Page 1

Maintenance and Service

Guide

HP Notebook Expansion Base

Document Part Number: 344524-001

January 2004

This guide is a troubleshooting reference used for maintaining

and servicing the HP Notebook Expansion Base. It provides

comprehensive information on identifying Expansion Base

features, components, and spare parts; troubleshooting problems;

and performing disassembly procedures.

Page 2

© Copyright 2004 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The

only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing

herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Maintenance and Service Guide

HP Notebook Expansion Base

First Edition January 2004

Document Part Number: 344524-001

Page 3

Contents

1 Product Description

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.2 External Components . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1.3 Wireless Accessories. . . . . . . . . . . . . . . . . . . . . . . . . 1–9

1.4 Design Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

2 Troubleshooting

Before Replacing Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

3 Illustrated Parts Catalog

3.1 Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 3–1

3.2 HP Notebook Expansion Base

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

4 Removal and Replacement Preliminaries

4.1 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.2 Service Considerations . . . . . . . . . . . . . . . . . . . . . . . 4–1

Plastic Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Cables and Connectors . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.3 Preventing Electrostatic Damage . . . . . . . . . . . . . . . 4–2

4.4 Packaging and Transporting Precautions . . . . . . . . . 4–3

4.5 Workstation Precautions . . . . . . . . . . . . . . . . . . . . . . 4–4

4.6 Grounding Equipment and Methods . . . . . . . . . . . . . 4–5

Maintenance and Service Guide iii

Page 4

Contents

5 Removal and Replacement Procedures

5.1 Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

5.2 Disassembly Sequence Chart . . . . . . . . . . . . . . . . . . 5–3

5.3 Preparing the HP Notebook Expansion Base

for Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

5.4 Base Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

5.5 Upper Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

5.6 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–10

5.7 System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–12

5.8 Front Tray Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . 5–14

5.9 Back Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–16

5.10 Expansion Cable . . . . . . . . . . . . . . . . . . . . . . . . . . 5–17

5.11 Speaker Assembly. . . . . . . . . . . . . . . . . . . . . . . . . 5–18

5.12 Front Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–20

6 Specifications

A Connector Pin Assignments

B Power Cord Set Requirements

3-Conductor Power Cord Set . . . . . . . . . . . . . . . . . . . . . . B–1

General Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

Country-Specific Requirements . . . . . . . . . . . . . . . . . . . . B–2

C Screw Listing

Index

iv Maintenance and Service Guide

Page 5

1

Product Description

The HP Notebook Expansion Base expands the connectivity

of HP Compaq Business Notebook nx9100 Series; HP Pavilion

zd7000, zv5000, and zx5000 Series notebook PCs; and the

Compaq Presario R3000 Series notebook PC. The Expansion

Base provides an efficient, less-cluttered work environment,

improved cable management, and wireless peripherals. It

eliminates the need to purchase a separate monitor, external

speakers, USB hub, and a wireless keyboard and mouse kit.

HP Notebook Expansion Base

Maintenance and Service Guide 1–1

Page 6

Product Description

1.1 Features

■ AC power (charges attached notebook while docked)

■ Supports panel sizes up to 17” wide

■ Altec Lansing speakers

■ Wireless keyboard

■ Wireless mouse

■ Wireless keyboard/mouse receiver

■ Security slots

■ Connectors:

❏ Expansion cable

❏ S/PDIF (Sony/Philips Digital Interface) audio connector

❏ Audio out/Headphone jack

❏ Composite out

❏ RJ-11 (modem) connection (from wall to

Expansion Base)

❏ RJ-11 (modem) connection (from Expansion Base to

notebook)

❏ RJ-45/Ethernet port

❏ Six Universal Serial Bus (USB) 2.0 connectors

❏ S-Video out

❏ Serial port

1–2 Maintenance and Service Guide

Page 7

1.2 External Components

The external components on the front panel of the

Expansion Base are shown below and described in Table 1-2.

Product Description

Front components

Maintenance and Service Guide 1–3

Page 8

Product Description

Tabl e 1-2

Front Components

Item Component Function

1 Expansion cable Connects the HP Notebook Expansion Base

2 Stereo speaker

assembly

3 Volume down button Lowers system volume.

4 Mute button Mutes or restores volume.

5 Volume up button Increases system volume.

6 Connection

indicator light

to the notebook computer.

Produces stereo sound from the notebook.

Glows solid blue when the notebook is

connected correctly.

1–4 Maintenance and Service Guide

Page 9

Product Description

The external components on the right side of the Expansion Base

are shown below and described in Table 1-3 .

Right-side components

Tabl e 1-3

Right-Side Components

Item Component Function

1 Audio out/Headphone

jack

2 USB connectors (3) Connect optional USB 2.0 devices.

3 Vent Allows airflow to cool internal components.

4 Kensington security

cable slot

Maintenance and Service Guide 1–5

Connects optional headphone or powered

stereo speakers.

To prevent overheating, do not

Ä

obstruct the vents.

Connects an optional security cable.

The purpose of security solutions is

✎

to act as a deterrent. These

solutions do not prevent the product

from being mishandled or stolen.

Page 10

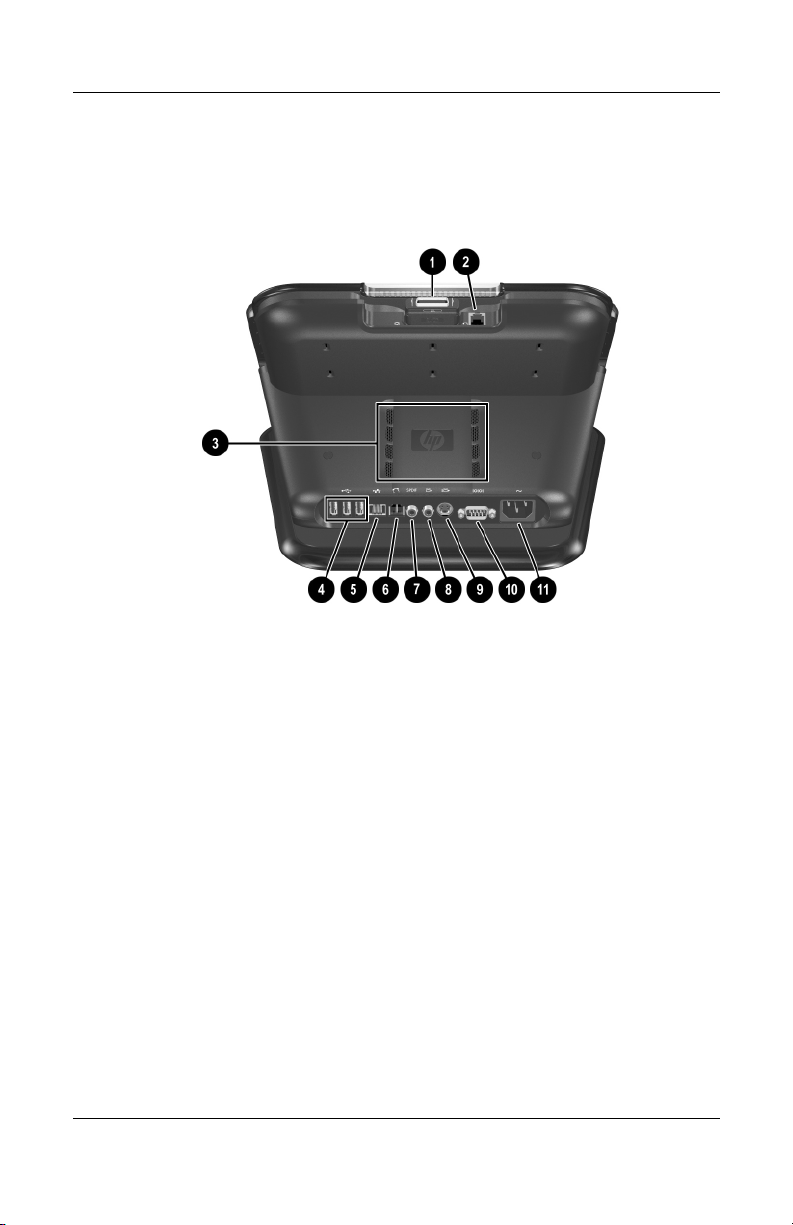

Product Description

The external components on the rear of the Expansion Base are

shown below and described in Table 1-4.

Rear components

1–6 Maintenance and Service Guide

Page 11

Table 1-4

Rear Panel Components

Item Component Function

Product Description

1 Expansion cable Connects the Expansion Base to a

2 RJ-11 jack Connects a modem cable from the

3 Vents (2) Allow airflow to cool internal components.

4 USB connectors (3) Connect optional USB 2.0 devices

5 RJ-45 network jack Connects an Ethernet network cable from

6 RJ-11 jack Connects the Expansion Base to an RJ-11

7 S/PDIF (Sony/Philips

Digital Interface) audio

connector

8 TV out/Composite jack Connects a television, VCR, camcorder, or

9 TV out/ S-Video jack Connects an optional S-Video device, such

10 Serial connector Connects a serial device, such as a mouse.

11 Power connector Connects AC power cord. Charges

notebook computer.

Expansion Base to a notebook.

To prevent overheating, do not

Ä

obstruct the vents.

the Expansion Base to an RJ-45 wall jack.

telephone wall jack.

Connects high-end digital systems, such as

surround sound or a home theatre.

projector.

as a television, VCR, camcorder, projector,

or video capture card.

notebook while docked.

Maintenance and Service Guide 1–7

Page 12

Product Description

The external components on the left side of the Expansion Base

are shown below and described in Table 1-5.

Left-Side Components

Tabl e 1-5

Left-Side Components

Item Component Function

1 Kensington security

cable slot

2 Vent Allows airflow to cool internal components.

1–8 Maintenance and Service Guide

Connects an optional security cable.

The purpose of security solutions is

✎

to act as a deterrent. These

solutions do not prevent the product

from being mishandled or stolen.

To prevent overheating, do not

Ä

obstruct the vents.

Page 13

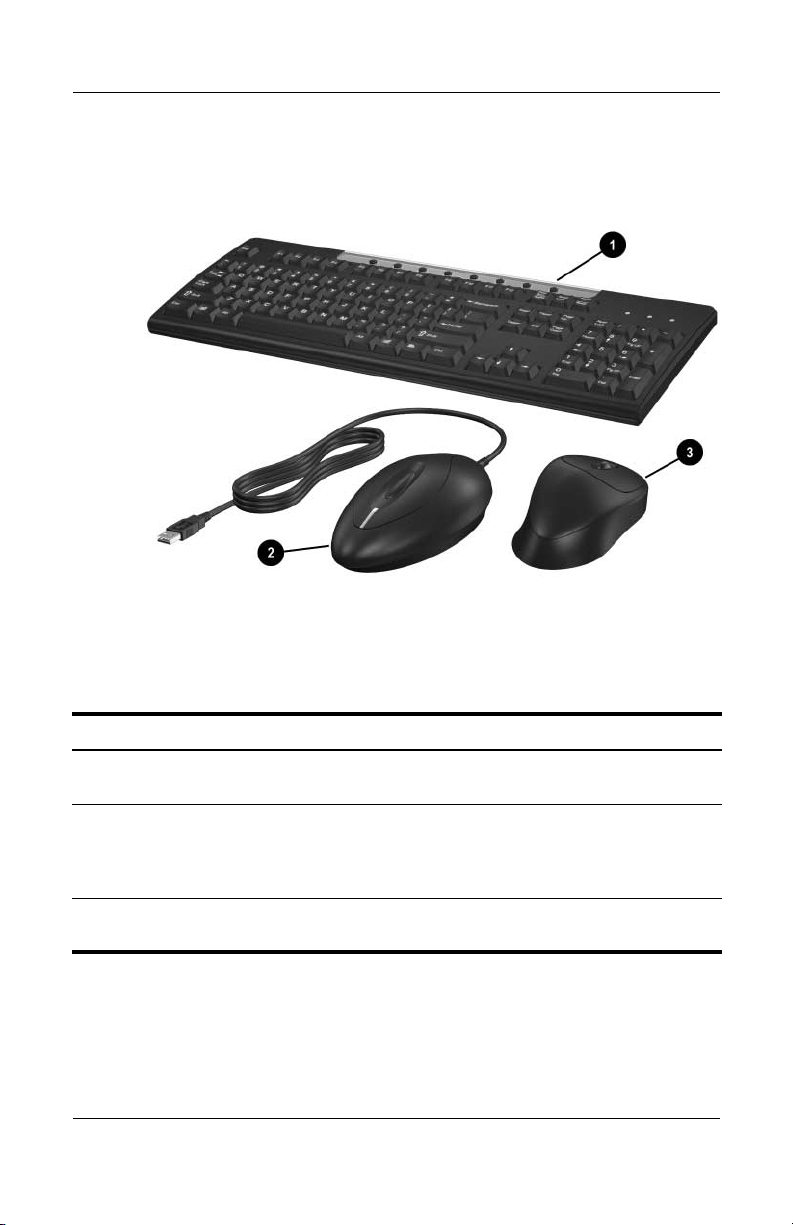

1.3 Wireless Accessories

Product Description

Tabl e 1-6

Wireless Accessories

Item Component Function

1 Wireless keyboard Connects to the Expansion Base without

acable.

2 Receiver Connects to a USB port on the Expansion

Base. Allows connection between the

Expansion Base and the wireless keyboard

and mouse.

3 Wireless mouse Connects to the Expansion Base without

Maintenance and Service Guide 1–9

acable.

Page 14

Product Description

1.4 Design Overview

This section presents a design overview of key parts and features

of the HP Notebook Expansion Base. Refer to Chapter 3,

“Illustrated Parts Catalog,” to identify replacement parts, and

Chapter 5, “Removal and Replacement Procedures,” for

disassembly steps.

The Expansion Base provides the following device connections:

■ Expansion cable

■ S/PDIF (Sony/Philips Digital Interface) audio connector

■ Audio out/Headphone jack

■ Composite out

■ RJ-11 (modem) connection (from wall to Expansion Base)

■ RJ-11 (modem) connection (from Expansion Base to

notebook)

■ RJ-45/Ethernet port

■ Six USB 2.0 connectors

■ S-Video out

■ Serial port

The HP Notebook Expansion Base uses electrical fans for

ventilation. The fans are controlled by a temperature sensor and

are designed to turn on automatically when high temperature

conditions exist. These conditions are affected by high external

temperatures, system power consumption, power

management/battery conservation configurations, and software

applications. Exhaust air is displaced through the ventilation grill

located on the right side, left side, and rear panel of the unit.

CAUTION: To properly ventilate the HP Notebook Expansion Base,

allow at least a 7.6-cm (3-inch) clearance on the left and right sides of

Ä

the unit.

1–10 Maintenance and Service Guide

Page 15

Troubleshooting

WARNING: Only authorized technicians trained by HP should repair

Å

this equipment. All troubleshooting and repair procedures are detailed

to allow only subassembly/module level repair. Because of the

complexity of the individual boards and subassemblies, do not attempt

to make repairs at the component level or modifications to any printed

wiring board. Improper repairs can create a safety hazard. Any

indication of component replacement or printed wiring board

modification may void any warranty or exchange allowances.

This chapter contains troubleshooting information for the

HP Notebook Expansion Base. Carefully match the symptoms of

the malfunction against the problem description in the

Troubleshooting tables to avoid a misdiagnosis. Refer to

Chapter 5 for all removal and replacement procedures.

Follow these guidelines when troubleshooting:

■ Complete the recommended actions in the order in which

they are given.

2

■ When the problem is resolved, do not complete the remaining

troubleshooting steps.

Before Replacing Parts

When troubleshooting a problem, check the following list for

possible solutions before replacing parts:

■ Verify that cables are connected properly to the suspected

defective part.

■ Verify that all required device drivers are installed on the

notebook.

Maintenance and Service Guide 2–1

Page 16

Troubleshooting

Problems and Solutions

The following tables list possible problems, the possible cause of

each problem, and the recommended solution.

Table 2 -1

Power Problems and Solutions

Problem Possible Cause Solution

The blue indicator

light does not

come on.

The notebook

shuts down.

The notebook is not

powered on.

The Expansion Base is not

connected to AC power.

The expansion cable on

the Expansion Base is not

properly connected to the

expansion connector on

the notebook.

If the above solutions are

unsuccessful, the

expansion cable may be

damaged.

If the above solutions are

unsuccessful, the power

supply may be

malfunctioning.

The Expansion Base is not

plugged into an AC power

outlet, draining the

notebook battery pack.

If the above solution is

unsuccessful, the power

supply may be

malfunctioning.

Turn on the notebook.

Verify that the AC cable is

properly connected to the

Expansion Base and to an

AC power outlet.

Turn off the notebook and

unplug the expansion cable.

Then plug the expansion

cable back in to the notebook

and turn the notebook on.

Replace the expansion

cable. (Section 5.10)

Replace the power supply.

(Section 5.6)

Plug the Expansion Base

into an AC power outlet.

Replace the power supply.

(Section 5.6)

2–2 Maintenance and Service Guide

Page 17

Table 2 -2

External Device Problems and Solutions

Problem Possible Cause Solution

Troubleshooting

A new device is not

recognized as part

of the notebook

system.

The device cable or power

cord is loose.

■ Test the device first by

plugging it into the

appropriate notebook

connector. Note that

composite TV out and

serial connectors are not

supported on the

notebook.

■ Ensure that all cables are

securely connected to

the device and the

Expansion Base.

■ Ensure that all power

cords are securely

connected to the device

and to an electrical

outlet.

Device cabling is incorrect. Ensure that the device cable

is in the correct connector on

the Expansion Base.

The device was connected

while the system was on.

Device drivers may need

to be installed on the

notebook.

Turn off the notebook, turn

on the device (if applicable),

and then turn on the

notebook.

Install drivers according to

the device manufacturer’s

instructions.

If the above solutions are

unsuccessful, the system

board may be

malfunctioning.

Maintenance and Service Guide 2–3

Replace the system board.

(Section 5.7)

Page 18

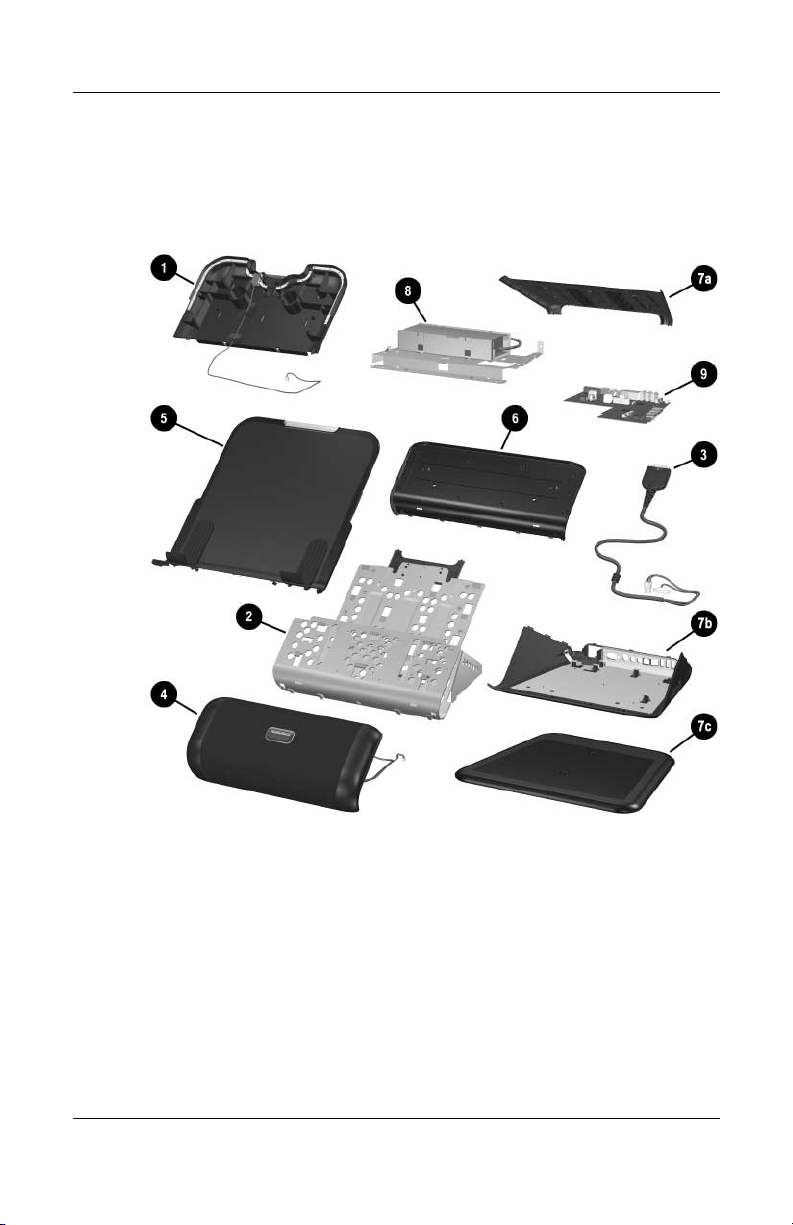

Illustrated Parts Catalog

This chapter provides an illustrated parts breakdown and a

reference for spare part numbers and option part numbers.

3.1 Serial Number Location

When ordering parts or requesting information, provide the

Expansion Base serial number and model number located on

the bottom of the base plate.

3

Serial number location

Maintenance and Service Guide 3–1

Page 19

Illustrated Parts Catalog

3.2 HP Notebook Expansion Base

Major Components

HP Notebook Expansion Base major components

3–2 Maintenance and Service Guide

Page 20

Illustrated Parts Catalog

Tabl e 3-1

Spare Parts: HP Notebook Expansion Base

Major Components

Spare Part

Item Description

1 Back panel (with modem connector and cable) 347433-001

2 Upper chassis 347434-001

3 Expansion cable 347435-001

4 Speaker assembly 347431-001

5 Front tray cover 347432-001

Number

Miscellaneous Plastics Kit (including the following

components)

6Front case

7a Rear cover

7b Base enclosure

7c Base plate

8 Power supply and shield 347438-001

9 System board 347437-001

347436-001

Maintenance and Service Guide 3–3

Page 21

Illustrated Parts Catalog

HP Notebook Expansion Base miscellaneous components

3–4 Maintenance and Service Guide

Page 22

Illustrated Parts Catalog

Tabl e 3-1

Spare Parts: HP Notebook Expansion Base Miscellaneous

Components

Spare Part

Item Description

1 Receiver 348088-001

2 Wireless mouse 348087-001

3 Wireless keyboard

ADP

Australia

Brazil

Canada (Fr.)

Czech Rep.

Denmark

Europe

France

Germany

Greece

Hong Kong

Hungary

India

Iceland

Israel

Italy

Japan

Korea

348086-371

348086-011

348086-201

348086-121

348086-221

348086-081

348086-021

348086-051

348086-041

348086-151

348086-DC1

348086-211

348086-D61

348086-DD1

348086-BB1

348086-061

348086-291

348086-AD1

Latin America

The Netherlands

Norway

Poland

Portugal

Peoples Republic of

China

Russia

Saudi Arabia

Sweden/Finland

Slovenia

Spain

Thailand

Tu r ke y

Ta i wa n

United Kingdom

United States

Number

348086-161

348086-331

348086-091

348086-241

348086-131

348086-AA1

348086-251

348086-171

348086-B71

348086-BA1

348086-071

348086-281

348086-141

348086-AB1

348086-031

348086-001

Maintenance and Service Guide 3–5

Page 23

Illustrated Parts Catalog

Spare Parts: HP Notebook Expansion Base

Miscellaneous Components (not illustrated)

Item Description

Power cord

Australia

Brazil

Denmark

Europe

French Canada

Israel

India

Italy

Japan

Korea

China

Switzerland

United Kingdom

United States

Table 3 -2

Spare Part

Number

345252-011

345252-201

345252-081

345252-021

345252-121

345252-BB1

345252-D61

345252-061

345252-291

345252-AD1

345252-AA1

345252-111

345252-031

345252-001

3–6 Maintenance and Service Guide

Page 24

Removal and Replacement

This chapter provides essential information for proper and safe

removal and replacement service.

4.1 Tools Required

You will need the following tools to complete the removal and

replacement procedures:

■ Magnetic screwdriver

■ Phillips P0 screwdriver

■ 5.0-mm hex socket for system board standoffs

■ Flat-bladed screwdriver

■ Tool kit (includes connector removal tool, loopback plugs,

and case utility tool)

4

Preliminaries

4.2 Service Considerations

The following sections include some of the considerations that

you should keep in mind during disassembly and assembly

procedures.

As you remove each subassembly from the Expansion Base,

✎

place the subassembly (and all accompanying screws) away from

the work area to prevent damage.

Maintenance and Service Guide 4–1

Page 25

Removal and Replacement Preliminaries

Plastic Parts

Using excessive force during disassembly and reassembly can

damage plastic parts. Use care when handling the plastic parts.

Apply pressure only at the points designated in the maintenance

instructions.

Cables and Connectors

Cables must be handled with extreme care to avoid damage.

Apply only the tension required to unseat or seat the cables

during removal and insertion. Handle cables by the connector

whenever possible. In all cases, avoid bending, twisting, or

tearing cables. Ensure that cables are routed in such a way that

they cannot be caught or snagged by parts being removed or

replaced. Handle flex cables with extreme care; these cables

tear easily.

CAUTION: When servicing the Expansion Base, ensure that cables

are placed in their proper locations during the reassembly process.

Ä

Improper cable placement can damage the Expansion Base.

4.3 Preventing Electrostatic Damage

Many electronic components are sensitive to electrostatic

discharge (ESD). Circuitry design and structure determine the

degree of sensitivity. Networks built into many integrated circuits

provide some protection, but in many cases, the discharge

contains enough power to alter device parameters or melt silicon

junctions.

A sudden discharge of static electricity from a finger or other

conductor can destroy static-sensitive devices or microcircuitry.

Often the spark is neither felt nor heard, but damage occurs.

An electronic device exposed to electrostatic discharge might not

be affected at all and can work perfectly throughout a normal

cycle. Or the device might function normally for a while, and then

degrade in the internal layers, reducing its life expectancy.

4–2 Maintenance and Service Guide

Page 26

Removal and Replacement Preliminaries

4.4 Packaging and Transporting

Precautions

Use the following grounding precautions when packaging and

transporting equipment:

■ To avoid hand contact, transport products in static-safe

containers, such as tubes, bags, or boxes.

■ Protect all electrostatic-sensitive parts and assemblies with

conductive or approved containers or packaging.

■ Keep electrostatic-sensitive parts in their containers until

the parts arrive at static-free workstations.

■ Place items on a grounded surface before removing items

from their containers.

■ Always be properly grounded when touching a sensitive

component or assembly.

■ Store reusable electrostatic-sensitive parts from assemblies in

protective packaging or nonconductive foam.

■ Use transporters and conveyors made of antistatic belts and

roller bushings. Ensure that mechanized equipment used for

moving materials is wired to ground and that proper materials

are selected to avoid static charging. When grounding is not

possible, use an ionizer to dissipate electric charges.

Maintenance and Service Guide 4–3

Page 27

Removal and Replacement Preliminaries

4.5 Workstation Precautions

Use the following grounding precautions at workstations:

■ Cover the workstation with approved static-shielding material

(refer to Table 4-2, Static-Shielding Materials).

■ Use a wrist strap connected to a properly grounded work

surface and use properly grounded tools and equipment.

■ Use conductive field service tools, such as cutters,

screwdrivers, and vacuums.

■ When using fixtures that must directly contact dissipative

surfaces, only use fixtures made of static-safe materials.

■ Keep the work area free of nonconductive materials, such as

ordinary plastic assembly aids and Styrofoam.

■ Handle electrostatic-sensitive components, parts, and

assemblies by the case or PCM laminate. Handle these items

only at static-free workstations.

■ Avoid contact with pins, leads, or circuitry.

■ Turn off power and input signals before inserting or removing

connectors or test equipment.

4–4 Maintenance and Service Guide

Page 28

Removal and Replacement Preliminaries

4.6 Grounding Equipment and

Methods

Grounding equipment must include either a wrist strap or a foot

strap at a grounded workstation.

■ When seated, wear a wrist strap connected to a grounded

system. Wrist straps are flexible straps with a minimum of

one megohm ±10% resistance in the ground cords. To

provide proper ground, wear a strap snugly against the skin

at all times. On grounded mats with banana-plug connectors,

use alligator clips to connect a wrist strap.

■ When standing, use foot straps and a grounded floor mat.

Foot straps (heel, toe, or boot straps) can be used at standing

workstations and are compatible with most types of shoes

or boots. On conductive floors or dissipative floor mats, use

foot straps on both feet with a minimum of one megohm

resistance between the operator and ground. To be effective,

the conductive strips must be worn in contact with the skin.

Other grounding equipment recommended for use in preventing

electrostatic damage includes:

■ Antistatic tape

■ Antistatic smocks, aprons, and sleeve protectors

■ Conductive bins and other assembly or soldering aids

■ Nonconductive foam

■ Conductive tabletop workstations with ground cords of

one megohm resistance

■ Static-dissipative tables or floor mats with hard ties to

the ground

■ Field service kits

■ Static awareness labels

Maintenance and Service Guide 4–5

Page 29

Removal and Replacement Preliminaries

■ Material-handling packages

■ Nonconductive plastic bags, tubes, or boxes

■ Metal tote boxes

■ Electrostatic voltage levels and protective materials

Table 4-1 shows how humidity affects the electrostatic voltage

levels generated by different activities.

Tabl e 4-1

Typical Electrostatic Voltage Levels

Relative Humidity

Event 10% 40% 55%

Walking across carpet 35,000 V 15,000 V 7,500 V

Walking across vinyl floor 12,000 V 5,000 V 3,000 V

Motions of bench worker 6,000 V 800 V 400 V

Removing DIPS from plastic tube 2,000 V 700 V 400 V

Removing DIPS from vinyl tray 11,500 V 4,000 V 2,000 V

Removing DIPS from Styrofoam 14,500 V 5,000 V 3,500 V

Removing bubble pack from PCB 26,500 V 20,000 V 7,000 V

Packing PCBs in foam-lined box 21,000 V 11,000 V 5,000 V

A product can be degraded by as little as 700 V.

✎

Table 4-2 lists the shielding protection provided by antistatic bags

and floor mats.

Table 4 -2

Static-Shielding Materials

Material Use Voltage Protection Level

Antistatic plastic Bags 1,500 V

Carbon-loaded plastic Floor mats 7,500 V

Metallized laminate Floor mats 5,000 V

4–6 Maintenance and Service Guide

Page 30

5

Removal and Replacement

Procedures

This chapter provides removal and replacement procedures.

There are 37 screws and standoffs, in six different sizes, that must

be removed, replaced, and loosened when servicing the

Expansion Base. Make special note of each screw size and

location during removal and replacement.

Refer to Appendix C, “Screw Listing,” for detailed information

on screw sizes, locations, and usage.

Maintenance and Service Guide 5–1

Page 31

Removal and Replacement Procedures

5.1 Serial Number

Report the Expansion Base serial number to HP when requesting

information or ordering spare parts. The serial number is located

on the bottom of the Expansion Base.

Serial number location

5–2 Maintenance and Service Guide

Page 32

Removal and Replacement Procedures

5.2 Disassembly Sequence Chart

Use the chart below to determine the section number to be

referenced when removing Expansion Base components.

Disassembly Sequence Chart

# of Screws

Section Description

5.3 Preparing the Expansion Base for disassembly

5.4 Base plate 4

5.5 Upper chassis 2

5.6 Power supply 5

5.7 System board 5

5.8 Front tray cover 4

5.9 Back panel 4

5.10 Expansion cable 4

5.11 Speaker assembly 2

5.12 Front case 6

Removed

Maintenance and Service Guide 5–3

Page 33

Removal and Replacement Procedures

5.3 Preparing the HP Notebook

Expansion Base for Disassembly

Perform the following steps before disassembling the

Expansion Base:

1. If the notebook computer is in the Expansion Base,

turn off the notebook and press the buttons on the end of

the expansion cable 1 to disconnect the cable from the

notebook 2.

2. Disconnect the AC adapter and all external devices.

The location of the expansion connector on the notebook may

✎

vary by notebook series and model.

Disconnecting the expansion cable

5–4 Maintenance and Service Guide

Page 34

5.4 Base Plate

Spare Part Number Information

Removal and Replacement Procedures

Base plate The base plate is included in the

Miscellaneous Plastics Kit

1. Turn the Expansion Base upside down with the front facing

away from you.

2. Remove the four PM2.5×17.0 screws 1 that secure the base

plate to the base enclosure.

3. Remove the base plate 2.

347436-001

Removing the base plate

Reverse the above procedure to install the base plate.

Maintenance and Service Guide 5–5

Page 35

Removal and Replacement Procedures

5.5 Upper Chassis

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Turn the Expansion Base right-side up with the rear panel

facing you.

4. Remove the adhesive-backed 8.0-mm diameter screw

covers 1.

5. Remove the two PM2.0×6.0 screws 2 that secure the rear

cover to the base enclosure.

Removing the rear cover screws

5–6 Maintenance and Service Guide

Page 36

Removal and Replacement Procedures

6. Lift the front edge of the rear cover up 1 until it disengages

from the base enclosure.

7. Slide the rear cover toward you 2 and remove it.

Removing the rear cover

Maintenance and Service Guide 5–7

Page 37

Removal and Replacement Procedures

8. Disconnect the following cables from the system board:

1 4-wire cable

2 2-wire RJ-11 modem cable

3 50-pin cable

4 6-wire cable

5 4-wire power cable

Disconnecting the cables from the system board

5–8 Maintenance and Service Guide

Page 38

Removal and Replacement Procedures

9. Remove the two PM2.0×4.0 screws 1 that secure the upper

chassis to the base enclosure.

10. Swing the top edge of the upper chassis upward 2 to

disengage it from the base enclosure.

11. Lift the upper chassis straight up 3 and remove it.

Removing the upper chassis

Reverse the above procedure to install the upper chassis.

Maintenance and Service Guide 5–9

Page 39

Removal and Replacement Procedures

5.6 Power Supply

Spare Part Number Information

Power supply 347438-001

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Remove the upper chassis (Section 5.5).

4. Turn the base enclosure upside down with the front

facing you.

5. While holding the power supply in place with one hand

underneath, remove the five PM2.0×6.0 screws that secure

the power supply to the base enclosure.

Removing the power supply screws

5–10 Maintenance and Service Guide

Page 40

Removal and Replacement Procedures

6. Turn the base enclosure right-side up with the rear

facing you.

7. On the base enclosure, disconnect the power supply cable 1

from the system board.

8. Lift the power supply and shield approximately one inch 2.

9. While holding the power supply and shield, remove the

power connector 3 from the supports in the base enclosure.

Removing the power supply

Reverse the above procedure to install the power supply.

Maintenance and Service Guide 5–11

Page 41

Removal and Replacement Procedures

5.7 System Board

Spare Part Number Information

System board 347437-001

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Remove the upper chassis (Section 5.5).

4. Remove the power supply (Section 5.6).

5. Position the base enclosure with the rear panel facing you.

6. Remove the three PM2.0×6.0 screws 1 that secure the

system board to the base enclosure.

7. Use a 5.0-mm hex socket to remove the two HM5.0x9.0

standoffs 2 on either side of the serial connector.

Removing the system board screws and standoffs

5–12 Maintenance and Service Guide

Page 42

Removal and Replacement Procedures

8. Swing the top left edge of the system board clockwise 1 until

the audio connector 2 disengages from the hole 3 in the base

enclosure.

9. Remove the system board from the base enclosure 4.

Removing the system board

Reverse the above procedure to install the system board.

Maintenance and Service Guide 5–13

Page 43

Removal and Replacement Procedures

5.8 Front Tray Cover

Spare Part Number Information

Front tray cover 347432-001

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Remove the upper chassis (Section 5.5).

4. Turn the upper chassis upside down with the docking

connector and cable facing away from you.

5. Cut all tie-wraps 1 that bundle the Expansion Base cables

and secure the RJ-11 modem cable to the chassis.

6. Remove the four PM2.0×4.0 screws 2 that secure the front

tray cover to the chassis.

Removing the front tray cover screws

5–14 Maintenance and Service Guide

Page 44

Removal and Replacement Procedures

7. Turn the upper chassis right-side up with the expansion cable

facing you.

8. Slide the front tray cover upward and then away from you to

remove it.

Removing the front tray cover

Reverse the above procedure to install the front tray cover.

Maintenance and Service Guide 5–15

Page 45

Removal and Replacement Procedures

5.9 Back Panel

Spare Part Number Information

Back panel with RJ-11 cable 347433-001

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Remove the upper chassis (Section 5.5).

4. Remove the front tray cover (Section 5.8).

5. Position the upper chassis right-side up with the speakers

facing you.

Make sure that the back panel is supported before performing the

✎

following steps.

6. Remove the four PM2.0×4.0 screws 1 that secure the back

panel to the chassis.

7. Remove the back panel with the RJ-11 cable attached 2.

Removing the back panel

Reverse the above procedure to install the back panel.

5–16 Maintenance and Service Guide

Page 46

Removal and Replacement Procedures

5.10 Expansion Cable

Spare Part Number Information

Expansion cable 347435-001

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Remove the upper chassis (Section 5.5).

4. Remove the front tray cover (Section 5.8).

5. Remove the back panel (Section 5.9).

6. Turn the upper chassis right-side up with the rear facing you.

Rotate the chassis so that the expansion cable connector is

facing away from you.

7. Remove the four PM2.0×2.0 screws 1 that secure the

expansion cable clamps to the chassis.

8. Remove the expansion cable clamps 2 and the

expansion cable 3.

Removing the expansion cable clamps and expansion cable

Reverse the above procedure to install the expansion cable.

Maintenance and Service Guide 5–17

Page 47

Removal and Replacement Procedures

5.11 Speaker Assembly

Spare Part Number Information

Speaker assembly 347431-001

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Remove the upper chassis (Section 5.5).

4. Remove the front tray cover (Section 5.8).

Although the back panel and expansion cable are not shown in the

✎

figure, it is not necessary to remove them.

5. Turn the upper chassis upside down, with the bottom facing

you and the speaker assembly facing down.

6. Remove the 6-wire audio control cable 1 and the 4-wire

speaker cable 2 from the chassis hole through which they are

routed.

7. Remove the two PM2.0×4.0 screws 3 that secure the speaker

assembly to the chassis.

Removing the speaker assembly screws

5–18 Maintenance and Service Guide

Page 48

Removal and Replacement Procedures

8. Rotate the chassis 180 degrees toward you.

9. Slide the speaker assembly away from you 1 to disengage it

from the chassis.

10. Lift the edge of the speaker assembly to remove it from the

chassis 2.

Removing the speaker assembly

Reverse the above procedure to install the speaker assembly.

Maintenance and Service Guide 5–19

Page 49

Removal and Replacement Procedures

5.12 Front Case

Spare Part Number Information

Front case (plastics kit) 347436-001

Upper chassis 347434-001

1. Prepare the Expansion Base for disassembly (Section 5.3).

2. Remove the base plate (Section 5.4).

3. Remove the upper chassis (Section 5.5).

4. Remove the front tray cover (Section 5.8).

5. Remove the speaker assembly (Section 5.11).

6. Turn the chassis right-side up with the rear facing you. Rotate

the top of the chassis toward you.

7. Remove the six PM2.0×5.0 screws 1 that secure the upper

chassis front case to the chassis.

8. Slide the front case toward you 2 to disengage it from the

chassis.

9. Remove the front case 3 from the chassis.

Removing the front case

Reverse the above procedure to install the front case.

5–20 Maintenance and Service Guide

Page 50

This chapter provides physical and performance specifications.

Dimensions

6

Specifications

Tabl e 6-1

HP Notebook Expansion Base

Height

Width

Depth

Weight

Stand-alone power requirements

Power supply 18.5 V at 8 amps

Tem pe rature

Operating (not writing

optical)

Operating (writing

optical)

Nonoperating

Applicable product safety standards specify thermal limits for plastic

✎

surfaces. The notebook operates well within this range of

temperatures.

Relative humidity (noncondensing)

Operating

Nonoperating

22.8 cm

31.8 cm

29.8 cm

3.5 kg 7.5 lb

0°C to 35°C

5°C to 35°C

-20°C to 60°C

10% to 90%

5% to 95%, 38.7°C (101.6°F) maximum wet bulb

temperature

9 in

12.5 in

11.75 in

32°F to 95°F

41°F to 95°F

-4°F to 140°F

Maintenance and Service Guide 6–1

Page 51

Specifications

Table 6 -2

Internal AC Adapter

Power supply 160 W with PFC

Rated input voltage

Rated input current

Rated frequency

100 to 240 VAC RMS

1.7 A RMS

47 to 63 Hz

6–2 Maintenance and Service Guide

Page 52

Connector Pin Assignments

Table A -1

RJ-45 Network Interface

Pin Signal Pin Signal

1 Transmit + 5 Unused

2 Transmit – 6 Receive –

3 Receive + 7 Unused

4Unused 8Unused

A

Maintenance and Service Guide A–1

Page 53

Connector Pin Assignments

Table A -2

RJ-11 Modem

Pin Signal Pin Signal

1Unused 4Unused

2 Tip 5 Unused

3Ring 6Unused

Table A -3

Universal Serial Bus

Pin Signal Pin Signal

1 +5 VDC 3 Data +

2 Data – 4 Ground

A–2 Maintenance and Service Guide

Page 54

Connector Pin Assignments

Table A -4

S-Video

43

12

Pin Signal Pin Signal

1 Ground (Y) 3 Y-Luminance (Intensity)

2 Ground (C) 4 C-Chrominance (Color)

Table A -5

Audio Line-Out

Pin Signal Pin Signal

1 Audio out 2 Ground

Maintenance and Service Guide A–3

Page 55

Connector Pin Assignments

Tabl e A-6

Serial

Pin Signal Pin Signal

1 Carrier detect 6 Data set ready

2 Receive data 7 Ready to send

3 Transmit data 8 Clear to send

4 Data terminal ready 9 Ring indicator

5Ground

A–4 Maintenance and Service Guide

Page 56

Connector Pin Assignments

Tabl e A-7

S/PDIF Audio Line-Out

12

Pin Signal Pin Signal

1 Audio signal 2 Ground/return

Tabl e A-8

Video

12

Pin Signal Pin Signal

1 Video signal 2 Ground/return

Maintenance and Service Guide A–5

Page 57

Power Cord Set Requirements

3-Conductor Power Cord Set

The wide range input feature of the notebook permits it to operate

from any line voltage from 100 to 120 or 220 to 240 volts AC.

The power cord set shipped with the notebook meets the

requirements for use in the country where the equipment is

purchased.

Power cord sets for use in other countries must meet the

requirements of the country where the notebook is used.

General Requirements

The requirements listed below are applicable to all countries:

■ The length of the power cord set must be at least 1.5 meters

(5.00 feet) and a maximum of 2.0 meters (6.50 feet).

B

■ All power cord sets must be approved by an acceptable

accredited agency responsible for evaluation in the country

where the power cord set will be used.

■ The power cord set must have a minimum current capacity of

10 amps and a nominal voltage rating of 125 or 250 volts AC,

as required by each country’s power system.

■ The appliance coupler must meet the mechanical

configuration of an EN 60 320/IEC 320 Standard Sheet C13

connector for mating with the appliance inlet on the back of

the notebook.

Maintenance and Service Guide B–1

Page 58

Power Cord Set Requirements

Country-Specific Requirements

3-Conductor Power Cord Set Requirements

Applicable Note

Country Accredited Agency

Australia EANSW 1

Austria OVE 1

Belgium CEBC 1

Canada CSA 2

Denmark DEMKO 1

Finland FIMKO 1

France UTE 1

Germany VDE 1

Italy IMQ 1

Japan METI 3

The Netherlands KEMA 1

Number

Norway NEMKO 1

Sweden SEMKO 1

Switzerland SEV 1

B–2 Maintenance and Service Guide

Page 59

Power Cord Set Requirements

3-Conductor Power Cord Set Requirements

(Continued)

Applicable Note

Country Accredited Agency

United Kingdom BSI 1

United States UL 2

Number

Notes

1. The flexible cord must be <HAR> Type HO5VV-F, 3-conductor, 1.0 mm²

conductor size. Power cord set fittings (appliance coupler and wall plug)

must bear the certification mark of the agency responsible for evaluation in

the country where it will be used.

2. The flexible cord must be Type SPT-3 or equivalent, No. 18 AWG,

3-conductor. The wall plug must be a 2-pole grounding type with a NEMA

5-15P (15 A, 125 V) or NEMA 6-15P (15 A, 250 V) configuration.

3. The appliance coupler, flexible cord, and wall plug must bear a “T” mark

and registration number in accordance with the Japanese Dentori Law.

The flexible cord must be Type VCT or VCTF, 3-conductor, 1.00 mm²

conductor size. The wall plug must be a 2-pole grounding type with a

Japanese Industrial Standard C8303 (7 A, 125 V) configuration.

Maintenance and Service Guide B–3

Page 60

C

Screw Listing

This appendix provides specification and reference information

for the screws used in the HP Notebook Expansion Base. All

screws listed in this appendix are available in the Miscellaneous

Screw Kit, spare part number 347439-001.

Maintenance and Service Guide C–1

Page 61

Screw Listing

Table C - 1

Phillips PM2.5×17.0 Screw

mm

Where used:

Four screws that secure the base plate to the base enclosure

(documented in Section 5.4)

Color Qty. Length Thread

Bronze 4 17.0 mm 2.5 mm 6.0 mm

Head

Width

Phillips M2.5×17.0 screw locations

C–2 Maintenance and Service Guide

Page 62

Table C - 2

Phillips PM2.0×6.0 Screw

mm

Where used:

Five screws that secure the power supply to the base enclosure

(documented in Section 5.6)

Color Qty. Length Thread

Bronze 10 6.0 mm 2.0 mm 4.5 mm

Screw Listing

Head

Width

Phillips M2.0×6.0 screw locations

Maintenance and Service Guide C–3

Page 63

Screw Listing

Table C - 2

Phillips PM2.0×6.0 Screw

mm

Where used:

Two screws that secure the rear cover to the base enclosure

(documented in Section 5.5)

Color Qty. Length Thread

Bronze 10 6.0 mm 2.0 mm 4.5 mm

(Continued)

Head

Width

Phillips M2.0×6.0 screw locations

C–4 Maintenance and Service Guide

Page 64

Tabl e C-2

Phillips PM2.0×6.0 Screw

mm

Where used:

Three screws that secure the system board to the base enclosure

(documented in Section 5.7)

Color Qty. Length Thread

Bronze 10 6.0 mm 2.0 mm 4.5 mm

(Continued)

Screw Listing

Head

Width

Phillips M2.0×6.0 screw locations

Maintenance and Service Guide C–5

Page 65

Screw Listing

Table C - 4

HM5.0×9.0 Standoff

mm

Where used:

Two standoffs that secure the system board to the base enclosure

(documented in Section 5.7)

Color Qty. Length Thread

Silver 2 9.0 mm 5.0 mm 5.0 mm

Head

Width

HM5.0×9.0 screw locations

C–6 Maintenance and Service Guide

Page 66

Table C - 5

Phillips PM2.0×4.0 Screw

mm

Where used:

Two screws that secure the upper chassis to the base enclosure

(documented in Section 5.5)

Color Qty. Length Thread

Bronze 18 4.0 mm 2.0 mm 4.0 mm

Screw Listing

Head

Width

Phillips M2.0×4.0 screw locations

Maintenance and Service Guide C–7

Page 67

Screw Listing

Table C - 5

Phillips PM2.0x4.0 Screw

mm

Where used:

Four screws that secure the front tray cover to the upper chassis

(documented in Section 5.8)

Color Qty. Length Thread

Bronze 18 4.0 mm 2.0 mm 4.0 mm

(Continued)

Head

Width

Phillips M2.0x4.0 screw locations

C–8 Maintenance and Service Guide

Page 68

Table C - 5

Phillips PM2.0×4.0 Screw

mm

Where used:

Four screws that secure the back panel to the chassis

(documented in Section 5.9)

Color Qty. Length Thread

Bronze 18 4.0 mm 2.0 mm 4.0 mm

(Continued)

Screw Listing

Head

Width

Phillips M2.0x4.0 screw locations

Maintenance and Service Guide C–9

Page 69

Screw Listing

Table C - 5

Phillips PM2.0×4.0 Screw

mm

Where used:

Two screws that secure the speaker assembly to the chassis

(documented in Section 5.11)

Color Qty. Length Thread

Bronze 18 4.0 mm 2.0 mm 4.0 mm

(Continued)

Head

Width

Phillips M2.0x4.0 screw locations

C–10 Maintenance and Service Guide

Page 70

Table C - 5

Phillips PM2.0×4.0 Screw

mm

Where used:

Six screws that secure the front case to the chassis

(documented in Section 5.12)

Color Qty. Length Thread

Bronze 18 4.0 mm 2.0 mm 4.0 mm

(Continued)

Screw Listing

Head

Width

Phillips M2.0x4.0 screw locations

Maintenance and Service Guide C–11

Page 71

Screw Listing

Table C - 6

Phillips PM2.0×2.0 Screw

mm

Where used:

Four screws that secure the expansion cable brackets to the chassis

(documented in Section 5.10)

Color Qty. Length Thread

Silver 4 2.0 mm 2.0 mm 8 mm

Head

Width

Phillips M2.0x2.0 screw locations

C–12 Maintenance and Service Guide

Page 72

Index

A

AC adapter specifications 6–2

audio line-out pin assignments

A–3

B

back panel

removal

spare part number

base enclosure, spare part number

3–3

base plate

removal

spare part number

5–16

3–3

5–5

3–3

C

cables, service considerations 4–2

components

1–3

front

left-side

rear

right-side

composite jack

connection indicator light

connector pin assignments

audio line-out

modem jack

network jack

RJ-11 telephone jack

1–5

1–5

1–3, 1–5

1–7

1–4

A–3

A–2

A–1

A–2

RJ-45 network jack

S/PDIF audio line-out jack

serial connector

S-Video connector

USB connectors

connectors, service considerations

4–2

A–4

A–3

A–2

D

design overview 1–10

disassembly sequence chart

E

electrostatic discharge 4–2, 4–6

expansion base specifications

expansion cable

disconnecting

removal

spare part number

1–4, 1–7

5–4

5–17

3–3

F

features 1–2

front case

removal

spare part number

front components

front tray cover

removal

spare part number

5–20

3–3

1–3

5–14

3–3

A–1

A–5

5–3

6–1

Maintenance and Service Guide Index–1

Page 73

Index

G

grounding equipment and methods

4–5

H

headphone jack 1–5

K

keyboard, wireless 1–9

L

left-side components 1–5

M

Miscellaneous Plastics Kit, spare

part number

modem jack, pin assignments

mouse, wireless

mute button

3–3

A–2

1–9

1–4

N

network jack, pin assignments A–1

P

packing precautions 4–3

plastic parts

power connector

power cord set requirements

power cord, spare part numbers

3–6

power supply

removal

spare part number

4–2

1–7

B–1

5–10

3–3

R

rear components 1–5

rear cover

removal

spare part number

5–6

3–3

receiver

function

spare part number

removal preliminaries

replacement preliminaries

right-side components

RJ-11 telephone jack

location

pin assignments

RJ-45 network jack

location

pin assignments

1–9

3–5

4–1

1–3, 1–5

1–7

A–2

1–7

A–1

S

S/PDIF audio line-out jack

pin assignments

S/PDIF connector location

screw listing

security cable slot

serial connector

location

pin assignments

serial number

service considerations

speaker assembly

location

removal

spare part number

specifications

AC adapter

expansion base

static shielding materials

S-Video connector

location

pin assignments

1–7

1–4

5–18

1–7

A–5

C–1

1–5, 1–8

A–4

3–1, 5–2

4–1

3–3

6–2

6–1

4–6

A–3

4–1

1–7

Index–2 Maintenance and Service Guide

Page 74

Index

system board

removal

spare part number

system board cables, removal

5–12

3–3

T

tools required 4–1

transporting precautions

troubleshooting

problems and solutions

TV out, location

2–1

1–7

4–3

2–2

U

upper chassis

removal

spare part number

USB connectors

location

pin assignments

5–6

3–3

1–5, 1–7

A–2

5–8

V

vent 1–5, 1–7, 1–8

volume down button

volume up button

1–4

1–4

W

wireless accessories 1–9

wireless keyboard

spare part numbers

wireless mouse

spare part number

workstation precautions

1–9

3–5

1–9

3–5

4–4

Maintenance and Service Guide Index–3

Loading...

Loading...