Page 1

Service Reference Guide

HP Compaq dx7510/dx7518 Business PC

Page 2

© Copyright 2009 Hewlett-Packard

Development Company, L.P. The

information contained herein is subject to

change without notice.

Microsoft and Windows are trademarks of

Microsoft Corporation in the U.S. and other

countries.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

This document contains proprietary

information that is protected by copyright. No

part of this document may be photocopied,

reproduced, or translated to another

language without the prior written consent of

Hewlett-Packard Company.

Service Reference Guide

Business PCs

First Edition (April 2009)

Document Part Number: 516947-001

Page 3

About This Book

WARNING! Text set off in this manner indicates that failure to follow directions could result in bodily

harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could result in damage

to equipment or loss of information.

NOTE: Text set off in this manner provides important supplemental information.

iii

Page 4

iv About This Book

Page 5

Table of contents

1 Installing and Customizing the Software

Installing the Operating System ........................................................................................................... 1

Installing or Upgrading Device Drivers ................................................................................................. 1

HP Backup and Recovery Manager ..................................................................................................... 1

2 Computer Setup (F10) Utility

Computer Setup (F10) Utilities ............................................................................................................. 3

Using Computer Setup (F10) Utilities .................................................................................. 3

Computer Setup—System Information ................................................................................ 5

Computer Setup—Standard CMOS Features ..................................................................... 6

Computer Setup—Advanced BIOS Features ...................................................................... 7

Computer Setup—Advanced Chipset Features ................................................................... 8

Computer Setup—Integrated Peripherals ............................................................................ 9

Computer Setup—Power Management Setup .................................................................. 10

Computer Setup—PnP/PCI Configurations ....................................................................... 10

Computer Setup—Hardware Monitor Setup ...................................................................... 11

Computer Setup—(Action Choices) ................................................................................... 12

Recovering the Configuration Settings ............................................................................................... 13

Backing Up the CMOS ....................................................................................................... 13

Restoring the CMOS .......................................................................................................... 13

3 Computer Diagnostic Features

HP Insight Diagnostics ....................................................................................................................... 14

Accessing HP Insight Diagnostics ..................................................................................... 14

Survey Tab ........................................................................................................................ 15

Diagnose Tab .................................................................................................................... 15

Test Tab ............................................................................................................................. 16

Status Tab ......................................................................................................................... 17

Log Tab .............................................................................................................................. 18

Help Tab ............................................................................................................................ 18

Saving and Printing Information in HP Insight Diagnostics ................................................ 18

Downloading the Latest Version of HP Insight Diagnostics ............................................... 19

Protecting the Software ...................................................................................................................... 19

HP Backup and Recovery Manager ................................................................................................... 20

v

Page 6

4 Serial ATA (SATA) Drive Guidelines and Features

SATA Hard Drives .............................................................................................................................. 21

SATA Hard Drive Cables .................................................................................................................... 21

SATA Data Cable .............................................................................................................. 21

SMART ATA Drives ............................................................................................................................ 22

Hard Drive Capacities ........................................................................................................................ 22

5 Identifying the Chassis, Routine Care, and Disassembly Preparation

Chassis Designations ......................................................................................................................... 23

Microtower (MT) ................................................................................................................. 23

Electrostatic Discharge Information .................................................................................................... 24

Generating Static ............................................................................................................... 24

Preventing Electrostatic Damage to Equipment ................................................................ 25

Personal Grounding Methods and Equipment ................................................................... 25

Grounding the Work Area .................................................................................................. 26

Recommended Materials and Equipment .......................................................................... 26

Operating Guidelines .......................................................................................................................... 27

Routine Care ...................................................................................................................................... 27

General Cleaning Safety Precautions ................................................................................ 27

Cleaning the Computer Case ............................................................................................ 27

Cleaning the Keyboard ...................................................................................................... 28

Cleaning the Monitor .......................................................................................................... 28

Cleaning the Mouse ........................................................................................................... 29

Service Considerations ...................................................................................................................... 29

Power Supply Fan ............................................................................................................. 29

Tools and Software Requirements .................................................................................... 29

Screws ............................................................................................................................... 29

Cables and Connectors ..................................................................................................... 30

Hard Drives ........................................................................................................................ 30

Lithium Coin Cell Battery ................................................................................................... 30

6 Removal and Replacement Procedures Microtower (MT) Chassis

Serial Number Location ...................................................................................................................... 31

Preparation for Disassembly .............................................................................................................. 32

Access Panel ...................................................................................................................................... 33

Front Bezel ......................................................................................................................................... 34

Bezel Blanks ....................................................................................................................................... 35

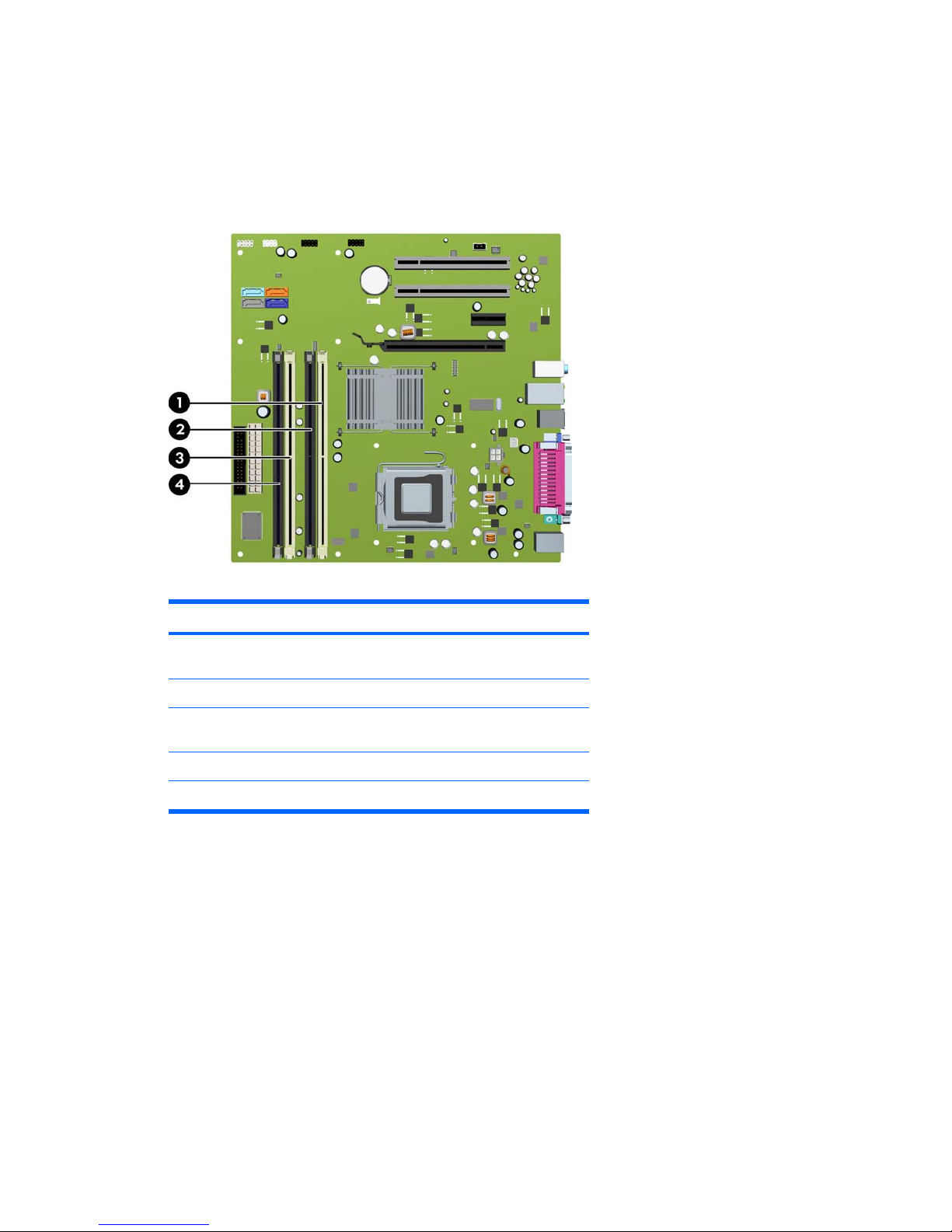

Installing Additional Memory .............................................................................................................. 36

DIMMs ............................................................................................................................... 36

DDR3-SDRAM DIMMs ...................................................................................................... 36

Populating DIMM Sockets ................................................................................................. 37

Installing DIMMs ................................................................................................................ 38

Expansion Cards ................................................................................................................................ 40

vi

Page 7

Cable Management ........................................................................................................................... 44

Cable Connections ............................................................................................................ 45

Drives ................................................................................................................................................. 46

Drive Positions .................................................................................................................. 46

Installing Additional Drives ................................................................................................. 47

System Board Drive Connections ..................................................................... 48

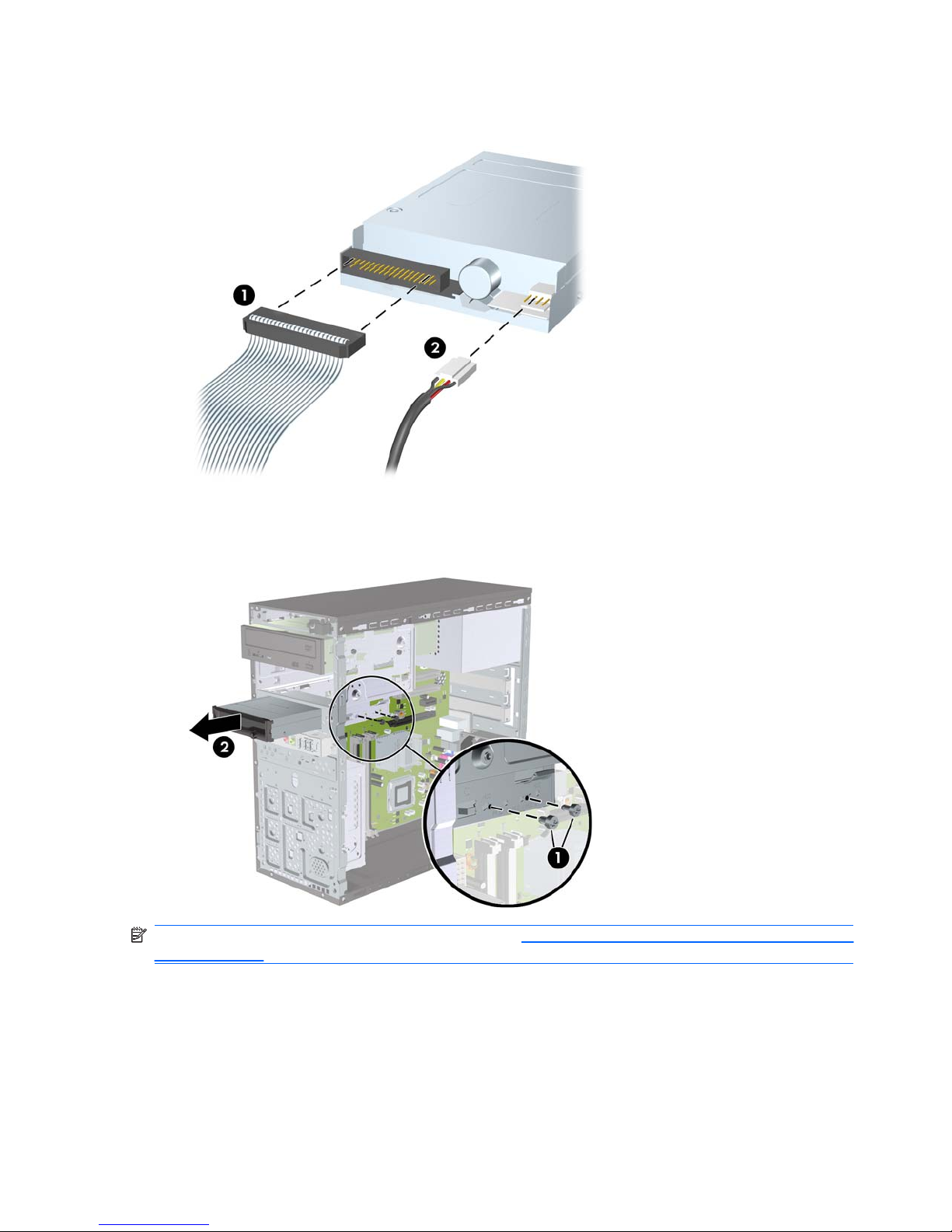

Removing an Optical Drive ............................................................................... 49

Installing an Optical Drive into the 5.25-inch Drive Bay .................................... 50

Removing an External 3.5-inch Drive ................................................................ 51

Installing a Drive into the 3.5-inch External Drive Bay ...................................... 53

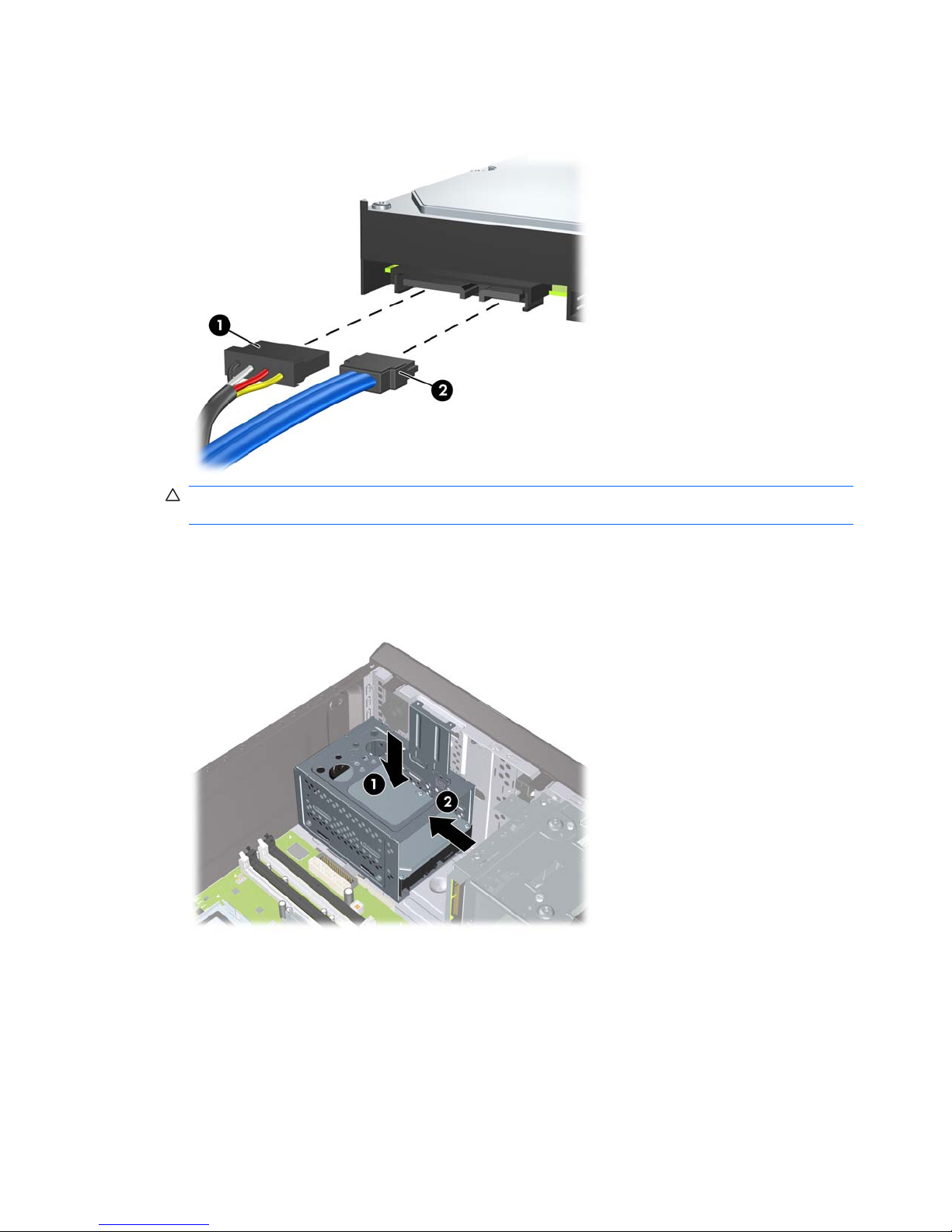

Removing an Internal 3.5-inch Hard Drive ........................................................ 54

Installing an Internal 3.5-inch Hard Drive .......................................................... 57

Front I/O and USB Panel Housing Assembly .................................................................................... 60

Power Switch/LED Assembly ............................................................................................................. 61

Speaker .............................................................................................................................................. 62

System Fan ........................................................................................................................................ 63

Heatsink assembly ............................................................................................................................. 64

Processor ........................................................................................................................................... 65

Power Supply ..................................................................................................................................... 66

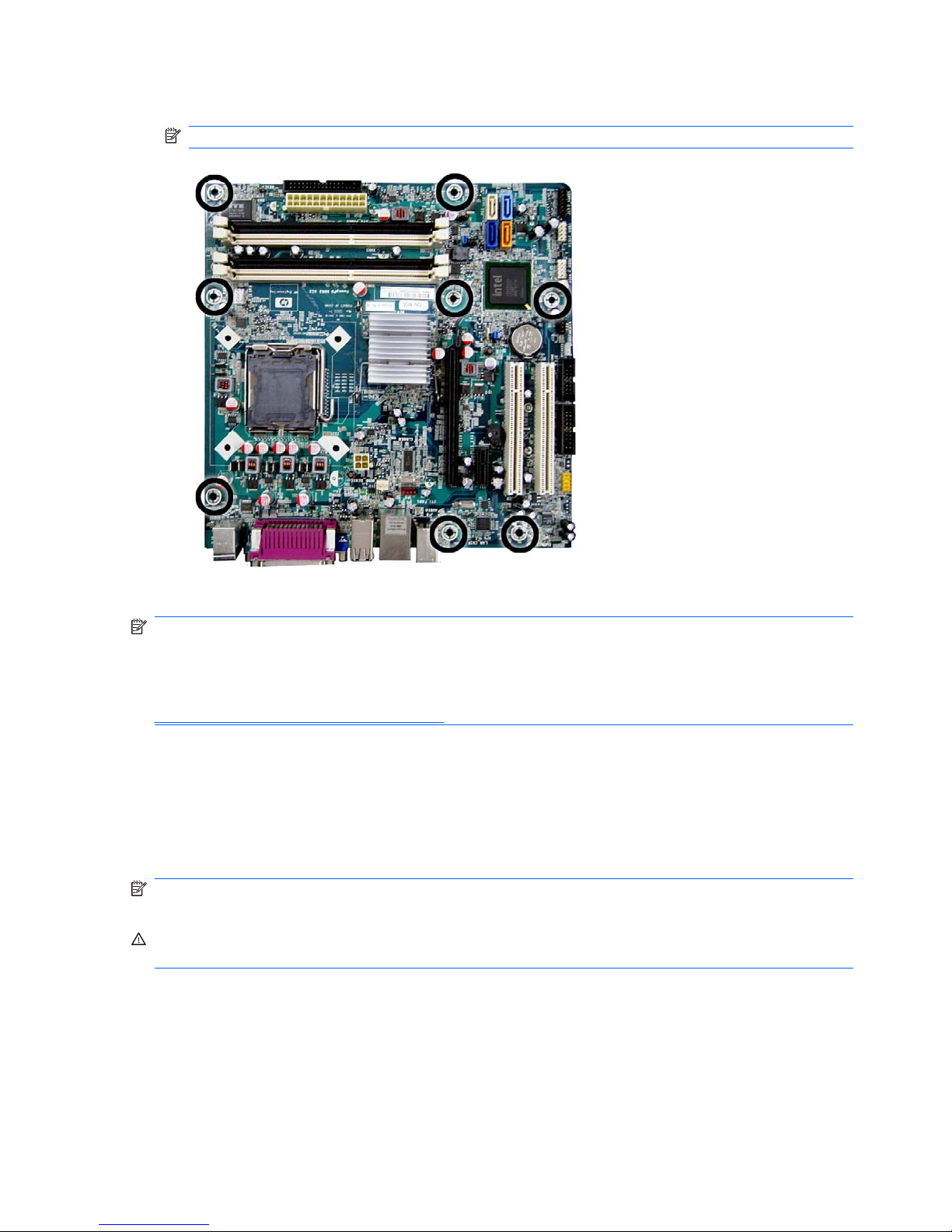

System Board ..................................................................................................................................... 67

Battery ................................................................................................................................................ 68

Type 1 Battery Holder ........................................................................................................ 69

Type 2 Battery Holder ........................................................................................................ 70

Type 3 Battery Holder ........................................................................................................ 71

Installing a Security Lock .................................................................................................................... 72

Cable Lock ......................................................................................................................... 72

Padlock .............................................................................................................................. 72

HP Business PC Security Lock .......................................................................................... 73

Hood Sensor ...................................................................................................................... 75

Port Cover .......................................................................................................................... 75

Appendix A Connector Pin Assignments

Keyboard ............................................................................................................................................ 76

Mouse ................................................................................................................................................. 76

Parallel Interface ................................................................................................................................ 77

Serial Interface, Powered and Non-Powered ..................................................................................... 77

USB .................................................................................................................................................... 78

Microphone ......................................................................................................................................... 78

Headphone ......................................................................................................................................... 78

Line-in Audio ...................................................................................................................................... 78

Line-out Audio .................................................................................................................................... 78

Monitor ............................................................................................................................................... 79

24-Pin Power ...................................................................................................................................... 79

vii

Page 8

PCI Express ...................................................................................................................................... 80

PCI Express ...................................................................................................................................... 81

4-Pin Power (for CPU) ........................................................................................................................ 82

Appendix B Power Cord Set Requirements

General Requirements ....................................................................................................................... 83

Japanese Power Cord Requirements ................................................................................................ 83

Country-Specific Requirements .......................................................................................................... 84

Appendix C Troubleshooting

Safety and Comfort ............................................................................................................................ 85

Before You Call for Technical Support ............................................................................................... 85

Helpful Hints ....................................................................................................................................... 86

Solving General Problems .................................................................................................................. 88

Solving Hardware Installation Problems ............................................................................................. 91

Interpreting POST Diagnostic Front Panel LEDs and Audible Codes ................................................ 92

Contacting Customer Support ............................................................................................................ 93

Appendix D Specifications

Index ................................................................................................................................................................... 96

viii

Page 9

1 Installing and Customizing the Software

NOTE: If the computer was shipped with Windows Vista loaded, you will be prompted to register the

computer with HP Total Care before installing the operating system. You will see a brief movie followed

by an online registration form. Fill out the form, click the Begin button, and follow the instructions on the

screen.

CAUTION: Do not add optional hardware or third-party devices to the computer until the operating

system is successfully installed. Doing so may cause errors and prevent the operating system from

installing properly.

Installing the Operating System

The first time you turn on the computer, the operating system is installed automatically. This process

takes about 5 to 10 minutes, depending on which operating system is being installed. Carefully read

and follow the instructions on the screen to complete the installation.

CAUTION: Once the automatic installation has begun, DO NOT TURN OFF THE COMPUTER UNTIL

THE PROCESS IS COMPLETE. Turning off the computer during the installation process may damage

the software that runs the computer or prevent its proper installation.

NOTE: If the computer shipped with more than one operating system language on the hard drive, the

installation process could take up to 60 minutes.

If your computer was not shipped with a Microsoft operating system, some portions of this documentation

do not apply. Additional information is available in online help after you install the operating system.

Installing or Upgrading Device Drivers

When installing optional hardware devices after the operating system installation is complete, you must

also install the drivers for each of the devices.

If prompted for the i386 directory, replace the path specification with C:\i386, or use the Browse button

in the dialog box to locate the i386 folder. This action points the operating system to the appropriate

drivers.

Obtain the latest support software, including support software for the operating system from

http://www.hp.com/support. Select your country and language, select Download drivers and software

(and firmware), enter the model number of the computer, and press Enter.

HP Backup and Recovery Manager

The HP Backup and Recovery Manager is an easy-to-use, versatile application that allows you to back

up and recover the primary hard drive on the PC. The application works within Windows to create

Installing the Operating System 1

Page 10

backups of Windows, all applications, and all data files. Backups can be scheduled to occur

automatically at designated intervals, or they can be initiated manually. Important files can be archived

separately from regular backups.

HP Backup and Recovery Manager is preinstalled on the C: drive and creates a Recovery Partition.

Recovery Points and file backups can be copied to CD or DVD discs, while all backups can be copied

to network or secondary hard disks.

HP highly recommends that you create a Recovery Disc Set immediately before using the computer

and schedule regular automatic Recovery Point backups.

To create the Recovery Disc Set:

1. Click Start > HP Backup and Recovery > HP Backup and Recovery Manager to open the

Backup and Recovery Wizard, then click Next.

2. Select Create a set of recovery discs (Recommended) and click Next.

3. Follow the instructions in the wizard.

For more information on using HP Backup and Recovery Manager, refer to the HP Backup and Recovery

Manager User Guide by selecting Start > HP Backup and Recovery > HP Backup and Recovery

Manager Manual.

NOTE: You can order a Recovery Disc Set from HP by calling the HP support center. Go to the

following Web site, select your region, and click the Technical support after you buy link under the

Call HP heading to obtain the support center telephone number for your region.

http://welcome.hp.com/country/us/en/wwcontact_us.html

2 Chapter 1 Installing and Customizing the Software

Page 11

2 Computer Setup (F10) Utility

Computer Setup (F10) Utilities

Use Computer Setup (F10) Utility to do the following:

●

Change factory default settings.

●

Set the system date and time.

●

Set, view, change, or verify the system configuration, including settings for processor, graphics,

memory, audio, storage, communications, and input devices.

●

Modify the boot order of bootable devices such as hard drives, diskette drives, optical drives, or

USB flash media devices.

●

Enable or disable Quick Power-On Self Test, which is faster than a full boot but does not run all of

the diagnostic tests run during a full boot.

●

Enter the Asset Tag or property identification number assigned by the company to this computer.

●

Establish a supervisor password that controls access to Computer Setup (F10) Utility and the

settings described in this section.

●

Secure integrated I/O functionality, including the serial, USB, or parallel ports, audio, or embedded

NIC, so that they cannot be used until they are unsecured.

●

Enable or disable removable media boot ability.

●

Enable or disable legacy diskette write ability (when supported by hardware).

Using Computer Setup (F10) Utilities

Computer Setup can be accessed only by turning the computer on or restarting the system. To access

the Computer Setup Utilities menu, complete the following steps:

1. Turn on or restart the computer.

2. As soon as the computer is turned on, press and hold theF10 key until you enter Computer Setup.

NOTE: If you do not press F10 at the appropriate time, you must restart the computer and press

and hold the F10 key again to access the utility.

3. The Computer Setup Utility screen is divided into menu headings and actions.

Computer Setup (F10) Utilities 3

Page 12

Eight menu headings appear on the Computer Setup Utility screen:

●

System Information

●

Standard CMOS Features

●

Advanced BIOS Features

●

Advanced Chipset Features

●

Integrated Peripherals

●

Power Management Setup

●

PnP/PCI Configurations

●

Hardware Monitor Setup

Five action choices are listed on the Computer Setup Utility screen:

●

Load Optimized Defaults

●

Set Supervisor Password

●

Set User Password

●

Save & Exit Setup

●

Exit Without Saving

Use the arrow keys to select the appropriate heading, then press Enter. Use the arrow (up and

down) keys to select the option you want, then press Enter. To return to the previous screen,

press Esc.

4. To apply and save changes, press F10 or select Save & Exit Setup on the Computer Setup Utility

screen and press Enter.

If you have made changes that you do not want applied, select Exit Without Saving and press

Enter.

CAUTION: Do NOT turn the computer power OFF while the ROM is saving the Computer Setup (F10)

changes because the CMOS could become corrupted. It is safe to turn off the computer only after exiting

the F10 Setup screen.

Table 2-1 Computer Setup (F10) Utility Main Menu

Heading Table

System Information Table 2-2 Computer Setup—System Information on page 5

Standard CMOS Features Table 2-3 Computer Setup—Standard CMOS Features

on page 6

Advanced BIOS Features Table 2-4 Computer Setup—Advanced BIOS Features

on page 7

Advanced Chipset Features Table 2-5 Computer Setup—Advanced Chipset Features

on page 8

Integrated Peripherals Table 2-6 Computer Setup—Integrated Peripherals

on page 9

4 Chapter 2 Computer Setup (F10) Utility

Page 13

Power Management Setup Table 2-7 Computer Setup—Power Management Setup

on page 10

PnP/PCI Configurations Computer Setup—PnP/PCI Configurations on page 10

Hardware Monitor Setup Table 2-9 Computer Setup—Hardware Monitor Setup

on page 11

(Action Choices) Table 2-10 Computer Setup—(Action Choices) on page 12

Computer Setup—System Information

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-2 Computer Setup—System Information

Option Description

System S/N (view only)

Product Name (view only)

Ownership Tag Enter ownership tag assigned by the owner.

BIOS Version (view only)

BIOS Release Date (view only)

System Chipset Type (view only)

Processor Type (view only)

Processor Speed (view only)

CPU ID (view only)

Cache Size (view only)

Memory DIMM1 (view only)

Memory DIMM2 (view only)

Memory DIMM3 (view only)

Memory DIMM4 (view only)

DDR3 Memory Size (view only)

UUID (view only)

Chassis Serial Number (view only)

Asset Tag Number Enter asset tag number assigned by the company.

Integrated MAC (view only)

Table 2-1 Computer Setup (F10) Utility Main Menu (continued)

Computer Setup (F10) Utilities 5

Page 14

Computer Setup—Standard CMOS Features

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-3 Computer Setup—Standard CMOS Features

Option Description

Date (mm:dd:yy) Allows you to set system date.

Time (hh:mm:ss) Allows you to set system time.

Floppy Drive A Allows you to set Drive A to None or 1.44M, 3.5 inch.

SATA Port 0

SATA Port 1

SATA Port 2

SATA Port 3

For each, allows you to:

●

detect HDD size and head on selected channel

●

set extended drive on selected channel to:

◦

None

◦

Auto

◦

Manual

●

set access mode on selected channel to:

◦

CHS

◦

LBA

◦

Large

◦

Auto

●

view:

◦

Capacity

◦

Cylinder

◦

Head

◦

Precomp

◦

Landing Zone

◦

Sector

●

SMART Support

◦

SMART Status Check

◦

SMART Short Self-Test

◦

SMART Extended Self-Test

SATA Mode Allows you to set the SATA mode to:

●

IDE

●

AHCI

6 Chapter 2 Computer Setup (F10) Utility

Page 15

Legacy Mode Support Disables/enables legacy mode support.

Halt On Allows you to set POST error behavior to:

●

All Errors

●

No Errors

●

All but Keyboard

●

All but Diskette

●

All but Diskette/Keyboard

Computer Setup—Advanced BIOS Features

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-4 Computer Setup—Advanced BIOS Features

Option Description

F11 Prompt Setting this feature to displayed will display the text F11 = Recovery during POST. Hiding this feature

prevents the text from being displayed. However, pressing F11 will still attempt to boot to the HP

Backup and Recovery partition.

Quick Power On Self

Test

Disables/enables the system to skip certain tests while booting.

Enabling this feature decreases the time required to boot the system.

POST Delay Time Allows you to set a POST delay time to:

●

None

●

5 Seconds

●

10 Seconds

●

15 Seconds

●

20 Seconds

Hard Disk Boot Priority Allows you to specify the order of attached hard drive devices (such as USB HDD storage, USB2

Drive Key, or USB flash media). The first drive in the order has priority in the boot sequence and is

recognized as drive C (if any devices are attached).

CD-ROM Boot Priority Allows you to specify the order in which attached optical drives (including USB ODD) are checked

for a bootable operating system image.

Network Boot Priority Allows you to specify the order in which network devices (including UP NIC cards) are checked for

a bootable operating system image.

Table 2-3 Computer Setup—Standard CMOS Features (continued)

Computer Setup (F10) Utilities 7

Page 16

First Boot Device

Second Boot Device

Third Boot Device

Fourth Boot Device

Allows you to specify which devices will boot first, second, third, and fourth or to disable any of the

four:

●

Removable

●

Hard Disk

●

CDROM

●

Network

●

Disabled

NOTE: MS-DOS drive lettering assignments may not apply after a non-MS-DOS operating system

has started.

Boot Other Device Disables/enables boot other device.

Load Boot Menu

Selectable

Disables/enables boot menu selectable.

APIC Mode Disables/enables the Advanced-PIC mode.

System Keyboard Allows you to set the system keyboard to Absent or Present.

Boot Up NumLock

Status

Allows you to set the default NumLock status to off or on.

Security Option Allows you to set the security option to Setup or System so that the password is required every time

the system boots or only when entering Computer Setup.

HDD S.M.A.R.T.

Capability

Disables/enables hard drive S.M.A.R.T. capability.

Computer Setup—Advanced Chipset Features

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-5 Computer Setup—Advanced Chipset Features

Option Description

On-Chip Frame Buffer

Size

(VGA Setting)

Select the On-Chip Frame Buffer Size to:

●

32MB

●

64MB

●

128MB

PEG/Onchip VGA

Control

Allows you to set VGA control to:

●

Onchip VGA

●

PEG port

●

Auto

DVMT Mode

(VGA Setting)

Disables/enables DVMT mode.

Table 2-4 Computer Setup—Advanced BIOS Features (continued)

8 Chapter 2 Computer Setup (F10) Utility

Page 17

DVMT/FIXED Memory

Size

(VGA Setting)

Allows you to set memory size to:

●

128MB

●

256MB

Init Display First

(VGA Setting)

Allows you to select the primary display device:

●

PCI Slot

●

Onboard

Computer Setup—Integrated Peripherals

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-6 Computer Setup—Integrated Peripherals

Option Description

USB Controller Disables/enables USB controller.

USB Legacy Support Disables/enables USB legacy support.

HD Audio Disables/enables HD audio controller.

Onboard LAN

Controller

Disables/enables onboard LAN controller.

Onboard LAN Boot

ROM

Disables/enables the boot ROM of the onboard LAN chip.

HP Network Clone

ROM

Disables/enables HP Network Clone ROM.

This option is available for Network Clone users only.

Onboard FDC

Controller

Disables/enables onboard FDC controller.

Serial Port 1 Allows you to select a setting for the onboard serial port:

●

Disabled

●

3F8/IRQ4

●

2F8/IRQ3

●

3E8/IRQ4

●

2E8/IRQ3

●

Auto

Parallel Port Allows you to select a setting for the onboard parallel port:

●

Disabled

●

378/IRQ7

●

278/IRQ5

●

3BC/IRQ7

Table 2-5 Computer Setup—Advanced Chipset Features (continued)

Computer Setup (F10) Utilities 9

Page 18

Parallel Port Mode Allows you to select parallel port mode:

●

SPP

●

EPP

●

ECP

●

ECP+EPP

ECP Mode Use DMA If Parallel Port Mode is set to ECP or ECP+EPP, allows you to set the DMA channel for ECP Mode

to 1 or 3.

Computer Setup—Power Management Setup

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-7 Computer Setup—Power Management Setup

Option Description

PCI-E Wake on PME Disables/enables PCI-E Wake on PME.

ACPI Function Disables/enables ACPI functions. Changing this item can make the existing OS unusable.

ACPI Suspend Type Allows you to set type of ACPI sleep mode:

●

S1 (Power On Suspend)

●

S3 (Suspend To RAM)

●

S1 & S3

Resume on PME Disables/enables Resume by PME.

Wake on Ring Disables/enables Resume by Ring.

Resume by Alarm Disables/enables RTC (real-time clock) alarm.

Date (of Month) Alarm If RTC Alarm Resume is enabled, allows you to select the day of the month for resumption of RTC

alarm. (Set to 0 for every day.)

Time (hh:mm:ss)

Alarm

If Resume on Alarm is enabled, allows you to select what time the RTC alarm will resume.

Restore on AC/Power

Loss

Allows you to select system power loss behavior:

●

Power On

●

Power Off

●

Last State

Computer Setup—PnP/PCI Configurations

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-8 Computer Setup—PnP/PCI Configurations

Option Description

Table 2-6 Computer Setup—Integrated Peripherals (continued)

10 Chapter 2 Computer Setup (F10) Utility

Page 19

Reset Configuration

Data

Disables/enables automatic reconfiguration.

The default is Disabled. Select Enabled to reset Extended System Configuration Data (ESCD) when

you exit Setup, if you have installed a new add-on and the system reconfiguration has caused such

a serious conflict that the OS cannot boot.

Resources ControlledByAllows you to select whether resources are controlled automatically or manually:

●

Auto (ESCD–Extended Storage Configuration Data)

●

Manual

BIOS can automatically configure all the bootable and Plug-and-Play-compatible devices. If you

choose Auto, you cannot select IRQ, DMA and memory base address fields since BIOS

automatically assigns them.

IRQ Resources

●

IRQ-3 assigned to

●

IRQ-4 assigned to

●

IRQ-5 assigned to

●

IRQ-7 assigned to

●

IRQ-9 assigned to

●

IRQ-10 assigned to

●

IRQ-11 assigned to

●

IRQ-12 assigned to

●

IRQ-14 assigned to

●

IRQ-15 assigned to

When resources are controlled manually, allows you to assign each system interrupt a type,

depending on the type of device using the interrupt.

Legacy ISA for devices compliant with the original PC AT bus specification, PCI/ISA PnP for devices

compliant with the Plug-and-Play standard whether designed for PCI or ISA bus architecture.

Computer Setup—Hardware Monitor Setup

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-9 Computer Setup—Hardware Monitor Setup

Option Description

Reset Case Open

Status

Disables/enables resetting of the case open status.

Fan Controller Disables/enables auto fan control mode.

CPU Fan Speed (view only)

System Fan Speed (view only)

CPU Fan Fault Detect Disables/enables detection of CPU failure during POST.

SYS Fan Fault Detect Disables/enables detection of fan failure during POST.

Table 2-8 Computer Setup—PnP/PCI Configurations (continued)

Computer Setup (F10) Utilities 11

Page 20

Computer Setup—(Action Choices)

NOTE: Support for specific Computer Setup options may vary depending on the hardware

configuration.

Table 2-10 Computer Setup—(Action Choices)

Option Description

Load Optimized

Defaults

Allows you to reset Computer Setup to factory defaults.

Set Supervisor

Password

Allows you to establish a password to control access to Computer Setup.

Set User Password Allows you to establish a password to control access to the computer. (Supervisor password must

be set before you can set a User password.)

Save & Exit Setup Allows you to save current settings and exit Computer Setup.

Exit Without Saving Allows you to exit Computer Setup without saving changes.

12 Chapter 2 Computer Setup (F10) Utility

Page 21

Recovering the Configuration Settings

Recovering the configuration settings established in the Computer Setup (F10) Utility requires that you

first back up the settings before a recovery is needed.

The CMOS Save/Load utility can be found at

http://www.hp.com under the Software & Driver Downloads

for your specific model. Download the firmware files into a folder on a removable storage device. It is

recommended that you save any modified computer configuration settings to a diskette, a USB flash

media device, or a diskette-like device (a storage device set to emulate a diskette drive) and save the

diskette or device for possible future use.

Backing Up the CMOS

1. Make sure the computer to be backed up is turned on. Connect the removable storage to the

computer.

2. Boot to DOS.

3. Type N:\folder\BIOS.exe SAVE:ABC001.DAT (where N is the drive letter of the removable

storage) to save the CMOS setting to the removable storage device.

Restoring the CMOS

1. Make sure the target computer is turned on. Connect the removable storage to the target computer.

2. Boot to DOS.

3. Type N:\folder\BIOS.exe LOAD:ABC001.DAT (where N is the drive letter of the removable

storage) to load the custom CMOS setting onto the target system.

Recovering the Configuration Settings 13

Page 22

3 Computer Diagnostic Features

HP Insight Diagnostics

NOTE: HP Insight Diagnostics is included on CD with some computer models only.

The HP Insight Diagnostics utility allows you to view information about the hardware configuration of

the computer and perform hardware diagnostic tests on the subsystems of the computer. The utility

simplifies the process of effectively identifying, diagnosing, and isolating hardware issues.

The Survey tab is displayed when you invoke HP Insight Diagnostics. This tab shows the current

configuration of the computer. From the Survey tab, there is access to several categories of information

about the computer. Other tabs provide additional information, including diagnostic test options and test

results. The information in each screen of the utility can be saved as an html file and stored on a diskette

or USB flash drive.

Use HP Insight Diagnostics to determine if all the devices installed on the computer are recognized by

the system and functioning properly. Running tests is optional but recommended after installing or

connecting a new device.

You should run tests, save the test results, and print them so that you have printed reports available

before placing a call to the Customer Support Center.

NOTE: Third party devices may not be detected by HP Insight Diagnostics.

Accessing HP Insight Diagnostics

You must boot to the Documentation and Diagnostics DVD, as described in the steps below, to access

HP Insight Diagnostics.

1. While the computer is on, insert the Documentation and Diagnostics DVD into an optical drive on

the computer.

2. Shut down the operating system and turn off the computer.

3. Turn on the computer. The system will boot to the DVD.

NOTE: If the system does not boot to the DVD in the optical drive, you may need to change the

boot order in the Computer Setup (F10) utility so that the system attempts to boot to the optical

drive before booting to the hard drive. Refer to the Computer Setup (F10) Utility Guide on the

Documentation and Diagnostics DVD for more information.

You can also change the boot order so that the system boots to the optical drive on a one-time

basis by pressing the Esc key at startup.

4. Select the appropriate language and click Continue.

14 Chapter 3 Computer Diagnostic Features

Page 23

NOTE: It is recommended that you accept the assigned default keyboard for your language

unless you want to test your specific keyboard.

5. In the End User License Agreement page, click Agree if you agree with the terms. The HP Insight

Diagnostics utility launches with the Survey tab displayed.

Survey Tab

The Survey tab displays important system configuration information.

In the View level field, you can select the Summary view to see limited configuration data or select

the Advanced view to see all the data in the selected category.

In the Category field, you can select the following categories of information to display:

All—Gives a listing of all categories of information about the computer.

Overview—Gives you a listing of general information about the computer.

Architecture—Provides system BIOS and PCI device information.

Asset Control—Shows product name, asset tag, system serial number, and processor information.

Communication—Shows information about the computer parallel (LPT) and serial (COM) port settings,

plus USB and network controller information.

Graphics—Shows information about the graphics controller of the computer.

Input Devices—Shows information about the keyboard, mouse, and other input devices connected to

the computer.

Memory—Shows information about all memory in the computer. This includes memory slots on the

system board and any memory modules installed.

Miscellaneous—Shows HP Insight Diagnostics version information, computer configuration memory

(CMOS) information, system board data, and system management BIOS data.

Storage—Shows information about storage media connected to the computer. This list includes all fixed

disks, diskette drives, and optical drives.

System—Shows information about the computer model, processor, chassis, and BIOS, plus internal

speaker and PCI bus information.

Diagnose Tab

NOTE: The Diagnose tab is only available in HP Insight Diagnostics Online Edition.

The Diagnosis feature of the HP Insight Diagnostics Online Edition enables high system availability by

performing various non-intrusive, in-depth system and component checks while the operating system

is up and running.

There are two types of diagnosis on the Diagnose tab: Smart Array Drive Diagnosis and Power

Supply Diagnosis.

The Power Supply Diagnosis allows you to assess the health of select power supply models.

Smart Array Drive Diagnosis is the premier feature of hardware diagnosis and it provides the ability to

assess the health of hard disk drives attached to Smart Array controllers and select Modular Smart Array

(MSA) products. The Smart Array Drive Diagnosis supports SCSI, serial Advanced Technology

HP Insight Diagnostics 15

Page 24

Attachment (SATA), and serial attached SCSI (SAS) disk drives that are attached to Smart Array

controllers and select MSA controllers configured as part of a logical volume. To determine the health

of a hard disk drive, Diagnosis looks at operational history provided by the hard disk drive and proprietary

information provided by the Smart Array controller or the MSA controller. HP has found through

experience that looking at operational history is one of the best ways to diagnose disk drive problems.

Systems Insight Manager (SIM) and Diagnosis are now the only tools that can be used to qualify the

replacement of defective disk drives under pre-failure warranty.

The Smart Array Drive Diagnosis feature should be used:

●

To determine if a disk drive in a fault mode should be replaced.

●

When Systems Insight Manager reports that a disk drive has failed.

●

When there is data corruption or storage related problems but there are no error LEDs or error

messages.

●

When there are inconsistent, intermittent, or repeated disk drive failures.

●

To determine the health of a logical volume.

NOTE: Smart Array Drive Diagnosis has the unique capability of identifying multiple disk drives in a

single volume that are functioning normally, but should be replaced.

To diagnose a logical volume:

1. Click the Diagnose tab.

2. Under Smart Array Drive Diagnosis, click + to expand Storage.

3. Select the logical volumes to diagnose and click the Diagnose button.

4. The test status of the logical volumes selected will be displayed on the Status tab when Diagnosis

has completed.

Test Tab

The Test tab allows you to choose various parts of the system to test. You can also choose the type of

test and testing mode.

There are three types of tests to choose from:

●

Quick Test—Provides a predetermined script where a sample of each hardware component is

exercised and requires no user intervention in either Unattended or Interactive mode.

●

Complete Test—Provides a predetermined script where each hardware component is fully tested.

There are more tests available in the Interactive mode, but these require user intervention.

●

Custom Test—Provides the most flexibility in controlling the testing of a system. The Custom Test

mode allows you to specifically select which devices, tests, and test parameters are run.

16 Chapter 3 Computer Diagnostic Features

Page 25

For each test type, there are two test modes to choose from:

●

Interactive Mode—Provides maximum control over the testing process. The diagnostic software

will prompt you for input during tests that require your interaction. You may also determine whether

the test passed or failed.

●

Unattended Mode—Does not display prompts and requires no interaction. If errors are found, they

are displayed when testing is complete.

To begin testing:

1. Select the Test tab.

2. Select the tab for the type of test you want to run: Quick, Complete, or Custom.

3. Select the Test Mode: Interactive or Unattended.

4. Choose how you want the test to be executed, either Number of Loops or Total Test Time. When

choosing to run the test over a specified number of loops, enter the number of loops to perform. If

you desire to have the diagnostic test for a specified time period, enter the amount of time in

minutes.

5. If performing a Quick Test or Complete Test, select the device to be tested from the drop-down

list. If performing a Custom Test, Click the Expand button and select the devices to be tested or

click the Check All button to select all devices.

6. Click the Begin Testing button at the bottom right corner of the screen to start the test. The Status

tab, which allows you to monitor the progress of the test, is automatically displayed during the

testing process. When the test is complete, the Status tab shows whether the device passed or

failed.

7. If errors are found, go to the Log tab and click the Error Log to display more detailed information

and recommended actions.

Status Tab

The Status tab displays the status of the selected tests. The type of test executed (Quick, Complete,

or Custom) is also displayed. The main progress bar displays the percent complete of the current set

of tests. While testing is in progress, a Cancel Testing button is displayed for use if you want to cancel

the test.

After testing has completed, the Cancel Testing button is replaced with a Retest button. The Retest

button will retest the last set of tests executed. This enables you to re-run the set of tests without having

to re-enter the data in the Test tab.

The Status tab also shows:

●

The devices being tested

●

The test status (running, passed, or failed) of each device being tested

●

The overall test progress of all devices being tested

●

The test progress for each device being tested

●

The elapsed test times for each device being tested

HP Insight Diagnostics 17

Page 26

Log Tab

The Log tab contains a Test Log tab and an Error Log tab.

The Test Log displays all tests that have been executed, the number of times of execution, the number

of times failed, and the time it took to complete each test. The Clear Test Log button will clear the

contents of the Test Log.

The Error Log displays the tests for devices that have failed during the diagnostic testing and includes

the following columns of information.

●

The Device section displays the device tested.

●

The Test section displays the type of test run.

●

The Description section describes the error that the diagnostic test found.

●

The Recommended Repair will give a recommended action that should be performed to resolve

the failed hardware.

●

The Failed Count is the number of times the device has failed a test.

●

The Error Code provides a numerical code for the failure. The error codes are defined in the Help

tab.

The Clear Error Log button will clear the contents of the Error Log.

Help Tab

On the Help tab contains an HP Insight Diagnostics tab, an Error Codes tab, and a Test

Components tab.

The HP Insight Diagnostics tab contains help topics and includes search and index features.

The Error Codes tab provides a description of each numerical error code that may appear in the Error

Log tab located on the Log tab. Each code has a corresponding error Message and a Recommended

Repair action that should help solve the problem. To find an error code description quickly, enter the

code in the box at the top of the tab and click the Find Error Codes button.

The Test Components tab displays low-level information on tests that are run.

Saving and Printing Information in HP Insight Diagnostics

You can save the information displayed in the HP Insight Diagnostics Survey and Log tabs to a USB

2.0 flash drive (64MB or higher). You can not save to the hard drive. The system will automatically create

an html file that has the same appearance as the information displayed on the screen.

1. Insert a USB 2.0 flash drive (capacity must be 64MB or higher). USB 1.0 flash drives are not

supported.

2. Click Save in the bottom right corner of the screen.

3. Select Save to the floppy or Save to USB key.

4. Enter a file name in the File Name box and click the Save button. An html file will be saved to the

inserted USB flash drive.

18 Chapter 3 Computer Diagnostic Features

Page 27

NOTE: Do not remove the USB key until you see a message indicating that the html file has been

written to the media.

5. Print the information from the storage device used to save it.

NOTE: To exit HP Insight Diagnostics, click the Exit Diagnostics button in the bottom left corner of

the screen then remove the Documentation and Diagnostics DVD from the optical drive.

Downloading the Latest Version of HP Insight Diagnostics

1. Go to http://www.hp.com.

2. Click the Software & Driver Downloads link.

3. Enter your product number (for example, dx2810) in the text box and press the Enter key.

4. Select your specific computer model.

5. Select your OS.

6. Click the Diagnostic link.

7. Click HP Insight Diagnostics Offline Edition.

8. Select a language and click Download.

NOTE: The download includes instructions on how to create the bootable CD.

Protecting the Software

To protect software from loss or damage, you should keep a backup copy of all system software,

applications, and related files stored on the hard drive. See the operating system or backup utility

documentation for instructions on making backup copies of data files.

Protecting the Software 19

Page 28

HP Backup and Recovery Manager

The HP Backup and Recovery Manager is an easy-to-use, versatile application that allows you to back

up and recover the primary hard drive on the PC. The application works within Windows to create

backups of Windows, all applications, and all data files. Backups can be scheduled to occur

automatically at designated intervals, or they can be initiated manually. Important files can be archived

separately from regular backups.

HP Backup and Recovery Manager is preinstalled on the C: drive and creates a Recovery Partition.

Recovery Points and file backups can be copied to CD or DVD discs, while all backups can be copied

to network or secondary hard disks.

HP highly recommends that you create a Recovery Disc Set immediately before using the computer

and schedule regular automatic Recovery Point backups.

To create the Recovery Disc Set:

1. Click Start > HP Backup and Recovery > HP Backup and Recovery Manager to open the

Backup and Recovery Wizard, then click Next.

2. Select Create a set of recovery discs (Recommended) and click Next.

3. Follow the instructions in the wizard.

For more information on using HP Backup and Recovery Manager, refer to the HP Backup and Recovery

Manager User Guide by selecting Start > HP Backup and Recovery > HP Backup and Recovery

Manager Manual.

NOTE: You can order a Recovery Disc Set from HP by calling the HP support center. Go to the

following Web site, select your region, and click the Technical support after you buy link under the

Call HP heading to obtain the support center telephone number for your region.

http://welcome.hp.com/country/us/en/wwcontact_us.html

20 Chapter 3 Computer Diagnostic Features

Page 29

4 Serial ATA (SATA) Drive Guidelines and

Features

NOTE: HP only supports the use of SATA hard drives on these models of computer. No Parallel ATA

(PATA) drives are supported.

SATA Hard Drives

Serial ATA Hard Drive Characteristics

Number of pins/conductors in data cable 7/7

Number of pins in power cable 15

Maximum data cable length 39.37 in (100 cm)

Data interface voltage differential 400-700 mV

Drive voltages 3.3 V, 5 V, 12 V

Jumpers for configuring drive N/A

Data transfer rate 3.0 Gb/s

SATA Hard Drive Cables

SATA Data Cable

Always use an HP approved SATA 3.0 Gb/s cable as it is fully backwards compatible with the SATA 1.5

Gb/s drives.

Current HP desktop products ship with SATA 3.0 Gb/s hard drives.

SATA data cables are susceptible to damage if overflexed. Never crease a SATA data cable and never

bend it tighter than a 30 mm (1.18 in) radius.

The SATA data cable is a thin, 7-pin cable designed to transmit data for only a single drive.

SATA Hard Drives 21

Page 30

SMART ATA Drives

The Self Monitoring Analysis and Recording Technology (SMART) ATA drives for the HP Personal

Computers have built-in drive failure prediction that warns the user or network administrator of an

impending failure or crash of the hard drive. The SMART drive tracks fault prediction and failure

indication parameters such as reallocated sector count, spin retry count, and calibration retry count. If

the drive determines that a failure is imminent, it generates a fault alert.

Hard Drive Capacities

The combination of the file system and the operating system used in the computer determines the

maximum usable size of a drive partition. A drive partition is the largest segment of a drive that may be

properly accessed by the operating system. A single hard drive may therefore be subdivided into a

number of unique drive partitions in order to make use of all of its space.

Because of the differences in the way that drive sizes are calculated, the size reported by the operating

system may differ from that marked on the hard drive or listed in the computer specification. Drive size

calculations by drive manufacturers are bytes to the base 10 while calculations by Microsoft are bytes

to the base 2.

Drive/Partition Capacity Limits

Maximum Size

File System Controller Type Operating System Partition Drive

FAT 32 ATA Windows 2000/XP/Vista 32 GB 2 TB

NTFS ATA Windows 2000/XP/Vista 2 TB 2 TB

22 Chapter 4 Serial ATA (SATA) Drive Guidelines and Features

Page 31

5 Identifying the Chassis, Routine Care,

and Disassembly Preparation

This chapter provides general service information for the computer. Adherence to the procedures and

precautions described in this chapter is essential for proper service.

CAUTION: When the computer is plugged into an AC power source, voltage is always applied to the

system board. You must disconnect the power cord from the power source before opening the computer

to prevent system board or component damage.

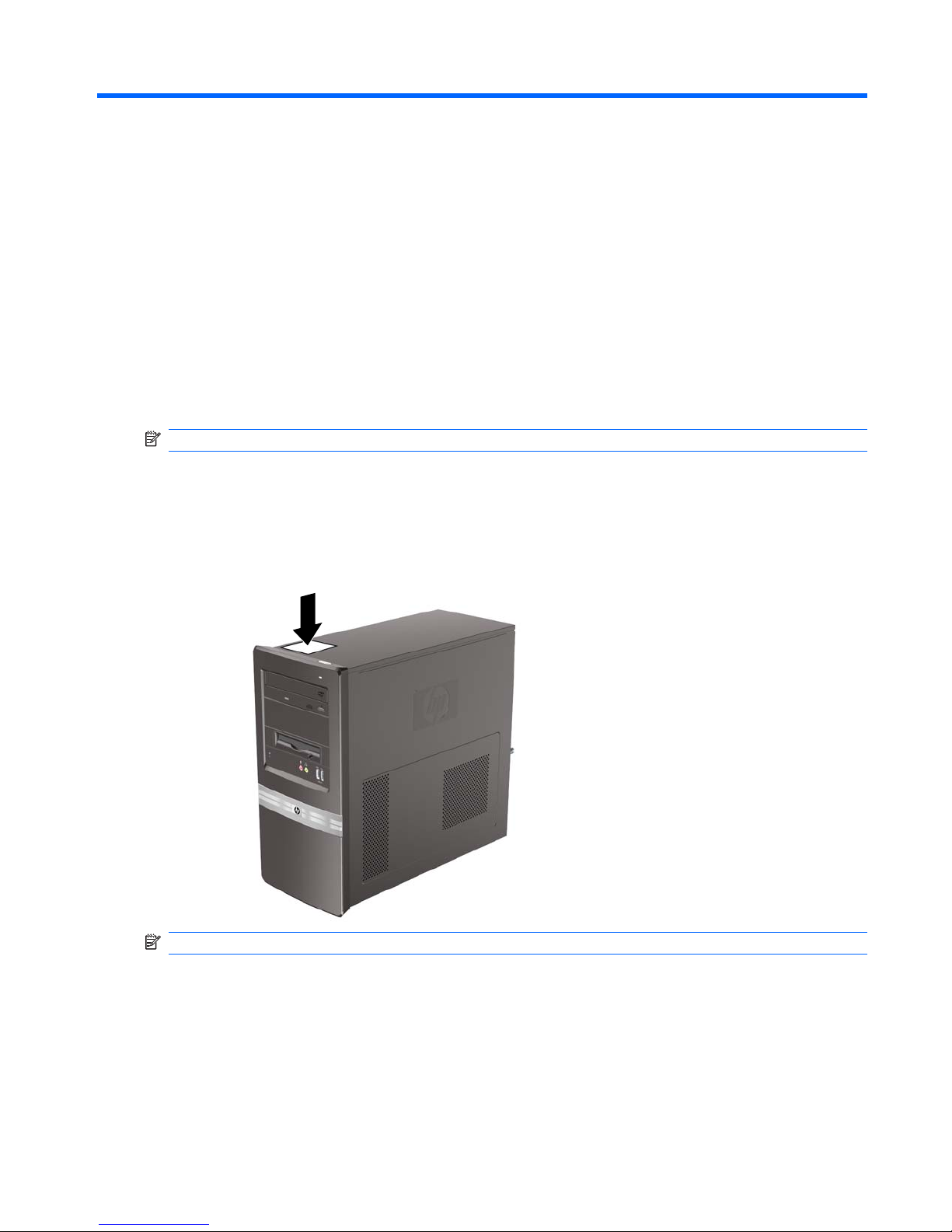

Chassis Designations

The following subsection illustrates the dx7500 chassis design.

Microtower (MT)

Figure 5-1 HP Compaq dx7510 Microtower

Chassis Designations 23

Page 32

Figure 5-2 HP Compaq dx7518 Microtower

NOTE: The appearance of the front bezel may vary.

Electrostatic Discharge Information

A sudden discharge of static electricity from your finger or other conductor can destroy static-sensitive

devices or microcircuitry. Often the spark is neither felt nor heard, but damage occurs. An electronic

device exposed to electrostatic discharge (ESD) may not appear to be affected at all and can work

perfectly throughout a normal cycle. The device may function normally for a while, but it has been

degraded in the internal layers, reducing its life expectancy.

Networks built into many integrated circuits provide some protection, but in many cases, the discharge

contains enough power to alter device parameters or melt silicon junctions.

Generating Static

The following table shows that:

●

Different activities generate different amounts of static electricity.

●

Static electricity increases as humidity decreases.

Relative Humidity

Event

55% 40% 10%

Walking across carpet

Walking across vinyl floor

Motions of bench worker

Removing DIPs* from plastic tube

7,500 V

3,000 V

400 V

400 V

15,000 V

5,000 V

800 V

700 V

35,000 V

12,000 V

6,000 V

2,000 V

24 Chapter 5 Identifying the Chassis, Routine Care, and Disassembly Preparation

Page 33

Removing DIPs* from vinyl tray

Removing DIPs* from Styrofoam

Removing bubble pack from PCB

Packing PCBs in foam-lined box

2,000 V

3,500 V

7,000 V

5,000 V

4,000 V

5,000 V

20,000 V

11,000 V

11,500 V

14,500 V

26,500 V

21,000 V

*These are then multi-packaged inside plastic tubes, trays, or Styrofoam.

NOTE: 700 volts can degrade a product.

Preventing Electrostatic Damage to Equipment

Many electronic components are sensitive to ESD. Circuitry design and structure determine the degree

of sensitivity. The following packaging and grounding precautions are necessary to prevent damage to

electric components and accessories.

●

To avoid hand contact, transport products in static-safe containers such as tubes, bags, or boxes.

●

Protect all electrostatic parts and assemblies with conductive or approved containers or packaging.

●

Keep electrostatic sensitive parts in their containers until they arrive at static-free stations.

●

Place items on a grounded surface before removing them from their container.

●

Always be properly grounded when touching a sensitive component or assembly.

●

Avoid contact with pins, leads, or circuitry.

●

Place reusable electrostatic-sensitive parts from assemblies in protective packaging or conductive

foam.

Personal Grounding Methods and Equipment

Use the following equipment to prevent static electricity damage to equipment:

●

Wrist straps are flexible straps with a maximum of one-megohm ± 10% resistance in the ground

cords. To provide proper ground, a strap must be worn snug against bare skin. The ground cord

must be connected and fit snugly into the banana plug connector on the grounding mat or

workstation.

●

Heel straps/Toe straps/Boot straps can be used at standing workstations and are compatible

with most types of shoes or boots. On conductive floors or dissipative floor mats, use them on both

feet with a maximum of one-megohm ± 10% resistance between the operator and ground.

Static Shielding Protection Levels

Method

Voltage

Antistatic plastic

Carbon-loaded plastic

Metallized laminate

1,500

7,500

15,000

Electrostatic Discharge Information 25

Page 34

Grounding the Work Area

To prevent static damage at the work area, use the following precautions:

●

Cover the work surface with approved static-dissipative material. Provide a wrist strap connected

to the work surface and properly grounded tools and equipment.

●

Use static-dissipative mats, foot straps, or air ionizers to give added protection.

●

Handle electrostatic sensitive components, parts, and assemblies by the case or PCB laminate.

Handle them only at static-free work areas.

●

Turn off power and input signals before inserting and removing connectors or test equipment.

●

Use fixtures made of static-safe materials when fixtures must directly contact dissipative surfaces.

●

Keep work area free of nonconductive materials such as ordinary plastic assembly aids and

Styrofoam.

●

Use field service tools, such as cutters, screwdrivers, and vacuums, that are conductive.

Recommended Materials and Equipment

Materials and equipment that are recommended for use in preventing static electricity include:

●

Antistatic tape

●

Antistatic smocks, aprons, or sleeve protectors

●

Conductive bins and other assembly or soldering aids

●

Conductive foam

●

Conductive tabletop workstations with ground cord of one-megohm +/- 10% resistance

●

Static-dissipative table or floor mats with hard tie to ground

●

Field service kits

●

Static awareness labels

●

Wrist straps and footwear straps providing one-megohm +/- 10% resistance

●

Material handling packages

●

Conductive plastic bags

●

Conductive plastic tubes

●

Conductive tote boxes

●

Opaque shielding bags

●

Transparent metallized shielding bags

●

Transparent shielding tubes

26 Chapter 5 Identifying the Chassis, Routine Care, and Disassembly Preparation

Page 35

Operating Guidelines

To prevent overheating and to help prolong the life of the computer:

●

Keep the computer away from excessive moisture, direct sunlight, and extremes of heat and cold.

●

Operate the computer on a sturdy, level surface. Leave a 10.2-cm (4-inch) clearance on all vented

sides of the computer and above the monitor to permit the required airflow.

●

Never restrict the airflow into the computer by blocking any vents or air intakes. Do not place the

keyboard, with the keyboard feet down, directly against the front of the desktop unit as this also

restricts airflow.

●

Occasionally clean the air vents on all vented sides of the computer. Lint, dust, and other foreign

matter can block the vents and limit the airflow. Be sure to unplug the computer before cleaning

the air vents.

●

Never operate the computer with the cover or side panel removed.

●

Do not stack computers on top of each other or place computers so near each other that they are

subject to each other’s re-circulated or preheated air.

●

If the computer is to be operated within a separate enclosure, intake and exhaust ventilation must

be provided on the enclosure, and the same operating guidelines listed above will still apply.

●

Keep liquids away from the computer and keyboard.

●

Never cover the ventilation slots on the monitor with any type of material.

●

Install or enable power management functions of the operating system or other software, including

sleep states.

Routine Care

General Cleaning Safety Precautions

1. Never use solvents or flammable solutions to clean the computer.

2. Never immerse any parts in water or cleaning solutions; apply any liquids to a clean cloth and then

use the cloth on the component.

3. Always unplug the computer when cleaning with liquids or damp cloths.

4. Always unplug the computer before cleaning the keyboard, mouse, or air vents.

5. Disconnect the keyboard before cleaning it.

6. Wear safety glasses equipped with side shields when cleaning the keyboard.

Cleaning the Computer Case

Follow all safety precautions in General Cleaning Safety Precautions on page 27 before cleaning the

computer.

Operating Guidelines 27

Page 36

To clean the computer case, follow the procedures described below:

●

To remove light stains or dirt, use plain water with a clean, lint-free cloth or swab.

●

For stronger stains, use a mild dishwashing liquid diluted with water. Rinse well by wiping it with a

cloth or swab dampened with clear water.

●

For stubborn stains, use isopropyl (rubbing) alcohol. No rinsing is needed as the alcohol will

evaporate quickly and not leave a residue.

●

After cleaning, always wipe the unit with a clean, lint-free cloth.

●

Occasionally clean the air vents on the computer. Lint and other foreign matter can block the vents

and limit the airflow.

Cleaning the Keyboard

Follow all safety precautions in General Cleaning Safety Precautions on page 27 before cleaning the

keyboard.

To clean the tops of the keys or the keyboard body, follow the procedures described in

Cleaning the

Computer Case on page 27.

When cleaning debris from under the keys, review all rules in

General Cleaning Safety Precautions

on page 27 before following these procedures:

CAUTION: Use safety glasses equipped with side shields before attempting to clean debris from under

the keys.

●

Visible debris underneath or between the keys may be removed by vacuuming or shaking.

●

Canned, pressurized air may be used to clean debris from under the keys. Caution should be used

as too much air pressure can dislodge lubricants applied under the wide keys.

●

If you remove a key, use a specially designed key puller to prevent damage to the keys. This tool

is available through many electronic supply outlets.

CAUTION: Never remove a wide leveled key (like the space bar) from the keyboard. If these keys

are improperly removed or installed, the keyboard may not function properly.

●

Cleaning under a key may be done with a swab moistened with isopropyl alcohol and squeezed

out. Be careful not to wipe away lubricants necessary for proper key functions. Use tweezers to

remove any fibers or dirt in confined areas. Allow the parts to air dry before reassembly.

Cleaning the Monitor

●

Wipe the monitor screen with a clean cloth moistened with water or with a towelette designed for

cleaning monitors. Do not use sprays or aerosols directly on the screen; the liquid may seep into

the housing and damage a component. Never use solvents or flammable liquids on the monitor.

●

To clean the monitor body follow the procedures in

Cleaning the Computer Case on page 27.

28 Chapter 5 Identifying the Chassis, Routine Care, and Disassembly Preparation

Page 37

Cleaning the Mouse

Before cleaning the mouse, ensure that the power to the computer is turned off.

●

Clean the mouse ball by first removing the retaining plate and the ball from the housing. Pull out

any debris from the ball socket and wipe the ball with a clean, dry cloth before reassembly.

●

To clean the mouse body, follow the procedures in

Cleaning the Computer Case on page 27.

Service Considerations

Listed below are some of the considerations that you should keep in mind during the disassembly and

assembly of the computer.

Power Supply Fan

The power supply fan is a variable-speed fan based on the temperature in the power supply.

CAUTION: The cooling fan is always on when the computer is in the “On” mode. The cooling fan is

off when the computer is in “Standby,” “Suspend,” or “Off” modes.

You must disconnect the power cord from the power source before opening the computer to prevent

system board or component damage.

Tools and Software Requirements

To service the computer, you need the following:

●

Torx T-15 screwdriver (HP screwdriver with bits, PN 161946-001)

●

Torx T-15 screwdriver with small diameter shank (for certain front bezel removal)

●

Flat-bladed screwdriver (may sometimes be used in place of the Torx screwdriver)

●

Phillips #2 screwdriver

●

Diagnostics software

●

HP tamper-resistant T-15 wrench (Smart Cover FailSafe Key, PN 166527-001) or HP tamperresistant bits (Smart Cover FailSafe Key, PN 166527-002)

Screws

The screws used in the computer are not interchangeable. They may have standard or metric threads

and may be of different lengths. If an incorrect screw is used during the reassembly process, it can

damage the unit. HP strongly recommends that all screws removed during disassembly be kept with

the part that was removed, then returned to their proper locations.

CAUTION: Metric screws have a black finish. U.S. screws have a silver finish and are used on hard

drives only.

CAUTION: As each subassembly is removed from the computer, it should be placed away from the

work area to prevent damage.

Service Considerations 29

Page 38

Cables and Connectors

Most cables used throughout the unit are flat, flexible cables. These cables must be handled with care

to avoid damage. Apply only the tension required to seat or unseat the cables during insertion or removal

from the connector. Handle cables by the connector whenever possible. In all cases, avoid bending or

twisting the cables, and ensure that the cables are routed in such a way that they cannot be caught or

snagged by parts being removed or replaced.

CAUTION: When servicing this computer, ensure that cables are placed in their proper location during

the reassembly process. Improper cable placement can damage the computer.

Hard Drives

Handle hard drives as delicate, precision components, avoiding all physical shock and vibration. This

applies to failed drives as well as replacement spares.

●

If a drive must be mailed, place the drive in a bubble-pack mailer or other suitable protective

packaging and label the package “Fragile: Handle With Care.”

●

Do not remove hard drives from the shipping package for storage. Keep hard drives in their

protective packaging until they are actually mounted in the CPU.

●

Avoid dropping drives from any height onto any surface.

●

If you are inserting or removing a hard drive, turn off the computer. Do not remove a hard drive

while the computer is on or in standby mode.

●

Before handling a drive, ensure that you are discharged of static electricity. While handling a drive,

avoid touching the connector. For more information about preventing electrostatic damage, refer

to

Electrostatic Discharge Information on page 24

●

Do not use excessive force when inserting a drive.

●

Avoid exposing a hard drive to liquids, temperature extremes, or products that have magnetic fields

such as monitors or speakers.

Lithium Coin Cell Battery

The battery that comes with the computer provides power to the real-time clock and has a minimum

lifetime of about three years.

See the appropriate removal and replacement chapter for the chassis you are working on in this guide

for instructions on the replacement procedures.

WARNING! This computer contains a lithium battery. There is a risk of fire and chemical burn if the

battery is handled improperly. Do not disassemble, crush, puncture, short external contacts, dispose in

water or fire, or expose it to temperatures higher than 140ºF (60ºC). Do not attempt to recharge the

battery.

NOTE: Batteries, battery packs, and accumulators should not be disposed of together with the general

household waste. In order to forward them to recycling or proper disposal, please use the public

collection system or return them to HP, their authorized partners, or their agents.

30 Chapter 5 Identifying the Chassis, Routine Care, and Disassembly Preparation

Page 39

6 Removal and Replacement Procedures

Microtower (MT) Chassis

Adherence to the procedures and precautions described in this chapter is essential for proper service.

After completing all necessary removal and replacement procedures, run the Diagnostics utility to verify

that all components operate properly.

NOTE: Not all features listed in this guide are available on all computers.

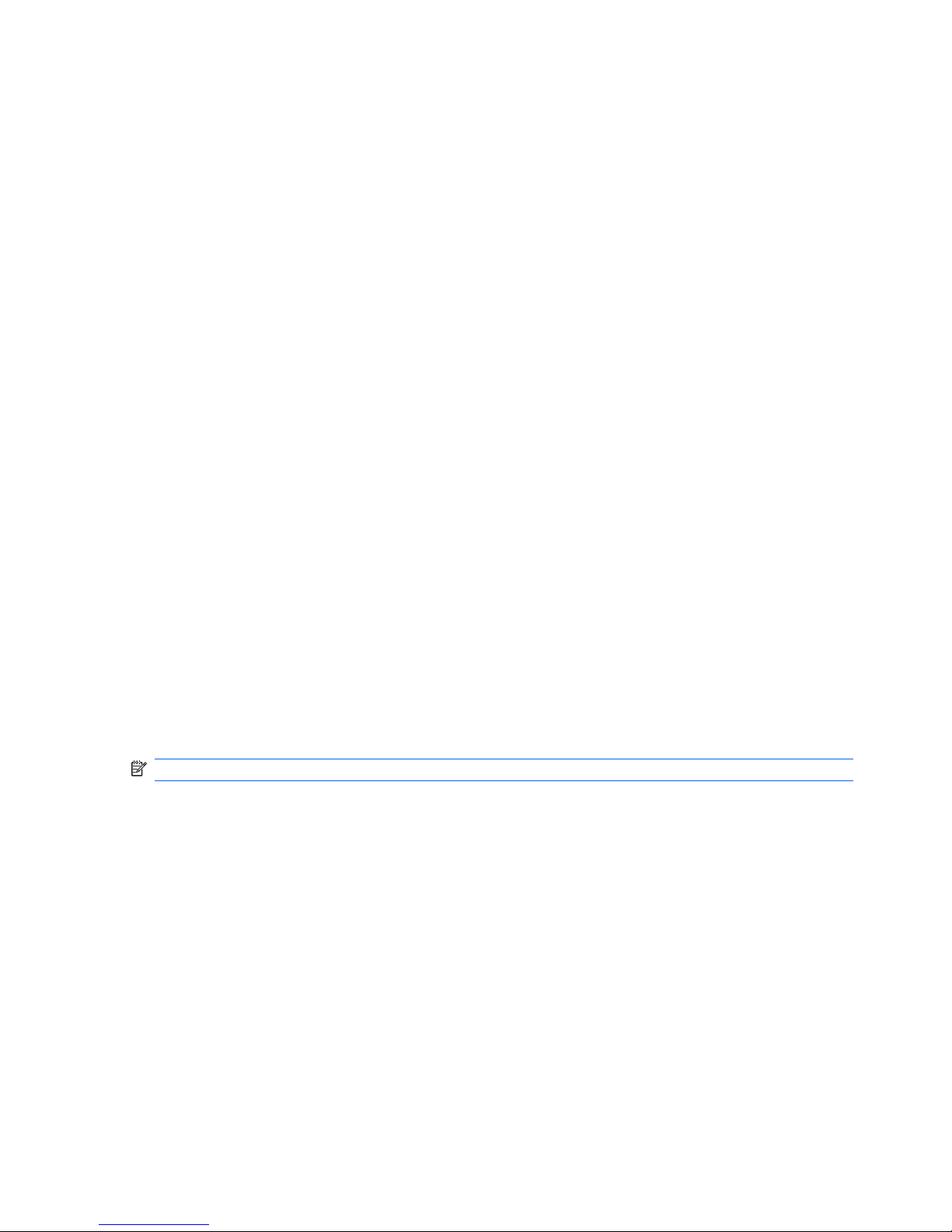

Serial Number Location

Each computer has a unique serial number and product ID number that are located on the top of the

computer. Keep these numbers available for use when contacting customer service for assistance.

Figure 6-1 Serial Number and Product ID Location

NOTE: Model dx7510 shown.

Serial Number Location 31

Page 40

Preparation for Disassembly

1. Close any open software applications.

2. Exit the operating system.

3. Remove any diskette or compact disc from the computer.

4. Turn off the computer and any peripheral devices that are connected to it.

CAUTION: Turn off the computer before disconnecting any cables.

CAUTION: Regardless of the power-on state, voltage is always present on the system board as

long as the system is plugged into an active AC outlet. In some systems the cooling fan is on even

when the computer is in the “Standby,” or “Suspend” modes. The power cord should always be