Page 1

User’s Guide

HP 83751A/B and

HP 83752AlB

Synthesized Sweepers

Page 2

HP part number:

Printed in USA

Serial Numbers.

83750-90004

March 1996

This manual applies directly to instruments with serial prefix

3610A

and

below.

This manual also applies to Ermware revision 2.0 and above. For Ermware

revisions below 2.0 contact your nearest Hewlett-Packard service center for a

Ermware upgrade.

Notice.

The information contained in this document is subject to change without

notice.

Hewlett-Packard makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and

Etness for a particular purpose. Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

@Copyright Hewlett-Packard Company 1993, 1996

All Rights Reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright laws.

1400 Fountaingrove Parkway, Santa Rosa, CA 95403, USA

Page 3

The HP 8375lA/B and HP

Synthesized Sweepers

83752A/B

The HP 83751AA and HP

“sweepers” throughout this manual) provide continuous analog or digital

stepped sweep capability. The HP

2 to 20

to 20

high power output (approximately + 17

sweepers are SCPI and

for drop-in replacement of an HP 8350 sweep oscillator. The sweepers are

designed for optimum use with HP 8757 scalar analyzers. For specillcation

and option information, refer to Chapter 17, “Specilkations and Options,” in

this manual.

This User’s Guide is written to provide operating information to the user who

is comfortable with the front panel layout and basic operation of the sweeper.

For installation and basic sweeper operation, refer to the HP

HP

provided with your shipment.

GHz,

while the HP

GHz.

The “B” versions of both the HP 83751 and HP 83752 provide

83752A/B

S~thesized Sweepers Installation and Quick Start Guide,

83752A/B

83752A/B

HP-II3

programmable, with HP 8350 HP-IB mnemonics

synthesized sweepers (referred to as

83751A/B

provides a frequency range of 10 MHz

provides a frequency range of

dBm

maximum leveled power). The

83751A/B

and

. . .

111

Page 4

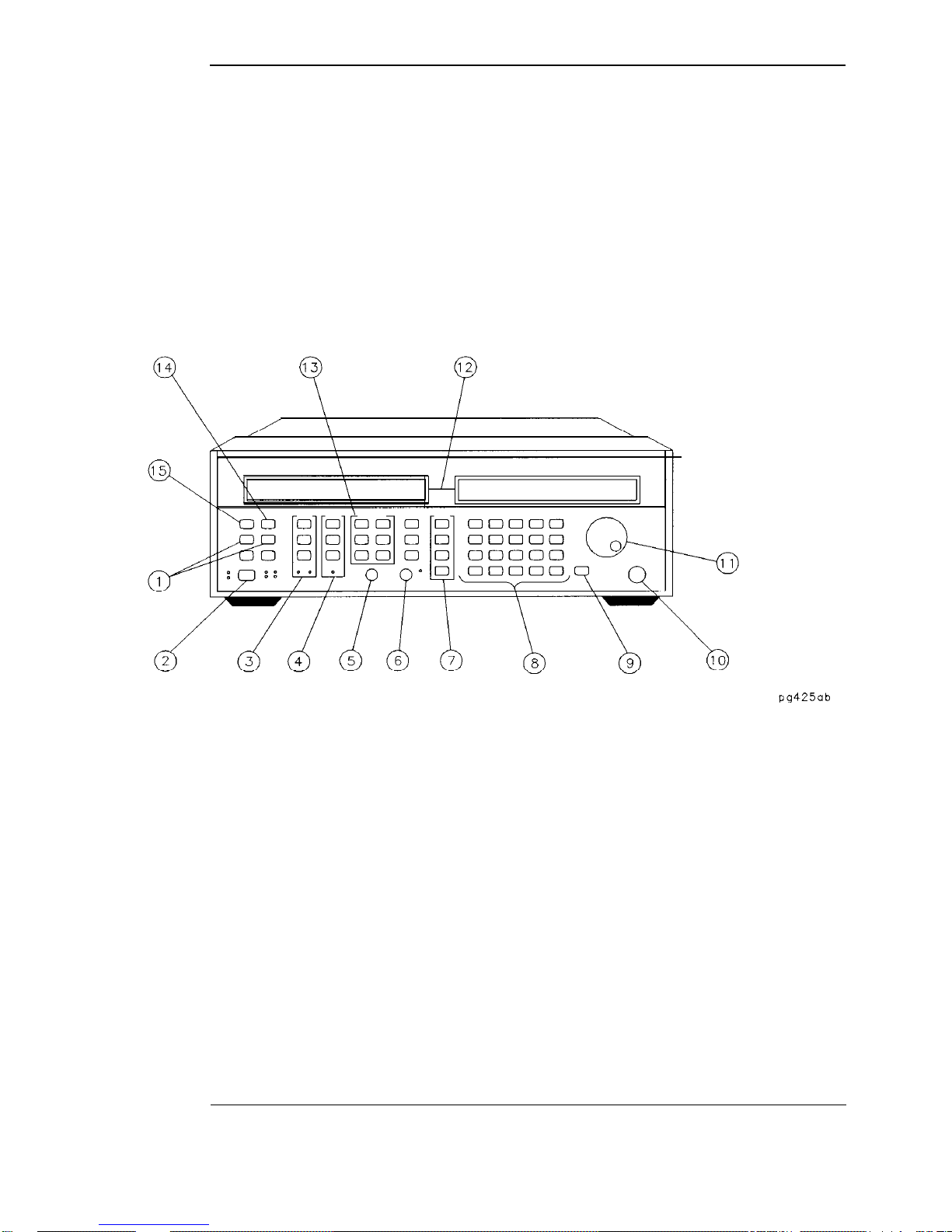

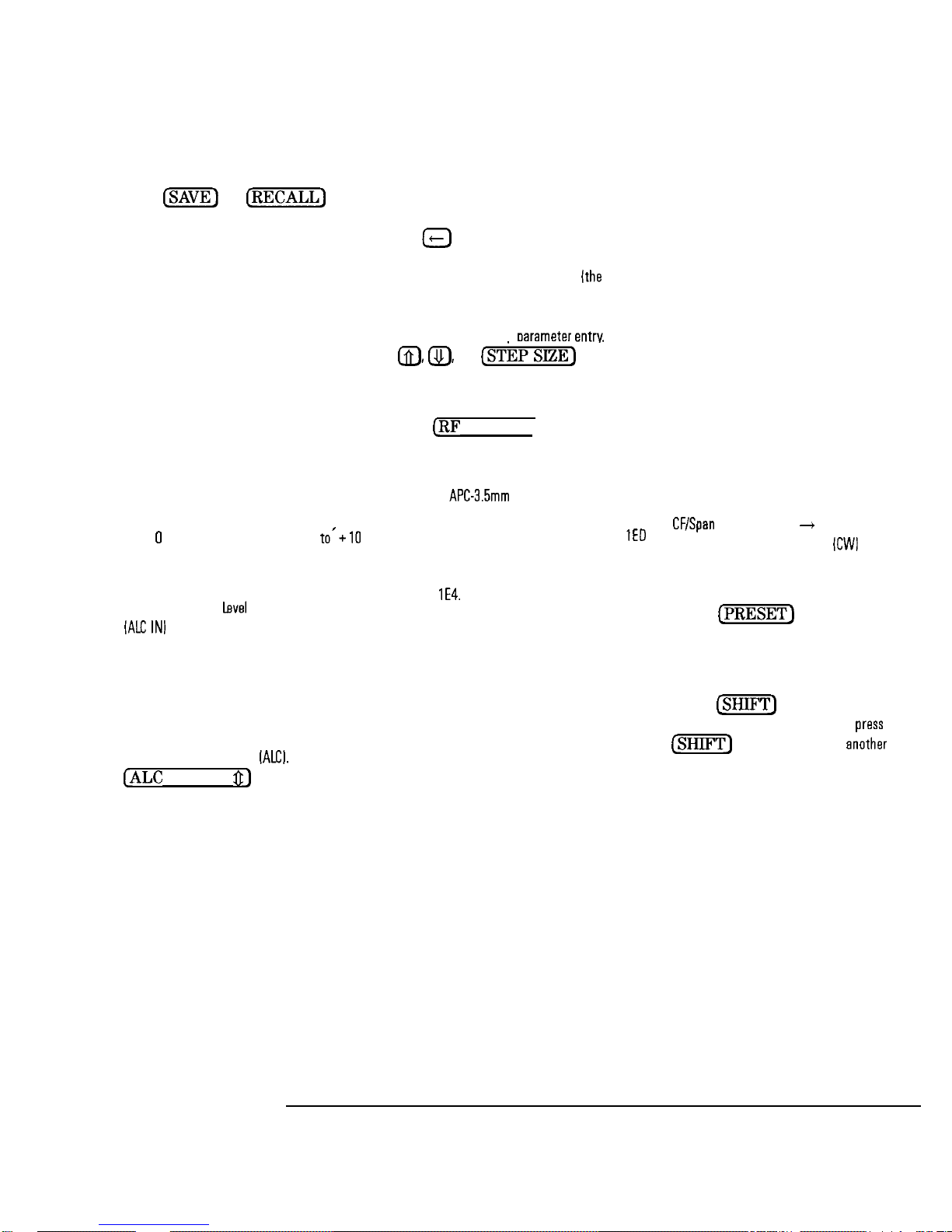

The Synthesized Sweeper at a Glance

The following Egure and accompanying text explain some features of the

sweeper.

iv

pg425ab

The Synthesized Sweeper

Page 5

1. The

(m)

are used to save and subsequently recall

sweeper operating parameters from one of

nine nonvolatile register locations.

2. The line POWER switch turns the sweeper

to either on or standby.

3. The Marker keys allow selection of up to

ten markers to be set anywhere within the

current frequency range. Marker A

measurements are made using these keys as

well.

4. The Modulation keys allow selection of

pulse, AM, or FM modulation.

6. The SWEEP OUT BNC connector provides

voltage proportional to the sweep ranging

from 0 V et the start of a sweep

at the end of the sweep, regardless of sweep

width.

6. The Automatic

[AK INI

connector is used as the feedback

path to the sweeper when its RF output

power level is being leveled externally.

7. The Power keys allow selection of the RF

output power level of the sweeper, as well

as other power related functions, such as

Automatic Level Control

[ALC

MODE 0) key is used to select

the method used to regulate the sweeper

output power level. Either internal leveling or

external leveling [with a diode, power meter,

or source module] can be selected. Additional

equipment is required when external leveling

is used.

and

(m)

level

Control voltage input

IALCI.

The

keys

to’+10

V

6. The date entry keys are used to enter

and/or modify various sweeper parameters.

The @ key cancels all or part of an

erroneous parameter entry before it has been

terminated. The terminator keys

rightmost column of keys) are used to choose

the units for the entered parameter as well

as to terminate the oarameter entry. The

a, 0,

used to increase or decrease a parameter in

predetermined steps.

9. The

toggle the RF output power on and off.

and

(-SIZE)

(RF

ON/OFF) key is used to

[the

keys are

10. The RF OUTPUT connector mates with

a female

standard instruments. The connector metes

with a type-N male connector on option

instruments. The RF OUTPUT connector will

be found on the rear panel of sweepers with

option

APC-3.5mm

lE4.

precision connector on

1ED

11. The front panel knob is used to increase

or decrease active parameters under the

pointers, and is used in manual frequency and

power sweeps.

12. The displays show the current values of

sweeper parameters as well as the status of

many of the sweeper functions. The left-hand

display shows the current frequency status,

whether it be swept or CW. The right-hand

display shows current marker, modulation end

sweep status parameters when they are

selected, as well as the current output power

level. The annunciators that appear below

the parameters are only visible when their

associated function is active. For example, the

STEP annunciator will only be visible when

operating in stepped sweep mode.

13. The Frequency keys are used to set the

various frequency parameters for the sweeper.

Swept frequency selections include Start/Stop,

CWSpan

and Marker 1 + Marker 2

functions. Continuous Wave

also be selected for- outputting single

frequencies.

14. The

(w)

the instrument into a known state. There are

two preset modes: the factory mode, and a

user-defined mode.

15. The

(m)

of some of the kevs. When vou

(m)

the sweeper performs the function printed in

blue above the key.

key changes the function

key and then press

ICWl

mode may

key is used to put

mess

the

enother

key,

Sweeper rear panel features are depicted and described in detail in Chapter 7,

“Front/Rear Panel” in this manual.

V

Page 6

In This Book

This book is divided into two sections: the task reference and the dictionary

reference. These sections are subdivided into chapters. The task reference

section (identified by light blue tabs) provides step-by-step instructions for

many of the tasks that you perform with your sweeper. The chapters in the

task reference section are as follows:

Chapter 1

Chapter 2

Chapter 3

“Performing the Operator’s Check, )) contains a procedure for

assuring you that your instrument is operating correctly.

“Externally Leveling the Sweeper, )) provides the

steps necessary to externally level your sweeper with

detectors/couplers/splitters, power meters, and source

modules.

“Generating a Stepped Sweep,” explains how to set up the

instrument to generate a stepped sweep.

Chapter 4 “Generating a Millimeter Signal,” illustrates the setups for

using a millimeter head with your option

Chapter 5

Chapter 6

The dictionary reference section (identified by dark blue tabs) provides

information about instrument features and functions. Information is divided

into chapters as follows:

“Creating User Flatness Arrays,” explains how to create user

flatness correction arrays, which calibrate the power level at

a remote test port.

“Operating a Master/Slave Setup, ’ shows the steps necessary

to configure two sweepers for two-tone measurement

capabilities.

1EE

sweeper.

Chapter 7

Chapter 8

Chapter 9 “Marker Keys,

vi

“Front/Rear Panel, ’ contains entries that explain different

aspects of the sweeper front and rear panel. (For example,

you turn to this chapter for information on the sweepers

various connectors).

“Instrument State Keys,” explains the functions of the keys

in the Instrument State group.

”

explains the functions of the keys in the

Markers group.

Page 7

Chapter 10

“Modulation Keys,’ explains the functions of the keys in the

Mod group.

Chapter 11

Chapter 12

Chapter 13

Chapter 14

Chapter 15

Chapter 16

Chapter 17

Chapter 18

“Frequency Keys,” explains the functions of the keys in the

Frequency group.

“Sweep Keys,” explains the functions of the keys in the

Sweep group.

“Power Keys, ” explains the functions of the keys in the

Power group.

“Entry Keys,” explains the functions of the keys in the Entry

group.

“Special Functions,

explains the various selections in the

”

special functions menu, which is accessed by selecting

m

SPECIAL.

“Error Messages,” contains lists of the error messages that

might be generated during use of the instrument.

“Specifications and Options,” contains a list of the sweeper’s

warranted performance specifications and typical operating

parameters, as well as the various mechanical, electrical,

warranty, and documentation options that are available.

“Safety and Regulatory information, ’ contains required

regulatory and safety information that is not included

elsewhere in the instrument documentation.

Vii

Page 8

Certification

Hewlett-Packard Company certihes that this product met its published

specifications at the time of shipment from the factory. Hewlett-Packard

further certifies that its calibration measurements are traceable to the United

States National Institute of Standards and Technology, to the extent allowed

by the Institute’s calibration facility, and to the calibration facilities of other

International Standards Organization members.

Regulatory

Information.

The “Safety and Regulatory Information” chapter contains regulatory

information.

. . .

Vlll

Page 9

Warranty

This Hewlett-Packard instrument product is warranted against defects in

material and workmanship for a period of one year from date of shipment.

During the warranty period, Hewlett-Packard Company will, at its option,

either repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service

facility designated by Hewlett-Packard. Buyer shall prepay shipping charges

to Hewlett-Packard and Hewlett-Packard shall pay shipping charges to return

the product to Buyer. However, Buyer shall pay all shipping charges, duties,

and taxes for products returned to Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and

Hewlett-Packard for use with an instrument will execute its programming

instructions when properly installed on that instrument. Hewlett-Packard

does not warrant that the operation of the instrument, or software, or

firmware will be uninterrupted or error-free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper

or inadequate maintenance by Buyer, Buyer-supplied software or

interfacing, unauthorized modihcation or misuse, operation outside of the

environmental specifications for the product, or improper site preparation

or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE

REMEDIES. HEWLETT-PACKARD SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER

LEGAL THEORY.

fumware

designated by

ix

Page 10

Assistance

Product maintenance agreements and other customer assistance agreements

are available

Fbr

any assistance, contact your nearest

Ome.

Refer

for

Hewlett-Packard products.

Haolett-Packard

to the list of Sales and Service 0me.s

Sales and Service

on

the following page.

X

Page 11

Hewlett-Packard Sales and Service Offices

IN THE UNITED STATES

California

Hewlett-Packard Co.

1421 South Manhattan Ave

PO.

Box 4230

Fullerton, CA 92631

17141 999-6700

Hewlett-Packard Co.

301 E. Evelyn

Mountain View, CA 94039

14151

694-2000

Colorado

iewlett-Packard

24 Inverness Place, East

Englewood, CO 80112

3031

649-5000

Co.

Georgia

iewlett-Packard

2000 South Park Place

?O.

Box 105005

Atlanta, GA 30339

Co.

4041 955-1500

:llinois

iewlett-Packard Co.

j201 Tollview

IoIling

3121

Drive

Meadows, IL 60008

255-9800

Yew Jersey

iewlett-Packard

120 W. Century Road

laramus,

201 I

265-5000

Co.

NJ 07653

rexas

hewlettPackard

130 E. Campbell Rd.

hchardson,

2141 231-6101

Co.

TX 75081

IN AUSTRALIA

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

895-2895

IN CANADA

Hewlett-Packard

17500 South Service Road

Trans.Canada

Kirkland,

15141 697-4232

[Canada]

Highway

Quebec H9J 2X8

Ltd.

IN FRANCE

Hewlett-Packard France

F-91947 Les

Orsey

161 907-78-25

Ulis Cedex

IN GERMAN FEDERAL

REPUBLIC

Hewlett-Packard

Vertriebszentrale Frankfurt

Berner Strasse 117

Postfach 560 140

D-6000

Frankfurt 56

1061 II

50-04-I

GmbH

IN GREAT BRITAIN

Hewlett-Packard Ltd.

King Street Lane

Winnersh, Wokingham

Berkshire

0734 784774

RGll 5AR

IN OTHER EUROPEAN

COUNTRIES

Hewlett-Packard

Allmend

2

CH-8967

Widen [Zurich]

100411 57 31 21 11

[Schweizl

AG

IN JAPAN

Yokogawa-Hewlett-Packard Ltd.

29-21 Takaido-Higashi, 3 Chome

Suginami-ku Tokyo 168

1031 331-6111

IN PEOPLE’S REPUBLIC

OF CHINA

China Hewlett-Packard, Ltd.

PO. Box 9610, Beijing

4th Floor,

Main Bldg.

Shuang Yu Shu,

Beijing, PRC

256-6888

2nd

Watch Factory

Bei

San Huan Rd.

IN SINGAPORE

Hewlett-Packard Singapore

Pm.

Ltd.

1150 Depot Road

Singapore 0410

273 7388

Telex HPSGSO

Fax

1651

AS34209

2788990

IN TAIWAN

Hewlett-Packard Taiwan

8th Floor, Hewlett-Packard

Building

337 Fu Hsing North Road

Taipei

1021 712-0404

IN ALL OTHER LOCATIONS

Hewlett-Packard Inter-Americas

3495 Deer Creek Rd.

Palo Alto, California 94304

xi

Page 12

Safety Notes

The following safety notes are used throughout this manual. Familiarize

yourself with each of the notes and its meaning before operating this

instrument.

CAUTION

WARNING

The caution note denotes a hazard. It calls attention to a procedure

tihich,

if not correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution note until

the indicated conditions are fully understood and met.

The warning note denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

iqiury

or

loss of life. Do not proceed beyond a warning note until the indicked

conditions are fully understood and met.

Instrument

Instruction

Manual

!

A

The

CE93

Markings.

The instruction manual symbol. The product is marked with this symbol when it is necessary

for the user to refer to the instructions in the manual.

mark shows compliance with European Community 1993 standards.

The CSA mark is the Canadian Standards Association safety mark.

The

&Ml-A

mark stands for Industrial Scientific and Medical Group 1. Class A.

xii

Page 13

General Safety Considerations

WARNING

WARNING

WARNING

CAUTION

Before this

instrummt

is

switched on, make sure it has been properly

grounded through the protective conductor of the ac power cable to a

socket outlet provided with protective earth contact.

This is a Safety Class I product (provided with a protective earthing

ground incorporated in the power cord). Any interruption of the

protective (grounding) conductor, inside or outside the instrument, or

disconnection of the protective earth terminal can result in personal

injury.

No operator serviceable parts inside the instrument. Refer servicing to

qualified personnel. To prevent electrical shock, do not remove covers.

Any adjustments or service procedures that require operation of the

instrument with protective covers removed should be performed only by

trained service personnel.

For continued protection against fire hazard, replace line fuse only

with the same type and rating (F

6.3A/250V).

The use of other fuses or

material is prohibited.

If this instrument is used in a manner not specihed by Hewlett-Packard Co.,

the protection provided by the instrument may be unpaired.

CAUTION

CAUTION

Always use the three-pronged ac power cord supplied with this instrument.

Failure to ensure adequate earth grounding by using this cord may cause

instrument damage.

This instrument has automatic selection input. Be sure the supply voltage is

within the speciEed range.

Xlll

. . .

Page 14

How to Use This Guide

This guide uses the following conventions.

(FRONT-PANEL

KEY_)

SHIFT FUNCTION

ANNUNCIATOR

This represents a key physically located on the

instrument.

This represents a shift function (blue text above

front panel keys).

Text in this font represents FREQUENCY,

MARKER/SWEEP/STATUS, and POWER displays.

Text in this font represents the annunciators that

are displayed in the lower portion of the sweeper

display.

Page 15

Contents

1.

Performing

To run the

To run peak power-tracking

To

check

To

check

If

you

If the self-test

If the maximum leveled power

2. Externally Leveling the Sweeper

Leveling

External leveling with the option 1El

See

also

Leveling

See

also

Leveling with millimeter-wave source modules

(option

See

also

the Operator’s Check

full

self-test

the maximum leveled power

the output

have

a

problem

fails

with detectors/couplers/splitters

.....................

with

a

power meter

.....................

1EE

only)

.....................

................

power

.................

.................

................

..............

..............

check fails

..............

.........

step

.......

.......

attenuator

l-3

1-5

1-6

l-8

l-10

l-10

l-11

2-3

.

2-6

2-6

2-7

2-8

2-9

2-11

3.

Generating a

Generating a

4.

Using

Using

Creating

5.

Creating

Creating a user flatness array for use in a scalar analysis

millimeter heads with “B” model

(high power) sweepers ................

millimeter heads with “A” model

(standard power) sweepers

See also

To

set up the sweeper ...............

To

set up the power meter

To

start the user flatness cal

measurement

To

set up

Stepped Sweep

Millimeter Signal

..............

.....................

User Flatness Arrays

a

user flatness array

..................

the sweeper

.............

.............

............

...............

4-3

4-5

4-6

5-3

5-4

5-5

5-5

5-6

5-7

Contents-l

Page 16

To

To set

To start the user flatness cal

To reactivate the

6.

Operating a

To

set up

To

set up

See

also

set up

up

the master sweeper

the

......................

the analyzer

the power meter

HP

8757 system interface

Master/Slave

slave

sweeper

...............

...............

Setup

.............

..............

..........

......

5-7

5-8

5-8

5-9

6-4

6-6

6-7

Front/Rear

7.

Connectors

BNC

Panel

.....................

Connectors

Multi-pin Connectors

AUXILIARY

HP-IB

.....................

SOURCE MODULE INTERFACE (Option

RF Output Connector

Display

......................

Frequency Display

Marker/Sweep/Status

Annunciators

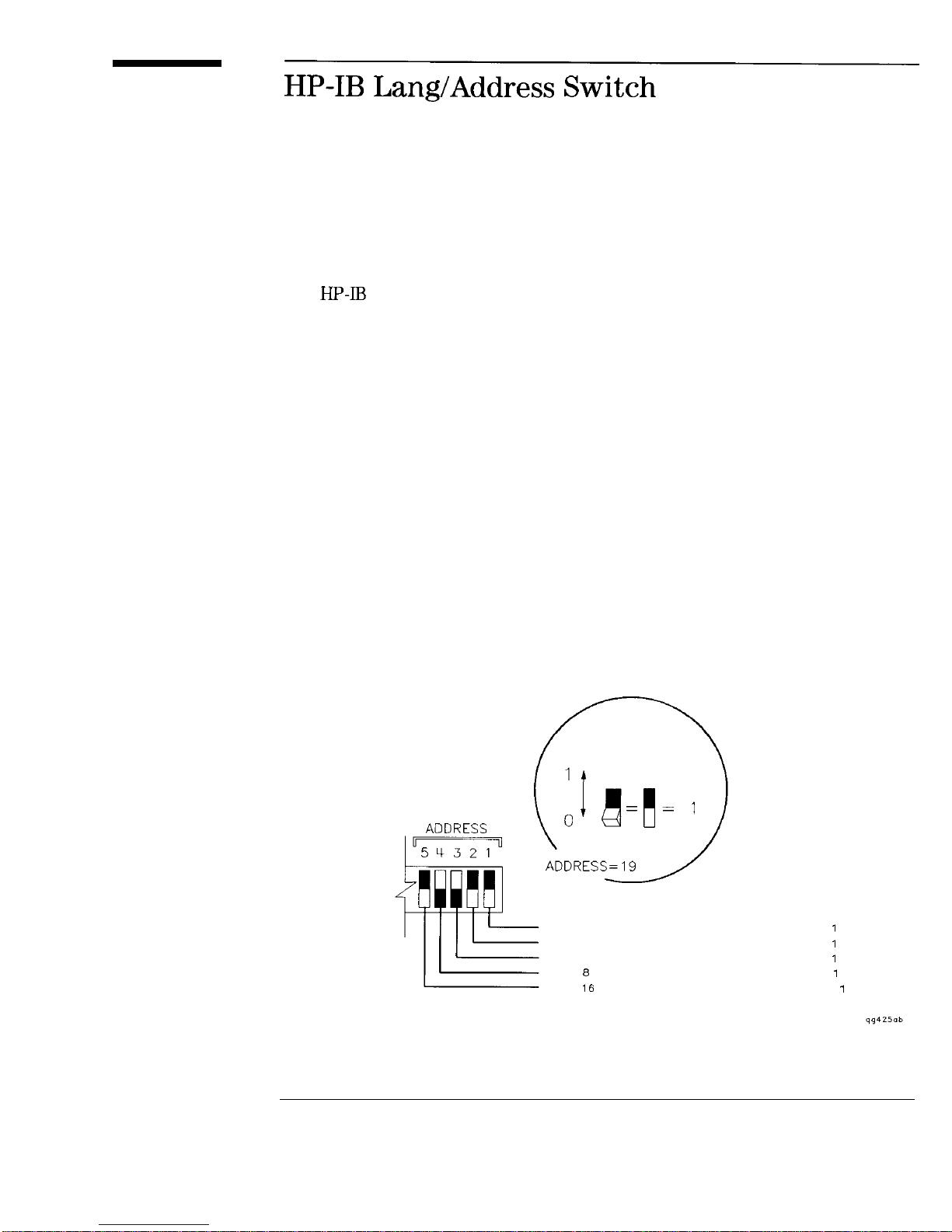

HP-IB Lang/Address Switch

See

Knob

Also

.....................

.......................

Equivalent SCPI Commands

Line

POWER Switch

Power

Cables

Instrument

....................

State

.....................

.....................

.....................

.....................

.....................

.....................

.................

...............

INTERFACE

...............

.................

and Power

...................

................

Keys

............

Display

.............

............

.......

1EE

Only)

7-3

7-5

7-8

7-8

7-10

7-13

7-15

7-16

7-17

7-18

7-19

7-23

7-25

7-26

7-26

7-27

7-29

8-3

8-4

8-6

8-8

B-10

8-11

Contents-2

Page 17

9.

Marker

10.

Modulation Keys

11.

12.

Sweep Keys

Keys

(iziG)

........................

m

(MKRa_l

(PULSE MODE

(AMMODEU

(FM MODE

ITIME) . . .

(TRIG MODE

[SINGLE/TRIG)

........................

.......................

8)

...................

....................

$1.

....................

....

.

....................

....................

Q)

....................

...............

...................

...................

...................

...................

...................

9-4

9-7

9-8

10-4

10-6

10-7

11-4

11-6

11-8

11-9

11-10

11-12

12-4

12-7

12-10

13.

Power Keys

14.

Entry

(POWER LEVEL]

@OWER/SWEEP)

[ALC

MODE 3) . . . . . . . . . . . . . . . . . . . .

(FLTNEss ON/OFF_) . . . . . . . . . . . . . . . . . . .

....................

...................

Keys

Q)a

@EEiz)

......................

Number Pad Keys

Unit

(j-ON/OFF)

......................

*+.

ENTRY OFF

PEgK

.......................

Keys

.....................

......................

.....................

.......................

..................

Contents-3

13-3

13-5

13-7

13-10

14-3

14-4

14-5

14-6

14-7

14-8

14-9

14-10

Page 18

15.

Special

l- CWCFAUTO

2 - CW PEAKNG . . . . . . . .

3 - SWPTIME AUTO . . . . .

4 - STEP SWPTIME . . . . ,

5 - SWPTIME

6 - ATT COUPLING . . . . .

7 - ATT SETTING . . . . . .

8 9 -

10 - V/GHz

11- V/GHz OFFSET . . . . .

12-PWRMETERTY

13-PWRMETERAD

14 -

15 - LANGUAGE . . . . . . .

16 - FW REVISION . . . . . .

17 -

18 - DP DEFIN : : : ‘. ‘. ‘. ‘. ’ .

19 - CONTROL MODE . . . .

21-

Functions

ROSC

ROSC

FM

AUTO

SOURCE : : : : : :

SENSITIVITY . . . .

*SECURITY

FULL

. . . . . .

LLIM . . . .

SCALE . . . . .

. . .

. . .

SELFTST . . . . .

...........

.

...........

...........

...........

.

...........

...........

...........

...........

...........

.

...........

...........

.

...........

.

...........

...........

...........

...........

...........

............

...........

...........

15-6

15-7

15-8

15-9

15-10

15-11

15-12

15-13

15-14

15-15

15-16

15-17

15-18

15-19

15-20

15-21

15-22

15-26

15-27

15-28

16. Error

The Error/Event Queue

Error numbers

Error

SCPI Error

Contents-4

Messages

................

....................

Messages List

Messages

Command Error

Execution Error

Device-specific Error

Query Error

Instrument

Block

Bus

Control Errors

Parsing and Compatibility Errors

Diagnostics and

Internal Hardware Errors

Hardware Configuration Errors

Calibration Routine Errors

Loops

Miscellaneous Hardware Dependent Errors

Specific

Transfer Errors

Unlocked Errors

.................

................

...................

..................

................

....................

Error

................

Self-test

Messages

...............

Errors

..............

.............

...............

.........

..........

...........

...........

......

16-3

16-4

16-5

16-7

16-7

16-13

16-19

16-21

16-23

16-23

16-24

16-25

16-28

16-32

16-32

16-33

16-35

16-36

Page 19

17.

Specifications and

Specifications

Frequency

Range

Timebase Stability

CW

Mode

Stepped

Ramp (Analog)

Bandswitch Points

RF Output

Maximum

Minimum Settable

Resolution

Accuracy and Flatness

Power Sweep

Power Slope

External

User

Source Match

Spectral Purity

Harmonics (at max leveled power)

Subharmonics

Non-harmonic Spurious

Residual

Modulation

Pulse

AM

FM

General

Compatibility : : : :

Programming

Master/Slave (two-tone) Measurements

Environmental

Warmup Time

Power

Dimensions

Weight

Options

Electrical Options

Option 1El - Add Output

Option lE4 - Rear Panel RF Output

Options

....................

.....................

......................

.................

....................

Sweep Mode

Sweep

.................

.....................

Leveled

Power (25 f5

Power

....................

...................

...................

Leveling

Flatness

(Level)

.................

Correction

...................

...................

...............

FM (0.05 to 15 kHz

.....................

......................

.......................

.......................

................

...................

..................

..................

Requirements

................

....................

......................

......................

.................

...............

Mode

..............

...............

..............

...............

Step

............

“C)

.........

..........

..........

bandwidth)

Attenuator

.......

.......

........

17-3

17-4

17-4

17-4

17-4

17-5

17-5

17-5

17-7

17-7

17-8

17-8

17-8

17-9

17-9

17-9

17-9

17-10

17-11

17-11

....

17-11

17-11

17-12

17-13

17-13

17-13

17-14

17-15

17-15

17-15

17-15

17-16

17-16

17-17

17-17

17-18

17-19

17-19

....

.

17-19

17-19

Contents-5

Page 20

Option lE5 - Add

Option

Option

Cable

.

1ED

1EE - Source

....................

Mechanical Options

Option 1CM -

Option

Option

1CP - Rack

AX2 -

Warranty Options

Option

W30 - Two

Service

Option

Option

W50 W52 -

Service

Option

W54 -

Documentation Options

High

Type-N RF

Stability Timebase

Output

Connector

Module Connector and Extension

................

Rack

Mount Kit without Handles

Mount Kit with Handles

Portable Handle and Front-panel

.................

Additional Rears Return-to-HP

...................

Five

Five

Year

Year

Return to

HP

Return-to-HP Calibration

...................

Five

Year MIL-STD

Calibration

..............

Option OB2 - Extra Operating Documentation

Option

Certification Options

Option 1BN - Certification

Option

OB3 - Service

................

1BP -

Certification with Data

Documentation

............

......

Repair

.......

.......

.....

....

Cover

Service

Service

...

. .

17-19

17-19

17-20

17-20

17-20

17-20

17-20

17-21

17-21

17-21

17-21

17-21

17-22

17-22

17-22

17-22

17-22

17-22

18.

Safety and

Regulations and Licensing

Safety

Index

Contents-6

Notice

for

Information

Statement

Regulatory

Germany:

of

Compliance

Information

Noise

..................

Environmental Conditions

Ventilation Requirements

Cleaning Instructions

..............

Declaration

..............

.............

..............

...............

........

18-3

18-3

18-8

18-8

18-8

18-9

18-9

Page 21

Figures

l-l. The UNLEV Annunciator Location ............. l-7

l-2. Connections for Checking Output Power ..........

2-l.

ALC Circuit Externally Leveled ..............

2-2. Typical Diode Detector Response at 25

2-3. Leveling with a Power Meter ...............

2-4. Millimeter-wave Source Module Leveling ..........

2-5. Millimeter-wave Source Module Leveling Using a Microwave

Ampliher ......................

4-1. Millimeter-wave Source Module Leveling ..........

4-2. Millimeter-wave Source Module Leveling Using a Microwave

Amplifier ......................

5-1. Creating a User Flatness Array ......... .....

5-2. Scalar Measurement System Setup ............

6-l.

Master/Slave Setup ...................

7-l.

Sweeper Connectors - Front Panel .............

7-2. Sweeper Connectors - Rear Panel .............

7-3. Auxiliary Interface Connector ...............

7-4. HP-B Connector and Cable ................

7-5. Interface Signals of the Source Module Connector ......

7-6. Sweeper Display ............... .....

7-7. Sweeper Display and LED Annunciators ..........

7-8. HP-B Address Switch Settings ..............

7-9. Instrument Language Switch Settings ...........

7-10. Clear Register Contents Settings .............

7-l 1. The Sweeper Line POWER Switch .............

7-12. Power Cable and Line (Mains) Plug Part Numbers ......

8-l.

Instrument State Group .................

9-l.

The Markers Group ...................

10-l. The Modulation Group ...................

11-l. The Frequency Group ..................

12-1. The Sweep Group ....................

13-1. The Power Group ....................

14-1. The Entry Group ....................

15-1. The Instrument Group ..................

17-l. Typical Swept Frequency Accuracy (100 ms sweep, ramp

mode) .......................

17-2. Typical Maximum Available Power ............

“C

.........

l-8

2-3

2-5

2-7

2-9

2-10

4-4

4-6

5-3

5-6

6-3

7-3

7-4

7-8

7-10

7-13

7-16

7-19

7-23

7-24

7-24

7-27

7-30

8-2

9-2

10-2

11-2

12-2

13-2

14-2

15-2

17-6

17-7

Contents-7

Page 22

Contents

17-3. Typical Phase Noise (10

17-4. Dimensions

.......................

GHz

Carrier)

...........

17-12

17-17

Contents-8

Page 23

l%bles

7-l.

Pin Description of the Auxiliary Interface

8-l.

Factory Preset Conditions

14-1. Step Sizes

15-1. Special Functions for the HP 83750 Series Sweepers

15-2. FM Sensitivity When Using Source Modules

.......................

................

.........

........

....

7-9

8-4

14-3

15-4

15-19

Contents-9

Page 24

1

Performing the Operator’s

Check

Page 25

Performing the Operator’s Check

The operator’s check consists of a series of tasks that, when completed, will

either assure you that your instrument is operating correctly, or will help

to point to problem areas if it is not. The operator’s check

performance to specifications.

The operator’s check should be performed on a weekly basis, or whenever

the integrity of the sweeper is in question.

To perform the operator’s check, the following tasks should be performed, in

order:

1. Run the full self-test.

2. Run peak power-tracking.

3. Check the maximum leveled power.

4. Check the output power.

does

not ensure

l-2

Page 26

To run the full self-test

Attention!

All external cables [including HP-IB and BNC cables) must be disconnected from the sweeper prior to

running the full self-test. Failure to do so may cause self-test failures or lock-ups.

1. Disconnect all external cables prior to running the self-test.

2. Activate the FULL SELFTST special function by pressing the following

keys on the sweeper:

The message that appears in the MARKER/SWEEP/STATUS display is

one of the following:

Full self-test has not been performed

since the last time the line power was

turned on.

Full self-test has been performed and

passed all tests.

Full self-test has been performed, and

test XXXXXX was either the only test

that failed, or was the most significant

failure.

3. Press the

While the self-test

(jj)

key again to initiate the self-test routine.

routine is running, a

M++I,,I.~ i t. ++s+

appear in the MARKER/SWEEP/STATUS display.

message

wfll

l-3

Page 27

Performing the Operator’s Check

To run the full self-test

4. When the self-test routine is

mushed,

a message will appear in the

MARKER/SWEEP/STATUS display. If the message does not say

“Ful 1

Ted PHASED,”

refer to the section entitled “If You Have a

Problem” at the end of this chapter.

The full self-test is actually a series of tests performed to check different

instrument functions. If the sweeper fails just one test, the display shows the

title of the failed test. If the instrument fails more than one test, the test title

shown is the most signilicant failure.

1-4

Page 28

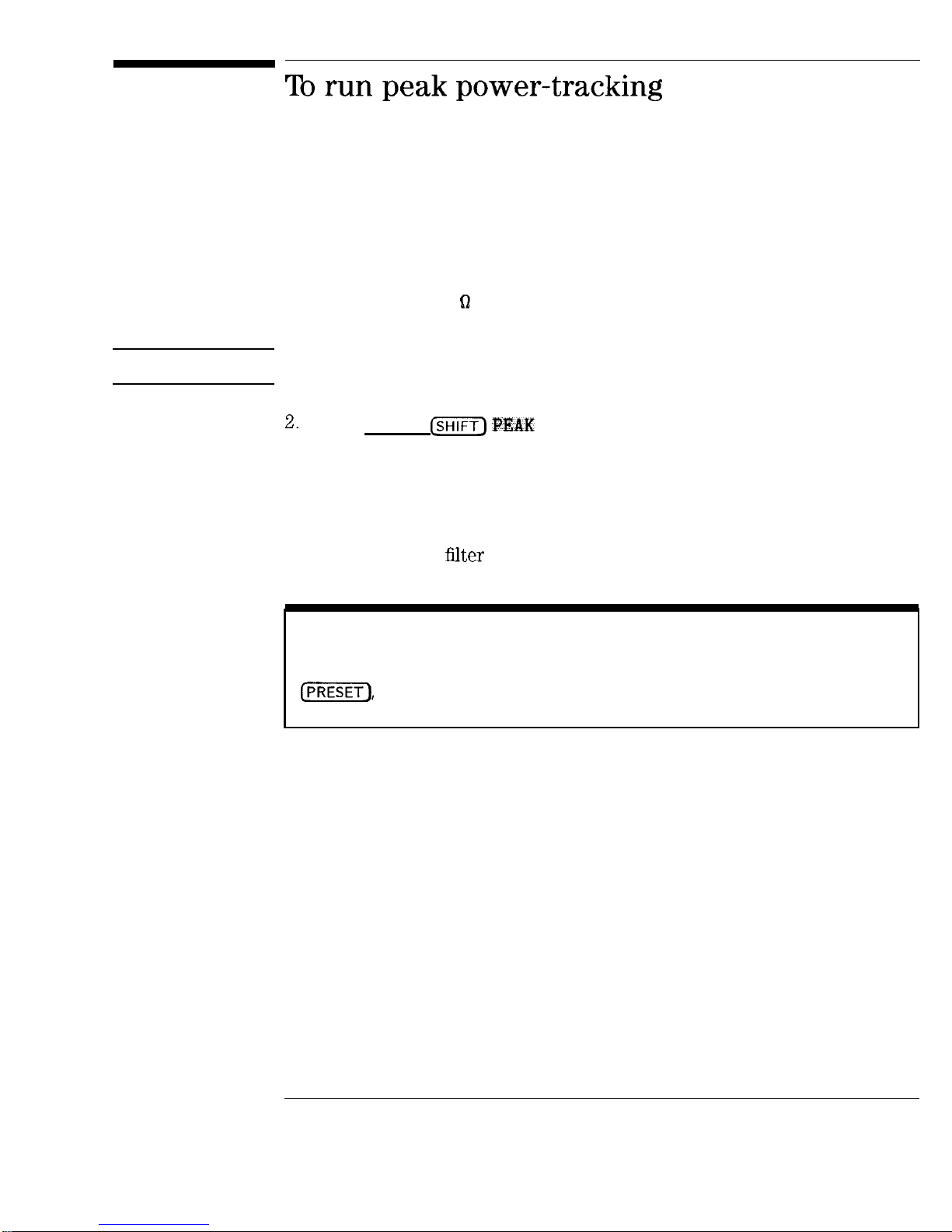

lb run peak power-tracking

1. Before running peak power-tracking, make sure the RF OUTPUT is either

connected in a 50 0 system, or has a load on it, such as a power sensor or

attenuator.

CAUTION

For optimum power at all frequencies, do not run peak power-tracking with a

millimeter head connected to the sweeper.

2.

Press (PRESET)

Cm)

P&W .

The MARKER/SWEEP/STATUS display shows the progression of the sweep

as the instrument adjusts the power-tracking.

When you run peak power-tracking (or autotracking), the instrument

optimizes its output power over the sweeper’s full frequency range by

tracking the output

NOTE

Peak power tracking takes approximately 1 to 3 minutes to complete, and can be aborted by pressing

(EEFi],

if necessary.

titer

with the RF source output.

1-5

Page 29

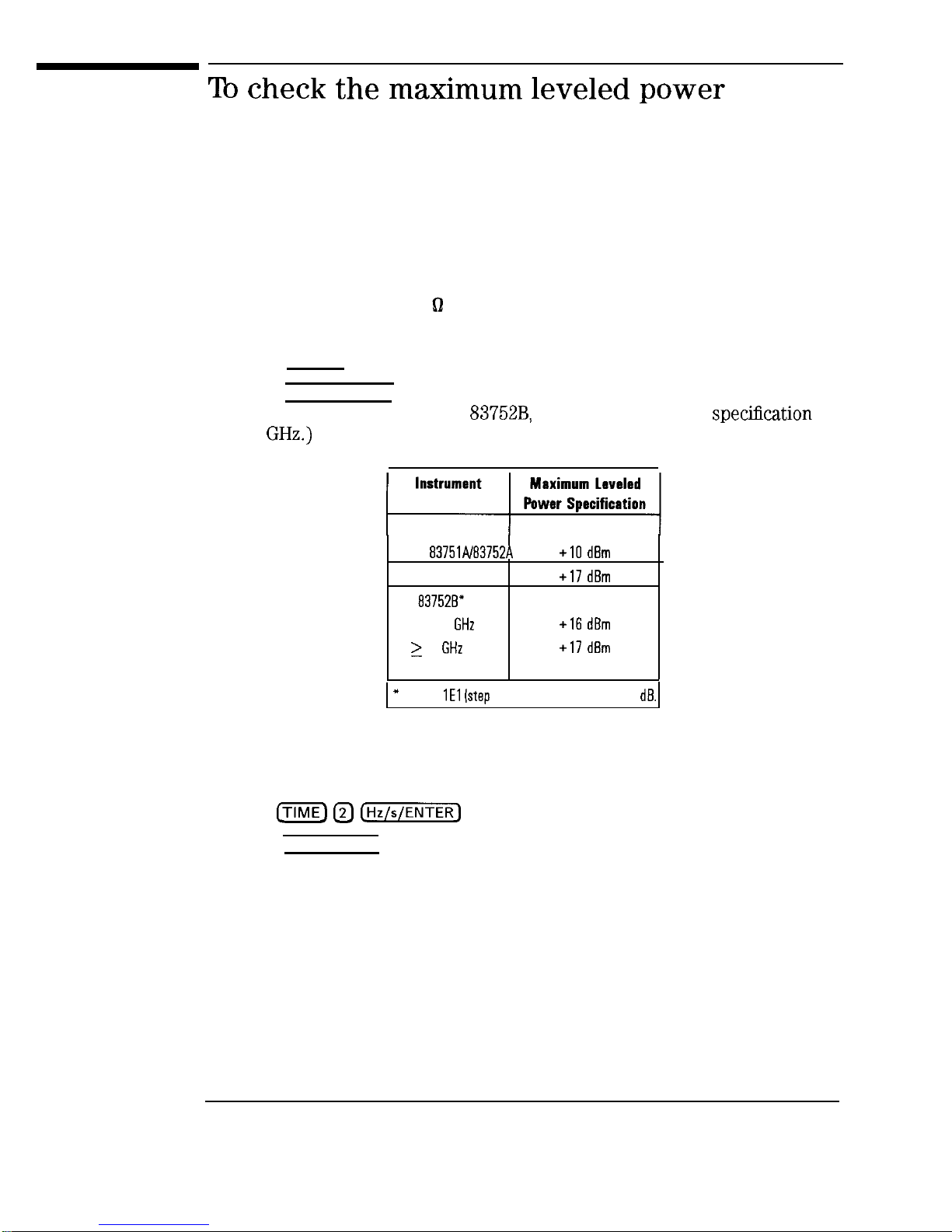

lb check the maximum leveled power

1. Before checking maximum leveled power, make sure the RF OUTPUT is

either connected in a 50 61 system, or has a load on it, such as a power

sensor or attenuator.

2. Press [PRESET).

3. Press [POWER LEVEL) and enter the specified maximum leveled power for

your instrument. (For an HP

< 2

GHz.)

83752B,

set the power to the

specikation

for

HP

83751N33752A

HP 837518”

HP

837528”

< 2

>

2

GHz

*

Option

1El

GHz

[step attenuatorl, reduce by 1

+lO dBm

+17 dBm

+16 dBm

+17 dBm

dB.

4. Make sure the UNLEV annunciator is not lit at any time. The UNLEV

annunciator is located in the POWER display area. (See Figure l-l.)

5. Press

m

@

cm)

to change the sweep time to 2 seconds.

6. Press [SINGLE TRIG] and make sure the UNLEV annunciator does not come

on at any point during the sweep. (If the annunciator comes on, it

indicates the instrument is unleveled.) The UNLEV annunciator is located

in the POWER display area. (See Figure l-l.)

1-6

Page 30

Performing the Operator’s Check

To check the maximum leveled power

\

000 0 000 0 00000

00

00

:a::

For HP

The HP

7. Press the following keys to set a sweep range of 2

power level of 17

0 0 000 0 00000

0 0 000 0 00000

-*

0

0

0’0

Figure l-l. The UNLEV Annunciator location

83752B

83752B

Instruments Only.

sweepers have a power specification that is split at 2

dBm

(or 16

000000

dBm

for instruments with option

0

0

0

GHz

’

to 20

UNLEV

ANNUNCLATOR

tiEARS

pg426ob

GHz.

GHz

and a

1El):

(START_) 0 @iqGqLq)

[POWER

8. Press @NGLE

on at any point during the sweep. (If the annunciator comes on, it

indicates the instrument is unleveled.) The UNLEV annunciator is located

in the POWER display area. (See Figure l-l.)

mm) 117)

TRIG_)

(or

[16)) [GHz/dB(mL)

and make sure the UNLEV annunciator does not come

l-7

Page 31

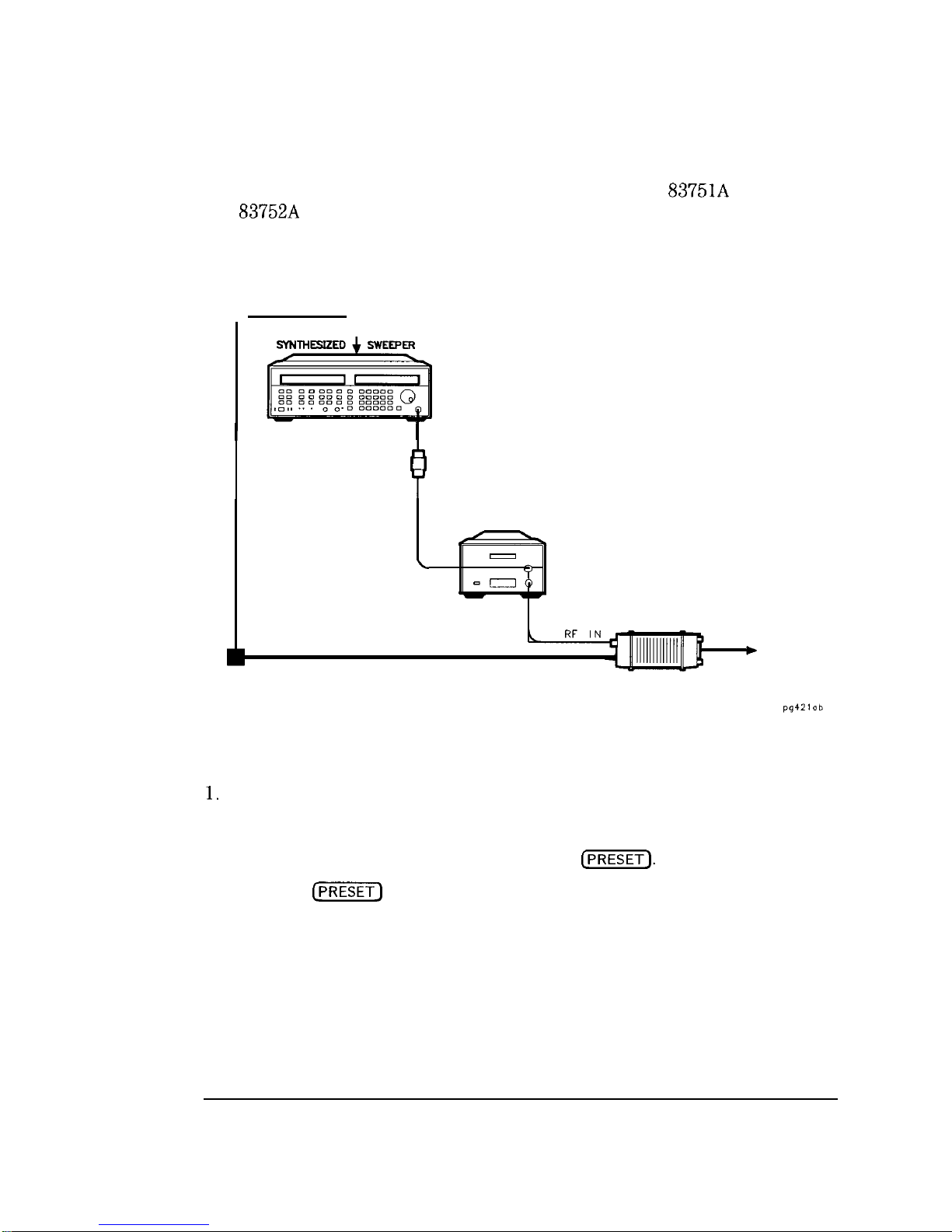

To check the output power

1. Connect the equipment as shown.

POWER METER

SENSOR

SYNTHESIZED SWEEPER

RF OUTPUl

I

POWER SENSOR ADAPTER

Figure 1-2. Connections for Checking Output Power

2.

Press (PRESET_).

3. Press ccw)

4. Press

you set. Refer to the following table. Terminate the power level entry by

pressing

(ZiJ CGHz/dB(mL).

POWER

LEVEL) and enter the specified power for the CW frequency

(GHz/dB(mZ).

pg427ob

l-8

Instrument

HP

83751Ml3752A”

HP 837518”

HP 837528”

< 2

1

2

1 *

Option

Maximum leveled

Power Specification

+I0 dBm

+I7 dBm

GHz

GHz

IEI

lstep attenuetorl, reduce by 1

+I6 dBm

+I7 dBm

dB.1

Page 32

Performing the Operator’s Check

To check the output power

5. Set the power meter calibration factor to the value listed on the power

sensor that corresponds to the frequency you set.

6. Verify that the measured output power meets the instrument specification.

l If the measured value is less than the specihed power, turn the front

panel knob until the value measured is at least the speciEed power level.

l Make sure that the UNLEV annunciator doesn’t light. (If the annunciator

does light, this indicates an unleveled condition.)

7. Repeat steps 3 through 6 for the following setting(s):

2.5

GHz

1.5

GHz -

for HP

83752AA

instruments only

50 MHz - for HP

83752A/B

instruments only

l-9

Page 33

If you have a problem

If you have a problem while performing the operator’s check, check the

following list of commonly encountered problems. If the problem you have

encountered is not here, contact the nearest Hewlett-Packard office for

assistance.

If the self-test fails

The self-test has failed if the message that appears when it is done, is

anything except

Full Test.

PHSSED.

q Make sure all external cables are disconnected from the sweeper and run

the self-test again.

q If the test still fails, send the instrument to an HP service center for repair,

including a description of the failed test and any other error messages.

NOTE

If you need to ship your sweeper, remove the front handles (if so equipped) and use the original

packaging (or comparable).

l-10

Page 34

Performing the Operator’s Check

If the maximum leveled power check fails

q Make sure that the RF OUTPUT connector was terminated before the peak

power-tracking sequence was run, and before the maximum leveled power

check.

q Make sure the power you entered in steps 2 and 5 of the maximum leveled

power check procedure are correct for your particular instrument.

q

If

the measured value of power in step 6 of “To check the output power” is

mo?-e

than the specified power, turn the front panel knob counterclockwise

until the value measured equals the specified power. Note the sweeper’s

front panel reading and use this value to repeat the maximum leveled

power check.

q If the check still fails, contact the nearest Hewlett-Packard office for

assistance.

NOTE

If you need to ship your sweeper, remove the front handles

packaging (or comparablel.

(if

so equipped) and use the original

l-11

Page 35

I

2

Externally Leveling the

Sweeper

Page 36

Externally Leveling the Sweeper

In externally leveled operations, the output power from the sweeper is

detected by an external sensor. The output of this detector is returned to the

leveling circuitry, and the output power is automatically adjusted to keep

power constant at the point of detection.

2-2

Page 37

Leveling with detectors/couplers/splitters

1. Connect the equipment as shown in Figure 2-1.

SYNTHESIZED SWEEPER

DIRECTIONAL COUPLER

OR POWER

SPLITTER)

pg417ab

Figure 2-1. ALC Circuit Externally leveled

2. Press

[ALC

shows

MODE

HLC=

8)

repeatedly until the MARKER/SWEEP/STATUS display

Diode. Note that the EXT ALC annunciator is lit.

3. Enter the coupling factor by selecting

the desired number.

m

LEVELED

OUTPUT

EXT CAL and then entering

2-3

Page 38

Externally Leveling the Sweeper

leveling with detectorslcouplerslsplitters

NOTE

The coupling factor (in

leveled power (P

locations of P lev and P det. After the coupling factor has been entered, the front panel knob

may be used to fine tune the displayed power to equal the actual leveled output power (P levl.

Figure

2-l

illustrates a typical setup for external leveling. When externally

dB)

is defined by the equation

lev) -

detected power (P

det).

Refer to Figure ‘2-1 for

leveled, the power level feedback is taken from the external negative detector

input rather than the internal detector. This feedback voltage controls the

ALC system to set the desired RF output.

Figure 2-2 shows the input power versus output voltage characteristics for

typical HP diode detectors. From the chart, the leveled power at the diode

detector input resulting from any external level voltage setting may be

determined. The ALC feedback voltage present at the output of the detector

must be between -0.2 mV and -0.5 V. For a typical

corresponds to a detector input of approximately -35

HF’

diode detector, this

dE%m

to +5

dBm.

(See

Figure 2-2.)

2-4

Page 39

Externally Leveling the Sweeper

leveling with detectors/couplers/splitters

10 v

1.0

100 mv

10

mv

1 mv

+20

dBV

+lO

dBV

+6

dBV

v

-10

-20

-30

-40

-50

-60

0 dBV

dBV

dBV

dBV

dBV

dBV

dBV

-66

dBV

-70 di3V

.I mv

-40 -30

-

DETECTOR INPUT POWER,

0

+10 +20 f30

Figure 2-2. Typical Diode Detector Response at 25

dBM

-80

dBV

pg431ob

‘C

2-5

Page 40

Externally leveling the Sweeper

leveling with detectors/couplers/splitters

External leveling with the option 1El step attenuator

Some external leveling applications require low output power from the

sweeper. The sweeper automatically uncouples the attenuator from the ALC

system for

the UNCPLD annunciator is lit.

For example, leveling the output of a 30 dB gain amplifier to a level of

-

10

leveled. At some frequencies this level is beyond the range of the ALC

modulator alone. If so, the UNLEV warning message is displayed. Inserting 40

dB

of attenuation results in an ALC level (power level + attenuator value) of

0

dBm,

AM or other functions that vary the power level.

all

external leveling points. Note that in external leveling modes,

dBm

requires the output of the sweeper to be around -40

which is well within the range of the ALC. This gives a margin for

dBm

when

The ALC level should be greater than or equal to -10

sweepers (standard power), and -5

power). Adjust the attenuator so that the ALC level is within the specified

power range of your sweeper. For an “A” model sweeper, this is achieved by

using attenuation equal to the tens digit of output power. Example: for a

desired sweeper output power of -43

1.

Press

2. Set the attenuator to 40

CSHIFT)

SPECIAL

(YJ

dB:

dBm

press

for “B” model sweepers (high

dBm;

do the following:

c40) [GHz/dB(mL)

dBm

for “A” model

See also

To obtain flatness corrected power refer to the chapter entitled “Creating User

Flatness Correction Arrays, n later in this manual.

2-6

Page 41

Leveling with a power meter

Leveling with a power meter is similar to leveling with a diode detector.

1. Set up the equipment as shown in Figure 2-3. Be sure to set the power

meter to the correct manual range mode for the output power setting at

which you are leveling.

POWER

METER

=j-$g;pLER

POWER SENSOR

I

Figure 2-3. leveling with a Power Meter

2. Press

3. Select

shows

(ALC

MODE $J repeatedly until the MARKER/SWEEP/STATUS display

ALC= Pcllwr Met.w-.

m

EXT CAL @

Note that the EXT ALC annunciator is lit.

CGHz/dB(mL).

enter the coupling factor of the coupler.)

LEVELED

OUTPUT

pg418ab

(If a directional coupler is used,

2-7

Page 42

Externally leveling the Sweeper

leveling with a power meter

NOTE

The coupling factor is defined by the equation

leveled power (P

locations of P lev and P det. After the coupling factor has been entered, the front panel knob

may be used to fine tune the displayed power to equal the actual leveled output power fP lev).

lev) -

detected power (P

det).

Refer to Figure 2-1 for

4. If the power meter and the sweeper power setting don’t agree, set the

coupling factor step size to 10 dR and then use the a Q) keys to adjust

the coupling factor up or down until the power meter and the sweeper

power setting agree.

5. Select the sweep tune by pressing

I‘TIME)

and then entering the desired

sweep rate.

NOTE

Due to the settling time required by power meters, it is recommended to use a 40 second sweep rate.

Unlike detector leveling, power meter leveling provides calibrated power out

of the leveled RF port.

See also

To obtain flatness corrected power refer to “Creating User Flatness Correction

Arrays, n later in this manual.

2-8

Page 43

Leveling with millimeter-wave source modules

(option 1EE only)

Millimeter-wave source module leveling is similar to power meter leveling,

except that a slow sweep time is not required. Figure 2-4 and Figure 2-5

illustrate the setups for leveling with a mm-wave source module.

Figure 2-4 illustrates the setup that is used with the HP

HP

83752B

(high power models). No external amplifier is required to obtain

maximum specified power. The interface extender cable

5062-7202) allows the source module to be positioned in front of the sweeper.

SOURCE MODULE

I NTERFACE

RF

OUTPUT

ADAPTER

( IF

REQUI

RED)

83751B

(HP

and

part number

MM-WAVE SOURCE

MODULE

RF IN

b LEVELED

OUTPUT

pg420ob

Figure 2-4. Millimeter-wave Source Module leveling

2-9

Page 44

Externally leveling the Sweeper

Figure 2-5 illustrates the setup that is used with the HP

HP

83752A

(standard power models). An external amplifier is required to

obtain maximum specified power.

SOURCE MODULE

I NSERFACE

RF OUTPUT

I

INTERFACE

EXTENDER

CABLE

I

ADAPTER

(IF REQUIRED)

MICROWAVE

AMPLIFIER

\

-cxJ@

0

0

RF IN

C

RF OUT

W-WAVE SOURCE

MODULE

83751A

and

LEVELED

OUTPUT

Figure 2-5. Millimeter-wave Source Module leveling Using a Microwave Amplifier

1.

Turn the sweeper line power off.

2. Set up the equipment as shown in Figure 2-4 or Figure 2-5.

3. Turn the sweeper line power on and press

4. When the

c-j

key is pressed, the sweeper configures itself for source

C-1.

module operation, and all of the ALC data necessary to communicate

properly with the sweeper is exchanged via the rear panel SOURCE

MODULE INTERFACE. Note that the EXT ALC annunciator is lit, and that

the POWER display shows the millimeter head output power.

2-10

Page 45

Externally leveling the Sweeper

See also

To obtain flatness corrected power refer to “Creating User Flatness Correction

Arrays, )) later in this manual.

2-11

Page 46

3

Generating a Stepped

Sweep

Page 47

Generating a Stepped Sweep

To generate a stepped sweep, perform the following steps:

1. Press (PRESET).

2.

Select the desired

3.

Select the desired number of points by pressing

entering the desired number.

4.

Press

m

SWEEP MODE $ .

5. Press the @J key. The MARKER/SWEEP/STATUS display should read

Sweep=

St>eF’

6. The instrument is now running in stepped sweep mode.

Iknt

(START_)

and the STEP annunciator should be lit.

and IsTopl frequencies.

(=I

POINTS and

NOTE

The stepped sweep time is calculated by the following formula:

SteppedSweep

stepped sweep time can be changed in one of two ways:

l By changing the dwell time. (Press

l By changing the number of points. (Press

Time = Dwell Time *Number of Points. Therefore the

CTIME)

while in stepped sweep

(GiiFF~ PDINTS .)

mode.1

3-2

Page 48

4

Generating a Millimeter

Signal

Page 49

Generating a Millimeter Signal

If your sweeper was ordered with Option lEE, you have the capability of

using HP 83550 series millimeter head source modules with the sweeper. The

interface extender cable (HP part number 5062-7202) that is provided with all

option

sweeper.

After a source module is connected to the sweeper via the SOURCE MODULE

INTERFACE connector, the sweep will automatically configure itself for source

module operation when the line power is cycled, when the sweeper is preset,

or when a register is recalled.

1EE

sweepers allows the source module to be positioned in front of the

4-2

Page 50

Using millimeter heads with “B” model

(high power) sweepers

Figure

HP

1.

2. Turn the sweeper on, and press

3. The sweeper automatically configures itself for source module operation

4-l

shows the equipment setup for using a millimeter head with your

83751B

Turn the sweeper line power off, and connect the equipment as shown in

Figure 4-

when the

or HP

1.

@EE]

83752B.

fjPRESET).

key is pressed.

4-3

Page 51

Generating a Millimeter Signal

Using millimeter heads with “B” model

SOURCE MODULE

I NTERFACE

I NTERFACE

EXTENDER

CABLE

RF

OUTPUT

ADAPTER

(IF REQUIRED)

(high power) sweepers

Figure

4-l. Millimeter.wave

MM-WAVE SOURCE

MODULE

LEVELED

OUTPUT

pg420ab

Source Module leveling

4-4

Page 52

Using millimeter heads with “A” model

(standard power) sweepers

Figure 4-2 shows the equipment setup for using a millimeter head with

your HP

maximum specihed power.

1. Turn the sweeper line power off, connect the equipment as shown in

Figure 4-1.

83751A

or HP

83752A.

An external amplifier is required to obtain

2. Turn the sweeper on, and press

3. The sweeper automatically configures itself for source module operation

when the (PRESET_) key is pressed.

(EE’EQ.

4-5

Page 53

Generating a Millimeter Signal

SOURCE MODULE

INTERFACE

RF OUTPUT

I

ADAPTER

(IF REQUIRED)

NTERFACE

:XTENDER

:ABLE

MICROWAVE

AMPLIFIER

RF IN

Wd-WAVE

SOURCE

MODULE

b

LEVELED

OUTPUT

Figure 4-2. Millimeter-wave Source Module leveling Using a Microwave Amplifier

See also

To obtain flatness corrected power refer to “Creating User Flatness Correction

Arrays,” later in this section.

4-6

Page 54

5

Creating User Flatness

Arrays

I-

Page 55

Creating User Flatness Arrays

This chapter explains how to create user flatness correction arrays, which

calibrate the power level at a remote test port. Two examples are provided:

l The first example shows the basic setup and steps to create a user flatness

array.

l The second example shows how to set up a scalar analysis measurement

using a user flatness correction array.

5-2

Page 56

Creating a user flatness array

In this example an HP

the interface bus

(HP-IB)

437B

power meter controlled by the sweeper through

is used to enter the correction data into a flatness

array.

Figure 5-l shows a typical system setup. The setup shown assumes that if

the setup has an external leveling configuration, that the steps necessary to

correctly level have been taken. Refer to Chapter 2, “Externally Leveling the

Sweeper, )) for information on external leveling.

;ALC

IN

I

1

--------.

I

I

;

I

I

----d

AND OTHER

i

*- - - -,-- --’

CAmEs

DO/ICES

I

1

RF

INPUT

PORT

I

,

OUTPUT

I

;

-0-uq-J-N

“l%tE”E::

TEST

----------

Figure

5.1.

IFLATNESS

CORRECTED

,OUTPUT

i .-----,--,

TEST PORT

POWER SENSOR

Creating a User Flatness Array

5-3

Page 57

Creating User Flatness Arrays

Creating a user flatness array

To set up the sweeper

Connect the equipment as shown in Figure 5-l. Do not connect the power

1.

sensor to the system yet. Press

If a frequency range other than the full range of the instrument is desired,

2.

use the

If external cables and/or devices are used between the sweeper leveling

3.

CSTART)

and

m

point (the RF OUTPUT if internally leveled, or the coupler/splitter output

if externally leveled) and the remote test port, the nominal (average) loss

of these components should be entered as an offset. To enter the power

offset, press

nominal loss from the leveling point of the sweeper to the test port. (For

(SHIFT)

OFFSET (in the POWER key group) and then enter the

example, if there is a 6 dB loss from the leveling point to the remote test

port, enter a power offset of +6

(PRESET)

on the sweeper.

keys to input the desired frequency range.

dB.)

Set the power level to the level desired at the test

4.

[POWER LEVEL) and entering the desired number.

5.

Select

[ml

SPECIAL

112) (jj).

Use the @j @J keys to select

the type of power meter you will be using.

6.

Select (SHIFT) SPECIAL

113) (w’.

Enter the HP-IB address of the

(437B

purt

by pressing,

for this example.)

power meter you will be using for the calibration. (Thirteen is the default

address for power meters.)

7.

Press

[%iW)

a. Select whether to calibrate over

FLTNESS

CAL

S?.at-:~t,op

(correction points will be

linearly spaced over the selected Start/Stop frequency range, or Fu 11

Bard (correction points will be linearly spaced over the full frequency

range of the instrument). Use the m Q) keys to make your selection,

then press [Hz/s/ENTER).

b. Select the number of correction points, using the keypad for your entry

(valid entries range from 2 to Sol), then press

I-1.

c. The MARKER/SWEEP/STATUS display should now read:

Conned.

437B PM

--

EHTER.

5-4

Page 58

Creating User Flatness Arrays

Creating a user flatness array

To set up the power meter

l Zero and calibrate the power meter/sensor.

l Enter the appropriate power sensor calibration factors into the power

meter.

l Enable the power meter/sensor

on the HP

l Connect the power sensor to the point where corrected

437B

power meter refer to its operating and service manual.

cal

factor array. For operating information

power

is desired.

(See Figure 5- 1.)

To start the user flatness cal

l

The MARKER/SWEEP/STATUS display should still read:

C:onnect.

l Press

correction point’s frequency and power as it is measured.

l When the calibration is finished, the flatness correction is automatically

turned on, and the FLTNESS ON LED annunciator is lit on the front panel

of the sweeper. Power correction will be linearly interpolated between the

measured correction points. The POWER display will

port power.

437B

PM -- ENTER.

(Hz/s/ENTEji)

to start the calibration. The display will show each

now.show

the test

Attention!

Before doing anything else, save this calibration in one of the instrument’s registers. If the calibration

has not been saved, and the instrument is preset, a register is recalled, or the power offset is

changed, the calibration will be lost. To save the calibration, press

of the instrument register you wish to save it in.

ISAVE)

and then enter the number

5-5

Page 59

Page 60

Creating User Flatness Arrays

Creating a user flatness array for use in a scalar analysis measurement

To set up the sweeper

1. Connect equipment as shown in Figure 5-2. Do not connect the power

sensor to the system yet.

2. Press (PRESET) on the scalar analyzer (HP 8757).

3. If a frequency range other than the full range of the instrument is desired,

use the

frequency range.

4. If external cables and/or devices are used between the sweeper leveling

point (the RF OUTPUT if interrmlly leveled, or the coupler/splitter output

if externally leveled) and the remote test port, the nominal (average) loss

of these components should be entered as an offset. To enter the power

offset, press

nominal loss from the leveling point of the sweeper to the test port. (For

example, if there is a 6 dB loss from the leveling point to the remote test

port, enter a power offset of +6

m

and

@iYWj

CsTopl

keys on the sweeper to input the desired

OFFSET (in the POWER key group) and then enter the

dB.)

5. Set the power level to the level desired at the tat port by pressing

(POWER LEVEL] and entering the desired number.

6.

Select

the type of power meter you will be using.

7.

Select (SHIFT)

@iiF]

SPECIAL (12)

SPECfAL @

(HZ/S/ENTER_).

Use the

(437B

Q) @Jj

for this example.)

(Hz/s/ENTER_). Enter the

keys to select

HP-R3

address of the

power meter you will be using for the calibration. (Thirteen is the default

address for power meters.)

To set up the analyzer

1. On the analyzer, set up the appropriate measurement (i.e. gain for an

amplifier). Calibrate the measurement (thru and short/open calibration).

Press

sweeper parameters in storage register 1.

m

(iJ on the analyzer to store the analyzer configuration and

5-7

Page 61

Creating User Flatness Arrays

Creating a user flatness array for use in a scalar analysis measurement

Attention!

Do not proceed until the HP 8757 system interface is turned off by pressing

pressing softkeys, MORE,

SWEZP

MODE, and

SYSIElTF

ON

@FiiZ].

OFF

on the analyzer.

Then by

To set up the power meter

1. Zero and calibrate the power meter/sensor.

2. Enter the appropriate power sensor calibration factors into the power

meter.

3. Enable the power meter/sensor cal factor array. For operating information

on the HP

437B

power meter refer to its operating and service manual.

I

4. Connect the power sensor to the point where corrected power is desired.

(See Figure 5-2.)

To start the user flatness cal

1. On the sweeper, press

a. Select whether to calibrate over St>arSt.op (correction points will be

linearly spaced over the selected Start/Stop frequency range, or

Band

(correction points will be linearly spaced over the full frequency

range of the instrument). Use the @)

then press (Hz/s/ENTER).

5-8

m

FLTMESS

CAL

(JJ

keys to make your selection,

FIJ

11

Page 62

Creating User Flatness Arrays

b. Select the number of correction points, using the keypad for your entry.

Valid entries range from 2 to 801, then press

CH+./ENTER).

c. The MARKER/SWEEP/STATUS display should now read:

Connel:t.

437E:

PM --

Et,ITER.

2. Press

CHZ/S/ENTER)

to start the calibration. The display will show each

correction point’s frequency and power as it is measured.

3. When the calibration is finished, the flatness correction is automatically

turned on, and the FLTNESS ON LED annunciator is lit on the front panel

of the sweeper. Power correction will be linearly interpolated between the

measured correction points.

4. Save the calibration by pressing

Attention!

If the calibration is not saved in an instrument register, and the sweeper or analyzer is preset, a

register is recalled, or the power offset is changed, the calibration will be lost. Reactivating the

SYSINTF on the analyzer will also cause a preset and loss of the calibration. Be sure to save the

calibration as described in the previous step before continuing.

CsAVEJ

(iJ on the sweeper.

To reactivate the HP 8757 system interface

1.

Press the softkey SYSINTF OH OFF on the analyzer and the sweeper will

preset.

2. Press

3. Devices can now be tested.

(RECALL_)

(iJ to pull up the calibration.

5-9

Page 63

I

I

6

Operating a Master/Slave

Setup

Page 64

Operating a Master/Slave Setup

Two HP 83750 series sweepers can be configured for two-tone measurement

capabilities. Two synchronously tracking sweepers can be configured as a

“master/slave” pair for mixer characterization or inter-modulation distortion

measurements. The swept frequency accuracy allows control of the sweepers

at Exed- or swept-frequency offsets.

To implement master/slave operation, configure the sweepers as shown in

Figure 6-l. The master sweeper generates the 10 MHz frequency reference

for both sources. The source synchronization cable (HP part no. 83750-60059)

must be connected between the auxiliary interface connectors on the rear

panels of the sweepers.

When conEguring a two-tone measurement system, the slave does not need

to interface with any instruments other than the master. The master should

interface with the display device (scalar analyzer or oscilloscope, for example)

as if it were a stand-alone sweeper.

6-2

Page 65

SOURCE

SYNCHRONIZATION

CABLE

AUXILIARY

INTERFACE

:

I

I

Operating a Master/Slave Setup

-----------.e---

10 MHz

REF OUT

pg424ab

Figure

“SLAVE”

SYNTHESIZED

SWEEPER

6-l.

Master/Slave Setup

AUXILIARY

INTERFACE

10 MHz

REF IN

6-3

Page 66

Tb set up the master sweeper

1. Press

2. Activate the master mode by pressing

If the display does not read

(jPRESETJ.

[M)

13-A rlMsde=MHSTER,

(SPECIAL)

then press the

(19) C-1.

once to set the control mode to master.

3. Set the desired frequencies by using the

(CJV(SPAN)

NOTE

It is recommended that the master and slave sweepers frequencies not differ more than 5

point in the sweep. If this requirement is not met, it is possible for unlocks to occur. If frequency

offsets greater than 5

unlocks.

keys, or the

GHz

are required, it may be necessary to reduce the sweep speeds to eliminate

Icw]

key.

CSTARTY(STOP_)

keys, the

4. Set the desired power level using the (POWER LEVEL] key.

m

GHz

key

at any

For swept measurements.

5. Set the desired sweep time using the (TIME) key. (The recommended

minimum sweep time for master/slave mode is 100 ms.)

NOTE

The master and slave sweepers must have identical sweep times. Therefore, the value entered here

must also be entered into the slave sweeper.

6-4

Page 67

Operating a Master/Slave Setup

To set up the master sweeper

For stepped measurements.

6.

Set the sweep mode to stepped by pressing

then pressing the @) key until the display reads:

7.

Set the number of points by pressing

@iE)

(GiF]

SWEEP MODE $ , and

Si>Jeep=

St. ep lzt:tr,t.

POINTS and entering the

desired number of points.

NOTE

The master and slave sweepers must have identical sweep mode, number of points, and sweep time

settings. Therefore, the values entered here must also be entered into the slave sweeper.

.

6-5

Page 68

31 set up the slave sweeper

1. Press (PRESET).

2. Activate the slave mode by pressing (SHIFT)

Press the @) key until the display reads

3. Set the desired frequencies by using the

(EEiK] 119) (-1.

Cnt.

t- 1

Mode=SLHVE.

(START)/0

keys, the

@J(SPAN) keys, or the ccw) key.

NOTE

It is recommended that the master and slave sweepers frequencies not differ more than 5

point in the sweep. If this requirement is not met, it is possible for unlocks to occur. If frequency

offsets greater than 5

unlocks.

4. Set the desired power level using the

For

swept measurements.

GHz

are required, it may be necessary to reduce the sweep speeds to eliminate

POWER

LEVEL] key.

GHz

at any

5. Set the sweep time to the same value as the master sweeper using the

m

key. (The recommended minimum sweep time for master/slave

mode is 100 ms.)

For stepped measurements.

6.

Set the sweep mode to stepped by pressing (SHIFT)

then pressing the @) key until the display reads:

7. Set the number of points to the same value as the master sweeper by

pressing

6-6

(SHIFTI)

SWEEP

Sweep= St. ep

MODE $ , and

POINTS and entering the number of points.

C:ont..

Page 69

See also

For a

“Multi-pin Connectors” section of Chapter 7, “Front/Rear Panel.”

pinout

description of the source synchronization cable, see the

6-7

Page 70

7

I

-

-

Front/Rear Panel

Page 71

Front/Rear Panel

This chapter contains detailed information on various aspects of the sweeper

front and rear panel. Information on the following can be found in this

chapter:

0

Connectors

l Display

l HP-B Lang/Address Switch

l Knob

l Line Power Switch

l Power Cables

7-2

Page 72

Connectors

pg412ab

00

00

00

.-I

0 ::

0

0

a

0 0

-

LJLJ 00 00 00 0

@

I \

SWEEP OUT

Figure 7-1. Sweeper Connectors - Front Panel

0

@@”

0

ALC IN

‘El0000

00000

moooo

l30000

Cl

0

0

la

Q @I

L

RF

,

\

\/

OUTPUT

7-3

Page 73

(OPT

RF

OUTPUT

(OPT lE4 ONLY)

Front/Rear Panel

Connectors

SOURCE MODULE

I NTERFACE

1EE

ONLY)

I

SWEEP

OUTPUT

Z AXIS

BLANK/MKRS

I

STOP

SWEEP

PULSE

I N/OUT

FM INPUT

AUX

I NTE

I

LIARY

DIARY

:RFACE:RFACE

HP-IB

HPllB

VOLTi/GHz

VOLTS/GHz

OUTPUTOUTPUT

A’M

AM

INPUTINPUT

TRIGGER TRIGGERTRIGGER TRIGGER

OUTPUTOUTPUT

INPUTINPUT

Figure 7-2. Sweeper Connectors - Rear Panel

1OilHz

1OMHz

REF

REF

OUT

OUT

1OivlHz

1OMHz

REF

REF

IN

IN

pg413ab

7-4

Page 74

BNC Connectors

Front/Rear Panel

Connectors

10 MHz REF IN

10 MHz REF

OUT

ALC IN

AM INPUT

FM

INPUT

This rear panel female BNC connector accepts a -5 to + 10

dBm

signal from an external time base reference which is

within

MHz. The nominal input impedance is 50

510

ppm of 10 MHz or any sub-multiple down to 1

61.

This connector

detects when a valid reference signal is connected to it and

automatically switches from internal to external reference

operation.

This rear panel female BNC connector provides a nominal

signal level of 0

dBm,

and output impedance of 50 0. The

accuracy is determined by the tune base used.

This front panel female BNC connector is used for external

power meter leveling or external negative detector leveling.

The damage level is

100

kQ.

f15 V.

The nominal input impedance is

This rear panel female BNC connector accepts the amplitude

modulating signal input when External AM is enabled. The

nominal input impedance is 3.5

f15

v.

kQ.

The damage level is

This rear panel female BNC connector accepts the frequency

modulating signal input when DC or AC FM is enabled. The

nominal input impedance is 1

f15

v.

k62.

The damage level is

PULSE IN/OUT

This rear panel female BNC connector can be used as

either an external pulse input or output for internal pulse

modulation. In either case, it is TTL level compatible and

has a nominal impedance of 5

khl.

The damage level is

2 +lOVor< -5V.

A TTL high level (> +2 V) enables the selected power level

to be at the RF OUTPUT connector, while a TTL low level

turns the RF off.

7-5

Page 75

Front/Rear Panel

Connectors

STOP SWEEP

SWEEP OUT

This rear panel female BNC connector causes a sweep to be

stopped when this input is pulled low. Retrace does not

occur, and the sweep resumes when this input is pulled

high. The open circuit voltage is TTL high and is internally

pulled low when the instrument stops its sweep. The

damage level is 2 + 10 V or 5 -4

V.

These front and rear panel female BNC connectors provide

a voltage range of 0 to + 10 V. When the instrument is

sweeping, the SWEEP OUT ranges from 0 V at the beginning

of the sweep and + 10 V at the end of the sweep regardless

of the sweep width. In CW mode, the SWEEP OUT ranges

from 0 V at the sweeper minimum frequency to + 10 V

at the specifled maximum frequency, with a proportional