Page 1

HP A6616 Router

Installation Manual

Page 2

About This Manual

Organization

HP A6616 Routers Installation Manual is organized as follows:

Chapter Contents

1 Router Overview

Briefly introduces the product specifications, as well as

the features and applications of the HP A6616.

2 Preparing for Installation

Describes the requirements on installation site, the

safety recommendations before and during installation,

and the required tools.

3 Installing the Router

Introduces how to install the A6616, as well as how to

connect the power cable, console cable, AUX port

cable, Ethernet cable, interface card and interface

module cable.

4 Starting and Configuring the Router

Helps you get familiar with the basic knowledge of how

to boot and configure the HP A6616, including device

startup, power-on, and initialization of system files, and

so on.

5 Maintaining Software

Introduces how to maintain the software of the HP

A6616, including upgrading the software and updating

the configuration files.

6 Maintaining Hardware

Introduces how to maintain the hardware of the HP

A6616.

7 Troubleshooting

Describes some problems that may occur during

installation and startup of the router and how to solve

them.

Conventions

The manual uses the following conventions:

Command conventions

Convention Description

Boldface The keywords of a command line are in Boldface.

italic Command arguments are in italic.

[ ] Items (keywords or arguments) in square brackets [ ] are optional.

{ x | y | ... }

Alternative items are grouped in braces and separated by vertical bars. One is

selected.

[ x | y | ... ]

Optional alternative items are grouped in square brackets and separated by

vertical bars. One or none is selected.

Page 3

Convention Description

{ x | y | ... } *

Alternative items are grouped in braces and separated by vertical bars. A

minimum of one or a maximum of all can be selected.

[ x | y | ... ] *

Optional alternative items are grouped in square brackets and separated by

vertical bars. Many or none can be selected.

&<1-n> The argument(s) before the ampersand (&) sign can be entered 1 to n times.

# A line starting with the # sign is comments.

GUI conventions

Convention Description

Boldface

Window names, button names, field names, and menu items are in Boldface.

For example, the New User window appears; click OK.

>

Multi-level menus are separated by angle brackets. For example, File >

Create > Folder.

Convention Description

< > Button names are inside angle brackets. For example, click <OK>.

[ ]

Window names, menu items, data table and field names are inside square

brackets. For example, pop up the [New User] window.

/

Multi-level menus are separated by forward slashes. For example,

[File/Create/Folder].

Symbols

Convention Description

Means reader be extremely careful. Improper operation may cause bodily

injury.

Means reader be careful. Improper operation may cause data loss or damage

to equipment.

Means an action or information that needs special attention to ensure

successful configuration or good performance.

Means a complementary description.

Means techniques helpful for you to make configuration with ease.

Related Documentation

In addition to this manual, each HP A6600 Routers documentation set includes the following:

Manual Description

HP A6600 Routers User Manual

It is a guide for the user to perform the operations

correctly. It is organized into the parts of access, IP

services, IP routing, MPLS, VPN, QoS, security,

Page 4

Manual Description

system, multicast, and OAA.

It also gives the user a detailed description of the

operating commands. It is organized into the parts of

access, IP services, IP routing, MPLS, VPN, QoS,

security, system, multicast, and OAA, as well as a

command index.

HP A6600 Routers Interface Card and Interface

Module Manual

This manual introduces all kinds of interface modules

that SR6600 routers support, the means of

connection the interface cables and the interface

module purchase guide.

Low-End and Mid-Range Series Routers Cable

Manual

This manual introduces all cable pinouts available

with low-end and mid-range series routers.

Environmental Protection

This product has been designed to comply with the requirements on environmental

protection. For the proper storage, use and disposal of this product, national laws and

regulations must be observed.

Page 5

1 Router Overview

Introduction

The HP A6616 router (hereinafter referred to as the A6616) is a high-performance service

router developed by Hewlett Packard (hereinafter referred to as HP), serving as the core router

on a carrier network or large enterprise network.

The A6616 adopts two main processing units (MPUs), redundant power modules, and a

distributed modular architecture. Abundant optional modules are available so that the two

service routers can have a powerful processing capability and support flexible configuration to

fully meet the requirements of the carrier network and enterprise network. The A6616 can work

at the core layer of small- and medium-sized MANs or provincial networks.

With the high-performance microprocessor technology, advanced hardware architecture and HP

proprietary Comware V5 platform, the A6616 provides high service processing capacity, flexible

service scalability, and high reliability. The A6616 can work together with other HP network

routers to provide comprehensive network solutions for medium- and large-sized enterprises,

carriers, and users in the fields of electric power, finance, taxation, public security, railway and

education. The full compliance with national and international standards ensures interoperability

with products of other manufacturers at different layers.

The A6616 supports high-speed interface modules (HIMs) and provide a bus processing

capability up to 10 Gbps, which can meet the high-speed performance requirements of users. In

addition, the A6616 is compatible with some multi-functional interface modules (MIMs) of the HP

MSR/AR series routers to guarantee the smooth upgrade from narrowband access to

broadband access, improve the competitiveness, and protect existing investments.

You can configure MPUs and flexible interface platforms (FIPs) on the A6616 as needed. Table

1-1 describes MPUs' support for FIPs on the A6616.

Table 1-1 MPUs' support for FIPs

MPU FIP-100 FIP-110 FIP-200 FIP-210

RPE-X1 Supported Supported Supported Supported

RSE-X1 Not supported Supported Not supported Supported

The A6616 supports two types of MPUs, route processing engine (RPE) and route switch

engine (RSE).

To facilitate description, the term "FIP" is used throughout this document to refer to the FIP-

100, FIP-110, FIP-200, and FIP-210 if not otherwise specified.

The FIP-100 and FIP-110 support MIMs only.

The FIP-200 and FIP-210 support MIMs, HIMs, and HIM/MIM intermixing.

For details about the slot arrangement, refer to Chapter 2 "Arranging Slots and Numbering

Interfaces."

For details about installation and removal of HIMs and MIMs, refer to Chapter 4 "Installing the

Router.”

Page 6

Physical Description

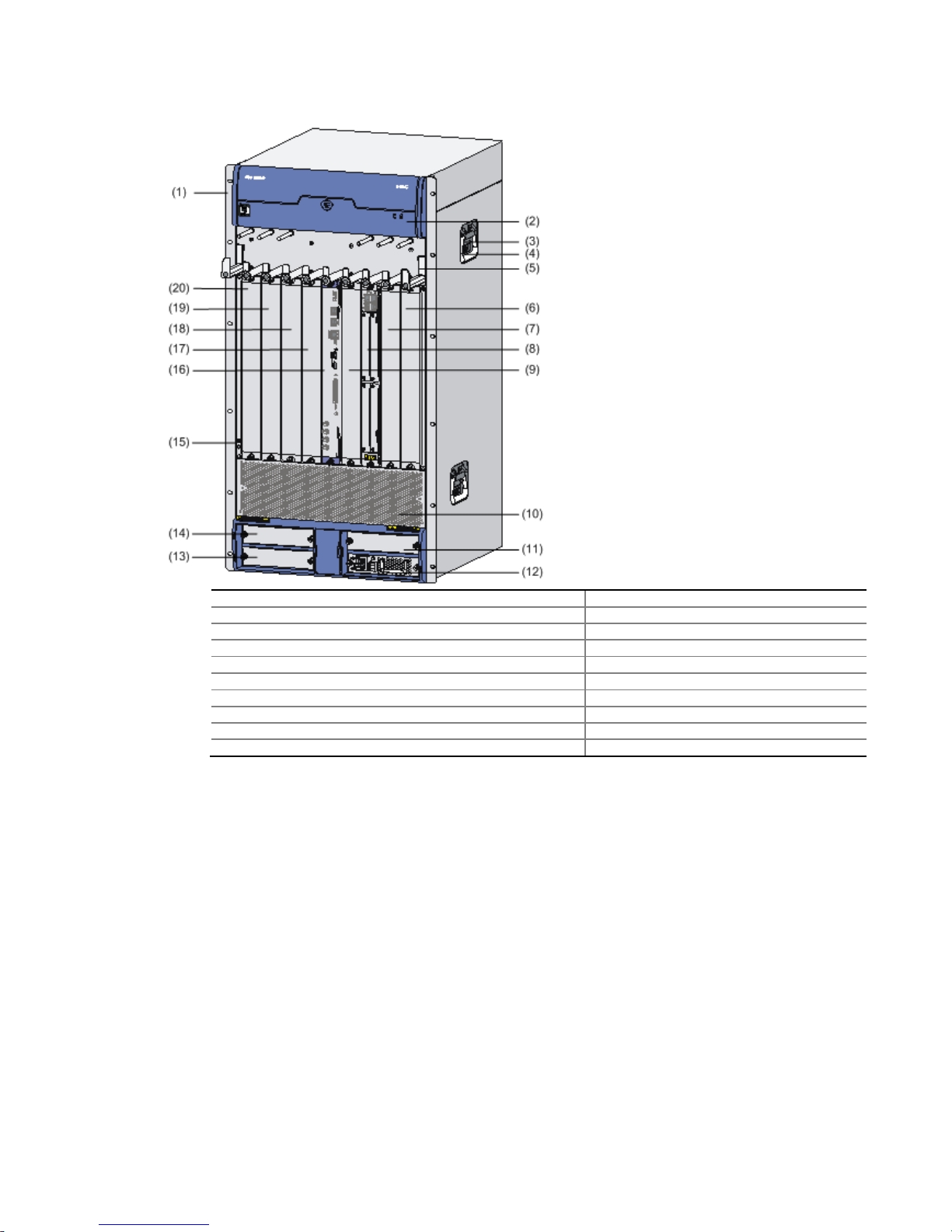

Front View

Figure 1-1 Front view of the A6616 (configured with an RPE-X1)

(1) Mounting bracket (2) Fan tray

(3) Weight-bearing warning label (100 kg/220.46 lb) (4) Chassis handle

(5) Cable management bracket (6) FIP slot (Slot 9)

(7) FIP slot (Slot 8) (8) FIP-200 (Slot 7)

(9) FIP slot (Slot 6) (10) Air inlets (air filters are optional)

(11) Power module slot (PWR3) (12) AC power module (PWR1)

(13) Power module slot (PWR2) (14) Power module slot (PWR4)

(15) ESD socket and silkscreen (16) MPU slot (Slot 4)

(17) RPE-X1 (Slot 5) (18) FIP slot (Slot 3)

(19) FIP slot (Slot 2) (20) FIP slot (Slot 1)

(21) FIP slot (Slot 0)

Page 7

Figure 1-2 Front view of the A6616 (configured with an RSE-X1)

(1) Mounting bracket (2) Fan tray

(3) Weight-bearing warning label (100 kg/220.46 lb) (4) Chassis handle

(5) Cable management bracket (6) FIP slot (Slot 9)

(7) FIP slot (Slot 8) (8) FIP-210 (Slot 7)

(9) FIP slot (Slot 6) (RSE-X1 compatible) (10) Air inlets (air filters are optional)

(11) Power module slot (PWR3) (12) AC power module (PWR1)

(13) Power module slot (PWR2) (14) Power module slot (PWR4)

(15) ESD socket and silkscreen (16) RSE-X1 (Slot 5)

(17) FIP slot (Slot 3) (18) FIP slot (Slot 2)

(19) FIP slot (Slot 1) (20) FIP slot (Slot 0)

Page 8

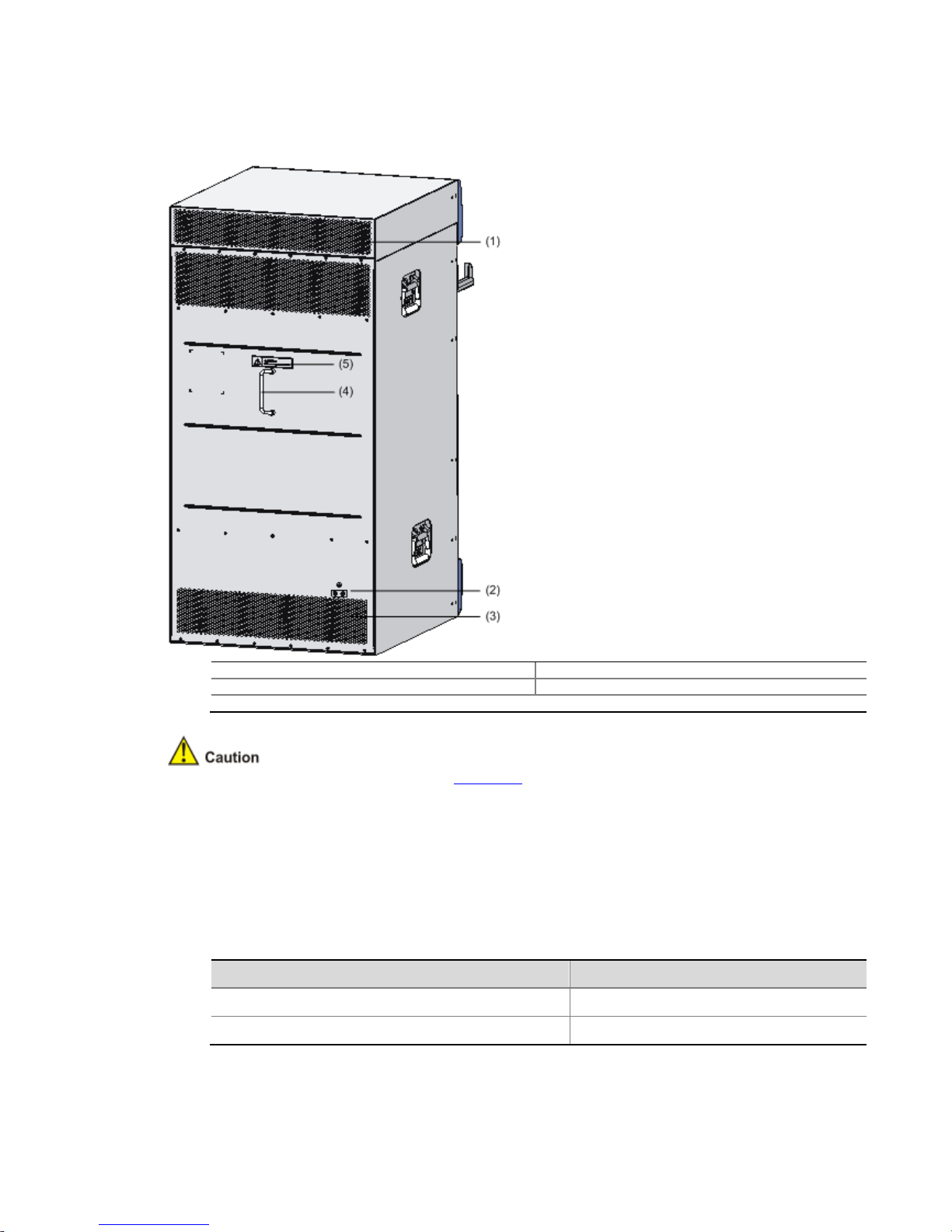

Rear View

Figure 1-3 Rear view of the A6616

(1) Air exhaust vents for the chassis (2) Grounding screw and sign

(3) Air exhaust vents for power modules (4) Handle on the rear chassis panel

(5) Warning label

Do not hold the handle indicated by (4) in Figure 1-3 on the rear chassis panel to move the

chassis because it is designed for the convenience of the rear chassis panel removal, but not

for bearing the chassis weight.

System Specifications

Dimensions and Weight

Table 1-2 Dimensions and weight

Item Specification

Dimensions without feet and mounting ears (H × W × D) 886 × 436 × 480 mm (34.9 × 17.2 × 18.9 in.)

Weight (fully configured) < 100 kg (220.5 lb.)

Page 9

Power Modules

Table 1-3 Power module specifications

Item Specification

Rated voltage range

AC powered: 100 VAC to 240 VAC; 50 Hz or 60 Hz

DC powered: –48 VDC to –60 VDC

Maximum input current

AC powered: 10 A

DC powered: 25 A

Maximum power provided by one power

module

650 W

Physical dimensions (H × W × D) 40 × 140 × 354 mm (1.57 × 5.51 ×13.94 in.)

Power module slots

Four power module slots are offered. The power modules must

have the same specifications.

Intelligent power supply management is supported.

Power module redundancy backup is recommended for high

reliability.

Power consumption range 97.5 W to 1166.5 W

Figure 1-4 AC power module

(1) Captive screw (2) Bail latch

(3) Power socket (4) Power switch

(5) Power LED (6) Power module handle

Page 10

Figure 1-5 DC power module

(1) Captive screw (2) Power input terminals

(3) Power switch (4) Power LED

(5) Power module handle

Table 1-4 Description of AC and DC power LEDs

Status Meaning

Solid green The power module is working normally.

Solid red The power module is faulty.

Intelligent Power Supply Management

The A6616 supports either AC or DC power supply. Power modules of different types cannot

operate on the same A6616.

The A6616 provides four power module slots. You are recommended to configure power

redundancy backup to ensure high reliability.

The A6616 supports FIP power-on priorities management, power redundancy management,

and power management. These functions effectively prevent service anomalies caused by

power failure.

The A6616 supports online insertion but not online removal of a power module.

Online refers to first switching off the power module and then removing it from the router or

inserting it into the router. Before doing that, make sure that the router is configured with

redundant power modules and the system services are running normally.

FIP power-on priorities management

The A6616 provides eight FIP slots, including Slot 0 through Slot 3, and Slot 6 through Slot 9.

You can configure FIPs with different power-on priorities, namely, Level 1 through Level 3.

Level 1 is the highest power-on priority, while Level 3 is the lowest.

The default power-on priority of an inserted FIP is Level 2. Use the power-supply policy

priority priority level slot slot number command to set the power-on priority of an inserted FIP.

Power redundancy management

To avoid service interruption caused by power module failure during the operation of a device,

you are recommended to configure power redundancy for the device. The redundant power

modules can automatically implement backup without further configurations.

Use the display power-supply command to view the system power information, so that you

can take countermeasures in time.

Page 11

Take 650 W power modules for example. If a device requires an actual operation power of 1000

W, you need to install two 650 W power modules to ensure normal working of the device.

Optionally, you can install altogether three such power modules with one of them for power

redundancy or four such power modules with two of them for power redundancy.

Power management

The A6616 supports power management. This function prevents a single faulty power module

from affecting the whole router, and hence ensures the normal operation of services.

To be more specific, after the MPU starts up, the online FIPs are powered on in descending

order of their priorities. FIPs with the same priority are powered on in ascending order of their

slot numbers. This process goes on until the system power is insufficient or all the FIPs are

powered on.

For example, on an A6616, suppose that the system power is sufficient. If FIP-200s are inserted

into Slot 1, Slot 3, Slot 7, and Slot 9 with power-on priorities Level 2, Level 3, Level 2, and Level

1 respectively, the FIP-200s are powered on in the order of Slot 9, Slot 1, Slot 7, and Slot 3.

Use the display power-supply command or the display power-supply verbose command to

view the power management information. You can manually power on or power off the FIPs as

needed, in order to adjust the available system power. Use the undo remove slot slot-number

command to power on the FIP in the specified slot. Use the remove slot slot-number command

to power off the FIP forcibly.

Do not power off a running power module. Otherwise, the power supply may be insufficient, and

a system power failure or FIP power failure may occur.

For details about commands in intelligent power supply management, refer to Device

Management in the System Volume of HP SR6600 Routers User Manual.

Fan Tray

Table 1-5 Fan tray specifications

Fan tray Specification

Number of fans 9 (supporting automatic fan speed adjustment)

Fay tray dimensions (H × W × D) 78.1 × 410.2 × 447.8 mm (3.07 × 16.15 × 17.63 in.)

Weight 5 kg (11.02 lb)

Failsafe Supported

Hot swappable Supported

Table 1-6 Description of fan tray LEDs

LED Status Meaning

RUN (green)

Off The system is powered off or the fan tray is faulty.

On The fan tray is working normally.

ALM (red)

Off The fan tray is working normally.

On The fan tray is faulty.

Page 12

Operating environment

Table 1-7 Operating environment specifications

Item Specification

Operating temperature 0°C to 45°C (32°F to 113°F)

Operating humidity 10% to 95%, noncondensing

Altitude –60 m to +4 km (–196.85 ft. to +2.49 miles)

System Software

The router uses the Comware V5 software platform, HP's core software platform.

Based on the IPv4/IPv6 dual stack, the Comware V5 software platform integrates link-layer

protocols, routing, Multi-Protocol Label Switching (MPLS), Virtual Private Network (VPN), quality

of service (QoS), security, and multicast technologies. It is scalable and portable because it

adopts a modular architecture and effectively encapsulates and masks different operating

systems and hardware. The Comware V5 software platform is the basis of all series of IP

network products of HP.

MPU

RPE-X1

Front view

Figure 1-6 Front view of the RPE-X1

(1) Captive screw (2) Ejector lever

(3) RESET button (RESET) (4) Run LED (RUN)

(5) Active LED of the RPE-X1 (ACT) (6) Alarm LED (ALM)

(7) Link state/data reception & transmission LED (LINK/ACT)

(8) Management Ethernet interface (MANAGEMENT) (10/100/1000BASE-T)

(9) Console port (CONSOLE) (10) CF card eject button

(11) AUX port (AUX) (12) CF card slot

(13) USB interface 0 (0) (host mode) (14) USB interface 1 (1) (device mode)

(15) CF LED (CF) (16) USB interface 1 LED (USB)

Technical specifications

Table 1-8 Technical specifications for the RPE-X1

Item Specification

Processor Power PC 1GHz

Processor cores 1

Flash 4 MB

Page 13

Item Specification

Memory type and size

DDR2 SDRAM

1 GB (default, one memory module)

2 GB (maximum)

NVRAM 128 KB

Console port 1 (9600 bps to 115200 bps, 9600 bps by default)

AUX port 1 (9600 bps to 115200 bps, 9600 bps by default)

Management Ethernet interface 1 (10Base-T/100Base-TX/1000Base-T)

CF card

256 MB by default for the built-in CF card

256 MB, 512 MB, or 1 GB for an optional external CF card (CF

cards less than 256 MB are not supported)

USB interfaces

2 (USB 0: Type A connector, operating in the host mode; USB 1:

Type B connector, operating in the device mode)

Reset Button 1

Dimensions (H × W × D) 40 × 199 × 282 mm (1.57 × 7.83 × 11.10 in.)

Power consumption 37 W

Hot swapping Supported

Flash is used for storing the boot file—the BootWare program.

The memory is used for storing the data during system operation and caching the data during

data forwarding.

The non-volatile random access memory (NVRAM) is used for storing the exception information

of the system during operation.

A CF card is used for storing the programs and configuration files of the device.

Hot-swapping a module refers to first using the remove slot slot-number command to stop the

module, and then manually pulling it out, or inserting the module into its slot without powering

off the device. For details about the remove slot command, refer to Device Management in the

System Volume of HP SR6600 Routers User Manual.

LEDs

Figure 1-7 LEDs on the RPE-X1

(1) Run LED (RUN) (2) Active LED (ACT) (3) Alarm LED (ALM)

(4) Ethernet link state/data reception & transmission LED (LINK/ACT)

(5) CF LED (CF) (6) USB interface 1 LED (USB)

Table 1-9 Description of the LEDs

LED Status Meaning

Device LEDs RUN (green) Off No power input is available, or the RPE-X1 is faulty.

Page 14

LED Status Meaning

Slow blinking

(1 Hz)

The RPE-X1 is operating normally.

Fast blinking

(8 Hz)

The application software is being loaded (in this case,

never power off the device or hot-swap the RPE-X1;

otherwise the RPE-X1 may be damaged).

ACT (green)

Off The RPE-X1 is in the standby state.

On The RPE-X1 is in the active state.

ALM (red)

Off The system is operating normally and there is no alarm.

On

A fault has occurred to the system or the power is

insufficient. In this state, you need to check the system

log immediately.

Fast blinking

(8 Hz)

A critical fault has occurred to the system. In this state,

you need to handle the fault immediately.

Management

Ethernet

interface LED

LINK/ACT

(yellow/green)

Solid yellow A 10/100 Mbps link is present.

Solid green A 1000 Mbps link is present.

Blinking

yellow

Data is being received or transmitted at a rate of 10/100

Mbps.

Blinking

green

Data is being received or transmitted at a rate of 1000

Mbps.

USB LED USB (green)

Off No host is connected to the device-mode USB interface.

On

A host is connected to the device-mode USB interface.

The USB cable can be unplugged in this state.

Blinking

Data is being transmitted or received through the devicemode USB interface. In this state, do not unplug the USB

cable.

CF LED CF (green)

Off No CF card is present or the CF card is not recognizable.

On A CF card is in position and has passed the POST.

Blinking

The system is accessing the CF card. In this state, do not

remove the CF card.

Do not remove the CF card when the CF LED is blinking. Otherwise, the file system on the CF

card will be damaged.

Page 15

RSE-X1

Front view

Figure 1-8 Front view of RSE-X1

(1) Captive screw (2) Ejector lever

(3) SMB coaxial clock interface (reserved) (4) RESET button (RESET)

(5) CF card eject button (6) CF card slot

(7) CF LED (CF) (8) USB interface 0 (0) (host mode)

(9) USB interface 1 (1) (device mode) (10) USB interface 1 LED (USB)

(11) Link state/data reception & transmission LED (LINK/ACT)

(12) Management Ethernet interface (MANAGEMENT) (10/100/1000BASE-T)

(13) Console port (CONSOLE) (14) AUX port (AUX)

(15) Active LED of the RSE-X1 (ACT) (16) Power management alarm LED (PALM)

(17) Run LED (RUN) (18) Alarm LED (ALM)

Technical specifications

Table 1-10 Technical specifications for the RSE-X1

Item Specification

Processor MIPS 1GHz

Number of processor cores 2

Flash 4 MB

Memory type and size

DDR2 SDRAM

2 GB (default, two memory modules)

2 GB (maximum)

NVRAM 128 KB

Console port 1 (9600 bps to 115200 bps, 9600 bps by default)

AUX port 1 (9600 bps to 115200 bps, 9600 bps by default)

Management Ethernet interface 1 (10Base-T/100Base-TX/1000Base-T)

CF card

256 MB by default for the built-in CF card

256 MB, 512 MB, or 1 GB for an optional external CF card (CF

cards less than 256 MB are not supported)

USB interfaces

2 (USB 0: Type A connector, operating in the host mode; USB 1:

Type B connector, operating in the device mode)

Reset button 1

Dimensions (H × W × D) 45 × 399 × 412 mm (1.77 × 15.71 × 16.22 in.)

Power consumption 75 W

Hot swapping Supported

Page 16

"Hot-swapping" a module refers to first using the remove slot slot-number command to stop the

module, and then manually pulling it out, or inserting the module into its slot without powering

off the device. For details about the remove slot command, refer to Device Management in the

System Volume of HP SR6600 Routers User Manual.

LEDs

Figure 1-9 LEDs on the RSE-X1

(1) CF LED (CF) (2) USB interface 1 LED (USB)

(3) Ethernet link state/data reception & transmission LED (LINK/ACT)

(4) Active LED of the RSE-X1 (ACT) (5) Power management alarm LED (PALM)

(6) Run LED (RUN) (7) Alarm LED (ALM)

Table 1-11 Description of the LEDs of the RSE-X1

LED Status Meaning

Device LEDs

RUN (green)

Off No power input is available, or the RSE-X1 is faulty.

Slow

blinking (1

Hz)

The RSE-X1 is operating normally.

Fast

blinking (8

Hz)

The application software is being loaded (in this case,

never power off the device or hot-swap the RSE-X1;

otherwise the RSE-X1 may be damaged).

ACT (green)

Off The RSE-X1 is in the standby state.

On The RSE-X1 is in the active state.

ALM (red)

Off The system is operating normally and there is no alarm.

On

A fault has occurred to the system. In this state, you need

to check the system log immediately.

Fast

blinking (8

Hz)

A critical fault has occurred to the system. In this state,

you need to handle the fault immediately.

PALM (red)

Off The system power supply is normal.

On The system power is insufficient.

Management

Ethernet

interface LED

LINK/ACT

(yellow/green)

Solid

yellow

A 10/100 Mbps link is present.

Solid green A 1000 Mbps link is present.

Blinking

yellow

Data is being received or transmitted at a rate of 10/100

Mbps.

Blinking

green

Data is being received or transmitted at a rate of 1000

Mbps.

USB LED USB (green) Off No host is connected to the device-mode USB interface.

Page 17

LED Status Meaning

On

A host is connected to the device-mode USB interface.

The USB cable can be unplugged in this state.

Blinking

Data is being transmitted or received through the devicemode USB interface. In this state, do not unplug the USB

cable.

CF LED CF (green)

Off No CF card is present or the CF card is not recognizable.

On A CF card is in position and has passed the POST.

Blinking

The system is accessing the CF card. In this state, do not

remove the CF card.

Do not remove the CF card when the CF LED is blinking. Otherwise, the file system on the CF

card will be damaged.

Components

An MPU is the control center of the device. It is responsible for:

Computing device routes and maintaining forwarding tables

Configuring and monitoring FIPs; updating and resetting FIPs or interface modules

Providing high-precision clock for the system and the real-time clock (RTC) function

Processor

The RPE-X1 uses the Power PC 1GHz processor as the routing processing engine.

The RSE-X1 uses the MIPS 1GHz processor as the routing processing engine.

Flash

The Flash size is 4 MB, of which 1 MB is used for storing the boot file—BootWare and the

remaining space for BootWare backup and important system parameters.

Memory

A memory module is used for storing the data exchanged between the system and the CPU.

The default memory size of the RPE-X1 is 1 GB (one 1 GB memory module) and the maximum

memory size is 2 GB. An RPE-X1 provides two memory slots in which you can insert two DDR2

SDRAMs of different sizes.

The DDR2 SDRAMs for the RPE-X1 have two sizes:

DDR2 SDRAM-512MB

DDR2 SDRAM-1GB

The default memory size of the RSE-X1 is 2 GB (two 1 GB memory modules) and the maximum

memory size is 2 GB. An RSE-X1 provides two memory slots in which you can insert two DDR2

SDRAM-1GB modules.

NVRAM

The NVRAM is 128 KB in size and is used for storing exception information of the system during

operation.

CF card

1) Introduction

A compact flash (CF) card is used for storing logs, host files, and configuration files.

The device is equipped with a built-in 256 MB CF card, which is identified with cfa0. In addition,

the device provides an external CF card slot to expand the local storage space. A CF card

inserted into the external CF card slot is identified with cfb0.

The CF cards supported by the device are available in three sizes:

256 MB

Page 18

512 MB

1 GB

Use CF cards provided by HP only. The device may be incompatible with other CF cards.

CF cards less than 256 MB are not supported.

2) CF card and slot

Figure 1-10 CF card and slot

(1) Eject button (CF card) (2) CF card slot (3) CF LED (CF)

3) CF LED

For the description of the CF LED, see Table 1-9 and Table 1-11.

The CF card is hot-swappable. When the CF LED is blinking, do not unplug the CF card.

Otherwise, the file system on the CF card will be damaged.

Console port

1) Introduction

The router provides an RS-232 asynchronous serial console port that can be connected to a

computer for system debugging, configuration, maintenance, management, and host software

loading.

2) Technical specifications for the console port

Table 1-12 Technical specifications for the console port

Item Specification

Connector RJ-45

Compliant standard Asynchronous EIA/TIA-232

Baud rate

9600 bps to 115200 bps

9600 bps (default)

Transmission Distance ≤ 15 m (49.21 ft.)

Services

Connection to an ASCII terminal

Connection to the serial interface of a local PC to run the terminal

emulation program

Command line interface (CLI)

3) Console cable

The console cable is an 8-core shielded cable. The RJ-45 connector at one end of the cable is

for the console port on the router, and the DB-9 female connector at the other end is for the

serial port on a configuration terminal.

Figure 1-11 illustrates the console cable.

Page 19

Figure 1-11 Console cable

Table 1-13

Console cable connector pinouts

RJ-45 pin

1

2

3

4

5

6

7

8

For the connection of the console cable, refer to “Connecting the Console Cable” in Chapter 4

“Installing the Router”

AUX port

1) Introduction

The AUX port is an RS-

232 asynchronous serial interface used for remote configuration or

dialup backup. You need to connect the local modem to the remote modem through PSTN and

then to the remote device for remote system deb

management. In the event that the console port fails, the AUX port can be connected to a

terminal as a backup port of the console port. For details, refer to “Using the Port AUX as

Backup Console Port” in Chapter 7 “

2)

Technical specifications for the AUX port

Table 1-14

Technical specifications for the AUX port

Item

Connector

Compliant standard

Baud rate

Services

3) AUX cable

The AUX cable is an 8-

core shielded cable. At one end of the cable is an RJ

which is connected to the AUX port on the router. At the other end are a DB

Signal direction DB-9 pin

8

6

2

1

— 5

3

4

7

ugging, configuration, maintenance, and

Troubleshooting.”

Specification

RJ-45

Asynchronous EIA/TIA-232

9600 bps to 115200 bps

9600 bps (default)

Used to connect the serial interface of a remote PC through a pair of

modems to establish a dial-

up connection with the PC

-

9 (male) connector

Signal

CTS

DSR

RXD

DCD

GND

TXD

DTR

RTS

-45 connector,

Page 20

and a DB-

25 (male) connector, of which you can select one to the serial

needed.

Figure 1-12

AUX cable connectors

Table 1-15

AUX cable connector pinouts

RJ-45 pin

1

234

5

—

6

78

For the connection of the AUX cable, refer to “Connecting the AUX Port to a Modem” in Chapter

4 “Installing the Router.”

USB interfaces

Universal serial bus (USB) interfaces can connect multiple types of devices and provide a

higher data transfer rate than common parallel interfaces and serial interfaces.

The device fully supports USB 1.1. The USB interfaces of the device allow for conven

storage.

Figure 1-13 USB interfaces

(1) USB interface 0

1) USB interface 0

port on a modem as

Signal direction DB-25 pin DB-

9 pin

4 7

20 4

2 3

8 1

7 5

3 2

6 6

5 8

(2) USB interface 1

(3) USB interface 1 LED

Signal

RTS

DTR

TXD

DCD

GND

RXD

DSR

CTS

ient

Page 21

USB interface 0 on the device is a USB 1.1-compliant type-A interface. USB interface 0 can be

connected to an external USB storage device to expand the router’s storage space for storing

files and logs and facilitate file transfer.

Insert and remove a USB storage device correctly. Otherwise, the software, hardware and file

system of the USB storage device may get damaged.

After you insert a USB storage device and information is displayed on the terminal, prompting

the USB storage device is inserted into the device, the LED on the USB storage device will be

on.

When the LED on the USB storage device is blinking, do not remove the USB storage device.

Before removing the USB storage device, execute the umount usba0: command in user view

to unmount the USB storage device. If the information that the USB storage device is

successfully unmounted is displayed on the terminal, you can remove the USB storage device.

After the USB storage device is removed, information will also be displayed on the terminal,

prompting the USB storage device has been removed.

The device only supports the USB storage devices provided by HP and may be incompatible

with those from other manufacturers.

For details about the umount command, refer to File System Management in the System

Volume of HP SR6600 Routers User Manual.

2) USB interface 1 and LED

USB interface 1 on the device is a USB 1.1-compliant type-B interface. USB interface 1 can be

connected to a host device through a standard USB cable. The host recognizes the device as

an external storage device so that you can access the internal CF card quickly and perform file

operations on it. For the description of the USB 1 status LED, see Table 1-9.

Management Ethernet interface

The management Ethernet interface is a 10Base-T/100Base-TX/1000Base-T RJ-45 interface. It

allows you to upgrade software and manage the router through a network management server

without using any service interface of the router. The management Ethernet interface is used

only for managing the device and it has no service processing capabilities such as data

forwarding.

Table 1-16 Technical specifications for the management Ethernet interface

Item Specification

Connector RJ-45

Number of interfaces 1

Interface type Automatic MDI/MDI-X

Frame format

Ethernet_II

Ethernet_SNAP

Interface speed and duplex mode

10 Mbps, half/full-duplex

100 Mbps, half/full-duplex

1000 Mbps, full-duplex

Interface cable and maximum

transmission distance

Straight-through or crossover cable, Category-5 twisted pair with a

maximum transmission distance of 100 m (328.08 ft.)

Function Used for router software upgrading and network management

The media dependent interface (MDI) standard is typically used on the Ethernet interface of

network adapters. The media dependent interface crossover (MDI-X) standard is typically used

on hubs or LAN switches.

Page 22

RESET button

To reset the current RPE-X1, you can press the RESET button.

If you press the RESET button when only one RPE-X1 is equipped, the whole system will be

reset.

If you want to perform an active-standby switchover when two RPE-X1s are equipped, press

the RESET button on the active RPE-X1. The system will automatically switch the services to

the standby RPE-X1, without interrupting the ongoing services.

If you press the RESET button on the standby RPE-X1 when two RPE-X1s are equipped, the

standby RPE-X1 will be reset but the system operation will not be affected.

The RUN LED goes off when the RPE-X1 is reset, flashes fast (at 8 Hz) when BootWare is

running, and flashes slowly (at 1 Hz) after the system is booted and operates normally.

If you perform no save operation before resetting the router, the current system configuration

will not be saved after the router is reset.

Never press the RESET button when the RUN LED is blinking fast or when the router is

accessing the CF card or a USB storage device. Otherwise, the file system of the router may be

damaged.

Clock

The device is designed with an internal clock module that provides the system time. You can set

the system time through a command line interface. Use the clock datetime time date command

in user view to set the system date and time. For the description of the clock datetime

command, refer to Basic System Configuration in the System Volume of HP SR6600 Routers

User Manual.

When a power failure occurs to the router, the clock module can continue working to ensure the

system time is correct next time the router boots. With the router powered off, the clock module

can work for at least 10 years.

When the router is powered on, note the following points:

Never replace the clock module battery.

The system time gets lost once the clock module battery is removed, and you need to set the

system time again through the command line interface. However, the system time will still get

lost after the router is powered off.

Switchover between the active and standby MPUs

The device can be equipped with two RPE-X1s. One is active and operates in the master mode,

and the other is standby and operates in the slave mode. By default, the MPU in Slot 5 operates

in the master mode. The configuration of the standby MPU is synchronized with that of the

active MPU. Thus, in the event that the active MPU fails, the standby MPU immediately

becomes active to ensure that the device works properly and its configuration is synchronized

with that of the original active MPU. This process is known as active-standby switchover.

An active-standby switchover occurs when:

The active MPU fails.

The active MPU is removed.

A remote switchover is performed through SNMP.

A manual switchover is performed.

The active-standby switchover process is as follows:

1) The standby MPU automatically connects and controls the system bus while the original active

MPU disconnects the system bus.

2) The standby MPU goes active whereas the original active MPU automatically reboots and goes

standby.

You can use the slave switchover command to perform a manual active-standby switchover.

For details about the slave switchover command, refer to HA in the System Volume of HP

SR6600 Routers User Manual.

Page 23

The standby MPU does not support any system configuration commands. Therefore, you

cannot execute any commands on the standby MPU unless it goes active.

When the standby MPU is started, the active MPU will initially synchronize the standby MPU. If

you press Enter on the terminal during synchronization, the system will display on the active

and standby MPUs that no command can be entered. After the initial synchronization is

completed, you can execute the configuration commands on the active MPU, and the standby

MPU keeps synchronized with the active MPU in real time way (the configuration on the active

MPU is copied to the standby MPU).

Do not use centralized device–specific software to update the router that supports the active-

standby switchover feature. Otherwise, the router may become unavailable.

FIPs

FIP-100

Introduction

The FIP-100 supports MIMs only. It provides high-density narrowband aggregation, and hence

can protect legacy investment. The FIP-100 supports four MIMs at the same time.

Figure 1-14 Front view of the FIP-100

(1) Slot 1 (2) Slot 2

(3) Slot 3 (4) Slot 4

(5) Combo interface 0 (6) Combo interface 1

(7) OPEN BOOK sign

"OPEN BOOK" sign – Refer to related sections when performing the following operations:

Operation Reference

Plug/unplug a FIP-100 “Installing and Removing a FIP” in Chapter 4 “Installing the Router”

Plug/unplug a MIM “Installing and Removing a MIM” in Chapter 4 “Installing the Router”

Connect an Ethernet cable

“Connecting the Management Ethernet Interface” and “Connecting

Ethernet Cables” in Chapter 4 “Installing the Router”

Plug/unplug an optical fiber

“Connecting an optical Ethernet interface” in Chapter 4 “Installing the

Router”

Technical specifications

Table 1-17 Technical specifications for the FIP-100

Item Specification

Processor Power PC 1 GHz

Processor cores 1

Flash 4 MB

Page 24

Item Specification

Memory type and size

DDR2 SDRAM

1 GB (default, one 1 GB memory module)

2 GB (maximum)

NVRAM 128 KB

Combo interfaces

2

2 electrical interfaces

(automatic MDI/MDIX)

10 Mbps, half/full-duplex

100 Mbps, half/full-duplex

1000 Mbps, full-duplex

2 optical interfaces 1000 Mbps, full-duplex

HIM Not supported

MIM 4 MIMs supported at the same time

Dimensions (H × W × D) 45 × 399 × 412 mm (1.77 × 15.71 × 16.22 in.)

Hardware encryption Supported

Power consumption 50 W

hot-swapping Supported

For a Combo interface, the default operating interface is the electrical interface.

For a Combo interface, you can use either the electrical Ethernet interface or the optical

Ethernet interface. You can use the combo enable { copper | fiber } command in interface

view to switch between the optical and electrical interfaces. For details about the combo

enable { copper | fiber } command, refer to Ethernet Interfaces in the Access Volume of HP

SR6600 Routers User Manual.

Use optical transceivers provided by HP only. The device may be incompatible with other

optical transceivers and thus displays alarms automatically.

"Hot-swapping" a module refers to first using the remove slot slot-number command to stop

the module, and then manually pulling it out, or inserting the module into its slot without

powering off the device. For details about the remove slot command, refer to Device

Management in the System Volume of HP SR6600 Routers User Manual.

LEDs

Figure 1-15 FIP-100 LEDs

(1) LED for 10/100/1000 Mbps electrical Ethernet interface 0 (GE0)

(2) LED for 10/100/1000 Mbps electrical Ethernet interface 1 (GE1)

(3) 1000 Mbps optical Ethernet interface LED (SFP0)

Page 25

(4) 1000 Mbps optical Ethernet interface LED (SFP1)

(5) Run LED (RUN)

Table 1-18 Description of FIP-100 LEDs

LED Status Meaning

RUN (green)

Off No power input is available or the FIP-100 has failed.

Slow blinking (1 Hz) The FIP-100 is working normally.

Fast blinking (8 Hz)

Application program is being loaded (in this case, never power

off the device or hot-swap the FIP-100; otherwise, the FIP-100

may be damaged) or the FIP-100 is not working.

SFP0 and SFP1

(yellow/green)

Off No optical link is present.

Solid green An optical link is present.

Blinking green Data is being sent or received at a rate of 1000 Mbps.

Solid yellow The optical transceiver has failed in POST.

GE0 and GE1

(yellow/green)

Off No link is present.

Solid green A 1000 Mbps link is present.

Blinking green Data is being received or transmitted at a rate of 1000 Mbps.

Solid yellow A 10/100 Mbps link is present.

Blinking yellow Data is being received or transmitted at a rate of 10/100 Mbps.

Slots

FIP-100s can be inserted into Slot 0 through Slot 3, and Slot 6 through Slot 9 on the A6616. The

slots on a FIP-100 are numbered 1 to 4 from the bottom up and from right to left, as shown in

Figure 1-16.

Figure 1-16 Interface module slots on the FIP-100

The numbers 1 through 4 in Figure 1-16 represent Slot 1 through Slot 4 respectively.

Maximum interface modules provided by FIP-100s in full configuration

Table 1-19 Maximum interface modules provided by FIP-100s in full configuration

Interface module One RPE-X1 Two RPE-X1s One RSE-X1 Two RSE-X1s

FIP-100 8 8 Not supported Not supported

MIMs 32 32 — —

HIMs Not supported Not supported Not supported Not supported

Page 26

FIP-110

Introduction

The FIP-110 supports MIMs only. It provides high-density narrowband aggregation, and hence

can protect legacy investment. The FIP-110 supports four MIMs at the same time.

Figure 1-17 Front view of the FIP-110

(1) Slot 1 (2) Slot 2

(3) Slot 3 (4) Slot 4

(5) OPEN BOOK sign (6) Combo interface 0

(7) Combo interface 1

"OPEN BOOK" sign – Refer to related sections when performing the following operations:

Operation Reference

Plug/unplug a FIP-110 “Installing and Removing a FIP” in Chapter 4 “Installing the Router”

Plug/unplug a MIM “Installing and Removing a MIM” in Chapter 4 “Installing the Router”

Connect an Ethernet cable

“Connecting the Management Ethernet Interface” and “Connecting

Ethernet Cables” in Chapter 4 “Installing the Router”

Plug/unplug an optical fiber

“Connecting an optical Ethernet interface” in Chapter 4 “Installing the

Router”

Technical specifications

Table 1-20 Technical specifications for the FIP-110

Item Specification

Processor MIPS 1 GHz

Processor cores 2

Flash 4 MB

Memory type and size

DDR2 SDRAM

1 GB (default, one 1 GB memory module)

2 GB (maximum)

NVRAM 128 KB

Combo interfaces

2

2 electrical interfaces

(automatic MDI/MDIX)

10 Mbps, half/full-duplex

100 Mbps, half/full-duplex

1000 Mbps, full-duplex

2 optical interfaces 1000 Mbps, full-duplex

HIM Not supported

Page 27

Item

MIM

Dimensions (H × W × D)

Hardware encryption

Power consumption

hot-swapping

For a Combo interface, the default operating interface is the

For a Combo interface, you can use either the electrical Ethernet interface or the optical

Ethernet interface. You can use the

view to switch between the optical and elec

enable { copper | fiber

} command, refer to

SR6600 Routers

User Manual

Use optical transceivers provided by

optical transceivers and thus displays alarms automatically.

"Hot-

swapping" a module refers to first using the

the module, and then manually pulling it out, or inserting the module into its slot without

powering off the device. For details about the

Management in the

System Volume

LEDs

Figure 1-18 FIP-110 LEDs

(1) LED for 10/100/1000 Mbps electrical Ethernet interface 0 (GE0)

(2) LED for 10/100/1000 Mbps electrical Ethernet interface 1 (GE1)

(3) Run LED (RUN)

(4) 1000 Mbps optical Ethernet interface LED (SFP1)

(5) 1000

Mbps optical Ethernet interface LED (SFP0)

Table 1-21

Description of FIP

LED

RUN (green)

Off

Slow blinking (1 Hz)

Fast blinking (8 Hz)

Specification

4 MIMs supported at the same time

45 × 399 × 412 mm (1.77 × 15.71 × 16.22 in.)

Supported

75 W

Supported

electrical interface.

combo enable { copper | fiber

} command in interface

trical interfaces. For details about the

Ethernet Interfaces in the

Access Volume

.

HP

only. The device may be incompatible with other

remove slot slot-number

remove slot

command, refer to

of HP SR6600 Routers User Manual.

-110 LEDs

Status

Meaning

No power input is available or the FIP

The FIP-

110 is working normally.

Application program is being loaded (in this case, never power

off the device or hot-

swap the FIP

may be damaged) or the FIP-

110 is not working.

combo

of HP

command to stop

Device

-110 has failed.

-110; otherwise, the FIP-110

Page 28

LED Status Meaning

SFP0 and SFP1

(yellow/green)

Off No optical link is present.

Solid green An optical link is present.

Blinking green Data is being sent or received at a rate of 1000 Mbps.

Solid yellow The optical transceiver has failed in POST.

GE0 and GE1

(yellow/green)

Off No link is present.

Solid green A 1000 Mbps link is present.

Blinking green Data is being received or transmitted at a rate of 1000 Mbps.

Solid yellow A 10/100 Mbps link is present.

Blinking yellow Data is being received or transmitted at a rate of 10/100 Mbps.

Slots

FIP-110s can be inserted into Slot 0 through Slot 3, and Slot 6 through Slot 9 on the A6616. The

slots on a FIP-110 are numbered 1 to 4 from the bottom up and from right to left, as shown in

Figure 1-19.

Figure 1-19 Interface module slots on the FIP-110

The numbers 1 through 4 in Figure 1-19 represent Slot 1 through Slot 4 respectively.

Maximum interface modules provided by FIP-110s in full configuration

Table 1-22 Maximum interface modules provided by FIP-110s in full configuration

Interface module One RPE-X1 Two RPE-X1s One RSE-X1 Two RSE-X1s

FIP-110 8 8 8 7

MIMs 32 32 32 28

HIMs Not supported Not supported Not supported Not supported

FIP-200

Introduction

The FIP-200 provides a high-speed service processing capability. The FIP-200 supports

SR6600 HIMs and MIMs, and provides two Combo interfaces. In consideration of smooth

upgrade requirements, the FIP-200 supports two HIMs or two MIMs, or intermixing of a HIM and

a MIM. The FIP-200 is hot-swappable.

Page 29

Figure 1-20 Front view of the FIP-200

(1) Slot 1 (2) Slot 2

(3) Combo interface 0 (4) Combo interface 1

(5) OPEN BOOK sign

"OPEN BOOK" sign – Refer to related sections when performing the following operations:

Operation Reference

Plug/unplug a FIP-200 “Installing and Removing a FIP” in Chapter 4 “Installing the Router”

Plug/unplug an interface module

"Installing and Removing a HIM" and “Installing and Removing a

MIM” in Chapter 4 “Installing the Router”

Connect an Ethernet cable

“Connecting the Management Ethernet Interface” and “Connecting

Ethernet Cables” in Chapter 4 “Installing the Router”

Plug/unplug an optical fiber

“Connecting an optical Ethernet interface" in Chapter 4 “Installing

the Router”

Technical specifications

Table 1-23 Technical specifications for the FIP-200

Item Specifications

Processor MIPS 1 GHz

Processor cores 8

Flash 4 MB

Memory type and size

DDR2 SDRAM

1 GB (default, two 512 MB memory modules)

2 GB (maximum, 1.5 GB not supported)

Memory modules must be used in pairs. Make sure they are of the same type

and size.

NVRAM 128 KB

Combo interfaces

2

2 electrical interfaces

(automatic MDI/MDI-X)

10 Mbps, half/full-duplex

100 Mbps, half/full-duplex

1000 Mbps, full-duplex

2 optical interfaces 1000 Mbps, full-duplex

HIMs 2

MIMs 2

Dimensions (H × W × D) 45 × 399 × 412 mm (1.77 × 15.71 × 16.22 in.)

Hardware encryption Supported

Page 30

Item

Power consumption

Hot-swapping

For

a Combo interface, the default operating interface is the electrical interface.

For a Combo interface, you can use either the electrical Ethernet interface or the optical

Ethernet interface. You can use the

view to switch between the optical and electrical interfaces. For details about the

enable { copper | fiber

} command, refer to

SR6600 Routers

User Manual

Use optical transceivers provided by

optical transceivers and thus displays alarms automatically.

"Hot-

swapping" a module refers to first using the

the module, and then manually pulling it out, or inserting the module into its slot without

powering off the device. For details about the

Management in the

System Volume

LEDs

Figure 1-21 FIP-200 LEDs

(1) LED for 10/100/1000 Mbps electrical Ethernet interface 0 (GE0)

(2) LED for 10/100/1000 Mbps electrical Ethernet interface 1 (GE1)

(3) 1000 Mbps optical Ethernet interface LED (SFP0)

(4) 1000 Mbps optical

Ethernet interface LED (SFP1)

(5) Run LED (RUN)

Table 1-24

Description of FIP

LED

RUN (green)

Off

Slow blinking (1 Hz)

Fast blinking

SFP0 and SFP1

(yellow/green)

Off

Solid green

Blinking green

Solid yellow

Specifications

125 W

Supported

combo enable { copper | fiber

} comman

Ethernet Interfaces in the

Access Volume

.

HP

only. The device may be incompatible with other

remove slot slot-number

remove slot

command, refer to

of HP SR6600 Routers User Manual.

-200 LEDs

Status

Meaning

No power input is available or the FIP

The FIP-

200 is working normally.

(8 Hz)

Application program is being loaded (in this case, never power

off the device or hot-

swap the FIP

may be damaged).

No optical link is present.

An optical link is present.

Data is being sent or received at a rate of 1000 Mbps.

The optical transceiver has failed in POST.

d in interface

combo

of HP

command to stop

Device

-200 has failed.

-200; otherwise, the FIP-200

Page 31

LED Status Meaning

GE0 and GE1

(yellow/green)

Off No link is present.

Solid green A 1000 Mbps link is present.

Blinking green Data is being received or transmitted at a rate of 1000 Mbps.

Solid yellow A 10/100 Mbps link is present.

Blinking yellow Data is being received or transmitted at a rate of 10/100 Mbps.

Slots

FIP-200s can be inserted in Slot 0 through Slot 3 and Slot 6 through Slot 9 on the A6616. The

interface module slots on a FIP-200 are numbered 1 and 2 from right to left, as shown in Figure

1-22.

Figure 1-22 Interface module slots on the FIP-200

The numbers 1 and 2 in Figure 1-22 represent Slot 1 and Slot 2 respectively.

If only one MIM module is to be inserted into the FIP-200, it should be inserted into Slot 2

because only this slot has a connector.

Maximum interface modules provided by FIP-200s in full configuration

Table 1-25 Maximum interface modules provided by FIP-200s in full configuration

Interface module One RPE-X1 Two RPE-X1s One RSE-X1 Two RSE-X1s

FIP-200 8 8 Not supported Not supported

MIMs 16 16 — —

HIMs 16 16 — —

FIP-210

Introduction

The FIP-210 provides a high-speed service processing capability. The FIP-210 supports

SR6600 HIMs and MIMs. In consideration of smooth upgrade requirements, the FIP-210

supports two HIMs or two MIMs, or intermixing of a HIM and a MIM.

Figure 1-23 Front view of the FIP-210

(1) Slot 1 (2) Slot 2

(3) OPEN BOOK sign (4) Combo interface 1

Page 32

(5) Combo interface 0

"OPEN BOOK" sign – Refer to related sections when performing the following operations:

Operation Reference

Plug/unplug a FIP-210 “Installing and Removing a FIP” in Chapter 4 “Installing the Router”

Plug/unplug an interface module

"Installing and Removing a HIM" and “Installing and Removing a

MIM” in Chapter 4 “Installing the Router”

Connect an Ethernet cable

“Connecting the Management Ethernet Interface” and “Connecting

Ethernet Cables” in Chapter 4 “Installing the Router”

Plug/unplug an optical fiber

“Connecting an optical Ethernet interface" in Chapter 4 “Installing

the Router”

Technical specifications

Table 1-26 Technical specifications for the FIP-210

Item Specifications

Processor MIPS 1 GHz

Processor cores 8

Flash 4 MB

Memory type and size

DDR2 SDRAM

2 GB (default, two 1 GB memory modules)

2 GB (maximum)

NVRAM 128 KB

Combo interfaces

2

2 electrical interfaces

(automatic MDI/MDI-X)

10 Mbps, half/full-duplex

100 Mbps, half/full-duplex

1000 Mbps, full-duplex

2 optical interfaces 1000 Mbps, full-duplex

HIMs 2

MIMs 2

Dimensions (H × W × D) 45 × 399 × 412 mm (1.77 × 15.71 × 16.22 in.)

Hardware encryption Supported

Power consumption 125 W

Hot-swapping Supported

Page 33

For a Combo interface, the default operating interface is the electrical interface.

For a Combo interface, you can use either the electrical Ethernet interface or the optical

Ethernet interface. You can use the

view to switch between the optical and electrical interfaces. For details ab

enable { copper | fiber

} command, refer to

SR6600 Routers

User Manual

Use optical transceivers provided by

optical transceivers and thus displays alarms automatically.

"Hot-

swapping" a module refers to first using the

the module, and then manually pulling it out, or inserting the module into its slot without

powering off the device. For details about the

Management in the

System Volume

LEDs

Figure 1-24 FIP-210 LEDs

(1) LED for 10/100/1000 Mbps electrical Ethernet interface 0 (GE0)

(2) LED for 10/100/1000 Mbps electrical Ethernet interface 1 (GE1)

(3) Run LED (RUN)

(4) 1000 Mbps optical Ethernet interface LED (SFP1)

(5) 1000

Mbps optical Ethernet interface LED (SFP0)

Table 1-27

Description of FIP

LED

RUN (green)

Off

Slow blinking (1 Hz)

Fast blinking (8 Hz)

SFP0 and SFP1

(yellow/green)

Off

Solid green

Blinking green

Solid yellow

GE0 and GE1

(yellow/green)

Off

Solid green

Blinking green

Solid yellow

combo enable { copper | fiber

} command in interface

Ethernet Interfaces in the

Access Volume

.

HP

only. The device may be incompatible with other

remove slot slot-number

remove slot

command, refer to

of HP SR6600 Routers User Manual.

-210 LEDs

Status

Meaning

No power input is available or the FIP

The FIP-

210 is working normally.

Application program is being loaded (in this case, never power

off the device or hot-

swap the FIP

may be damaged).

No optical link is present.

An optical link is present.

Data is being sent or received at a rate of 1000 Mbps.

The optical transceiver has failed in POST.

No link is present.

A 1000 Mbps link is present.

Data is being

received or transmitted at a rate of 1000 Mbps.

A 10/100 Mbps link is present.

out the combo

of HP

command to stop

Device

-210 has failed.

-210; otherwise, the FIP-210

Page 34

LED Status Meaning

Blinking yellow Data is being received or transmitted at a rate of 10/100 Mbps.

Slots

FIP-210s can be inserted in Slot 0 through Slot 3 and Slot 6 through Slot 9 on the A6616. The

interface module slots on a FIP-210 are numbered 1 and 2 from right to left, as shown in Figure

1-25.

Figure 1-25 Interface module slots on the FIP-210

The numbers 1 and 2 in Figure 1-25 represent Slot 1 and Slot 2 respectively.

If only one MIM module is to be inserted into the FIP-210, it should be inserted into Slot 2

because only this slot has a connector.

Maximum interface modules provided by FIP-210s in full configuration

Table 1-28 Maximum interface modules provided by FIP-210s in full configuration

Interface module One RPE-X1 Two RPE-X1s One RSE-X1 Two RSE-X1s

FIP-210 8 8 8 7

MIMs 16 16 16 14

HIMs 16 16 16 14

Detailed Descriptions of FIPs

Ethernet interface introduction

The FIP of the router provides two Combo interfaces, each of which consists of an electrical

Ethernet interface and an optical Ethernet interface. The default operating interface is the

electrical Ethernet interface.

For the rate and duplex mode when the electrical Ethernet interface is operating, see Table 1-

29.

Table 1-29 Rate and duplex mode when the electrical Ethernet interface is operating

Rate Duplex mode

10 Mbps Half/full-duplex auto-negotiation

100 Mbps Half/full-duplex auto-negotiation

1000 Mbps Full-duplex

The electrical Ethernet interface LEDs are above the RJ-45 connectors. The LEDs in triangle

and inverted triangle indicate the status of the lower and upper electrical Ethernet interfaces,

respectively. For the description of the electrical Ethernet interface LEDs, see Table 1-18, Table

1-21, Table 1-24, and Table 1-27.

The optical Ethernet interface supports 1000 Mbps in full-duplex mode. The optical Ethernet

interface LEDs are on the left of the two Combo interfaces and use separate LEDs to indicate

the status of the corresponding optical Ethernet interfaces. For the description of the optical

Ethernet interface LEDs, see Table 1-18, Table 1-21, Table 1-24, and Table 1-27.

Page 35

Figure 1-26 Combo interfaces on a FIP-100

(1) 1000 Mbps optical Ethernet interface (SFP1)

(2) 10/100/1000 Mbps electrical Ethernet interface (GE0) LED

(3) 10/100/1000 Mbps electrical Ethernet interface (GE1)

(4) 10/100/1000 Mbps electrical Ethernet interface (GE1) LED

(5) 10/100/1000 Mbps electrical Ethernet interface (GE0)

(6) 1000 Mbps optical Ethernet interface (SFP0)

(7) 1000 Mbps optical Ethernet interface (SFP0) LED

(8) 1000 Mbps optical Ethernet interface (SFP1) LED

(9) Run LED (RUN)

For a Combo interface, you can use either the electrical Ethernet interface or the optical

Ethernet interface. You can use the combo enable { copper | fiber } command in interface

view to switch between the optical and electrical Ethernet interfaces. For details about the

combo enable { copper | fiber } command, refer to Ethernet Interfaces in the Access Volume

of HP SR6600 Routers User Manual.

Technical specifications for Combo interfaces

Technical specifications for electrical Ethernet interfaces

Table 1-30 Technical specifications for electrical Ethernet interfaces

Item Specification

Connector RJ-45

Interface type Automatic MDI/MDI-X

Frame format

Ethernet_II

Ethernet_SNAP

Rate and duplex mode

10 Mbps, half/full-duplex

100 Mbps, half/full-duplex

1000 Mbps, full-duplex

The media dependent interface (MDI) is a typical Ethernet interface provided by network

adapters. The media dependent interface crossover (MDI-X) is commonly found on hubs or

LAN switches.

When 10/100 Mbps and half duplex/full duplex are specified for an electrical Ethernet interface,

the electrical Ethernet interface operates in the forced mode. When 1000 Mbps is specified or

Page 36

the rate and the duplex mode are not simultaneously specified for an electrical Ethernet

interface, the electrical Ethernet interface operates in the auto-negotiation mode.

No matter whether an electrical Ethernet interface operates in the forced or auto-negotiation

mode, it supports automatic MDI/MDI-X.

Technical specifications for optical Ethernet interfaces

Table 1-31 Technical specifications for 1000 Mbps optical Ethernet interfaces

Item Specification

Connector SFP/LC

Compliant standard 802.3, 802.3u, and 802.3ab

Optical

transmit

power

Type

Short-haul

multimode

optical

interface

module (850

nm)

Medium-haul

single-mode

optical interface

module (1310

nm)

Long-haul

Optical

interface

module

(1310 nm)

Long-haul

optical

interface

module

(1550 nm)

Ultra-long

haul optical

interface

module

Min –9.5 dBm –9 dBm –2 dBm –4 dBm –4 dBm

Max 0 dBm –3 dBm 5d Bm 1 dBm 2 dBm

Receiving

sensitivity

–17 dBm -20 dBm –23 dBm –21 dBm –22 dBm

Central wavelength 850 nm 1310 nm 1310 nm 1550 nm 1550 nm

Fiber type

62.5/125 μm

multimode

fiber

9/125 μm singlemode fiber

9/125 μm

single-mode

fiber

9/125 μm

single-mode

fiber

9/125 μm

single-mode

fiber

Maximum

transmission

distance

0.55 km (0.34

miles)

10 km (6.21

miles)

40 km (24.86

miles)

40 km (24.86

miles)

70 km (43.50

miles)

Operating mode 1000 Mbps in full duplex mode

Use optical transceivers provided by HP only. The device may be incompatible with other

optical transceivers and thus displays alarms automatically.

RJ-45 connector

The 10Base-T/100Base-TX/1000Base-T electrical Ethernet interfaces of the device use RJ-45

connectors and support MDI/MDI-X auto-sensing. Category-5 twisted pair cables are used for

RJ-45 connectors. Figure 1-27 shows the appearance of an RJ-45 connector.

Figure 1-27 RJ-45 connector

Page 37

LC connector and SC connector

Optical fiber connectors are indispensable passive components in optical fiber communication

system. Their application enables the removable connection between optical channels, which

makes the optical system debugging and

dispatching of the system more flexible.

Some optical fiber connector types are as follows:

LC: square optical fiber connector of the push

SC: standard optical fiber conn

FC: round optical fiber connector with screw thread

ST: round plug-

in optical fiber connector

MT-

RJ: square transceiver optical fiber connector

Currently, the HP

SR6600 routers support only the LC connectors.

Figure 1-28 LC connector

Before plugging or unplugging a fiber, make sure that the received optical power at the local

end does not exceed the upper threshold of the optical receive power of the optical transceiver.

Otherwise, the optical transceiver

Cable connecting a 1000 Mbps electrical Ethernet interface

Usually, you can use a category

interface. Figure 1-29

shows an Ethernet

Figure 1-29 Ethernet cable

Ethernet cables fall into the following two categories:

Standard cable: Also called straight

crimped in the RJ-

45 connectors in the same sequence. a straight

connect a terminal (for example, PC or router) to a hub or LAN Switch.

with the router are straight-

through cables.

Crossover cable: At both ends of a crossover cable, wires are crimped in the RJ

in different sequences. A crossover cable is used to connect a (for example, PC or

another terminal. You can make crossover cables by yourself as needed.

Table 1-32 Straight-

through cable connector pinouts

RJ-45 pin

1 Tx+

2 Tx–

3 Rx+

4 —

maintenance more convenient and the transit

-pull snap-in type

ector

may be damaged.

-

5 twisted pair cable to connect a 1000 Mbps electrical Ethernet

cable.

-

through cable. At both ends of a standard cable, wires are

-

through cable is used to

The cables delivered

Signal Category-5 twisted pair

Signal direction

White (Orange)

Orange

White (Green)

Blue —

-45 connectors

router) to

RJ-45 pin

1

2

3

4

Page 38

RJ-45 pin Signal Category-5 twisted pair Signal direction RJ-45 pin

5 — White (Blue) — 5

6 Rx– Green

6

7 — White (Brown) — 7

8 — Brown — 8

Table 1-33 Crossover cable connector pinouts

RJ-45 pin Signal direction Category-5 twisted pair Signal direction RJ-45 pin

1 Tx+ White (Orange)

3

2 Tx– Orange

6

3 Rx+ White (Green)

1

4 — Blue — 4

5 — White (Blue) — 5

6 Rx– Green

2

7 — White (Brown) — 7

8 — Brown — 8

You can refer to the table above when distinguishing between or preparing these two types of

Ethernet cables.

When preparing Ethernet cables, please follow the chromatogram given in the table to arrange

the wires. Otherwise communication quality will be affected even if the equipment at two ends

are connected.

When preparing Ethernet cables, use shielded cables preferentially for electromagnetic

compatibility (EMC).

Fiber connecting 1000 Mbps optical Ethernet interface

You can use a single-mode or multimode optical fiber to connect a 1000 Mbps optical Ethernet

interface to an Ethernet. You can select proper fibers for the installed 1000Base-X SFP

modules (GE SFP for short). Since the optical interfaces on these SFP modules use LC optical

connectors, you must use fibers with LC connectors. All SFP modules are hot-swappable.

No SFP module is shipped with the device.

Use only the SFP modules provided by HP. The device cannot recognize SFP modules from

other manufacturers.

For the connection of electrical Ethernet interfaces or optical Ethernet interfaces, refer to

“Connecting Ethernet Cables” in Chapter 4 “Installing the Router."

Interface modules supported by FIPs

HIMs supported by the router provide a bus processing capability of up to 10 Gbps, which can

meet the high-speed performance requirements of users. In addition, the modular architecture

allows the router to support a wide range of optional MIMs. The interface module series provide

abundant interfaces such as synchronous serial interface, Ethernet interface, POS interface,

and E1 interface.

For the interface modules supported by the router, see Table 1-34.

Page 39

Table 1-34 FIPs' support for HIMs and MIMs

Interface module FIP-100 FIP-110 FIP-200 FIP-210

HIM Not supported Not supported Supported Supported

MIM Supported Supported Supported Supported

State description of FIPs

A FIP can be in one of six states as shown in Table 1-35.

Table 1-35 State description of FIPs

Status Meaning Remarks

Absent Outof position No FIP is installed in a slot of the router.

Disable Powered off through the CLI The user powers off a FIP through the CLI.

Fault Faulty Thesystem fails to identify a FIP.

Normal Normal

The FIP has completed the startup process and

works normally.

Startup Powered on The FIP is being powered on.

Wait Wait due to insufficient power

The FIP is waiting for being powered on due to

insufficient power.

Use the display version command to view the state of all slots. For example:

<HP>display device

Slot No. Board type Status Primary SubSlots

--------------------------------------------------------------------0 FIP-200 Startup N/A 2

1 N/A Absent N/A N/A

2 N/A Absent N/A N/A

3 N/A Absent N/A N/A

4 RPE-X1 Normal Slave 0

5 RPE-X1 Normal Master 0

6 N/A Absent N/A N/A

7 N/A Absent N/A N/A

8 FIP-200 Normal N/A 2

9 N/A Absent N/A N/A

Table 1-36 display device command output description

Field Description

Slot No Slot number of the board

Board type Type of the board

Status Board status

Primary Whether the MPU is in the active state or not.

SubSlots Number of sub slots

For details about the display device command, refer to Device Management in the System

Volume of HP SR6600 Routers User Manual.

Page 40

Accessories

Chassis Accessory

Before installing an RPE-X1 on the A6616, you need to insert a chassis accessory into Slot 4 or

Slot 5. The chassis accessory can bear two RPE-X1s. For the installation of the chassis

accessory and RPE-X1, refer to "Installing and Removing an RPE-X1" in Chapter 4 "Installing

the Router."

Fiber Management Tray

A fiber management tray is installed in a cabinet for accommodating redundant fibers between

the A6616 and other devices. For the installation of the fiber management tray, refer to

"Installing the FMTs (Optional)" in Chapter 4 "Installing the Router."

Port Lightning Arrester

Before connecting an outdoor Ethernet cable to an Ethernet port, you can install a port lightning

arrester to protect the router against lightning strokes. The following port lightning arrester can

be installed on the router. The specifications for the port lightning arrester are as follows:

Port protective unit–single port, maximum discharge current (8/20μs waveform): 5 kA, output

voltage (10/700μs waveform): core-core < 40 V, core-ground < 600 V.

For the installation of the port lightning arrester, refer to “Installing a Port Lightning Arrester

(Optional)” in Chapter 4 “Installing the Router.”

Power Lightning Arrester

Before connecting an outdoor AC power to the router, you need to install a lightning protection

busbar at the AC power input end and then connect the AC power cord to a lightning protection

busbar to protect the router against lightning strokes. In a heavy lightning area, you are

recommended to install a power lightning arrester.

The following power lightning arrester can be installed on the device. The specifications for the

power lightning arrester are as follows:

Maximum discharge current: 6500 A, protection voltage: 500 VAC to 220 VAC.

For the installation of the power lightning arrester, refer to “Installing a Power Lightning Arrester

(Lightning Protection Busbar) (Optional)” in Chapter 4 “Installing the Router.”

Signal Lightning Arrester

Generally, you need to connect a signal lightning arrester (namely, a transient over-voltage

protection) before connecting a signal cable to the router. This can protect electronic devices

against surge over-voltage resulting from lightning strokes and other interferences, and

minimize impact on the router.

The device supports three types of signal lightning arresters:

Voltage-limiting protection parts-signal lightning arrester-maximum discharge current

2.5KA/protection voltage 25V--SMB-75J/SMB-75J-1W-10Mbps.

Page 41

Voltage-limiting protection parts-signal lightning arrester-maximum discharge current

2.5KA/protection voltage 25V-BNC-75K/BNC-75K-10MBit/s.

Voltage-limiting protection parts-signal lightning arrester (U port)-maximum discharge current

3KA/common mode: 400 V/differential mode: 170V-RJ11.

For the installation of the signal lightning arrester, refer to “Selecting and Installing a Signal

Lightning Arrester (Optional)” in Chapter 4 “Installing the Router.”

Page 42

2 Arranging Slots and Numbering Interfaces

Slot Arrangement

The router provides many types of interfaces, such as console, AUX, GigabitEthernet, serial

(synchronous), POS, and E1 ports. This chapter describes how these interfaces are numbered.

Figure 2-1 Slot arrangement on the A6616 configured with an RPE-X1

Page 43

Figure 2-2 Slot arrangement on the A6616 configured with an RSE-X1

The numbers 0 through 9 in Figure 2-1 respectively represent Slot 0 through Slot 9 on the

A6616 configured with an RPE-X1. Actually, these numbers are not silk-screened on the

router.

The numbers 0 through 3 and 5 through 9 in Figure 2-2 respectively represent Slot 0

through Slot 3 and Slot 5 through Slot 9 on the A6616 configured with an RSE-X1. Note

that no slot is named Slot 4 on the A6616 when it is configured with the RSE-X1.

Slot Arrangement for MPUs and FIPs

Table 2-1 Slot arrangement for MPUs

MPU Slot arrangement

RPE-X1 (supporting 1+1 redundancy) Slot 4 and Slot 5

RSE-X1 (supporting 1+1 redundancy) Slot 5 and Slot 6

Table 2-2 Slot arrangement for FIPs

FIP Slot arrangement

FIP-100 Slot 0 through Slot 3, Slot 6 through Slot 9

FIP-110 Slot 0 through Slot 3, Slot 6 through Slot 9

Page 44

FIP Slot arrangement

FIP-200 Slot 0 through Slot 3, Slot 6 through Slot 9

FIP-210 Slot 0 through Slot 3, Slot 6 through Slot 9

Numbering Interfaces

Before installing a HIM/MIM, you must install a FIP first. A FIP-200/FIP-210 supports both HIMs

and MIMs, while a FIP-100/FIP-110 supports only MIMs.

The interfaces of the router are numbered in the form of interface-type X/Y/Z,

Where,

interface-type: Type of the interface such as GE interface and serial interface.

X: Number of the slot where the FIP resides.

Y: Sub-slot number, namely, the number of the slot where the HIM/MIM resides on

the FIP.

Z: Sequence number of the interface on the HIM/MIM.

Different interface modules on the same FIP have the same slot number X.

Different interfaces on the same interface module have the same sub-slot number Y.

For each type of interface, the sequence number Z starts from 0 on the interface module.

Examples

Example 1

A FIP-100 is installed in Slot 3 and a MIM-2GBE module is installed on the FIP-100.

Numbers of fixed GigabitEthernet interfaces on the FIP-100

GigabitEthernet 3/0/0

GigabitEthernet 3/0/1

The sub-slot number Y of fixed GE interfaces on a FIP of the router is 0.

Numbers of GigabitEthernet interfaces on the MIM-2GBE module

1) If a MIM-2GBE module is installed in Slot 1 of the FIP-100, the numbers of

GigabitEthernet interfaces are:

GigabitEthernet 3/1/0