Page 1

Service Handbook

HP 9000 Series 700

Model 715 Workstations

HP Part Number. A2600–90039

Click to go to the Table of Contents

3404 East Harmony Road, Fort Collins, CO. 80525

Page 2

The information contained in this document is subject to change without notice.

HEWLETT–PACKARD MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL, IN-

CLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. Hewlett–Packard shall not be liable for errors contained herein or direct,

indirect, special, incidental, or consequential damages in connection with the furnishing, performance, or

use of this material.

A copy of the specific warranty terms applicable to your Hewlett–Packard product and replacement parts

can be obtained from your local Sales and Service Office.

Copyright Hewlett–Packard Company 1995

This document contains information which is protected by copyright. All rights are reserved. Reproduction, adapta-

tion, or translation without prior written permission is prohibited, except as allowed under the copyright laws.

Restricted Right Legend

Use, duplication or disclosure by the U.S. Government Department of Defense is subject to restrictions as set forth in

paragraph (b)(3)(ii) of the Rights in Technical Data and Software clause in FAR 52.227–7013.

AT & T, Inc. 1980, 1984

Copyright

Copyright The Regents of the University of California 1979, 1980, 1983

This software and documentation is based in part on the Fourth Berkeley Software Distribution under licence from

the Regents of the University of California.

ii

Page 3

Printing History

New Editions of this manual incorporate all material updated since the previous edition. Update packages may be issued between editions and contain replacement and

additional pages to be merged into the manual by the user.

The manual printing date and part number indicate its current edition. The printing

date changes when a new edition is printed. (Minor corrections and updates which

are incorporated at reprint do not cause the date to change.) The manual part number

changes when extensive technical changes are incorporated.

October 1992 Edition 1 (P/N A2084–90602)

Update to A2084–90602 (P/N A2673–90099)

July 1993 Edition 2 (P/N A2084–90617)

May 1994 Edition 3 (P/N A2084–90630)

August 1995 Edition 4 (P/N A2600–90039)

iii

Page 4

Emissions Regulations

Federal Communications Commission (FCC)

The Federal Communications Commission of the U.S. government regulates the radio frequency energy emanated by computing devices through published regulations.

These regulations specify the limits of radio frequency emission to protect radio and

television reception. All HP nodes and peripherals have been tested and comply with

these limits. The FCC regulations also require that computing devices used in the

U.S. display the agency’s label and that the related documentation include the following statement:

NOTICE: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference

in which case the user will be required to correct the

interference at his own expense.

Compliance to these regulations requires the use of shielded cables.

Canadian Department of Communications (CDC)

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus as set out in the Radio Interference Requirements of the Canadian Department of Communications.

Compliance to these regulations requires the use of shielded cables.

iv

Page 5

VCCI Class 1 ITE

Emissions Regulations Compliance

Any third–party I/O device installed in HP system(s) must be in accordance with the

requirements set forth in the preceding Emissions Regulations statements. In the

event that a third–party noncompliant I/O device is installed, the customer assumes

all responsibility and liability arising therefrom.

Compliance to these regulations requires the use of shielded cables.

Electrostatic Discharge (ESD) Precautions

Electrostatic charges can damage the integrated circuits on printed circuit boards. To

prevent such damage from occurring, observe the following precautions when unpacking and installing the board.

S Stand on a static–free mat.

S Wear a static strap to ensure that any accumulated electrostatic charge dis-

charges from your body to ground.

S Connect all equipment together, including the static–free mat, static straps,

routing nodes, and peripheral units.

S Keep uninstalled printed circuit boards in their protective antistatic bags.

S Once you have removed the printed circuit boards from their protective antis-

tatic bags, handle them by their edges.

v

Page 6

Laser Safety Statement (For U.S.A. Only)

(For workstations that have a CD ROM drive installed.)

The CD ROM mass–storage system is certified as a Class–1 laser product under the

U.S. Department of Health and Human services (DHHS) Radiation Performance

Standard according to the Radiation Control for Health and Safety Act of 1968.

This means that the mass–storage system does not produce hazardous laser radiation.

Because laser light emitted inside the mass–storage system is completely confined

within protective housings and external covers, the laser beam cannot escape from

the machine during any phase of user operation.

vi

Page 7

Warnings and Cautions

WARNING:

Removing device cover may expose sharp edges in equipment chassis. To avoid injury,

use care when installing customer add–on devices.

WARNUNG:

Das Entfernen der Geräteabdeckung legt die scharfen Kanten im Inneren des Gerätes

frei. Um Verietzungen zu vermeiden, seien Sie vorsichtig beim Einbau von zusätzlichen

Bauteilen, die vom Kunden selber eingebaut werden können.

AVERTISSEMENT:

Des bords tranchants du châssis de l’équipement peuvent être exposés quand le cache de

l’unité n’est pas en place. Pour éviter des blessures, faire très attention lors de

l’installation de modules supplémentaires par le client.

WARNING:

Disconnect power plug from wall outlet or source power before moving or removing the

device, or installing add–on components.

WARNUNG:

Entfernen Sie die Stromzuführung von der Steckdose oder der Stromquelle bevor Sie das

Gerät bewegen, abbauen, oder zusätzliche Bauteile installieren.

AVERTISSEMENT:

Débrancher la fiche de la prise de courant ou de la source d’alimentation électrique avant

de déplacer ou de retirer l’unité, ou avant d’installer des modules supplémentaires.

CAUTION:

System power cord must be plugged into an accessible dedicated ac mains receptacle.

VORSICHT:

Das System–Netzanschlußkabel muß an eine zugängliche spezielle Wechselstrom–

Hauptzuführungssteckdose angeschlossen werden.

ATTENTION:

Le fil d’alimentation électrique du système doit être branché dans une prise de courant

c.a. spécialisée accessible.

vii

Page 8

Table of Contents

Product Information 1–1

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Unit Controls and Front Panel Connectors 1–4. . . . . . . . . . .

Understanding the LEDs 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Unit Rear Panel Connectors 1–7. . . . . . . . . . . . . . . . . . . . . . .

SCSI Connector 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP Parallel I/O Connector 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

HP–HIL Connector 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10–Pin Modular Jack 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Serial Input/Output Connectors 1–9. . . . . . . . . . . . . . . .

802.3 Network Connector 1–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Built–In Graphics Connector 1–10. . . . . . . . . . . . . . . . . . . . . . . .

Optional Connector for EISA, CRX, or HCRX Graphics 1–11. .

Power Cord Connector 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio Line In and Audio Line Out Connectors 1–12. . . . . . . . .

Monitor Controls, Connectors, and Indicators 1–13. . . . . . . . . . . . . .

Keyboards 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard Differences 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental/Installation/PM 2–1

Environmental Specifications 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulatory Requirements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 9

Configuration 3–1

Workstation and System Unit Configurations 3–1. . . . . . . . . . . . . . .

FRU Configurations 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mass Storage Configurations 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Additional Memory 3–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Built–In Graphics Configuration Switches

(Models 715/C, 715/33, 715/50, 715/75) 3–17. . . . . . . . . . . . . . .

Configuring the CRX Graphics Options 3–18. . . . . . . . . . . . . . . . . . .

Setting Up a Single Monitor System 3–18. . . . . . . . . . . . . . . . . .

Setting Up a Dual Monitor System 3–21. . . . . . . . . . . . . . . . . . .

Troubleshooting 4–1

LED Error Codes 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealing with a Boot Failure 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boot Administration Environment 4–14. . . . . . . . . . . . . . . . . . .

Stable Storage 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boot Command Notations 4–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Boot Paths 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ISL Environment 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Invoking the ISL Environment from a SCSI Device 4–17. . . . . .

ISL User Commands 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the ISL-Based Diagnostics 4–19. . . . . . . . . . . . . . . . . .

Verifying the System Operation with SupportWave 4–21. . . . . . . . . .

Dealing With HPMC (Uncorrectable Error) 4–23. . . . . . . . . . . . . . . .

HPMC Caused by a Multi-Bit Memory Parity Error 4–25. . . . .

HPMC Caused by a Data Cache Parity Error 4–29. . . . . . . . . . .

Troubleshooting CRX and HCRX Graphics 4–30. . . . . . . . . . . . . . . .

Field Replaceable Units 5–1

External Graphics Processor 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floor Stand 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening the System Unit 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Drives 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Audio Board Assembly 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Bezel Cover Plate Assembly 5–19. . . . . . . . . . . . . . . . . . . . . . .

EISA Assembly Components 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the EISA Assembly Components (End Cap) 5–21. . .

Removing EISA Assembly Components (Retaining Clips) 5–24

Installing the EISA Assembly Components (End Cap) 5–27. . . .

Installing EISA Assembly Components (Retaining Clips) 5–32.

x

Page 10

CRX and HCRX Graphics 5–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Audio Board 5–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory 5–40

PCX-T Module (Model 715/75) 5–42. . . . . . . . . . . . . . . . . . . . . . . . .

Processor Board 5–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System EEPROM 5–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calendar Battery 5–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams 6–1

Reference 7–1

Service Notes 8–1

Index

xi

Page 11

Figures Click on the page number to view a figure

1–1 System Unit Controls 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Front Panel LEDs 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 System Unit Rear Panel Connectors 1–8. . . . . . . . . . . . . . . . . . .

1–4 CRX and HCRX Graphics Connector 1–11. . . . . . . . . . . . . . . .

1–5 CRX–48Z Graphics Connections 1–12. . . . . . . . . . . . . . . . . . . .

3–1 Default SCSI IDs 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Quantum 525–MB and 1–GB Disk Drive Jumpers 3–3. . . . . . .

3–3 Quantum 1–GB/2–GB Low Profile Disk Drive Jumpers 3–4. . .

3–4 Hewlett–Packard 1–GB Winchester Drive Jumpers 3–5. . . . . . .

3–5 Seagate 525–MB/1–GB/ 2–GB Winchester Drive Jumpers 3–6.

3–6 Micropolis 1–GB Winchester Drive Jumpers 3–7. . . . . . . . . . . .

3–7 Quantum 210–MB/425–MB Winchester Drive Jumpers 3–8. . .

3–8 DEC 1–GB and 2–GB Disk Drive Jumpers 3–9. . . . . . . . . . . . .

3–9 Hewlett–Packard 420–MB Drive Jumpers 3–10. . . . . . . . . . . .

3–10 Hewlett–Packard 1–GB/2–GB Drive Jumpers 3–11. . . . . . . .

3–11 SCSI Floppy Drive Address Jumper Settings 3–12. . . . . . . . . .

3–12 CD–ROM SCSI Address Jumper Settings 3–13. . . . . . . . . . . .

3–13 DDS SCSI Address Jumper Settings 3–14. . . . . . . . . . . . . . . .

3–14 Memory SIMM Locations 3–15. . . . . . . . . . . . . . . . . . . . . . . .

3–15 Memory Connector Configuration 3–16. . . . . . . . . . . . . . . . . .

3–16 Changing the Graphics Configuration Switches 3–17. . . . . . . .

xii

4–1 Front Panel LEDs 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2 LED Display for CRX or HCRX Graphics Check 4–30. . . . . . .

5–1 Illustrated Parts Breakdown 5–2. . . . . . . . . . . . . . . . . . . . . . . . .

5–2 Removing the External Graphics Processor 5–6. . . . . . . . . . . . .

5–3 Unlocking the Floor Stand 5–7. . . . . . . . . . . . . . . . . . . . . . . . . .

5–4 Removing the Floor Stand 5–7. . . . . . . . . . . . . . . . . . . . . . . . . .

5–5 Opening the System Unit 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

5–6 Removing the First Hard Disk Drive 5–9. . . . . . . . . . . . . . . . . .

5–7 Removing the Second Hard Disk Drive 5–10. . . . . . . . . . . . . . .

5–8 Removing the Floppy, CD–ROM, or DDS Drive 5–11. . . . . . . .

5–9 Removing the Drive Brackets 5–12. . . . . . . . . . . . . . . . . . . . . . .

5–10 SCSI and PC Floppy Cable Connections 5–13. . . . . . . . . . . . .

5–11 SCSI Cable Connections 5–14. . . . . . . . . . . . . . . . . . . . . . . . . .

5–12 Connecting SCSI Cable to Processor Board 5–15. . . . . . . . . . .

5–13 CD–ROM Audio Cable 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

5–14 Connecting the PC–Style Floppy Drive 5–16. . . . . . . . . . . . . .

Page 12

Figures Click on the page number to view a figure

5–15 Removing the Power Supply 5–17. . . . . . . . . . . . . . . . . . . . . .

5–16 Removing the Front Audio Board Assembly 5–18. . . . . . . . . .

5–17 Removing the Blank Cover Plate 5–19. . . . . . . . . . . . . . . . . . .

5–18 EISA Option Mounting 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

5–19 Removing the EISA Adapter Assembly (End Cap) 5–21. . . . .

5–20 Disconnecting the EISA Board from the Adapter Board 5–22.

5–21 Removing the Connector Bucket 5–22. . . . . . . . . . . . . . . . . . .

5–22 Removing the End Cap 5–23. . . . . . . . . . . . . . . . . . . . . . . . . . .

5–23 Unsecuring the EISA Board 5–24. . . . . . . . . . . . . . . . . . . . . . .

5–24 Removing the EISA Assembly (Retainer Clips) 5–25. . . . . . .

5–25 Disconnecting the EISA Board 5–26. . . . . . . . . . . . . . . . . . . . .

5–26 Removing the Connector Bucket 5–26. . . . . . . . . . . . . . . . . . .

5–27 Installing the End Cap 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–28 Installing the Connector Bucket 5–28. . . . . . . . . . . . . . . . . . . .

5–29 Connecting the EISA Board 5–29. . . . . . . . . . . . . . . . . . . . . . .

5–30 Inserting the EISA Assembly 5–30. . . . . . . . . . . . . . . . . . . . . .

5–31 Securing the EISA Board with the End Cap 5–31. . . . . . . . . . .

5–32 Installing the Connector Bucket 5–32. . . . . . . . . . . . . . . . . . . .

5–33 Connecting the EISA Board 5–32. . . . . . . . . . . . . . . . . . . . . .

5–34 Inserting the EISA Assembly (Retaining Clips) 5–33. . . . . . . .

5–35 Securing the EISA Board(Retaining Clips) 5–34. . . . . . . . . . .

5–36 Removing the CRX or HCRX Graphics 5–36. . . . . . . . . . . . . .

5–37 Removing the Bucket and Flex Cable 5–37. . . . . . . . . . . . . . .

5–38 Removing the Mounting Bracket 5–38. . . . . . . . . . . . . . . . . . .

5–39 Removing the Rear Audio Board 5–39. . . . . . . . . . . . . . . . . . .

5–40 Removing Memory Boards 5–40. . . . . . . . . . . . . . . . . . . . . . . .

5–41 Installing Memory Boards 5–41. . . . . . . . . . . . . . . . . . . . . . . .

5–42 Disconnecting the PCX-T Grounding Wire 5–42. . . . . . . . . . .

5–43 Disconnecting the PCX-T Module 5–43. . . . . . . . . . . . . . . . . .

5–44 Removing the PCX-T Module 5–44. . . . . . . . . . . . . . . . . . . . .

5–45 Removing the Processor Board 5–46. . . . . . . . . . . . . . . . . . . . .

5–46 Component and Internal Connector Locations

5–47 Component and Internal Connector Locations

5–48 Component and Internal Connector Locations 715/75 5–49. . .

5–49 Removing the EEPROM (UV17) 5–50. . . . . . . . . . . . . . . . . . .

5–50 Removing the Calendar Battery 5–51. . . . . . . . . . . . . . . . . . . .

Model 715/C, 715/33, and 715/50 5–47. . . . . . . . . . .

Model 715/64, 715/80, 715/100, 715/100XC 5–48. .

xiii

Page 13

Figures

6–1 Power Distribution Diagram 6–1. . . . . . . . . . . . . . . . . . . . . . . . .

6–2 System Unit Functional Block Diagram

6–3 System Unit Functional Block Diagram

Model 715/C, 715/33, 715/50, and 715/75 6–3. . . . . .

Model 715/64, 715/80, 715/100, and 715/100XC 6–4.

Tables Click on the page number to view a table

1–1 LED Display During Normal System Activity 1–6. . . . . . . . . . .

1–2 Serial I/O Pins 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 PC/AT Keyboard to ITF Keyboard Equivalent Keys 1–15. . . . .

2–1 Environmental Specifications for Models 715 2–1. . . . . . . . . .

4–1 Model 715/C, 715/33, 715/50, 715/75 LED Error Codes 4–3. . .

4–2 Model 715/C, 715/33, 715/50, 715/75 PDC LED Codes 4–6. . .

4–3 Model 715/C, 715/33, 715/50, 715/75 ISL LED Codes 4–8. . .

4–4 Model 715/C, 715/33, 715/50, 715/75 Kernel LED Codes4–10

4–5 Model 715/64, 715/80, , 715/100, 715/100XC LED Codes4–11

4–6 PIM_INFO Action 4–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–7 Multi-Bit Memory Parity Error 4–25. . . . . . . . . . . . . . . . . . . . . .

4–8 Memory Address Ranges 4–26. . . . . . . . . . . . . . . . . . . . . . . . . .

4–9 Processor Module Error (Data Cache Parity) 4–29. . . . . . . . . . .

xiv

5–1 FRU List 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–2 EISA Interface Options 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–1 Power Supply Connector P6 Pinouts 6–2. . . . . . . . . . . . . . . . . .

6–2 Power Supply Pinouts for Storage Device Connectors 6–2. . . .

Page 14

Product Information 1

This chapter introduces the Model 715 workstation, controls, and indicators. Included in this chapter are the following topics:

Product description

System unit controls

Understanding the LEDs

System unit rear panel connectors

Monitor controls, connectors, and indicators

Product Description

The HP 9000 Series 700 Model 715 workstation uses one of the following versions

of the HP–UX operating system:

Model 715/33, 715/50, and 715/C workstations use version 9.01 or later

Model 715/75 workstations use version 9.03 or later

Model 715/64, 715/80, 715/100, and 715/100XC workstations use version 9.05

or later

The Model 715 workstations can house up to two hard disk drives and a removable–

media drive, which are connected to the internal SCSI interface. The workstation is

available in diskless as well as disked configurations. Disked configurations have one

or two hard disk drives of the following densities: 525 MB, 1 GB, or 2 GB. These

hard disk drives are preformatted. The workstation’s removable–media drive can be

either a 3.5–inch floppy drive, a CD–ROM drive, or a DDS–format tape drive.

NOTICE: Model 715s/t workstations that have been upgraded

The workstation contains the following key features:

from a Model 425e, 705, or 710 system may have

210–MB and 420–MB hard disk drives.

Model 715/C has two 420–MB hard disk drives.

Operating Systems

– Native HP/UX

– DOS emulation

Source and binary code compatible with Series 700 product family

Product Information 1–1

Page 15

Built–In Graphics

8–plane graphics with choice of one of the following:

– 19/20–inch 1280 x 1024 color monitor

– 19–inch 1280 x 1024 grayscale monitor (available only on the

Model 715/33, 715/50, and 715/75)

– 17–inch 1280 x 1024 color monitor (Model 715/64, 715/80, 715/100,

and 715/100XC)

– 17–inch 1024 x 768 color monitor (Model 715/33 and 715/50)

– 15–inch 1024 x 768 color monitor (Model 715/33)

Graphics Options

19/20–inch color monitor with choice of one of the following:

– 8–plane HCRX color graphics (available

only on the Model 715/64, 715/80, 715/100, and 715/100XC)

– 24–plane CRX color graphics

– 24–plane HCRX color graphics (available only on the Model 715/64,

715/80, 715/100, 715/100XC)

– 8–plane HCRX Z–buffered color graphics (available only on the

Model 715/64, 715/80, 715/100, and 715/100XC)

– 24–plane HCRX Z–buffered color graphics (available only on the

Model 715/64, 715/80, 715/100, and 715/100XC)

– 24–plane CRX Z–buffered color graphics

– 48–plane CRX Z–buffered color graphics (available only on the

Model 715/50, 715/75, 715/100, and 715/100XC)

Main Memory

– Model 715/33 8–192 MB

– Model 715/50 16–256 MB

– Model 715/64 32–256 MB

– Model 715/75 32–256 MB

– Model 715/80 32–256 MB

– Model 715/100 32–256 MB

– Model 715/C 32–256 MB

– Model 715/100XC 32–256 MB

Mass Storage

– 1–GB SCSI hard disk drive (full height, 3.5–inch, Micropolis, DMD, DEC,

and Seagate 1–GB drives are supported)

– 2–GB SCSI hard disk drive (full height, 3.5–inch, DEC or

Segate 2–GB drives are supported)

– 525–MB SCSI hard disk drive (low profile, 3.5–inch, Seagate and Quantum

525–MB drives are supported)

– 420–MB SCSI hard drive (full height, 3.5–inch, Quantum Pro 420s drive is

available on Model 715/C workstations, and on workstations that have

been upgraded from a Model 425e, 705, or 710)

– 210–MB SCSI hard drive (full height, 3.5–inch drive is supported only on

workstations that have been upgraded from a Model 425e, 705, or 710.)

– Floppy disk drive (3.5–inch)

– CD–ROM disk drive (5.25–inch)

– DDS–format tape drive (3.5–inch)

Network

– IEEE 802.3 AUI connection

– Supports connections to 10BASE2 (ThinNet), 10BASE5 (ThickNet),

and 10BASE–T (EtherTwist) networks with the use of an external

transceiver

1–2 Product Information

Page 16

I/O

– Two 9–pin RS–232 Ports

– One 25–pin HP parallel port

– 8–bit, single–ended SCSI–2 interface

– HP–HIL port (715/C, 715/33, 715/50, and 715/75 systems only) for HP–UX

keyboards and other HP–HIL devices

– Dual mini–DIN ports on the Keyboard Adapter Module (715/64, 715/80, and

715/100 Systems only) for AT–style keyboard and other mini–DIN

(PS/2–style) devices

– CD–quality audio and speaker output

– CD–quality microphone or audio input

Expansion slot for one EISA card (optional on Model 715/33)

Product Information 1–3

Page 17

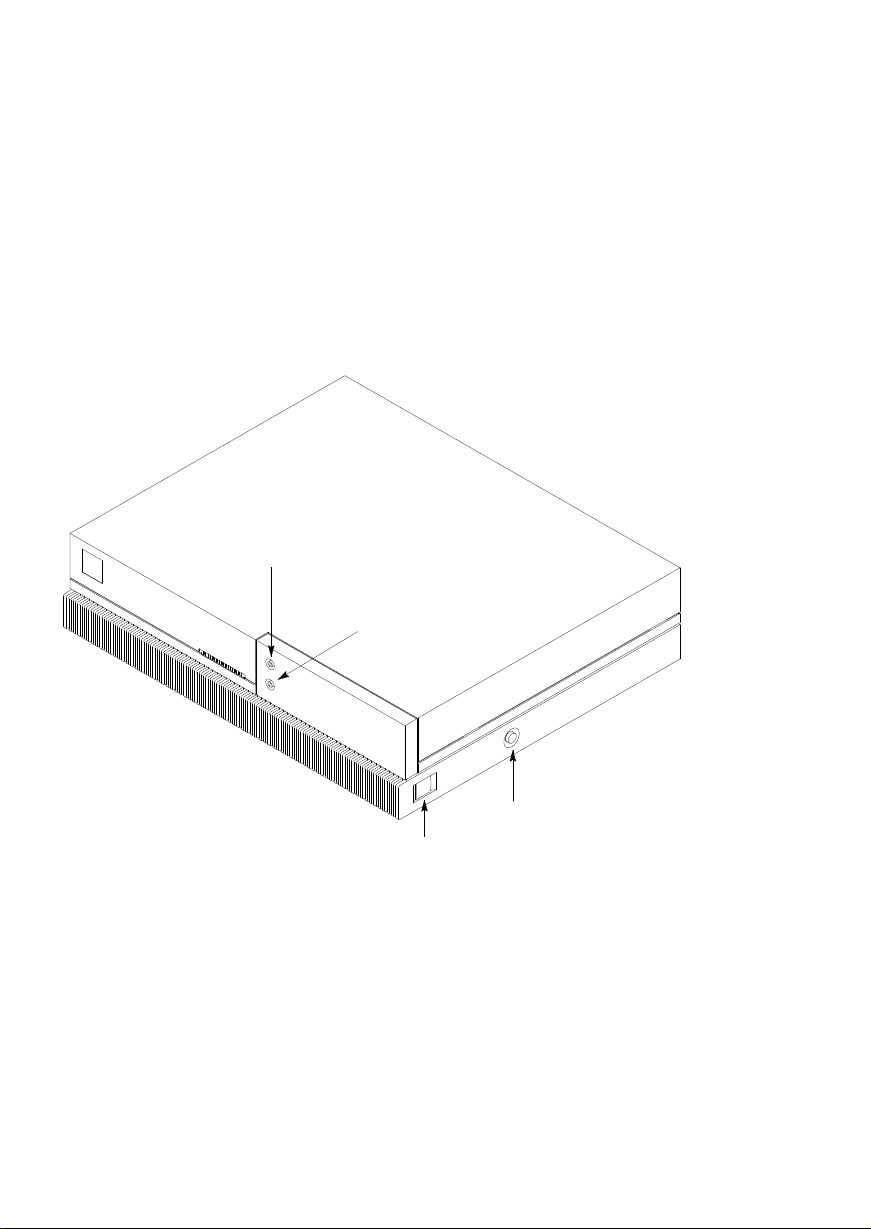

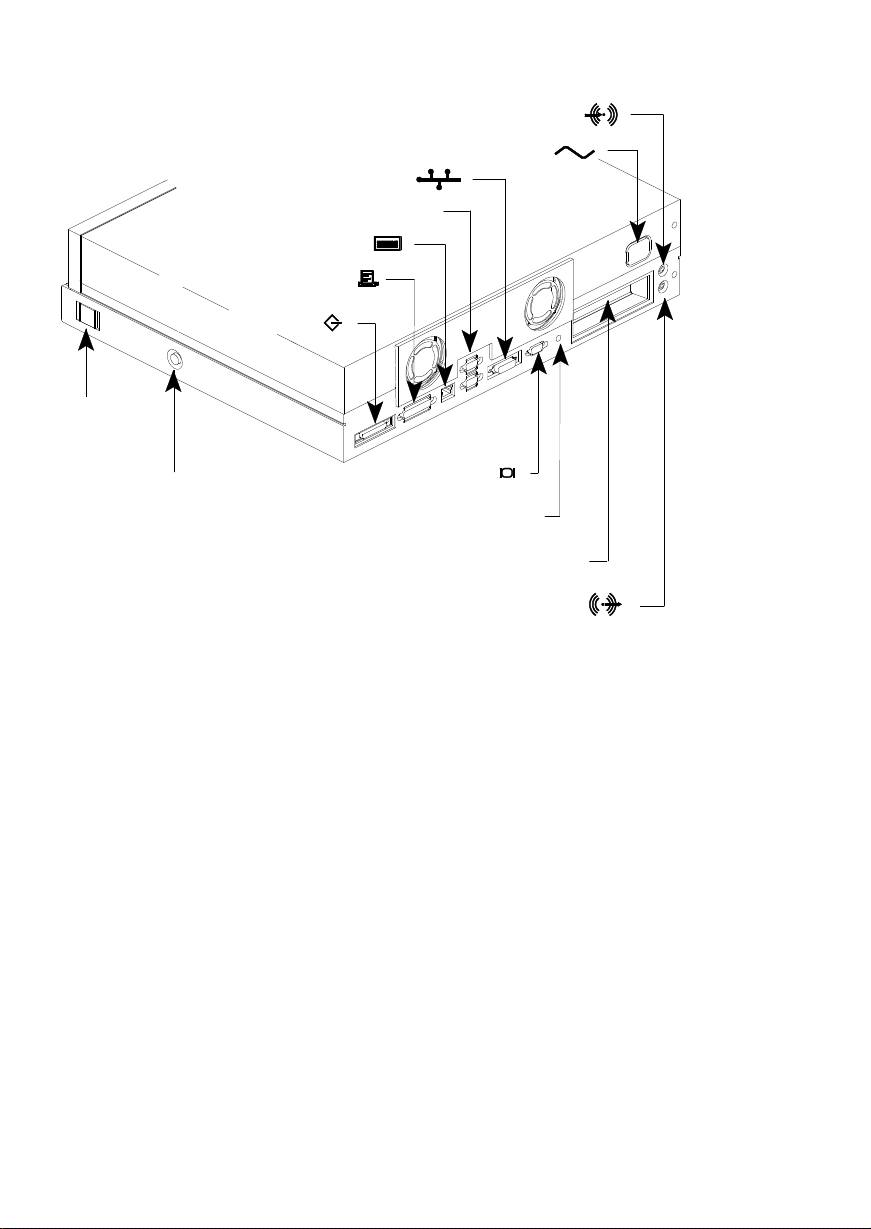

System Unit Controls and Front Panel Connectors

Figure 1–1 shows the Power and TOC (Transfer Of Control) switches.

Use the Power switch to power the system unit on and off.

Use the TOC switch to reset the operating system. Do not push the TOC switch un-

less you have first shutdown the operating system by using the shutdown command.

NOTICE: Model 715/64, 715/80, 715/100, and 715/100XC

workstations are equipped with a soft shutdown feature. These systems shut down the file system automatically when you power the system off.

Audio/Headphones OUT

Connector (Stereo)

Audio/Microphone IN

Connector (Stereo)

Front

Power Switch

TOC Switch

Figure 1–1. System Unit Controls

Figure 1–1 also shows the Audio connectors on the front panel. The workstation has

audio input and output capability through external input and output connectors and

an internal speaker. The line–in and line–out connectors are located on the rear panel

and are described later in this chapter. The front panel contains the Audio/Headphone

OUT and Audio/Microphone IN connectors.

The Audio/Headphone OUT connector is a stereo headphone output. The Audio/Mi-

crophone IN connector is a mono microphone input. The ring connector of the microphone jack supplies +1.5 volts dc for microphones that require it. A microphone for

1–4 Product Information

Page 18

audio input is not supplied with the workstation. The audio connectors are standard

stereo audio mini–jacks.

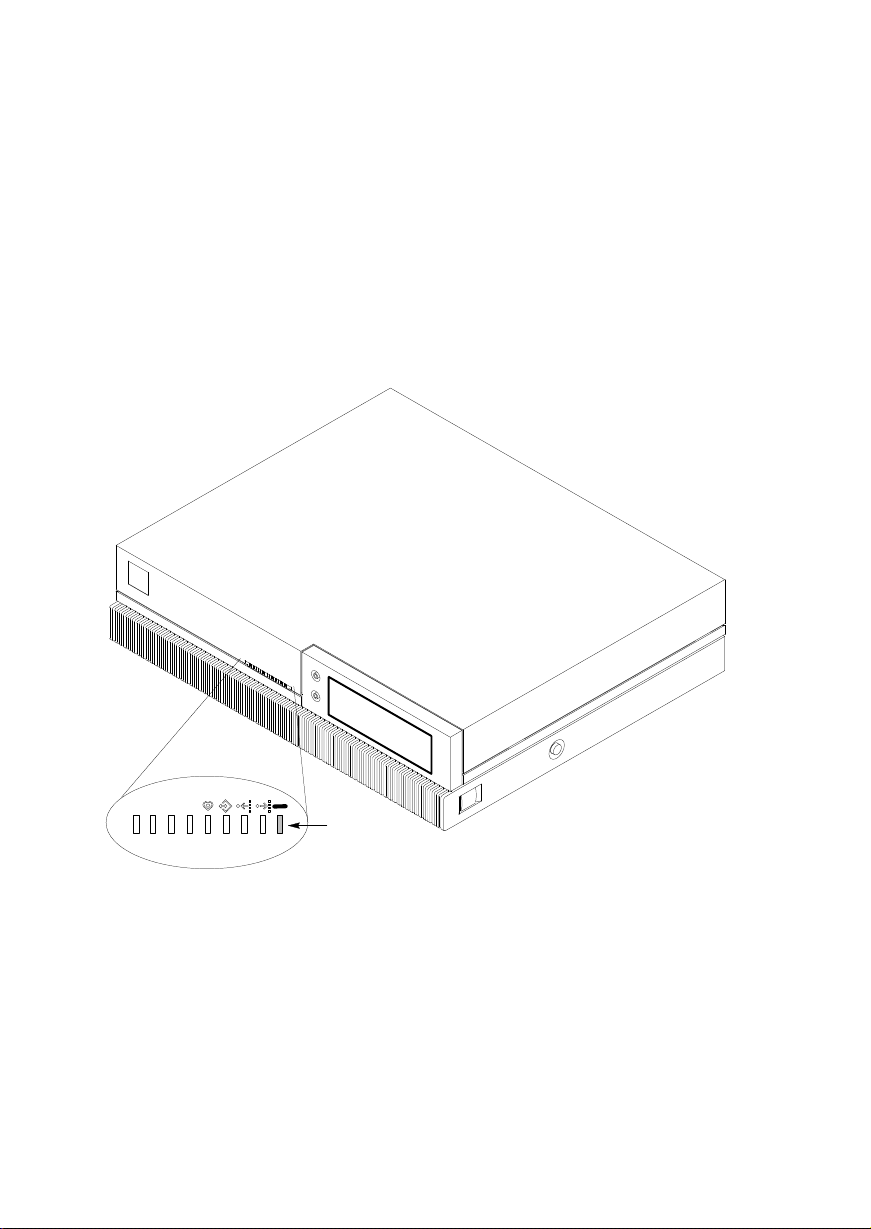

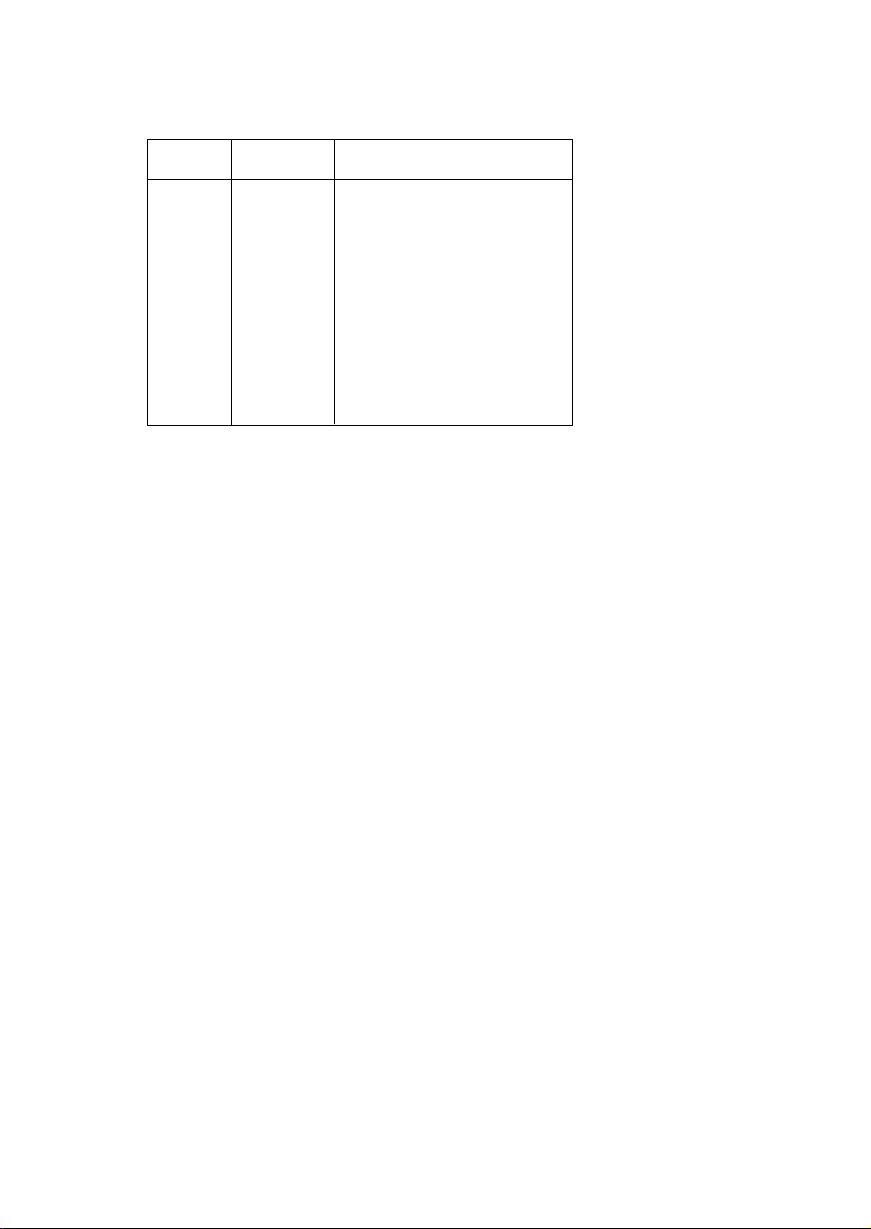

Understanding the LEDs

There are 9 Light Emitting Diodes (LEDs) located on the front of the system unit, as

shown in Figure 1–2. The green one on the far right is the Power LED. It lights when

the system unit power is on. The other eight are labeled 8 through 1 (left to right).

The rightmost four amber LEDs (labeled 4, 3, 2, and 1) show that the system is running the operating system and communicating over the network. Along with the leftmost four amber LEDs (8, 7, 6, and 5), they also help you to troubleshoot the workstation by coming on in certain patterns during system failures (see Chapter 4).

Front

Table 1–1 lists how the LEDs report during normal HP–UX system activity. The

green Power LED remains lit while the system is powered on.

Power

LED

Figure 1–2. Front Panel LEDs

Product Information 1–5

Page 19

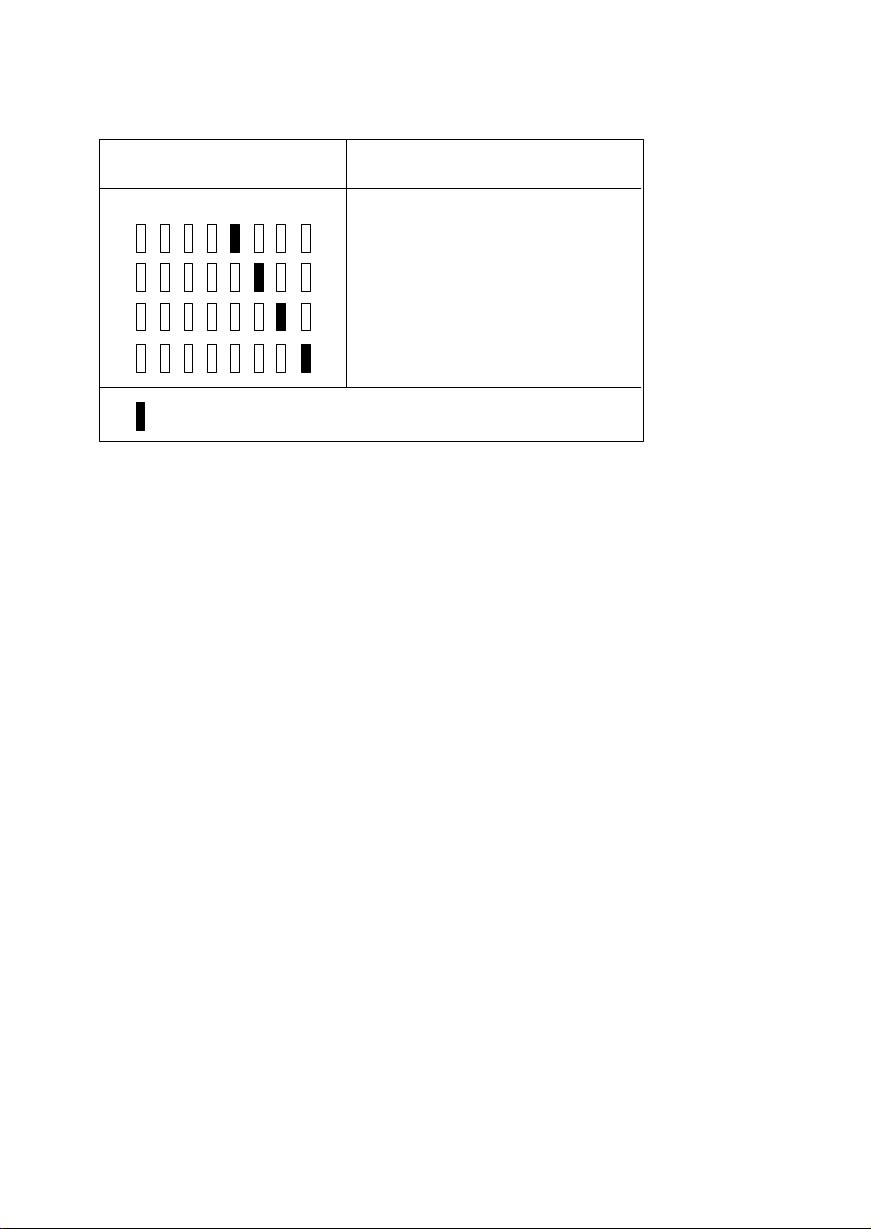

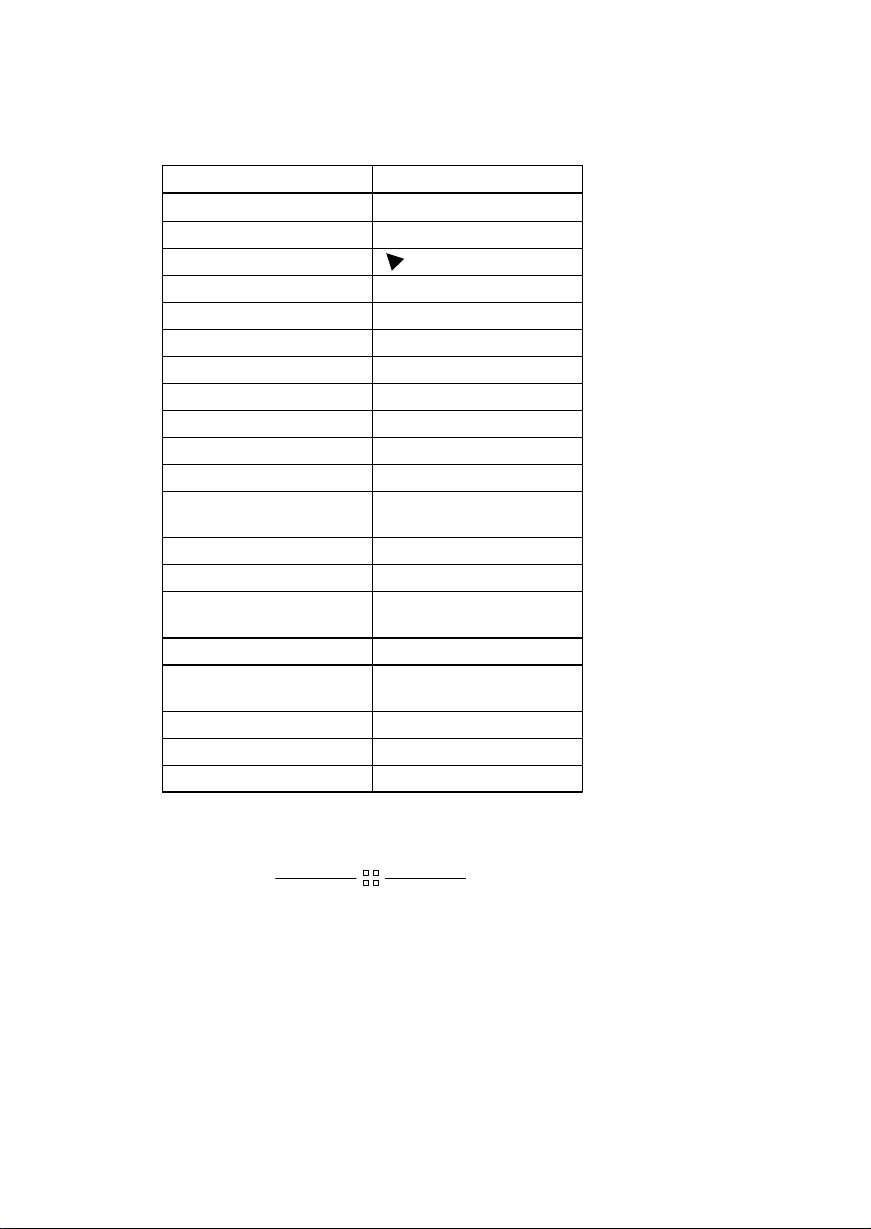

Table 1–1. LED Display During Normal System Activity

LED Display

(1 Through 4 Flashing)

7658

= LED On or Flashing

Meaning

1234

Operating System Running

Disk Access In Progress

Network Receive In Progress

Network Transmit In Progress

1–6 Product Information

Page 20

System Unit Rear Panel Connectors

This section describes the following connectors on the system unit’s rear panel:

SCSI connector

HP parallel I/O connector

HP–HIL connector (Model 715/C, 715/33, 715/50, and 715/75 workstations)

10–pin modular jack (Model 715/64, 715/80, 715/100, and 715/100XC

workstations)

RS–232 serial input/output connectors

802.3 network connector

Built–in graphics connector

Optional connector for EISA, CRX, or HCRX graphics

Power cord connector

Audio connectors

NOTICE: To maintain FCC/EMI compliance, verify that all

Figure 1–3 shows the locations of the connectors on the system unit’s rear panel. The

symbols shown are depicted on the rear panel.

cables are fully seated and properly fastened.

Product Information 1–7

Page 21

Audio Line IN Connector

Power Cord Connector

LAN AUI Connector

RS–232 Connectors

HP–HIL Connector or 10–pin

Modular Jack

HP Parallel Connector

SCSI Connector

Power

Switch

Built–In Graphics

Transfer of Control

(TOC) Switch

Graphics Configuration Switches*

Connector

Optional Connector for EISA, CRX, or HCRX Graphics

Audio Line OUT Connector

*These switches are not present on Model 715/64, 715/80, 715/100, and 715/100XC

workstations. Model 715/64, 715/80, 715/100, and 715/100XC workstations are

autoconfiguring.

Figure 1–3. System Unit Rear Panel Connectors

1–8 Product Information

Page 22

SCSI Connector

Use the SCSI connector to connect external SCSI devices such as DDS–format tape

drives and CD–ROM drives. Consult the documentation that accompanies each SCSI

device for specific information concerning its use.

NOTICE: When attaching external SCSI devices, be sure to

terminate the last device on the external SCSI bus. If

no external devices are attached, the SCSI connector

does not need to be terminated.

HP Parallel I/O Connector

The 25–pin HP Parallel I/O interface port is provided for use with peripheral devices

using the Centronics interface protocols such as printers and plotters. Consult the

documentation that accompanies each peripheral device for specific information concerning its use.

HP–HIL Connector

Model 715/C, 715/33, 715/50, and 715/75 workstations are equipped with an

HP–HIL connector, which provides an interface for the system’s keyboard, mouse,

and other optional HIL input devices. Consult the documentation that accompanies

each input device for specific information concerning its use.

10–Pin Modular Jack

Model 715/64, 715/80, 715/100, and 715/100XC workstations are equipped with a

10-pin modular jack. A Keyboard Adapter Module attaches to this connector by

means of a special cable shipped with the unit. The Keyboard Adapter Module includes two mini–DIN connectors and an HP–HIL connector. The mini–DIN connectors provide an interface for a AT–style keyboard and other mini–DIN input devices.

The HP–HIL connector provides an interface for an HP keyboard, mouse, or other

optional HIL input devices. Consult the documentation that accompanies each input

device for specific information concerning its use.

RS–232 Serial Input/Output Connectors

You can attach a variety of peripheral devices to the two RS–232 Serial Input/Output

(SIO) ports on the workstation. These peripheral devices include printers, plotters,

modems, and scanners. Consult the documentation that accompanies each peripheral

device for specific information concerning its use.

Both SIO ports are programmable. You can set functions such as bit rate, character

length, parity, and stop bits. SIO Ports 1 and 2 are used as interfaces for serial

asynchronous devices to the CPU. Both ports operate at up to a 19.2 K baud rate.

Table 1–2 shows the SIO connector pin listings. The serial connectors are 9–pin

D–sub connectors. Signal names are those specified in the EIA RS–232 standard.

Product Information 1–9

Page 23

Table 1–2. Serial I/O Pins

Pin No. Signal

1

2

3

4

5

6 DSR

7

8

9RI

DCD

RXD

TXD

DTR

GND

RTS

CTS

Description

Data Carrier Detect

Receive Data

Transmit Data

Data Terminal Ready

Ground

Data Set Ready

Request To Send

Clear To Send

Ring Indicator

802.3 Network Connector

Figure 1–3 shows the location of the connector for the 802.3 (ETHERNET) network.

Connect an ETHERNET transceiver to this connector for communicating with a network.

Built–In Graphics Connector

If the workstation does not have the CRX, HCRX, or VISUALIZE graphics option

installed, use the built–in graphics connector to connect the monitor’s video cable to

the system. If the workstation is equipped with optional graphics, connect the monitor or external graphics unit to the optional graphics connect as described below. If

you are setting up a dual monitor system, connect one monitor to the built–in graphics connector and the other monitor to the optional graphics connector.

1–10 Product Information

Page 24

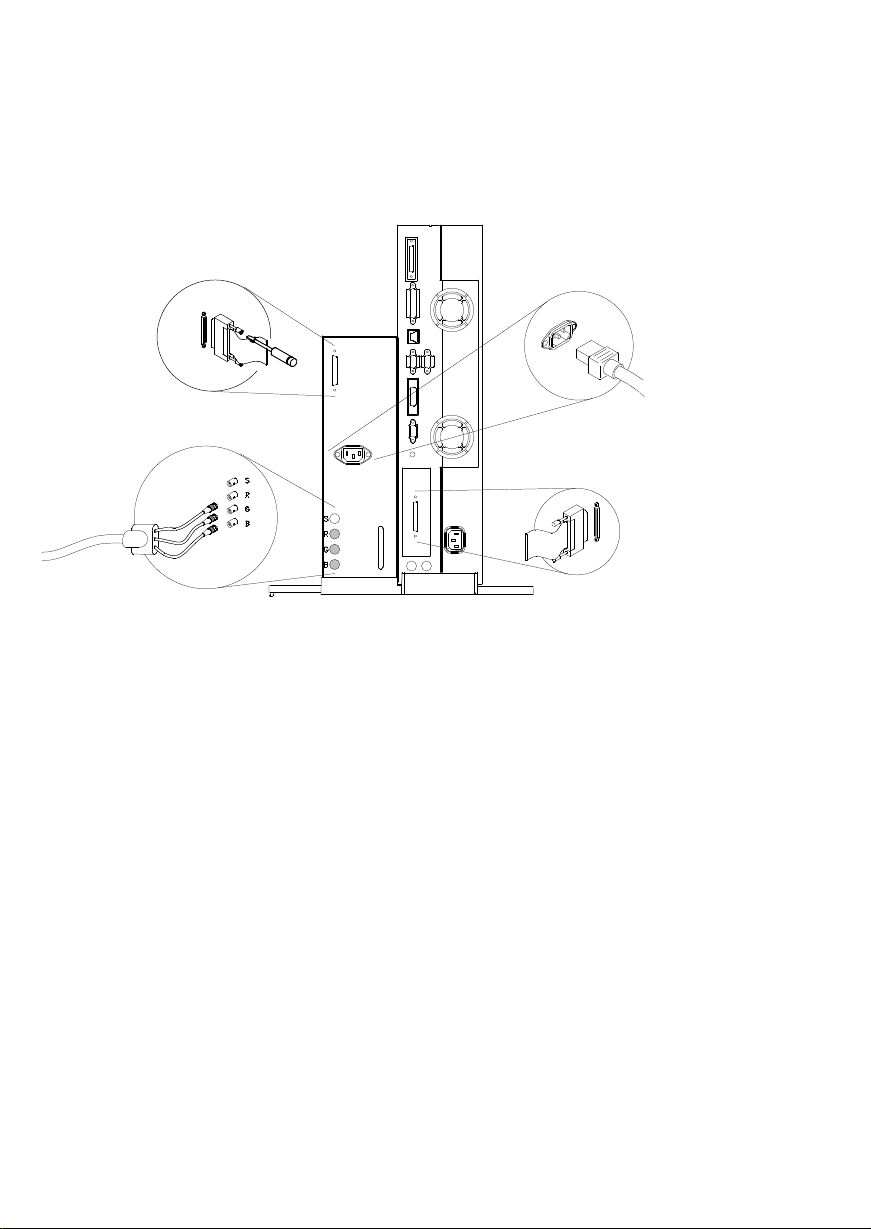

Connectors for EISA, and Optional Graphics

The system has a slot for an optional EISA (Extended Industry Standard Architecture) board or an optional CRX , HCRX , VISUALIZE or CRX–48 graphics board.

EISA

The one–slot EISA I/O port is a superset of ISA (Industry Standard Architecture). It

extends the capabilities of that standard while maintaining compatibility with ISA

expansion boards. EISA provides 32–bit memory addressing and 32–bit data transfers. The EISA slot allows quick and easy integration in heterogeneous networks as

well as simple connections of high–speed, low–cost disks and other peripherals.

Some EISA option boards have external connectors for connecting these devices.

Consult the documentation that accompanies each device for specific information

concerning its use.

Optional Graphics

If the system has an optional graphics board installed, it will have one of the following graphics connectors:

Color graphics card (CRX–24, CRX–24Z, HCRX–8, HCRX–8Z, HCRX–24,

HCRX–24Z , or VISUALIZE graphics) — This device has a D–sub miniature

connector which is connected to the monitor by a cable, as shown in Figure

Figure 1–4.

Graphics interface card (CRX–48Z graphics) — This device is connected by a

cable to an external graphics processor, which in turn is connected to a video

monitor, as shown in Figure Figure 1–5.

Figure 1–4 shows the location of the CRX or HCRX graphics connector on the system unit’s rear panel.

Product Information 1–11

Page 25

Figure 1–4. CRX and HCRX Graphics Connector

Figure 1–5 shows the locations of the CRX–48Z graphics connections on the system

unit’s rear panel and on the rear panel of the external graphics processor.

Graphics Processor Cable

to Graphics Processor

Tighten connections with

a flat–blade screwdriver.

Monitor Cable to

Graphics Processor

Figure 1–5. CRX–48Z Graphics Connections

Graphics Processor Cable

to Graphics Interface Board

Power Cable

to Graphics

Processor

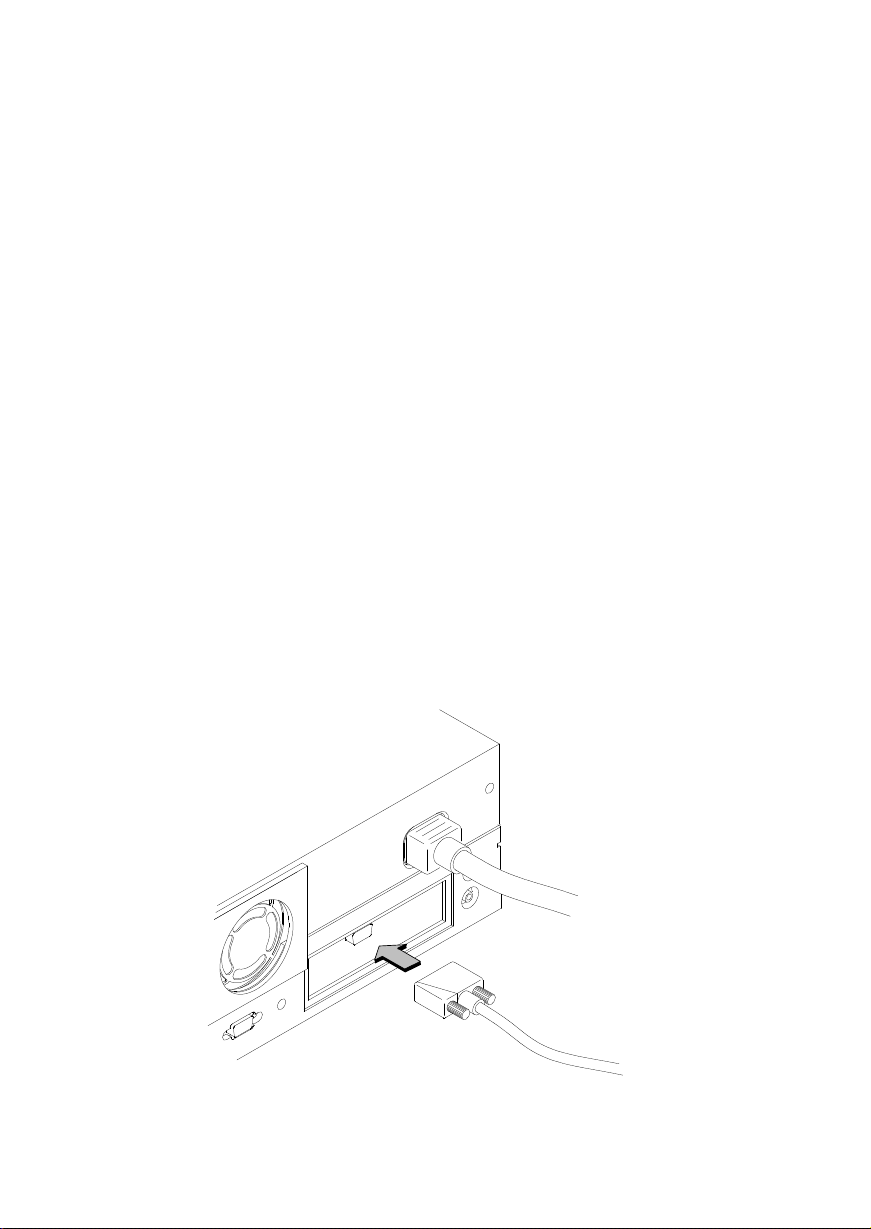

Power Cord Connector

Plug the workstation’s power cord into the power cord connector to provide ac power

to the system.

Audio Line In and Audio Line Out Connectors

The Model 715 workstation has CD quality stereo audio input and output capability

through external input and output connectors on the front and rear panels and an internal speaker. A microphone for audio input is not supplied with the workstation.

The rear panel audio connectors are standard stereo audio mini–jacks and use audio

“line” levels.

1–12 Product Information

Page 26

Monitor Controls, Connectors, and Indicators

The Power–On LED, when lit, indicates that the monitor has ac power applied. Use

the following controls to adjust the monitor:

The Power–On/Off button turns the monitor’s power on and off.

The Brightness control adjusts the brightness of the display.

The Contrast control adjusts the light–to–dark and dark–to–light contrast of the

display.

The Degauss control demagnetizes the color monitor. Degaussing disperses any

accumulated magnetic charge from the face of the monitor. Magnetic disturbances such as picture distortion or color impurity can be caused by either

moving the monitor from one place to another or swiveling the monitor on its

base. No degauss control exists on the 19–inch grayscale monitor.

Refer to the manual that came with the monitor for detailed information about the

monitor’s controls, connectors, and indicators.

Product Information 1–13

Page 27

Keyboards

There are three types of Hewlett–Packard keyboards available for use with the

workstation. They are the following:

ITF Keyboard (Also known as Model # A1099C Keyboard)

PC Keyboard (Also known as the PC–101 (HIL) Keyboard, the “Enhanced

Vectra” Keyboard, and Model # A2205B Keyboard)

AT Keyboard (Industry–standard AT–style keyboard that uses

a mini–DIN, PS/2–style, connector, Model # A4030B)

CAUTION: When connecting a HIL device (such as the ITF key-

board) ensure that the device conforms to the

HP–HIL specification. Devices that are not HP–HIL

compatible but have similar connectors may appear

to be compatible, but will damage the system.

Keyboard Differences

Aside from the obvious difference in the appearance of the ITF and PC/AT keyboards

due to the arrangement of the keys, there is also a difference in the keys and their

output codes. Some keys on one keyboard (the ITF keyboard for example) may not

exist on the other keyboard. These keys generate codes which also may not exist as

output from the other keyboard (or may be generated by a different key). Codes that

are generated when a key is pressed are called keycodes.

Some applications expect to use keycodes generated by keys existing on one of the

keyboards (the ITF keyboard for example). Since the keys do not exist on the other

keyboard (the PC and AT keyboards), an accommodation must be made if the PC/AT

keyboard is to be used. In most cases, it is still possible to use some other key that is

equivalent (generates the same keycode from a different keycap). To do this, it is

necessary to know which keys are equivalent on the two keyboards. Table 1–3

compares the equivalent keys on the ITF and PC/AT keyboards.

NOTICE: Keyboard keys not mentioned in Table 1–3 are the

same on all the keyboards.

1–14 Product Information

Page 28

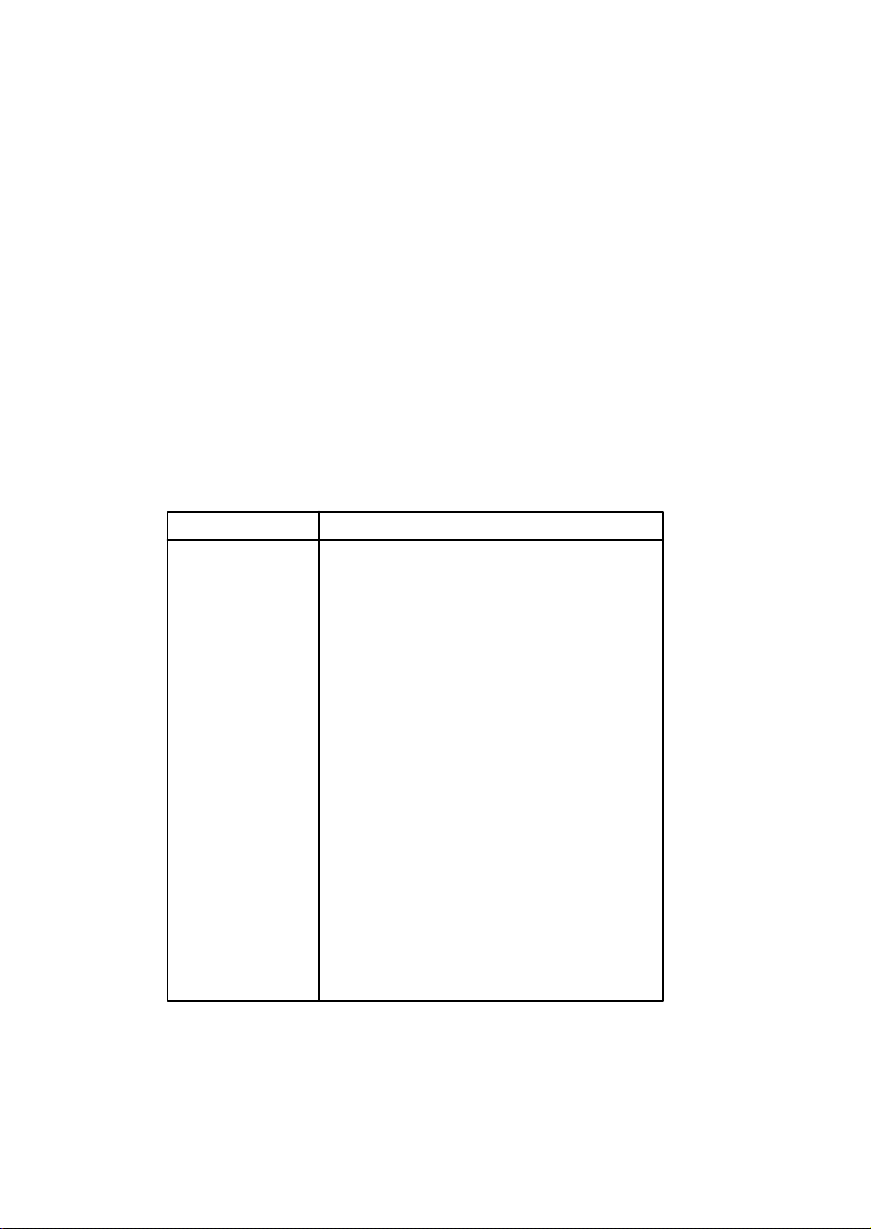

Table 1–3. PC/AT Keyboard to ITF Keyboard Equivalent Keys

PC/AT Keycap Symbol

F9 blank1 (left)

F10 blank2

F11 blank3

F12 blank4 (right)

PrintScreen / SysReq Menu

Scroll Lock Stop

Pause / Break Break / Reset

Page Up Prev

Num Lock System / User

End Select

Page Down Next

Enter Return

Alt (left) Extend Char (left)

Alt (right) Extend Char (right)

No Equivalent Clear Line

No Equivalent Clear Display

No Equivalent Insert Line

No Equivalent Delete Line

No Equivalent Print / Enter

No Equivalent , (number pad)

No Equivalent Tab (number pad)

ITF Keycap Symbol

(Continued)

Product Information 1–15

Page 29

Table 1–3. PC/AT Keyboard to ITF Keyboard Equivalent Keys (cont.)

PC/AT Keycap Symbol

Esc Esc / Del

Insert Insert Char

Home

Delete Delete Char

Caps Lock Caps

Esc Shifted Esc / Del Shifted

Pause / Break Shifted Break / Reset Shifted

Num Lock Shifted System / User Shifted

0 / Ins (number pad) 0 (number pad)

1 / End (number pad) 1 (number pad)

2 / B (number pad)

3 / Pg Dn

(number pad)

4 / A (number pad)

6 / " (number pad

7 / Home

(number pad)

8 / Y (number pad)

9 / Pg Up

(number pad)

. / Del (number pad) . (number pad)

Ctrl (left) Ctrl

Ctrl (right) No Equivalent

ITF Keycap Symbol

2 (number pad)

3 (number pad)

4 (number pad)

6 (number pad)

7 (number pad)

8 (number pad)

9 (number pad)

1–16 Product Information

Page 30

Environmental/

Installation/PM 2

This chapter lists the environmental specifications and regulatory requirements for

the system. Installation and preventive maintenance information, if applicable, is also

provided.

Environmental Specifications

Table 2–1 lists the environmental specifications.

Table 2–1. Environmental Specifications for Models 715

Type Specification

Operating

Temperature +5 to +40° C

Non–Operating

Temperature -40 to +70° C

Humidity 15–80% maximum operating @ 40° C

Operating

Altitude 3100 meters

Acoustic Noise Sound Power Level (LWA) < 4.4 Bells

to 30° C (diskless)

Electrical Input 100 to 120 Vac

220 to 240 Vac

60 Hz range, 57 to 63 Hz

50 Hz range, 47 to 53 Hz

Minimum voltage 88 Vac

Maximum voltage 269 Vac

3.8 amps @ nominal 110 Vac

1.8 amps @ nominal 220 Vac

Maximum

Heat Dissipation 205 W or 700 BTUs

Environmental/Installation/PM 2–1

Page 31

Regulatory Requirements

The following regulatory requirements are met:

FCC Class A

VCCI Class 1

EN55022 Class A

UL1950

GS Mark

– IEC 950/EN60950

– ZH1/618

CSA C22.2–950M

Installation

Refer to the following manuals for system installation information:

HP 9000 Series 700 Model 715 Hardware Installation Guide (Part Number

A2084–90628)

HP 9000 Series 700 Model 715 Owner’s Guide (Part Number A2084–90629)

Preventive Maintenance

There is no preventive maintenance for the system unit. Removable media storage

devices may require operator preventive maintenance. Refer to the HP 9000 Series

700 Model 715 Owner’s Guide (Part Number A2084–90629) for more information.

2–2 Environmental/Installation/PM

Page 32

Configuration 3

This chapter provides details on setting up and changing the system configuration.

Workstation and System Unit Configurations

Refer to the HP 9000 Series 700 Configuration Guide for a complete list of supported accessories, peripherals, and operating systems.

FRU Configurations

This section provides information for setting up or changing the configuration of the

system Field Replaceable Units (FRUs).

Mass Storage Configurations

Figures 3–1 through 3–11 show the SCSI ID settings for mass storage devices.

NOTICE: The SCSI terminators must be removed from all in-

ternal SCSI devices. An external terminator is not

required if there are no external devices attached.

Configuration 3–1

Page 33

Internal System Drives:

System SCSI Drive(s)

1st Winchester Drive (if present, uses SCSI ID 6)

2nd Winchester Drive (if present, uses SCSI ID 5)

Floppy Disk Drive* (if present, uses SCSI ID 0)

CD–ROM Drive (if present, uses SCSI ID 2)

4–mm DDS Tape Drive (if present, uses SCSI ID 3)

External Device Drives:

External SCSI HP 6000 Series 660A Disk Subsystem,

Product No. C2213A (These are not default IDs as shipped –

you must set the IDs to the correct setting.)

1st Winchester Drive (ID No. 4)

2nd Winchester Drive (ID No. 3)

3rd Winchester Drive (ID No. 0)

4–mm DDS Tape Drive (ID No. 3)

Magneto–Optical Drive (ID No. 0)

600–MB CD–ROM (ID No. 2)

External SCSI HP Standalone

Magneto–Optical Drive (C1701A) (ID No. 0)

CD–ROM Drive (A1999A) (ID No. 2)

20–GB Magneto–Optical Autochanger (C1700A)

st

1

(ID No. 3)

2nd (ID No. 4)

3rd (ID No. 5)

*Model 715/64, 715/80, 715/100, and 715/100XC workstations have a PC–

style floppy and do not use a SCSI address for the floppy drive.

Figure 3–1. Default SCSI IDs

NOTICE: These SCSI IDs are the recommended IDs for each

storage device. If an existing device already uses an

ID, select an alternate ID.

3–2 Configuration

Page 34

LED

NOTICE: A0, A1, and A2 are the SCSI

ID jumpers. The jumpers TE,

SS, WS, and I/O should be

removed

and INT should be

, and the jumper EP

in place

.

SCSI

ID

6

SCSI

ID

5

I/O

INT

SS

TE

EP

WS

A0 (LSB)

A1

A2 (MSB)

Figure 3–2. Quantum 525–MB and 1–GB Disk Drive Jumpers

(1 GB only)

Configuration 3–3

Page 35

SCSI

1 2 3 4 5 6 7 8 9 10

ID

6

5

4

3

2

1

0

No Jumper

Figure 3–3. Quantum 1–GB and 2–GB Low Profile Disk Drive Jumpers

3–4 Configuration

Page 36

LED

Front View

1 — Write Protect

2 — Unit Attention

3 — SDTR

4 — Parity Enable

5 — Auto Spin–Up

6 — Sync Spindle

7 — Sync Spindle

(First Drive)

(Second Drive)

1 2 3 4 5

Bottom View

6 71 2 3 4 5

6 7

Front

SCSI ID 6

8 9 10

SCSI ID 5

8 9 10

NOTICE: The last three jumpers

(8, 9, and 10) are the

SCSI ID jumpers.

Jumpers 1, 2, and 7

should be

removed

, and

jumpers 3, 4, 5, and 6

should be

in place

.

Terminator

Power

Figure 3–4. Hewlett–Packard 1–GB Winchester Drive Jumpers

Configuration 3–5

Page 37

Terminator Power

Terminator Resistor

Modules

(Must be removed)

(First Drive)

2345

(Second Drive)

2345

61

61

Parity Enable Configuration

NOTICE: The first three jumpers

(1, 2, and 3) should be

removed

SCSI

ID 6

SCSI

ID 5

jumpers are jumpers

4, 5, and 6.

. The SCSI ID

Figure 3–5. Seagate 525–MB, 1–GB, and 2–GB Winchester Drive Jumpers

3–6 Configuration

Page 38

Terminator Resistor Modules

(Must be removed)

Factory–Installed Jumpers

(Do not remove)

(First Drive) (Second Drive)

SCSI

ID 6

ID 0

ID 1

ID 2

P ARITY

WPROT

SPIN 0

SPIN 1

SCSI

ID 5

ID 0

ID 1

ID 2

P ARITY

WPROT

SPIN 0

SPIN 1

NOTICE:

ID 0, ID 1, and ID 2 are the SCSI ID jumpers. The jumpers PARITY,

WPROT, SPIN 0, and SPIN 1 should be

Figure 3–6. Micropolis 1–GB Winchester Drive Jumpers

removed

.

Configuration 3–7

Page 39

LED

NOTICE: A0, A1, and A2 are the

SCSI Terminators

(Must be removed)

Figure 3–7. Quantum 210–MB and 425–MB Winchester Drive Jumpers

(Models ProDrive 210S and ProDrive 425S)

SCSI ID jumpers.

SCSI

ID 5

SCSI

ID 6

Sync Spindle

Parity Enable

Write Protect

A2

A1

A0

3–8 Configuration

Page 40

LED

Front View

J3

SCSI ID

J3

5

1 2345678910

Termination Header

Bottom View

J3

Figure 3–8. DEC 1–GB and 2–GB Disk Drive Jumpers

NOTICE: The first three jumpers (1, 2,

and 3) are the SCSI ID

jumpers. Only jumpers 1, 3,

and 7 should be

other jumpers should be

removed

.

Back

NOTICE:

Remove

all jumpers.

in place.

All

Configuration 3–9

Page 41

10

9

8

New Board

SCSI

ID 5

SCSI

ID 6

A0

A1

A2

Front of Drive

7

6

5

4

3

2

1

Synch Spindle

Synch Spindle

Auto Spin Up

Parity

SDTR

Unit Attention

Write Protec

t

Old Board

SCSI

ID 5

9

8

7

6

5

4

3

2

1

SCSI

ID 6

A0

A1

A2

Synch Spindle

Synch Spindle

Auto Spin Up

Parity

SDTR

Unit

Attention

SCSI Terminators

(Old Board)

SCSI Terminator

Jumpers

(New Board)

Figure 3–9. Hewlett–Packard 420–MB Winchester Drive Jumpers (Model C2235)

3–10 Configuration

Page 42

SCSI

ID

6

5

4

3

2

1

0

1 GB is Model HPC3324A

2 GB is Model HPC3325A

Figure 3–10. Hewlett–Packard 1–GB and 2–GB Low Profile Drive Jumpers

Configuration 3–11

Page 43

Top of Floppy Disk Drive

SCSI ID Address Jumpers

ID 2

ID 1

ID 0

Jumper in = 0; out = 1

Terminator

Resistor

Modules

(Must be removed)

ID2

Jumpers

ID1

ID0

Figure 3–11. SCSI Floppy Drive Address Jumper Settings

3–12 Configuration

Target ID

012345

(Default)

6

Page 44

Model

XM–3201B

SCSI

Address

Switches

Target

ID

0

1

(Default)

2

3

SCSI Terminators

(must be removed)

T arget

ID

0

Address

Settings

Jumpers

Target ID

4

5

6

Model

XM–3301B

T arget

ID

4

Address

Settings

Jumpers

1

2

(Default)

5

6

3

Figure 3–12. CD–ROM SCSI Address Jumper Settings

Configuration 3–13

Page 45

SCSI Terminators

(must be removed)

Target

ID

0

1

2

T erm

PWR

Jumpers

ID2 ID1 ID0 ID2 ID1 ID0

Target

ID

T erm

PWR

4

5

6

3

(Default)

Figure 3–13. DDS SCSI Address Jumper Settings (Model C1504C)

Jumpers

3–14 Configuration

Page 46

Installing Additional Memory

Figure 3–14 shows the location of the memory boards within the system unit.

Memory Boards

Figure 3–14. Memory SIMM Locations

Configuration 3–15

Page 47

%')0 ')* %,*+ #&*+$$ #& (#)* ' +" *% %%')0 (#+0 ',

%0 #&*+$$ ,( +' +") (#)* ') +" '$ & ,( +' ',) (#)* '

%%')0 ')* ') $$ '+") %'$*

&

" %%')0 '&&+')* ) $$ #) +")',!" #) ') +" '$

& #) +")',!" #) ') $$ +" '+") %'$* &*+$$ %%')0 ')* #& +"

$'.*+&,%) %(+0 '&&+') (#) #)*+ ') /%($ # 0', "- +.' (#)*

' %%')0 ')* #&*+$$ +" #)*+ (#) #& +" '&&+')* $$ & +"

*'& (#) #& +" '&&+')* $$

%'-$)($%&+ ()',)* ') * ) ()'-# #& "(+)

Right

Side of

System

Unit

Figure 3–15. Memory Connector Configuration

3–16 Configuration

A B

A B A B A B

Front of System Unit

Pair 0Pair 1Pair 2Pair 3

Page 48

Changing the Built–In Graphics Configuration

Switches (Models 715/C, 715/33, 715/50, 715/75)

Figure 3–16 shows the built–in graphics configuration switch settings. Set the

switches according to the type of monitor that is connected to the system unit’s built–

in graphics connector. First open the system unit, as described in Chapter 5, to allow

a clear view of the switches. Use a small probe to set the switches through the access

hole on the rear of the system unit.

NOTICE: The built–in graphics configuration switches have no

affect on the operation of the optional CRX graphics

unit (if installed).

Access Hole

20” Color

17” Color

19” Grayscale

15” Color

(Model 715/33 only)

Figure 3–16. Changing the Graphics Configuration Switches

Configuration 3–17

Page 49

Configuring the CRX Graphics Options

This section describes how to configure the system to use the CRX graphics options

(if installed).

For information about HCRX graphics, refer to the HP A4070A/A4071A/A4072A CE

Handbook (A4070–90099).

If you update or reinstall HP–UX, and after a few minutes, there is no output on the

monitor, use the following procedures to configure the workstation:

1. Power off the workstation.

2. Connect the monitor to the built–in graphics connector as shown in Chapter 1

of this manual.

3. For Model 715/C, 715/33, 715/50, and 715/75 workstations, check the

workstation’s graphics configuration switches, as shown earlier in this chapter, to make sure the graphics switches are set correctly for the monitor.

4. Power on the monitor and the workstation.

5. Immediately after you power on the workstation, press the TOC switch on

the right side of the system unit. (See Chapter 1 of this manual for the TOC

switch location.)

6. If you are setting up a single monitor system, follow the steps in the next

subsection. If you are setting up a dual monitor system, go to the subsection

“Setting Up a Dual Monitor System” for further configuration instructions.

Setting Up a Single Monitor System

This subsection describes how to set up the workstation to use only the CRX graphics.

NOTICES: Only the 20–inch color monitors are supported on the

CRX graphics adapters.

The built–in graphics adapter can use any of the supported monitors.

1. Log in as root.

2. Enter the following command line to create a device file to support the CRX

graphics:

/etc/mknod /dev/crt24 c 12 0x100000

3–18 Configuration

Return

Page 50

3. Enter the following command line to set the attributes of the device file:

chmod 666 /dev/crt24

Return

4. Make a backup copy of /usr/lib/X11/X0screens by entering the following

command line:

cp /usr/lib/X11/X0screens /usr/lib/X11/X0screens.backup

Return

5. Use a text editor, such as vuepad or vi, to edit the following file:

/usr/lib/X11/X0screens

6. Edit the file so that every line begins with a pound sign (#).

7. Add the following line to the file exactly as shown:

/dev/crt24

8. Save the changes and close the file.

9. Enter the following command:

/etc/reboot

10. The system shuts down and starts to reboot. Press and hold

Return

Esc

when

the following message is displayed:

Selecting a system to boot. To stop selection

process press and hold the ESCAPE key.

In a few seconds, the following message appears:

Terminating selection process.

A short time later, the following message appears:

Searching for potential boot devices. To

terminate search, press and hold the ESCAPE key.

Configuration 3–19

Page 51

The workstation is now searching for devices that may hold file systems from

which it can boot HP–UX. As they are found, they appear in a list similar to

the following example:

Device Selection Device Path

Device Type

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

QUANTUM LPS525s

QUANTUM LPS525s

TOSHIBA CD–ROM DRIVE:XM

P0 scsi.6.0

P1 scsi.5.0

P2 scsi.2.0

11. The following list of actions appears:

b) Boot from specified device

s) Search for bootable devices

a) Enter boot administration mode

x) Exit and continue boot sequence

?) Help

Select from menu:

Press a

Return

The following prompt appears:

BOOT_ADMIN>

12. Set the default console to the CRX graphics option by entering the following

command line:

BOOT_ADMIN> path console graphics_2

Return

13. Enter the following command:

BOOT_ADMIN> exit

Return

14. Power off the workstation and the monitor.

15. Connect the color monitor to the CRX graphics connector as shown in Chapter 1 of this manual.

16. Power on the monitor and the workstation.

3–20 Configuration

Page 52

Setting Up a Dual Monitor System

This subsection describes how to set up the workstation to use both the optional

graphics (CRX) and the built–in graphics.

The CRX graphics is set up as the default display and console device and the built–in

graphics is set up as the secondary display device.

NOTICES: Dual monitors are supported only with the CRX–24

graphics options.

Only the 20–inch color monitors are supported on the

CRX graphics adapters.

The built–in graphics adapter can use any of the supported monitors.

1. Log in as root.

2. Enter the following command line to create a device file to support the CRX

graphics adapter:

/etc/mknod /dev/crt24 c 12 0x100000

Return

3. Enter the following command line to set the attributes of the device file:

chmod 666 /dev/crt24

Return

4. Make a backup copy of /usr/lib/X11/X0screens by entering the following

command line:

cp /usr/lib/X11/X0screens /usr/lib/X11/X0screens.backup

Return

5. Use a text editor, such as vuepad or vi, to edit the following file:

/usr/lib/X11/X0screens

6. Edit the file so that every line begins with a pound sign (#).

Configuration 3–21

Page 53

7. Add the following two lines to the file exactly as shown and in the order

shown:

/dev/crt24

/dev/crt

Since the device file for the CRX graphics is listed first, it becomes the default (0.0) display device and the built–in graphics becomes the secondary

(0.1) display device.

8. Save the changes and close the file.

9. Use a text editor, such as vuepad or vi, to edit the following file:

/usr/vue/app–defaults/Vuewm

10. Add the following two lines exactly as shown:

Vuewm*multiScreen: True

Vuewm*screenList: One Two

11. Save the changes and close the file.

12. Enter the following command:

/etc/reboot

Return

13. The system shuts down and starts to reboot. Press and hold

the following message is displayed:

Selecting a system to boot. To stop selection

process press and hold the ESCAPE key.

In a few seconds, the following message appears:

Selection process stopped.

A short time later, the following message appears:

Searching for potential boot devices. To terminate

search, press and hold the ESCAPE key.

Esc

when

3–22 Configuration

Page 54

The workstation is now searching for devices that may hold file systems from

which it can boot HP–UX. As they are found, they appear in a list similar to

the following example:

Device Selection Device Path

Device Type

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

QUANTUM LPS525s

QUANTUM LPS525s

TOSHIBA CD–ROM DRIVE:XM

P0 scsi.6.0

P1 scsi.5.0

P2 scsi.2.0

14. The following list of actions appears:

b) Boot from specified device

s) Search for bootable devices

a) Enter boot administration mode

x) Exit and continue boot sequence

?) Help

Select from menu:

Press a

Return

The following prompt appears:

BOOT_ADMIN>

15. Set the default console to the CRX graphics option by entering the following

command line:

BOOT_ADMIN> path console graphics_2

Return

16. Enter the following command:

BOOT_ADMIN> exit

Return

17. Power off the workstation and the monitor.

18. Connect the color monitor to the CRX graphics connector as shown in Chapter 1 of this manual. Connect the second monitor to the built–in graphics

connector on the rear of the workstation, as shown in Chapter 1. For Model

715/C, 715/33, 715/50, and 715/75 workstations, check the workstation’s

graphics configuration switches, as shown in earlier in this chapter, to make

sure the graphics switches are set correctly for the second monitor.

19. Power on the monitors and the workstation.

Configuration 3–23

Page 55

Troubleshooting 4

This chapter provides information about isolating a failing Field Replaceable Unit

(FRU).

To troubleshoot HP workstations, you must be familiar with the HP–UX operating

system. You must be able to start and stop processes. You should also be familiar

with the Boot ROM Test Mode, ISL diagnostics, and the SupportWave online tests.

For Series 700 systems, note any error or status messages, and then run the power–up

boot ROM diagnostics, known as Self Test. If the Self Test diagnostics fail, replace

the FRU that is indicated. If the tests pass but you still suspect a problem, run the ISL

diagnostics and the SupportWave online tests. Refer to the following sections for

more information about Self Test.

For a complete description on using ISL diagnostics and SupportWave, see the

Precision Architecture RISC HP 9000 Series 700 Diagnostics Manual.

Troubleshooting 4–1

Page 56

LED Error Codes

This section contains information about the error codes displayed by the LEDs on the

system’s front panel.

If an error occurs during the power–up diagnostics tests, the diagnostics use the front

panel LEDs to display a code for the failing component.

Figure 4–1 shows the location of the system unit’s front panel LEDs. There are nine

LEDs on the front panel. The green LED on the far right indicates that the system is

powered up. The amber LEDs labeled 1 through 8, right to left, indicate system

status and error codes.

Front

8765432

Table 4–1 through Table 4–4 show the LED error codes as they appear on the front

panel display of Model 715/C, 715/33, 715/50, and 715/75 workstations.

Table 4–1 shows the Self Test error codes.

Table 4–2 shows the PDC error codes.

Table 4–3 shows the ISL error codes.

Table 4–4 shows the HP–UX kernel error codes.

Table 4–5 shows the LED error codes as they appear on the front panel display of

Model 715/64, 715/80, , 715/100, and 715/100XC workstations.

Use these LED codes to determine the failing component.

4–2 Troubleshooting

1

Power

LED

Figure 4–1. Front Panel LEDs

Page 57

Table 4–1. Model 715/C, 715/33, 715/50, and 715/75 Self Test LED Error Codes

LED Display Error Message

7658

1234

CPU Error - Model 715/33 and 50.

PCX-T FRU Error – Model 715/75.

CPU Error - Model 715/33 and 50.

PCX-T FRU Error - Model 715/75.

CPU Error - Model 715/33 and 50

Motherboard Error - 715/75

CPU Error - Model 715/33 and 50.

PCX-T FRU Error - Model 715/75.

FP Register Test Failure. Loops Until Passes

Possible PCX–T Error*

FP Register Test Failure. Loops Until Passes

Possible PCX–T Error*

FP Register Test Failure. Loops Until Passes

Possible PCX–T Error*

EISA Interface Error.

EISA Interface Error.

EISA Interface Error.

EISA Interface Error.

EISA Interface Error.

EISA Interface Error.

PDC ROM Checksum Error.

Memory Pair 0, Slot B Error.

Memory Pair 0, Slot A Error.

= LED On or Flashing

* If you see this error code and it continues to appear, power the system down

and reboot. If you see the error code again, replace the PCX–T card.

= LED Either On or Off

(Continued)

Troubleshooting 4–3

Page 58

Table 4–1. Model 715/C, 715/33, 715/50, and 715/75 Self Test LED Error Codes

LED Display Error Message

(Cont.)

7658

1234

Memory Pair1, Slot B Error.

Memory Pair 1, Slot A Error.

Memory Pair 2, Slot B Error.

Memory Pair 2, Slot A Error.

Memory Pair 3, Slot B Error.

Memory Pair 3, Slot A Error.

No Memory found.

Unknown I/O device.

Error while trying to boot from SCSI Device.

Error while trying to boot from LAN.

Error Trying to access Console Keyboard.

Error while trying to access Serial

Console Device, Port A.

Error while trying to access Serial

Console Device, Port B.

Error while trying to access Parallel Port.

Error while trying to access Graphical

Console Device.

= LED On or Flashing

4–4 Troubleshooting

(Continued)

Page 59

Table 4–1. Model 715/C, 715/33, 715/50, and 715/75 Self Test LED Error Codes

LED Display Error Message

(Cont.)

7658

= LED On or Flashing

1234

Unable to initialize EISA Slot.

Error on SGC Slot 1 (Built–in Graphics)

Error on SGC Slot 2 (Optional Graphics)

Troubleshooting 4–5

Page 60

Table 4–2. Model 715/C, 715/33, 715/50, and 715/75 PDC LED Codes

LED Display

87 432156

Status

Destructive Memory init.

Non–Destructive Memory init.

Console selection.

Boot Device selection.

Autoselection failure to find Boot Device.

Launching IPL.

TOC Handler entered.

Branching to OS TOC Handler.

Branching to OS HPMC Handler.

EISA Subsystem Init.

Setting Up Default EISA config.

At least one Selftest failed (Service Mode).

= LED On or Flashing

4–6 Troubleshooting

Error reading EEPROM or

Invalid Stable Storage.

Unexpected interrupt.

No Console located.

(Continued)

Page 61

Table 4–2. Model 715/C, 715/33, 715/50, and 715/75 PDC LED Codes (Cont.)

LED Display

87 432156

= LED On or Flashing

Status

HPMC Handling initiated.

HPMC due to Cache Error.

HPMC due to Memory Error.

HPMC due to Bus Error.

Nested HPMC detected.

Error writing to EEPROM.

Unable to determine valid Processor Speed.

ROM Checksum error.

Processor Speed sensing.

Illegal Processor Speed/Clock Ratio sensing.

Bad Memory Hardware.

Troubleshooting 4–7

Page 62

Table 4–3. Model 715/C, 715/33, 715/50, and 715/75 ISL LED Codes

LED Display

87 432156

Status

ISL executing.

ISL is autobooting from the Autoexec File.

ISL cannot find Autoexecute File.

No Console found. ISL Autobooting.

Directory of Utilities is too large.

Autoexec File is inconsistent.

Error reading Autoexec File.

Error reading from Console.

Error writing to Console.

Not an ISL command or utility.

Utility File Header inconsistent:

Invalid System ID.

Error reading Utility File Header.

= LED On or Flashing

4–8 Troubleshooting

Utility File Header inconsistent:

Bad Magic Number.

Utility would overlay ISL in Memory.

Utility requires more Memory than is

configured.

Error reading Utility into Memory.

Incorrect Checksum: Reading Utility into

Memory.

(Continued)

Page 63

Table 4–3. Model 715/C, 715/33, 715/50, and 715/75 ISL LED Codes (Cont.)

LED Display

87 432156

= LED On or Flashing

Status

System Console needed.

Internal inconsistency: Invalid Boot Device

Class.

Destination Memory Address of Utility is

invalid.

Internal inconsistency: pdc_cache entry.

Internal inconsistency: IODC ENTRY_INIT.

Internal inconsistency: IODC

ENTRY_INIT Console.

Internal inconsistency: IODC

ENTRY_INIT Boot Device.

Utility File Header inconsistent: Bad aux_id.

Bad Utility File Type.

Troubleshooting 4–9

Page 64

Table 4–4. Model 715/C, 715/33, 715/50, and 715/75 HP–UX Kernel LED Codes

LED Display

87 432156

= LED On or Flashing

Status

Kernel loaded and Initialization begun.

Kernel has entered main().

Kernel is about to configure I/O System.

Kernel is about to mount Root File System.

Kernel is about to set up Page–Out Daemon.

Kernel is about to start the “INIT” Process.

Shutdown in process.

TOC Dump.

HPMC Dump.

Operating System executing with Load

Indicator X.

4–10 Troubleshooting

Page 65

Table 4–5. Model 715/64, 715/80, , 715/100, and 715/100XC LED Error Codes

LED Display Status

87 432156

CPU Error

Fatal Error

RAM Test Error

Cache Error

FP Co–processor Error

Fatal FP Co–processor Error

I/O Device Error

ROM Checksum Error

HPMC Error

HPMC due to Cache Error

= LED On or Flashing

HPMC due to Bus Error

HPMC due to Memory Error

Console Initialization Error

No working console found, unable to boot

(Continued)

Troubleshooting 4–11

Page 66

Table 4–5. Model 715/64, 715/80, , 715/100, and 715/100XC LED Error Codes

LED Display Status

87 432156

= LED On or Flashing

(Cont.)

No bootable device found

Memory Error

Initialization Error

4–12 Troubleshooting

Page 67

Dealing with a Boot Failure

If the workstation’s usual boot device (typically a disk) is not responding as it should,

you must attempt to boot from the disk (or another boot device) by selecting it manually.

To boot a device manually, follow these steps:

1. Turn off the power to the workstation, wait a few seconds, then turn the power

back on.

2. Press and hold

Selecting a system to boot.

To stop selection process, press and hold the ESCAPE

key.

Release

Selection process stopped.

Esc

as soon as the following message appears:

Esc

as soon as this message appears:

A short time later, this message appears:

Searching for potential boot devices.

To terminate search, press and hold the ESCAPE key.

The workstation is now searching for devices that may hold file systems from

which it can boot HP–UX. As they are found, they appear in a list, similar to

the following sample list:

Device Selection Device Path Device Type

––––––––––––––––––––––––––––––––––––––––––––––––––––––

P0 scsi.6.0 QUANTUM LPS525S

P1 scsi.5.0 QUANTUM LPS525S

P2 scsi.2.0 TOSHIBA CD–ROM DRIVE

This process may take several minutes. You can terminate the search at any

time by pressing

Esc

.

Troubleshooting 4–13

Page 68

When the search ends, the following list of actions appears:

b) Boot from specified device

s) Search for bootable devices

a) Enter Boot Administration mode

x) Exit and continue boot sequence

?) Help

Select from menu:

If no disk devices are listed, then the workstation is failing to communicate

with its disks. Recheck the SCSI connections and try again.

If no devices are listed at all, try alternative methods for booting, such as connecting an external CD–ROM drive.

3. If the search locates a disk, attempt to boot from it by entering the b (boot)

command and a device selection number from the list. For example, if a SCSI

disk is listed as item P0 (as in the example list above), enter the following:

Select from menu: b p0

Return

After a few seconds, the boot messages begin to appear on the screen. You may

hear sounds coming from the disk drive and see a sequence of changing patterns on the LED display.

4. If the workstation still fails to boot, there is either something wrong with the

file system or with the hardware.

Boot Administration Environment

The Boot Console User Interface provides an “autoselect” or “interactive” environment after the power–on sequence. The Boot Console User Interface must be invoked before the Initial Program Loader (IPL) routine. Users do not have to interact

with the interface when the AUTOSELECT mode is enabled.

The Boot Console User Interface executes user–entered commands that perform the

following functions:

Display the state of Autoselect mode using the AUTO command.

Set the state of the Autoselect mode using the AUTOSELECT command with

either the ON or OFF option.

Boot from the primary or alternate boot path or any specified path using the

BOOT command.

Set or display the real–time clock value using the DATE command (this com-

mand is not supported on Model 715/64, 715/80, , 715/100, and 715/100XC

workstations).

Return to previous menu using the EXIT command.

4–14 Troubleshooting

Page 69

Set or display the Fastsize value (amount of memory initialized during boot)

using the FASTSIZE command.

Display a menu of commands using the HELP command or a description of

any command as an option to the HELP command.

Display the model number, version numbers, and jumper settings on the Sys-

tem card using the INFO command.

Display the current STATION ADDRESS value in stable storage using the

LAN_ADDR command. You must use SS_CONFIG to set this value.

Select an operating system for the next boot attempt using the OS command.

Set or display the current values for the console, keyboard, primary, or alter-

nate boot paths using the PATH command.

Display the most recent HPMC, LPMC, or TOC error information logged into

Stable Storage using the PIM_INFO command.

Reset the System Unit using the RESET command.

Search for possible boot devices using the SEARCH command.

Set or display secure boot mode or the ability to interact with the console de-

vice within the first 10 seconds before boot device selection is disabled using

the SECURE command.

Display the results of the previous search command using the SHOW com-

mand (this command is not supported on Model 715/64, 715/80, , 715/100, and

715/100XC workstations).

Syntax checking is performed for any supported commands. Error status is displayed

on the console along with any relevant information.

Stable Storage

Stable Storage is non–volatile memory associated with each PA–RISC processor

module. Stable storage is used by the processor (CPU) to store device path information, the state of the boot flags, HPMC error information, and operating system initialization data.

Troubleshooting 4–15

Page 70

Boot Command Notations

The BOOT command supports the following three notations:

Mnemonic

PA–RISC I/O

Path number

Type help scsi or help lan for more information on the boot path parameters.

Here are examples of mnemonic notation:

BOOT

Return

with “no parameters” selects the primary boot path in stable

storage.

BOOT with the ALTERNATE or ALT parameter selects the alternate boot

path in stable storage.

Here are examples of PA–RISC I/O notation:

BOOT scsi.<scsi_addr>.<scsi_lun> or

BOOT 2/0/1.<scsi_addr>.<scsi_lun>

BOOT lan.<server_address>.<init_timeout>.<io_timeout>or

BOOT 2/0/2.<server_address>.<init_timeout>.<io_timeout>

Here is an example of path number notation:

BOOT P1

Return

attempts to boot from the second path indicated by the

SEARCH command.

Supported Boot Paths

SCSI devices are bootable when connected to the SCSI port on the System card.

Diskless workstations can only boot from the LAN port on the System card.

4–16 Troubleshooting

Page 71

ISL Environment

The ISL environment provides the means to load the operating system (HP–UX)

environment. The ISL environment also provides an offline platform to execute diagnostic and utility programs from a boot device when HP–UX does not load.

The ISL program is the first program loaded into main memory from an external

media (LAN, disk, or tape) and launched by the initial program loader (IPL) routine

during the Boot Administration environment.

The ISL environment provides the following capabilities:

Execute user–entered commands to modify boot device paths and boot options

in stable storage.

Run off–line diagnostic programs (TDIAG, EISADIAG, and IOMAP).

Provide automatic booting of the HP–UX O/S after power–on or reset.

The ISL program provides a standalone environment for loading offline diagnostic

and utility programs from the LIF directory. The ISL program also provides user

commands to configure the boot parameters into Stable Storage.

Invoking the ISL Environment from a SCSI Device

Perform the following steps to invoke the ISL environment from a SCSI device:

1. Power–on the System Unit (or cycle the power) to invoke the Boot