six switches through RPS cables,

but can provide redundant power to only one switch whose AC power or

internal power supply fails. The unit can provide up to 180 W of power at

+12 VDC to a single switch.

Each RPS port has a priority, with port 1 the highest and port 6 the lowest.

The HP 600 RPS/EPS always provides power to a switch connected to a higher

priority port, if necessary by dropping power to a switch on a lower priority

port. The switching of power from low-priority ports to high-priority ports is

completely automatic and effectively instantaneous.

The HP 600 RPS/EPS is able to detect switches connected to each RPS port

and also the status of their primary AC power supply. The unit supports a hotplug feature where switches can be connected or disconnected to the RPS

ports without causing any disruption either to switch operation or the HP 600

RPS/EPS. Over-current protection on each RPS port prevents any switch from

exceeding the power supply limit of the unit. Any overload condition causes

the HP 600 RPS/EPS to shut down the port.

1-8

EPS Port Operation

The HP 600 RPS/EPS supports two EPS ports and the HP 610 EPS supports

four EPS ports that can provide power to PoE capable switches through EPS

cables. Each external power supply unit can provide PoE power to a switch

as a primary source or as a backup to a switch that has its own internal PoE

power supply.

The EPS ports operate as a pair. The HP 600 RPS/EPS has one pair of EPS

ports that can provide up to 408 W of PoE power at -50 VDC. The HP 610 EPS

has two pairs of EPS ports, each of which can provide up to 408 W of PoE

power at -50 VDC. There are four possible power allocations for each EPS port

pair:

■ Maximum power allocated to the first port and none to the second

■ Maximum power allocated to the second port and none to the first

■ Each port in the pair are allocated half of the maximum power

■ No power allocated to either port in the pair

Page 17

Introducing the HP ProCurve 600/610 External Power Supplies

EPS Backup Power Port Operation

For example, the HP 600 RPS/EPS can allocate 408 W of power to port 1 and

none to port 2, or each port can be allocated 204 W. The HP 610 EPS can

allocate all 408 W of power to port A1 (in pair A) and none to port A2, or each

port can be allocated 204 W.

If power is shared between the two EPS ports, current limits are set to prevent

an over-current condition. An over-current condition causes the port power

to be shut down. Also, EPS power may not be delivered if a connected device

has not successfully communicated for EPS power. Lastly, if the internal EPS

power supply fails, EPS power will be lost unless backup power is provided

from another HP 610 EPS in a backup power group. Try disconnecting, then

reconnecting the EPS cable to restore EPS power. See “Recommended

Connection Topologies” on page 2-16.

EPS Backup Power Port Operation

Up to five HP 610 EPS units can be connected together through EPS backup

power cables, but the EPS backup power ports can provide redundant power

to only one unit whose AC power fails. The active units can provide up to

850 W of power to a single failed HP 610 EPS.

The HP 610 EPS is able to detect other units connected to the backup power

ports and also the status of their primary AC power supply. The HP 610 EPS

supports a hot-plug feature where units can be connected or disconnected to

the backup power ports without causing any disruption to the units in the

backup power group.

Introducing the HP ProCurve 600/

610 External Power Supplies

Note HP recommends connecting the “IN” connector first, then connect the “OUT”

connector. Connecting in this manner ensures there is no voltage on the cable.

1-9

Page 18

Introducing the HP ProCurve 600/610 External Power Supplies

Supported Switches

Supported Switches

Switch HP Product Number EPS/RPS Support

HP ProCurve Switch 2824 J4903A RPS power only

HP ProCurve Switch 2848 J4904A RPS power only

610 External Power Supplies

Introducing the HP ProCurve 600/

HP ProCurve Switch 2626-PWR J8164A Both EPS and RPS power

HP ProCurve Switch 2650-PWR J8165A Both EPS and RPS power

HP ProCurve Switch xl PoE Module J8161A EPS power only

1-10

Page 19

Installing and Connecting the HP 600/610 External Power Supplies

The HP 600 RPS/EPS and HP 610 EPS come with an accessory kit that

includes the brackets for mounting the unit in a standard 19-inch telco rack

or in an equipment cabinet, and rubber feet that can be attached so the unit

can be securely located on a horizontal surface. The brackets are designed to

allow mounting the unit in a variety of locations and orientations.

This chapter shows you how to install the HP 600 RPS/EPS and HP 610 EPS

including:

■ included parts (page 2-2)

■ installation procedures (page 2-3)

■ recommended connection topologies (page 2-16)

2

Installing and Connecting the HP

600/610 External Power Supplies

2-1

Page 20

600/610 External Power Supplies

Installing and Connecting the HP

Installing and Connecting the HP 600/610 External Power Supplies

Included Parts

Included Parts

The HP 600 RPS/EPS and HP 610 EPS have the follo wing components shipped

with them:

■ HP ProCurve 600/610 External Power Supplies Installation and Getting

Started Guide (5990-8800), this manual

■ HP ProCurve PoE Planning and Implementation Guide (5990-8801)

■ Read Me First (5990-8799)

■ Customer Support/Warranty booklet (5990-6019)

■ Accessory kits

(5069-6535) for HP 600 RPS/EPS (5069-5705) for HP 610 EPS

• two mounting brackets

• eight 8-mm M4 screws to attach the

mounting brackets to the unit

• four 5/8-inch number 12-24 screws to

attach the unit to a rack

• four rubber feet

* The mounting brackets differ from the 5069-6535 mounting brackets by being longer to

support the increased depth of the unit.

■ EPS cables; two for the HP 600 RPS/EPS, four for the HP 610 EPS

■ Six RPS cables (HP 600 RPS/EPS only)

■ One EPS backup power cable (HP 610 EPS only)

■ AC power cord, one of the following:

• two mounting brackets*

• eight 8-mm M4 screws to attach the

mounting brackets to the unit

• four 5/8-inch number 12-24 screws to

attach the unit to a rack

• four rubber feet

Japan Power

Cord Warning

2-2

United States/Canada/Mexico

Continental Europe

United Kingdom/Hong Kong/Singapore

Australia/New Zealand

Japan

China

Denmark

Switzerland

HP 610 EPS only:

United States/Canada/Mexico

Japan

8120-5337

8120-5336

8120-5334

8120-5335

8120-5342

8120-8385

8120-5340

8120-5339

8121-0914

8120-5338

Page 21

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

Installation Procedures

Summary

Follow these easy steps to install your HP 600 RPS/EPS or HP 610 EPS. The

rest of this chapter provides details on these steps.

1. Prepare the installation site (page 2-6). Make sure the physical

environment into which you will be installing the unit is properly

prepared, including having the correct cabling ready to connect to the unit

and having an appropriate location for the unit. Please see page 2-4 for

installation precautions.

2. Mount the unit (page 2-6). The unit can be mounted in a 19-inch telco

rack, in an equipment cabinet, or on a horizontal surface.

3. Connect devices to the unit (page 2-9). Using the supplied RPS and

EPS cables, connect the unit to the devices that it will support with

redundant power or PoE power.

4. Connect up to five HP 610 EPS units together to form a backup

power group (page 2-11). The backup power ports can support a single

failed HP 610 EPS connected in a group.

Installing and Connecting the HP

600/610 External Power Supplies

5. Connect power to the unit (page 2-13). Once the unit is mounted,

plug it into a nearby main AC power source.

6. Verify the unit is operating correctly (page 2-14). This is a simple

process of observing that the LEDs on the unit’s front panel indicate

correct operation.

At this point, your unit is fully installed. See the rest of this chapter if you need

more detailed information on any of these installation steps.

2-3

Page 22

600/610 External Power Supplies

Installing and Connecting the HP

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

Installation Precautions:

Follow these precautions when installing your HP 600 RPS/EPS or

HP 610 EPS:

WARNINGS ■ The rack or cabinet should be adequately secured to prevent it

from becoming unstable and/or falling over.

Devices installed in a rack or cabinet should be mounted as low as

possible, with the heaviest devices at the bottom and progressively

lighter devices installed above.

■ Do not use power cord, part number 8120-5337 or 8120-5342, with

the HP 610 EPS. A power cord with a minimum wire gauge of

14 Awg is required to prevent overloading of the power cord. (This

applies to voltages of less than 127 volts.)

■

Cautions ■ Make sure the power source circuits are properly grounded, then use the

power cord supplied with the unit to connect it to the power source.

■ If your installation requires a different power cord than the one supplied

with the unit, be sure to use a power cord displaying the mark of the safety

agency that defines the regulations for power cords in your country. The

mark is your assurance the power cord can be used safely with the unit.

2-4

■ When installing the unit, note that the AC outlet should be near the unit

and should be easily accessible in case the unit must be powered off.

■ Ensure the unit does not overload the power circuits, wiring, and over-

current protection. To determine the possibility of overloading the supply

circuits, add together the ampere ratings of all devices installed on the

same circuit as the unit and compare the total with the rating limit for the

circuit. The maximum ampere ratings are usually printed on devices near

the AC power connectors.

■ Do not install the unit in an environment where the operating ambient

temperature might exceed 55°C (131°F) for the HP 600 RPS/EPS or 50°C

(122°F) for the HP 610 EPS.

■ Make sure the air flow around the sides and back of the unit is not

restricted. If this unit is placed in a fully enclosed rack, make certain the

ambient temperature inside the rack near the unit does not exceed 55°C

(131°F) for the HP 600 RPS/EPS or 50°C (122°F) for the HP 610 EPS.

Page 23

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

■ For safe operation and to prevent equipment damage, DO NOT connect

EPS, RPS, or HP 610 EPS backup power cables to non-supported equipment or in non-supported configurations.

■ If the HP 610 EPS is actively providing backup power to another

HP 610 EPS, disconnect AC power cord before removing backup power

cables. This will reduce possible sparking and equipment damage.

Installing and Connecting the HP

600/610 External Power Supplies

2-5

Page 24

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

1. Prepare the Installation Site

■ Cabling - Only use the EPS cables supplied with the unit for external

power connections to switches. Only use the EPS backup power cables

supplied with the HP 610 EPS to connect to other HP 610 EPS units in the

backup power group. Only use the RPS cables supplied with the

HP 600 RPS/EPS for redundant power connections to switches.

■ Installation Location - Before installing the unit, plan its location and

orientation relative to other devices and equipment:

• In both the front and back of the unit, leave at least 7.6 cm (3 inches)

of space for the EPS and RPS cables, EPS backup power cables, and

the power cord.

• On the sides of the unit, leave at least 7.6 cm (3 inches) for cooling.

2. Mount the Unit

The HP 600 RPS/EPS and HP 610 EPS can be mounted in these ways:

■ in a rack or cabinet

■ on a horizontal surface

600/610 External Power Supplies

Installing and Connecting the HP

Rack or Cabinet Mounting

The HP 600 RPS/EPS and HP 610 EPS are designed to be mounted in any EIAstandard 19-inch telco rack or communication equipment cabinet. The

mounting brackets have multiple mounting holes and can be rotated allowing

for a wide variety of mounting options.

WARNING For safe operation, please read the mounting precautions on

page 2-4, before mounting the unit.

Equipment

Cabinet

Note

2-6

The 12-24 screws supplied with the unit are the correct threading for standard

EIA/TIA open 19-inch racks. If you are installing the unit in an equipment

cabinet such as a server cabinet, use the clips and screws that came with the

cabinet in place of the 12-24 screws that are supplied with the unit.

1. Use a #1 Phillips (cross-head) screwdriver and attach the mounting

brackets to the unit with the included 8-mm M4 screws. The screws must

be tightened sufficiently to provide proper support for the unit in the rack.

Page 25

8 mm

M4 screws

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

Attaching brackets to the HP 600 RPS/EPS

Installing and Connecting the HP

600/610 External Power Supplies

8 mm

M4 screws

Attaching brackets to the HP 610 EPS

2-7

Page 26

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

WARNING For safe reliable installation, only use the screws provided in the

accessory kit to attach the mounting brackets to the unit.

Note Note that the mounting brackets have multiple mounting holes and can be

rotated allowing for a wide variety of mounting options. These include

mounting the unit so that its front face is flush with the face of the rack, or

mounting it in a more balanced position as shown in the illustration above.

2. Hold the unit with attached brackets up to the rack and move it vertically

until rack holes line up with the bracket holes, then insert and tighten the

four number 12-24 screws holding the brackets to the rack.

600/610 External Power Supplies

Installing and Connecting the HP

Horizontal Surface Mounting

Place the unit on a table or other horizontal surface. The unit comes with

rubber feet in the accessory kit that can be used to help keep the unit from

sliding on the surface.

Attach the rubber feet to the four corners on the bottom of the unit within the

embossed angled lines. Use a sturdy surface in an uncluttered area. You may

want to secure the EPS and RPS cables and the unit’s power cord to the table

leg or other part of the surface structure to help prevent tripping over the

cords.

Caution Make sure the air flow is not restricted around the sides and back of the unit.

2-8

Page 27

Installing and Connecting the HP 600/610 External Power Supplies

S

Installation Procedures

3. Connect to Switches

Connect the EPS and RPS cables from the supported network switches to the

appropriate ports on the HP 600 RPS/EPS and HP 610 EPS.

Connecting RPS Ports to Switches

To connect:

Push the RPS cable plug into the d esired

RPS port until the thumb screws engage

with the screw holes in the unit. Tighten

the plug thumb screws to secure the

connection.

When power is on for the HP 600 RPS/

EPS and for the connected switch, the

Device Connected LED should go on to

confirm a powered-on switch is at the

other end of the cable.

If the Device Connected LED does not

go on when the RPS cable is connected

to the port, see Diagnosing with the

LEDs in chapter 3, “Troubleshooting.”

RPS Cable:

• Only use the cables supplied with the unit

• The cable connectors are keyed and can

only be attached in one orientation

R3

3

R4

RPS 4

RP

Installing and Connecting the HP

600/610 External Power Supplies

Note Connect switches to the RPS ports based on their priority, with the highest

priority switch connected to port 1.

To disconnect:

Unscrew the thumb screws on the plug and pull the plug out of the port.

2-9

Page 28

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

Connecting EPS Ports to Switches

To connect:

Push the EPS cable plug into the EPS

port until the tab on the plug clicks into

place. When power is on for the

HP 600 RPS/EPS or HP 610 EPS and for

the connected device, the Device

Connected LED should go on to confirm

a powered-on switch is at the other end

of the cable.

If the Device Connected LED does not

go on when the EPS cable is connected

to the port, see Diagnosing with the

LEDs in chapter 3, “Troubleshooting.”

R6

EPS 1

E1

EPS 2

600/610 External Power Supplies

Installing and Connecting the HP

To disconnect:

Press the small tab on the plug and pull

the plug out of the port.

EPS Cable:

• Only use the cables supplied with the unit

• The cable connectors are keyed and can

only be attached in one orientation

Refer to “EPS Port Operation” on page 1-8 for detailed information and on PoE

power usage, and to “Limitations” on page 2-18 for information on maximum

available PoE power.

2-10

Page 29

Installing and Connecting the HP 600/610 External Power Supplies

d

d

d

d

Installation Procedures

4. HP 610 EPS Only: Connect the EPS Backup Power Ports

Connect the EPS backup power cables to EPS backup power ports on the

HP 610 EPS.

WARNING For safe reliable operation only connect HP 610 EPS backup power

ports to other HP 610 EPS backup power ports. Do not connect to RPS

ports of other devices.

See Connection Topologies specific to the EPS backup power ports for more

information (page 2-21).

Note HP recommends connecting the “IN” connector first, then connect the “OUT”

connector. Connecting in this manner ensures there is no voltage on the cable.

To connect:

1. Attach the end of the backup power cable marked “IN” to the backup

power “In” port on the first unit in the group of HP 610 EPS units. Push

the cable plug into the port until the thumb screws engage with the screw

holes in the unit. Tighten the plug thumb screws to secure the connection.

Installing and Connecting the HP

600/610 External Power Supplies

2. Attach the end of the EPS backup power cable marked “OUT” to the EPS

backup power “Out” port on the next unit in the group.

PS Backup Power Ports

EPS Backup

EPS Backup

Rea

In

Internal

Internal

Power

Power

Status

Status

In

IN

Rea

IN

EPS Power Backup Cable:

• Only use the cables supplied with the unit

PS Backup Power Ports

Ready

Ready

Rea

Out

Out

OUT

Rea

OUT

• The cable connectors are keyed and can

only be attached in one orientation

2-11

Page 30

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

3. If you are connecting up to five units, attach backup power cables in the

same way between the other units to complete the backup power group.

4. (Optional) To form a closed loop or “ring,” connect a backup power cable

from the backup power “In” port on the last unit to the backup power

“Out” port on the first unit. See “EPS Backup Power” on page 2-21 for more

information on the ring topology.

When power is on for each of the HP 610 EPS units in the group, the EPS

Backup Power Port Status LEDs should go on to confirm that these ports are

functioning properly, and backup power is available to other units in the group.

If an EPS Backup Power Port Status LED does not go on when the backup

power cable is connected to the port, see Diagnosing with the LEDs in chapter

3, “Troubleshooting.”

To disconnect:

Unscrew the thumb screws on the plug and pull the plug out of the port.

Refer to “EPS Backup Power Port Operation” on page 1-9 for detailed information and on backup power, and to “EPS Backup Power” on page 2-21 for

information on maximum available backup power.

600/610 External Power Supplies

Installing and Connecting the HP

2-12

Page 31

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

5. Connect to AC Power

Connect the AC power cord supplied with the HP 600 RPS/EPS or HP 610 EPS

to the power connector on the back of the unit, and then into a properly

grounded electrical outlet.

HP 600 RPS/EPS

RPS 5

R5 R6

RPS 6

E1

EPS 1

Device

E2

Connected

EPS 2

Power

Status

Connect the AC power cord to

the power connector

HP 610 EPS

Hz

Line: 50/60

240 V~

110

connect both the AC cord and EPS B ackup power cables to completely remove power from the unit.

11 6 A

Connect the AC power cord to

the power connector

Note The HP 600 RPS/EPS and HP 610 EPS do not have a power switch. They are

powered on when the power cord is connected to the unit and to a power

source. For safety, the power outlet should be located near the unit installation.

The HP 600 RPS/EPS automatically adjusts to any voltage between 100--240

volts and either 50 or 60 Hz, and the HP 610 EPS between 110--240 volts and

either 50 or 60 Hz. There are no voltage range settings required.

Installing and Connecting the HP

600/610 External Power Supplies

If your installation requires a different power cord than the one supplied with

the unit, be sure the cord is adequately sized for the unit’s current requirements. In addition, be sure to use a power cord displaying the mark of the

safety agency that defines the regulations for power cords in your country.

The mark is your assurance that the power cord can be used safely with the

unit.

2-13

Page 32

Installing and Connecting the HP 600/610 External Power Supplies

a

Installation Procedures

6. Verify Correct Operation

When the HP 600 RPS/EPS or HP 610 EPS is mounted in its location and

powered on, you should first verify that it is working properly by checking the

unit’s LEDs.

Check the LEDs on the unit as described below.

600/610 External Power Supplies

Installing and Connecting the HP

Fan/Temp

Power

Status

Fan/TempStatus flash = Temperature too high

Fault

Fan/TempStatus + Fault flash = Fan failure

Power and

Fault LEDs

HP ProCurve

610 EPS

J8169A

Power

Fan/TempStatus flash = Temperature too high

Fault

Fan/TempStatus + Fault flash = Fan failure

Power and

Fault LEDs

Internal Power Status

Fan/Temp Status

RPS port LEDs

R6 R5

RPS Port Status

R4 R3

Device Connected

Power Status

EPS port LEDs

EPS Port Status

E1

E2

Device Connected

Power Status

Fan/Temp Status LED

EPS Ports Pair A

EPS A1

EPS port LEDs

(

408 W total for PoE applications

EPS A2

)

Device

A2A1

Connected

Power

Status

Fan/Temp

Status LED

EPS Backup Power port LEDs

EPS Backup Power Ports Status

Out Ready

In Ready

Internal Power

Status LED

When the unit is powered on, it performs its diagnostic self test. The self test

takes approximately 5 seconds to complete.

HP 600 RPS/EPS

R2

HP 610 EPS

EPS Ports: 50 V

8.3 A max per port p

R1

2-14

LED Behavior:

During the self test:

• Initially, all the unit and port LEDs are on and stay on for most of the

duration of the self test.

• Most of the LEDs go off and then may come on again during phases

of the self test.

When the self test completes successfully:

•The Power, Internal Power Status, and Fan/Temp Status LEDs remain on.

•The Fault LED goes off.

Page 33

Installing and Connecting the HP 600/610 External Power Supplies

Installation Procedures

• The EPS and RPS Port Status LEDs on the HP 600 RPS/EPS and the

EPS Port Status LEDs on the HP 610 EPS go into their normal operational mode:

– If the ports are connected to active devices, the Device Connected

LEDs should be on.

– If the ports are not connected to active devices, the LEDs stay off.

• The EPS Backup Power Port Status LEDs on the front and rear of the

HP 610 EPS go into their normal operational mode:

– If the ports are connected to active HP 610 EPS units and these

units have adequate reserve power to provide backup service, the

LEDs should be on.

– If the ports are not connected to active HP 610 EPS units or these

units do not have adequate reserve power to provide backup

service, the LEDs stay off.

If the LED display is different than what is described above, especially if

the Fault LED stays on for more than 15 seconds or it starts blinking, the

self test has not completed correctly. Refer to chapter 3, “Trouble-

shooting” for diagnostic help.

Installing and Connecting the HP

600/610 External Power Supplies

2-15

Page 34

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

Recommended Connection Topologies

This section shows you some recommended connection topologies using the

HP 600 RPS/EPS and HP 610 EPS. For more topology information, see the HP

ProCurve web site, http://www.hp.com/go/hpprocurve.

RPS Connections on the HP 600 RPS/EPS

Recommendations

The HP 600 RPS/EPS can provide backup power support for up to six HP

ProCurve switches. In the illustration below, six HP ProCurve Switch 2650PWR units are connected to the RPS ports on an HP 600 RPS/EPS.

HP ProCurve Switch 2650-PWR units

600/610 External Power Supplies

Installing and Connecting the HP

Lowest priority

connected to port 6

Highest priority

connected to port 1

RPS cables

RPS

50 V 16 A

50 V 16 A

50 V 16 A

50 V 16 A

50 V 16 A

50 V 16 A

Device Connected

RPS 1

Power Status

R2

RPS 2

12 V 7.5 A

RPS

12 V 7.5 A

RPS

12 V 7.5 A

RPS

12 V 7.5 A

RPS

12 V 7.5 A

RPS

12 V 7.5 A

R3R1

RPS 3

RPS 4

R5

R4

RPS 5

RPS 6

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

R6

EPS 1

Device

E1

E2

Connected

EPS 2

Power

Status

HP 600 RPS/EPS

AC power

2-16

Page 35

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

Limitations

The HP 600 RPS/EPS can supply power to only one connected and failed

switch at a time. In the illustration above, the switch connected to RPS port 1

has the highest priority and the switch connected to RPS port 6 has the lowest

priority. When multiple switches fail, a switch connected to a higher priority

port always receives power before a switch connected to a lower priority port.

Status Indication

The Power Status LEDs on the HP 600 RPS/EPS indicate if a port can provide

power. For example, if six switches are connected to the HP 600 RPS/EPS and

the power to the switch on port 4 fails, the Power Status LED for port 4 turns

on and for ports 5 and 6 it blinks. The Power Status LEDs for ports 1, 2, and 3

remain off. The blinking Power Status LEDs for ports 5 and 6 indicate that

they are lower priority ports and cannot supply power to the connected

switches. The Power Status LED’s are off for ports 1, 2, and 3 because they

have higher priority and if either port requests power, the power will be

removed from port 4 and given to either 1, 2, or 3.

EPS Connections on the HP 600 RPS/EPS

Installing and Connecting the HP

600/610 External Power Supplies

Recommendations

The HP 600 RPS/EPS is designed to provide primary or backup power to up

to two HP PoE switches. In the illustration below, two HP ProCurve Switch

2650-PWR units are being supplied with external PoE power from an

HP 600 RPS/EPS. The switches provide PoE power to Ethernet devices

connected to their ports.

2-17

Page 36

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

HP ProCurve Switch 2650-PWR units

600/610 External Power Supplies

Installing and Connecting the HP

Device Connected

RPS 1

Power Status

EPS cables

RPS

50 V 16 A

50 V 16 A

R2

RPS 2

12 V 7.5 A

RPS

12 V 7.5 A

R3R1

RPS 3

RPS 4

R5

R4

RPS 5

RPS 6

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

R6

EPS 1

Device

E1

E2

Connected

EPS 2

Power

Status

HP 600 RPS/EPS

AC Power

Limitations

In the illustration above, the two switches connected to the HP 600 RPS/EPS

are limited to 204 W of power on each EPS port. If a switch tries to draw more

than 204 W of power from the HP 600 RPS/EPS, an over-current condition

occurs and the EPS port shuts down. To supply more than 204 W on one EPS

port, the other port must first be disconnected. The maximum power that can

be provided when only one EPS port is connected to a switch is 408 W.

2-18

Page 37

Installing and Connecting the HP 600/610 External Power Supplies

hp procurve

PoE

xl module

J8161A

xl

module

PoE

Link

Mode

1

2

3

4

56

PoE-Ready 10/100-TX Ports (1-24) all ports are HP Auto-MDIX

13

14

20

19121110

9

8

7

15

21

16

22 23 24

17 18

Std

PoE

PoE

EPS

Status

LED Mode

Mode

Link

hp procurve

PoE

xl module

J8161A

xl

module

PoE

Link

Mode

1

2

3

4

56

PoE-Ready 10/100-TX Ports (1-24) all ports are HP Auto-MDIX

13

14

20

19121110

9

8

7

15

21

16

22 23 24

17 18

Std

PoE

PoE

EPS

Status

LED Mode

Mode

Link

hp procurve

PoE

xl module

J8161A

xl

module

PoE

Link

Mode

1

2

3

4

56

PoE-Ready 10/100-TX Ports (1-24) all ports are HP Auto-MDIX

13

14

20

19121110

9

8

7

15

21

16

22 23 24

17 18

Std

PoE

PoE

EPS

Status

LED Mode

Mode

Link

hp procurve

PoE

xl module

J8161A

xl

module

PoE

Link

Mode

1

2

3

4

56

PoE-Ready 10/100-TX Ports (1-24) all ports are HP Auto-MDIX

13

14

20

19121110

9

8

7

15

21

16

22 23 24

17 18

Std

PoE

PoE

EPS

Status

LED Mode

Mode

Link

Recommended Connection Topologies

EPS Connections on the HP 610 EPS

Recommendations

The HP 610 EPS is designed to provide primary or backup PoE power to up

to four HP PoE devices. It can be used to supply primary PoE power to up to

four HP ProCurve Switch xl PoE modules (J8161A), after they have been

installed in an HP ProCurve Switch 5308xl switch chassis. The HP 610 EPS

can also be used to supply backup PoE power to up to four HP Procurve

Switch 2650-PWR or 2626-PWR devices or a mix of primary and backup PoE

power to both types of switch devices. For more information regarding

connectivity, see the HP ProCurve PoE Planning and Implementation Guide.

Installing and Connecting the HP

600/610 External Power Supplies

EPS cables

Power

Fault

HPProCurve

610 EPS

J8169A

Internal Power Status

Fan/Temp Status

Fan/TempStatusflash = Temperature too high

Fan/TempStatus+ Fault flash = Fan failure

EPS Backup Power Ports Status

In Ready

HP 610 EPS

(

408 W total for PoE applications

EPS Ports PairA

Out Ready

EPS A1

)

Device

A2

A1

Connected

EPS A2 EPS B1

Power

Status

EPS Ports: 50 V

8.3 A max per port pair.

(

408 W total for PoE applications

)

EPS Ports PairB

Device

B1

B2

Connected

EPS B2

Power

Status

HP ProCurve Switch 5308XL

2-19

Page 38

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

HP ProCurve Switch 2650-PWR units

600/610 External Power Supplies

Installing and Connecting the HP

Power

Fault

EPS cables

HPProCurve

610 EPS

J8169A

Internal Power Status

Fan/Temp Status

Fan/TempStatusflash = Temperature too high

Fan/TempStatus+ Fault flash = Fan failure

50 V 16 A

50 V 16 A

50 V 16 A

50 V 16 A

EPS Backup Power Ports Status

In Ready

RPS

12 V 7.5 A

RPS

12 V 7.5 A

RPS

12 V 7.5 A

RPS

12 V 7.5 A

(

408 W total for PoE applications

EPS Ports PairA

Out Ready

EPS A1

)

Device

A2

A1

Connected

EPS A2 EPS B1

Power

Status

EPS Ports: 50 V

8.3 A max per port pair.

EPS Ports PairB

(

408 W total for PoE applications

B1

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

Line: 50/60 Hz.

100-240 V~ 7.5 A

EPS B2

)

Device

B2

Connected

Power

Status

AC power

HP 610 EPS

Limitations

EPS ports A1 and A2 share one common internal power supply; ports B1 and

B2 share a second common internal power supply. The maximum power that

can be supplied to each port pair is 408 W. In other words, if both ports in a

pair are connected to PoE switches, then the maximum power that each port

can provide is 204 W; but if only one port in a pair is connected to a PoE switch,

that port can provide up to 408 W.

2-20

In the illustration above, the four switches connected to the HP 610 EPS are

limited to 204 W of power on each EPS port. If a switch tries to draw more

than 204 W of power from the HP 610 EPS, an over-current condition occurs

and the EPS port shuts down. To supply more than 204 W on one EPS port,

the other port in the pair must first be disconnected. The maximum power

that can be provided when only one EPS port in a pair is connected to a switch

is 408 W.

Status Indication

The EPS Port Power Status LEDs on the HP 610 EPS indicate if an EPS port

is providing power to the connected device. For example, if four switches are

connected to the HP 610 EPS and the power to the switch on port A1 fails, the

Power Status LED for port A1 turns off, but for ports A2, B1, and B2 it remains

on.

Page 39

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

EPS Backup Power

The purpose of the backup power is to provide redundancy to the PoE power

provided by the HP 610 EPS. Redundancy in PoE power can prevent loss of

power to PoE devices in the event of AC power failure or a power supply

failure on a connected HP 610 EPS.

Each HP 610 EPS incorporates a PoE power supply that is connected so it can

provide power to itself or another HP 610 EPS connected by a cable. The back

of the HP 610 EPS has backup power input and output connectors for

connecting multiple units together to back up each other. There are two

supported configurations for connectivity:

■ Daisy chain, sometimes referred to as a string. Used when incorporating

an unloaded unit as the backup unit for any failed unit in the string.

Therefore, this backup unit must be the first unit in the string.

■ Closed loop, sometimes referred to as a ring. This allows for distributing

loads across all units. See Limitations. HP recommends the closed-loop

configuration.

For example, in the closed loop, the first HP 610 EPS uses the output

connector to connect to the second or next HP 610 EPS input connector, and

so forth until the final HP 610 EPS output connector connects to the input

connector of the first HP 610 EPS. This then completes the connectivity and

closes the loop.

Installing and Connecting the HP

600/610 External Power Supplies

The main difference between the closed loop and the daisy chain is in the daisy

chain the output of the final HP 610 EPS does not connect to anything.

2-21

Page 40

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

EPS Backup Power Ports

First

Last

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

HP 610 EPS units

connected in a string

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

600/610 External Power Supplies

Installing and Connecting the HP

EPS Backup Power cables

AC power

Note The “First” unit is the one with only the “Out” port connected.

The cable connectors are keyed so they must connect an output to an input.

You cannot connect an input to an input. When HP 610 EPS units are

connected in this manner, this allows the sharing of PoE power from one unit

to the other, down the line, should a failure occur.

2-22

Page 41

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

HP 610 EPS units

connected in a ring

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

In

In

Internal

Internal

Power

Power

Status

Status

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Ready

Ready

Ready

Ready

Out

Out

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

Installing and Connecting the HP

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

600/610 External Power Supplies

EPS Backup Power cables

The illustration above shows an example of five HP 610 EPS units connected

in a closed-loop configuration.

Recommendations

The recommended installation is to connect all of the HP 610 EPS units into

one ring. The more units there are in a ring, the more efficient the redundancy.

For example, with three units in a ring the maximum total load for redundancy

is 2/3 of the maximum available power. However with five units in the ring,

the maximum total load is 4/5 of the maximum available power.

Limitations (Calculating required number of HP 610 EPS units)

The total PoE load on all HP 610 EPS units must be less than the total power

available from N-1 of the power supplies, where N is the number of connected

units. The load on each HP 610 EPS must be no greater than the maximum

allowable for a single unit (850 W).

AC power

2-23

Page 42

600/610 External Power Supplies

Installing and Connecting the HP

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

There is a need for some way to ensure this requirement is met. There are two

ways to do this:

■ Sum up all the loads and divide by 850 W (round up to next whole number),

this gives you the required number of HP 610 EPS units. Now for backup

redundancy add one more HP 610 EPS unit.

Or

■ Do not put any load on ONE of the HP610 EPS units, (in a string this must

be the “First” unit). See the illustration and note on page 2-22.

For example, you have 150 phones at 8 W each and 10 wireless access points

at 12 W each, this totals 1320 W. Now you must divide 1320 W by 850 W (the

power of one HP 610 EPS) to get the number of units you will need to support

the 1320 W. 1320 W divided by 850 W equals 1.55. Therefore, you need two

HP 610 EPS units to support these devices. You must round up to the next

whole number. For full backup redundancy, you will need to add one more

HP 610 EPS for a total of three units.

The loads do not have to be distributed equally, for example:

■ With four HP 610 EPS units in a ring, redundancy is achieved if unit A has

a full single load, and B, C, and D each have 2/3 of a maximum single load.

■ With four HP 610 EPS units in a ring, redundancy is achieved if A, B, C,

and D each have 3/4 of a maximum single load.

■ With five HP 610 EPS units, redundancy is achieved if four units have the

maximum single load, and one unit has zero load.

■ With five HP 610 EPS units, redundancy is achieved if all five units have

4/5 of a maximum single load.

2-24

All the preceding examples require a closed-loop configuration. If any unit in

the chain fails, all units then share their power to support the failed unit.

Page 43

Failed unit supported by

other units in the group

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

HP 610 EPS units

connected in a ring

EPS Backup Power Ports

EPS Backup Power Ports

Ready

Ready

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

Ready

Ready

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

Ready

Ready

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

Ready

Ready

In

In

Internal

Internal

Power

Power

Status

Status

EPS Backup Power Ports

EPS Backup Power Ports

Ready

Ready

In

In

Internal

Internal

Power

Power

Status

Status

Ready

Ready

Out

Out

Ready

Ready

Out

Out

Ready

Ready

Out

Out

Ready

Ready

Out

Out

Ready

Ready

Out

Out

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Multiplepower sources disconnectboththe AC cord and EPS Backup power cables to completely remove power from the unit.

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

Installing and Connecting the HP

Hz

Line: 50/60

240 V~

110

11 6 A

Hz

Line: 50/60

240 V~

110

11 6 A

600/610 External Power Supplies

EPS Backup Power cables

AC power

Status Indication

The backup power connector status LEDs indicate if an HP 610 EPS is

connected to another HP 610 EPS unit, and the other unit is powered on. On

the front of the HP 610 EPS there are two LEDs indicating the status of the

backup power. One LED is labeled “IN,” and when it is ON it indicates the

backup power input is connected to another live HP 610 EPS backup power

output.

The other LED is labeled “Out,” and when it is on it indicates the backup power

output is connected to another HP 610 EPS backup power input.

These LEDs do not indicate whether power is flowing or not. They only

indicate that the connections are good and that power is available. In a normal

operating ring, all of these LEDs should be on. These LEDs are also duplicated

on the HP 610 EPS rear panel.

Fault Conditions

A faulty backup power cable connection is indicated by an LED that goes off

for two connected HP 610 EPS units. One unit will have its “In” LED off, and

the other unit will have its “Out” LED off. These LEDs are replicated on both

the front and back of the HP 610 EPS.

2-25

Page 44

Installing and Connecting the HP 600/610 External Power Supplies

Recommended Connection Topologies

A power supply failure is indicated by:

■ Blinking Internal Power Supply LED on the front and back of the

HP 610 EPS

■ EPS Backup Power “Out” LED off on the failed unit

■ EPS Backup Power “In” LED off on the next unit in line

■ Blinking Fault LED on switch connected to the failed HP 610 EPS

Replacement Procedures

In the event of a failure, this is the recommended procedure to follow to

replace a failed unit.

1. Identify the failed unit and schedule downtime for the attached PoE

devices.

2. Reduce the PoE load of the failed unit.

3. Remove the EPS cables.

4. Remove the backup power cables. Additionally, remove the cable

attached to the “Out” port of the previous unit.

5. Remove the AC power.

600/610 External Power Supplies

Installing and Connecting the HP

6. Remove the failed unit.

7. Install a new unit, then reverse this procedure.

Remember, it is the preferred procedure for connecting backup power cables

to attach the “IN” cable end before attaching the “OUT” cable end.

UPS Support

The HP 600 RPS/EPS and HP 610 EPS may be used in configurations where

an Uninterruptible Power Supply (UPS) is desired. See Appendix A, “Specifi-

cations,” for the power requirements of the HP 600 RPS/EPS and HP 610 EPS

for use in determining your UPS requirements.

2-26

Page 45

Troubleshooting

This chapter describes how to troubleshoot your HP 600 RPS/EPS and

HP 610 EPS.

This chapter describes the following:

■ basic troubleshooting tips (page 3-1)

■ diagnosing with the LEDs (page 3-2)

■ diagnostic tests (page 3-5)

■ HP customer support services (page 3-6)

Basic Troubleshooting Tips

Most problems are caused by the following situations. Check for these items

first when starting your troubleshooting:

■ Faulty or loose cables. Look for loose or obviously faulty connections.

If the cables appear to be OK, make sure the connections are secure. If

that does not correct the problem, try a different cable.

■ Connection topologies. It is important to make sure you have a valid

connection topology. The HP 600 RPS/EPS can support two HP PoE

devices on its EPS ports, but with limited power output. Up to six HP

ProCurve switches can be connected to RPS ports, but only one can be

supplied power based on port priority. The HP 610 EPS can support four