Page 1

HP 8360 L-Series Swept CW Generator

(Including Options 001, 004, and 008)

User’s Guide

SERIAL NUMBERS

This manual applies directly to any swept CW generator with the

model and serial number prefix combination shown below. You

may have to modify this manual so that it applies directly to your

instrument version. Refer to the “Instrument History” chapter.

HP

83623L/3OL/4OL/5OL

3844A and below

Pii

HEWLETT

PACKARD

HP Part No. 08380-90134

Printed in USA

February 1999 Supersedes: September 1997

Page 2

Notice

Restricted Rights

Legend

The information contained in this document is subject to change

without notice.

Hewlett-Packard makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing,

performance, or use of this material.

Use, duplication, or disclosure by the U.S. Government is subject

to restrictions as set forth in subparagraph (c) (1) (ii) of the

Rights of Technical Data and Computer Software clause at DFARS

252.227-7013 for DOD agencies, and subparagraphs (c) (1) and

(c) (2) of the C

ommercial

Computer Software Restricted Rights

clause at FAR 52.227-19 for other agencies.

@

Copyright Hewlett-Packard Company 1996, 1997, 1999

All Rights Reserved. Reproduction, adaptation, or translation

without prior written permission is prohibited, except as allowed

under the copyright laws.

1400 Fountaingrove Parkway, Santa Rosa, CA 95403-1799, USA

Page 3

Certification

Hewlett-Packard Company certifies that this product met its

published specifications at the time of shipment from the factory.

Hewlett-Packard further certifies that its calibration measurements

are traceable to the United States National Institute of Standards

and Technology, to the extent allowed by the Institute’s calibration

facility, and to the calibration facilities of other International

Standards Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against

defects in material and workmanship for a period of one year from

date of shipment. During the warranty period, Hewlett-Packard

Company will, at its option, either repair or replace products which

prove to be defective.

For warranty service or repair, this product must be returned to a

service facility designated by Hewlett-Packard. Buyer shall prepay

shipping charges to Hewlett-Packard and Hewlett-Packard shall pay

shipping charges to return the product to Buyer. However, Buyer

shall pay all shipping charges, duties, and taxes for products returned

to Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and firmware designated

by Hewlett-Packard for use with an instrument will execute

its programming instructions when properly installed on that

instrument. Hewlett-Packard does not warrant that the operation

of the instrument, or software, or firmware will be uninterrupted or

error-free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE

AND EXCLUSIVE REMEDIES. HEWLETT-PACKARD SHALL

NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

. . .

III

Page 4

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Hewlett-Packard products. For any

assistance, contact your nearest Hewlett-Packard Sales and Service

Ofice.

Safety Notes

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning before

operating this instrument.

WARNING

Warning denotes a hazard. It calls attention to a procedure which, if

not correctly performed or adhered to, could result in injury or loss

of life. Do not proceed beyond a warning note until the indicated

conditions are fully understood and met.

CAUTION

Caution denotes a hazard. It calls attention to a procedure that, if

not correctly performed or adhered to, would result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign

until the indicated conditions are fully understood and met.

iv

Page 5

General Safety

Considerations

WARNING

n

No operator serviceable parts inside. Refer servicing to qualified

personnel. To prevent electrical shock, do not remove covers.

n

For continued protection against fire hazard replace line fuse only

with same type and rating (F 5A/250V). The use of other fuses or

material is prohibited.

w

This is a Safety Class I product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only

be inserted in a socket outlet provided with a protective earth

contact. Any interruption of the protective conductor, inside or

outside the instrument, is likely to make the instrument dangerous.

Intentional interruption is prohibited.

n

If this instrument is used in a manner not specified by

Hewlett-Packard Co., the protection provided by the instrument may

be impaired. This product must be used in a normal condition (in

which all means for protection are intact) only.

w

Position the instrument according to the enclosure protection

provided. This instrument does not protect against the ingress of

water. This instrument protects against finger access to hazardous

parts within the enclosure.

V

Page 6

CAUTION

n Before switching on this instrument, make sure that the line

voltage selector switch is set to the voltage of the power supply and

the correct fuse is installed.

n Always use the three-prong ac power cord supplied with this

instrument. Failure to ensure adequate earth grounding by not

using this cord may cause instrument damage.

n Before switching on this product, make sure that the line voltage

selector switch is set to the voltage of the power supply and

the correct fuse is installed. Assure the supply voltage is in the

specified range.

n Ventilation Requirements: When installing the instrument in a

cabinet, the convection into and out of the instrument must not be

restricted. The ambient temperature (outside the cabinet) must be

less than the maximum operating temperature of the instrument

by 4 “C for every 100 watts dissipated in the cabinet. If the total

power dissipated in the cabinet is greater than 800 watts, then

forced convection must be used.

n This product is designed for use in Installation Category II and

Pollution Degree 2 per IEC 1010 and 664, respectively.

Note

The detachable power cord is the instrument disconnecting device.

It disconnects the mains circuits from the mains supply before other

parts of the instrument. The front panel switch is only a standby

switch and is not a LINE switch.

vi

Page 7

PREFACE

This manual provides user information for the HP 8360 L-Series

Swept CW Generator.

Instruments Covered

This manual applies to instruments having a serial number prefix

By This Manual

listed on the title page (behind the “Documentation Map” tab).

Some changes may have to be made to this manual so that it

applies directly to each instrument; refer to Chapter 5, “Instrument

History”, to see what changes may apply to your instrument.

A serial number label (Figure O-l) is attached to the instrument’s

rear panel. A prefix (four digits followed by a letter), and a suffix

(five digits unique to each instrument), comprise the instrument

serial number.

SERIAL NUMBER

h

I \

PREFIX

SUFFIX

-A

SER

1234A 12345

\I

INSTALLED

OPTIONS

!

Figure O-l. Typical Serial Number Label

User’s Guide

Tabs divide the major chapters of this manual. The contents of each

Organization

chapter is listed in the Table of Contents.

HP 8360 L-Series

Documentation

Documentation Map

For a pictorial representation of the HP 8360 L-Series documentation,

see the ‘Documentation Map” at the front of this manual.

Ordering Manuals

A manual part number is listed on the title page of this manual.

You may use it to order extra copies of this manual. See

“Replaceable Parts” in HP 8360 B-Series Swept Signal Generator/

HP 8360 L-Series Swept CW Generator Service Guide for a complete

list of HP 8360 documentation and ordering numbers.

vii

Page 8

Typeface

Conventions

The following conventions are used in the HP 8360 L-Series

documentation:

Italics Italic type is used for emphasis, and for titles of manuals and

other publications.

Computer Computer type is used for information displayed on the

instrument. For example: In this sequence, POWER LEVEL is displayed.

(Hardkeys)

Instrument keys are represented in “key cap.” You are

instructed to press a

hardkey.

Softkeys

Softkeys are located just below the display, and their

functions depend on the current display. These keys are represented

in “softkey.” You are instructed to select a softkey.

Regulatory

Information

This product has been designed and tested in accordance with IEC

Publication 1010, Safety Requirements for Electronic Measuring

Apparatus, and has been supplied in a safe condition. The

instruction documentation contains information and warnings

which must be followed by the user to ensure safe operation and to

maintain the instrument in a safe condition.

. . .

VIII

Page 9

Manufacturer’s

Declaration

Note

This is to certify that this product meets the radio frequency

interference requirements of Directive FTZ 1046/1984. The German

Bundespost has been notified that this equipment was put into

circulation and has been granted the right to check the product type

for compliance with these requirements.

Note: If test and measurement equipment is operated with

unshielded cables and/or used for measurements on open set-ups, the

user must insure that under these operating conditions, the radio

frequency interference limits are met at the border of his premises.

Model HP 8360 L-Series Swept CW Generator

Note

Hiermit wird bescheinigt, dass dieses

Gerat/System

in

fibereinstimmung

mit den Bestimmungen von

Postverfiigung

1046/84

funkentst”rt

ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Gerates/Systems

angezeight und die Berechtigung

zur Uberpriifung

der Serie auf Einhaltung der Bestimmungen

eingeraumt.

Zustzinformation fiir Mess-und Testgerate:

Werden Mess- und Testgerate mit ungeschirmten Kabeln

und/oder

in offenen Messaufbauten verwendet, so ist vom Betreiber

sicherzustellen, dass die Funk-Entst”rbestimmungen unter

Betriebsbedingungen an seiner Grundstiicksgrenze eingehalten

werden.

ix

Page 10

Declaration of

Conformity

DECLARATION OF CONFORMITY

aomrding

to

lSO/lEC

Guide 22 and EN 45014

hanufacturetis

Name:

Hewlett-Packard Co.

lanufactureh

Address:

declares

that the products

Microwave Instruments

Division

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799

USA

Product Name:

Synthesized Sweeper

Model Numbers:

HP 83623L, HP

8363OL,

HP 836401.

HP 83650L

Product Options:

This declaration covers all options of the

above products.

:onform

to the following Product specifications:

Safety: IEC

348:1978/HD

401

S1:1981

CAN/CSA-C22.2 No. 231 (Series M-89)

EMC:

CISPR 11:1990/EN 55011:1991

Group I, Class A

IEC

801-2:1984/EN

50082-1:1992

4 kV

CD, 8

kV

AD

IEC

801-3:1984/EN

50082-1:1992

3

V/m, 27-500

MHz

IEC

801-4:1988/EN

50082-I:1992 0.5 kV Sig. Lines, 1 kV Power Lines

IEC

555-2:1982

+

Al:1985 I

EN

60555-2:1987

IEC

555-3:1982

+

Al:1990 /

EN

60555-3:1987

+ Al:1991

Supplementary Information:

-hese

products herewith comply with the requirements of the Low Voltage Directive

‘3/23/EEC and the EMC Directive 89/336/EEC and carry the CE-marking accordingly.

Voduct safety qualification testing for these products was performed prior to 1

December 1993.

Santa

Rosa, California, USA

19 Dec. 1996

J

Manager

European Contact: Your local Hewlett-Packard Sales and Service Office or Hewlett-Packard

GmbH.

Deparlment HQ-TRE.

Herrenbarger

Slrasse

130, D-71 034 BBblingen. Germany (FAX +497031-l 4-3143)

X

Page 11

Compliance with

This is to declare that this instrument is in conformance with the

German Noise

Requirements

German Regulation on Noise Declaration for Machines (Laermangabe

nach

der Maschinenlaermrerordnung -3.GSGV Deutschland).

I

Acoustic Noise Emmission/Geraeuschemission

I

LpA <70 dB

Operator position

Normal position

per IS) 7779

LpA <70 dB

am Arbeitsplatz

normaler Betrieb

nach

DIN 45635 t.19

Instrument Markings !

A

CC

“ISMl-A”

I

I

0

I

N

The instruction documentation symbol. The product is

marked with this symbol when it is necessary for the

user to refer to the instructions in the documentation.

The CE mark is a registered trademark of the European

Community.

The CSA mark is a registered trademark of the

Canadian Standards Association.

This is a symbol of an Industrial Scientific and Medical

Group 1 Class A product.

This is an ON symbol. The symbol ON is used to mark

the position of the instrument power line switch.

This is an ON symbol. The symbol ON is used to mark

the position of the instrument power line switch.

This is a STANDBY symbol. The STANDBY symbol is

used to mark the position of the instrument power line

switch.

This is an OFF symbol. The OFF symbol is used to

mark the position of the instrument power line switch.

This is an AC symbol. The AC symbol is used to

indicate the required nature of the line module input

power.

xi

Page 12

Table O-l. Hewlett-Packard Sales and Service Offices

UNITED STATES

Instrument Support Center

Hewlett-Packard Company

(800) 403-0801

EUROPEAN FIELD OPERATIONS

Headquarters

France

Hewlett-Packard S.A. Hewlett-Packard France

150, Route du Nant-d’Avri1

1 Avenue Du Canada

1217 Meyrin a/Geneva

Zone

D’Activite

De Courtaboeuf

Switzerland

F-91947 Les Ulis

Cedex

(41 22) 780.8111

France

(33 1) 69 82 60 60

Great Britain

Hewlett-Packard Ltd.

Eskdale Road, Winnersh Triangle

Wokingham, Berkshire RG41 5DZ

England

(44 734) 696622

Germany

Hewlett-Packard GmbH

Hewlett-Packard Strasse

61352 Bad Homburg v.d.H

Germany

(49 6172) 16-O

INTERCON

FIELD OPERATIONS

Headquarters

Hewlett-Packard Company

3495 Deer Creek Road

Palo Alto, California, USA

94304-1316

(415) 857-5027

China

China Hewlett-Packard Company

38

Bei

San

Huan

Xl Road

Shuang Yu Shu

Hai

Dian District

Beijing, China

(86 1) 2566888

Taiwan

Hewlett-Packard Taiwan

8th Floor, H-P Building

337 Fu Hsing North Road

Taipei, Taiwan

(886 2) 712-0404

Australia

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

(61 3) 895-2895

Japan

Hewlett-Packard Japan, Ltd

9-1

Takakura-Cho, Hachioji

Tokyo 192, Japan

(81 426) 60-2111

Canada

Hewlett-Packard (Canada) Ltd.

17500 South Service Road

Trans-Canada Highway

Kirkland, Quebec

H9J

2X8

Canada

(514) 697-4232

Singapore

Hewlett-Packard Singapore (Pte.) Ltd.

150 Beach Road

#29-00 Gateway West

Singapore 0718

(65) 291-9088

xii

Page 13

Contents

Contents-l

1. Getting Started

What Is In This Chapter

............

How To Use This Chapter

............

Equipment Used In Examples

.........

Introducing the HP 8360 L-Series Swept CW

Generators

.................

Display Area

..................

Entry Area

..................

CW Operation and Start/Stop Frequency Sweep . .

CW Operation

................

Start/Stop Frequency Sweep

..........

Center Frequency/Span Operation

........

Power Level and Sweep Time Operation

......

Power Level Operation

............

Sweep Time Operation

............

Continuous, Single, and Manual Sweep Operation

.

Marker Operation

...............

Saving and Recalling an Instrument State

.....

Power Sweep and Power Slope Operation

.....

Power Sweep Operation

............

Power Slope Operation

............

Getting Started Advanced

............

Externally Leveling the Swept CW Generator ...

Leveling with Detectors/Couplers /Splitters ...

External Leveling Used With the Optional Step

Attenuator

...............

Leveling with Power Meters

..........

Leveling with MM-wave Source Modules

.....

Working with Mixers/Reverse Power Effects ....

Working with Spectrum Analyzers/Reverse Power

Effects

...................

Optimizing Swept CW Generator Performance ...

Creating and Applying the User Flatness Correction

Array

..................

Creating a User Flatness Array Automatically,

Example 1

...............

Creating a User Flatness Array, Example 2

. .

Swept mm-wave Measurement with Arbitrary

Correction Frequencies, Example 3 ....

Scalar Analysis Measurement with User Flatness

Corrections, Example 4

.........

Using Detector Calibration

..........

l-l

l-2

l-2

1-3

l-4

1-5

1-6

l-6

l-6

l-8

l-10

l-10

l-10

l-12

1-14

1-16

1-18

1-18

1-19

l-21

l-23

l-23

l-26

l-27

l-28

l-30

l-32

l-33

l-33

l-34

1-36

1-39

l-43

l-47

Page 14

Using the Tracking Feature ..........

Peaking ..................

Tracking .................

ALC Bandwidth Selection ............

Using Step Sweep ...............

Creating and Using a Frequency List .......

Using the Security Features ...........

Changing the Preset Parameters .........

Getting Started Programming ..........

HP-IB General Information ...........

Interconnecting Cables ............

Instrument Addresses .............

HP-IB Instrument Nomenclature ........

Listener ..................

Talker. ..................

Controller .................

Programming the Swept CW Generator .....

HP-IB Command Statements .........

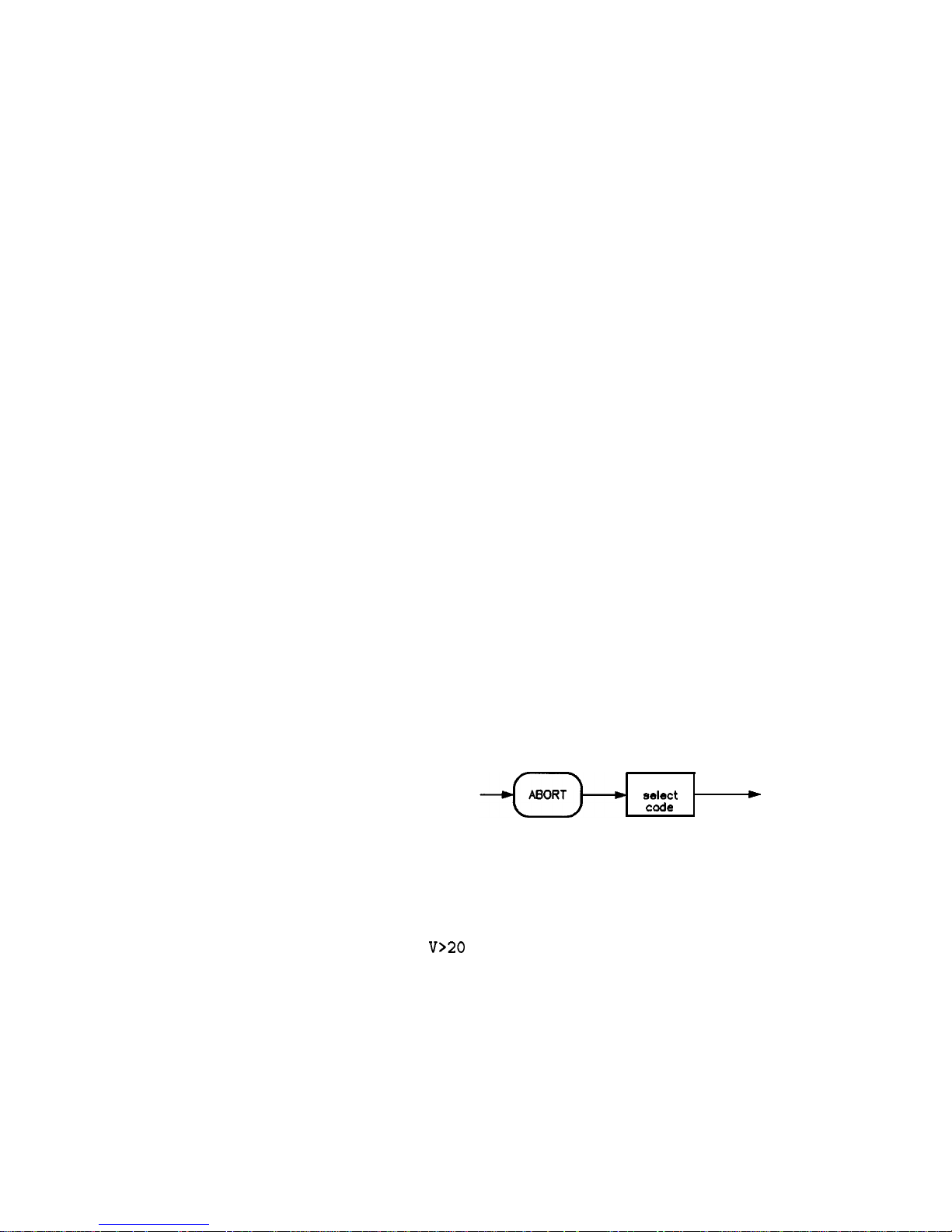

Abort ...................

Remote ..................

Local Lockout ...............

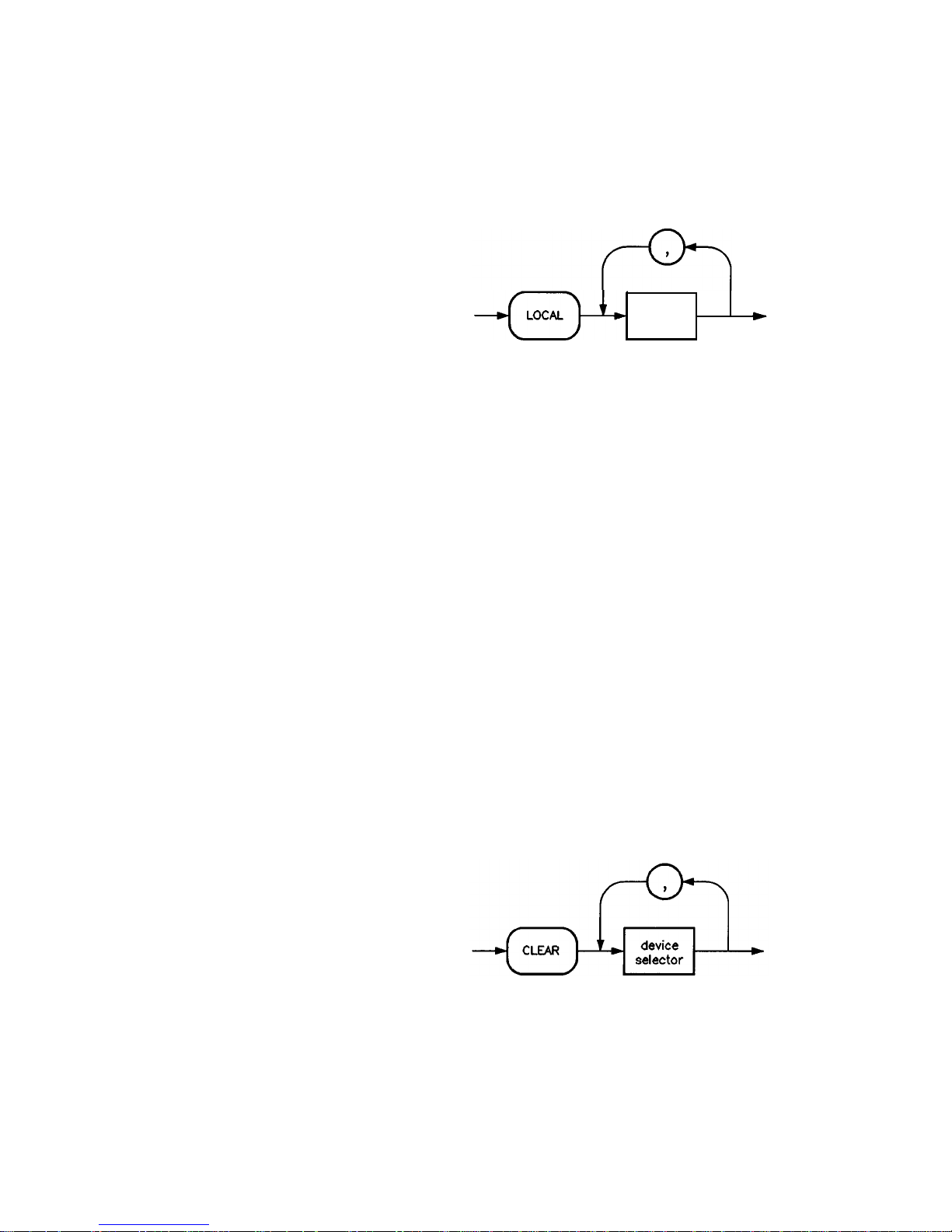

Local ...................

Clear ...................

output ..................

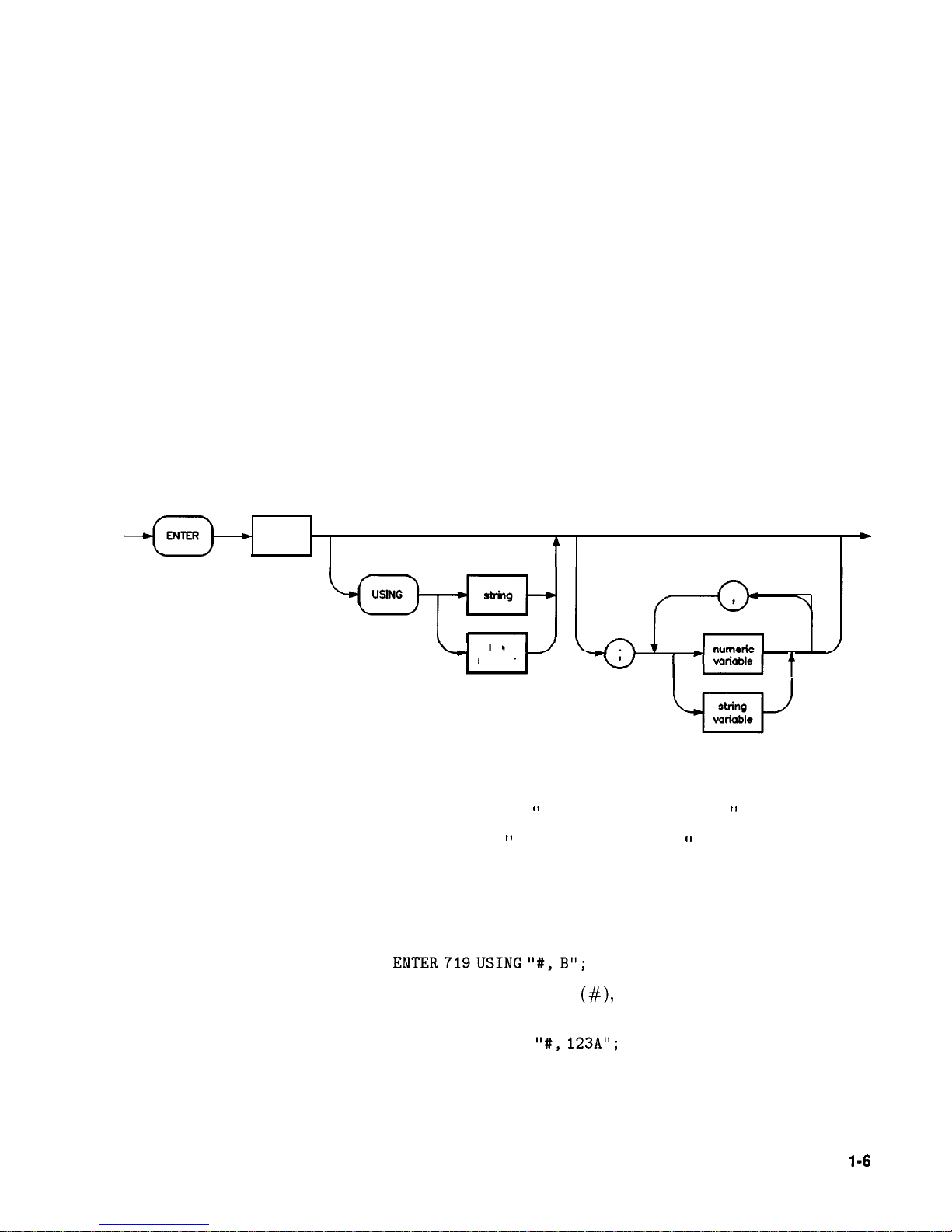

Enter ...................

Getting Started with SCPI ...........

Definitions of Terms ..............

Standard Notation ..............

Command Mnemonics ...........

Angle Brackets ...............

How to Use Examples .............

Command Examples ............

Response Examples .............

Essentials for Beginners .............

Program and Response Messages .......

Forgiving Listening and Precise Talking ....

Types of Commands ............

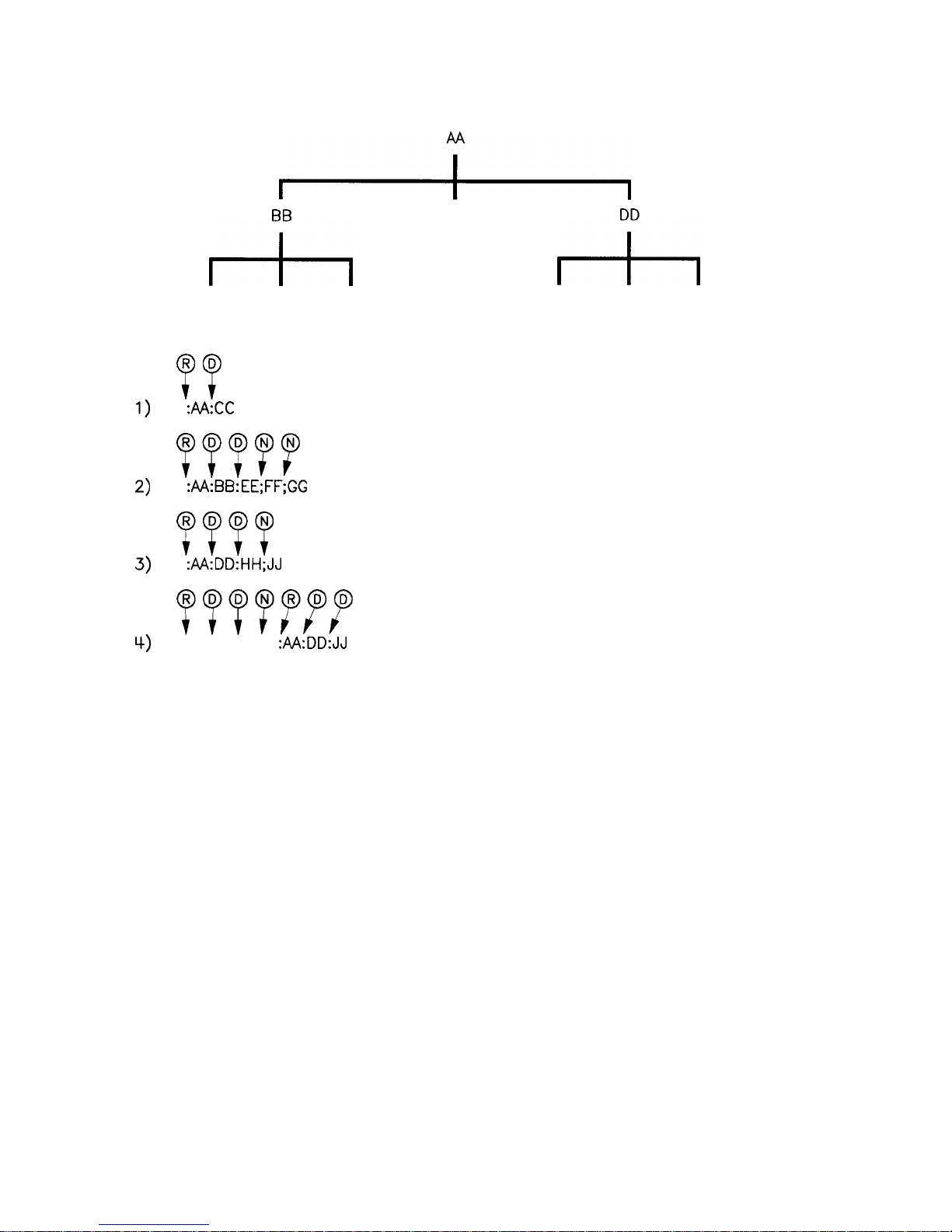

Subsystem Command Trees ..........

The Command Tree Structure ........

Paths Through the Command Tree ......

Subsystem Command Tables ..........

Reading the Command Table ........

More About Commands ...........

Query and Event Commands ........

Implied Commands ............

Optional Parameters ...........

Program Message Examples .........

Parameter Types ..............

Numeric Parameters ...........

Extended Numeric Parameters .......

Discrete Parameters ...........

l-49

l-49

1-49

l-50

1-51

l-52

l-53

l-54

l-55

l-56

1-56

1-56

1-56

l-56

l-56

l-56

l-56

l-57

l-57

l-58

l-58

l-59

l-59

l-60

1-61

1-63

l-63

l-64

l-64

l-64

1-64

l-64

l-65

l-66

l-66

l-66

l-67

l-68

l-68

l-68

1-71

1-71

l-72

l-72

l-72

l-72

l-72

l-73

l-73

l-74

l-75

Contents-2

Page 15

Boolean Parameters

...........

Reading Instrument Errors

..........

Example Programs

..............

Example Program

.............

Description

...............

Program Listing

.............

Program Comments

...........

Details of Commands and Responses

.......

In This Subsection

..............

Program Message Syntax

...........

Subsystem Command Syntax

........

Common Command Syntax

.........

Response Message Syntax

...........

SCPI Data Types

..............

Parameter Types

..............

Numeric Parameters

...........

Extended Numeric Parameters

.......

Discrete Parameters

...........

Boolean Parameters

...........

Response Data Types

............

Real Response Data

...........

Integer Response Data

..........

Discrete Response Data

..........

String Response Data

...........

Programming Typical Measurements

.......

In This Subsection

..............

Using the Example Programs

.........

Use of the Command Tables

.........

HP-IB Check, Example Program 1

.......

Program Comments

............

Local Lockout Demonstration, Example Program 2

Program Comments

............

Setting Up A Typical Sweep, Example Program 3

Program Comments

............

Queries, Example Program 4

..........

Program Comments

............

Saving and Recalling States, Example Program 5 .

Program Comments

............

Looping and Synchronization, Example Program 6

Program Comments

............

Using the

*WA1

Command, Example Program 7 .

Program Comments

............

Using the User Flatness Correction Commands,

Example Program 8

............

Programming the Status System

.........

In This Subsection

..............

General Status Register Model

.........

Condition Register

.............

Transition Filter

..............

Event Register

...............

Enable Register

..............

l-75

l-76

1-77

l-77

l-77

l-77

l-78

l-80

l-80

l-80

1-81

1-81

l-82

l-83

l-83

l-83

l-84

l-85

l-85

l-85

l-85

1-86

l-86

l-86

1-87

l-87

l-87

l-88

l-90

l-90

l-91

l-92

l-93

l-93

l-95

l-95

l-97

l-97

l-99

1-99

l-101

l-101

l-103

l-106

l-106

l-106

l-106

l-107

l-107

l-107

Contents-3

Page 16

An Example Sequence ...........

Programming the Trigger System

.........

In This Subsection ..............

Generalized Trigger Model ...........

Overview .................

Details of Trigger States ...........

Inside the Idle State ...........

Inside the Initiate State ..........

Inside Event Detection States .......

Inside the Sequence Operation State ....

Common Trigger Configurations ........

The

INIT

Configuration ...........

The TRIG Configuration ..........

Description of Triggering in the HP 8360 L-Series

Swept CW Generators ...........

Advanced Trigger Configurations .......

Trigger Keyword Definitions ..........

ABORt

..................

IMMediate

................

ODELay

.................

SOURce ..................

Related Documents

...............

The International Institute of Electrical and

Electronics Engineers. ...........

Hewlett-Packard Company ...........

l-107

l-109

l-109

l-109

l-109

l-110

l-111

l-111

1-112

l-114

l-115

1-115

1-116

l-117

1-118

1-118

l-118

1-118

1-118

1-119

l-120

l-120

l-120

2. Operating and Programming Reference

How To Use This Chapter . . . . . . . . . . . .

2-1

A.

Address . . . . . . . . . . . . . . . . . . . .

A-l

Adrs

Menu . . . . . . . . . . . . . . . . . .

A-l

(ALC).

....................

A-3

ALC Bandwidth Select Auto

..........

A-10

ALC Bandwidth Select High

..........

A-10

ALC Bandwidth Select Low

..........

A-11

ALC3WMenu

.................

A-11

Altrnate Regs

................

A-12

Amp1

Markers

.................

A-13

ANALYZER STATUS REGISTER

........

A-13

Arrow Keys

..................

A-16

[ASSIGN).

....................

A-17

Auto Fill

Incr

................

A-18

Auto Fill #Pts

................

A-19

Auto Fill Start

...............

A-20

Auto Fill Stop

................

A-21

Auto Track

..................

A-22

Contents-4

Page 17

B.

BLankDisp

. . . . . . . . . . . . . . . . . .

B-l

C.

(CENTER)

.....................

C-l

Center=Marker

................

c-2

Clear Fault

.................

c-2

Clear Memory

.................

c-3

Clear Point

.................

c-4

CONNECTORS ................

c-4

(CONT)

.....................

c-10

CopyList

..................

c-11

CorPair

Disable

...............

c-11

Coupling Factor

...............

c-12

(cw

.....................

c-12

CW/CF

Coupled

................

c-13

D.

Dblr Amp Menu

................

D-l

Delete Menu

.................

D-2

Delete All

..................

D-2

Delete Current

................

D-3

Delete Undef

.................

D-3

DeltaMarker

.................

D-4

Delta Mkr Ref

................

D-5

Disp Status

.................

D-5

Doubler Amp Wode AUTO

............

D-7

Doubler

Amp

Mode Off

............

D-7

Doubler

Arap

Mode On

.............

D-8

Dwell Coupled

................

D-9

E.

8360Adrs

..................

EnterCorr

..................

EnterFreq..

................

Enter List Dwell

..............

Enter List Freq

...............

Enter List Offset

..............

ENTRY KEYS .................

ENTRY ON/OFF)

.................

ExtDet Cal

.................

E-l

E-l

E-2

E-2

E-3

E-4

E-4

E-5

E-5

Contents-5

Page 18

F.

Fault Menu

..................

F-l

Fault Info 1

.................

F-2

Fault Info 2

.................

F-3

Fault Info 3

.................

F-4

Fltness Menu

.................

F-5

(FLTNEss ON/OF)

................ F-10

Freq Cal Menu

................

F-11

Freq Follow .................

F-11

FREQUENCY

(e)

...............

F-12

Freq

Mult

.................. F-13

Freq Offset

.................

F-14

FullUsr

Cal

.................

F-14

G.

Global Dwell . . . . . . . . . . . . . . . . .

G-l

Global Offset . . . . . . . . . . . . . . . .

G-l

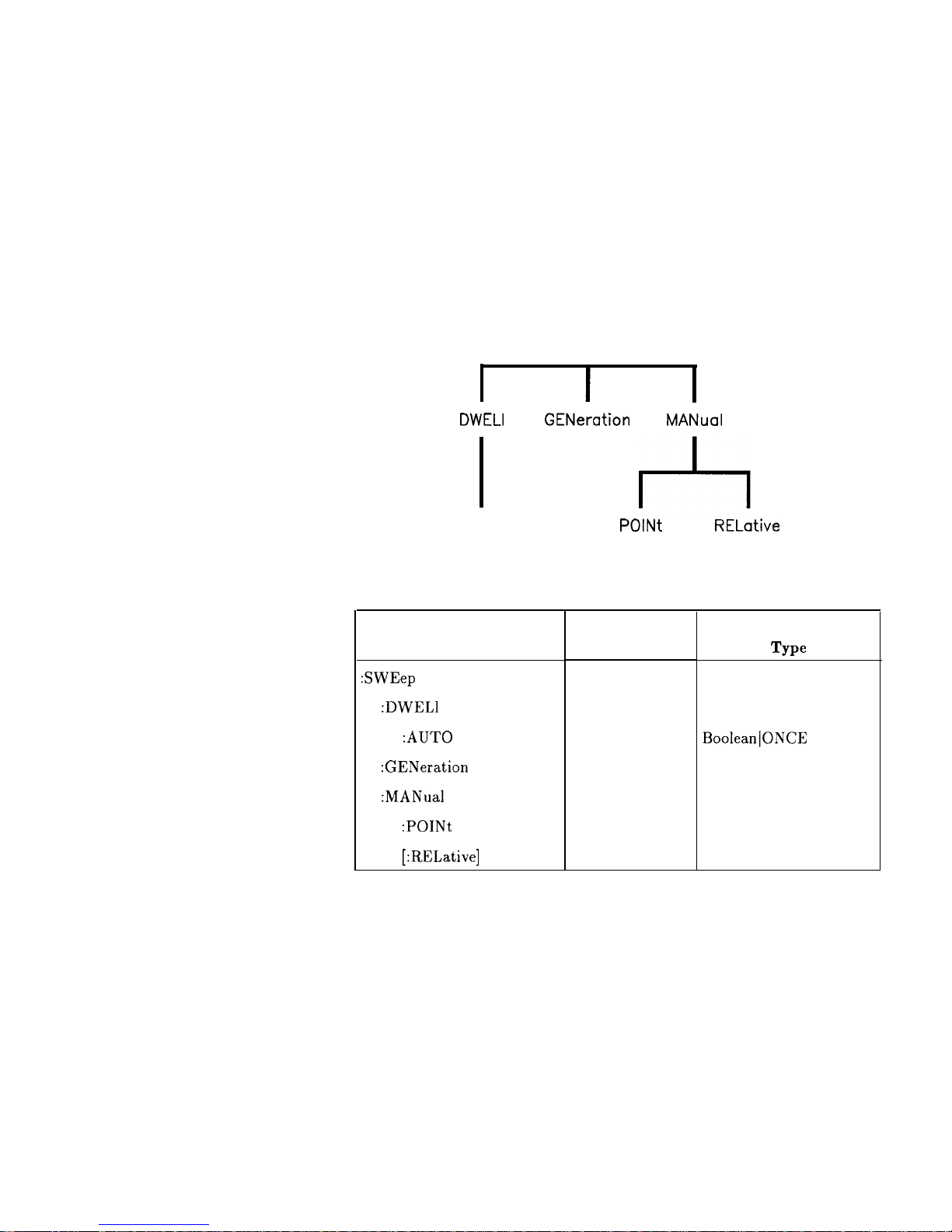

H.

HP-IB Address . . . . . . . . . . . . . . . . . H-l

HP-IB Menu . . . . . . . . . . . . . . . . . .

H-l

L.

Leveling

ModeALCof f

............. L-l

Leveling

ModeNorxtal

.............

L-2

Leveling

ModeSearch

.............

L-2

Leveling

PointExtDet

............

L-3

Leveling PointIntml

............

L-3

Leveling

PointModule

............

L-4

Leveling

PointPwrMtr

............

L-5

LINE SWITCH

................

L-5

ListMenu

..................

L-6

List

Mode

Pt

TrigAuto

............

L-8

List Mode Pt

TrigBus

............

L-9

List Mode Pt

TrigExt

............

L-9

(TEL-)

.....................

L-10

Contents-6

Page 19

MI--M2

Sweep . . . .

Manual Sweep . . . .

(MARKER) . . . . . .

Marker Mi . . . . .

Marker M2 . . . . .

Marker M3 . . . . .

Marker M4 . . . . .

Marker

M5

. . . . .

Markers All Off . .

Measure Corr All .

Measure Corr Current

Measure Corr Undef

Meter Adss . . . . .

INIOD)

. . . . . . . .

Module Menu . . . .

Module Select AUTO

Module Select Front

Module Select None

Module Select Rear

more n/m . . . . . .

Mtr

Meas

Menu . . .

P.

Peak RF Always . . .

. . . . . . . . . . . . .

Pulse

On/OffScal.ar

Pwr Mtr Range . . .

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

Analyzr

........

CIIL

..........

SCPI

. . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

M-l

M-l

M-3

M-4

M-5

M-5

M-6

M-6

M-7

M-7

M-8

M-8

M-9

M-9

M-10

M-11

M-11

M-12

M-13

M-13

M-14

P-l

P-2

P-2

P-5

P-6

P-7

P-8

P-9

P-10

P-11

P-11

P-12

P-13

P-13

P-14

P-15

P-15

P-16

Contents-7

Page 20

R.

(RECALL)

....................

R-l

Ref Osc Menu

.................

R-l

@Eqz--

..................

R-2

ROTARY KNOB ................

R-2

S.

LSAVE)

.....................

S-l

SaveLock

..................

s-2

Save User Preset

..............

s-2

SCPI Conformance Information

.........

s-3

SCPI COMMAND SUMMARY

SCPI STATUS REGISTER

STRUbitiRi

. : : : :

s-12

S-48

Security Menu

................

s-50

Selftest

(Full)

...............

s-51

SetAtten

..................

s-51

[piEiF)

.....................

S-52

Software Rev

.................

S-52

@KJ

.....................

s-53

(START)

.....................

s-53

Start=Ml Stop=M2

..............

s-54

Start Sweep Trigger Auto

..........

s-55

Start Sweep Trigger Bus

...........

s-55

Start Sweep Trigger Ext

...........

S-56

Step Control Master

.............

S-56

Step Control Slave

.............

S-58

Step Dwell

..................

s-59

Step Points

.................

S-60

StepSize

..................

S-60

Step

Sup

Menu

................

S-61

Step

Sup

PtTrig Auto

............

S-62

Step

Sup

PtTrig Bus

.............

S-62

Step

Sup

PtTrig Ext

.............

S-63

ISTOP)

.....................

S-63

SWEEP

(MENU)

.................

S-64

Sweep Mode List

...............

S-65

Sweep Mode Ramp

...............

S-66

Sweep Mode Step

...............

S-66

Sup

Span

CalAlways

.............

S-67

Sup

Span

CalOnce

..............

S-67

(SWEEP TIME)

..................

S-68

SwpTime

Auto

.................

S-68

SYSTEM

(MENU)

.................

S-69

Contents-8

Page 21

m

1.

10

MHz Freq Std Auto

............

10

MHz Freq Std Extrnl

...........

10 MHz Freq Std Intrnl

...........

10 MHz Freq Std None

............

Tracking Menu

................

TrigOut

Delay

................

U.

Uncoupl Atten

......

Unlock Info

.......

Up/Down Power

......

Up/Dn Size CW

......

Up/Dn Size Swept

....

(USER)

..........

USER DEFINED

(FV1ENU)

. .

VsrKev

Clear

.......

*

UsrMenu Clear . . . . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. .

. .

. .

. .

. .

. .

. .

. .

. .

Zero Freq . . . . . . . . . . . . . . . . . .

z-1

Zoom . . . . . . . . . . . . . . . . . . . . .

z-1

2a. Error Messages

Introduction . . . . . . . . . . . . . . . . . .

Front Panel Error Messages in Alphabetical Order

.

SCPI Error Messages in Numerical Order . . . . .

Swept CW Generator Specific SCPI Error Messages

Universal SCPI Error Messages . . . . . . . .

Error Messages From -499 To -400 . . . . .

Error Messages From -399 To -300 . . . . .

Error Messages From -299 To -200 . . . . .

Error Messages From -199 to -100 . . . . . .

2b. Menu Maps

ALC Menu

..................

Frequency Menu

................

Marker Menu

.................

Modulation Menu

...............

Power Menu

..................

Service Menu

.................

Sweep Menu

..................

System Menu

.................

User Cal Menu

.................

T-l

T-l

T-2

T-2

T-3

T-3

U-l

U-l

u-2

u-2

u-3

u-4

u-4

u-5

u-5

2a-1

2a-1

2a-5

2a-5

2a-6

2a-6

2a-6

2a-6

2a-7

2b-3

2b-5

2b-7

2b-9

2b-11

2b-13

2b-15

2b-17

2b-19

Contents-9

Page 22

2c. Specifications

Frequency ...................

Range ....................

Resolution ..................

Frequency Bands (for CW signals)

.......

Frequency Modes: ..............

CW and Manual Sweep

............

Synthesized Step Sweep

............

Synthesized List Mode

............

Ramp Sweep Mode ..............

Internal 10 MHz Time Base

..........

RF Output ..................

Output Power ................

Accuracy ( dB)4

..............

Flatness

(dB)

...............

Analog Power Sweep .............

External Leveling ...............

Source Match ................

Spectral Purity .................

Spurious Signals ...............

Single-Sideband Phase Noise (dBc/Hz)

.....

Offset from Carrier .............

Residual FM (RMS, 50 Hz to 15 kHz bandwidth) .

General ....................

Environmental ................

Warm-Up Time ...............

Power Requirements .............

Weight & Dimensions .............

Adapters Supplied ..............

Inputs & Outputs ..............

Auxiliary Output ..............

RF Output ................

External ALC Input

............

Trigger Input ...............

Trigger Output ...............

10 MHz Reference Input

...........

10 MHz Reference Output

..........

Sweep Output ...............

Stop Sweep Input/Output

..........

Z-Axis Blanking/Markers Output

.......

Volts/GHz Output .............

Source Module Interface

...........

Auxiliary Interface .............

Models ...................

Options ...................

Option 001 Add Step Attenuator

.......

Option 004 Rear Panel RF Output

......

Option 008 1 Hz Frequency Resolution

....

Option 700 MATE System Compatibility

...

Option 806 Rack Slide Kit

..........

Option 908 Rack Flange Kit

.........

2c-2

2c-2

2c-2

2c-2

2c-2

2c-2

2c-3

2c-3

2c-3

2c-3

2c-4

2c-4

2c-5

2c-5

2c-6

2c-6

2c-6

2c-7

2c-7

2c-9

2c-9

2c-9

2c-10

2c-10

2c-10

2c-10

2c-10

2c-10

2c-11

2c-11

2c-11

2c-11

2c-11

2c-11

2c-11

2c-11

2c-11

2c-11

2c-12

2c-12

2c-12

2c-12

2c-12

2c-12

2c-12

2c-12

2c-12

2c-12

2c-13

2c-13

Contents- 10

Page 23

Option 910 Extra Operating & Service Guides .

Option 013 Rack Flange Kit

.........

Option W30 Two Years Additional Return-To-HP

Service

.................

3. Installation

Initial Inspection

................

Equipment Supplied

..............

Options Available

...............

Preparation for Use

...............

Power Requirements

.............

Line Voltage and Fuse Selection

........

Power Cable

.................

Language Selection

..............

How to View or Change a Language Selection from

the Front Panel

.............

How to Select a Language on a Swept CW

Generator without a Front Panel

.....

HP-IB Address Selection

...........

How to View or Change an HP-IB address from

the Front Panel

.............

How to Prevent a Front Panel Change to an HP-IB

Address

................

How to Set the HP-IB Address on a Swept CW

Generator without a Front Panel

.....

Mating Connectors

..............

10 MHz Frequency Reference Selection and Warmup

Time

..................

Operating Environment

............

Chassis Kits

..................

Rack Mount Slide Kit (Option 806)

.......

Installation Procedure

............

Rack Flange Kit for Swept CW Generators with

Handles Removed (Option 908)

.......

Installation Procedure

............

Rack Flange Kit for Swept CW Generators with

Handles Attached (Option 913)

.......

Installation Procedure

............

Storage and Shipment

..............

Environment

.................

Package the Swept CW Generator for Shipment

.

Converting HP 8340/41 Systems to HP 8360 L-Series

Systems

..................

Manual Operation

..............

Compatibility

...............

Front Panel Operation

...........

Instrument Preset Conditions

.......

System Connections

.............

The HP 8510 Network Analyzer

.......

The HP

8757C/E

Scalar Network Analyzer

. .

2c-13

2c-13

2c-13

3-l

3-2

3-2

3-3

3-3

3-3

3-4

3-6

3-6

3-6

3-7

3-8

3-8

3-8

3-8

3-8

3-9

3-10

3-10

3-11

3-13

3-14

3-15

3-16

3-17

3-17

3-18

3-19

3-20

3-20

3-20

3-20

3-21

3-21

3-22

Contents-l 1

Page 24

The HP 83550 Series Millimeter-wave Source

Modules . . . . . . . . . . . . . . .

The HP 8970B Noise Figure Meter . . . . .

Remote Operation . . . . . . . . . . . . .

Language Compatibility . . . . . . . . . .

Network Analyzer Language . . . . . . . .

Test and Measurement System Language . .

Control Interface Intermediate Language . .

Converting from Network Analyzer Language to

SCPI

. . . . . . . . . . . . . . . . .

Numeric Suffixes . . . . . . . . . . . . .

Status Bytes . . . . . . . . . . . . . . .

3-22

3-22

3-23

3-23

3-23

3-23

3-23

3-23

3-24

3-24

4. Operator’s Check and Routine Maintenance

Operator’s Checks

...............

Service Information

..............

Local Operator’s Check

.............

Description

.................

Preliminary Check

..............

Main Check

.................

Routine Maintenance

..............

How to Replace the Line Fuse

.........

How to Clean the Fan Filter

..........

How to Clean the Cabinet

...........

How to Clean the Display Filter

........

4-l

4-l

4-2

4-2

4-2

4-3

4-4

4-4

4-5

4-6

4-6

5. Instrument History

Index

Contents-12

Page 25

Figures

Contents-13

O-l. Typical Serial Number Label

..........

l-l. The HP 8360 L-Series Swept CW Generator

...

l-2. Display

...................

l-3. Entry Area

.................

l-4. CW Operation and Start/Stop Frequency Sweep .

l-5. Center Frequency and Span Operation

.....

l-6. Power Level and Sweep Time Operation

.....

l-7. Continuous, Single, and Manual Sweep Operation

l-8. Marker Operation

..............

l-9. Saving and Recalling an Instrument State

....

l-10. Power Sweep and Power Slope Operation

....

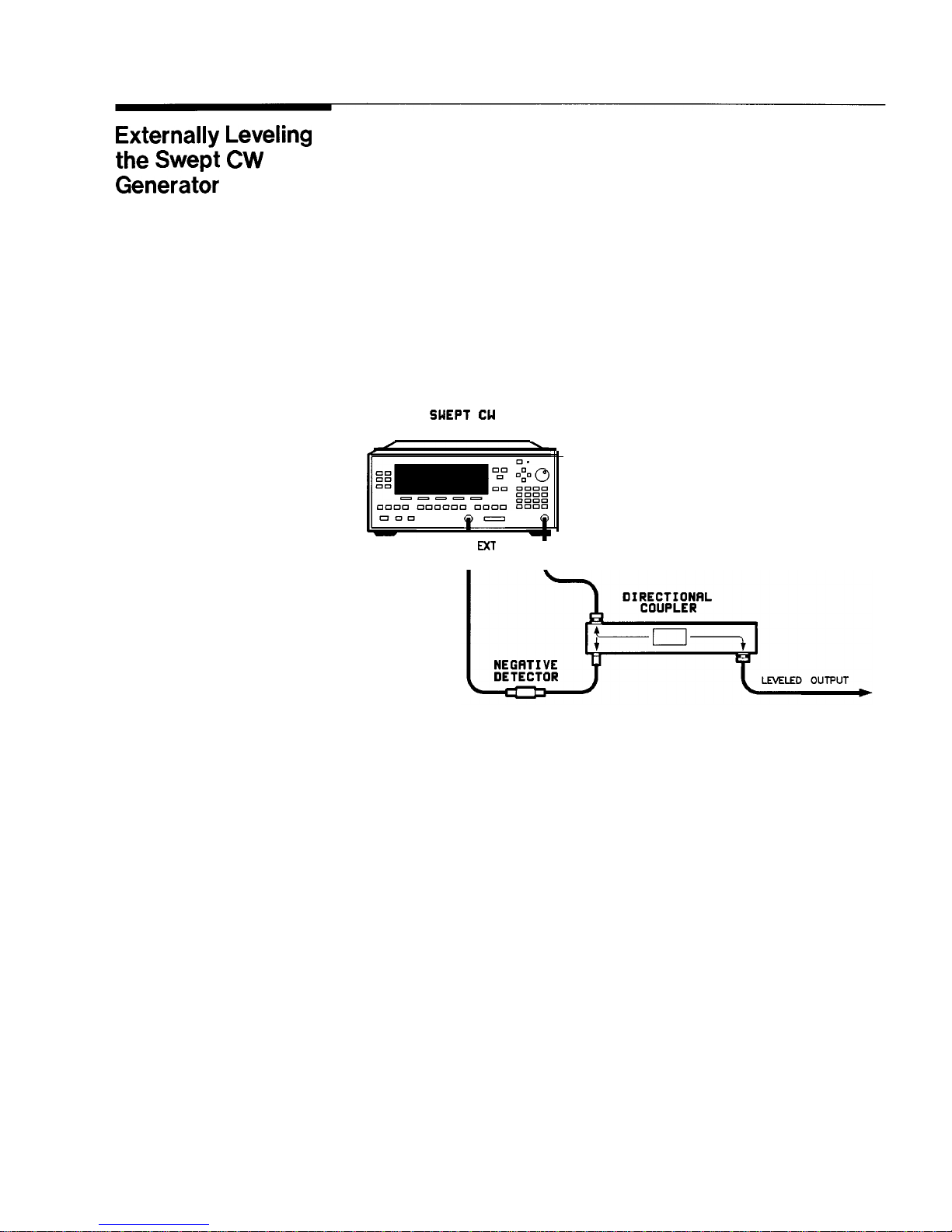

l-11. ALC Circuit Externally Leveled

........

1-12. Typical Diode Detector Response at 25°C

....

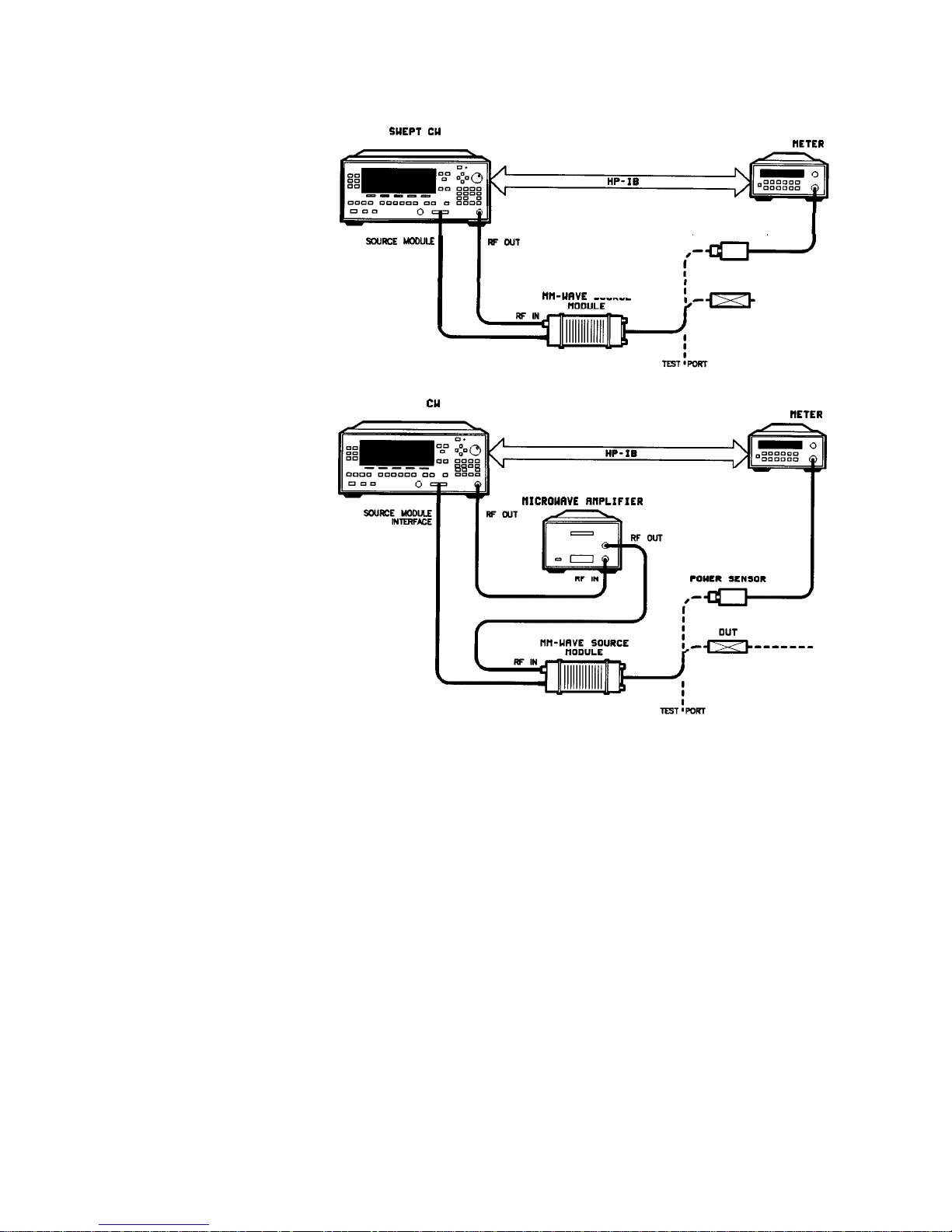

1-13. Leveling with a Power Meter

..........

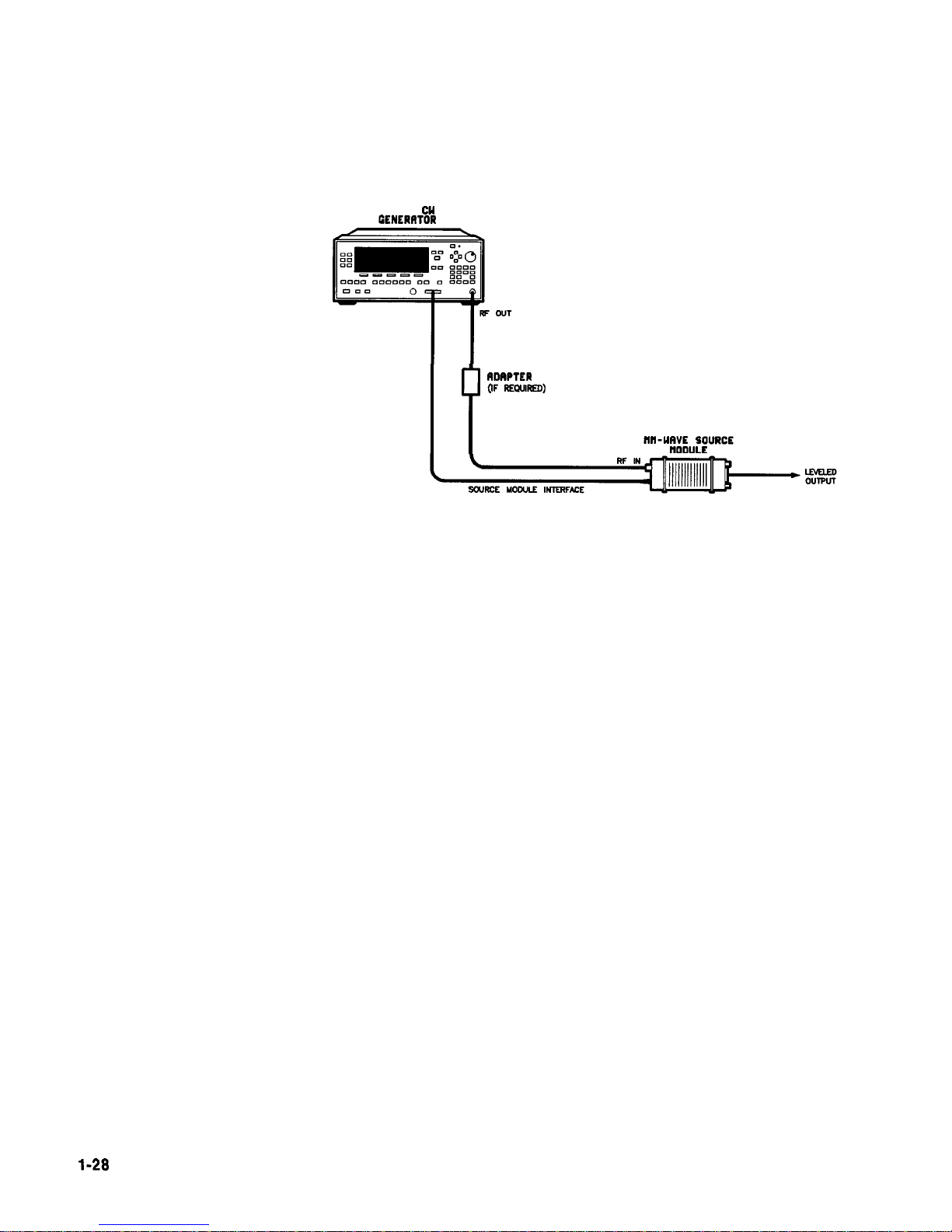

1-14. MM-wave Source Module Leveling

.......

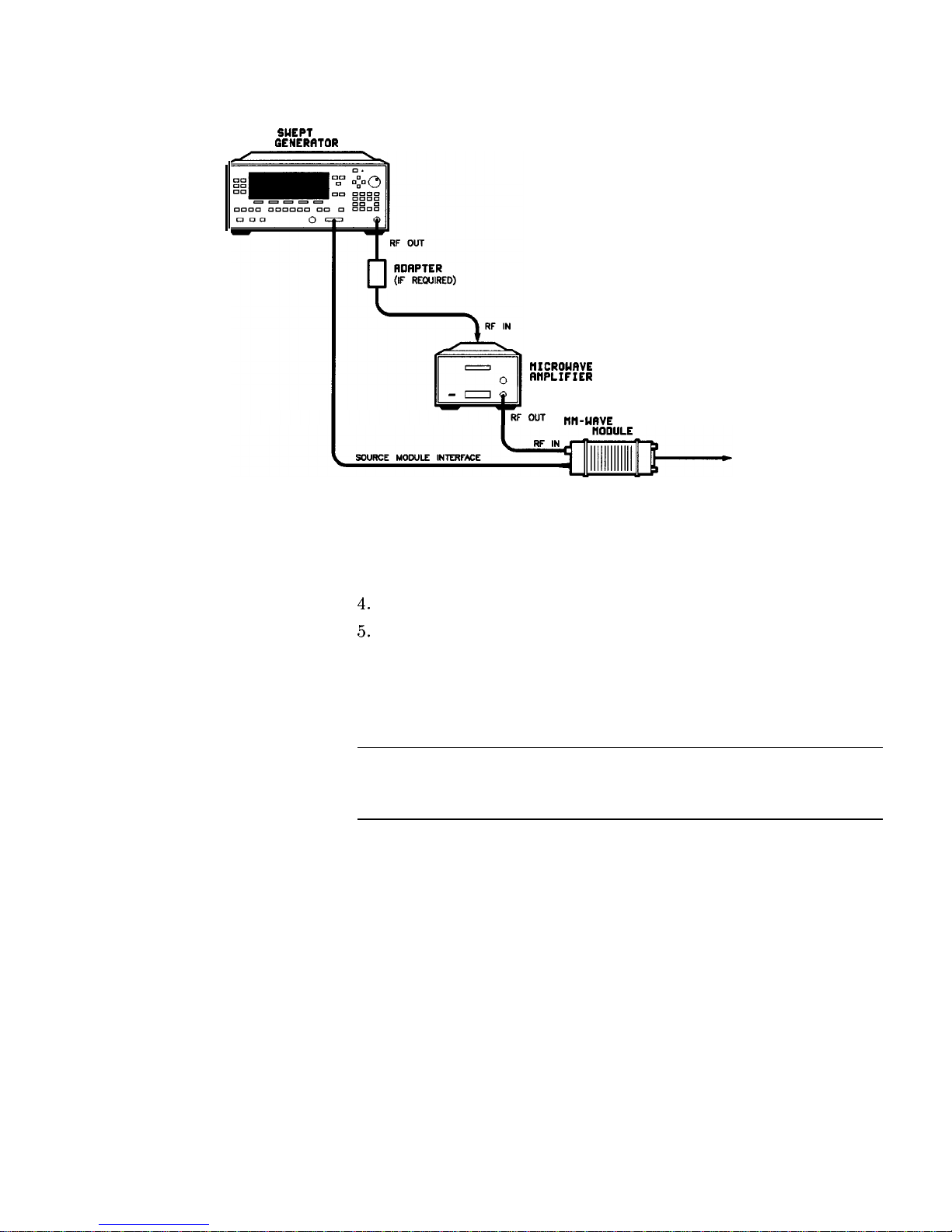

1-15. MM-wave Source Module Leveling Using a Microwave

Amplifier

.................

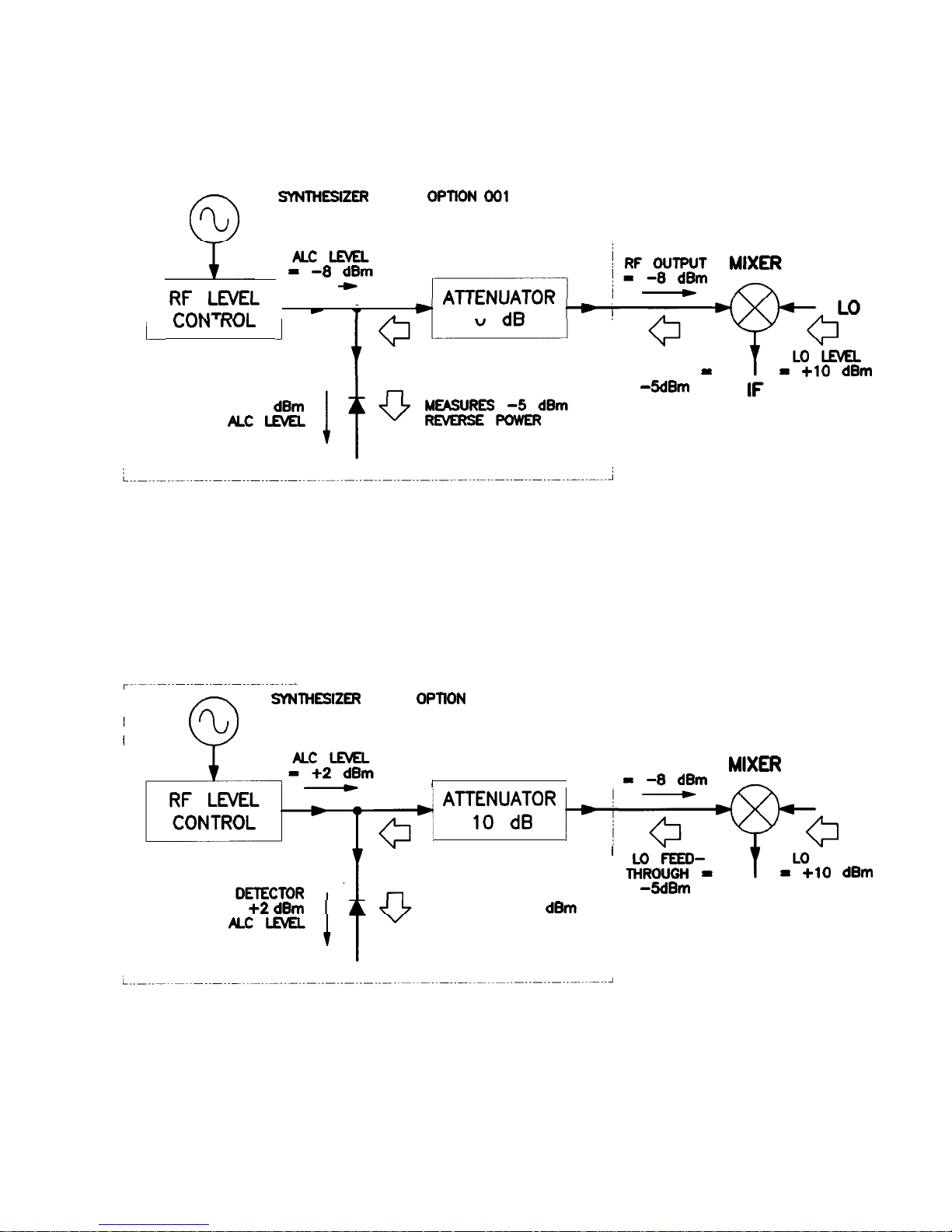

1-16. Reverse Power Effects, Coupled Operation with

-8dBm Output

..............

1-17. Reverse Power Effects, Uncoupled Operation with

-8dBm Output

..............

1-18. Creating a User Flatness Array Automatically . .

1-19. Creating a User Flatness Array

.........

l-20. Creating Arbitrarily Spaced Frequency-Correction

Pairs in a Swept mm-wave Environment ...

1-21. Scalar System Configuration

..........

l-22. Automatically Characterizing and Compensating for

a Detector

................

l-23. Decision Tree for ALC Bandwidth Selection

...

l-24. SCPI Command Types

............

l-25. A Simplified Command Tree

..........

l-26. Proper Use of the Colon and Semicolon

.....

l-27. Simplified

SWEep

Command Tree

.......

l-28. Voltage Controlled Oscillator Test

.......

l-29. Simplified Program Message Syntax

.......

l-30. Simplified Subsystem Command Syntax

.....

1-31. Simplified Common Command Syntax

.....

l-32. Simplified Response Message Syntax

......

l-33. Generalized Status Register Model

.......

l-34. Typical Status Register Bit Changes

......

l-35. Generalized Trigger Model

...........

l-36. Inside the Idle State

.............

vii

l-3

1-4

1-5

1-7

1-9

l-11

l-13

1-15

1-17

1-19

l-23

l-25

l-27

l-28

l-29

1-31

1-31

l-34

l-37

l-40

l-43

1-47

l-50

l-67

l-68

l-70

1-71

l-77

l-80

1-81

l-82

1-82

l-106

l-108

l-110

l-111

Page 26

l-37. Inside the Initiate State . . . . . . . . . . . .

l-38. Inside an Event Detection State . . . . . . . .

l-39.

Inside the Sequence Operation State . . . . . .

l-40.

The

INIT

Trigger Configuration . . . . . . . .

1-41.

The TRIG Trigger Configuration . . . . . . . .

l-42. HP 8360 Simplified Trigger Model . . . . . . .

A-l.

ALC System Simplified Block Diagram . . . . .

A-2.

Typical External Leveling Hookup . . . . . . .

C-l. Auxiliary Interface Connector . . . . . . . . .

c-2.

HP-IB Connector and Cable . . . . . . . . . .

c-3. Interface Signals of the Source Module Connector .

F-l.

Basic User Flatness Configuration Using an HP 437B

F-2.

F-3.

F-4.

Power Meter . . . . . . . . . . . . . . .

User Flatness Correction Table as Displayed by the

Swept CW Generator . . . . . . . . . . .

The Sources of ALC Calibration Correction Data .

Array Configuration when the Correction Data

Frequency Span is a Subset of the Swept CW

Generator Frequency Span . . . . . . . . .

P-l.

S-l.

How(PRIOR)Works . I

.-.

. . . . . . . . . .

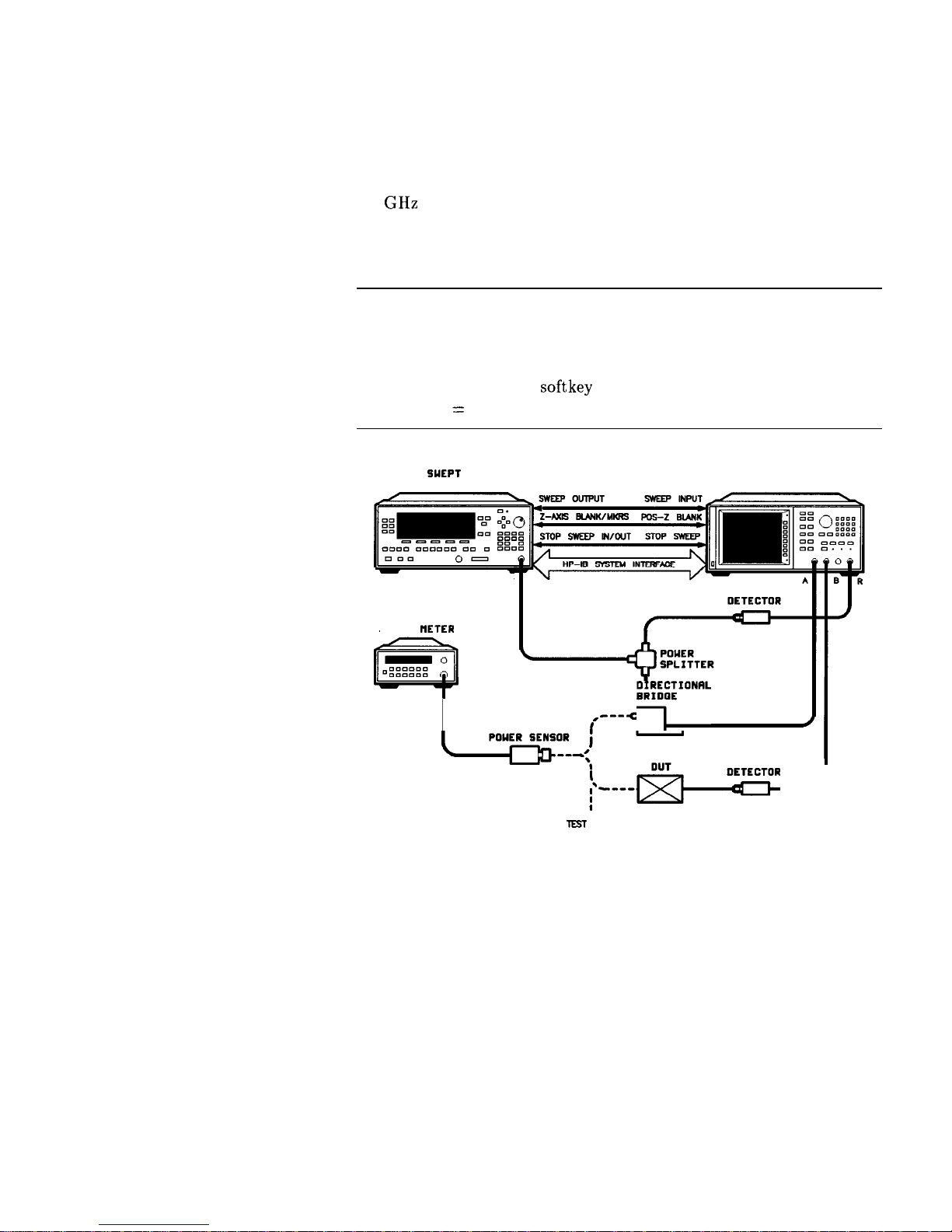

Connections Required for a Two-Tone Scalar

2b-1.

2b-2.

2b-3.

2b-4.

2b-5.

2b-6.

2b-7.

2b-8.

2b-9.

3-l.

3-2.

3-3.

3-4.

3-5.

3-6.

4-l.

Network Analyzer Measurement System

...

ALC Menu

.................

Frequency Menu

.............

.,

.

Marker Menu

................

Modulation Menu

..............

Power Menu

.................

Service Menu

................

Sweep Menu

.................

System Menu

................

User Cal Menu

................

AC Power Cables Available

..........

Rear Panel HP-IB Switch

...........

Removing the Side Straps and Feet

.......

Chassis Slide Kit

...............

Rack Mount Flanges for Swept CW Generators with

Handles Removed

.............

Rack Mount Flanges for Swept CW Generators with

Handles Attached

.............

Replacing the Line Fuse

............

4-2. Removing the Fan Filter . . . . . . . . . . .

l-111

1-113

1-114

l-115

l-116

1-117

A-5

A-8

C-6

c-7

c-9

F-6

F-7

F-8

F-8

P-12

s-57

2b-3

2b-5

2b-7

2b-9

2b-11

2b-13

2b-15

2b-17

2b-19

3-5

3-7

3-11

3-12

3-14

3-16

4-4

4-5

Contents-14

Page 27

Tables

l-l. Keys Under Discussion in This Section

.....

l-2.

SWEep

Command Table

...........

l-3. SCPI Data Types

..............

l-4. Sample Swept CW Generator Commands

....

C-l. Pin Description of the Auxiliary Interface

....

D-l. Mnemonics used to Indicate Status

.......

S-l. HP 8360 SCPI COMMAND SUMMARY

....

3-l. Adapter Descriptions and Part Numbers Shipped

with Each Swept CW Generator Model

...

3-2. Language HP-IB Addresses

..........

3-3. Factory-Set HP-IB Addresses

.........

3-4. Rack Mount Slide Kit Contents

........

3-5. Rack Flange Kit for Swept CW Generators with

Handles Removed Contents

.........

3-6. Rack Flange Kit for Swept CW Generators with

Handles Attached Contents

.........

3-7. Instrument Preset Conditions for the HP

8360/8340/8341

..............

3-8. Numeric Suffixes ...............

3-9. Programming Language Comparison

......

4-l. Fuse Part Numbers

..............

1-21

1-71

l-83

l-88

C-6

D-6

S-16

3-2

3-6

3-7

3-10

3-13

3-15

3-20

3-24

3-25

4-4

Contents-15

Page 28

1

Getting Started

What Is In This

Chapter

This chapter contains information on how to use the

HP 8360 L-Series Swept CW Generator. The information is

separated into three sections.

Basic For the novice user unfamiliar with the

HP 8360 L-Series Swept CW Generator. This

section describes the basic features of the swept CW

generator.

Note

Advanced

Programming

For the user familiar with swept CW generators,

but not necessarily familiar with how to use the

special features of the HP 8360 L-Series Swept CW

Generator.

For the user wishing to program an HP 8360 L-Series

Swept CW Generator. This section contains

an introduction to Standard Commands

for Programmable Instruments language

(SCPI), Hewlett-Packard’s implementation of

IEEE-488.2-1987, and an introduction to the

Analyzer programming language.

If you are unpacking a new swept CW generator, refer to the

installation suggestions provided in Chapter 3, “Installation”.

Getting Started Introduction

l-1

Page 29

How To Use This

Chapter

To use this chapter effectively, refer to the tabbed section “Menu

Maps”. Menu maps can be folded out to be viewed at the same time

as the Getting Started information, as illustrated.

tl-

I

1

Equipment Used In

The following table lists the equipment used in the operation

Examples

examples shown in this chapter. You can substitute equipment, but

be aware that you may get different results than those shown.

Equipment Used In Examples

Equipment

Recommended

Model Numbers

I

Power Meter

HP

436A/437B

I

Power Sensor

I

HP 8485A

I

Oscilloscope

mm-Wave Source Module HP 83556A

I

Power Amplifier

HP 8349B

1

Detector

t

HP 8474D

1-2 Getting Started Introduction

Page 30

Getting Started Basic

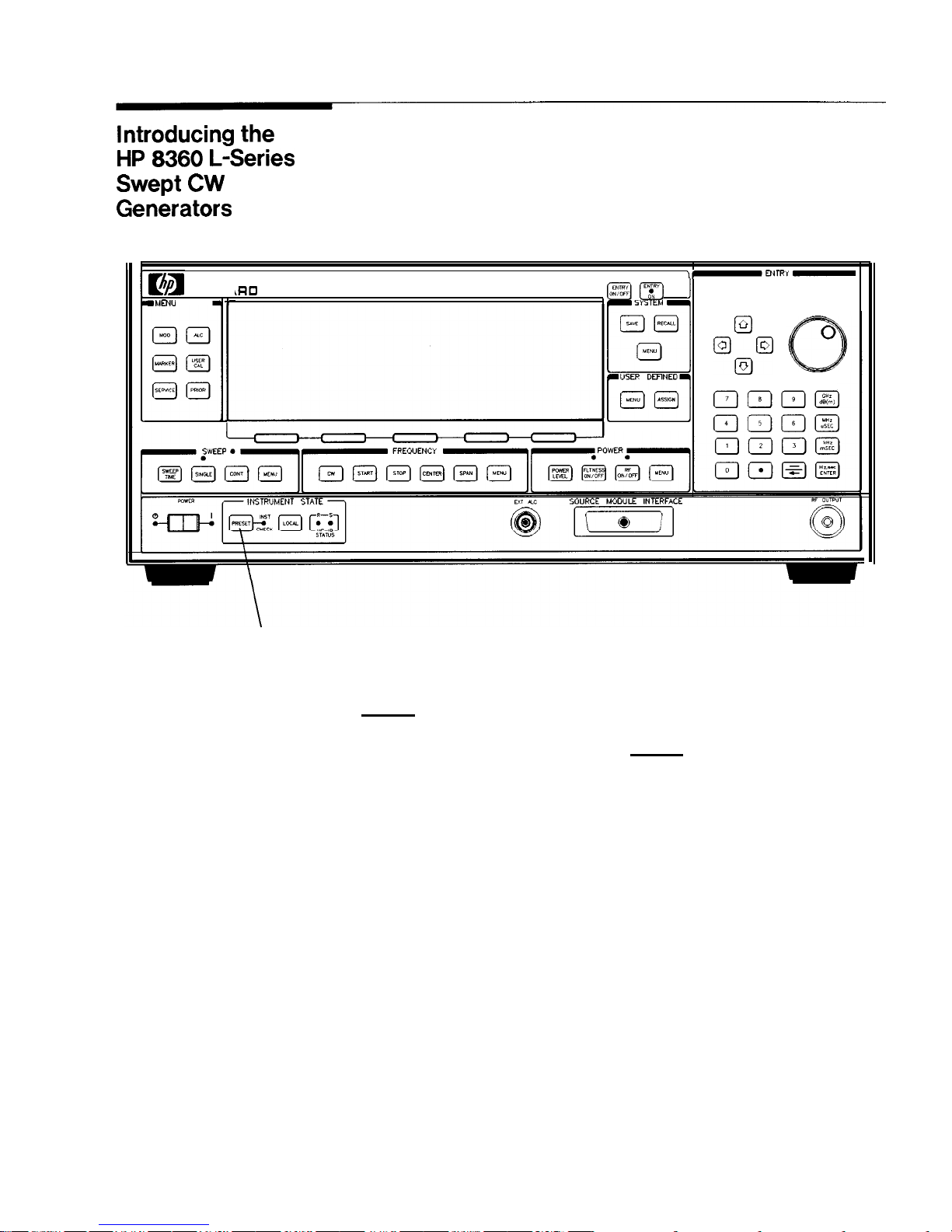

Introducing the

HP 8360 L-Series

Swept CW

Generators

The HP 8360 L-Series Swept CW Generators are high performance,

broadband frequency swept CW generators.

HEWLETT

PACKP

rR0

.MENU

SELECT

,,-ENTRY-

IzEJm

J

SYSTEM

[YM]

@

u

cEil

%I@

USER

DrnNED

u

@1Lalc*l

pJ(TJm@J

rmrm

PRESET

Figure l-l. The HP 8360 L-Series Swept CW Generator

(PRESET) initializes the front panel settings and runs the swept CW

generator through a brief self-test. In the following examples, unless

stated otherwise, begin by pressing (PRESET).

Getting Started Basic l-3

Page 31

Display Area

\

SOFTKEYS

ACTIVE ENTRY AND

DATA DISPLAY AREA

J

-

MESSAGE LINE

1

SOFTKEY

LABEL AREA

Figure l-2. Display

Active Entry and Data Display Area: This area typically displays

the frequency and power information of the current instrument

state. When data entry is expected, the swept CW generator uses

all or part of this area to record the entries. The active entry

arrow (

-->)

indicates the active entry function and its current

value.

Message Line: This line is used to display:

ALC level status.

Unlock information.

Timebase

status.

RF output status.

Softkey

Label Area: This area displays the name of the softkey

directly below it.

Softkeys: These keys activate the functions indicated by the labels

directly above them.

l-4 Getting Started Basic

Page 32

Entry Area

All function values are changed via the rotary knob and/or keys of

the entry area.

ENTRY

ENTRY ON

ON/OFF

LED

ARROW KEYS

ROTARY KNOB

NUMkIC

NEGAti

SIGN/

ENTRY KEYS

BACKSPACE

Figure l-3. Entry Area

The following are active only when the swept CW generator expects

an input.

(ENTRY ON/OFF): This key lets you turn off or on the active entry

area. Turning off the entry area after a value is entered prevents

accidental changes.

ENTRY ON LED: This LED lights when the entry area is active.

Arrow Keys: The up/down arrow keys let you increase or decrease

a numeric value. The left/right arrow keys choose a significant

digit indicated by an underline.

Rotary Knob: The rotary knob increases or decreases a numeric

value. The rotary knob can be used in combination with the

left/right arrow keys to change the increment size.

Terminator Keys: After the numeric entry keys are used to enter a

value, these keys define the units.

Negative Sign/Backspace Key: If a data entry is in progress, this

key backspaces over the last digit entered, otherwise a negative

sign is entered.

Numeric Entry Keys: These keys enter specific numbers in the

active entry area and must be followed by one of the terminator

keys before the function value changes.

Getting Started Basic

l-5

Page 33

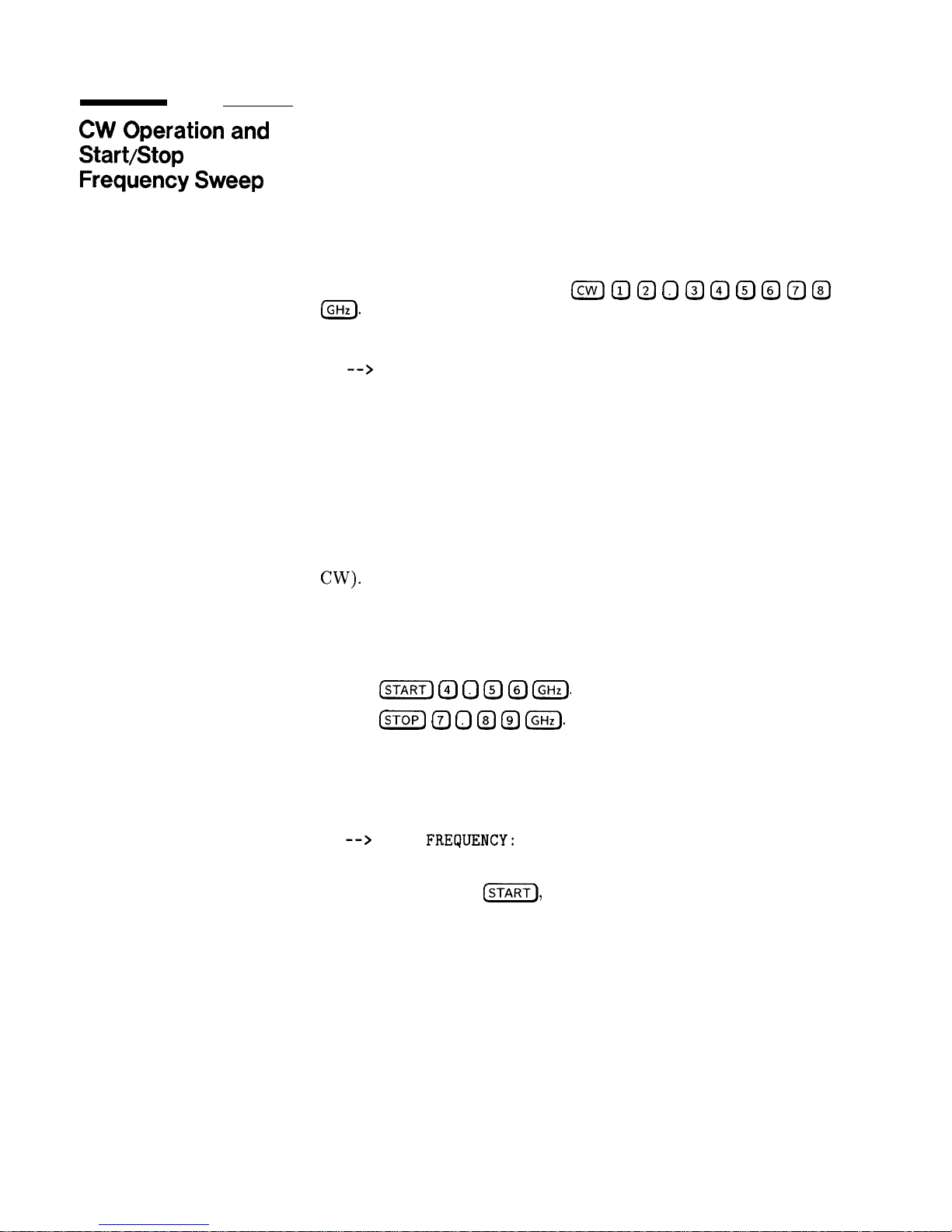

CW Operation and

Start/Stop

Frequency Sweep

CW Operation

CW operation is one of the major functions of the swept CW

generator, and is easy to do using front panel keys. In CW operation,

the swept CW generator produces a single, low-noise, synthesized

frequency. Try this example: Press

m (i-J @ (J @ @ (?J @ 0 @

@J.

Check the active entry area. It indicates:

-->

cw:

12345.678000 MHz

The data display area indicates CW operation and the frequency

that you entered. The ENTRY ON LED is lit and the green SWEEP

LED is off.

Try other frequencies. Experiment with the rotary knob and the

arrow keys as alternate methods of data entry.

Start/Stop Frequency

The swept CW generator can sweep a frequency span as wide as

Sweep

the frequency range of the instrument, or as narrow as 0 Hz (swept

CW).

In start/stop sweep operation, the swept CW generator produces

a sweep from the selected start frequency to the selected stop

frequency.

For example:

Press

[START) @ (J @ @ [GHz).

Press

ISTOP) 0 0 @ @ LGHz).

The data display area indicates the start frequency and the stop

frequency. The green SWEEP LED is on (periodically off when

sweep is retracing). Because this is the active function, the active

entry area indicates:

-->

STOP

FREqUENCY:

7890.000000 MHz

Any subsequent entries change the stop frequency. To change the

start frequency, press

[START),

which remains the active function until

you press a different function key.

1-6 Getting Started Basic

Page 34

HEWLETT

PACKARD

IMENU

SELECT

FREQUENCY

SWEEP LED

cw

START

STOP

Figure 1-4. CW Operation and Start/Stop Frequency Sweep

CW Operation

start/stop

Frequency Sweep

1. Press

[cw).

1. Press

@iZF).

2. Enter value.

2. Enter value.

3. Press terminator key.

3. Press terminator key.

4. Press (STOP).

5. Enter value.

6. Press terminator key.

Getting Started Basic 1-7

Page 35

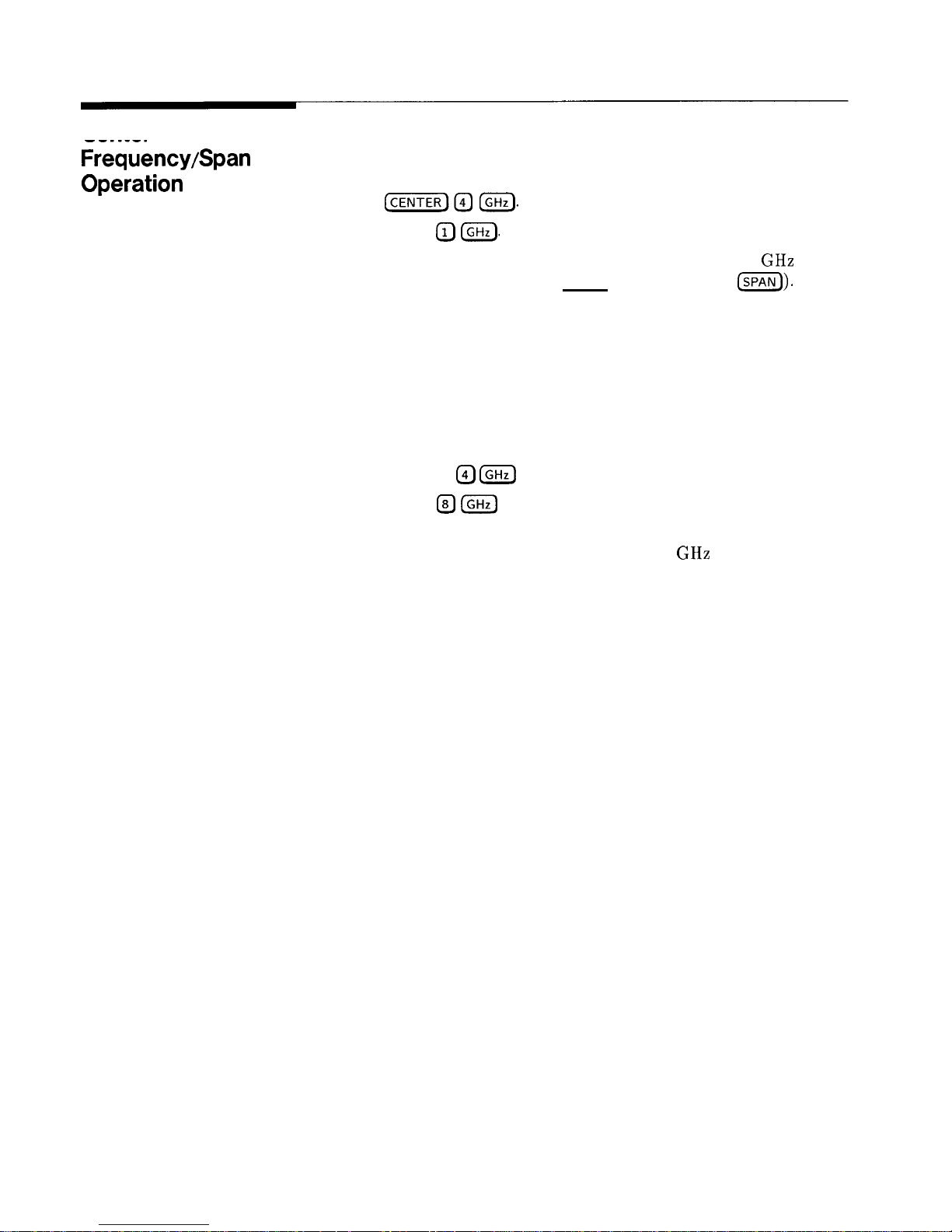

Center

Center frequency/span is another way of establishing swept

- ------

Frequency/Span

dperation

operation. This is just a different way of defining sweep limits. As an

example of center frequency/span operation:

Press

m@

(GHz).

Press (SPAN)

(iJ IGHz).

The swept CW generator is now sweeping from 3.5 to 4.5

GHz

(to

view these figures, press either (START) or (STOP), then

ml).

The

data display area indicates the center frequency, as well as, the span.

Notice that the green SWEEP LED is on.

While span is the active function, try the rotary knob and arrow

keys. This symmetrical increase or decrease of the frequency span

about the center frequency is one reason that center frequency/span

swept operation is used instead of start/stop frequency sweep.

Another example illustrates the subtleties of center frequency/span.

Press (CENTER) @

(GHz)

Press (SPAN @

IGHz)

Notice that the center frequency changed. This is because the center

frequency could not accommodate a span of 8 GHz without exceeding

the lower frequency limit of the swept CW generator’s specified

frequency range. If the low or high frequency range limits are

exceeded, the inactive (center or span) function is reset. Experiment

with the rotary knob and the arrow keys as alternate methods of

data entry.

1-8 Getting Started Basic

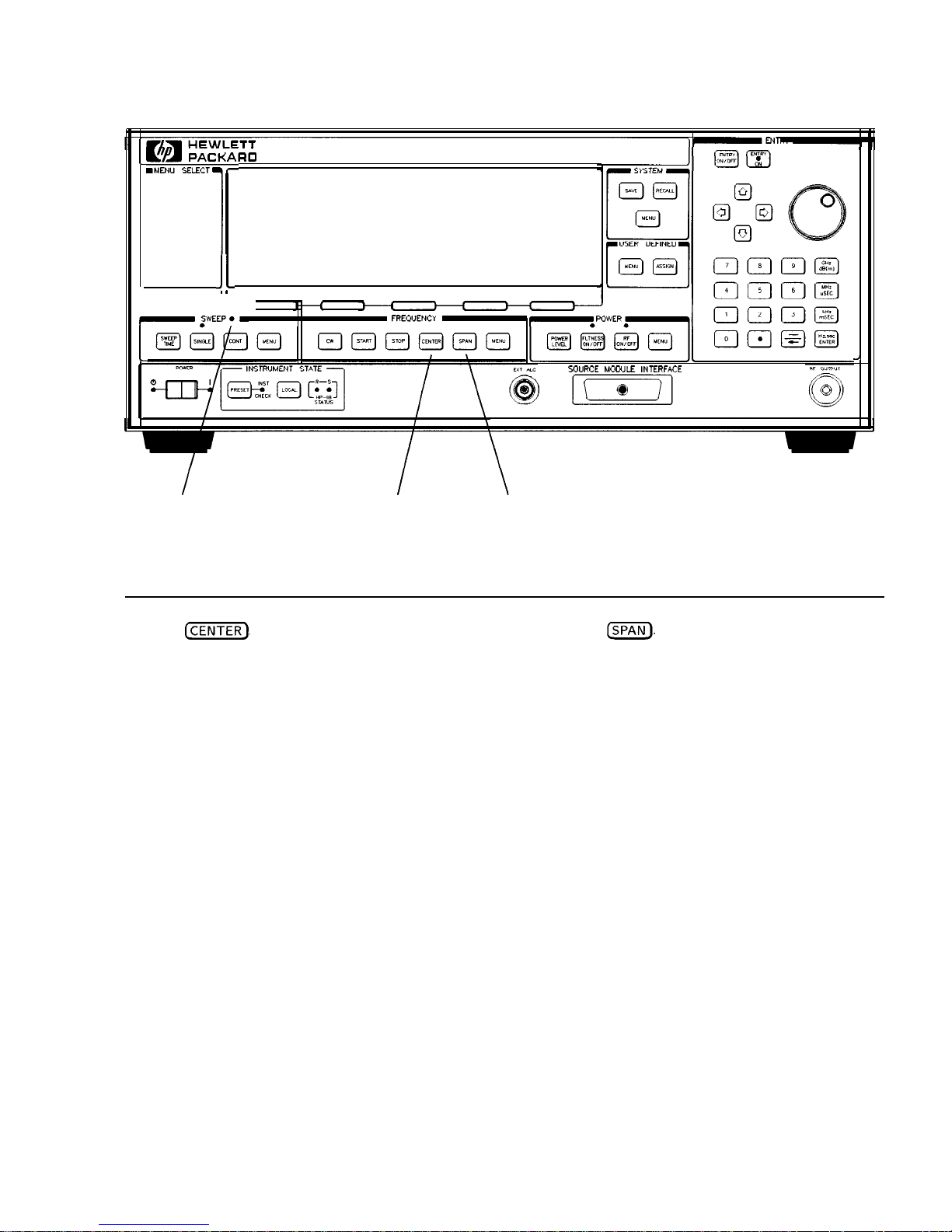

Page 36

1 y[!&i$i--

-

.

:ARO

.

’

JI

I

C

2

1

FREQUENCY

SOURCE MOWLE INTERFACE

SWEEP LED

CENTER

SPAN

Figure 1-5. Center Frequency and Span Operation

Center Frequency

Operation

Span Operation

1. Press

@?TiiFj,

2. Enter value.

1. Press

m).

2. Enter value.

3. Press terminator key.

3. Press terminator key.

Getting Started Basic 1-9

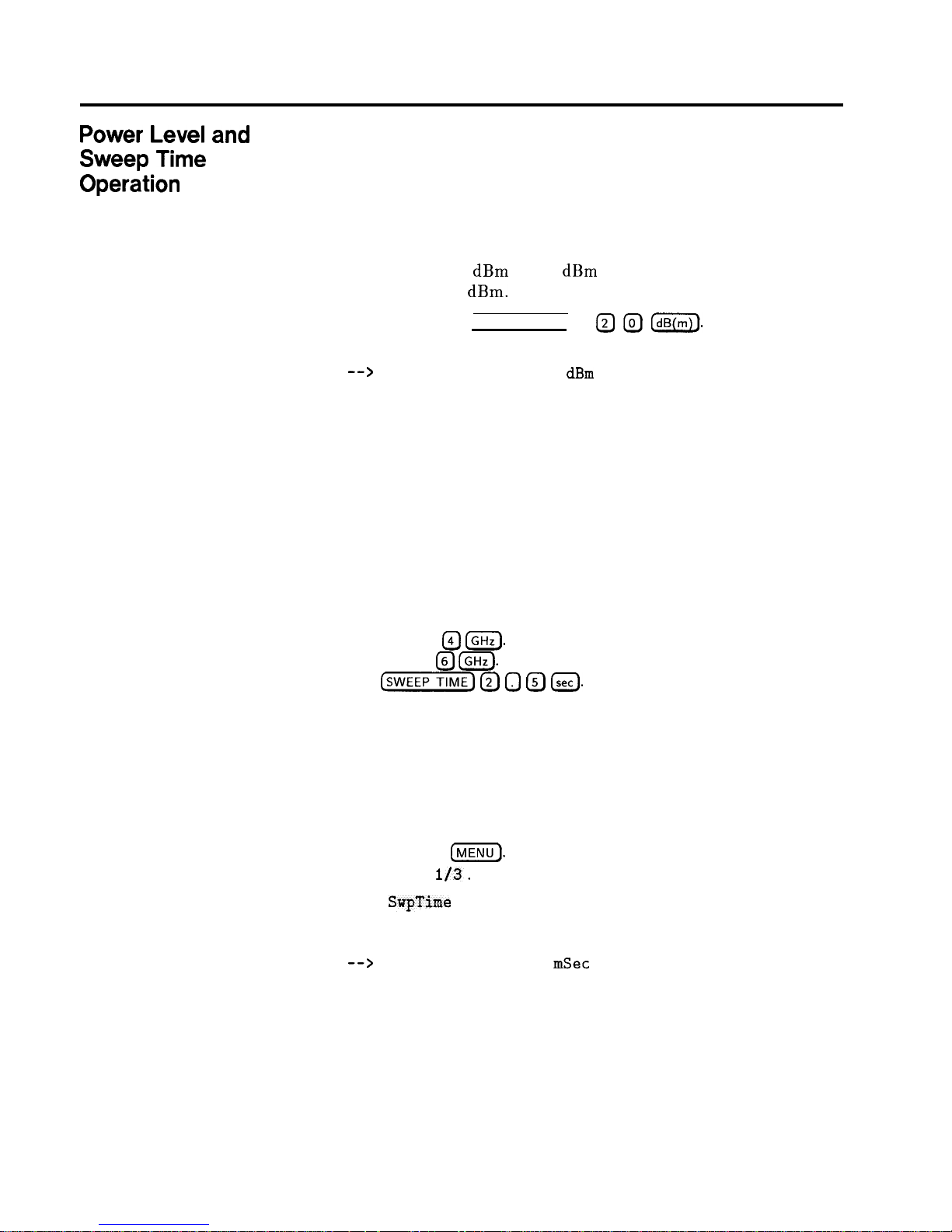

Page 37

Power Level and

Sweep Time

Operation

Power Level Operation

The swept CW generator can produce leveled power for CW, swept

frequency, or power sweep operation. The selected power level

can range from -20

dBm

(-110

dBm

for Option 001 swept CW

generators) to -l-25

dBm.

For practice: Press [POWER LEVEL] I-) @ @

m.

The active entry

area shows:

-->

POWER LEVEL: -20.00

dBm

If the selected power level is beyond the range of the swept CW

generator, the closest possible power is shown in both the data

display area and the active entry area. If the selected power level

exceeds the maximum leveled power the swept CW generator is

able to produce, the unleveled message UNLVLED appears on the

message line. Experiment with the rotary knob and the arrow keys

as alternate methods of data entry.

Sweep Time Operation

In typical applications the sweep time can vary tremendously, from

milliseconds in a network analyzer system, to more than a minute in

thermistor-based power meter systems.

Press (START) @

IGHz).

Press (STOP) @

(GHz).

Press

lsWEEP

(Y?J 0 @ (,,,I.

Watch the green SWEEP LED, it blinks every 2.5 seconds. The LED

blinks at each retrace.

For the fastest sweep speed for which all specifications are

guaranteed, the swept CW generator must be in automatic sweep

time selection.

Refer to menu map 7, SWEEP.

Press SWEEP

I=).

Select more

l/3.

Select

SwpTime

Auto .

Notice that the active entry area indicates:

-->

SWEEP TIME:

100.0

mSec

AUTO

When the swept CW generator is in automatic sweep time selection,

the active entry area displays AUTO along with the current sweep

time. Faster sweep speeds than this are possible, turn the rotary

knob counter-clockwise until the display no longer changes. Notice

that AUTO is no longer displayed.

l-10 Getting Started Basic

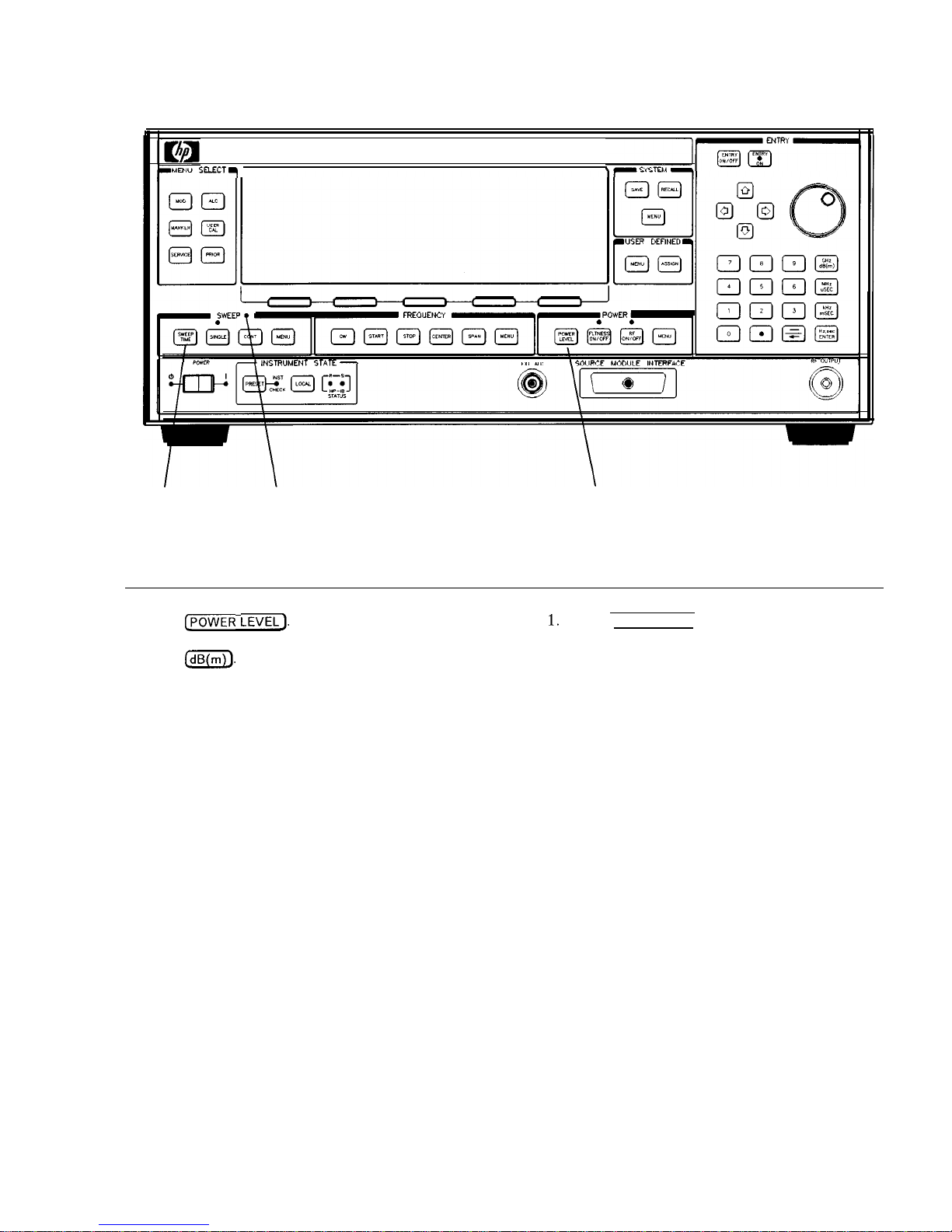

Page 38

HEWLETT

PACKARO

se..Ecr’l

,

INSTRUMENT SrATE -

IF OUTPVT

SWEEP TIME

SWEEP LED

POWER LEVEL

Figure 1-6. Power Level and Sweep Time Operation

Power Level

Sweep Time

Operation

Operation

1.

Press ~POWER

LEVEL].

1. Press

SWEEP TIME

2.

Enter value.

2. Enter

value.

3.

Press

0.

3. Press

terminator key.

Getting Started Basic l-11

Page 39

Continuous,

and Manual

Operation

Single,

Continuous sweep is the operation mode set when the swept

Sweep

CW generator is preset. It simply means that when the swept

CW generator is performing a swept operation, the sweeps will

continuously sweep-retrace-sweep-retrace until a different sweep mode

is selected. To choose this sweep mode, press

(CONT).

To change from continuous sweep to single sweep operation, press

(SINGLE). This causes the swept CW generator to abort the sweep in

progress and switch to the single sweep mode. This initial keystroke

causes the swept CW generator to switch sweep modes, but it does

not initiate a single sweep. A second keystroke (press (SINGLE))

initiates a single sweep. When the swept CW generator is in single

sweep operation, the amber LED above the key lights. When the

swept CW generator is actually performing a sweep in single sweep

mode, the green SWEEP LED lights.

The manual sweep mode lets you use the rotary knob to either sweep

from the start frequency to the stop frequency or to sweep power.

Refer to menu map 7, SWEEP.

Press

(PRESET).

Press SWEEP (MENU).

Select Manual Sweep.

The active entry area displays:

-->

SWEPT MANUAL: XXXXXXXXX MHz

Use the rotary knob to sweep from the start to the stop frequency.

The green SWEEP LED is off in manual sweep mode because the

sweeps are synthesized.

1-12 Getting Started Basic

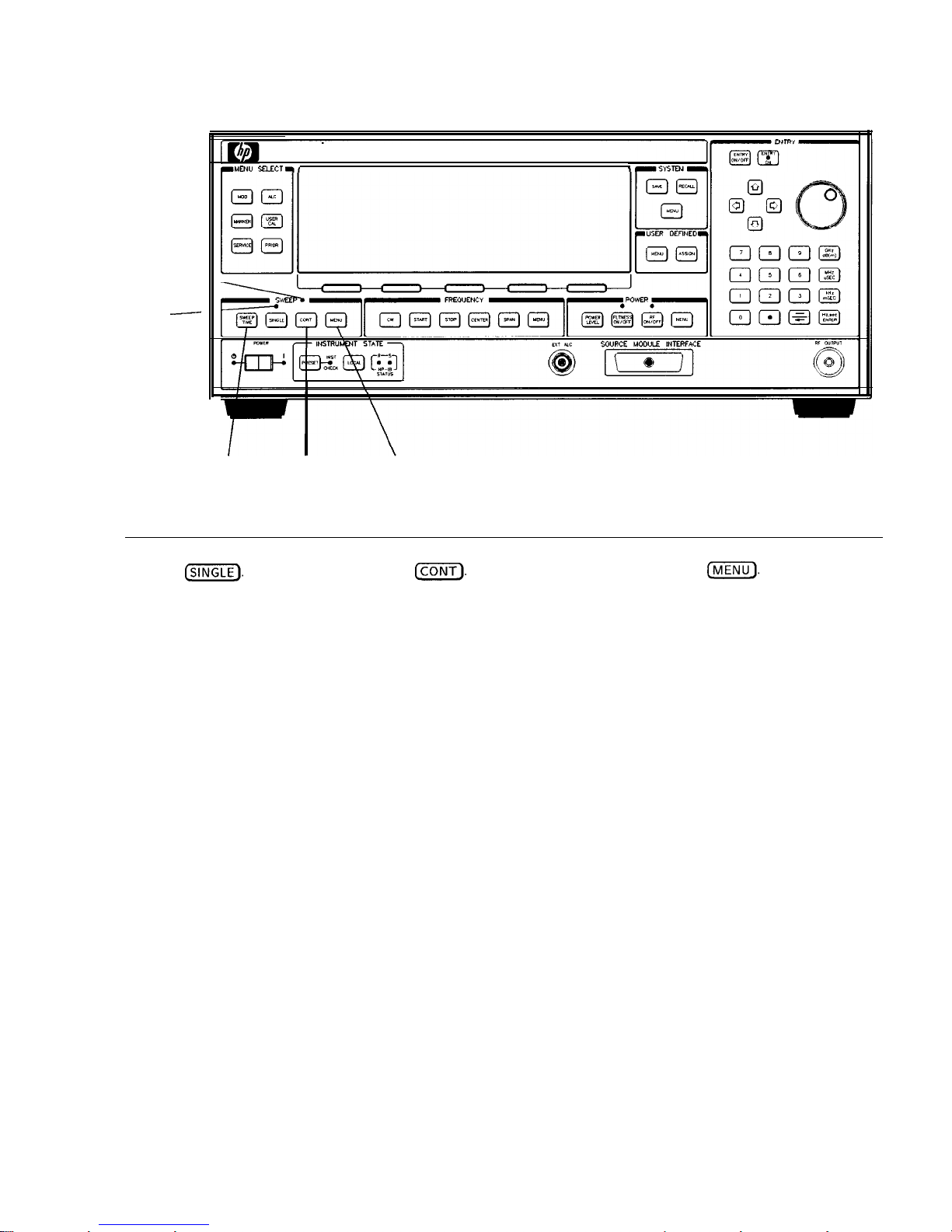

Page 40

SWEEP

LED ----

SINGLE

-

LED

HEWLETT

PACKARD

LMENU m.ECT.,

SINGLE CONT

SWEEP MENU

Figure 1-7. Continuous, Single, and Manual Sweep Operation

Single Sweep

1. Press

@iETQ

Continuous Sweep

1. Press

ICONT).

Manual Sweep

1. Press SWEEP

IrV1ENU_).

2. Press Manual Sweep.

3. Use the rotary knob to adjust frequency.

Getting Started Basic 1-13

Page 41

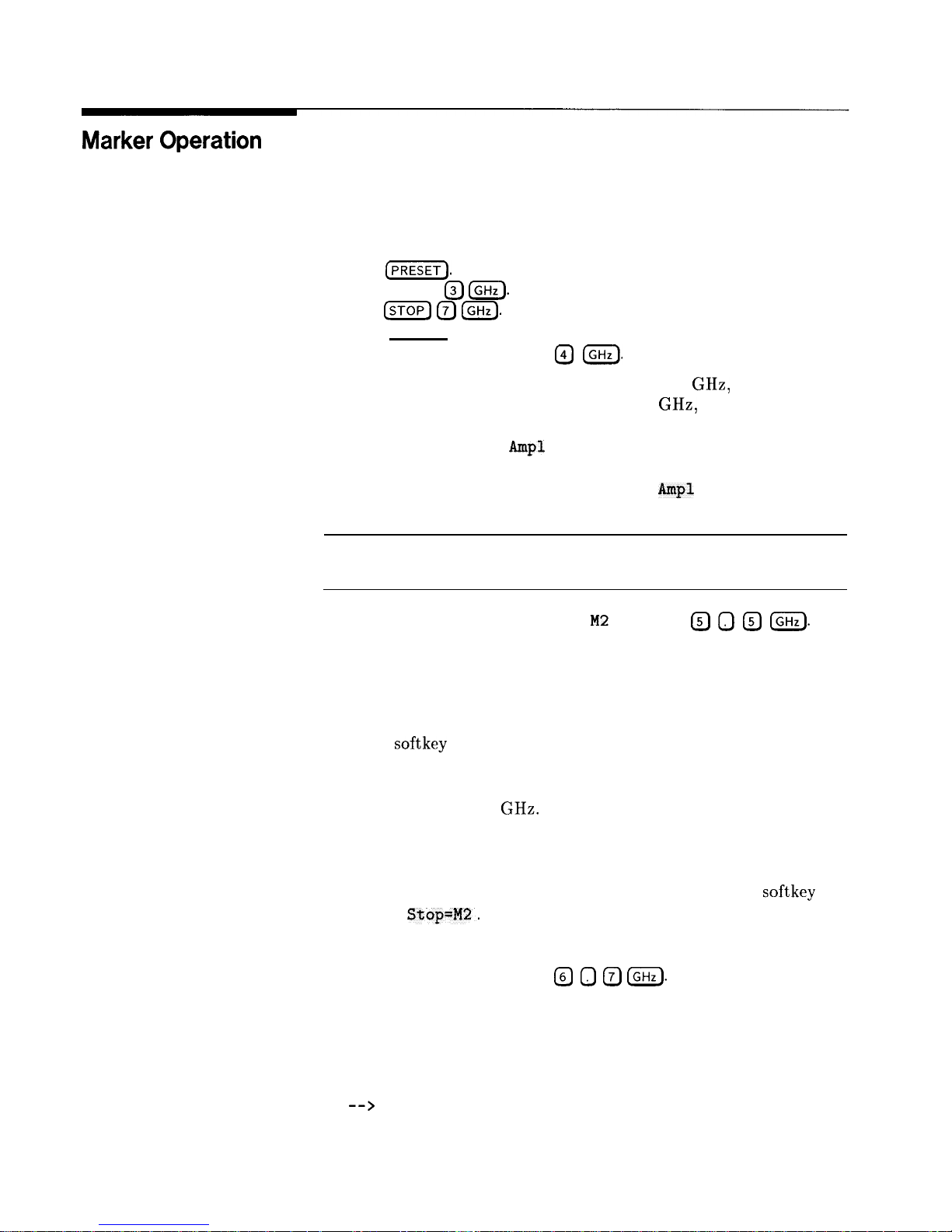

Marker Operation

The swept CW generator has five frequency markers that can be used

as fixed frequency “landmarks,”

or as variable frequency pointers

on a CRT display. To view the marker features of the swept CW

generator on a CRT, connect the swept CW generator as shown in

Figure l-8.

Refer to menu map 3, MARKER.

Press

[m).

Press (START) @

(GHzl.

Press

ISTOP) @ (GHz).

Press [MARKER).

Select Marker Ml and enter @

LGHz).

The swept CW generator is sweeping from 3 to 7 GHz, with a 100 ms

sweep speed. A frequency marker is set at 4 GHz, which causes an

intensified dot to appear on the CRT. To obtain an amplitude spike

at that frequency, select

Amp1

Markers . Notice that you can set the

amplitude of the spike with the rotary knob or entry keys. To return

to the intensified dot representation, select

Amp1

Markers (asterisk

off).

Caution

Amplitude markers increase the output power at the marker

frequency. Provide protection to devices that could be damaged.

For a second marker, select Marker M2 and enter @ 0 @

(GHz).

This process can be continued for all five markers. Note that the

marker displayed in the active entry area is “active” and can be

controlled by the rotary knob, arrow keys, and numeric entry keys.

Once the Ml and M2 markers are established, the marker sweep

function,

softkey

Ml--M2 Sweep, temporarily changes the original

start/stop frequencies to those of markers Ml and M2. Select

Ml--M2 Sweep.

Notice that the swept CW generator now is

sweeping from 4 to 5.5 GHz. Use this function to focus in on a

selected portion of the frequency sweep. Select Ml--M2 Sweep again.

This turns the function off and returns the swept CW generator to

its original sweep parameters. To change the start/stop frequencies

for the swept CW generator, not just temporarily, use the softkey

Start=Ml Stop=M2.

As an example of the delta marker function:

Select

Marker

M3

and enter @ 0

am.

Select

Delta Marker.

The frequency difference between marker 3 and marker 1 is displayed,

and the CRT trace is intensified between the two markers. The active

entry area displays:

-->

DELTA MKR (3-l) : 2700.000000 MHz

1-14 Getting Started Basic

Page 42

Marker 1 was chosen because it is selected as the delta marker

reference. To change reference markers, select Delta Mkr Ref .

Select M2 as the reference. Watch the display change to indicate:

-->

DELTA MKR

(3-2)

: 1200.000000 MHz

You can choose any of the five markers as a reference, but when delta

marker is on, if the reference marker has a frequency value higher

than the last active marker, the difference between the frequencies is

negative and is displayed as such by the swept CW generator. The

CRT display continues to intensify the difference between the two

markers.

When delta marker is showing in the active entry area, the ENTRY

area is active. Rotate the rotary knob and watch the frequency

difference change. The last active marker (in this case, marker 3)

changes frequency value, not the reference marker.

OSCILLOSCOPE

Figure 1-8. Marker Operation

Marker Operation

Delta Marker

Operation

1. Press

(jiXi?K).

2. Select a marker key (Ml .

MS

).

3. Enter value.

4. Press terminator key.

1. Press

($iZKKj.

2. Select a marker key (MI

~5).

3. Enter value.

4. Press terminator key.

5. Select a different marker key ( Mi M5 ).

6. Enter value.

7. Press terminator key.

8. Select Delta

Hkr

Ref.

9. Select one of the previously chosen markers.

10. Press

IPRIOR).

11. Select Delta Marker

Getting Started Basic l-15

Page 43

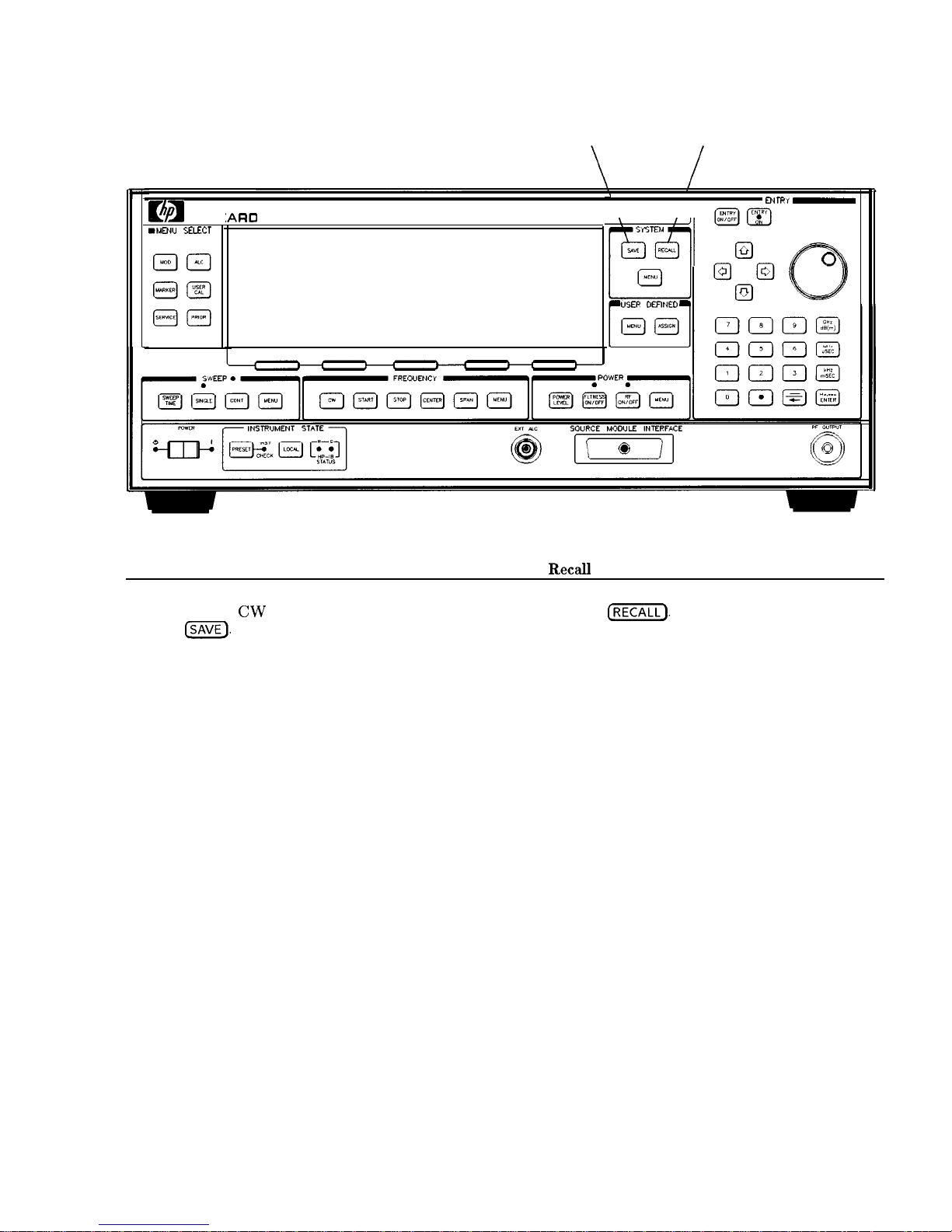

Saving and

The save/recall registers store and access a previously set instrument

Recalling an

state.

Instrument State

For example, set the swept CW generator to sweep from 3 to 15

GHz at a -10 dB power level, with markers 1 and 2 set at 4.5 and

11.2 GHz.

Press (START)

(?J LGHz).

Press

LSTOP) (iJ @ (GHz).

Press (POWER LEVEL)

(-) (iJ (TJ IdBo).

Press

(MARKER).

Select Marker Ml

@ 0 @ IGHz).

Select Marker M2

(iJ 0 0 @ LGHz).

To save this instrument state in register 1, press

(SAVE]

(iJ. To verify

that the swept CW generator has saved this state:

Press

[PRESET).

Press

IRECALL] 0.

Press

(MARKER).

The active entry area displays:

-->

RECALL REGISTER: 1 RECALLED

Notice the sweep end points, power level, and the asterisks next to

the marker 1 and 2 key labels.

You can save instrument states in registers 1 through 8. Register

0 saves the last instrument state before power is turned off. When

power is turned on, register 0 is automatically recalled.

1-16 Getting Started Basic

Page 44

m

HEWLETT

PACK

IARC

IlMENU SELPX

1

SAVE

RECALL

\ /II

ENrRRy -

USER

DEWED

Figure 1-9. Saving and Recalling an Instrument State

Save

1. Set up swept CW generator as desired.

2. Press

ISAVE).

3. Press a number

1

through 8.

Recall

1. Press

IjZKiJ.

2.

Press a number0through

8.

Getting Started Basic l-17

Page 45

Power Sweep and

Pow& Slope

Operation

Power Sweep Operation

The power sweep function allows the power output to be swept

(positive or negative) when the swept CW generator is in the CW

frequency mode. The power output of the swept CW generator

determines the maximum leveled power sweep that can be

accomplished. For this example, refer to the “Menu Map” section.

Zero and calibrate the power meter.

Connect the instruments as shown in Figure l-10.

Press

Icw @ IGHz).

Press (POWER LEVEL)

@ m.

Press (SWEEP

TIME) (TJ (,,,)

(SINGLE).

Set the power meter to dB[REF] mode.

The swept CW generator is ready to produce a 4 GHz CW signal

at 0

dBm

power out, with a 2 second sweep rate whenever a single

sweep is executed. The power meter is ready to measure the power

level relative to a starting point of 0

dBm.

Press

POWER,[jKQ

Select Power Sweep and enter 0

(dB(m))

(asterisk on).

Press (SINGLE).

Watch the relative power indication on the power meter. At the end

of the sweep the power meter indicates +7 dB. The active entry area

on the swept CW generator indicates:

-->

POWER SWEEP:

7.00 dB/SWP

Now enter @ @

(dB(mLj)

(p

ower sweep is still the active entry

function).

Press [SINGLE).

This time the power meter indicates less than the power sweep

requested. Note that the swept CW generator is unleveled, UNLVD.

This happens because the swept CW generator’s output power at the

start of the sweep is 0 dB and the requested power sweep takes the

swept CW generator beyond the range where it is able to produce

leveled power. The range of the power sweep is dependent on the

ALC range and can be offset if a step attenuator (Option 001) is

present.

Select Power Sweep to turn this function off (no asterisk).

Press

(POWER LEVEL)

I-] @

@.

On the power meter, press dB[REF] to reset the reference level.

1-18 Getting Started Basic

Page 46

Select power Sweep (asterisk on).

Press

@GE).

The swept CW generator performs a power sweep beginning at

-20

dBm

and ending at +5

dBm.

The power meter indicates

+25

dB.

Power Slope Operation

This function allows for compensation of high frequency system or

cable losses by linearly increasing the power output as the frequency

increases. For this example, refer to the “Menu Map” section.

Press Power Slope, the active entry area displays:

-->

RF SLOPE:X. XX

dB/GHz,

where X is a numeric value.

Power slope is now active, notice that an asterisk is next to the key

label.

Use the entry keys, rotary knob, or arrow keys to enter a value for

the linear slope.

Press Power Slope again to turn this feature off.

SUEPT

CU

GENERFITOR

\

POUER HETER

I

RF OUTPUT

AGAPTER

POWER SENSOR

Figure l-10. Power Sweep and Power Slope Operation

Power Sweep

Power Slope

1. Press POWER

(jj).

1. Press POWER

(&ii@.

2. Select Power Sweep.

2. Select Power Slope.

3. Enter a value.

3. Enter a value.

4. Press terminator key.

4. Press terminator key.

Getting Started Basic 1-19

Page 47

Advanced

Getting Started

Advanced

This section of Chapter 1 describes the use of many of the unique

features of the HP 8360 L-Series Swept CW Generators. The format

used is similar to the one used on the previous pages. When referred

to a menu map number, go to the Menu Map tab and unfold the

menu map so that you can view it together with the text.

Some menus have more than one page of softkeys. Select the

more

m/n softkey

to view the next page of softkeys. more m/n is

not included in the keystrokes given in these procedures.

Table l-l. Keys Under Discussion in This Section

Paragraph Heading Keys

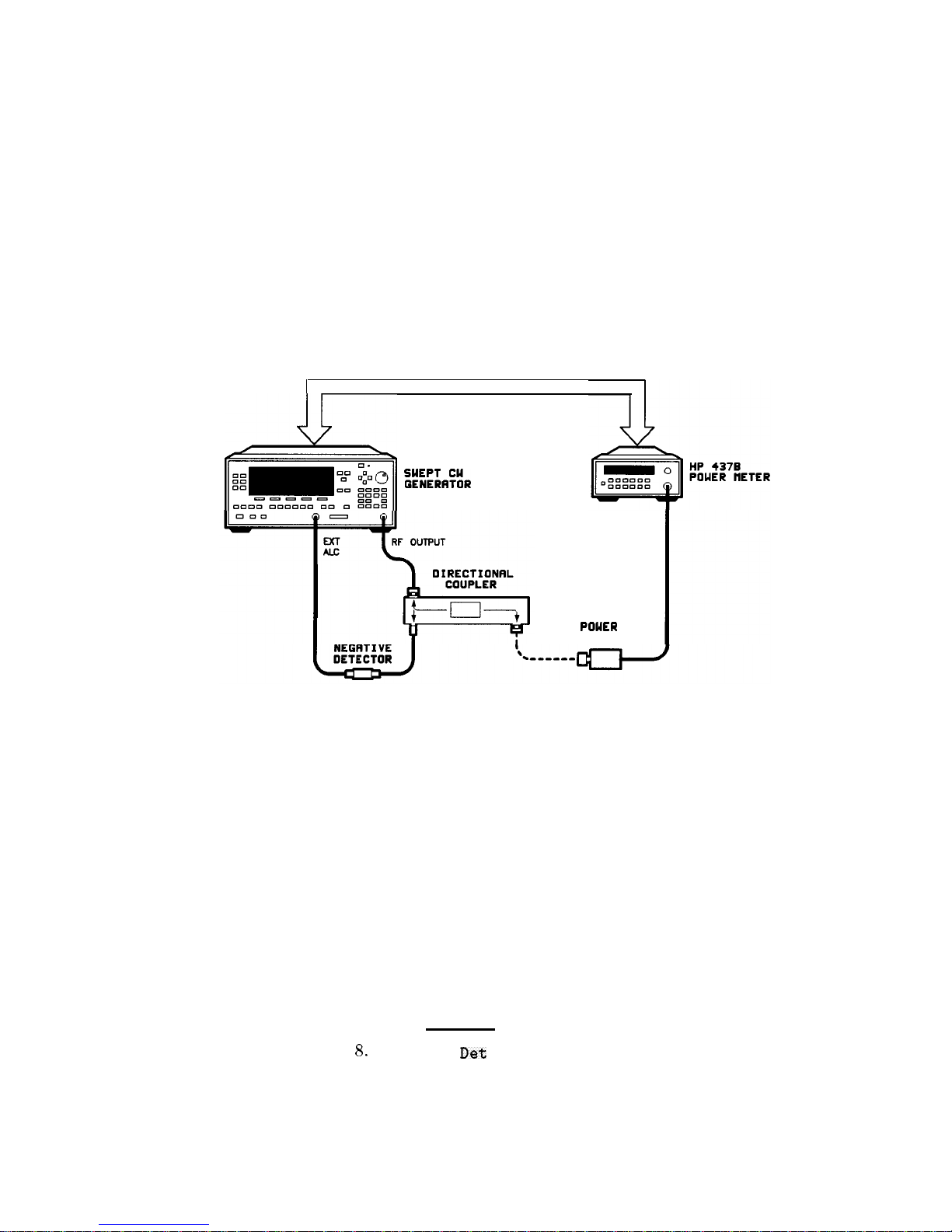

Externally Leveling the Swept CW Generator Leveling Point ExtDet

Coupling Factor

POWER LEVEL

Set

Atten

Leveling Point

PwrMtr

Pwr Mtr Range

Leveling Point Module

Mdl Lev Menu

Working with Mixers/Reverse Power Effects

Uncoupl Atten

Leveling Mode Normal

Working with Spectrum Analyzers/

Leveling Mode ALCoff

Reverse Power Effects

Leveling Mode Search

“Optimizing Swept CW Generator Performance” Fltness Menu

Delete Menu

Auto Fill Start

Auto Fill Stop

Auto Fill

Incr

Mtr

Meas

Menu

FLTNESS ON/OFF

Enter Freq

Enter Corr

Freq Follow

List Menu

Copy List

Sweep Mode List

Ext Det Cal

Getting Started Advanced 1-21

Page 48

Advanced

Table 1-1.