Page 1

HP 9250C Digital Sender

Service Manual

Page 2

Page 3

HP Digital Sender 9250c

Service Manual

Page 4

Copyright information

Trademark Credits

© 2007 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CB472-90938

Edition 1, 3/2007

Linux is a U.S. registered trademark of Linus

Torvalds.

Microsoft

®

, Windows®, and Windows NT

®

are U.S. registered trademarks of Microsoft

Corporation.

Page 5

Table of contents

1 Device information

Chapter contents .................................................................................................................................. 1

Device information ................................................................................................................................ 2

Where to get more information ............................................................................................ 2

Features ............................................................................................................................................... 4

Software features ................................................................................................................................. 5

Device parts ......................................................................................................................................... 6

Use the control panel ........................................................................................................................... 8

Control-panel layout ............................................................................................................. 8

Device software .................................................................................................................................. 10

Digital-sender software ...................................................................................................... 10

Paper handling ................................................................................................................................... 11

2 Installation and configuration

Chapter contents ................................................................................................................................ 13

Prepare the site .................................................................................................................................. 14

System requirements ......................................................................................................................... 14

Unpack the device .............................................................................................................................. 15

3 Maintenance

Chapter contents ................................................................................................................................ 17

Replace supplies and parts ................................................................................................................ 18

Replace the mylar sheet .................................................................................................... 18

Replace the ADF Maintenance Kit ..................................................................................... 19

Clean the device ................................................................................................................................. 20

Clean the exterior .............................................................................................................. 20

Clean the glass .................................................................................................................. 20

Clean the touchscreen ....................................................................................................... 20

Clean the ADF delivery system ......................................................................................... 20

Clean the ADF rollers ........................................................................................................ 22

4 Theory of operation

Chapter contents ................................................................................................................................ 25

Basic operation ................................................................................................................................... 26

Sequence of operation (scanner) ...................................................................................... 26

Formatter system ............................................................................................................................... 27

Sleep mode ........................................................................................................................ 27

CPU ................................................................................................................................... 27

ENWW iii

Page 6

Memory .............................................................................................................................. 28

Control panel ..................................................................................................................... 28

Keyboard ........................................................................................................................... 28

Scanner controller board ................................................................................................... 28

Engine control system ........................................................................................................................ 28

Engine power supply circuit ............................................................................................... 28

Flatbed unit and ADF system ............................................................................................................. 29

Electrical system ................................................................................................................ 29

Motors and fans ................................................................................................................. 30

Optical assembly ............................................................................................................... 30

ADF feed system ............................................................................................................... 32

Jam detection .................................................................................................................... 33

5 Removal and replacement

Removal and replacement strategy .................................................................................................... 36

Required tools .................................................................................................................... 36

Before performing service .................................................................................................. 36

After completing service .................................................................................................... 37

Screws that are used in the digital sender ......................................................................... 37

User-replaceable parts ....................................................................................................................... 38

Separation pad .................................................................................................................. 39

Pickup-roller cover ............................................................................................................. 41

Pickup roller assembly ....................................................................................................... 43

Mylar-holder assembly ....................................................................................................... 44

ADF mylar shield ............................................................................................................... 46

Control panel ..................................................................................................................... 47

Control-panel overlays ....................................................................................................... 48

Formatter assemblies ........................................................................................................ 49

Hinge flaps ......................................................................................................................... 53

Paper input tray ................................................................................................................. 54

External components and covers ....................................................................................................... 55

Keyboard ........................................................................................................................... 56

Control-panel lower cover .................................................................................................. 58

Control-panel upper cover ................................................................................................. 59

Control-panel cover assembly ........................................................................................... 60

External control-panel cable .............................................................................................. 63

Output bin base cover or output bin extender .................................................................... 64

Output bin paper lever ....................................................................................................... 65

ADF right cover .................................................................................................................. 66

ADF right-corner cover ...................................................................................................... 68

ADF left cover .................................................................................................................... 69

ADF left-corner cover ......................................................................................................... 71

ADF rear cover .................................................................................................................. 72

Scanner right cover ............................................................................................................ 73

Scanner left cover .............................................................................................................. 74

Scanner front cover ........................................................................................................... 75

Scanner rear cover ............................................................................................................ 76

Right hinge cover ............................................................................................................... 77

Left hinge cover ................................................................................................................. 78

Upper hinge cover ............................................................................................................. 79

iv ENWW

Page 7

Internal components ........................................................................................................................... 80

ADF assembly ................................................................................................................... 81

ADF jam access latch ........................................................................................................ 83

Right hinge guide ............................................................................................................... 84

Left hinge guide ................................................................................................................. 85

Damper cover, left damper spring, right damper spring, or damper base cover ............... 86

White mylar backing or white mylar backing spring ........................................................... 87

Fan filter ............................................................................................................................. 88

ADF cable .......................................................................................................................... 89

Separation pad case .......................................................................................................... 92

Clear plastic paper guide ................................................................................................... 93

White scan background ..................................................................................................... 94

Scanner controller board ................................................................................................... 95

Flatbed scanner assembly ................................................................................................. 96

Power supply ..................................................................................................................... 99

Keyboard cable ................................................................................................................ 102

Power-switch assembly ................................................................................................... 105

Scanner base fan ............................................................................................................. 106

Power plug ....................................................................................................................... 108

SCB cable ........................................................................................................................ 109

Internal control-panel cable ............................................................................................. 110

6 Troubleshooting

Troubleshooting process .................................................................................................................. 112

Control-panel messages .................................................................................................................. 114

Operational issues ............................................................................................................................ 122

LEDs ................................................................................................................................................. 126

Clear jams ........................................................................................................................................ 127

Calibrate the scanner ....................................................................................................................... 129

Resolve e-mail problems .................................................................................................................. 133

Resolve network-connectivity problems ........................................................................................... 135

Service-mode functions .................................................................................................................... 140

Initial troubleshooting checklist ........................................................................................ 112

Power-on checks ............................................................................................................. 113

Control-panel message types .......................................................................................... 114

Resolve control-panel messages ..................................................................................... 114

HP Jetdirect LEDs ........................................................................................................... 126

Formatter LED ................................................................................................................. 126

Solve repeated jams ........................................................................................................ 128

To print the calibration target ........................................................................................... 129

To calibrate the scanner .................................................................................................. 130

Calibrating the control panel ............................................................................................ 131

Finding the LDAP server address .................................................................................... 133

Verifying an LDAP address .............................................................................................. 133

Troubleshooting the LDAP Find Settings process ........................................................... 133

Finding an SMTP server address .................................................................................... 134

Verifying an SMTP address ............................................................................................. 134

Embedded LAN troubleshooting ...................................................................................... 135

Verifying communication over the network ...................................................................... 139

Cold reset ........................................................................................................................ 140

ENWW v

Page 8

NVRAM initialization ........................................................................................................ 140

Disk initialization .............................................................................................................. 141

Service menu ................................................................................................................................... 142

Troubleshooting tools ....................................................................................................................... 143

Embedded Web server .................................................................................................... 143

HP Web Jetadmin software ............................................................................................. 145

Diagnostic tools ................................................................................................................................ 146

Scanner tests ................................................................................................................... 146

Control-panel tests ........................................................................................................... 146

Upgrade the firmware ....................................................................................................................... 148

Determine the current level of firmware ........................................................................... 148

Download new firmware from the HP Web site ............................................................... 148

Use FTP to upgrade the firmware on a direct network connection .................................. 148

Use HP Web Jetadmin to upgrade the firmware ............................................................. 150

Upgrade the HP Jetdirect Inside firmware ....................................................................... 150

Troubleshooting diagrams ................................................................................................................ 152

Digital-sender wiring diagram .......................................................................................... 152

Scanner controller board diagram ................................................................................... 153

Parts used in troubleshooting .......................................................................................... 154

7 Parts and diagrams

Ordering parts and supplies ............................................................................................................. 158

How to use the parts diagrams and lists .......................................................................................... 158

Screws that are used in the digital sender ....................................................................................... 159

Related documentation and software ............................................................................................... 160

Customer-replaceable components ................................................................................................. 162

ADF components .............................................................................................................................. 170

Scanner and bottom assemblies ...................................................................................................... 186

Alphabetical parts list ....................................................................................................................... 202

Numerical parts list ........................................................................................................................... 208

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 215

Customer self repair warranty service .............................................................................................. 216

Hewlett-Packard limited warranty statement for software ................................................................ 217

Availability of support and service .................................................................................................... 218

HP maintenance agreements ........................................................................................................... 218

Next-Day Onsite Service ................................................................................................. 218

Appendix B Specifications

Physical specifications ..................................................................................................................... 220

Electrical specifications .................................................................................................................... 220

Power consumption specifications ................................................................................................... 220

Environmental specifications ........................................................................................................... 221

Acoustic emissions ........................................................................................................................... 221

Appendix C Regulatory information

FCC regulations ............................................................................................................................... 224

Environmental Product Stewardship program .................................................................................. 225

vi ENWW

Page 9

Protecting the environment .............................................................................................. 225

Ozone production ............................................................................................................ 225

Power consumption ......................................................................................................... 225

Plastics ............................................................................................................................ 225

Material restrictions .......................................................................................................... 225

Disposal of waste equipment by users in private households in the European Union .... 226

Material Safety Data Sheet (MSDS) ................................................................................ 226

For more information ....................................................................................................... 226

Declaration of conformity .................................................................................................................. 227

Country-/region-specific safety statements ...................................................................................... 228

Canadian DOC regulations .............................................................................................. 228

VCCI statement (Japan) .................................................................................................. 228

EMI statement (Korea) ..................................................................................................... 228

Index ................................................................................................................................................................. 229

ENWW vii

Page 10

viii ENWW

Page 11

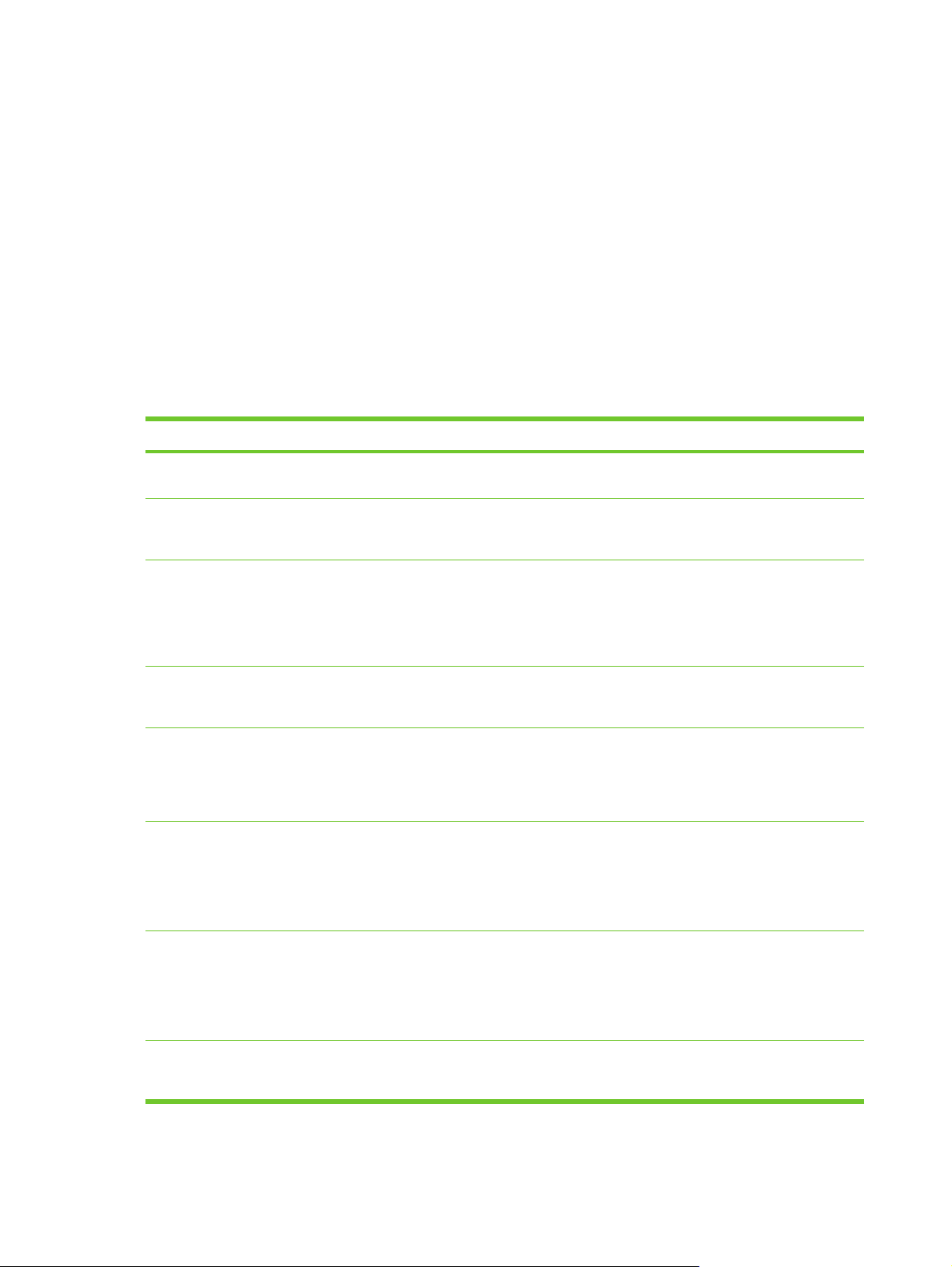

List of tables

Table 5-1 Common fasteners that are used in this digital sender .................................................................... 37

Table 6-1 Control-panel messages ................................................................................................................ 114

Table 7-1 Common fasteners ......................................................................................................................... 159

Table 7-2 Related documentation and software ............................................................................................ 161

Table 7-3 Customer-replaceable components ............................................................................................... 163

Table 7-4 Control-panel overlays ................................................................................................................... 165

Table 7-5 Maintenance kits ............................................................................................................................ 167

Table 7-6 Memory .......................................................................................................................................... 169

Table 7-7 ADF Assembly ............................................................................................................................... 171

Table 7-8 ADF base assembly ....................................................................................................................... 173

Table 7-9 Separation pad case ...................................................................................................................... 175

Table 7-10 Pickup roller assembly ................................................................................................................. 177

Table 7-11 Control-panel cover assembly ...................................................................................................... 179

Table 7-12 Control-panel assembly ............................................................................................................... 181

Table 7-13 ADF left cover .............................................................................................................................. 183

Table 7-14 ADF input tray assembly .............................................................................................................. 185

Table 7-15 Scanner assembly ........................................................................................................................ 187

Table 7-16 Bottom unit assembly ................................................................................................................... 189

Table 7-17 Power plug ................................................................................................................................... 191

Table 7-18 Top formatter ................................................................................................................................ 193

Table 7-19 Fan assembly ............................................................................................................................... 195

Table 7-20 Keyboard assembly ...................................................................................................................... 197

Table 7-21 Lower cover assembly ................................................................................................................. 199

Table 7-22 Scanner rear cover ....................................................................................................................... 201

Table 7-23 Alphabetical parts list ................................................................................................................... 202

Table 7-24 Numerical parts list ....................................................................................................................... 208

Table B-1 Physical specifications ................................................................................................................... 220

Table B-2 Electrical specifications .................................................................................................................. 220

Table B-3 Power consumption (average, in watts) ........................................................................................ 220

Table B-4 Environmental specifications ........................................................................................................ 221

Table B-5 Acoustic emissions ........................................................................................................................ 221

ENWW ix

Page 12

x ENWW

Page 13

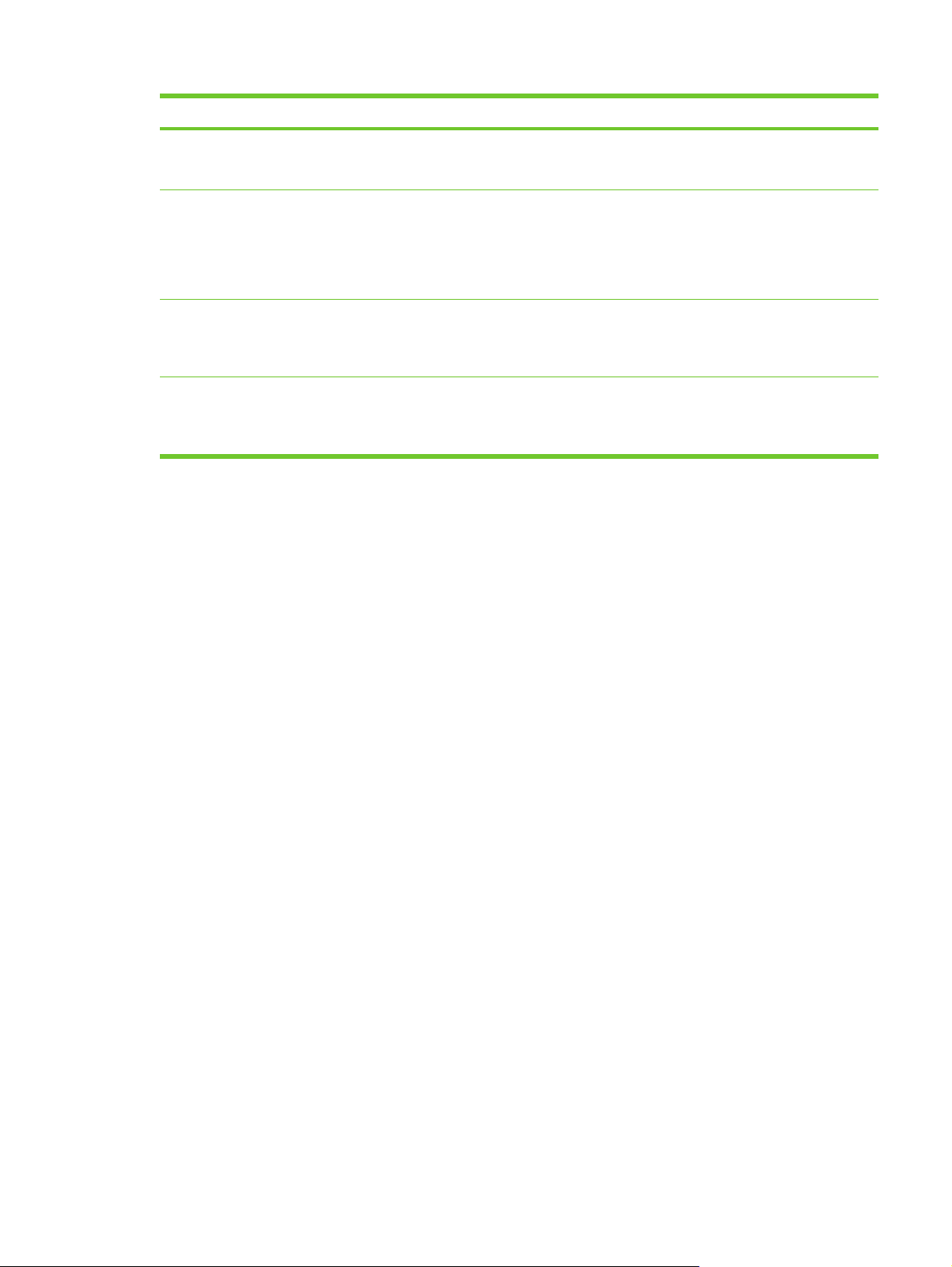

List of figures

Figure 1-1 Control-panel layout .......................................................................................................................... 8

Figure 4-1 Scanner assembly electrical structure ............................................................................................ 29

Figure 4-2 Scan carriage components ............................................................................................................. 30

Figure 4-3 Optical assembly ............................................................................................................................. 31

Figure 4-4 ADF paper path and sensors .......................................................................................................... 32

Figure 5-1 Removing the separation pad (1 of 3) ............................................................................................ 39

Figure 5-2 Removing the separation pad (2 of 3) ............................................................................................ 39

Figure 5-3 Removing the separation pad (3 of 3) ............................................................................................ 40

Figure 5-4 Removing the paper input tray (1 of 2) ........................................................................................... 41

Figure 5-5 Removing the pickup roller assembly (2 of 3) ................................................................................. 41

Figure 5-6 Removing the pickup-roller cover (2 of 2) ....................................................................................... 42

Figure 5-7 Removing the pickup roller assembly (1 of 3) ................................................................................. 43

Figure 5-8 Removing the pickup roller assembly (2 of 3) ................................................................................. 43

Figure 5-9 Removing the pickup roller assembly (3 of 3) ................................................................................. 43

Figure 5-10 Removing the mylar-holder assembly (1 of 3) .............................................................................. 44

Figure 5-11 Removing the mylar-holder assembly (2 of 3) .............................................................................. 44

Figure 5-12 Removing the mylar-holder assembly (3 of 3) .............................................................................. 45

Figure 5-13 Replacing the ADF mylar shield (4 of 7) ....................................................................................... 46

Figure 5-14 Replacing the ADF mylar shield (5 of 7) ....................................................................................... 46

Figure 5-15 Removing the control panel (1 of 2) .............................................................................................. 47

Figure 5-16 Removing the control panel (2 of 2) .............................................................................................. 47

Figure 5-17 Removing the control-panel overlays ........................................................................................... 48

Figure 5-18 Removing the formatter cage ........................................................................................................ 49

Figure 5-19 Removing the hard drive (1 of 2) .................................................................................................. 50

Figure 5-20 Removing the hard drive (2 of 2) .................................................................................................. 50

Figure 5-21 Removing the hard-disk drive cables (1 of 2) ............................................................................... 51

Figure 5-22 Removing the hard-disk drive cables (2 of 2) ............................................................................... 51

Figure 5-23 Removing the memory DIMM ....................................................................................................... 52

Figure 5-24 Removing the hinge flaps ............................................................................................................. 53

Figure 5-25 Removing the pickup-roller cover (1 of 2) ..................................................................................... 54

Figure 5-26 Removing the paper input tray (2 of 2) ......................................................................................... 54

Figure 5-27 Removing the keyboard (1 of 3) ................................................................................................... 56

Figure 5-28 Removing the keyboard (2 of 3) ................................................................................................... 56

Figure 5-29 Removing the keyboard (3 of 3) ................................................................................................... 57

Figure 5-30 Removing the control-panel lower cover ...................................................................................... 58

Figure 5-31 Removing the control-panel upper cover ...................................................................................... 59

Figure 5-32 Removing the control-panel cover assembly (1 of 6) ................................................................... 60

Figure 5-33 Removing the control-panel cover assembly (2 of 6) ................................................................... 60

Figure 5-34 Removing the control-panel cover assembly (3 of 6) ................................................................... 61

ENWW xi

Page 14

Figure 5-35 Removing the control-panel cover assembly (4 of 6) ................................................................... 61

Figure 5-36 Removing the control-panel cover assembly (5 of 6) ................................................................... 62

Figure 5-37 Removing the control-panel cover assembly (6 of 6) ................................................................... 62

Figure 5-38 Removing the external control-panel cable .................................................................................. 63

Figure 5-39 Removing the output bin base cover or output bin extender ........................................................ 64

Figure 5-40 Removing the output bin paper lever ............................................................................................ 65

Figure 5-41 Removing the ADF right cover (1 of 3) ......................................................................................... 66

Figure 5-42 Removing the ADF right cover (2 of 3) ......................................................................................... 66

Figure 5-43 Removing the ADF right cover (3 of 3) ......................................................................................... 67

Figure 5-44 Removing the ADF right-corner cover .......................................................................................... 68

Figure 5-45 Removing the ADF left cover (1 of 3) ............................................................................................ 69

Figure 5-46 Removing the ADF left cover (2 of 3) ............................................................................................ 69

Figure 5-47 Removing the ADF left cover (3 of 3) ............................................................................................ 70

Figure 5-48 Removing the ADF left-corner cover ............................................................................................. 71

Figure 5-49 Removing the ADF rear cover ...................................................................................................... 72

Figure 5-50 Removing the scanner right cover ................................................................................................ 73

Figure 5-51 Removing the scanner left cover .................................................................................................. 74

Figure 5-52 Removing the scanner front cover ................................................................................................ 75

Figure 5-53 Removing the scanner rear cover ................................................................................................. 76

Figure 5-54 Removing the right hinge cover .................................................................................................... 77

Figure 5-55 Removing the left hinge cover ...................................................................................................... 78

Figure 5-56 Removing the upper hinge cover .................................................................................................. 79

Figure 5-57 Removing the ADF assembly (1 of 3) ........................................................................................... 81

Figure 5-58 Removing the ADF assembly (2 of 3) ........................................................................................... 81

Figure 5-59 Removing the ADF assembly (3 of 3) ........................................................................................... 82

Figure 5-60 Removing the jam access latch .................................................................................................... 83

Figure 5-61 Removing the right hinge guide .................................................................................................... 84

Figure 5-62 Removing the left hinge guide ...................................................................................................... 85

Figure 5-63 Removing the damper cover ......................................................................................................... 86

Figure 5-64 Removing the white mylar backing or white mylar backing spring (1 of 2) ................................... 87

Figure 5-65 Removing the white mylar backing or white mylar backing spring (2 of 2) ................................... 87

Figure 5-66 Removing the fan filter .................................................................................................................. 88

Figure 5-67 Removing the ADF cable (1 of 5) .................................................................................................. 89

Figure 5-68 Removing the ADF cable (2 of 5) .................................................................................................. 89

Figure 5-69 Removing the ADF cable (3 of 5) .................................................................................................. 90

Figure 5-70 Removing the ADF cable (4 of 5) .................................................................................................. 90

Figure 5-71 Removing the ADF cable (5 of 5) .................................................................................................. 91

Figure 5-72 Removing the separation pad case .............................................................................................. 92

Figure 5-73 Removing the clear plastic paper guide (1 of 2) ........................................................................... 93

Figure 5-74 Removing the clear plastic paper guide (2 of 2) ........................................................................... 93

Figure 5-75 Removing the white scan background .......................................................................................... 94

Figure 5-76 Removing the scanner controller board (1 of 2) ........................................................................... 95

Figure 5-77 Removing the scanner controller board (2 of 2) ........................................................................... 95

Figure 5-78 Removing the flatbed scanner assembly (1 of 4) ......................................................................... 96

Figure 5-79 Removing the flatbed scanner assembly (2 of 4) ......................................................................... 97

Figure 5-80 Removing the flatbed scanner assembly (3 of 4) ......................................................................... 97

Figure 5-81 Removing the flatbed scanner assembly (4 of 4) ......................................................................... 98

Figure 5-82 Removing the power supply (1 of 6) ................................................................................

Figure 5-83 Removing the power supply (2 of 6) ............................................................................................. 99

Figure 5-84 Removing the power supply (3 of 6) ........................................................................................... 100

............. 99

xii ENWW

Page 15

Figure 5-85 Removing the power supply (5 of 6) ........................................................................................... 100

Figure 5-86 Removing the power supply (6 of 6) ........................................................................................... 101

Figure 5-87 Removing the keyboard cable (1 of 5) ........................................................................................ 102

Figure 5-88 Removing the keyboard cable (2 of 5) ........................................................................................ 103

Figure 5-89 Removing the keyboard cable (3 of 5) ........................................................................................ 103

Figure 5-90 Removing the keyboard cable (4 of 5) ........................................................................................ 104

Figure 5-91 Removing the keyboard cable (5 of 5) ........................................................................................ 104

Figure 5-92 Removing the power-switch assembly ........................................................................................ 105

Figure 5-93 Removing the scanner base fan (1 of 2) ..................................................................................... 106

Figure 5-94 Removing the scanner base fan (2 of 2) ..................................................................................... 107

Figure 5-95 Removing the power plug (1 of 2) ............................................................................................... 108

Figure 5-96 Removing the power plug (2 of 2) ............................................................................................... 108

Figure 5-97 Removing the SCB cable ............................................................................................................ 109

Figure 5-98 Removing the internal control-panel cable (1 of 2) ..................................................................... 110

Figure 5-99 Removing the internal control-panel cable (2 of 2) ..................................................................... 110

Figure 6-1 Digital-sender LEDs ...................................................................................................................... 126

Figure 6-2 Scanner calibration target ............................................................................................................. 130

Figure 6-3 Digital sender wiring diagram ........................................................................................................ 152

Figure 6-4 Scanner controller board ............................................................................................................... 153

Figure 6-5 ADF troubleshooting parts ............................................................................................................ 154

Figure 6-6 ADF internal troubleshooting parts ............................................................................................... 155

Figure 6-7 Flatbed base troubleshooting parts .............................................................................................. 156

Figure 6-8 Rear troubleshooting parts ........................................................................................................... 156

Figure 7-1 Related documentation and software ........................................................................................... 160

Figure 7-2 Customer-replaceable components .............................................................................................. 162

Figure 7-3 Control-panel overlays .................................................................................................................. 164

Figure 7-4 Maintenance kits ........................................................................................................................... 166

Figure 7-5 Memory ......................................................................................................................................... 168

Figure 7-6 ADF Assembly .............................................................................................................................. 170

Figure 7-7 ADF base assembly ...................................................................................................................... 172

Figure 7-8 Separation pad case ..................................................................................................................... 174

Figure 7-9 Pickup roller assembly .................................................................................................................. 176

Figure 7-10 Control-panel cover assembly .................................................................................................... 178

Figure 7-11 Control-panel assembly .............................................................................................................. 180

Figure 7-12 ADF left cover ............................................................................................................................. 182

Figure 7-13 ADF input tray assembly ............................................................................................................. 184

Figure 7-14 Scanner assembly ...................................................................................................................... 186

Figure 7-15 Bottom unit assembly .................................................................................................................. 188

Figure 7-16 Power plug .................................................................................................................................. 190

Figure 7-17 Top formatter .............................................................................................................................. 192

Figure 7-18 Fan assembly .............................................................................................................................. 194

Figure 7-19 Keyboard assembly .................................................................................................................... 196

Figure 7-20 Lower cover assembly ................................................................................................................ 198

Figure 7-21 Scanner rear cover ..................................................................................................................... 200

ENWW xiii

Page 16

xiv ENWW

Page 17

1 Device information

Chapter contents

Device information

●

Features

●

Software features

●

Device parts

●

Use the control panel

●

Device software

●

Paper handling

●

ENWW Chapter contents 1

Page 18

Device information

The HP Digital Sender 9250c converts black-and-white and color documents, drawings, and

photographs into an electronic form and then distributes them directly to several kinds of destinations.

You can also install the included HP Digital Sending Software (HP DSS) program to use advanced digital

sending features such as send-to-workflow with optical character recognition (OCR).

Installing the device is simply a matter of connecting it to your network and configuring the digital-sending

features. The digital sender operates as a standalone unit on the network and does not require network

privileges for administration.

Where to get more information

The following table outlines the digital sending features that are available, and where to find more

information about these features. All of the documentation listed in this table can be found on the

documentation CD that came in the box with the device.

Feature Description For more information

Scan to E-mail Scan a document and send it to any e-mail

address.

Scan to Folder Scan a document to a network folder. More

than one folder destination can be

configured.

Address Book for E-mail and

Fax

User PIN Authentication Enter names and personal identification

LDAP Addressing Configure the device to search an LDAP

LDAP Authentication Configure the device to require user

Enter names and e-mail addresses or names

and fax numbers for e-mail and fax recipients

into the device's address book. This feature

can also be used to manage the fax speed

dials list.

numbers (PIN) so that only authorized users

can use specific features of the device.

(Lightweight Directory Access Protocol)

directory for names and e-mail addresses.

This feature makes the addressing of send to

e-mail jobs easier.

authentication to use specific device

features. This feature relies on an existing

LDAP infrastructure, and can be configured

to support LDAP over a Secure Sockets

Layer (SSL).

User guide or DSS support guide

Embedded Web Server (EWS) user guide

User guide

●

EWS user guide (for detailed

●

information)

DSS support guide

●

EWS user guide

EWS user guide or DSS support guide

EWS user guide

Kerberos Authentication Configure the device to require user

authentication to use specific features of the

device. This feature relies on an existing

Kerberos Realm infrastructure. A Microsoft

Windows Domain environment supports

Kerberos natively.

DSS LAN Fax Use the device to route fax jobs via an

existing local area network (LAN) fax

infrastructure.

EWS user guide

DSS support guide

2 Chapter 1 Device information ENWW

Page 19

Feature Description For more information

DSS Send to Folder Scan a document to a network folder. More

than one folder destination can be

configured.

DSS Workflow Scan a document and capture information

about the scanned document by prompting

the user. The document can then be routed

to another application. This feature can be

configured to use OCR (optical character

recognition).

DSS Windows Negotiated

Authentication

DSS LDAP Authentication Configure the device to require user

Configure the device to require user

authentication to use specific features of the

device. This feature relies on an existing

Microsoft Windows domain infrastructure.

authentication to use specific features of the

device. This feature relies on an existing

LDAP infrastructure.

DSS support guide

DSS support guide

DSS support guide

DSS support guide

ENWW Device information 3

Page 20

Features

The digital sender includes the following features:

●

●

●

●

●

●

●

Digital sending—Send scanned files to e-mail addresses and network folders. Advanced digitalsending functions are carried out by the HP Digital Sending Software (HP DSS), which is included

with the device.

ADF(automatic document feeder)—The legal-size ADF accepts up to 50 pages, and includes builtin duplexing for scanning both sides of a double-sided document.

Interactive touchscreen control panel—Intuitive onscreen menus and wizards help you to

complete digital-sending tasks.

Flatbed scanner—The letter/A4-size scanner can scan in both black-and-white and color, with the

ability to scan up to 1 mm (0.04 inch) from the paper edge.

Memory—The device comes standard with 256 megabytes (MB) of random access memory

(RAM).

Hard disk—The device includes a 40-gigabyte (GB) internal hard drive for storing documents and

settings.

Connectivity—The device provides a 10/100Base-T port, through Jetdirect Inside an HP Jetdirect

Fast Ethernet port, and an enhanced input/output (EIO) expansion slot for connectivity.

4 Chapter 1 Device information ENWW

Page 21

Software features

The HP DSS program supports the digital sender by providing the following features:

Send to e-mail—Scan a document and send it to one or more e-mail recipients in the form of

●

a .PDF, .JPEG, .TIFF, or .MTIFF file.

Send to secondary (secure) e-mail—Send a document by using a secure third-party e-mail

●

solution.

Send to fax—Scan a document and send it to a local area network (LAN) fax, Internet fax, or

●

Windows® 2000 fax destination. (This device does not have analog fax capability.)

Send to workflow—Scan a document and save it to a network folder or file transfer protocol (FTP)

●

site along with a file containing additional information about the document. A third-party software

program can then retrieve and decipher the information, and perform the appropriate operation on

the scanned image. A printer can also be set up as a workflow destination, so that scanned

documents can be printed.

Send to network folder—Scan a document and send it to a folder on the network.

●

ENWW Software features 5

Page 22

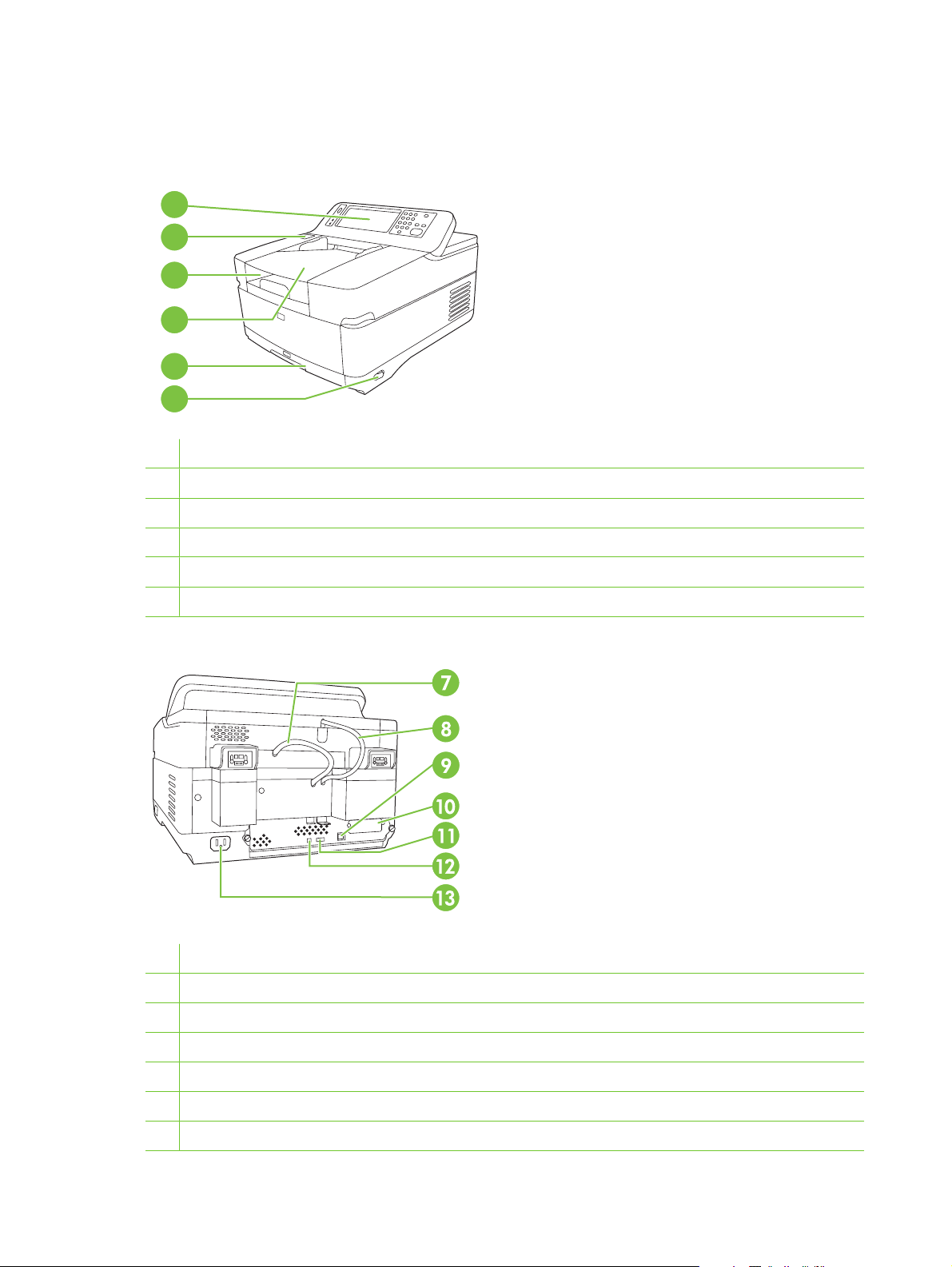

Device parts

Before using the digital sender, familiarize yourself with its parts.

1

2

3

4

5

6

1 Control panel

2 Jam release button

3 Output bin

4 ADF input bin

5 Keyboard (pull to open)

6 On/off switch

7 ADF cable

8 Control-panel cable

9 10/100Base-T network port

10 EIO slot

11 USB host port (for third-party devices only)

12 USB device port (for firmware upgrades only)

13 Power connector

6 Chapter 1 Device information ENWW

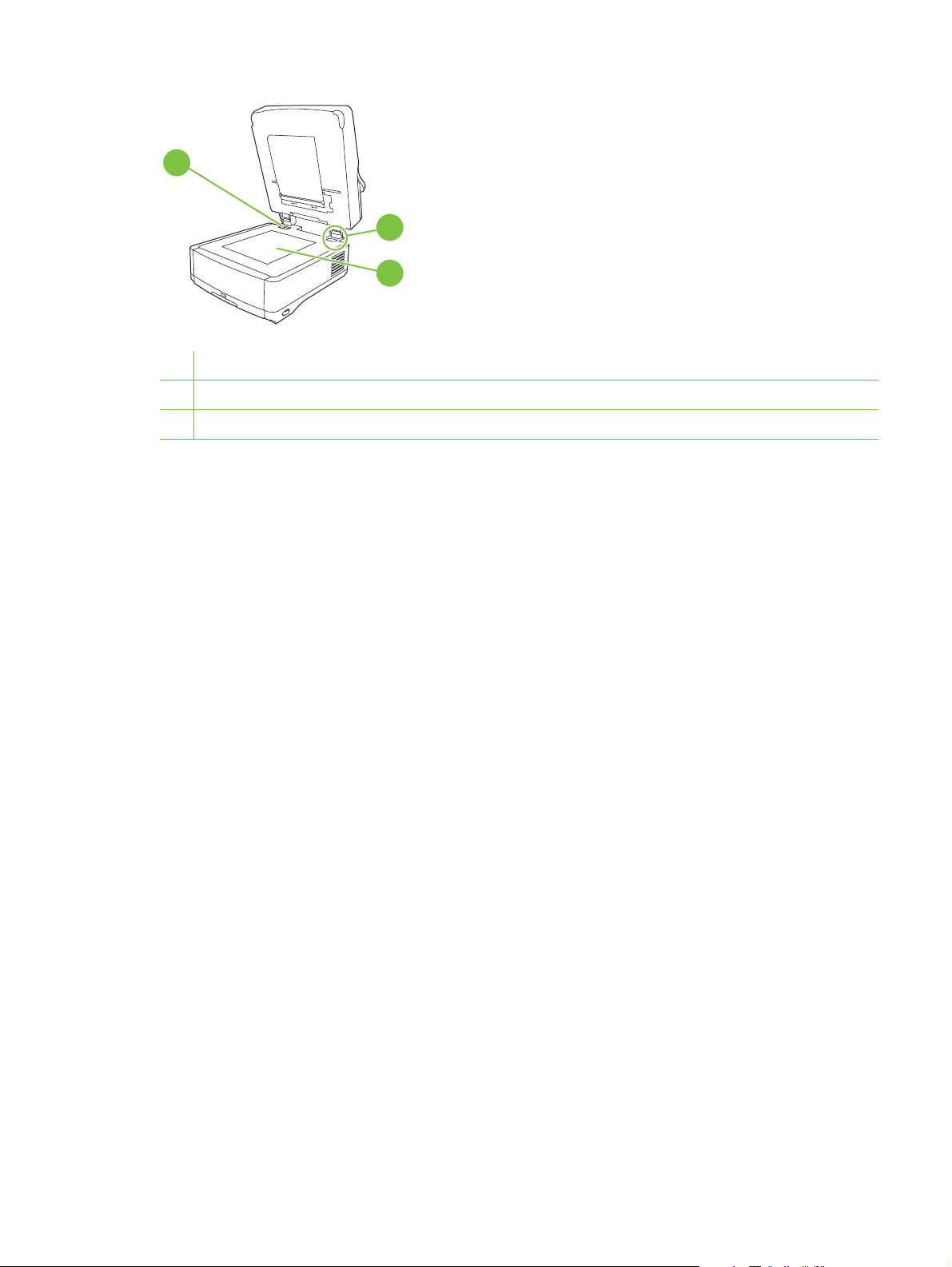

Page 23

14

14 Scanner lock

15 Serial number

16 Scanner glass

15

16

ENWW Device parts 7

Page 24

Use the control panel

The control panel has a VGA touchscreen that provides access to all device functions. Use the buttons

and numeric keypad to control jobs and the device status. The LEDs indicate overall device status.

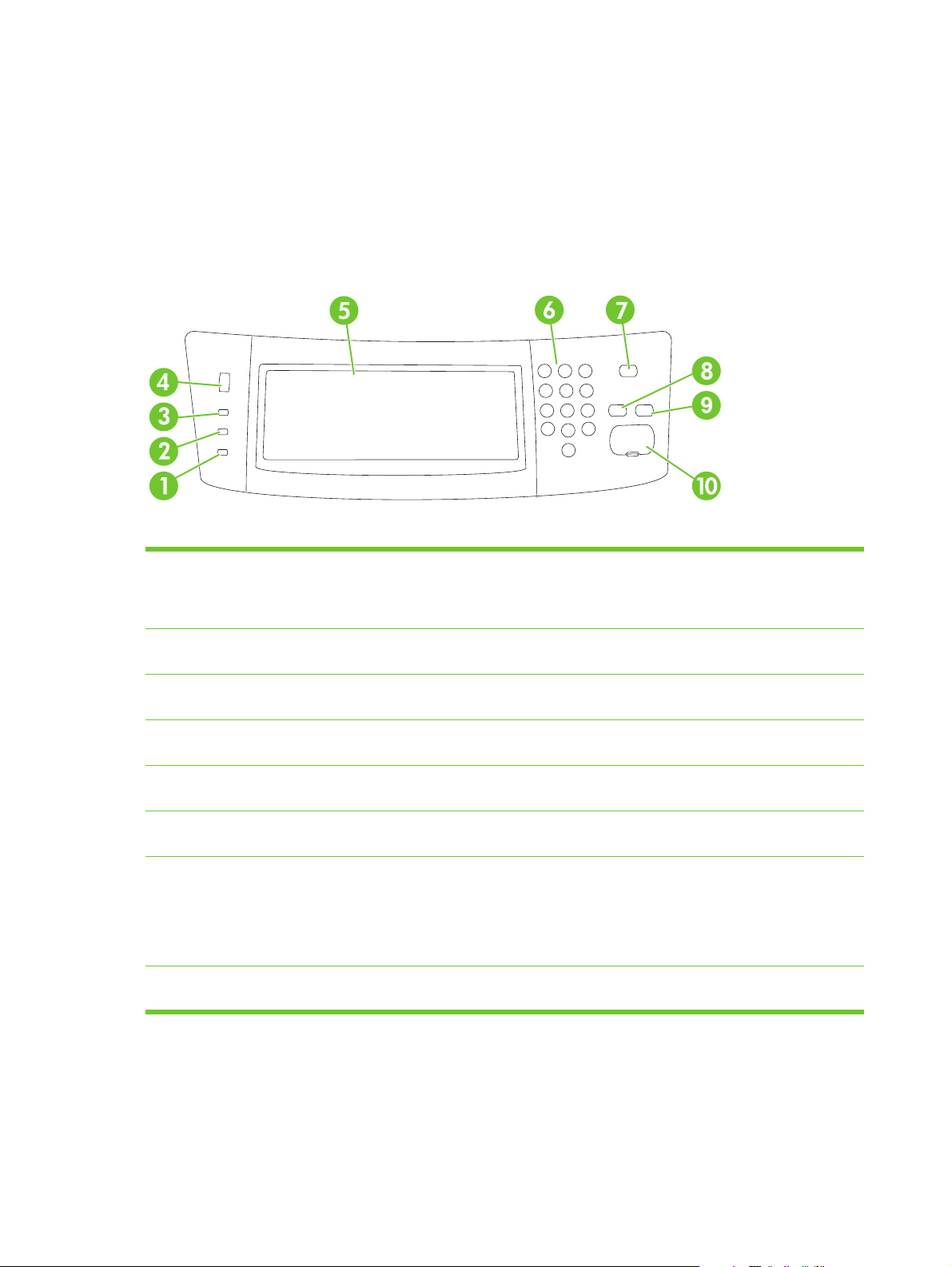

Control-panel layout

The control panel includes a touchscreen graphical display, job-control buttons, a numeric keypad, and

three light-emitting diode (LED) status lights.

Figure 1-1 Control-panel layout

1 Attention light The Attention light indicates that the

2 Data light The Data light indicates that the device is

3 Ready light The Ready light indicates that the device

4 Brightness-adjustment dial Turn the dial to control the brightness of

5 Touchscreen graphical display Use the touchscreen to open and set up

6 Numeric keypad Use the keypad to type numeric values,

7 Sleep button and light If the device is inactive for a long period

8 Reset button Resets the job settings to factory or user-

device has a condition that requires

intervention, such as an error message

on the touchscreen.

receiving data.

is ready to begin processing a job.

the touchscreen.

all device functions.

such as a fax number.

of time, it automatically enters Sleep

mode. To place the device into Sleep

mode or to reactivate the device, press

the Sleep button. When the light is

glowing, the device is in Sleep mode.

defined default values.

8 Chapter 1 Device information ENWW

Page 25

9 Stop button Stops the active job. While stopped, the

control panel shows the options for the

stopped job (for example, if you press

Stop while the device is processing an e-

mail job, the control panel message

prompts you to cancel or resume the

job).

10 Start button and light Starts digital sending, or resumes a job

that has been interrupted. When the light

is glowing, the device is ready to start

scanning.

ENWW Use the control panel 9

Page 26

Device software

Digital-sender software

To take advantage of advanced digital-sender features such as scanning with OCR or sending to a

workflow, you can install the HP Digital Sending Software Version 4.0 (HP DSS) that is provided on a

CD-ROM with the device. This software runs as a service on a network server. It is not necessary to

install any software or drivers on individual user's computers.

See the HP Digital Sending Software Support Guide on the documentation CD for software installation

and configuration instructions.

The most recent software updates are available on the Internet at

www.hp.com/support/dss.

10 Chapter 1 Device information ENWW

Page 27

Paper handling

The HP Digital Sender 9250c supports the following standard media sizes:

Letter: 215.9 x 279 mm (8.5 x 11 inches)

●

Executive: 190 x 254 mm (7.5 x 10 inches)

●

A4: 210 x 297 mm (8.3 x 11.7 inches)

●

A5: 148 x 210 mm (5.83 x 8.27 inches)

●

B5: 176 x 250 mm (6.9 x 9.8 inches)

●

Legal (from the ADF only): 215.9 x 355.6 mm (8.5 x 14 inches)

●

Paper weight: 60 to 120 g/m2 (16 to 32 lb)

Up to 50 sheets of paper can be stacked in the ADF, up to a maximum height of 5 mm (0.2 inch).

ENWW Paper handling 11

Page 28

12 Chapter 1 Device information ENWW

Page 29

2 Installation and configuration

Chapter contents

Prepare the site

●

System requirements

●

Unpack the device

●

ENWW Chapter contents 13

Page 30

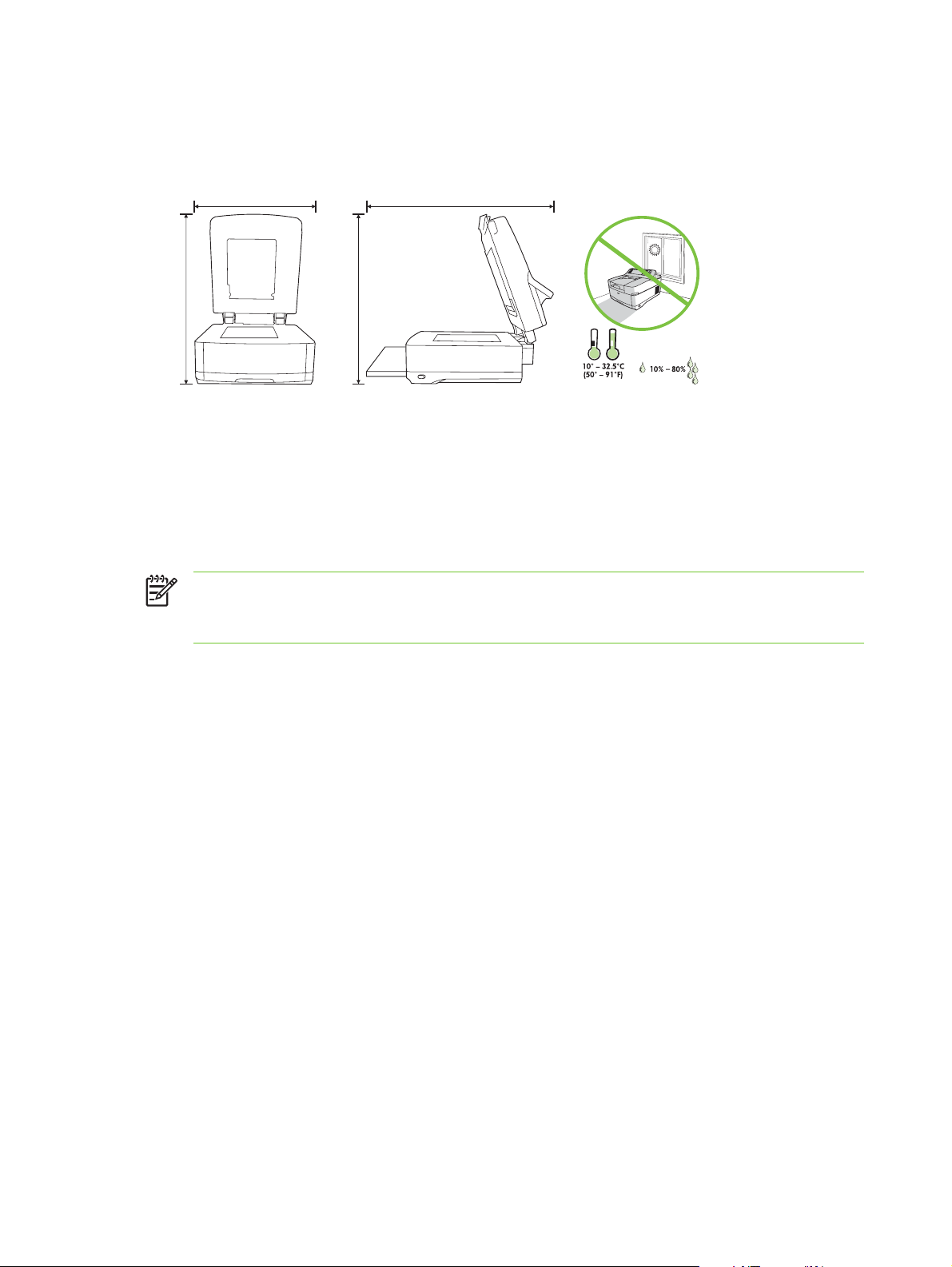

Prepare the site

720.85 mm

(28.38 inches)

720.85 mm

(28.38 inches)

452.62 mm

(17.82 inches)

724.20 mm

(28.51 inches)

Select a well-ventilated, dust-free area to install the device. Place the device on a sturdy surface.

452.62 mm

(17.82 inches)

720.85 mm

(28.38 inches)

720.85 mm

(28.38 inches)

System requirements

To install the HP Digital Sender 9250c, the computer system must have the following features:

Fast Ethernet 100Base-TX or Ethernet 10Base-T

●

Access to an SMTP e-mail gateway

●

NOTE: HP highly recommends establishing SMTP gateway on your own local area network.

However, the device can be configured for e-mail functionality even if mail services are provided

by an outside Internet service provider (ISP) over a digital subscription line (DSL).

724.20 mm

(28.51 inches)

14 Chapter 2 Installation and configuration ENWW

Page 31

Unpack the device

Remove all shipping bags, tape, and packing material.

1

2

3

4

5

1 Getting started guide (use the getting started guide for installation)

2 Digital sender documentation and HP DSS optional software

3 Digital sender

4 Control-panel overlays (if included)

5 Power cord

6 Calibration sheet

6

ENWW Unpack the device 15

Page 32

16 Chapter 2 Installation and configuration ENWW

Page 33

3 Maintenance

Chapter contents

Replace supplies and parts

●

Clean the device

●

ENWW Chapter contents 17

Page 34

Replace supplies and parts

Replace the mylar sheet

If you start to see vertical streaks on the scanned images, you might need to replace the mylar sheet at

the base of the ADF. The device ships with an envelope containing three extra mylar sheets and

installation instructions. The envelope is in a pocket behind the ADF vinyl backing, as shown in the

following figure.

C

B

A

a

A

a

A

a

A

a

A

a

c

b

b

B

C

c

C

B

c

b

C

B

c

b

C

B

c

b

Follow the instructions that come in the envelope to replace the mylar sheet.

NOTE: If necessary, you can order extra mylar sheet replacement kits from your HP sales

representative. The HP product number is Q6496A.

18 Chapter 3 Maintenance ENWW

Page 35

Replace the ADF Maintenance Kit

The device notifies you when it is time to replace the ADF Maintenance Kit by showing a message on

the control-panel display. You can view the remaining life of the Maintenance Kit at any time by pressing

the Supplies Status button on the control panel or visiting the EWS Supplies Status page (see the

embedded Web server guide on the device CD).

The ADF Maintenance Kit includes the following items:

One pickup roller assembly

●

One separation pad

●

One mylar sheet kit

●

An instruction booklet

●

Follow the instructions that come with the kit to install it.

After replacing the kit, reset the New Document Feeder Kit setting.

1. On the Home screen, touch Administration.

2. Scroll down and touch Resets.

3. Touch Reset Supplies.

4. Touch New Document Feeder Kit.

5. Touch Yes, and then touch Save.

ENWW Replace supplies and parts 19

Page 36

Clean the device

During the scanning process, paper and dust particles can accumulate inside the device. Over time,

this buildup can cause problems, such as specks on scanned documents.

Clean the exterior

Use a soft, damp, lint-free cloth to wipe dust, smudges, and stains off of the exterior of the device.

Clean the glass

Clean the glass only if dirt is visible, or if you see poor scan quality (such as streaking).

●

Clean the glass surface by wiping it gently with a clean, damp, lint-free cloth. Use an ammonia-

●

based surface cleaner to dampen the cloth.

CAUTION: Do not pour or spray liquids directly onto the glass. Do not press hard on the glass

surface, as this could break the glass.

Clean the touchscreen

Clean the touchscreen when needed to clear away fingerprints or dust build-up. To clean it, wipe the

touchscreen gently with a clean, water-dampened, lint-free cloth.

CAUTION: Use water only. Solvents or cleaners can damage the touchscreen. Do not pour or

spray water directly onto the touchscreen.

Clean the ADF delivery system

1. Open the scanner lid.

2. Locate the white, vinyl ADF backing.

20 Chapter 3 Maintenance ENWW

Page 37

3. Locate the white, vinyl calibration strips.

4. Clean the ADF backing and the calibration strips by wiping them with a clean, damp, lint-free cloth.

Use an ammonia-based surface cleaner to dampen the cloth.

5. Close the scanner lid.

ENWW Clean the device 21

Page 38

Clean the ADF rollers

You should clean the rollers in the ADF if you are experiencing misfeeds or if your originals show marks

as they exit the ADF.

CAUTION: Cleaning the rollers too frequently could introduce dust into the device.

1. Open the scanner lid.

2. Locate the rollers near the vinyl calibration strips.

3. Wipe the rollers gently with a clean, water-dampened, lint-free cloth.

CAUTION: Do not pour water directly onto the rollers. Doing so might damage the device.

4. Close the scanner lid.

5. Push the release button to open the ADF cover.

22 Chapter 3 Maintenance ENWW

Page 39

6. Locate the rollers.

7. Wipe the rollers with a clean, water-dampened, lint-free cloth.

CAUTION: Do not pour water directly onto the rollers. Doing so might damage the device.

8. Locate the separation pad.

9. Wipe the pad with a clean, water-dampened, lint-free cloth.

10. Close the ADF cover.

ENWW Clean the device 23

Page 40

24 Chapter 3 Maintenance ENWW

Page 41

4 Theory of operation

Chapter contents

Basic operation

●

Formatter system

●

Engine control system

●

Flatbed unit and ADF system

●

ENWW Chapter contents 25

Page 42

Basic operation

All high-level digital sender processes are routed through the formatter, which processes images and

communicates with other devices.

The basic digital sender operation can be divided into three systems:

The engine control system, which includes the power supply and the scanner controller board

●

The pickup-and-feed system, which consists of various rollers and transports the media through

●

the ADF

The scanner system, which scans documents and sends them to the formatter in the form of data

●

Sequence of operation (scanner)

Period (sequence) Description

Power on The period of time from when the digital sender power is turned on until the main motor begins

to rotate.

Initialization The period of time after the initial power-on sequence and before the digital sender is ready

to scan. During this time, the scanner and ADF initialization is completed, scanner calibration

is performed, and the ADF checks for media in the input tray.

Standby The period of time from the end of the initialization sequence until a request for a scan. During

this time, the scan carriage is in the Home position and the digital sender might go into Sleep

mode.

Scan The period of time immediately following a request for a scan. The scanner fan turns on, the

scan start position is adjusted, the digital sender performs the scan, and data is sent to the

formatter.

26 Chapter 4 Theory of operation ENWW

Page 43

Formatter system

The formatter is responsible for the following procedures:

Controlling Sleep mode

●

Receiving and processing scan data

●

Monitoring control-panel functions and relaying digital-sender status information (through the

●

control panel and the network)

Developing and coordinating data placement and timing with the scanner controller board

●

Communicating over the network

●

The formatter provides the electrical interface and mounting locations for one EIO card, one memory

DIMM, and the hard-disk drive. The formatter also provides two internal USB host ports (for third-party

devices), one external USB host port, and one external USB device port.

Sleep mode

This feature conserves power after the digital sender has been idle for an adjustable period of time.

When the digital sender is in Sleep mode, the control-panel backlight is turned off, but the digital sender

retains all settings. The default setting is for Sleep mode to be enabled, and the digital sender enters

the Sleep mode after a 30-minute idle time. Sleep mode can also be turned off from the

Administration menu.

CPU

The digital sender exits Sleep mode and enters the warm-up cycle when any of the following occurs:

A PML or PJL command is received

●

You touch the control-panel touchscreen or press a key on the keyboard or a button on the control

●

panel

The top cover is opened

●

Media is placed in the input tray

●

NOTE: Digital-sender error messages override the Sleep message. The digital sender enters

Sleep mode at the appropriate time, but the error message continues to appear.

The formatter incorporates a 480 MHz RISC processor.

ENWW Formatter system 27

Page 44

Memory

The formatter system contains the digital sender memory, which is divided into several components.

This section describes each memory component.

NOTE: If the digital sender encounters a problem when managing available memory, a

clearable warning message appears on the control panel.

Hard-disk drive. The digital sender comes standard with a hard disk that has a capacity of 40 GB

●

or greater. The hard disk is used to store settings.

Random-access memory on the formatter. The random-access memory (RAM) contains the

●

scanned image. Memory capacity can be increased by adding a dual inline memory module (DIMM)

to the formatter or replacing an existing DIMM with a larger DIMM. In most cases, additional

memory might be required to use the digital sender with certain other devices, such as third-party

devices. Typically, adding memory will not increase the performance of the device.

Nonvolatile memory. The digital sender uses nonvolatile memory (NVRAM) to store I/O

●

information and other permanent information, such as page counts and serial number. The

contents of NVRAM are retained when the digital sender is turned off or disconnected.

Control panel

The control panel contains both touchscreen and hard keys, and sends user commands to the formatter.

Keyboard

The keyboard tray contains a keyboard for entering e-mail addresses and other data.

Scanner controller board

The scanner controller board sends data to the formatter and receives commands from the formatter.

The scanner controller board controls motors, fans, and sensors.

Engine control system

Engine power supply circuit

The power supply consists of a low-voltage circuit. The low-voltage circuit provides uninterrupted 5 volt

(V) and 3.3 V power to the formatter, and provides 24 V, 5 V, and 3.3 V power to the scanner controller

board.

28 Chapter 4 Theory of operation ENWW

Page 45

Flatbed unit and ADF system

Electrical system

The scanner-assembly electrical system consists of the following components:

The charged-coupled device (CCD) PCA (optical assembly)

●

The inverter

●

The scanner controller board

●

The ADF intermediate board

●

Figure 4-1 Scanner assembly electrical structure on page 29 shows the scanner-assembly electrical

structure.

Scanner/controller

board

Fan drive circuit

Motor drive circuit

Motor drive circuit

Motor drive circuit

Solenoid drive circuit

Fan drive circuit

Inverter

PCA

Carriage home sensor

ADF open sensor

Flatbed fan

Carriage motor

Feed motor

Read motor

Solenoid

ADF intermediate

PCA

Carriage (Optical scan unit)

CCD

Scanning

Lamp

Image

scanner

ADF

ADF fan

Cover open sensor

Empty sensor

Registration sensor

Read sensor

Exit sensor

Bin full sensor

Paper detect

Formatter

SENPWR

Figure 4-1 Scanner assembly electrical structure

ENWW Flatbed unit and ADF system 29

+24V

Page 46

Motors and fans

The scanner assembly has three motors and three fans. The motors are stepping motors, which drive

the components inside the scanner assembly. The fans cool various motors and components in the

system.

Name Purpose Type Rotation Failure detection

Scanner motor (flatbed

motor)

Feed motor Drives the pickup, the

Read motor Drives the feed and

Scanner base fan Cools the power supply Fan Exhaust No

Scanner motor fan Cools the scanner lamp

ADF fan Cools the feed motor

Optical assembly

The optical assembly contains the lamp, five mirrors, a lens, and the charged coupled device (CCD).

Inverter

circuit

Drives the scanner

carriage unit

separation, and

registration rollers

delivery rollers

and the CCD

and the read motor

Scanning lamp

Stepping motor Varies No

Stepping motor Varies No

Stepping motor Varies No

Fan Intake Yes

Fan Exhaust Yes

Document

reflector Fourth mirror

Third mirror

Glass

Fifth mirror

Lens

CCD

CPU

Scanner

First mirror

Second mirror

Controller

Figure 4-2 Scan carriage components

The scanner lamp illuminates a small strip of the document that is called the raster line. The mirrors

direct the light through the lens to the CCD. The CCD senses and records the light, creating an analog

representation of the raster line. If the ADF is being used, the document then advances in the ADF to

the next raster line. If the flatbed is being used, the carriage advances to the next raster line. This

advancing and collection process continues to the end of the sheet.

30 Chapter 4 Theory of operation ENWW

Page 47

Optical unit home position

detection sensor

Sensor flag

MOTOR CONTROL

signals

CPU

Optical unit

motor drive circuit

MOTOR DRIVE

signals

Motor rotates in

the reverse direction

Unit moves backward carriage

Optical unit

Motor rotates in

the normal direction

Unit moves forward

glass

Motor

Optical unit motor

Figure 4-3 Optical assembly

The image data is collected on the scanner controller board, where it is processed and sent to the

formatter.

ENWW Flatbed unit and ADF system 31

Page 48

ADF feed system

The ADF has built-in duplexing capability for scanning two-sided documents. Pages from the original

document enter the ADF from the ADF input tray. A separation roller and separation pad work together

to separate the top sheet from the stack. The page passes through a set of registration rollers and two

sets of feed rollers that advance the page. A set of delivery rollers delivers the page to the ADF output

bin. A bin-full sensor detects when the ADF output bin is full and stops the feed mechanism until the bin

is emptied.

Read Motor

Registration sensor

Registration roller

Feed roller

Read sensor

Scanning position

Figure 4-4 ADF paper path and sensors

Separation roller

Empty sensor

Separation pad

Exit sensor

Optical unit