Page 1

Color LaserJet MFP E87640, E87650, E87660

LaserJet MFP E82540, E82550, E82560

On-Site Installation Guide

Page 2

Copyright and License

Trademark Credits

© Copyright 2017 HP Development Company,

L.P.

Reproduction, adaptation, or translation without

prior written permission is prohibited, except as

allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed as

constituting an additional warranty. HP shall not

be liable for technical or editorial errors or

omissions contained herein.

Edition 5, 4/2019

Adobe®, Acrobat®, and PostScript® are

trademark

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered trademarks

of Microsoft Corporation.

ENERGY STAR and the ENERGY STAR mark are

registered U.S. marks.

s of Adobe Systems Incorporated.

Page 3

Table of contents

1 About this printer ...................................................................................................................................................................................... 1

On-site installation guide purpose ........................................................................................................................................ 2

Order information ..................................................................................................................................................................... 3

Customer information ............................................................................................................................................................. 4

2 Conguration ............................................................................................................................................................................................. 5

Conguration options .............................................................................................................................................................. 6

HP Color LaserJet MFP E87640, E87650, E87660 and HP LaserJet MFP E82540, E82550,

E82560 .................................................................................................................................................................. 6

3 Worksheets ................................................................................................................................................................................................ 9

Technical site setup ................................................................................................................................................................ 10

Logistics information ............................................................................................................................................................. 12

Network/printer driver setup ............................................................................................................................................... 14

Email/Send To conguration ................................................................................................................................................ 15

4 Specications .......................................................................................................................................................................................... 17

Size and weight specications ............................................................................................................................................. 18

System conguration dimensions ....................................................................................................................................... 19

Base printer conguration ............................................................................................................................... 20

Printer with cabinet conguration .................................................................................................................. 21

Printer with booklet nisher conguration .................................................................................................... 22

Printer with booklet nisher and side HCI conguration ............................................................................. 23

Operational clearance space requirements ....................................................................................................................... 24

Environmental specications ............................................................................................................................................... 25

Power requirements .............................................................................................................................................................. 26

5 Staging ..................................................................................................................................................................................................... 27

Staging checklists ................................................................................................................................................................... 28

Unboxing and basic assembly .............................................................................................................................................. 29

Engine preparation ............................................................................................................................................ 30

ENWW iii

Page 4

Stacking .......................................................................................................................................... 30

HP Color LaserJet MFP E87640, E87650, E87660 and HP LaserJet MFP

E82540, E82550, E82560 ...................................................................................... 30

Finishers .............................................................................................................................................................. 32

Initial supplies installation .................................................................................................................................................... 34

Install toner ........................................................................................................................................................ 34

HP Color LaserJet MFP E87640, E87650, E87660 ................................................................. 34

HP LaserJet MFP E82540, E82550, E82560 ............................................................................ 37

Initial power on ....................................................................................................................................................................... 41

Install imaging drum (HP Color LaserJet MFP E87640, E87650, E87660) .............................................. 41

Install imaging drum (HP LaserJet MFP E82540, E82550, E82560) ........................................................ 45

Engine adjustments and tests ............................................................................................................................................. 49

Load paper in trays and input devices ............................................................................................................ 49

Prepare for shipment to customer location ....................................................................................................................... 56

Repack (from customer site) ................................................................................................................................................ 57

Local move ......................................................................................................................................................... 57

Long distance move .......................................................................................................................................... 57

6 Late point dierentiation conguration (LPDC) ................................................................................................................................. 59

LPDC installation steps .......................................................................................................................................................... 60

Automatically download and transfer speed license ................................................................................... 60

Process notes, cautions, and miscellaneous ................................................................................................ 64

Support information ..................................................................................................................... 64

7 On-site nal setup .................................................................................................................................................................................. 65

On-site nal setup checklist ................................................................................................................................................. 66

Clean laser scanner assembly after setup (HP Color LaserJet MFP E87640, E87650, E87660) .............................. 67

Cleaning the laser scanner assembly window (HP Color LaserJet MFP E87640, E87650, E87660

only) ..................................................................................................................................................................... 67

Cleaning the ow document feeder white bar and CIS ............................................................................... 68

Cleaning the scan glass .................................................................................................................................... 69

Check the vertical gap between engine and nisher ........................................................................................................ 70

Load paper trays .................................................................................................................................................................... 70

Install paper tray labels ......................................................................................................................................................... 70

Staples ..................................................................................................................................................................................... 71

Engine rmware upgrade after installing nisher ........................................................................................ 71

Print and copy tests ............................................................................................................................................................... 72

8 Complete installation procedures ........................................................................................................................................................ 73

Cabinet stand and dual cassette feeder (DCF) installation .............................................................................................. 74

Install the cabinet on the HP LaserJet MFP E82540, E82550, E82560 ................................................... 74

iv ENWW

Page 5

2000-sheet HCI ...................................................................................................................................................................... 76

Install the 2000-sheet HCI on the HP Color LaserJet MFP E87640, E87650, E87660 .......................... 76

Install the 3000-sheet sHCI .................................................................................................................................................. 79

Installing tray heater in a HP LaserJet 2000-sheet HCI ................................................................................................... 81

Finishers .................................................................................................................................................................................. 82

Install the Inner Finisher on the HP Color LaserJet MFP E87640, E87650, E87660 .............................. 82

Install the Inner Punch ...................................................................................................................................... 83

Stapler/Stacker Finisher .................................................................................................................................... 85

Stapler/Stacker Finisher .................................................................................................................................... 85

Booklet Maker Finisher with punch ................................................................................................................. 86

Installation of HP LaserJet job separator ...................................................................................................... 87

Staples ................................................................................................................................................................. 88

Stabilization Chocks ............................................................................................................................................................... 96

Index ............................................................................................................................................................................................................. 99

ENWW v

Page 6

vi ENWW

Page 7

1 About this printer

●

On-site installation guide purpose

●

Order information

●

Customer information

ENWW 1

Page 8

On-site installation guide purpose

Use this On-Site Installation Guide to assess the customer site before product deployment, to congure and

prepare the devices for installation. Identify all the required information and address any issues in advance to

make sure the site is ready for installation. This workbook includes information to make sure that the customer

site meets power, environment, networking, space, staging, and setup requirements.

There are mandatory questions and checklist items in the informational forms the customer or site technician

must answer. To avoid a poor customer experience, do not deploy the printer without answering these

questions. If the customer refuses to provide the information, it is the technician’s responsibility to inform them

of the potential consequences to the delivery and installation process. It is critical to validate if the customer’s

site can accommodate the printer and serviceability space requirements.

Some customer questions and checklist items are indicated as optional, but ll out the workbook as completely

as possible.

2 Chapter 1 About this printer ENWW

Page 9

Order information

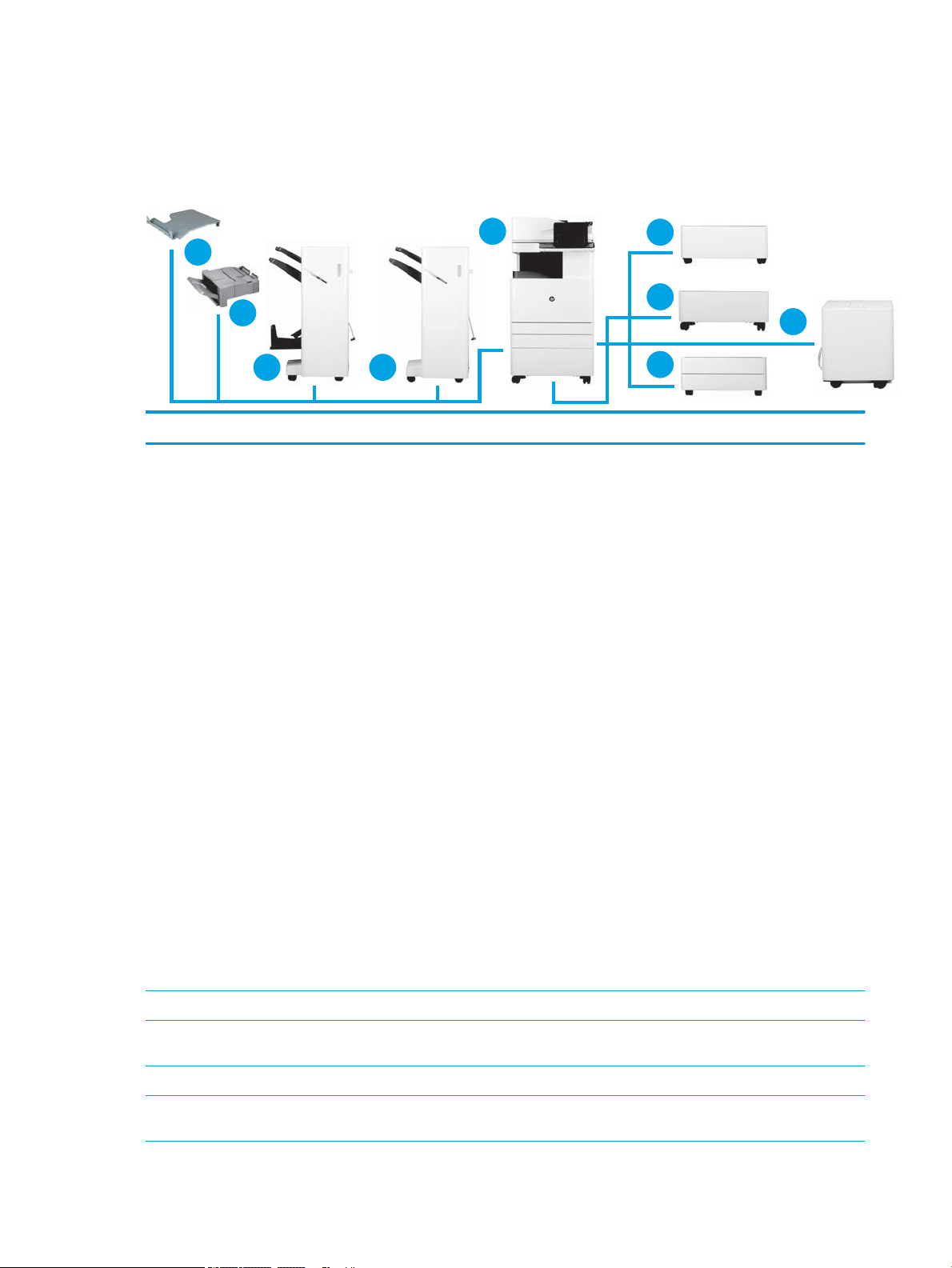

Table 1-1 Products and accessories

Category Product number Service part number

(Break/x)

Input Y1G16A SAM-SL-HPU501T HP LaserJet Department Cabinet

Y1F98A SAM-SL-PFP501D HP LaserJet Dual Cassette Department Feeder

Y1G21A SAM-SL-HCF501B HP LaserJet 2000 Sheet High Capacity Input Tray

Y1F20A SAM-SL-HCF501S HP LaserJet High Capacity Input Tray Side Department

Output Y1G00A SAM-SL-FIN502L HP LaserJet Inner Finisher

Y1G02A SAM-SL-HPU501T HP LaserJet Inner Finisher Hole 2/3 Punch

Y1G03A SAM-SL-HPU501F HP LaserJet Inner Finisher Hole 2/4 Punch

Y1G04A SAM-SL-HPU501S HP LaserJet Inner Finisher Swedish Punch

Y1G07A SAM-SL-FIN701B HP LaserJet Booklet Finisher

Y1G10A SAM-SL-HPU701T HP LaserJet Finisher Hole Punch 2/3 Accessory

Y1G11A SAM-SL-HPU701F HP LaserJet Finisher Hole Punch 2/4 Accessory

Y1G12A SAM-SL-HPU701S HP LaserJet Finisher Hole Punch Swedish Accessory

Y1G13A SAM-SL-STP000 HP LaserJet Inner/Booklet Finisher Staples

Y1G14A SAM-SCX-STP000 HP LaserJet Stapler/Stacker Finisher Staples

Product/accessory description Quantity

Department (HCI)

(sHCI)

Y1G01A Y1G01–67901 HP LaserJet Job Separator Department

Y1G18A SAM-SL-FIN701H HP LaserJet Stapler/Stacker Finisher

Accessories Y1G22A#BGJ SAM-CLX-DHK11C HP LaserJet Paper Tray Heaters Accessory Department

(110V)

Y1G22A#B19 SAM-CLX-DHK12C HP LaserJet Paper Tray Heaters Accessory Department

(220V)

ENWW Order information 3

Page 10

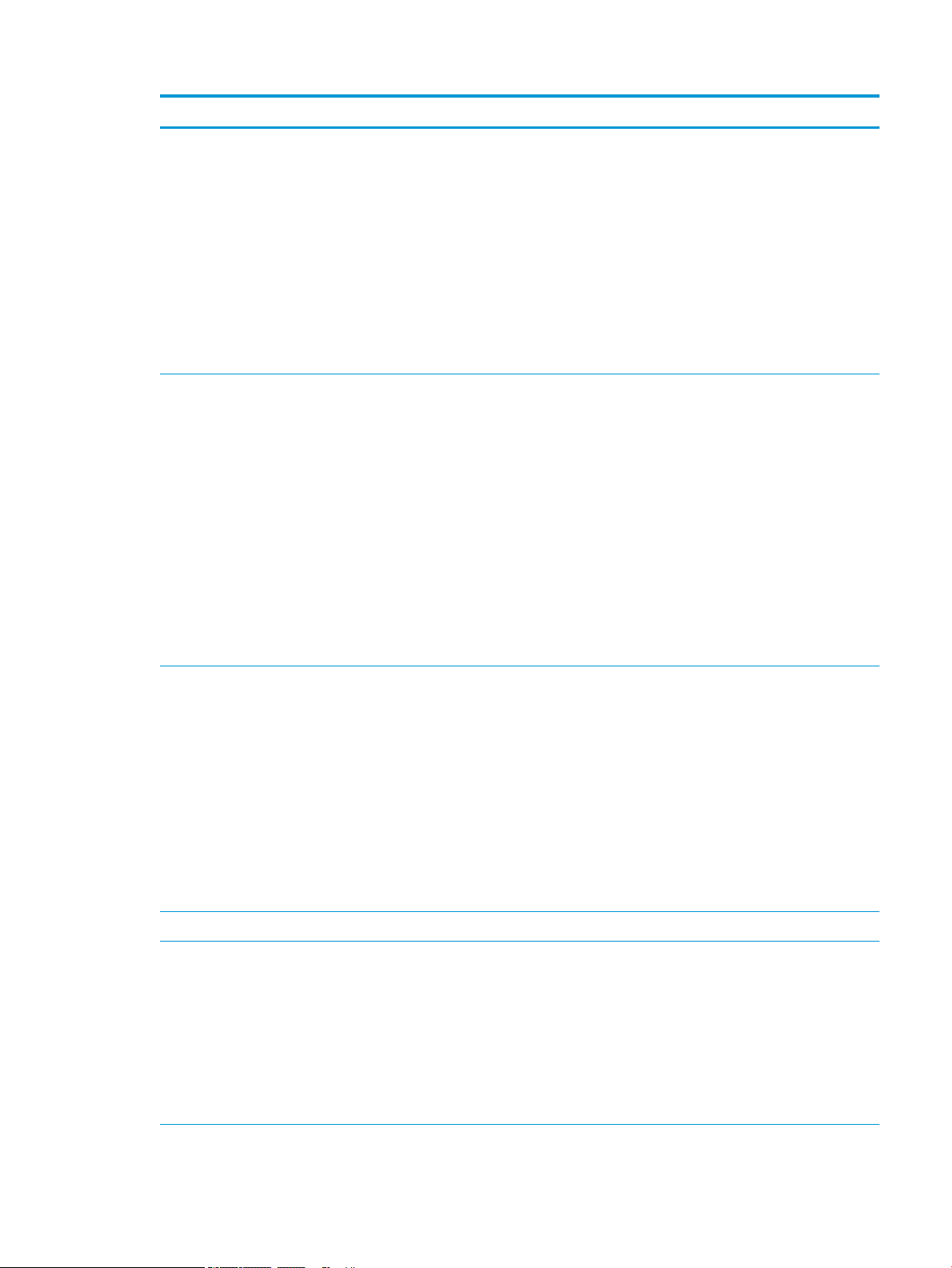

Customer information

Table 1-2 Customer information

Information type Customer details

Installation address (if dierent from

customer address)

Targeted delivery, or installation date and

time

Customer address

Customer contact name (optional)

Contact phone and fax number (optional)

Key operator or site installation contact name

(optional)

Key operator or site installation phone

number (optional)

Backup customer contact information

(optional)

IT contact name (optional)

Installation contact name

Installation contact phone number

HP sales person name (optional)

HP sales person phone number (optional)

HP solution architect

HP Hardware Support Technician

Reseller name (if indirect customer) (optional)

Reseller address (if indirect customer)

(optional)

Reseller phone number (if indirect customer)

(optional)

4 Chapter 1 About this printer ENWW

Page 11

2 Conguration

●

Conguration options

ENWW 5

Page 12

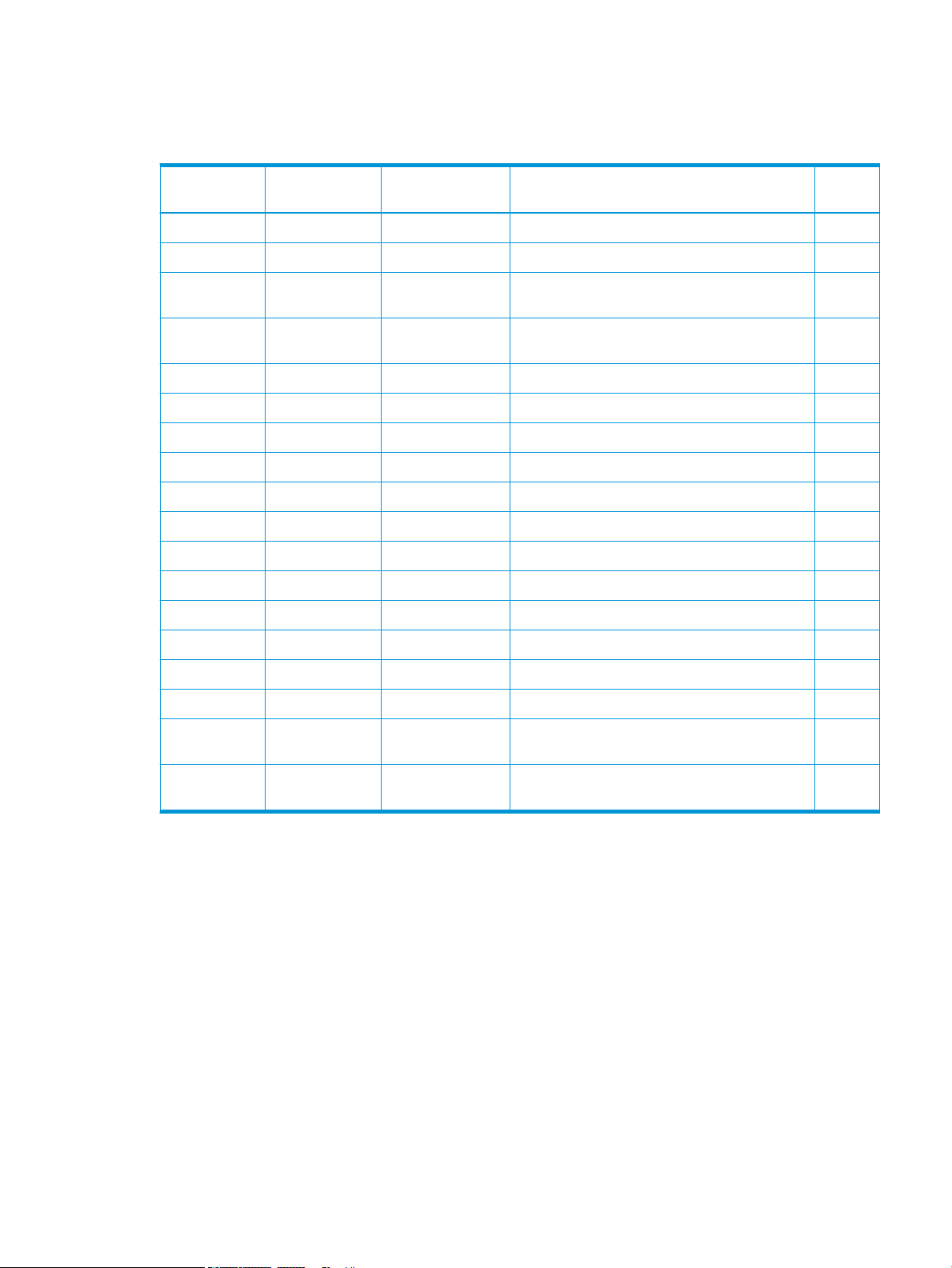

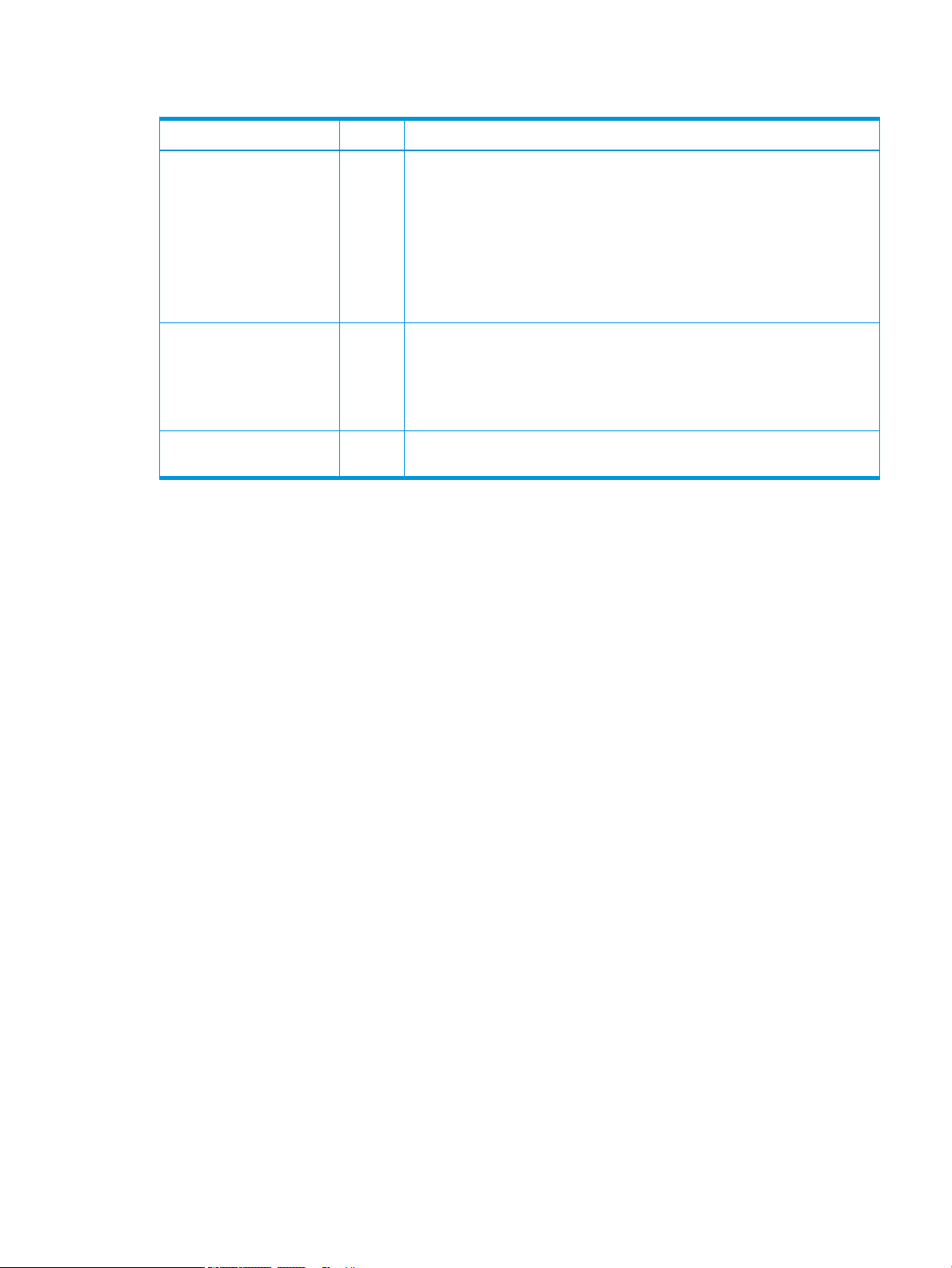

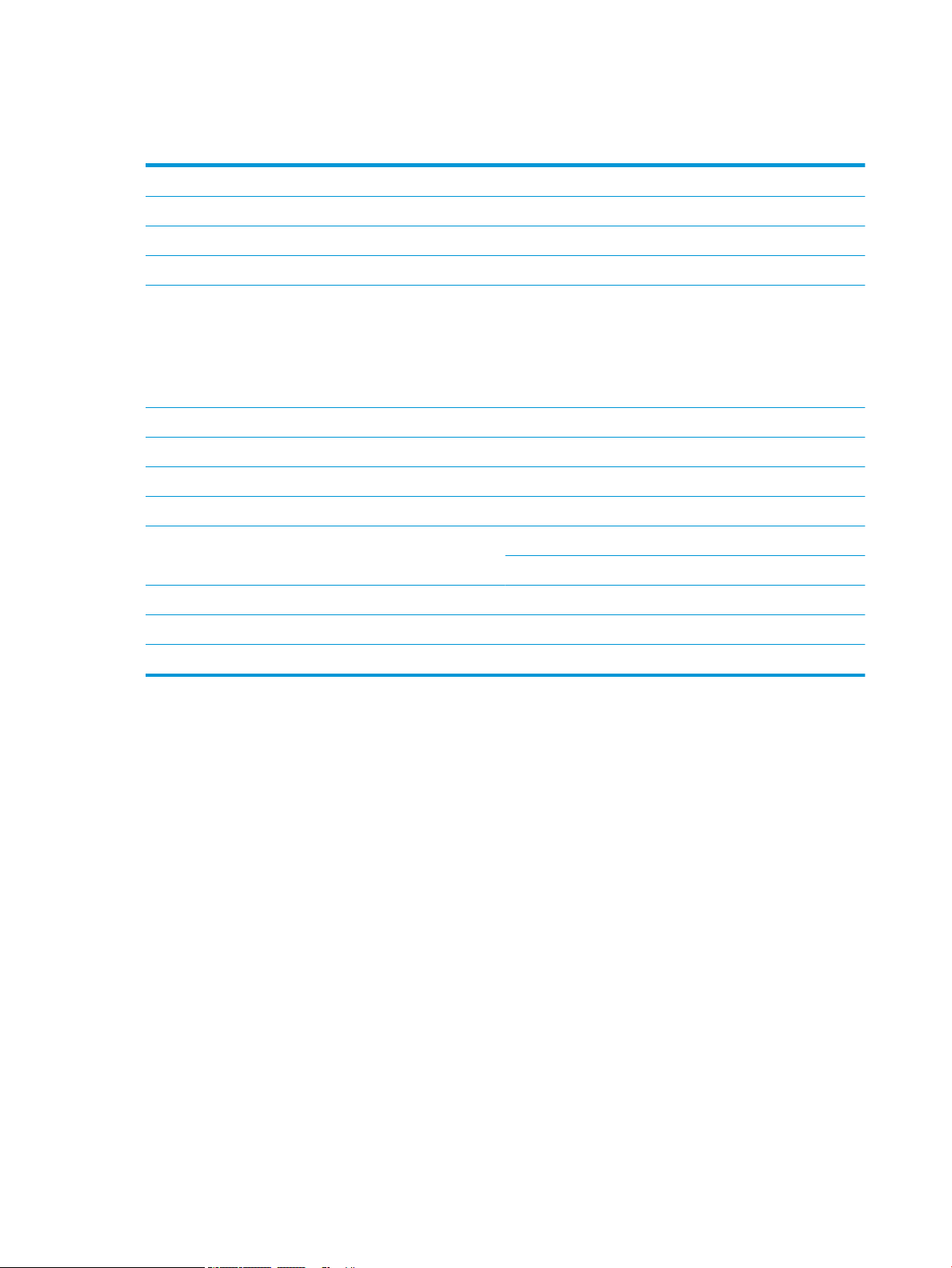

Conguration options

7 6

2

3

4

1

5

8

9

HP Color LaserJet MFP E87640, E87650, E87660 and HP LaserJet MFP E82540, E82550, E82560

Number Component Product number

1 HP Color LaserJet MFP E87640, E87650, E87660

HP LaserJet MFP E82540, E82550, E82560

●

E87640 (40 ppm)

–

–

●

E87650 (50 ppm)

–

–

●

E87660 (60 ppm)

–

–

●

E82540 (40 ppm)

–

–

●

E82550 (50 ppm)

–

–

●

E82560 (60 ppm)

dn models: X3A87A

z models: X3A86A

dn models: X3A90A

z models: X3A89A

dn models: X3A93A

z models: X3A92A

dn models: X3A69A

z models: X3A68A

dn models: X3A72A

z models: X3A71A

–

dn models: X3A75A

–

z models: X3A74A

2 HP LaserJet Department Cabinet Y1G16A

3 HP LaserJet 2000 Sheet High Capacity Input Tray

(HCI) Department

4 HP LaserJet Dual Cassette Feeder (DCF) Department Y1F98A

5 HP LaserJet High Capacity Input Tray Side

Department (sHCI)

Y1G21A

Y1G20A

6 Chapter 2 Conguration ENWW

Page 13

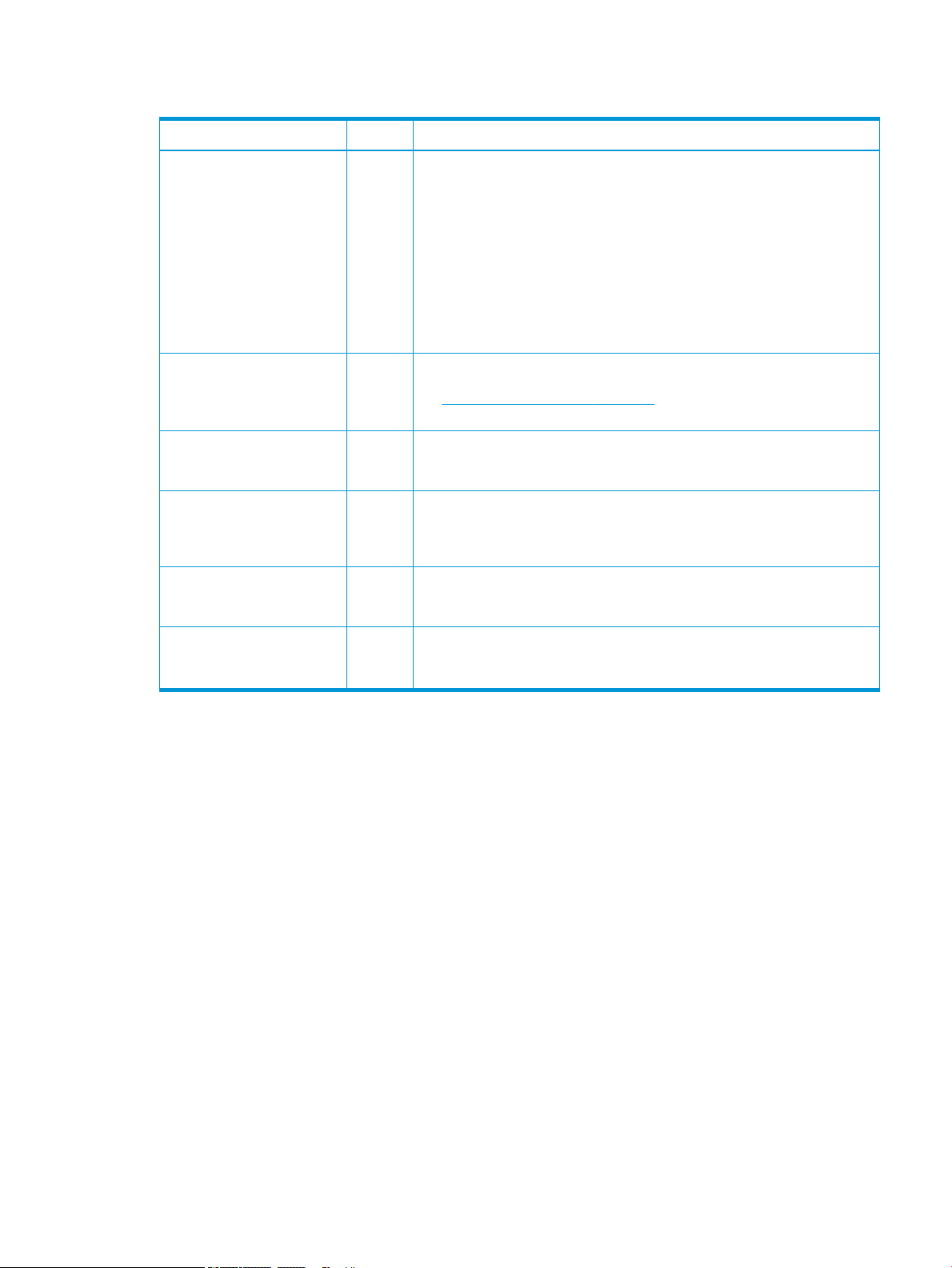

Number Component Product number

6 HP LaserJet Stapler/Stacker Finisher Y1G18A

The following punch kits are available:

●

Y1G10A – HP LaserJet Hole Punch 2/3

Accessory

●

Y1G11A – HP LaserJet Hole Punch 2/4

Accessory

●

Y1G12A – HP LaserJet Hole Punch Swedish

Accessory

●

Y1G14A – HP LaserJet Staple/Stacker Finisher

Rell Staple Cartridge

7 HP LaserJet Booklet Finisher Y1G07A

The following punch kits are available:

●

Y1G10A – HP LaserJet Hole Punch 2/3

Accessory

●

Y1G11A – HP LaserJet Hole Punch 2/4

Accessory

●

Y1G12A – HP LaserJet Hole Punch Swedish

Accessory

●

Y1G13A – HP LaserJet Inner Finisher and

Booklet Maker Finisher Rell Staple Cartridge

●

Y1G14A – HP LaserJet Staple/Stacker Finisher

Rell Staple Cartrdge

8 HP LaserJet Inner Finisher Y1G00A

The following punch kits are available:

●

Y1G02A – HP LaserJet Inner Finisher Hole 2/3

Punch

●

Y1G03A – HP LaserJet Inner Finisher Hole 2/4

Punch

●

Y1G04A - HP LaserJet Inner Finisher Swedish

Punch

●

Y1G13A – HP LaserJet Inner Finisher and

Booklet Maker Finisher Rell Staple Cartridge

9 HP LaserJet Job Separator Department Y1G15A

10 HP LaserJet Paper Tray Heaters Department Y1G22A

NOTE: Not shown in conguration.

The following accessories are also available:

●

Y1G22A#BGJ — HP LaserJet Paper Tray

Heaters Accessory Department (110V)

●

Y1G22A#B19 — HP LaserJet Paper Tray

Heaters Accessory Department (220V)

ENWW Conguration options 7

Page 14

Number Component Product number

11 HP LaserJet Rell Staple Cartridges

12 Re-usable black lift handle install assembly kit. JC82-00538A Kit

●

Y1G13A – HP LaserJet Inner Finisher and

Booklet Maker Finisher Rell Staple Cartridge

●

Y1G14A – HP LaserJet Staple/Stacker Finisher

Rell Staple Cartridge

SAM-JC82-00538A service part

These handles are for use during the initial engine

lifting operations. These are re-usable.

8 Chapter 2 Conguration ENWW

Page 15

3 Worksheets

●

Technical site setup

●

Logistics information

●

Network/printer driver setup

●

Email/Send To conguration

ENWW 9

Page 16

Technical site setup

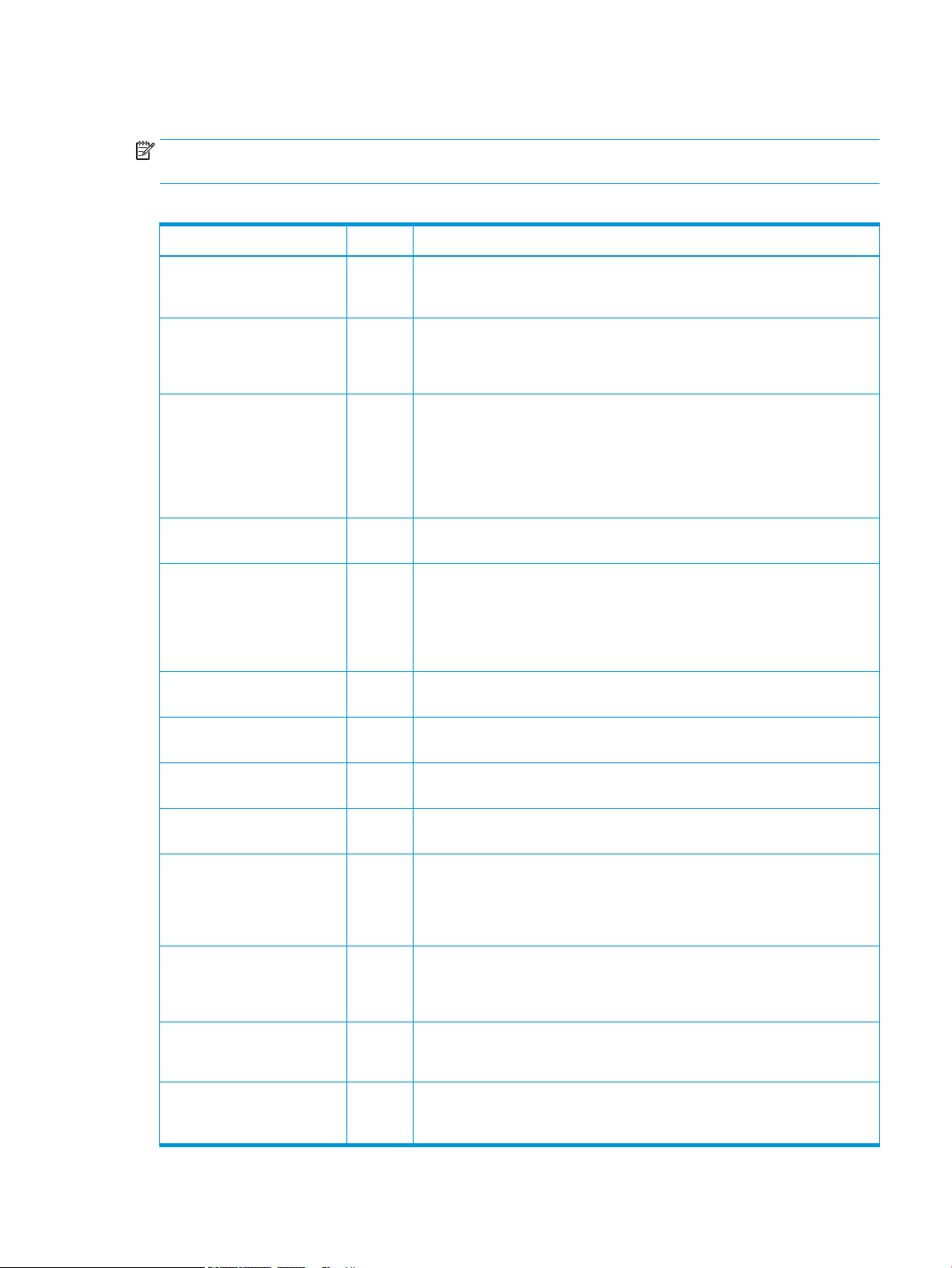

Table 3-1 Technical site setup worksheet

Yes/No Notes

Will the MFP physically t based

on the operating size

specication where it will be

installed?

Is the oor level? (optional)

Is the oor stable? (optional)

Is there any carpeting or

ooring that requires protection

or reinforcement?

If yes, what is the length of

ooring requiring covering?

Is required power available on a

dedicated circuit in the direct

vicinity?

US, EMEA, and AP require one

power outlet for the printer.

Or, is a power outlet in the direct

vicinity rated to supply the

specic conguration?

❑

Yes

See Specications on page 17.

❑

No

HP recommends that the installation site also support the Serviceability Space

Requirements that allows for 18 inches (457.2 mm) of servicing space on all four sides.

Equipment can be repositioned during the service visit to accommodate the Service Space

Requirements.

❑

Yes

See Specications on page 17, weight specs.

❑

No

❑

Yes

See Specications on page 17, weight specs.

❑

No

❑

Yes

Thick carpeting can cause misalignment between the MFP and Finisher.

❑

No

❑

Yes

The outlet needs to be within 6 feet of planned location of MFP. If a new dedicated circuit

❑

needs to be run, work with customer to complete prior to installation.

No

See Specications on page 17 for more information and check the order to conrm any

specic power requirements.

NOTE: HP recommends installing the printer on its own circuit to prevent possible

interference from other devices.

See Specications on page 17

for more information and check

the order to conrm any specic

power requirements.

Does the room meet the

Environmental Specications?

Is there a network connection in

the direct vicinity?

Will there be direct sunlight on

the MFP?

Is there suicient cooling?

Is there proper air ventilation?

(optional)

Has the customer IT approved

the installation? (optional)

❑

Yes

See Specications on page 17.

❑

No

❑

Yes

Be sure that it is Ethernet.

❑

No

❑

Yes

❑

No

❑

Yes

See Specications on page 17.

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

10 Chapter 3 Worksheets ENWW

Page 17

Table 3-1 Technical site setup worksheet (continued)

Yes/No Notes

Will the customer IT be testing

the products prior to making

them available for general use?

(optional)

If yes, does the customer agree

that the designated installation

location is also acceptable

during the testing period?

(optional)

Do the installation technicians

require security clearance at the

customer location?

If yes, what is the procedure for

obtaining the clearance?

Who will arrange for obtaining

the clearance? (optional)

❑

Yes

❑

No

❑

Yes

❑

No

ENWW Technical site setup 11

Page 18

Logistics information

Table 3-2 Logistics worksheet

Yes/No Remarks/Data

What are the customer’s

“normal” receiving hours?

What is the customer's preferred

delivery time? (optional)

Would "after hours" be preferred

at an additional charge?

(optional)

Is a certicate of insurance

required?

Are there any labor union

constraints or requirements?

Is there a truck height receiving

dock? Height restrictions?

What is the height from ground to

dock platform?

Does the receiving dock have

dock levelers? (optional)

Does the receiving dock have a

dock plate? (optional)

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

Is a lift gate truck required?

If no dock available and ground

delivery is required, will the area

require special covering?

Is delivery area tractor-trailer

accessible?

If no, what is the maximum size

truck accessibility?

Is there room to unpack the

system on the receiving dock?

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

12 Chapter 3 Worksheets ENWW

Page 19

Table 3-2 Logistics worksheet (continued)

Yes/No Remarks/Data

Is the delivery of the unit on the

same oor as receiving? If no, is

an elevator used? Please identify

below.

If no elevator is to be used, how is

the unit to be delivered?

What is the distance in meters

from the receiving area to the

planned copier location?

(optional)

Do the dimensions of doorways

and hallways along the delivery

path meet minimum system

dimensional requirements?

Is there a clear path to the

planned delivery location?

Is the copier room level with

oor?

If no, is there a ramp?

Are their enough people to lift the

engine assembly? (required)

❑

Yes

Note that stair climbers are not currently approved for moving MFP printers. If needed,

❑

❑

❑

❑

❑

❑

❑

❑

❑

lift or hoist the MFP printers in their crates and keep them in an upright position.

No

Yes

The box for the main MFP unit requires a doorway opening of 765 mm (30.1 in).

No

See Size and weight specications on page 18 for complete information about box

dimensions.

Yes

No

Yes

No

Yes

The engine assembly is heavy and requires four people to lift onto the stand or DCF. HP

recommends using the black lift assist handles when lifting the device.

No

Is there a possibility to discard

packaging materials at customer

site? (optional)

❑

Yes

❑

No

ENWW Logistics information 13

Page 20

Network/printer driver setup

(If done by an HP technician)

Table 3-3 Network/printer driver worksheet

Yes/No Remarks/Data

What network topology is in use?

What operating system will be

used on the server?

What operating system will be

used on the clients?

Is DHCP/BOOTP in use?

If no, what TCP/IP address will be

used for the MFP?

What version of TCP/IP is used in

the deployment?

If no, what subnet mask address

will be used for the MFP?

If no, what default gateway

address will be used for the MFP?

If no, does a host name need to

be congured (+name)?

(optional)

❑

Yes

❑

No

❑

Yes

❑

No

14 Chapter 3 Worksheets ENWW

Page 21

Email/Send To conguration

NOTE: Optional: Complete only if the hardware technician is responsible for conguring the Email/Send To

features.

Table 3-4 Email/Send To conguration worksheet

Yes/No Remarks/Data

Is Active Directory, Novell, NTLM

or something else in use?

(optional)

Is DNS in use? (optional)

If yes, what is the domain name?

(optional)

What type of SMTP server is in

use? (MS Exchange, Lotus Notes,

etc.) (optional)

Or, if an ISP mail server is being

used, what is the IP or host name

to the server? (optional)

On what OS is the SMTP server

installed? (optional)

Is LDAP installed on the same

server as the SMTP server?

(optional)

If not, what is the OS of the LDAP

server? (optional)

What is the TCP/IP address of the

SMTP server or host name?

What is the TCP/IP address of the

LDAP server?

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

What is the port number that

LDAP uses?

What is the search root of the

LDAP server?

Is Send to Folder supported /

required?

If yes, what OS are the shared

folders on?

What type of fax is required to be

supported?

Analog, LAN, Internet?

If LAN fax is required, is there a

LAN fax server available?

If Internet fax is required, is there

a subscription to an Internet fax

service?

❑

Yes

❑

No

❑

Yes

❑

No

❑

Yes

❑

No

ENWW Email/Send To conguration 15

Page 22

16 Chapter 3 Worksheets ENWW

Page 23

4 Specications

●

Size and weight specications

●

System conguration dimensions

●

Operational clearance space requirements

●

Environmental specications

●

Power requirements

ENWW 17

Page 24

Size and weight specications

Table 4-1 Individual unit weight and size information

Description Master Carton Size / Gross Weight (boxed) Net Weight

HP Color LaserJet MFP E87640, E87650,

E87660

HP LaserJet MFP E82540, E82550, E82560 dn models:

HP LaserJet Dual Cassette Feeder (DCF)

Department

HP LaserJet Cabinet Department 585 mm (23

HP LaserJet 2000 Sheet High Capacity Input

Tray (HCI) Department

1

Width Depth Height Weight (boxed)

dn

, du models:

585 mm (23

in)

z models:

585 mm (23

in)

585 mm (23

in)

z models:

585 mm (23

in)

585 mm (23

in)

in)

575 mm (23

in)

dn

, du models:

764.3 mm

(30.

1 in)

z models:

764.3 mm

(30.1 in

)

dn models:

764.3 mm

(30.1 in)

z models:

764.3 mm

(30.1 in

)

706.8 mm

(27.8 in)

706.8 mm

(27.8 in)

706.8 mm

(27.8 in)

dn

, du models:

883.7 mm

(34.8

in)

z models: 932.2

mm (36.7 in)

dn models:

883.7 mm

(34.8 in)

z models: 932.2

mm (36.7 in)

254 mm (10 in) 24.6 kg (54.2

254 mm (10 in) 15 kg (33.07

254 mm (10 in) 33.8 kg (74.4

dn

, du models:

131.6 kg

(290.2 lb)

z models:

131.6 kg

(290.2 lb

dn models:

114.5 k

g

(252.5 lb)

z models:

114.5 k

g

(252.5 lb)

lb)

lb)

lb)

models: 113.1 kg (249.3 lb)

dn

du models: 100.9 kg (224.44 lb)

z models: 113.1 kg (249.3 lb)

dn, du models: 95.6 kg

(210.8 lb)

z models: 95.6 kg (210.8 lb)

21 kg (46.3 lb)

11.9 kg (26.3 lb)

28.3 (62.48 lb)

HP LaserJet High Capacity Input Tray Side (sHCI)

Department

HP LaserJet Inner Finisher 458 mm (18

HP LaserJet Booklet Finisher 1003.3 mm

HP LaserJet Stapler/Stacker Finisher 1003.3 mm

1

Weight and size information is approximate and for reference only.

412.5 mm

(16.25 in)

in)

(39.75 in)

(39.75 in)

362 mm (14

in)

491 mm (19.3

in)

673 mm

(26.75 in)

673 mm

(26.75 in)

533.4 mm (21

in)

173 mm (6.8 in) 72.6 kg (33 lb) 18.2 kg (40.1 lb)

587.5 mm (23.5

in)

587.5 mm (23.5

in)

23.3 kg (51.4

lb)

86.8 kg

(191.36 lb)

61.6 kg (135.7

lb)

20.05 kg (44.22 lb)

62 kg (136.68 lb)

194 kg (88 lb)

18 Chapter 4 Specications ENWW

Page 25

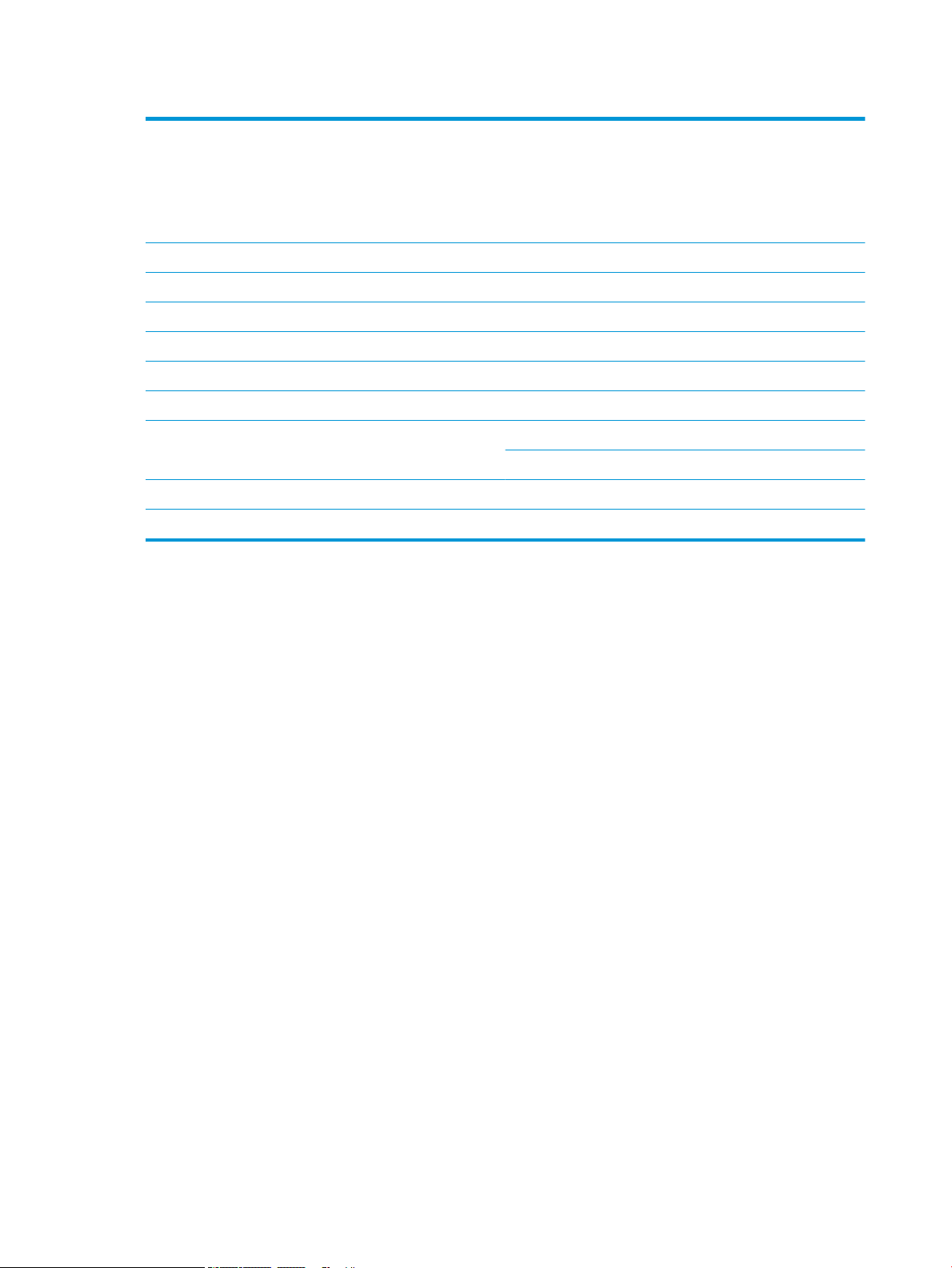

System conguration dimensions

ENWW System conguration dimensions 19

Page 26

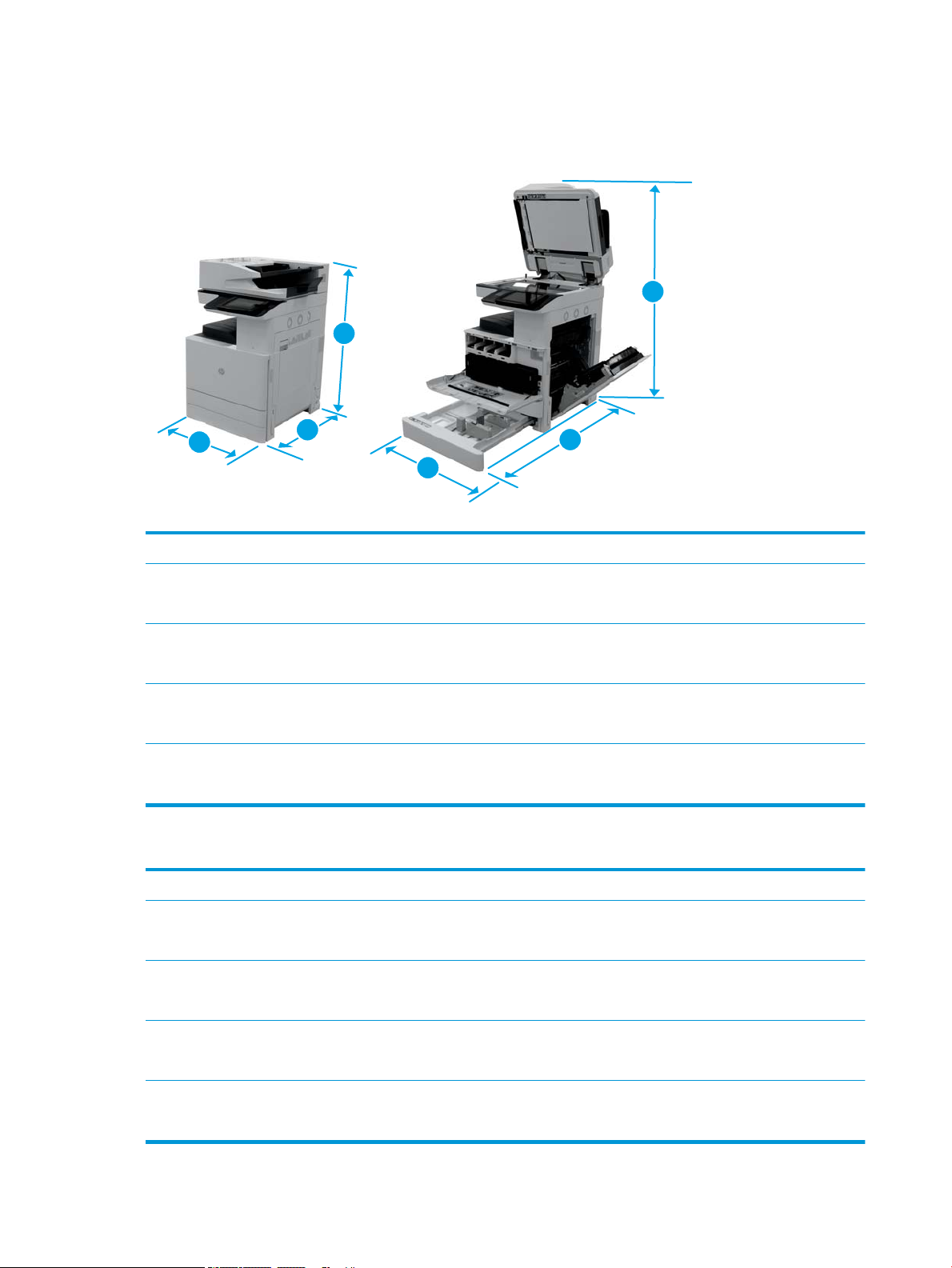

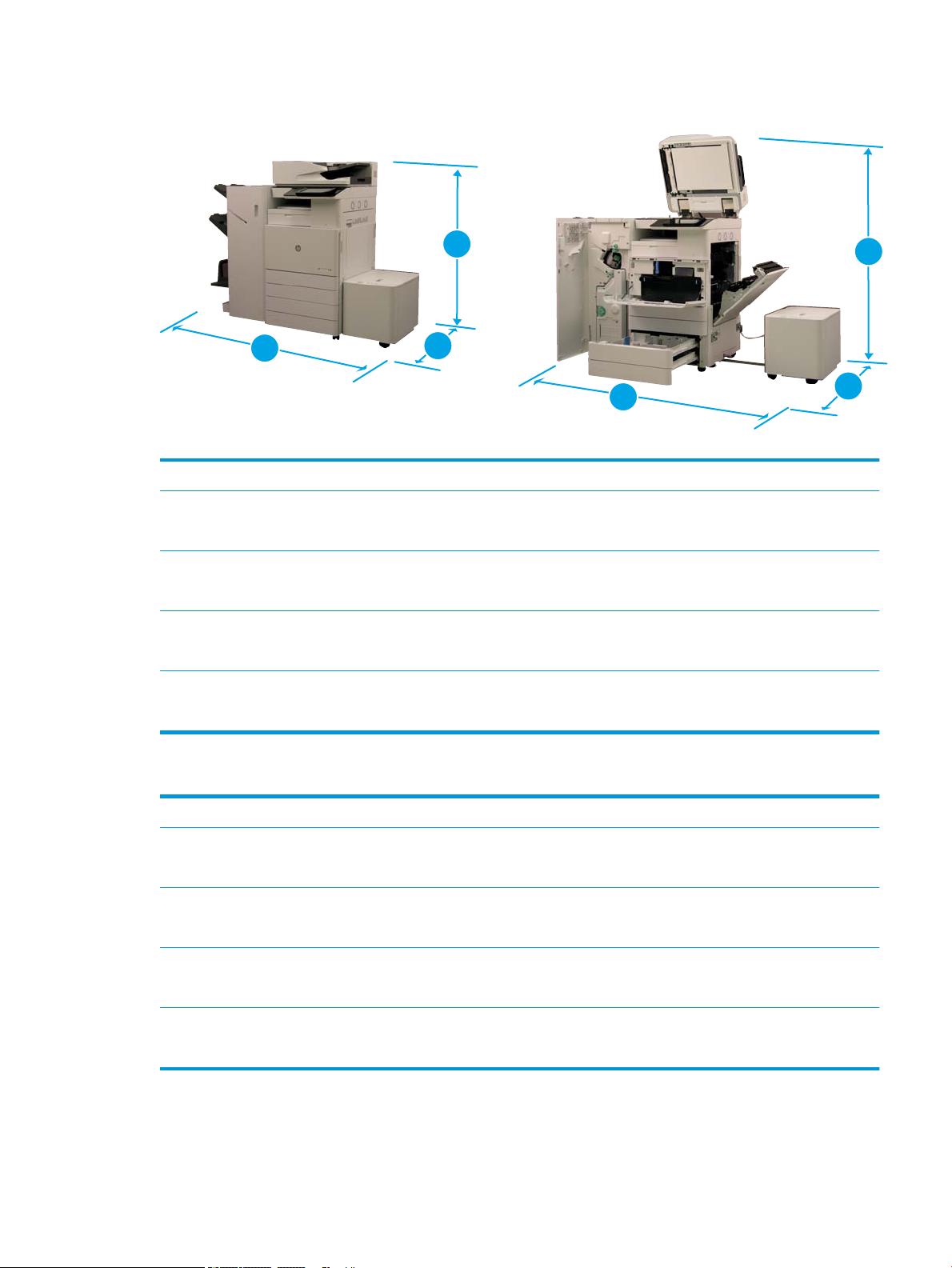

Base printer conguration

2

1

3

2

3

1

The base conguration includes the following components:

Table 4-2 Dimensions of the E87640, E87650, E87660

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 932.2 mm (36.7 in)

z models: 932.2 mm (36.7 in)

2. Depth dn models: 771.1 mm (30.3 in)

z models: 771.1 mm (30.3 in)

3. Width dn models: 585 mm (23 in)

z models: 585 mm (23 in)

Weight dn models: 113.1 kg (249.3 lb)

z models: 113.1 kg (249.3 lb)

dn models: 775 mm (36.1 in)

z models: 775 mm (36.1 in)

dn models: 1676 mm (66 in)

z models: 1676 mm (66 in)

dn models: 1134 mm (47 in)

z models: 1134 mm (47 in)

Table 4-3 Dimensions of the E82540, E82550, E82560

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 932.2 mm (36.7 in)

z models: 932.2 mm (36.7 in)

2. Depth dn models: 771.1 mm (30.3 in)

z models: 771.1 mm (30.3 in)

3. Width dn models: 585 mm (23 in)

z models: 585 mm (23 in)

dn models: 775 mm (36.1 in)

z models: 775 mm (36.1 in)

dn models: 1676 mm (66 in)

z models: 1676 mm (66 in)

dn models: 1134 mm (47 in)

z models: 1134 mm (47 in)

Weight dn models: 95.6 kg (210.8 lb)

z models: 95.6 kg (210.8 lb)

20 Chapter 4 Specications ENWW

Page 27

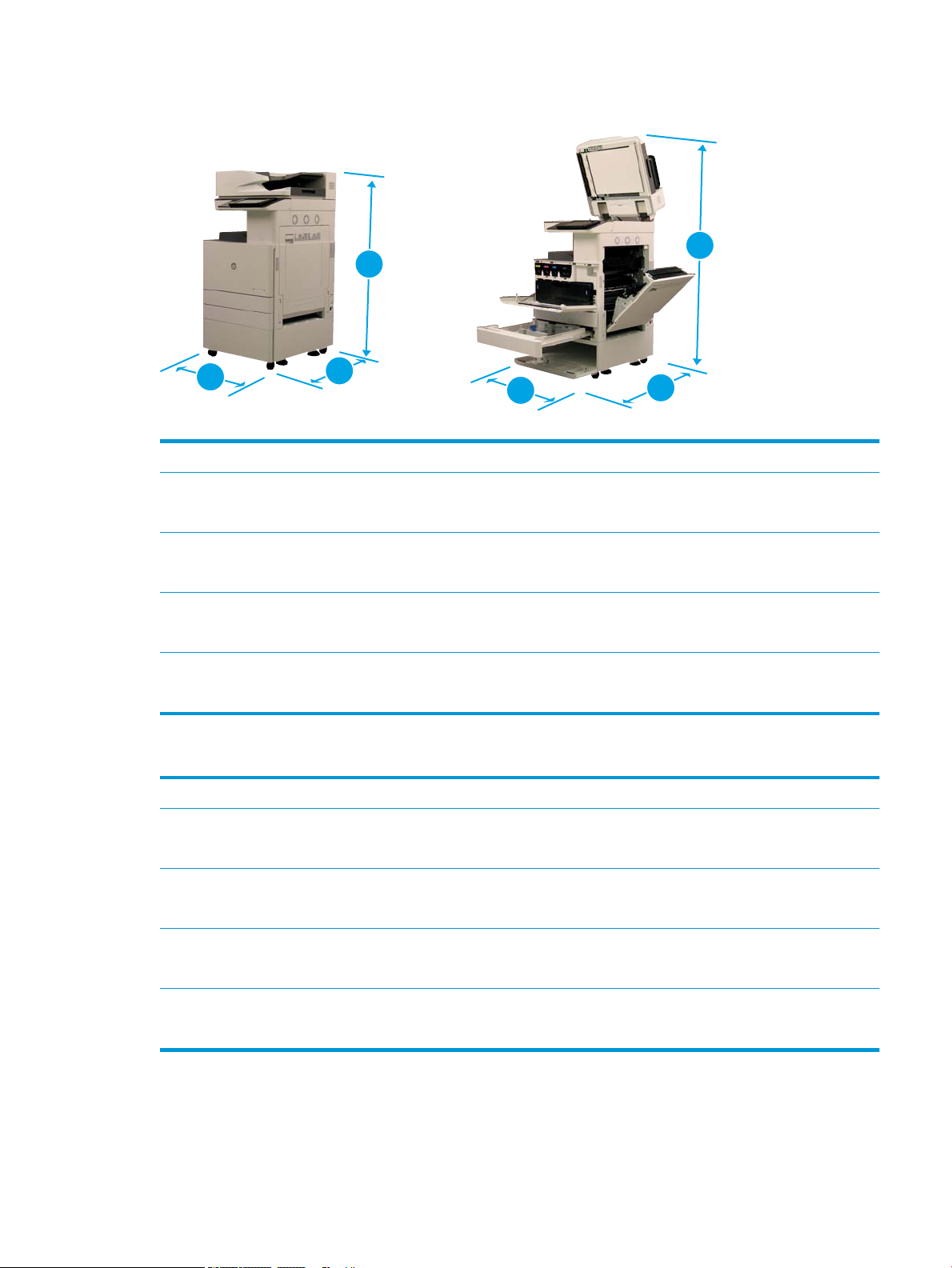

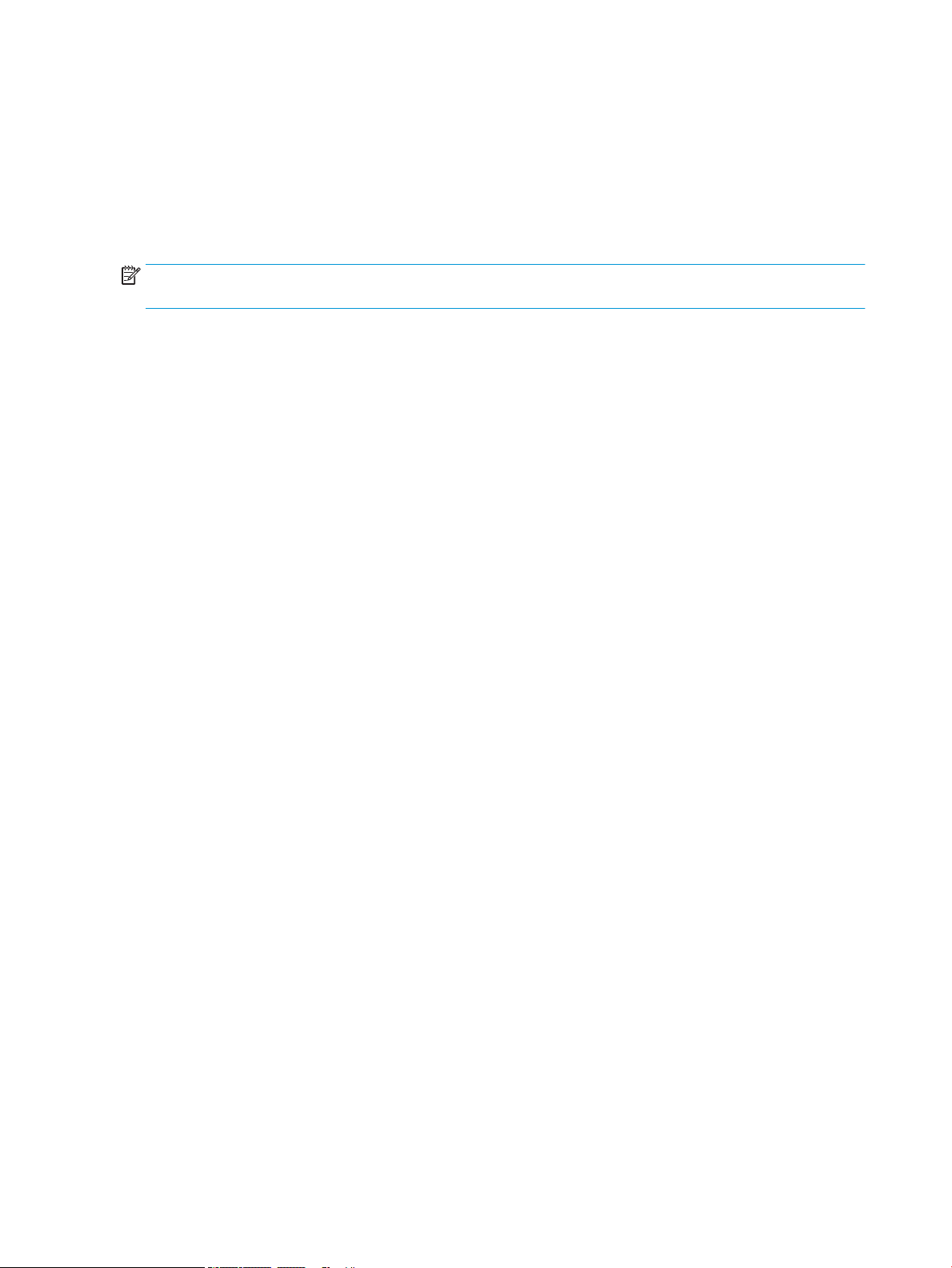

Printer with cabinet conguration

3

2

1

3

1

2

Table 4-4 Dimensions of the E87640, E87650, E87660

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 1186.2 mm (46.7 in)

z models: 1186.2 mm (46.7 in)

2. Depth dn models: 771.1 mm (30.3 in)

z models: 771.1 mm (30.3 in)

3. Width dn models: 585 mm (23 in)

z models: 585 mm (23 in)

Weight dn models: 125 kg (275.6 lb)

z models: 125 kg (275.6 lb)

Table 4-5 Dimensions of the E82540, E82550, E82560

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 1186.2 mm (46.7 in)

z models: 1186.2 mm (46.7 in)

2. Depth dn models: 771.1 mm (30.3 in)

z models: 771.1 mm (30.3 in)

3. Width dn models: 585 mm (23 in)

dn models: 1029 mm (46.1 in)

z models: 1029 mm (46.1 in)

dn models: 1676 mm (66 in)

z models: 1676 mm (66 in)

dn models: 1134 mm (47 in)

z models: 1134 mm (47 in)

dn models: 1029 mm (46.1 in)

z models: 1029 mm (46.1 in)

dn models: 1676 mm (66 in)

z models: 1676 mm (66 in)

dn models: 1134 mm (47 in)

z models: 585 mm (23 in)

Weight dn models: 107.5 kg (237.1 lb)

z models: 107.5 kg (237.1 lb)

z models: 1134 mm (47 in)

ENWW System conguration dimensions 21

Page 28

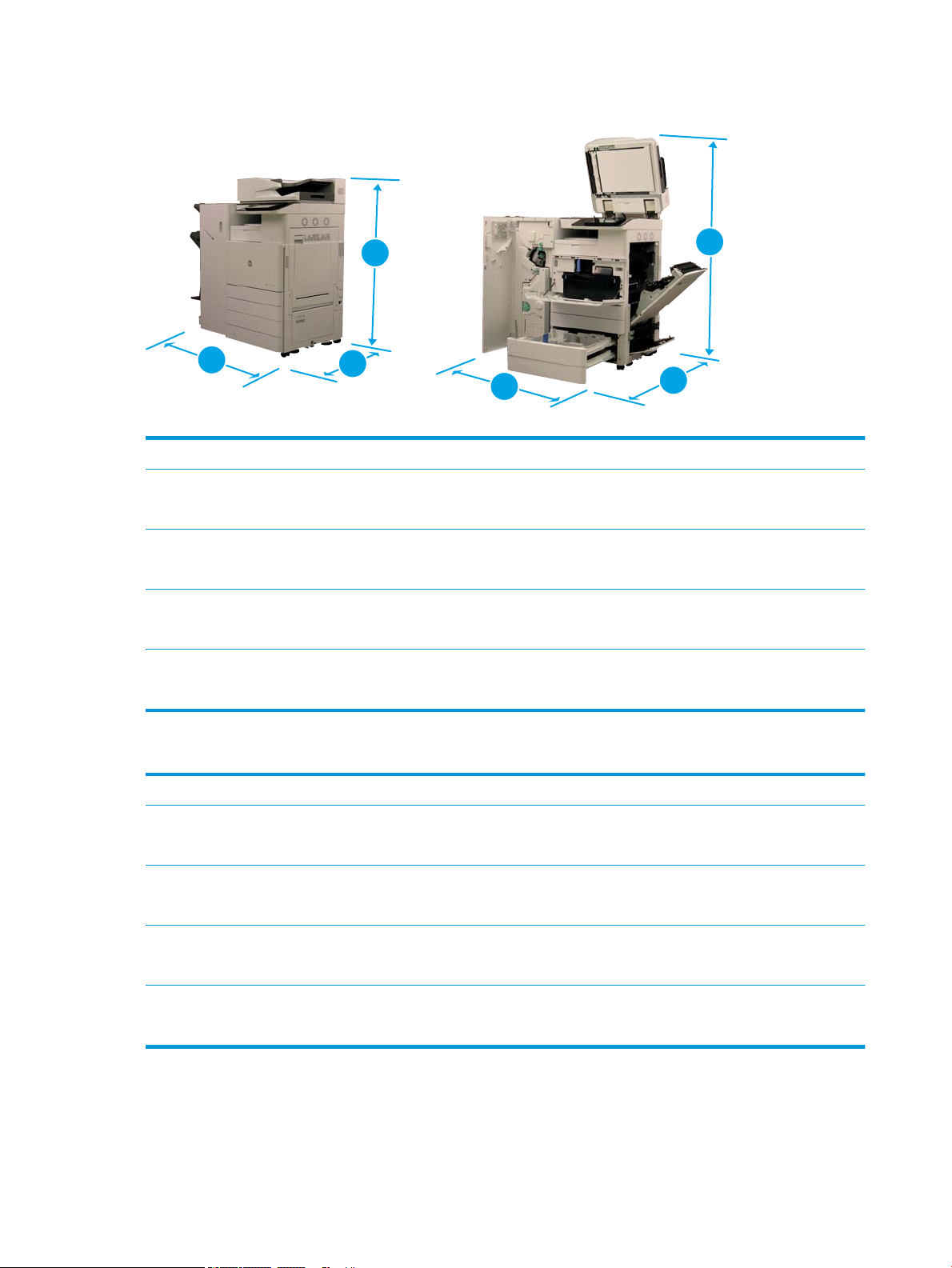

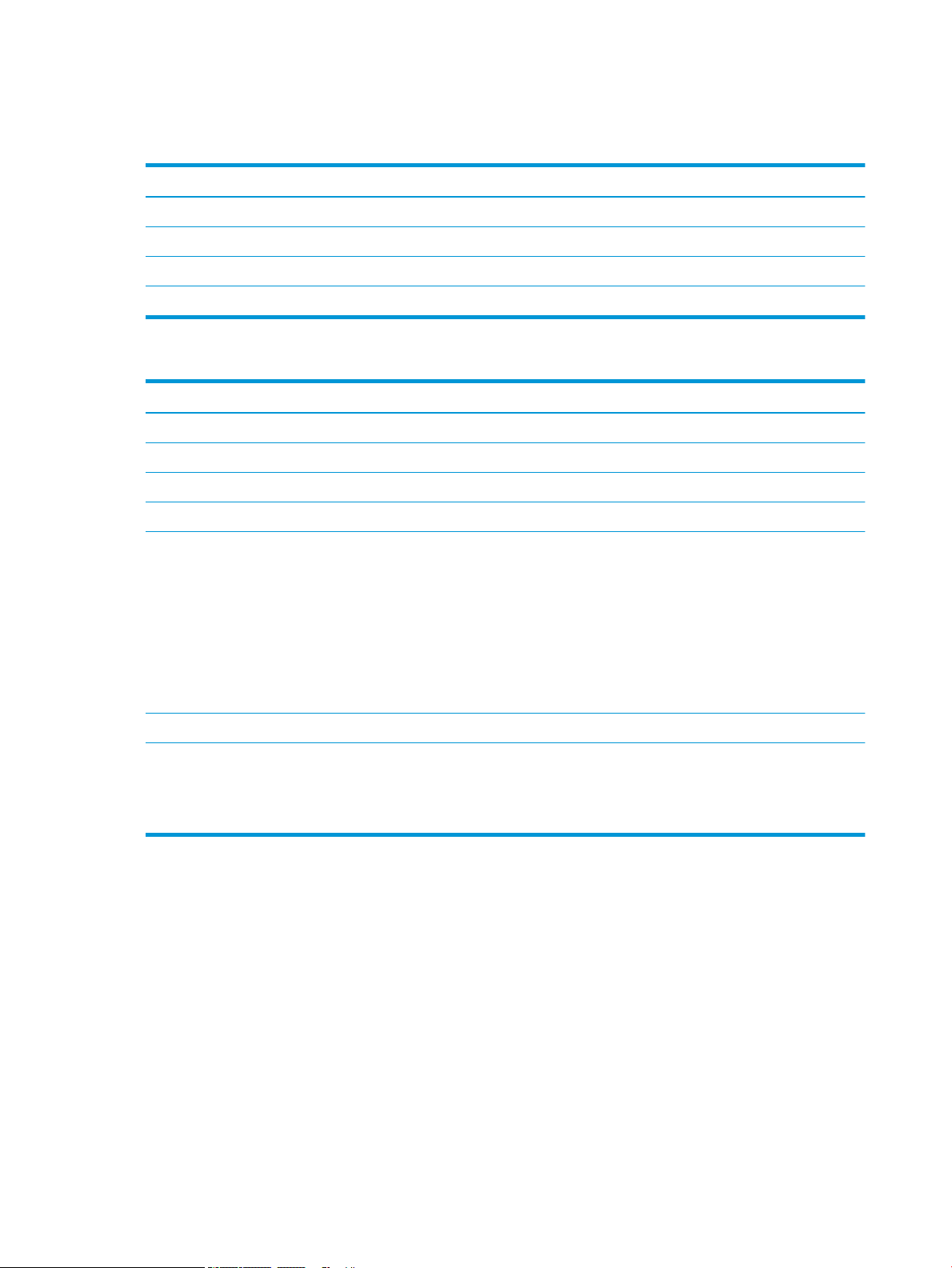

Printer with booklet nisher conguration

3

2

1

3

1

2

Table 4-6 Dimensions of the E87640, E87650, E87660

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 1186.2 mm (46.7 in)

z models: 1186.2 mm (46.7 in)

2. Depth dn models: 771.1 mm (30.3 in)

z models: 771.1 mm (30.3 in)

3. Width dn models: 1588.3 mm (62.75 in)

z models: 1588.3 mm (62.75 in)

Weight dn models: 196.1 kg (432.28 lb)

z models: 196.1 kg (432.28 lb)

Table 4-7 Dimensions of the E82540, E82550, E82560

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 1186.2 mm (46.7 in)

z models: 1186.2 mm (46.7 in)

2. Depth dn models: 1774.1 mm (70.05 in)

z models: 1774.1 mm (70.05 in)

3. Width dn models: 1588.3 mm (62.75 in)

dn models: 1029 mm (46.1 in)

z models: 1029 mm (46.1 in)

dn models: 1676 mm (66 in)

z models: 1676 mm (66 in)

dn models: 2137.3 mm (86.75 in)

z models: 2137.3 mm (86.75 in)

dn models: 1029 mm (46.1 in)

z models: 1029 mm (46.1 in)

dn models: 2679.3 mm (105.75 in)

z models: 2679.3 mm (105.75 in)

dn models: 2137.3 mm (86.75 in)

z models: 1588.3 mm (62.75 in)

Weight dn models: 178.6 kg (393.78 lb)

z models: 178.6 kg (393.78 lb)

z models: 2137.3 mm (86.75 in)

22 Chapter 4 Specications ENWW

Page 29

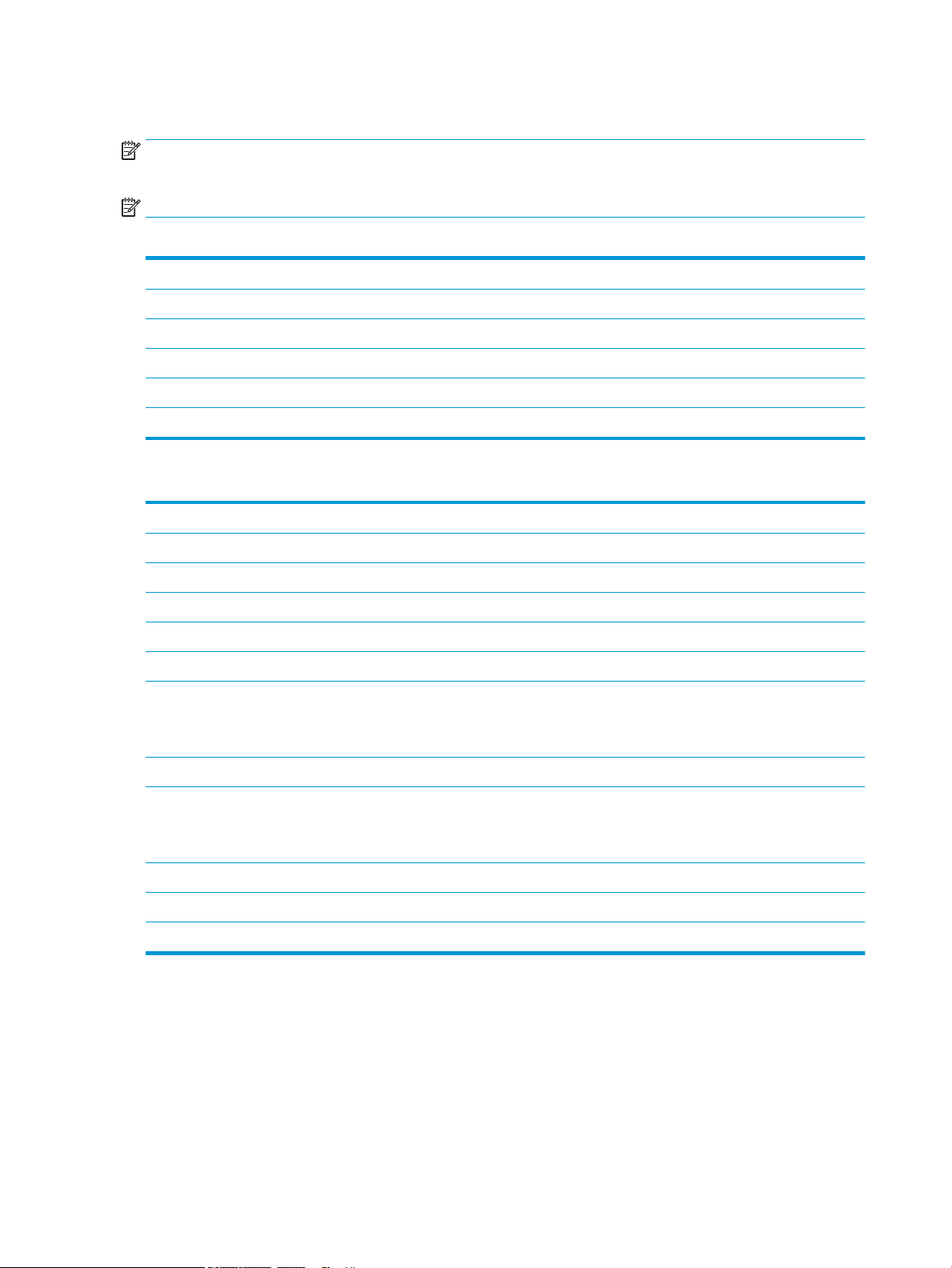

Printer with booklet nisher and side HCI conguration

3

2

1

3

2

1

Table 4-8 Dimensions of the E87640, E87650, E87660

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 1186.2 mm (46.7 in)

z models: 1186.2 mm (46.7 in)

2. Depth dn models: 771.1 mm (30.3 in)

z models: 771.1 mm (30.3 in)

3. Width dn models: 2000.3 mm (79 in)

z models: 2000.3 mm (79 in)

Weight dn models: 216.16 kg (476.5 lb)

z models: 216.16 kg (476.5 lb)

Table 4-9 Dimensions of the E82540, E82550, E82560

Normal operating dimensions Maximum operating dimensions

1. Height dn models: 1186.2 mm (46.7 in)

z models: 1186.2 mm (46.7 in)

2. Depth dn models: 1774.1 mm (70.05 in)

z models: 1774.1 mm (70.05 in)

3. Width dn models: 2000.3 mm (79 in)

dn models: 1029 mm (46.1 in)

z models: 1029 mm (46.1 in)

dn models: 1676 mm (66 in)

z models: 1676 mm (66 in)

dn models: 2549.3 mm (103 in)

z models: 2549.3 mm (103 in)

dn models: 1029 mm (46.1 in)

z models: 1029 mm (46.1 in)

dn models: 2679.3 mm (105.75 in)

z models: 2679.3 mm (105.75 in)

dn models: 2549.3 mm (103 in)

z models: 2000.3 mm (79 in)

Weight dn models: 198.65 kg (438 lb)

z models: 198.65 kg (438 lb))

ENWW System conguration dimensions 23

z models: 2549.3 mm (103 in)

Page 30

Operational clearance space requirements

Make sure the printer is installed in an area with enough space around the device for proper service access and

ventilation. The ADF when fully opened requires 20 inches (508 mm) above the level of the top. The back of

copier and wall needs proper ventilation.

The following space must be provided around the machine to assure machine performance and proper

operations. If any option is installed, provide the additional space for installing it.

NOTE: HP recommends that 18 inches (457.2 mm) be added to the printer sides and front to make sure there

is suicient space to open doors and covers.

●

Rear clearance space: 18 inches (457.2 mm)

●

Left clearance space: 18 inches (457.2 mm)

●

Right clearance space: 18 inches (457.2 mm)

24 Chapter 4 Specications ENWW

Page 31

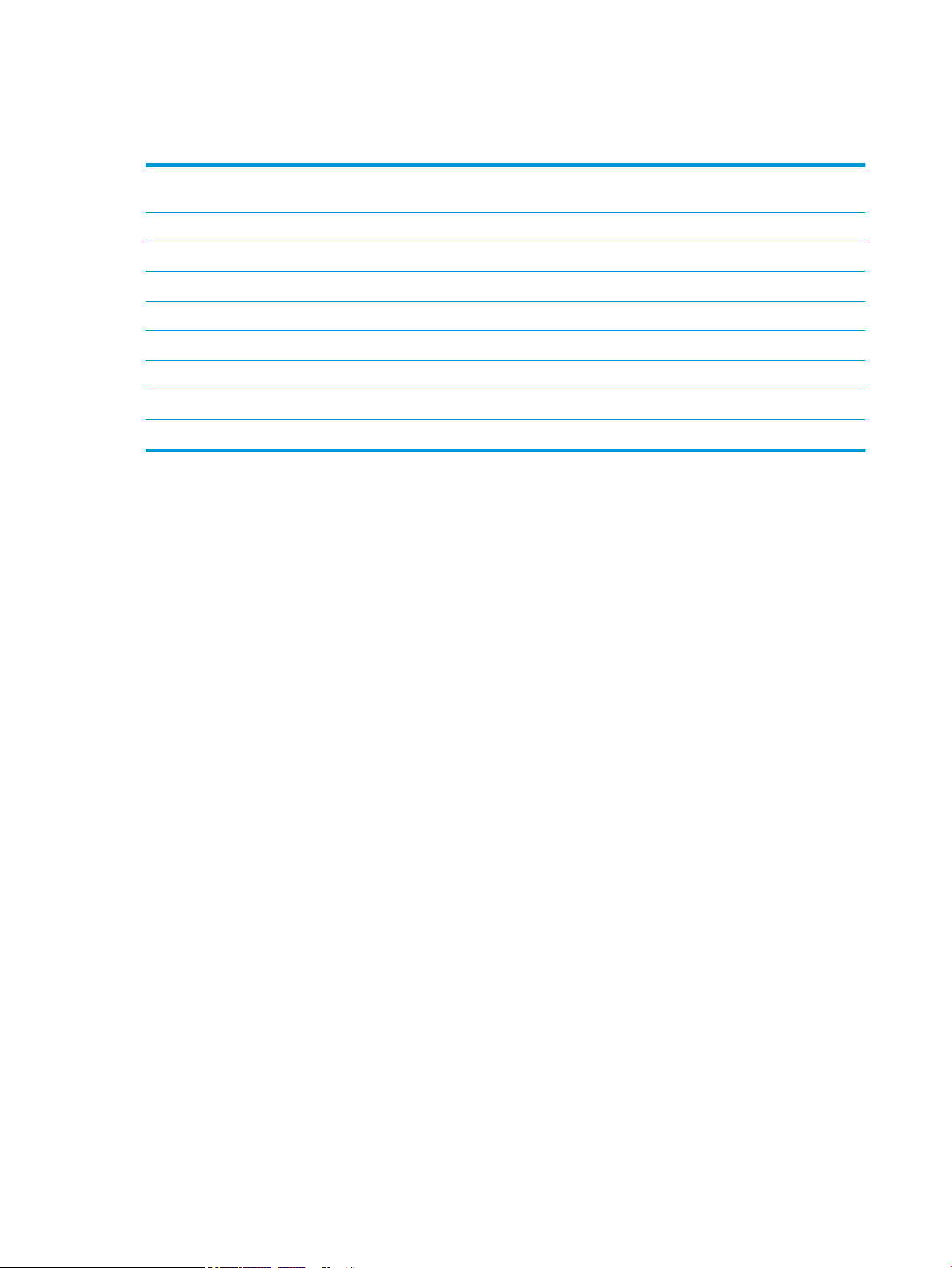

Environmental specications

Table 4-10 Operating-environment specications

Environment Recommended Allowed

Temperature 15° to 30°C (59° to 86°F) 15° to 30°C (59° to 86°F)

Relative humidity 20% to 80% (RH) 20% to 80% (RH)

NOTE: The operating environment of the printer must remain stable.

ENWW Environmental specications 25

Page 32

Power requirements

Table 4-11 Power requirements

Item Specication

Input Voltage (Europe) AC 220—240 V (+/- 10%)

Input Voltage (USA) AC 110—127 V (+/- 10%)

Input Voltage (AP) AC 220—240 V (+/- 10%)

Rated Frequency 50/60 Hz (+/- 3%)

Table 4-12 Power consumption

Item Specication

Ready Less than 300 Wh

Normal operation Less than 900 Wh

Max/Peak Less than 1300 Wh

Sleep Less than 2.0 Wh

TEC

Default Sleep Delay Time 2 minutes

Maximum Sleep Delay Time

●

E87640: 2.1 kWh

●

E87650: 2.717 kWh

●

E87660: 3.05 kWh

●

E82540: 2.1 kWh

●

E82550: 2.717 kWh

●

E82560: 3.1 kWh

●

E82540, E82550: 60 minutes

●

E82560: 120 minutes

●

E87640, E87650, E87660: 60 minutes

26 Chapter 4 Specications ENWW

Page 33

5 Staging

●

Staging checklists

●

Unboxing and basic assembly

●

Initial supplies installation

●

Initial power on

●

Engine adjustments and tests

●

Prepare for shipment to customer location

●

Repack (from customer site)

ENWW 27

Page 34

Staging checklists

NOTE: Stagers must take appropriate training and download and utilize all installation guides in order to do the

following steps correctly. Staging is typically performed at an o site location.

NOTE: Assemblers must be trained and qualied/certied to perform this activity.

Table 5-1 Staging (minimum 30 min + options)

❑

Unbox and inventory miscellaneous items – 4 person lift (10 mins).

❑

Unbox the tray or cabinet (5 mins).

❑

Unbox the engine (5 mins).

❑

Place the engine on the lower accessory, if ordered – 4 person lift (2 mins).

❑

Remove the shipping tape and scanner lock (5 mins).

❑

Unpackage and install the toner cartridge(s) (2 mins).

Table 5-2 Assembly and testing (minimum 55 mins + options)

❑

Attach the paper handling or other accessories (based on conguration).

❑

Install the imaging unit(s) (5 mins).

❑

Adjust the tray paper guides to the appropriate size for the account.

❑

Load the paper trays and lock the rear guides (5 mins).

❑

Connect the power and LAN cables and turn on the main switch.

❑

Power on and wait for the initial screen (2 mins).

❑

Perform the Late Point Dierentiation Conguration (LPDC) (3 min).

NOTE: LPDC will be automatically set up after power on. If this fails or no internet is available, the LPDC information will need to be

installed manually.

❑

Select a language and set the date/time (1 min)

❑

Update to latest rmware (up to 20 min)

CAUTION: All accessories need to be attached to the device before upgrading rmware. After installing accessories the rmware

must be updated to make sure the printer rmware is compatible with the accessory.

❑

Print the conguration and demo pages (2 min)

❑

Perform a basic functionality test (10 minutes) – test print, copy, and each accessory

❑

Disassemble the accessories and prepare the printer for transportation (3 min)

28 Chapter 5 Staging ENWW

Page 35

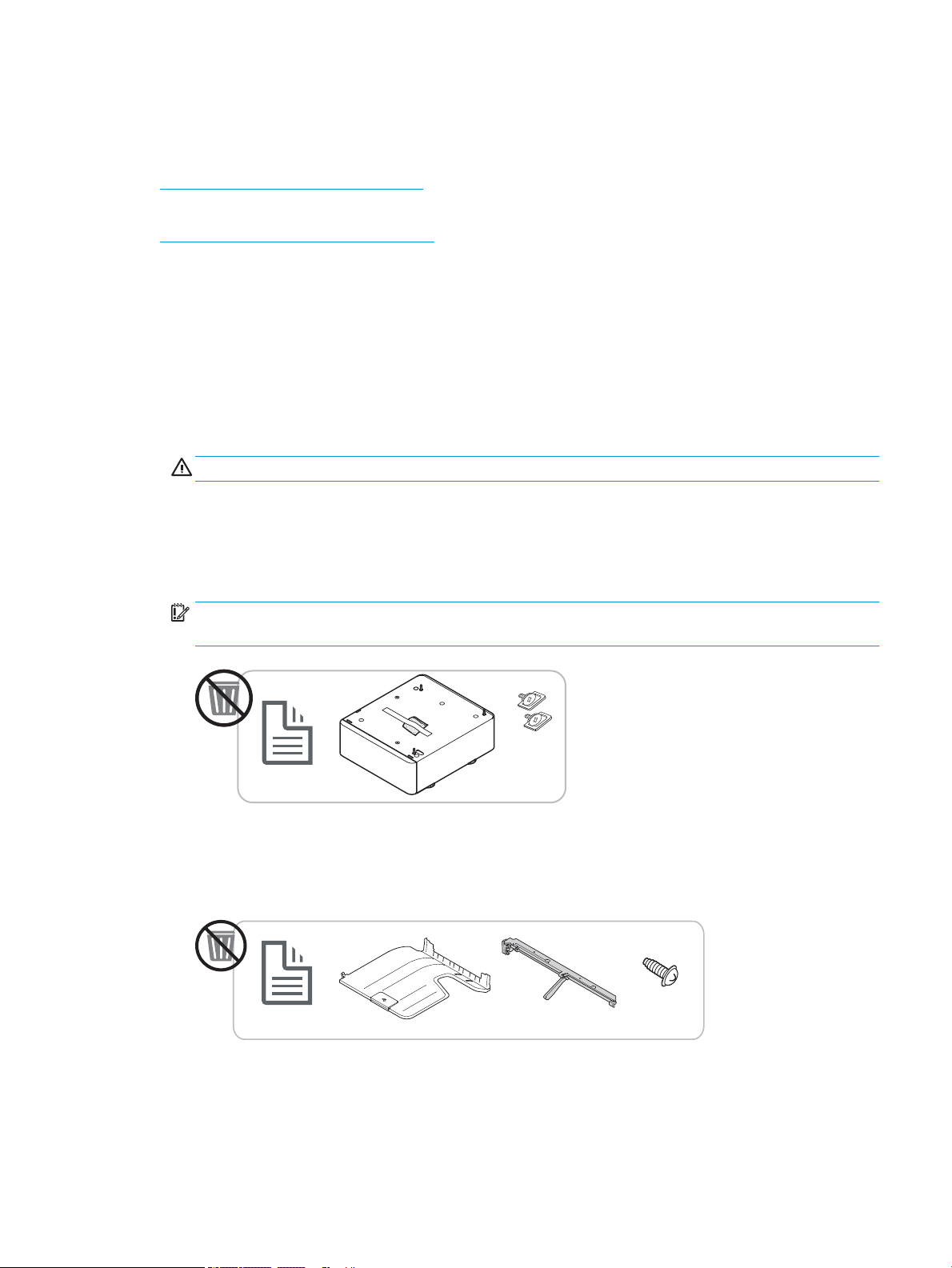

Unboxing and basic assembly

x 2

For HP Color LaserJet MFP E87640, E87650, E87660 products and the Y1F99A HP LaserJet 2000-sheet HCI.

Click here to view video of this procedure.

For HP LaserJet MFP E82540, E82550, E82560 products and the Y1G16A HP LaserJet Cabinet

Click here to view a video of this procedure..

HP Color LaserJet E87640, E87650, E87660 or HP LaserJet E82540, E82550, E82560 engine

1. Open the box, then remove the packing materials and accessories packed on top of the engine.

2. Lift the box from the engine, then pull down the plastic bag around the engine.

HP LaserJet Dual Cassette Department Feeder (DCF) and HP LaserJet Department Cabinet or 2000-sheet HCI

1. Open the box, and then remove all accessories, manuals, and packing materials on top of the DCF/Cabinet

or 2000-sheet HCI.

CAUTION: The DCF/Cabinet or 2000-sheet HCI requires two people to lift.

2. Tilt the shipping box on its side, and then carefully remove the DCF/Cabinet or 2000-sheet HCI from the

box.

3. Remove the DCF/Cabinet or 2000-sheet HCI from its shipping bag, and then remove all tape and packing

materials from the exterior of the DCF and the trays.

IMPORTANT: Two wingnuts are taped to the top of the 2000-sheet HCI/Cabinet chassis. Retain the

wingnuts/alignment pins for installing the engine to the DCF/Cabinet and 2000-sheet HCI.

HP Job Separator

▲

Unpack the job separator.

HP LaserJet Paper Tray Heaters

▲

Verify the contents of the heaters, and then leave them boxed for the service technician or installer.

ENWW Unboxing and basic assembly 29

Page 36

Engine preparation

For HP Color LaserJet MFP E87640, E87650, E87660: Click here to view a video of this procedure.

For HP LaserJet MFP E82540, E82550, E82560: Click here to view a video of this procedure.

CAUTION: The engine assembly is heavy and requires four people to lift.

1. Remove the packaging, such as foam and plastic.

2. Leave the tape on the engine intact.

Stacking

For HP Color LaserJet MFP E87640, E87650, E87660: Click here to view a video of this procedure.

For HP LaserJet MFP E82540, E82550, E82560: Click here to view a video of this procedure.

HP Color LaserJet MFP E87640, E87650, E87660 and HP LaserJet MFP E82540, E82550, E82560

CAUTION: The engine assembly is heavy and requires four people to lift.

Stacking the engine on the DCF/Cabinet or HCI

1. Install the two black re-usable lifting handles in the hand-holds on the left-side of the printer.

2. Open two lift bars on the right-side of the printer.

30 Chapter 5 Staging ENWW

Page 37

3. Carefully lift the engine assembly from each corner, align the engine to the locator pins and connector on

the DCF/2000-sheet HCI, and then carefully lower the engine onto the DCF/2000-sheet HCI.

4. Install two thumbscrews for the 2000-sheet HCI and cabinet.

5. Remove the scanner lock screw.

CAUTION: The scanner lock screw must be removed prior to powering on the printer.

Staging the side HCI (sHCI)

Click here to view a video of this procedure.

1. Cut the top of the container.

2. Open container for the cabinet.

3. Remove the shipping foam that includes rail, alignment bracket, additional hardware, and screws. Set these

aside.

CAUTION: The sHCI requires two people to lift out of the container.

4. Tilt carton on its side to allow easier removal of the cabinet from carton.

5. Slide the sHCI out of the carton.

6. Remove plastic bag from the sHCI.

7. Rotate the sHCI to its upright position with casters on the bottom.

8. Remove all shipping material and shipping tape from sHCI.

9. Open top of the sHCI and remove the shipping foam and shipping tape.

NOTE: To remove shipping foam, lift from the bottom of the foam and lift straight up to remove.

ENWW Unboxing and basic assembly 31

Page 38

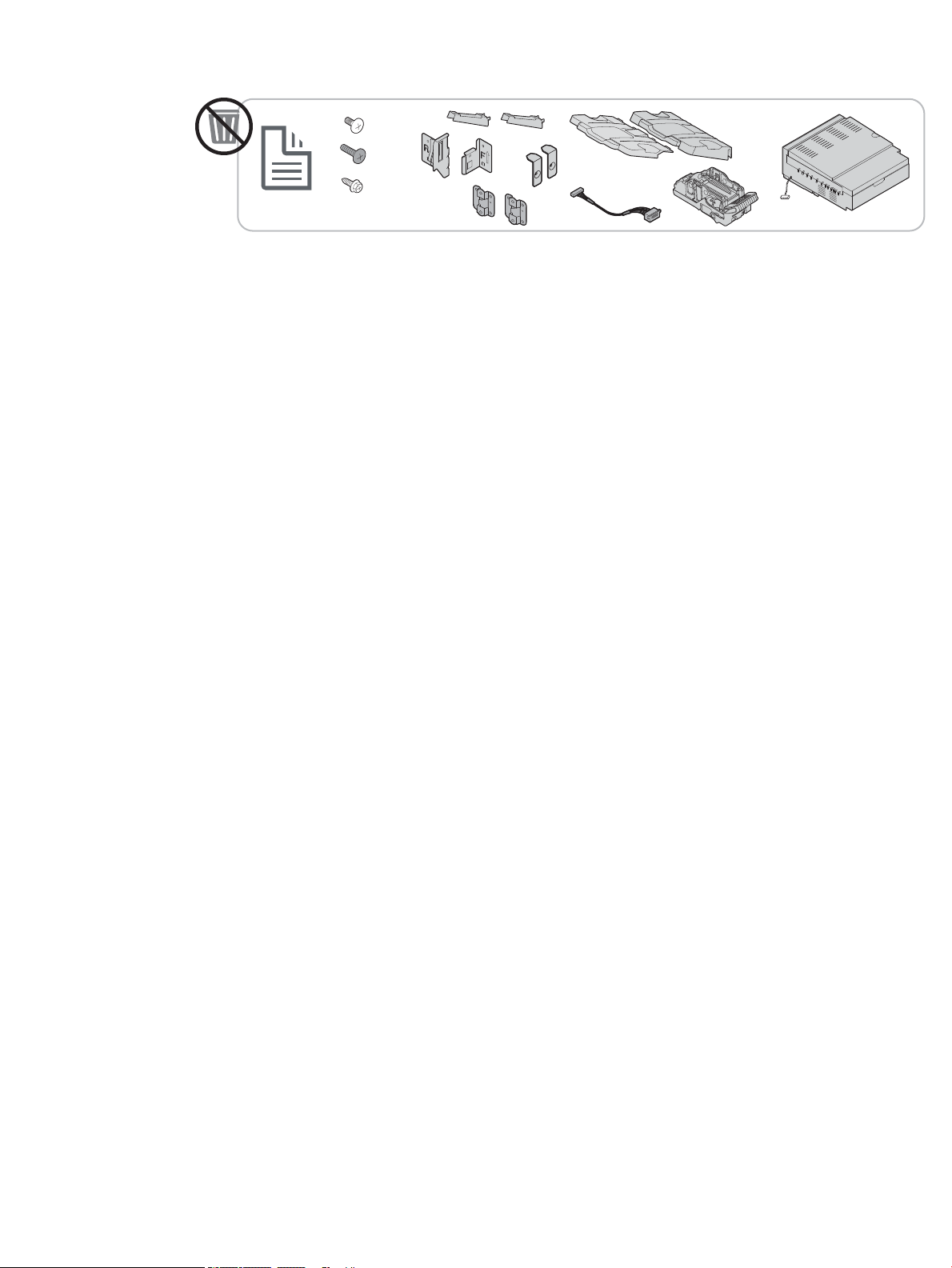

Finishers

b

x 4

a

x 6

c

x 1

62kg

137lb

HP LaserJet Inner nisher

Click here to view video of this procedure.

▲

Unpack the inner nisher.

NOTE: Some parts may be buried in the packing foam.

HP LaserJet Booklet Finisher

Click here to view a video of this procedure.

▲

Unpack the booklet nisher.

NOTE: Some parts may be buried in the packing foam.

HP LaserJet Stapler/Stacker Finisher

Click here to view a video of this procedure.

▲

Unpack the stapler/stacker nisher.

NOTE: Some parts may be buried in the packing foam.

32 Chapter 5 Staging ENWW

Page 39

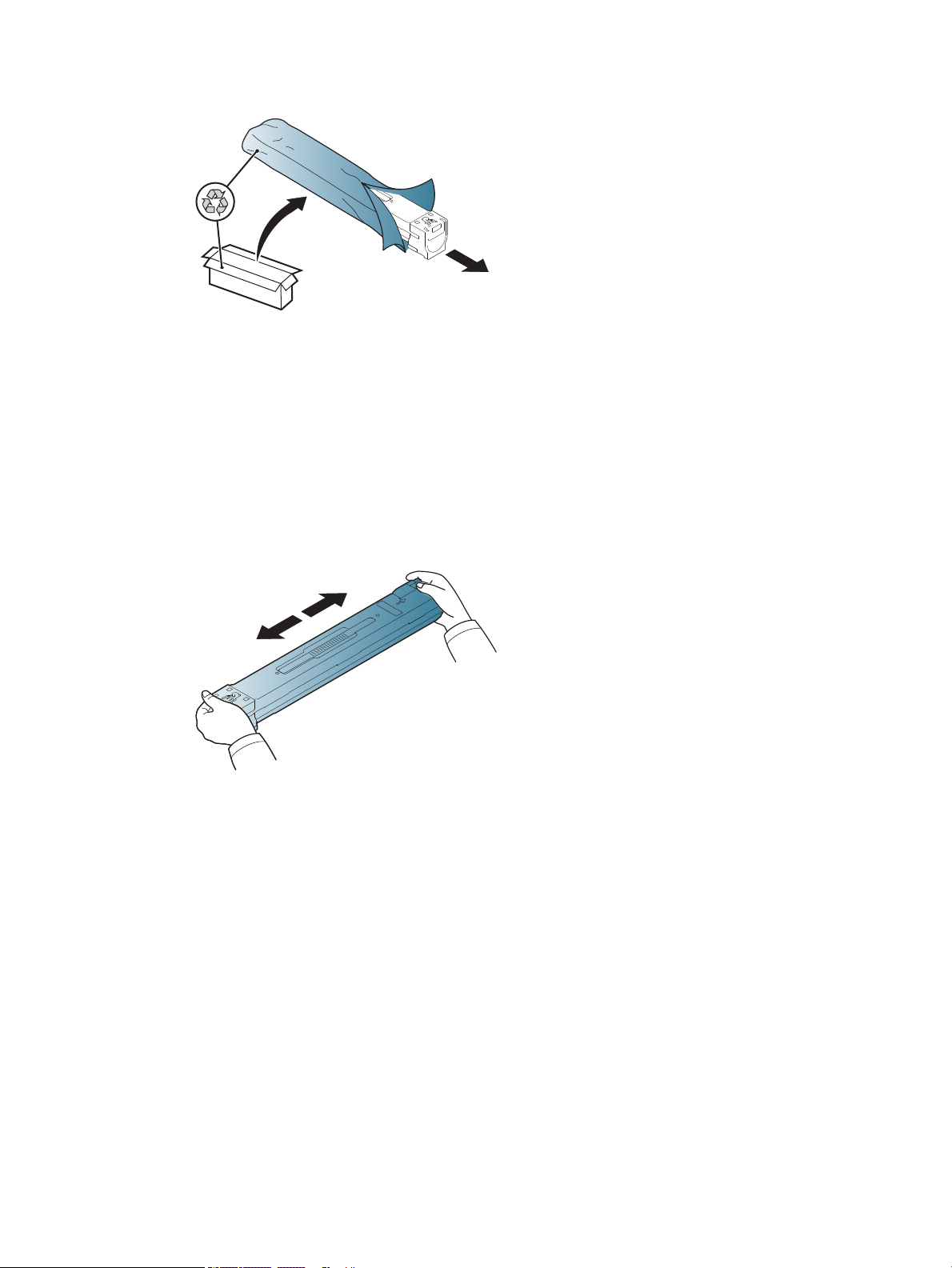

x 7

x 13

c

x 4

b

a

ENWW Unboxing and basic assembly 33

Page 40

Initial supplies installation

2

1

Install toner

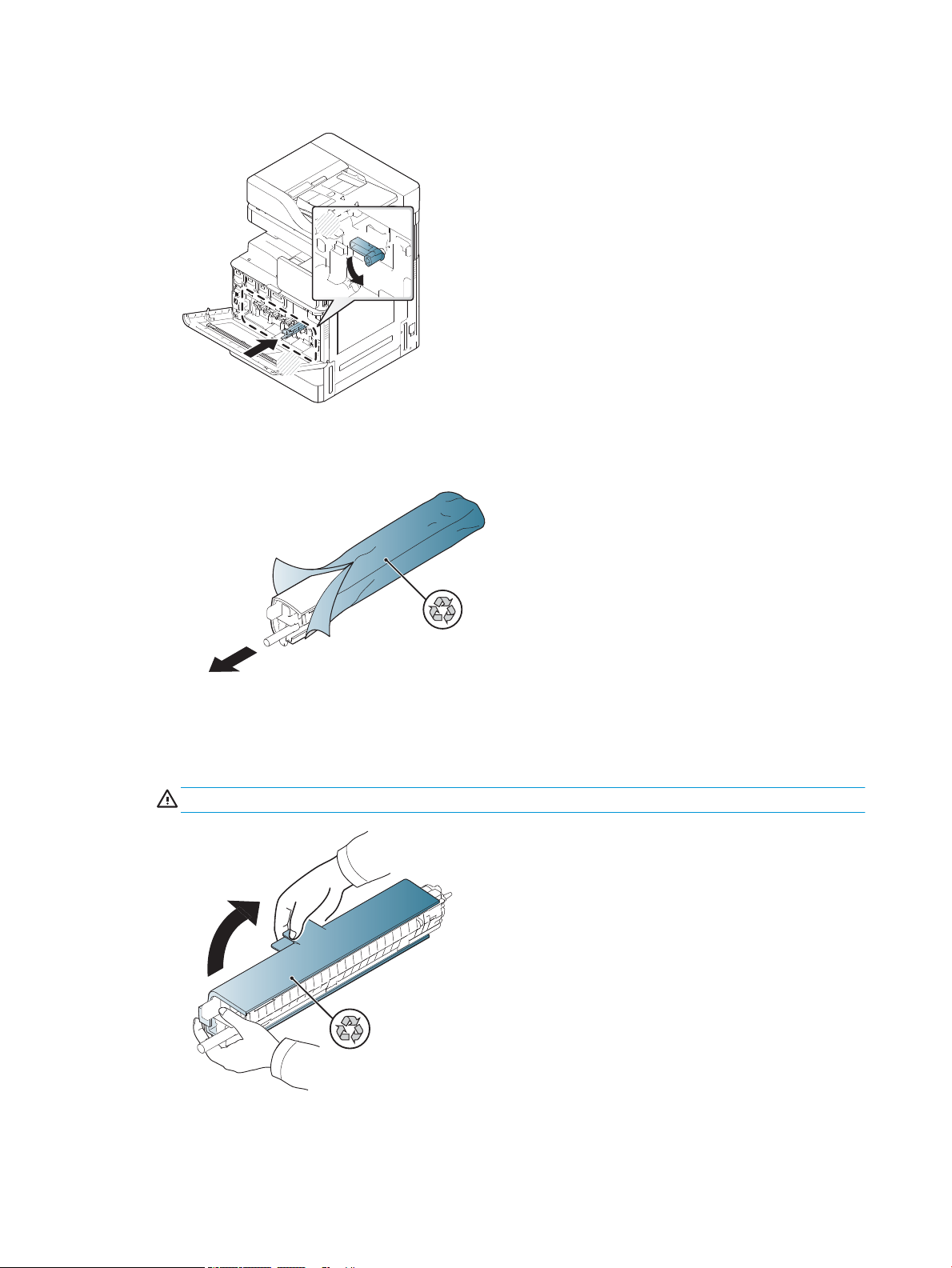

HP Color LaserJet MFP E87640, E87650, E87660

Click here to view a video of this procedure.

NOTE: Follow the instructions on the inside of the printer.

For the latest information on how to install the toner cartridges click here

Click here to view a video for this procedure.

1.

2.

34 Chapter 5 Staging ENWW

Page 41

3.

4. Shake the toner cartridge vigorously from side to side at least ten times.

–

Rotate the toner cartridge 90 degrees until the blue top handle is facing away from you, and repeat

the shaking process.

–

Rotate the toner cartridge 90 degrees until the blue top handle is facing down and the shutter is

facing up, and repeat the shaking process.

–

Rotate the toner cartridge 90 degrees until the blue handle is facing toward you, and repeat the

shaking process.

ENWW Initial supplies installation 35

Page 42

5.

1

2

21

6.

7.

36 Chapter 5 Staging ENWW

Page 43

8.

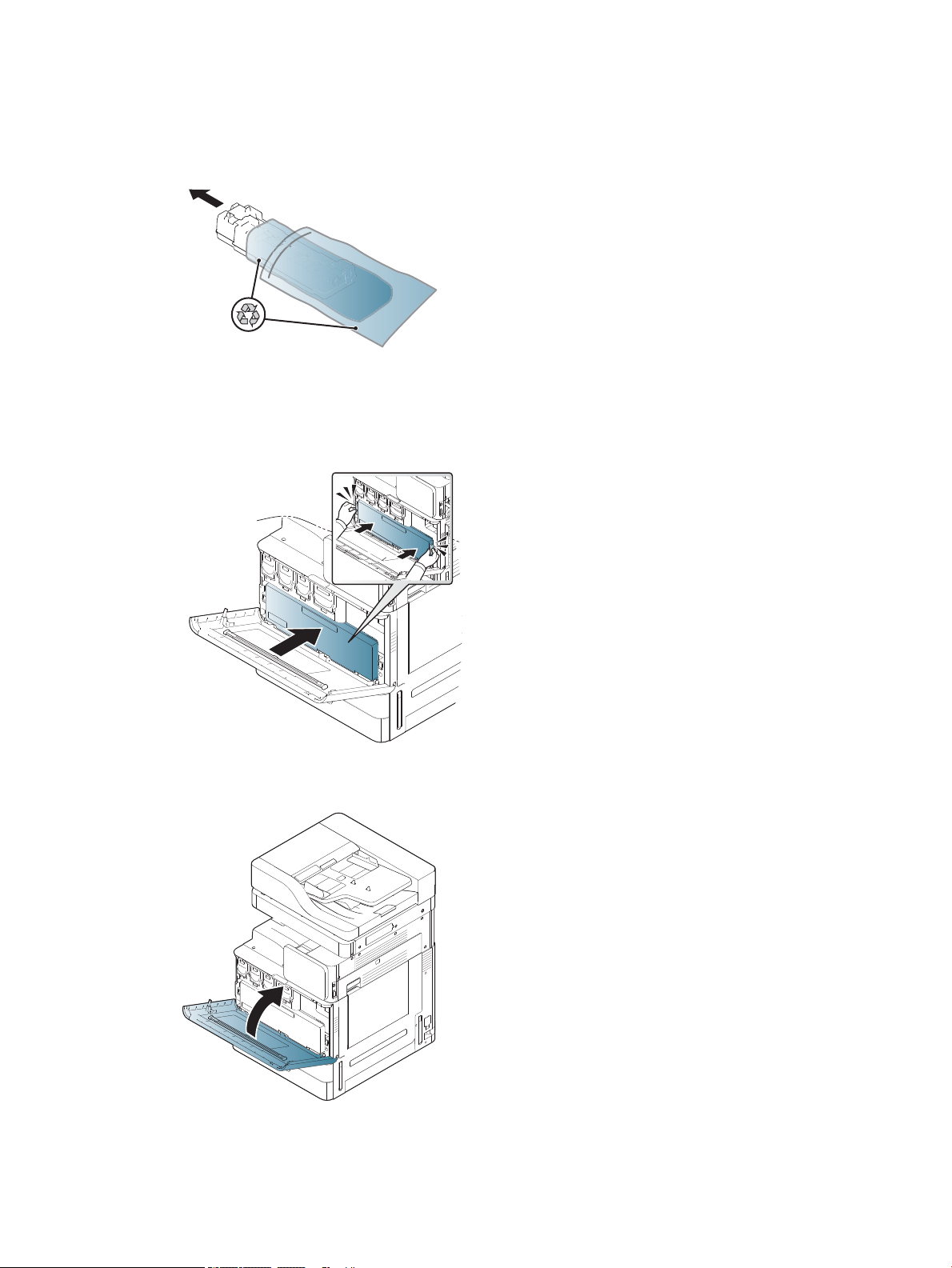

HP LaserJet MFP E82540, E82550, E82560

Click here to view a video of this procedure.

NOTE: Follow the instructions on the inside of the printer.

1.

ENWW Initial supplies installation 37

Page 44

2.

1

2

3. Vigorously shake side-to-side the toner cartridge to distribute toner throughout the toner container (about

10 times).

4.

38 Chapter 5 Staging ENWW

Page 45

5.

1

2

6.

ENWW Initial supplies installation 39

Page 46

7.

40 Chapter 5 Staging ENWW

Page 47

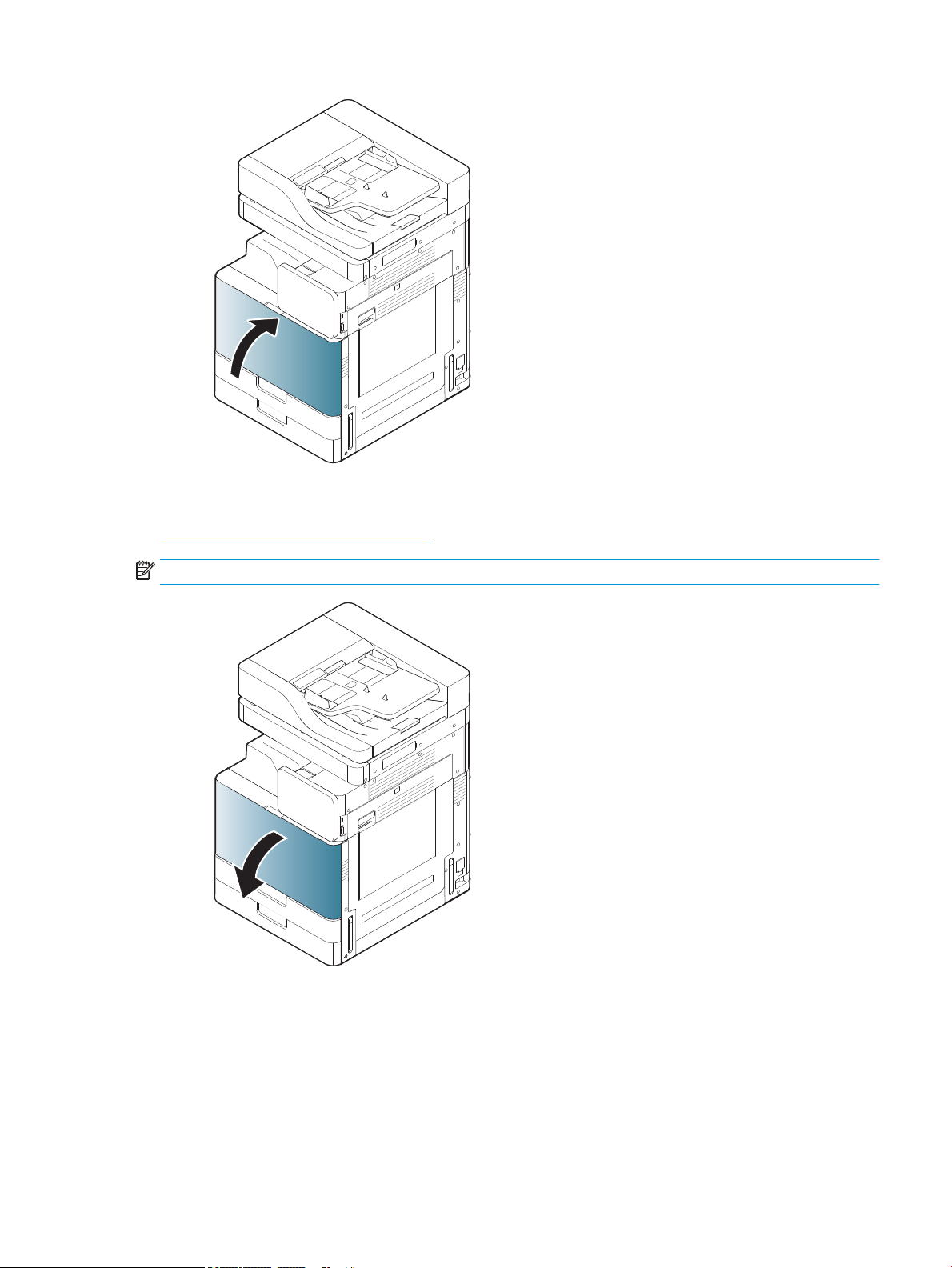

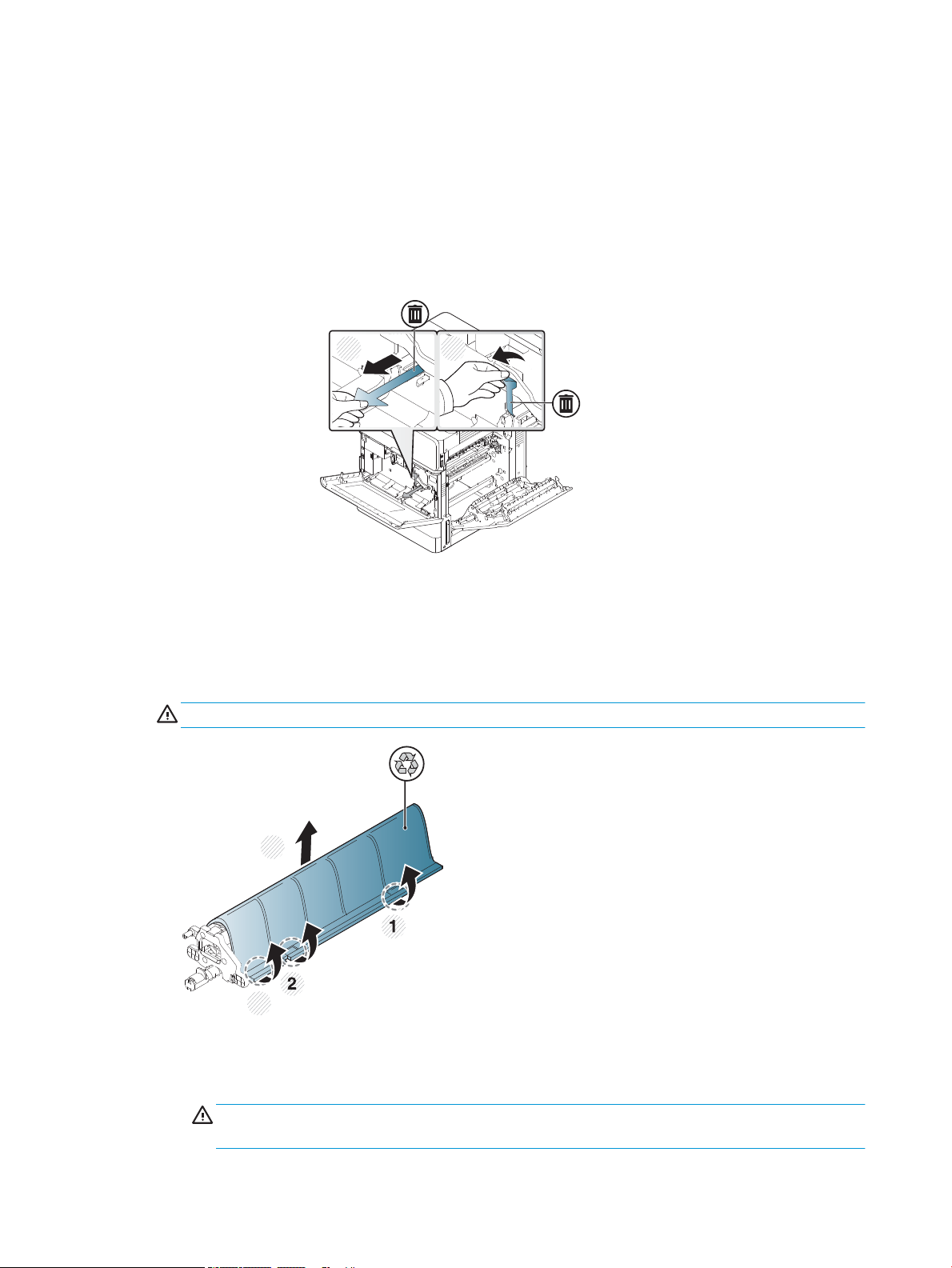

Initial power on

1

2

Install imaging drum (HP Color LaserJet MFP E87640, E87650, E87660)

. Click here to view a video for this procedure.

NOTE: The technician must be trained and qualied/certied to perform this activity.

CAUTION: To prevent damage to the printer, use only the power cord that is provided with the printer.

CAUTION: The scanner lock screw must be removed prior to powering on the printer.

A label with the printer voltage rating is located on the back of the printer.

NOTE: Make sure that the power source is adequate for the printer voltage rating. The voltage rating is on the

printer label. The printer uses either 110-127 Vac or 220-240 Vac and 50/60 Hz.

1. Remove the shipping material from each of the developing units by pulling the red tape down o the

engine and then pull straight out of the developing unit.

CAUTION: Ensure all shipping tape is removed.

ENWW Initial power on 41

Page 48

2. Lower the drum lock lever for each color location.

1

2

3. Remove the imaging drum from packaging.

4. Remove the orange plastic cover by ipping image drum over and releasing the two orange tabs at both

ends. Remove in the direction of the arrow.

CAUTION: Do not touch the green drum.

42 Chapter 5 Staging ENWW

Page 49

5. Support the imaging drum with one hand on the bottom and one hand holding the handle on the front. Do

1

2

not use the waste toner connection as a handle.

NOTE: Guide on the right top side of image drum that aligns with a guide inside the engine.

6. Slide into printer using the guide.

7. Rotate lower lever up to locking position (about 90°)

ENWW Initial power on 43

Page 50

8. Remove toner collection unit from shipping bag.

9. Install the TCU by pushing in on both sides until the tabs snap into place.

10. Close the front door.

44 Chapter 5 Staging ENWW

Page 51

Install imaging drum (HP LaserJet MFP E82540, E82550, E82560)

1

2

Click here to view a video of this procedure.

NOTE: The technician must be trained and qualied/certied to perform this activity.

CAUTION: To prevent damage to the printer, use only the power cord that is provided with the printer.

CAUTION: The scanner lock screw must be removed prior to powering on the printer.

A label with the printer voltage rating is located on the back of the printer.

NOTE: Make sure that the power source is adequate for the printer voltage rating. The voltage rating is on the

printer label. The printer uses either 110-127 Vac or 220-240 Vac and 50/60 Hz.

1. Open the right door by grasping latch and releasing in the direction of the arrow.

ENWW Initial power on 45

Page 52

2. Remove red tape pull straight in direction of the arrow. Remove second shipping material from the

1 2

4

3

developing unit by pulling the red tape down o the engine and then pull straight out of the developing

unit.

3. Remove image drum from shipping bag. Remove orange shipping material from drum, release tabs on

center (callout 2) and at each ends (callout 1,3) to release orange shipping material (callout 4).

CAUTION: Do not touch the green drum and reduce its exposure to light.

4. Underneath, there is a plastic handle located in the middle to assist in the installation into engine.

▲

Install image drum in the upper opening in the engine.

CAUTION: Verify the guide on top of the imaging drum is properly aligned to the guide inside the

engine before pushing. If it is not, the drum will be scratched.

46 Chapter 5 Staging ENWW

Page 53

5. Screw in thumbscrew located on the left side and rotate the developing unit lock lever up.

1 2

6. Close the right door.

ENWW Initial power on 47

Page 54

7. Remove Toner Collection Unit from shipping bag.

8. Install by pushing in on both sides until the tabs snap into place.

9. Close the front door.

48 Chapter 5 Staging ENWW

Page 55

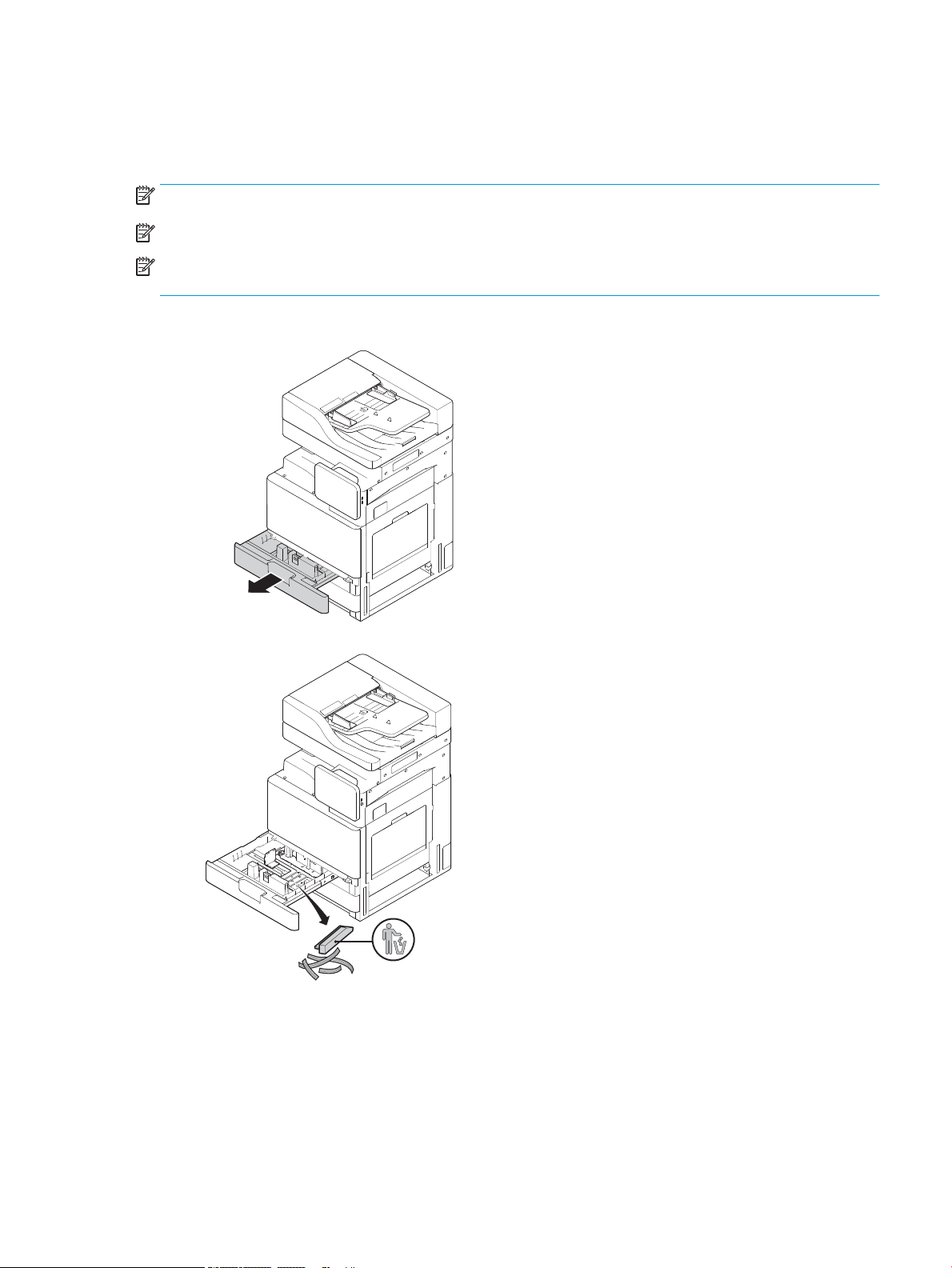

Engine adjustments and tests

Load paper in trays and input devices

NOTE: Make sure all shipping tape and other packing materials are remove from the tray before loading paper.

NOTE: Make sure to keep the paper tray labels for installation on the tray front panel.

NOTE: The trays default conguration is set to A4 paper size. If using letter paper size, adjust the guides for

letter size.

Loading paper in trays on the printer

1.

2.

ENWW Engine adjustments and tests 49

Page 56

3.

1

2

4.

5.

50 Chapter 5 Staging ENWW

Page 57

6.

7.

ENWW Engine adjustments and tests 51

Page 58

Loading paper into the HCI (bottom)

1.

52 Chapter 5 Staging ENWW

Page 59

2.

ENWW Engine adjustments and tests 53

Page 60

Loading paper into the sHCI

1.

2.

54 Chapter 5 Staging ENWW

Page 61

3.

ENWW Engine adjustments and tests 55

Page 62

Prepare for shipment to customer location

Table 5-3 Transportation preparation

❑

Power down and disconnect all nishing devices.

❑

Separate the engine and input/output devices.

❑

For long distance transportation, reinstall the scanner lock screw.

❑

Leave the attachment brackets in place.

NOTE: If the attachment brackets for the nisher are left in place, be careful not to damage them when securing the device during

transport.

NOTE: If attachment hardware for sHCI is left in place, the attachment rail must be secured under the device by using packing tape

at both ends.

❑

Retract stabilizer feet on bottom of the units for move.

❑

Protect the casters.

❑

Reinstall the shipping lock on the Booklet Finisher.

❑

HP recommends placing the nishers on pallet for transportation.

❑

Arrange for local shipping.

❑

Blanket wrap the engines and make sure they are properly strapped to the truck.

❑

Whenever rolling over any rough surface (asphalt, cobble stones, and other rough surface) lay down 4 x 8 sheets of 1/4 in hardboard.

❑

When transporting across gaps use appropriate support devices to make sure the transportation of the printer is smooth.

❑

Verify truck shipment requirements.

❑

Verify securing requirements.

56 Chapter 5 Staging ENWW

Page 63

Repack (from customer site)

Local move

Table 5-4 Transportation preparation

❑

Power down and disconnect all nishing devices.

❑

Separate the engine and input/output devices.

❑

For long distance transportation, reinstall the scanner lock screw.

❑

Leave the attachment brackets in place.

NOTE: If the attachment brackets for the nisher are left in place, be careful not to damage them when securing the device during

transport.

NOTE: If attachment hardware for sHCI is left in place, the attachment rail must be secured under the device by using packing tape

at both ends.

❑

Retract stabilizer feet on bottom of the units for move.

❑

Lock the scanner and lock the booklet nisher with support rod.

❑

Protect the casters.

❑

Reinstall the shipping lock on the Booklet Finisher.

❑

HP recommends placing the nishers on pallet for transportation.

❑

Arrange for local shipping.

❑

Blanket wrap the engines and make sure they are properly strapped to the truck.

❑

Whenever rolling over any rough surface (asphalt, cobble stones, and other rough surface) lay down 4 x 8 sheets of 1/4 in hardboard.

❑

When transporting across gaps use appropriate support devices to make sure the transportation of the printer is smooth.

Long distance move

NOTE: If the product will be transported more than 500 miles, transported by air, or placed in storage more

than 30 days, contact the factory for recommendations.

Table 5-5 Long distance move

❑

Air freight

❑

Power down and disconnect all nishing devices.

❑

Separate the engine and input/output devices.

❑

For long distance transportation, reinstall the ADF scanner lock screw.

❑

Verify truck shipment requirements.

❑

Verify securing requirements.

❑

Long distance truck shipment

ENWW Repack (from customer site) 57

Page 64

Table 5-5 Long distance move (continued)

❑

Leave the attachment brackets in place.

NOTE: If the attachment brackets for the nisher are left in place, be careful not to damage them when securing the device during

transport.

NOTE: If attachment hardware for sHCI is left in place, the attachment rail must be secured under the device by using packing tape

at both ends.

❑

Retract stabilizer feet on bottom of the units for move.

❑

Install the scanner lock and the support lock for the booklet nisher.

❑

Protect the casters.

❑

Reinstall the shipping lock on the Booklet Finisher.

❑

HP recommends placing the nishers on pallet for transportation.

❑

For long distance transportation, HP recommends crating the printers and accessories or using pallets with heavy padding.

❑

Arrange for long distance shipping.

❑

Whenever rolling over any rough surface (asphalt, cobble stones, and other rough surface) lay down 4 x 8 sheets of 1/4 in hardboard.

❑

When transporting across gaps use appropriate support devices to make sure the transportation of the printer is smooth.

❑

Verify truck shipment or air freight requirements.

❑

Verify securing requirements.

58 Chapter 5 Staging ENWW

Page 65

6 Late point dierentiation conguration (LPDC)

●

LPDC installation steps

NOTE: The LPDC procedure has two components that must be performed by a trained person during the device

install, staging or setup process.

NOTE: Up to a 24 hour delay from the time the unit is shipped to when the license becomes available in the

cloud. You will be unable to download the license to the device until the license is available.

ENWW 59

Page 66

LPDC installation steps

Automatically download and transfer speed license

1. Connect the device to the power source but do NOT connect the network cable yet.

2. Turn on the device, wait for the Setup Wizard to display, and then congure each setting.

3. Allow the device to nalize the initialization and internal communications.

4. Print a conguration page and make sure that the device is working.

5. Manually update the device rmware using the USB ash drive but do NOT connect the network cable.

NOTE: Do not skip this step.

6. Make sure all accessories are installed before upgrading rmware. This is the only way to update the

rmware on the accessories.

NOTE: Accessories might not update automatically if attached later.

7. Wait for the device to complete the rmware update process. The device will automatically reboot several

times and might take up to 30 minutes to complete. Be patient and do not interrupt the rmware process.

8. After the device comes to a Ready state, wait another 10 minutes to allow the device rmware to nish

copying rmware to all the PCAs.

9. Print a conguration page and make sure the rmware has been updated correctly and conrm that LPDC

status is “Not congured (XX, XX, XX)”.

10. Turn the device o from the front and then power o the main switch o.

NOTE: The device speed cannot be changed after it is set by the LPDC license. The device serial number is

locked to the speed setting based on what was ordered by the customer and is placed in HPI’s license

activation site located in the cloud.

11. Connect the network cable to the device.

12. Turn the device on and wait for it to reach the Ready state.

13. Make sure the printer has a valid IP address and working internet connection. A proxy server may need to

be congured at this time in EWS or directly input into the control panel menu.

14. Wait for the LPDC process to start automatically within 10 minutes of having a working internet connection.

NOTE: The device will reboot automatically after the LPDC process is complete and the device

congurations will be reset.

15. When the Setup Wizard displays, re-congure each of the settings.

16. Wait another 5 minutes to allow the device to nish the LPDC process.

17. Print another conguration page and make sure that the LPDC is congured with the correct license speed,

and make sure the device model number is correct. The device product model will change to the ordered

model number. In the LPDC status the rst number in the parentheses (x) will be either (0, 1 or 2”. 0

corresponds to the slowest speed,; 1 is the middle speed; and 2 is the fastest speed. This conforms LPDC

has been completed.

60 Chapter 6 Late point dierentiation conguration (LPDC) ENWW

Page 67

NOTE: The status will read LPDC Congured either a (0), a (1), or a (2) after it.

If not internet connection is available or the LPDC process is not possible via the network connection, the

speed license can be downloaded to the USB ash drive and then manually transferred to the printer.

Download the speed license manually (USB ash drive)

1. Make sure the network cable is disconnected from the device.

2. Press the power switch on the front of the device, wait for the device to power o, and then turn of the

main power switch on the device.

3. Download the speed license to the USB ash drive.

a. With an internet connected PC, open a browser and go to the HP Jet Advantage Management (JAM)

Activation site https://activation.jamanagement.hp.com/redirect?ReturnUrl=%2F#!/.

b. Type the HP Passport sign in credentials including the UserID and password.

c. Wait to be directed back to the JAM Activation site and then type the following information:

NOTE: If the following information is available, type the individual serial number and either the

generic model number “X3AxxA” or ordered speed model number “X3AxxA”, or the “Z8Zxx” speed

model.

If the model and serial number is not available and the customer number and SAP PO number are

known, it can also be entered here.

●

Sold to number or CBN (customer number).

●

SAP order number.

d. Select the Get license button next to the device SN# to download the LPDC license le.

NOTE: Use the ‘edit nd’ function to quickly nd the device’s serial number.

e. Save the le to the root directory of the USB ash drive that has been FAT32 formatted.

4. Transfer the license information with the device at ready state, then what you have in A.

a. With the device at a Ready state, insert the USB ash drive into the walk up USB port on the device

(formatter or HIP USB).

b. Make sure the control panel acknowledges that a USB ash drive has been installed (a quick message

will appear on the control panel), then turn the device OFF.

c. Turn the device ON, and then wait for the device to reach a Ready state.

NOTE: If the USB ash drive is not detected, remove the USB ash drive, turn device o, reinsert the

USB ash drive, and then try again.

d. Wait for the LPDC process to complete (1–2 minutes).

e. Wait for the device to reboot automatically.

f. When the Setup Wizard displays, re-congure each of the settings.

5. Wait another 5 minutes to allow the device to nish the LPDC process.

ENWW LPDC installation steps 61

Page 68

6. Print a conguration page and make sure the LPDC is congured with the correct license speed, and make

sure the device model number is correct.

7. Connect the network cable.

Install the model nameplate and barcode label

1. Locate the large bag containing the CD, power cord, tray labels, etc.

2. Inside the large bag , locate the smaller bag containing the three HP LaserJet model nameplates and three

“XA3” barcodes.

62 Chapter 6 Late point dierentiation conguration (LPDC) ENWW

Page 69

3. Select the appropriate ‘XA3” bar code label that accurately corresponds with the pre-determinded engine

speed listed on the conguration page.

4. Remove and then discard the barcode axed inside front cover.

5. Select the appropriate model nameplate that accurately corresponds with the pre-determined engine

speed listed on the conguration page.

6. Install the model number nameplate on the front door of the device (snaps into place).

ENWW LPDC installation steps 63

Page 70

Process notes, cautions, and miscellaneous

Support information

●

SKUs are shipped at the slowest speed.

●

LPDC: Engine speed should be set when the printer is unboxed and rst installed.

●

Engine speed conguration is provided from HP cloud service as an LPDC license.

–

The license contains values of the model name and speed that are stored on the Formatter.

–

The license is signed by HP and validated by rmware.

–

The license is locked to a specic printer via HP immutable identity and HP serial number that cannot

be changed.

–

The printer will continue to look for speed setting for 10 minutes after the device has come to a Ready

state. Each time the device is rebooted, it will look for speed until it completes a successful LPDC

process.

–

NOTE: Printer checks for USB after start up once after entering UI ready.

NOTE: Printer checks the cloud once per minute for ten minutes after the USB check.

–

HP immutable identity is tied to a private key and secured on a trusted platform module (TPM) on the

printer MSOK.

–

Printer automatically obtains license from an HP Cloud Server when rst turned on and connected to

the internet.

–

If the printer connected to internet is behind a rewall using a proxy server and port address, it will

need to be congured in EWS or the control panel prior to using the automatic cloud LPDC process.

●

After the LPD license is installed, all customer settings on the printer are set back to the factory defaults.

64 Chapter 6 Late point dierentiation conguration (LPDC) ENWW

Page 71

7 On-site nal setup

●

On-site nal setup checklist

●

Clean laser scanner assembly after setup (HP Color LaserJet MFP E87640, E87650, E87660)

●

Check the vertical gap between engine and nisher

●

Load paper trays

●

Install paper tray labels

●

Staples

●

Print and copy tests

ENWW 65

Page 72

On-site nal setup checklist

Table 7-1 On-site nal setup checklist

❑

Remove any shipping materials or brackets that were installed for shipment after the device was tested during the installation

process.

❑

Reinstall any input or output devices/nishers.

❑

Clean the laser scanner assembly window.

❑

Clean the scanner glass.

❑

Check the vertical gap between the engine and nisher, if installed.

❑

Load paper in trays.

❑

Label paper trays, if required.

❑

Load staples.

❑

Perform print and copy tests.

66 Chapter 7 On-site nal setup ENWW

Page 73

Clean laser scanner assembly after setup (HP Color LaserJet MFP E87640, E87650, E87660)

Cleaning the laser scanner assembly window (HP Color LaserJet MFP E87640, E87650, E87660 only)

1. Open the front cover and remove the toner collection unit (TCU).

Figure 7-1 Remove the TCU

2. Remove the laser scanner assembly window cleaning tool located on the front cover.

Figure 7-2 Remove laser scanner assembly window cleaning tool

ENWW Clean laser scanner assembly after setup (HP Color LaserJet MFP E87640, E87650, E87660) 67

Page 74

3. Insert the laser scanner assembly window cleaning tool into each color entrance.

Figure 7-3 Laser scanner assembly color entrances

4. Slowly remove and reinsert the cleaning tool.

5. Repeat step 4 at least four times for each laser scanner assembly window.

Cleaning the ow document feeder white bar and CIS

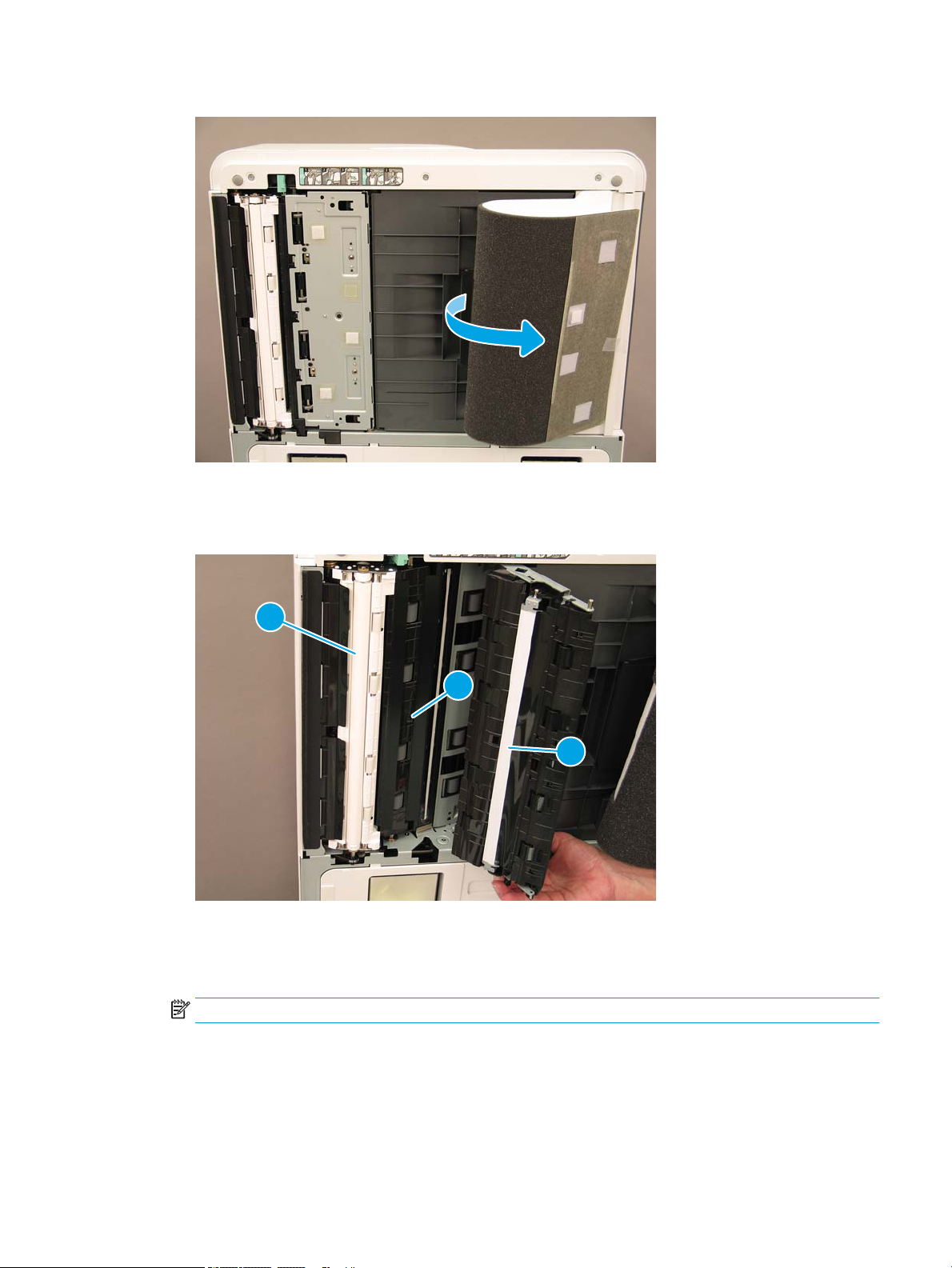

1. Open the ADF unit, and peel back the white backing.

CAUTION: Do not bend or fold white foam backing generating a crease in the white foam backing.

68 Chapter 7 On-site nal setup ENWW

Page 75

Figure 7-4 Open ADF unit

1

2

3

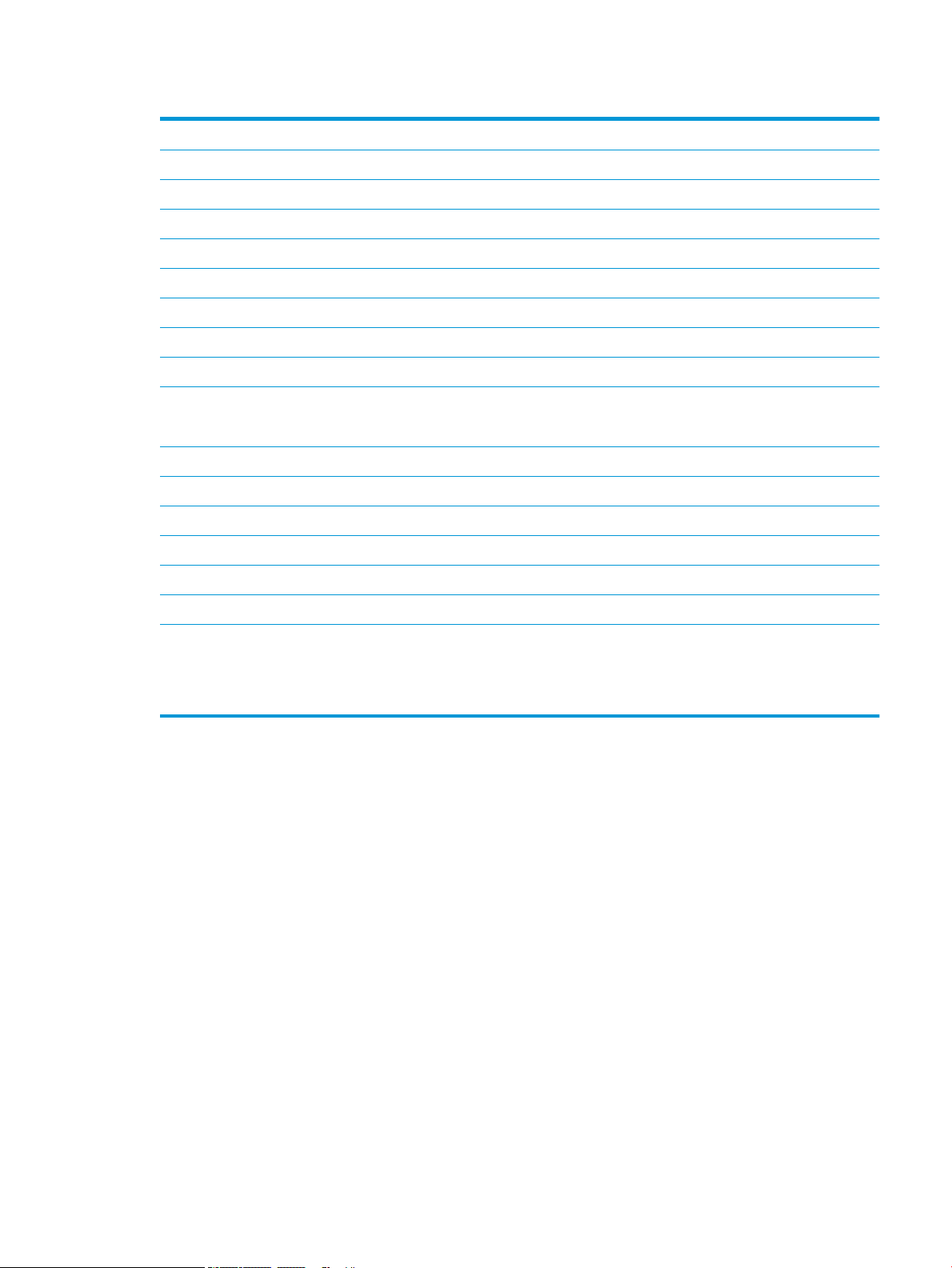

2. Clean the simplex white bar (callout 1), the CIS (callout 2), and the duplex white bar (callout 3) using a soft,

lint-free, clean cloth.

Figure 7-5 Clean ADF white bar

Cleaning the scan glass

▲

Open the ow document feeder unit. Clean the scanner glass (callout 1) using a soft, lint-free, clean cloth.

NOTE: Make sure to clean the main scanner glass area.

ENWW Clean laser scanner assembly after setup (HP Color LaserJet MFP E87640, E87650, E87660) 69

Page 76

Figure 7-6 Clean the scanner glass

1

Check the vertical gap between engine and nisher

Check the vertical gap between the nisher and engine. If the space is not equal at top and bottom, adjust the

casters on the nisher to make the gap even.

Load paper trays

NOTE: See the Load paper in trays and input devices in the Engine adjustments and tests in the Staging section

for detailed instructions.

Install paper tray labels

1. Locate the appropriate label size.

70 Chapter 7 On-site nal setup ENWW

Page 77

2. Locate the embossed line on the lower right of the tray and apply the label.

Staples

NOTE: See the Staples task in the Complete installation procedures section for detailed instructions.

Engine rmware upgrade after installing nisher

CAUTION: After installing any accessory the rmware must be updated to make sure the printer rmware is

compatible with the accessory.

1. Perform the rmware upgrade.

2. Verify the new nishing accessory is recognized and available.

ENWW Staples 71

Page 78

Print and copy tests

1. Print a conguration page.

2. Print a color page. (HP Color LaserJet MFP E87640, E87650, E87660 only)

3. Run at least one single and one double sided copy.

4. Run at least one scan to USB, if active. (Applies to all models.)

5. Run print output to verify the stapler stacker and/or booklet maker is functioning properly, if installed.

72 Chapter 7 On-site nal setup ENWW

Page 79

8 Complete installation procedures

●

Cabinet stand and dual cassette feeder (DCF) installation

●

2000-sheet HCI

●

Install the 3000-sheet sHCI

●

Installing tray heater in a HP LaserJet 2000-sheet HCI

●

Finishers

●

Stabilization Chocks

ENWW 73

Page 80

Cabinet stand and dual cassette feeder (DCF) installation

Install the cabinet on the HP LaserJet MFP E82540, E82550, E82560

Click here to view a video of this procedure.

Please review the LaserJet A3 videos for a complete understanding of the installation of each device. Use these

checklists as a reminder of the steps demonstrated in the videos.

CAUTION: The engine assembly is heavy and requires four people to lift.

Table 8-1 Cabinet installation

❑

Unbox the cabinet.

❑

Install three alignment pins on top of the cabinet.

❑

Locate and set aside the two thumbscrews for later.

❑

Unpack the MFP.

❑

Remove the packing foam and tape.

❑

Remove the scanner support bracket.

❑

Remove the package containing the imaging unit and set aside.

❑

Locate and install two lift assist handles on the left side of the MFP.

CAUTION: The device weighs 113.1 kg (249.3 lbs).

❑

Use four people to lift the device and carefully align on the cabinet.

❑

Remove the lift assist handles.

❑

Remove the remaining tape and packing foam from the device.

❑

Remove the foam shipping block from the MP tray (Tray 1).

❑

Remove the packing materials from the trays and then remove the trays.

❑

Install the two thumbscrews to secure the MFP to the cabinet.

❑

Reinstall the trays.

❑

Remove the protective lm from the logo on the front door.

❑

Remove the scanner lock screw and label and install the screw cover.

❑

Open the front door.

❑

Remove the seal from the toner cartridge opening.

❑

Remove the developer unit shipping support.

❑

Pull down then straight out to remove the developer unit shipping seal.

❑

Verify the seal is not torn and no pieces are left attached to the developing unit shutter.

❑

Unpack the toner cartridge and locate the two seals.

❑

Pull DOWN to remove the seal on the bottom. Pull OUT to remove the seal at the rear.

❑

Shake the toner cartridge to distribute the toner.

❑

Install the toner cartridge and while holding IN, rotate the handle to the left to lock the toner cartridge into place.

74 Chapter 8 Complete installation procedures ENWW

Page 81

Table 8-1 Cabinet installation (continued)

❑

Open the right door – this removes the interlock blocking the drum unit opening.

❑

Remove the drum from the foam packing.

❑

Cut open the black protective bag and remove the drum unit.

❑

On the orange cover, locate the arrows numbered 1, 2, 3.

❑

Pull up at each location in order to release the cover from the drum unit.

❑

Rotate the drum unit and grasp the gray handle on top.

❑

Locate and grasp the handle on the front of the drum unit.

❑

Align the slots along the top of the drum unit with the rails on the engine.

❑

Carefully insert the drum unit until it is seated, and then use the thumbscrew to secure the drum unit in the engine.

❑

Install the TCU (toner collection unit).

TIP: Push rmly on both sides at the same time to lock the TCU into the engine.

❑

Close the front door.

❑

Close the right door.

❑

Perform Late Point Dierentiation and Conguration (LPDC).

❑

Apply the “XA3” barcode inside the front door and nameplate on the outside of the front door.

❑

Upgrade rmware with the latest available on hp.com.

❑

Insert the thumb drive with rmware at the connector on the control panel.

❑