Page 1

10 Hints for

Making Successful

Noise Figure Measurements

Application Note 57-3

Page 2

2

Table of Contents

Introduction 3

● HINT 1: Select the appropriate noise source 4

● HINT 2: Minimize extraneous signals 5

● HINT 3: Minimize mismatch uncertainties 6

● HINT 4: Use averaging to minimize display jitter 7

● HINT 5: Avoid non-linearities 8

● HINT 6: Account for mixer characteristics 9

● HINT 7: Use proper measurement correction 11

● HINT 8: Choose the optimal measurement

bandwidth 12

● HINT 9: Account for path losses 13

● HINT 10: Account for the temperature of

the measurement components 14

Appendix A: Checklist 15

Appendix B: Total uncertainty calculations 16

Appendix C: References 18

Appendix D: Abbreviations 18

Appendix E: Glossary and definitions 19

Key web resources 20

Page 3

3

Introduction

To achieve accurate and repeatable results at RF or

microwave frequencies, measurement uncertainties and

barriers to measurement repeatability must be minimized.

The performance of a device can be obscured if errors

are allowed to accumulate. For the most accurate

measurement, it is important to understand the nature

of the error contributors and identify which of these can be

influenced or changed to improve the quality of the results.

This application note provides useful tips that

will assist in making accurate noise figure measurements.

The checklist in Appendix A is a helpful tool to verify

that all hints have been considered for a particular

measurement.

A detailed explanation of the uncertainties in noise

figure measurements is provided in Agilent Technologies’

Application Note 57-2, Noise Figure Measurement

Accuracy (see reference 5). For a general understanding

of noise figure and its variety of measurement techniques,

refer to Agilent Technologies Application Note 57-1,

Fundamentals of Noise Figure Measurement (see

reference 2).

Page 4

4

Frequency range

Commercial noise sources cover frequencies up to

50 GHz with choices of co-axial or waveguide connectors.

The frequency range of the noise source must include the

input frequency range of the DUT, of course. If the DUT

is a mixer or frequency translation device, the output

frequency range of the DUT must also be addressed.

If one source does not include both frequency ranges,

a second source will be required. A second noise source

may also be necessary when measuring a non-frequency

translating device with low noise and high gain. Low

ENR is best for the measurement, however, high ENR

is necessary to calibrate the full dynamic range of the

instrument. In either case, a full-featured noise figure

analyzer can account for the different ENR tables

required for calibration and measurement.

Match

If possible, use a noise source with the lowest

change in output impedance between its ON and

OFF states. The noise source’s output impedance

changes between its ON and OFF states, which varies

the match between the noise source and the DUT. This

variation changes the gain and noise figure of the DUT,

especially for active devices like GaAs FET amplifiers.

To minimize this effect, 6 dB ENR noise sources are

commercially available that limit their changes in

reflection coefficient between ON and OFF states to

better than 0.01 at frequencies to 18 GHz.

Adapters

Use a noise source with the correct connector for the

DUT rather than use an adapter, particularly for devices

with gain. The ENR values for a noise source apply only at

its connector. An adapter adds losses to these ENR values.

The uncertainty of these losses increases the overall

uncertainty of the measurement. If an adapter must be

used, account for the adapter losses.

● HINT 1:

Select the appropriate noise source

ENR

The output of a noise source is defined in terms of its

frequency range and excess noise ratio (ENR). Nominal

ENR values of 15 dB and 6 dB are commonly available.

ENR values are calibrated at specific spot frequencies.

The uncertainties of these calibrations vary over the

frequency range of the noise source and add to the

uncertainty of the measurement. This uncertainty is

typically limited to approximately 0.1 dB using the

root-sum-of-squares method (RSS).

Use a 15 dB ENR noise source for:

• general-purpose applications to measure noise

figure up to 30 dB.

• user-calibrating the fullest dynamic range of an

instrument (before measuring high-gain devices)

Use a 6 dB ENR noise source when:

• measuring a device with gain that is especially

sensitive to changes in the source impedance

• the device under test (DUT) has a very low

noise figure

• the device’s noise figure does not exceed 15 dB

A low ENR noise source will minimize error due to

noise detector non-linearity. This error will be smaller

if the measurement is made over a smaller, and therefore

more linear, range of the instrument’s detector. A 6 dB

noise source uses a smaller detector range than a

15 dB source.

A low ENR noise source will require the instrument to

use the least internal attenuation to cover the dynamic

range of the measurement, unless the gain of the DUT

is very high. Using less attenuators will lower the noise

figure of the measurement instrument, which will lower

the uncertainty of the measurement.

If ENR values must be entered into the instrument

manually, double-check them to ensure that the table in

the instrument is correct.

Page 5

5

Follow these guidelines:

(a) Ensure that mating connectors are clean and

not worn or damaged (see Reference 8 for further

information). If the measurement becomes unstable

when the cables and connectors are shaken lightly by

hand, try other cables or connectors.

(b) Use threaded connectors in the signal path

whenever possible. (For example BNC connectors are

very susceptible to stray signals.)

(c) Use double shielded cables (common flexible

braided coaxial cable is too porous to RF).

(d) Use shielded GPIB cables.

(e) Move the measurement setup to a screened room.

If a transmitter that has any frequency content within the

measurement bandwidth is nearby and any covers are off

of the DUT, move the measurement setup to a screened

room. Test for such signals with a spectrum analyzer with

a simple wire antenna on the input. Attenuate these stray

signals by 70 to 80 dB.

(f) Use shielding. This is especially important for

making measurements on an open PC breadboard. (See

Reference 5 for further information.)

(g) Use an analyzer with minimal electromagnetic

emissions. Devices may be susceptible to stray emissions

from some measurement instruments. Some modern

noise figure analyzers have electromagnetic emission

characteristics low enough to have negligible impact on

the measurement.

● HINT 2:

Minimize extraneous signals

A noise figure analyzer measures the noise power from

the noise source as affected by the DUT. It uses the power

ratio at two detected noise levels to measure the noise

figure of whatever is between the noise source and the

instrument’s detector. Any interference, airborne or

otherwise, is measured as noise power from the DUT

and can cause an error of any magnitude.

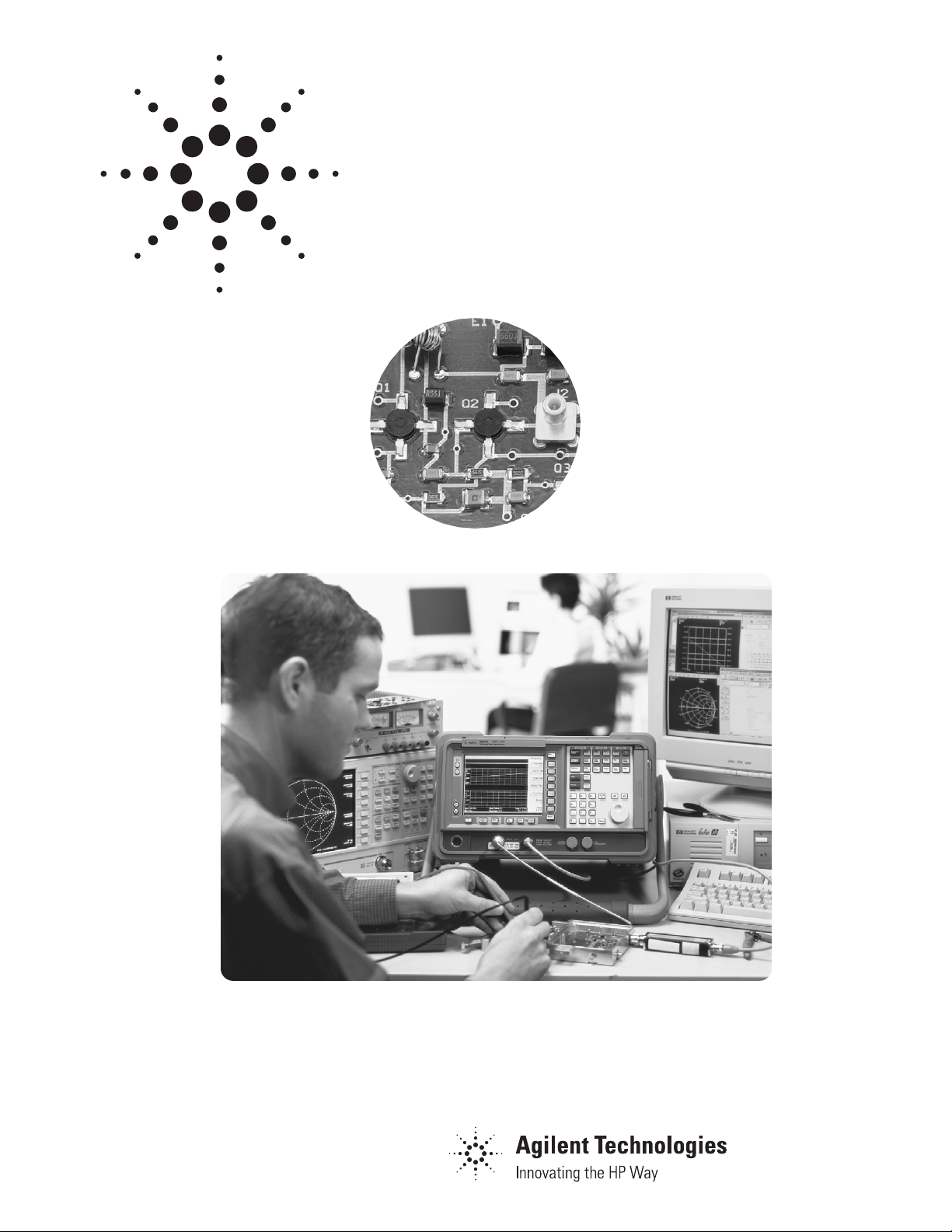

Figure 2-1 demonstrates the types of stray signals that

can get coupled into the signal path and affect the

measurement. Fluorescent lights, adjacent instruments,

computers, local TV and Radio stations, pocket pagers,

mobile phones and base stations are notorious for their

adverse effects on noise measurements. Random stray

signals can cause several tenths of a dB difference

between individual readings, and result in unstable

measurements (i.e. jitter that will not average to a

stable mean).

Figure 2-1

Interference

Noise

Source

Lights ( esp. fluorescent)

FM

TV

Computers

Double-shielded cables for IF (ordinary braid is

too porous)

Shielded GPIB Cables

Enclose all circuits

NF

Analyzer

RF comms basestation

Test connectors by shaking leads

DUT

Page 6

6

Alternately, insert a well matched attenuator

(pad) between the noise source and the DUT to

attenuate multiple reflections. As an example, with a

10 dB attenuator, the re-reflections are attenuated by

20 dB. The advantage of an attenuator vs. an isolator is

broadband response. The disadvantage is that the noise

source’s ENR values will be reduced by the attenuator’s

insertion loss (10 dB in this example).

If the DUT has a high output reflection coefficient

(S22) and low or no insertion gain (S21), then, in some

cases, place a low noise pre-amp between

the DUT and the measurement instrument to

reduce the total measurement uncertainty. The

pre-amp should have an input reflection coefficient (S11)

as low as possible. The effective bandwidth of a pre-amp

with very low S11 is usually narrow. More than one may

be required for the entire frequency range of interest. To

identify an appropriate pre-amp, see Agilent Technologies

Application Note 57-2 (Reference 5).

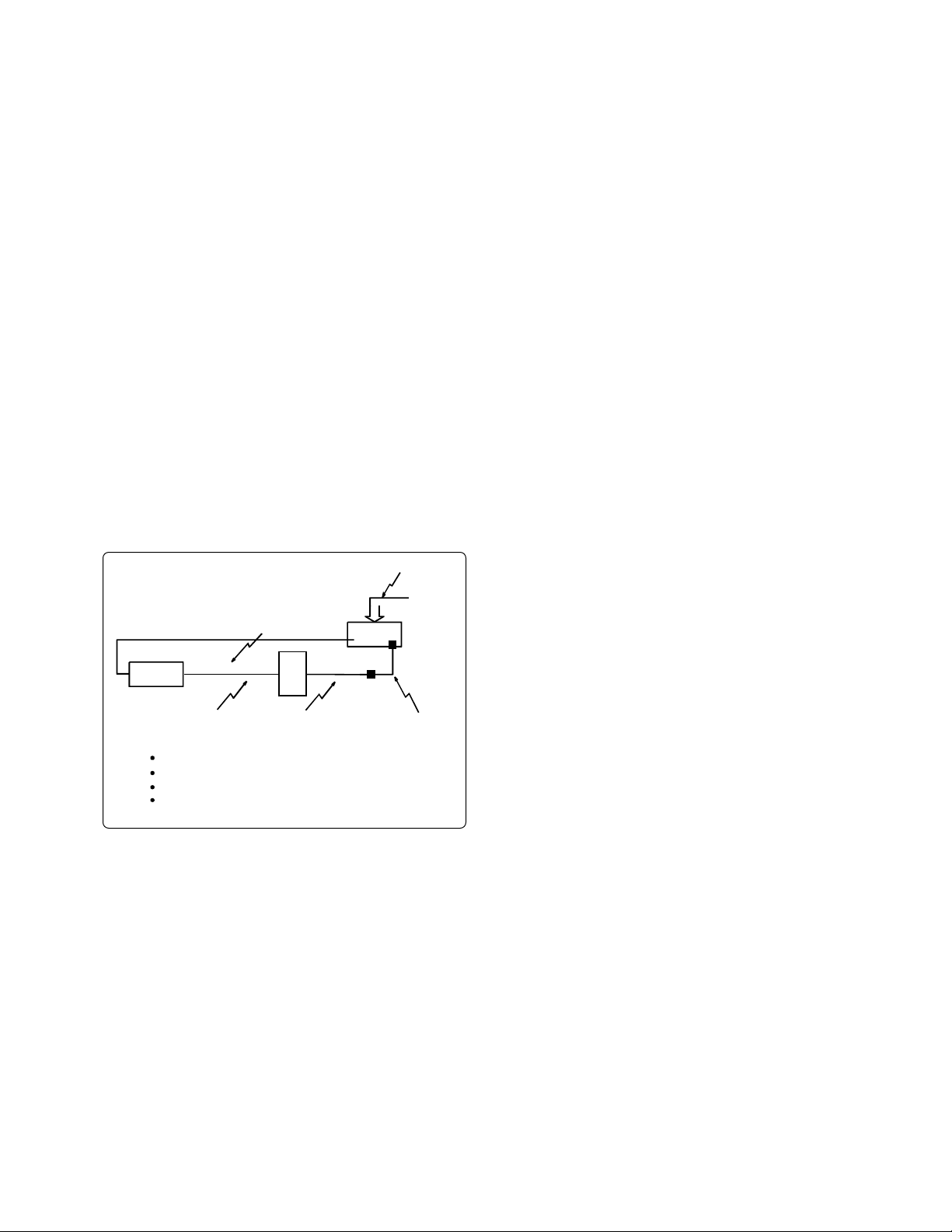

● HINT 3:

Minimize mismatch uncertainties

Mismatch at connection planes will create multiple

reflections of the noise signal in the measurement and

calibration paths (as shown in Figure 3-1). Mismatch

uncertainties at these planes will combine vectorially

and will contribute to the total measurement uncertainty.

One method to reduce the mismatch uncertainty is to

place an isolator in the RF path between the noise

source and the DUT. This isolator can prevent multiple

re-reflections from reaching the DUT and can suppress

the build-up of error vectors. Isolators, however, operate

over restricted frequency ranges. Several may be needed

for the frequency range of interest. Isolators also add to

path losses. As a result compensation is required. Fullfeatured noise figure analyzers have a loss compensation

feature to account for the insertion losses of any isolators.

Figure 3-1

Measuring

System

Noise

Source

DUT

Calibration

Measurement

Mismatch

Uncertainty

ρ1ρ

2

ρ

4

ρ

3

ρ

= reflection coefficient at a reference plane

Page 7

7

If time constraints limit the number of averages during

DUT measurement (e.g. in manufacturing), use more

averages during calibration. This will make the

correction for all subsequent DUT measurements more

accurate.

Modern noise figure analyzers have the ability to do point

averaging or trace averaging. Point averaging makes all

measurements for the first frequency point, calculates and

displays their average, then moves to the next frequency

point. The process is repeated until each frequency

has been measured and averaged the number of times

specified in the measurement setup. Trace averaging

measures only once at each frequency point through one

entire sweep of the frequency range. It then begins the

second sweep, averaging each individual measurement

at each frequency with the previous average for that

frequency, as it sweeps. It repeats this process until the

number of sweeps or “traces” averaged together equals the

number of averages specified in the measurement setup.

Both types of averaging give the same answer. Point

averaging is faster overall since the analyzer’s tuner has

to retune fewer times for all measurements to complete.

Trace averaging displays a rough measurement over the

entire frequency range faster. This enables a user to see

any obvious problems with the measurement (e.g. an

extraneous signal) sooner.

Use trace averaging first. Watch a few sweeps across

the display and look for indications of RF interference

such as a spike in the response at a single frequency, or

even a small step in the response.

● HINT 4:

Use averaging to minimize display jitter

Noise measurement inherently displays variability or

jitter because of the random nature of the noise being

measured. Averaging many readings can minimize

displayed jitter and bring the measurement closer to

the true mean of the noise’s gaussian distribution.

Modern noise figure analyzers enable the user to select

the number of readings that will be averaged for each

measurement. This will reduce jitter in the measurement

by the square root of N, where N is the number of

measurements in the average. The table below shows

some examples of the effect of averaging on jitter. For

example, jitter may be reduced by almost 70% by averaging

approximately 10 readings.

Increasing the averaging will add time to make the

measurement. This would affect the device test time and

total test throughput in manufacturing. There is a trade-off

between the speed of the measurement and the level of

jitter.

Decreasing the bandwidth of the measurement increases

proportionately the number of readings necessary to

obtain the same level of jitter reduction. For example,

half the bandwidth requires twice as many readings of

noise figure averaged together to obtain the same jitter

reduction; one fourth requires four time as many readings,

and so on. These additional readings do not necessarily

extend the time for the measurement proportionately.

N SQRT % jitter

(N) reduction

110

4250

16 4 75

64 8 87.5

256 16 93.75

Page 8

8

A Y-Factor noise figure analyzer assumes a linear

change in the detected noise power as the noise source

is switched between T

hot

and T

cold

. Any variations

from linearity in either the DUT or in the detector directly

produce an error in the Y value and hence in the noise

figure that is displayed. The instrumentation uncertainty

specification accounts for the linearity of the analyzer’s

detector. The linearity of the DUT, however, should be

carefully considered when making the measurement.

The measured noise figure is determined by the power in

the instrument’s resolution bandwidth. The instrument’s

attenuation settings, however, may be determined by

the power in the instrument’s overall frequency range

that reaches the range detector. The analyzer is therefore

susceptible to being overdriven by noise outside the

bandwidth of any one individual measurement, and

therefore vulnerable to non-linearity errors. In such

cases, attenuate any broadband power outside the

analyzer’s resolution bandwidth. Use a filter wider than

the measurement frequency range and before the DUT.

Consider measuring a familiar “reference” or “gold

standard” device at the beginning of each day to assure

that the same result is obtained as prior days for the same

device, to add assurance that the measurement instrument

is warmed up sufficiently.

● HINT 5:

Avoid non-linearities

Avoid all predictable sources of nonlinearities:

• circuits with phase lock loops (and any circuit

that relies on signal presence to set its operating

condition)

• circuits that oscillate (even if at a far-removed

frequency)

• amplifiers or mixers that are operating

near saturation

• AGC circuits or limiters (AGC circuits have been

known to contribute additional noise power at the

power levels near its operational point, even when

disabled.)

• High Gain DUT’s without in-line attenuation

(Attenuate the output of the DUT if necessary.

See Hint 7 for details)

• power supply drifts

• DUTs or measurement systems that have not

warmed up

• logarithmic amplifiers (The standard Y-Factor

measurement is invalid for amplifiers in a logarithmic

mode.)

Page 9

9

Figure 6-1

DSB measurements are easier to perform since they don’t

require the additional burden of image rejection filter

design and matching. When a mixer with a DSB specified

noise figure is going to be used in an SSB application,

careful correction is needed. (See reference 5 for more

information)

b) For double sideband measurements, select

a LO frequency as close as possible to the

RF band of interest.

The choice of LO frequency, and the resulting IF, can make

a dramatic difference in the results of DSB measurements.

Instruments typically display the average of the LSB and

USB noise figures. They measure the power in the IF band

(which is the sum of both sidebands after conversion),

diminish that power by half (3 dB), and display the result.

The closer the USB and LSB are together, the more likely

they are to be equal (as shown in Figure 6-1) and the more

likely the default 3 dB correction will be accurate. Since

noise power versus frequency for a mixer is rarely flat, if

too wide an IF is used the error and its correction will be

unknown. To minimize this error, choose the LO frequency

as close as possible to the RF band of interest, within the

limitation that the resulting IF cannot be below the lower

frequency limit of the instrument being used (often

10 MHz).

● HINT 6:

Account for mixer characteristics

If the device under test is a mixer:

• Measure the same sideband(s) that will be used in

the application of the mixer.

• For double sideband measurements, select a LO

frequency close to the RF band of interest.

• For single sideband measurements, select a LO far

from the RF band of interest, if possible.

• Choose the LO to suit the mixer.

• Filter the RF signal (i.e. the noise source) if necessary

to remove unwanted signals that would mix with the

LO’s harmonics or spurious signals.

• Always document a frequency plan to identify which

of the above precautions are necessary.

a) Select a double sideband or a single

sideband measurement.

A mixer will translate input signals and noise from the

upper sideband (USB) and lower sideband (LSB) as

Figure 6-1 shows. (Note that the LSB and USB are

separated by twice the IF.) A double sideband (DSB)

measurement, shown in Figure 6-2, measures the noise

powers for both the USB and LSB. Some receiver systems,

like those in radio astronomy, intentionally use both

sidebands. DSB noise figure measurement is appropriate in

these cases. In many applications the desired signal

will be seen in only one sideband. A single sideband (SSB)

measurement is appropriate in these cases. In SSB

measurement setups, the noise power in the unwanted

sideband is suppressed by appropriate “image rejection”

filtering at the input of the mixer.

Noise Power

Freq

LSB

USB

F

LO

F

IF

average

Page 10

10

Balanced and double-balanced mixers have more than

one diode to perform the frequency conversion. This

improves the LO to IF isolation (20 dB and better), but

usually requires more LO power or biasing. This higher

power may raise the LO’s noise output, produce spurs

away from the set frequency, or produce LO harmonics

inside the mixer. Any of these can mix additional, yet

unwanted, RF signal into the IF, or leak through to the IF.

This may raise the measured noise and possibly overdrive

the analyzer’s first stage to a non-linear state. Experiment

with the LO to see what improves performance and

produces the lowest noise figure.

e) Filter the RF signal (i.e. the noise source)

if necessary.

It may be necessary to filter the RF noise source to remove

frequencies that are outside the band of interest as shown

in Figure 6-4. This can remove unwanted signals that

would mix with the LO or its harmonics or spurious signals

and raise the measured noise figure.

To determine if sideband-averaging error is a problem, set

up the noise figure measurement for a mixer with swept

LO and fixed IF (modern noise figure analyzers allow this).

Monitor the noise figure reading. If the noise figure values

change dramatically as the LO sweeps, then SSB

measurement is recommended (See reference 5 for

further information.)

Figure 6-2

c) For single sideband measurements, select

a LO far from the RF band of interest,

if possible.

The farther the LO is from the RF, the higher will be the

IF, and the less stringent will be the rolloff requirement

for the filter that suppresses the unwanted sideband as

shown in Figure 6-3.

d) Choose the LO to suit the mixer.

Choose the LO to avoid spurious output where the mixer is

sensitive and to avoid high broadband noise floor.

Filter the LO if necessary to diminish spurious signals

and broadband noise, since the IF pass band will include

noise power one IF away from the LO frequency and

one IF away from any spurious signals or harmonics of

the LO.

Noise

Figure

Analyzer

Noise source

IF Amplifier

Mixer

f

LO

IF

f

RF

LO

Measurement System

Noise

Source

Drive

(DUT)

f

Page 11

11

FIG 6-3

FIG 6-4

f) Filter the IF signal (ie, the DUT output)

if necessary.

Keep the LO outside of the frequency range of the

instrument if possible. LO power will almost certainly

leak through to the IF port of the mixer. Assume that

LO to IF isolation will be insufficient. If this leakage is

within the band of the measurement, it will add to the

noise figure measured. If it is outside the band of the

measurement but within (or close to) the overall

frequency range of the instrument, it could cause the

instrument to autorange itself to use more attenuation,

which would increase the uncertainty of the measurement.

Filter the output of the mixer to remove this LO

leakage and any LO harmonics created in the mixer

without appreciably attenuating the wanted mixer

output signal.

g) Document a frequency plan to evaluate

which of the above precautions are

necessary.

A frequency plan will help identify which of the

precautions above are the most important before the

measurement is made.

Noise

Figure

Analyzer

Noise source

IF Amplifier

Mixer

f

f

LO

IF

f

MEAS

LO

Measurement System

Noise

Source

Drive

(DUT)

Noise Power

Freq

LSB

USB

F

LO

F

IF

filter response

Page 12

12

The cascade equation shows how F12 is very sensitive

to uncertainty margins in the second stage term

[(F2 - 1) / G1]. (To see how F12 would vary with marginal

changes in F2 or G1, see reference 6.) If the DUT has

insertion loss (e.g. a mixer, attenuator, etc.), use a low

noise pre-amplifier before the instrument to reduce

the uncertainty margin. Choose a pre-amp with the

lowest noise figure and a gain of more than 100 (20 dB +).

(See Agilent Technologies Application Note 57-2 for more

information on selecting the pre-amp.) Make the noise

figure of the second stage as low as practical and the

uncertainty of F12 (and hence F1), as low as possible.

Adding a pre-amp also gives the measurement some

resilience against noise figure variations versus frequency

of the second stage.

In the case of a high-gain DUT, there may not be a need

for a pre-amp. In order to make that decision, place the

DUT’s linear gain and the measurement system’s linear

noise figure (i.e. noise factor) into the Cascade Equation.

Notice the noise figure of the cascade will converge to the

noise figure of the DUT.

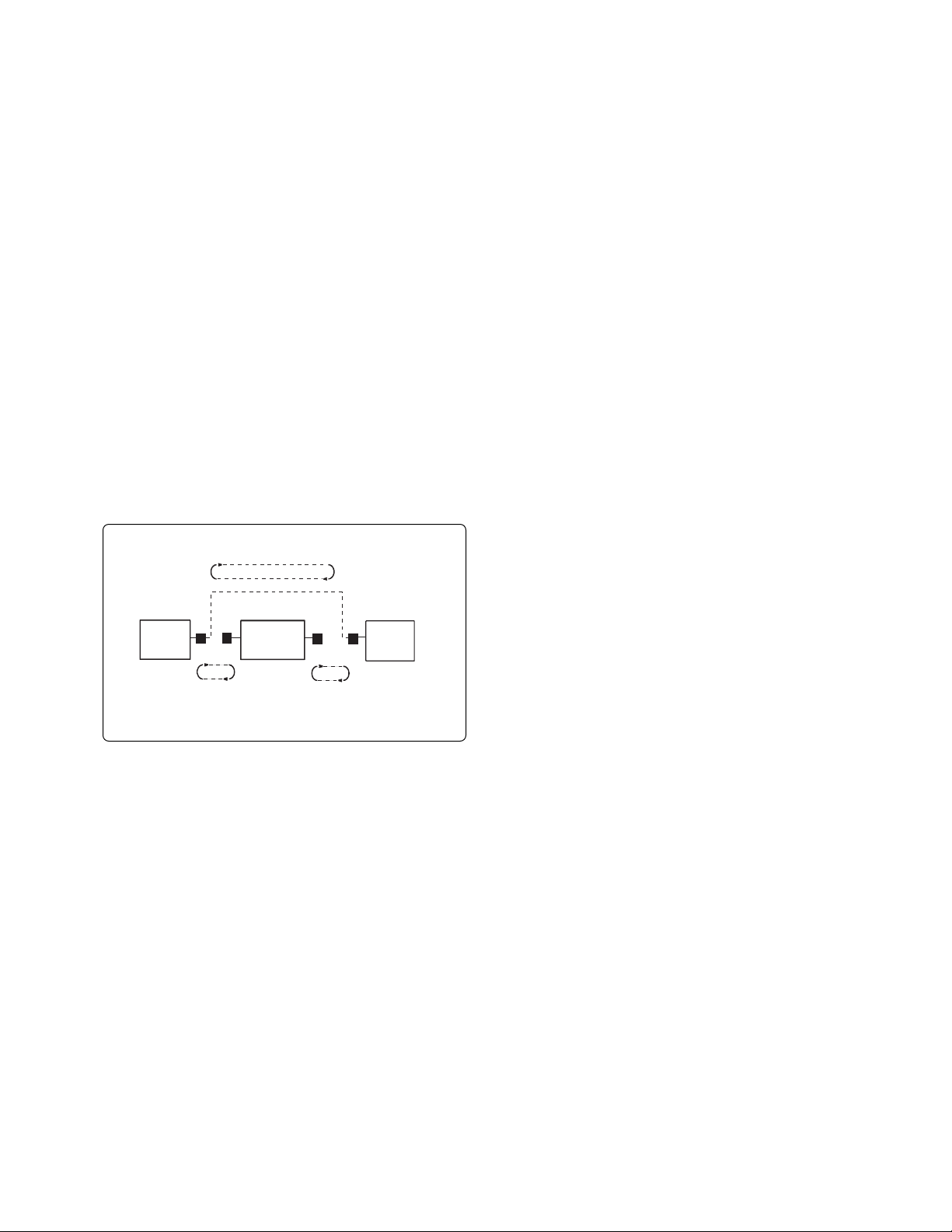

Figure 7-1.

● HINT 7:

Use proper measurement correction

Take the following steps to ensure the measurement

system itself does not add error to the measurement.

• Remove the noise figure of the measurement

system with regular user calibration.

• Avoid exceeding the maximum input power of

the measurement instrument. Modern instruments

can handle around 65 dB of device gain for narrow

band devices. For wider band devices with high gains

it is likely that an attenuator will be required after the

device to keep the overall power within the

instrument’s range. Use the analyzer’s compensation

feature to account for the losses of the attenuator.

Use appropriate filters/isolators/circulator to suppress

out-of-band responses that would otherwise

contribute noise power at the high gain level and

overpower the instrument’s input.

A Y-Factor noise figure analyzer measures the noise figure

of the measurement system and the DUT combined (see

Figure 7-1). Below is F12 in the cascade equation:

F12 = F1 + [(F2 - 1 ) / G1] (7-1)

F1 and F2 are linear noise figure values for the DUT and

the measurement system, respectively, and G1 is the

gain of the DUT. User calibration (termed “second stage

correction”) determines F2; measurement determines

F12 and G1. The analyzer calculates F1 from the cascade

equation.

Perform user-calibration prior to the measurement to

remove the second stage contribution. Calibrate out the

second stage contribution at regular intervals depending

on how sensitive the noise figure and gain are to

temperature drifts.

Noise

source

Measuring

system

DUT

Gain, G

Calibration path

Measurement

path

F2 = noise figure of the measurement system

F1 = noise figure of the device under test (DUT)

Page 13

13

Figure 8-1

● HINT 8:

Choose the optimal measurement bandwidth

Select a measurement bandwidth no larger than the

pass band of the DUT. Modern noise figure analyzers

provide a selection of various measurement bandwidths

to enable measurements that are more relevant to current

practical applications (e.g. individual wireless GSM

channels). 4 MHz bandwidths were common in past

generations of noise figure instruments; modern analyzers

can measure down to at least 100 kHz bandwidth.

If the measurement bandwidth is similar to the DUT’s

operational pass band, then any instabilities between

the center frequency of the analyzer’s final IF and the

DUT’s operational bandwidth will lead to an error in the

displayed gain. The analyzer may recognize the noise

power outside of the DUT’s pass band during calibration

and inside during measurement. The extent of this effect

depends on the shape of the DUT’s pass band overlapping

with the shape of the analyzer’s final IF pass band. This

issue is less significant if the analyzer’s pass band is

narrower than the DUT’s pass band.

Past generations of noise figure instruments required

additional time to obtain the same level of jitter reduction

in a narrower bandwidth. For the same jitter reduction,

half the bandwidth required twice the time, one fourth

required four times as long, etc. In modern full-featured

noise figure analyzers, this time penalty is mostly

eliminated due to digital signal processing (DSP)

techniques that measure a group of adjacent frequencies

simultaneously.

Frequency

Measurement

Bandwidth Setting

Noise power detected during

calibration but not during

DUT measurement

understates DUT's noise figure

Noise

Power

Lowest possible actual

measurement bandwidth due

to downward frequency drift

Analyzer's frequency instability

due to drift during time required

for all measurements to be made

and averaged

Highest possible actual

measurement bandwidth due

to upward frequency drift

Page 14

14

Figure 9-1

● HINT 9:

Account for path losses

Adapters must be used if the connectors between the noise

source, DUT, and measurement system do not mate, as in

Figure 9-1. It is most important to avoid adapters where

the signal is smallest in the measurement setup. For

devices with gain, avoid adapters before the DUT.

For devices with loss, avoid adapters after the DUT.

Keep track of the insertion losses of adapters and

any additional components such as cables, baluns,

filters, pads, and isolators that are not part of the

DUT. These insertion losses have to be taken into account

by subtracting them from the measurement result. Any

adapters used between the noise source and the DUT

will introduce some loss, effectively reducing the ENR

of the noise source.

Modern noise figure analyzers can subtract these losses

from the measurement automatically. The analyzer

will also need to know the temperature of these

components and whether they are before or after

the DUT. The analyzer will correct the displayed noise

figure for all loss elements and their temperatures that

are entered.

Losses in the measurement system are corrected by user

calibration. Adapters and cables that are connected to the

instrument during both user calibration and measurement

are considered part of the measurement system and are

accounted for during user calibration.

If a pre-amp is needed prior to the measurement system

then choose a pre-amp with the correct connector

for the noise source, and include the pre-amp as part

of the calibration setup that measures the second stage

noise figure.

Connection Diagram

Noise

Source

DUT

Measurement

system

G 1

G 2

Cable C1

Cable C 2

Coax/WG adapter

Coax/WG adapter

A

B

Page 15

15

If the actual local ambient temperature is not entered

into the analyzer, it will make its calculations with the

wrong temperature assumption. An extra error term in

the over-all uncertainty margin will be present. This can

be a significant value if the true noise figure of the DUT is

low. Figure 10-2 shows typical differences between the

displayed and actual noise figures for different ambient

temperatures.

Figure 10-2

● HINT 10:

Account for the temperature of

the measurement components

Y-Factor noise figure analyzers assume that the surface

temperatures of all components in the measurement

(noise source, DUT, connectors, cables, etc.) are the

default value for Tcold, 290K (16.8°C, 62.2°F). If this is

not the case, enter the correct temperature of each

component into the analyzer and monitor them

regularly. Full featured noise figure analyzers allow the

entry of the temperatures of any components added before

and after the device.

Figure 10-1 shows the measurement response curve

where the noise powers N

1

and N2are due to input noise

temperatures Tcold and Thot, respectively. The solid

line on this graph represents the response when T

0

is

considered as the reference ambient temperature of 290K.

If the T

cold

of the noise source (for a solid state noise

source, its surface temperature) is not equal to T

0

, then the

dotted line may become the response curve. The noise

power added by the DUT would then be N

a

´ and not Na.

Figure 10-1

+1K

T

amb

= 296.5K (=74 F)

T

amb

= 305K (=89 F)

0.24

0.20

0.16

0.12

0.08

0.04

0 0.4 0.8 1.2 1.4 1.8

NF(dB)

NF(dB) = F mea - Factual

P

out

N

2

N

1

N

a

´

N

a

T

o

T

c

ThT

s

Page 16

16

❑ Account for mixer characteristics. See Hint # 6.

❑ Measure the same sideband(s) that will be used in

the application.

❑ For double-sideband measurements, select a LO

frequency close to the RF band of interest.

❑ For single-sideband measurements, select a LO far

from the RF band of interest, if possible.

❑ Choose the LO to suit the mixer.

❑ Filter the LO if necessary to diminish spurious signals

and broadband noise.

❑ Keep the LO outside of the measurement bandwidth

if possible.

❑ Filter the IF if necessary to remove LO harmonics

created inside the mixer.

❑ Filter the RF to prevent unwanted mixing.

❑ Test for DSB error by changing IF.

❑ Experiment with different LOs to get the most

accurate (i.e. lowest) noise figure.

❑ Document a frequency plan to evaluate which of the

above precautions are necessary.

❑ Enter proper measurement correction.

See Hint # 7.

❑ Calibrate regularly.

❑ Keep overall gain below the instrument’s spec.

❑ Filter out-of-band power.

❑ If 2nd stage effect is large, add a low-noise pre-amp

(with proper connectors).

❑ Choose the optimal bandwidth. See Hint # 8.

❑ Select a measurement bandwidth no larger than the

pass band of the DUT.

❑ Account for path losses. See Hint # 9.

❑ Avoid adapters as much as possible.

❑ If used, enter their losses into the instrument.

❑ Account for the temperature of measurement

components. See Hint # 10.

❑ Enter physical temperatures of the noise source and

the components of the measurement setup into the

instrument.

Appendix A:

Checklist

Use this checklist to assist with locating the hint relating to

specific issues or considerations. Reading the 10 Hints

Application Note sequentially is not necessary.

❑ Select the appropriate noise source. See Hint # 1.

❑ Use a low ENR source whenever possible.

❑ Avoid adapters between the noise source and DUT.

❑ Double check manually entered ENR values.

❑ Reduce EMI influence. See Hint # 2.

❑ Use clean, undamaged connectors.

❑ Use threaded connectors.

❑ Use double shielded cables.

❑ Use shielded GPIB cables.

❑ Use a screened room.

❑ Use shielding.

❑ Use an analyzer with minimal electromagnetic

emissions.

❑ Minimize mismatch uncertainties. See Hint # 3.

❑ Use an attenuator or isolator if needed.

❑ Use a pre-amp if needed.

❑ Use averaging to minimize display jitter.

See Hint # 4.

❑ Select enough averages to stabilize the measurement.

❑ Use “trace averaging” first to spot measurement setup

problems soonest.

❑ Look for spikes or even small steps in the display that

indicate RF interference.

❑ If time constrained, use more averaging during

calibration than during DUT measurement.

❑ Avoid non-linearities. See Hint # 5.

❑ Avoid the following:

❑ Circuits with phase lock loops

❑ Circuits that oscillate

❑ Amplifiers or mixers operating near saturation

❑ AGC circuits or limiters

❑ High-gain DUTs without in-line attenuation

❑ Power supply drifts

❑ DUTs or instruments that have not warmed up

❑ Logarithmic amplifiers

Page 17

17

Figure B-2 shows the typical display for the entry point

to this interactive model. Figures B-3, B-4 and B-5 show

simulated results for the uncertainty calculator. There

are a number of graphs that can be plotted. These figures

show examples of RSS uncertainty with respect to

instrument match, DUT input match and instrument noise

figure, respectively. This interactive uncertainty calculator

and the spreadsheet version shown in Figure B-1 can be

accessed via the Internet by using the URL on the back

page of this application note.

Figure B-2

Figure B-3

Appendix B:

Total uncertainty calculations

The error model in the spreadsheet shown in Figure B-1

is obtained from the derivative of the Cascade equation

(F1 = F12 - [(F2-1) / G1]). It takes into account the

individual mismatch uncertainty calculations at each

reference or incident plane of the DUT, noise source and

measurement system. This example represents the total

noise figure measurement uncertainty, RSS analysis, for

a microwave transistor with an S11 of 0.5, S22 of 0.8 and

S21 of 5 (14dB). Noise figure uncertainty, here is

calculated as ±0.48 dB. The uncertainty dramatically

improves to ±0.26dB, in this instance, if the gain is

improved to 20dB. The calculation for this error model

is derived in Reference 6.

Figure B-1

Page 18

Figure B-4

Figure B-5

18

Appendix C:

References

1. Agilent 346A, 346B, and 346C Noise Sources

(10 MHz to 26.5 GHz), Technical Specification Sheet,

literature number 5953-6452

2. Fundamentals of RF and Microwave Noise Figure

Measurements, Application Note 57-1,

literature number 5952-8255E

3. Noise Parameter Measurement Using the Agilent

8970B Noise Figure Meter and the ATN NP4 Noise

Parameter Test Set, Product Note 8970B/S-3,

literature number 5952-6639

4. Noise Parameter Measurement Accuracy and

Repeatability Considerations, ATN Application Note 001

5. Noise Figure Measurement Accuracy,

Application Note 57-2, literature number 5952-3706

6. “Calculate the Uncertainty of NF Measurements”

Microwaves and RF, October 1999.

Also available at: http:\\www.mwrf.com

(select Editorial Archives; then October 1999).

7. Agilent R/Q 347B Solid-State Noise Sources at

Millimeter-Wave Frequencies, Technical Specifications,

literature number 5954-8888

8. Principles of microwave connector care

(for higher reliability and better measurements),

Application Note 326, literature number 5954-1566

Page 19

19

Appendix E:

Glossary and definitions

1. Excess Noise Ratio (ENR):

ENR is the measure of how much more noise power is

output from a noise source when “ON” (i.e. operating at

virtual temperature T

hot

) than is output when “OFF” (i.e.

operating at ambient temperature T

cold

), normalized by its

output power at the standard temperature 290K.

ENR = 10 log (T

h

- Tc) / T

0

For example, an ENR of 15 dB means that the noise source

output when ON is greater than when OFF by the antilog

of 15/10 times the noise power ouput at 290K. This is

equivalent to a resistor at 9171K, calculated as antilog

(15/10) x 290.

2. Second Stage Contribution:

During the measurement process the noise source is

connected to the input of the DUT and the DUT’s output is

connected to the measurement system. In this cascade, the

DUT is the first stage and the measurement system is the

second stage. The measurement system will measure the

noise figure of the cascade. Correction requires that the

noise figure (F1) value of the DUT has to be de-embedded”

from the cascade’s combined noise figure (F12) by

removing the contribution of the second stage in the

cascade or Friis equation:

F12 = F1 + [(F2 - 1) / G1]

The expression in the brackets is the second stage

contribution. G1 is the gain of the DUT.

3. Y-Factor:

This is the linear ratio of the noise power seen by the

measurement system when the noise source is turned ON,

to that when the noise source is turned OFF. This is the

basis of the calculation of noise figure. After the

instrument recognizes the ENR, the noise figure is derived

from the equation:

NF = ENR - 10 log (Y - 1)

Appendix D:

Abbreviations

AGC Automatic Gain Control

DUT Device Under Test

DSB Double Sideband

ENR Excess Noise Ratio

F Noise Factor (linear expression of NF)

LSB Lower Sideband

NF Noise Figure (noise factor [F] expressed in dB)

RSS Root Sum of Squares

SSB Single Sideband

T

c

Cold Temperature

T

cold

Cold Temperature

T

h

Hot Temperature

T

hot

Hot Temperature

USB Upper Sideband

URL Universal Reference Locator

WG Waveguide

Page 20

Agilent Technologies’ Test and Measurement

Support, Services, and Assistance

Agilent Technologies aims to maximize

the value you receive, while minimizing

your risk and problems. We strive to ensure that

you get the test and measurement

capabilities you paid for and obtain the

support you need. Our extensive support

resources and services can help you

choose the right Agilent products for your

applications and apply them successfully. Every

instrument and system we sell has

a global warranty. Support is available for

at least five years beyond the production

life of the product. Two concepts underlie

Agilent’s overall support policy:

“Our Promise” and “Your Advantage.”

Our Promise

Our Promise means your Agilent test and

measurement equipment will meet its

advertised performance and functionality.

When you are choosing new equipment,

we will help you with product information,

including realistic performance specifications

and practical recommendations from

experienced test engineers. When you use

Agilent equipment, we can verify that it

works properly, help with product operation,

and provide basic measurement assistance

for the use of specified capabilities, at no

extra cost upon request. Many self-help

tools are available.

Your Advantage

Your Advantage means that Agilent offers

a wide range of additional expert test and

measurement services, which you can

purchase according to your unique technical

and business needs. Solve problems

efficiently and gain a competitive edge by

contracting with us for calibration, extra-cost

upgrades, out-of-warranty repairs, and

on-site education and training, as well as

design, system integration, project

management, and other professional

engineering services. Experienced Agilent

engineers and technicians worldwide

can help you maximize your productivity,

optimize the return on investment of your

Agilent instruments and systems, and obtain

dependable measurement accuracy for the

life of those products.

For more assistance with your test &

measurement needs go to

www.agilent.com/find/assist

Or contact the test and measurement experts

at Agilent Technologies

(During normal business hours)

United States:

(tel) 1 800 452 4844

Canada:

(tel) 1 877 894 4414

(fax) (905) 206 4120

Europe:

(tel) (31 20) 547 2000

Japan:

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Latin America:

(tel) (305) 267 4245

(fax) (305) 267 4286

Australia:

(tel) 1 800 629 485

(fax) (61 3) 9272 0749

New Zealand:

(tel) 0 800 738 378

(fax) 64 4 495 8950

Asia Pacific:

(tel) (852) 3197 7777

(fax) (852) 2506 9284

Product specifications and descriptions in this

document subject to change without notice.

Copyright © 2000

Agilent Technologies

Printed in U.S.A. 11/21/00

5980-0288EN

Loading...

Loading...