Datasheet HCPL-530K, HCPL-5301, HCPL-5300, 5962-9685201HYC, 5962-9685201HYA Datasheet (HP)

...

1-498

H

Intelligent Power Module

and Gate Drive Interface

Optocouplers

Technical Data

Applications

• Military and Space

• High Reliability Systems

• Harsh Industrial

Environments

• Transportation, Medical, and

Life Critical Systems

• IPM Isolation

• Isolated IGBT/MOSFET Gate

Drive

• AC and Brushless DC Motor

Drives

• Industrial Inverters

Description

The HCPL-5300/5301 devices

consist of a GaAsP LED optically

coupled to an integrated high

gain photo detector in a

hermetically sealed package. The

The connection of a 0.1 µF bypass capacitor between pins 5 and 8 is recommended.

products are capable of operation

and storage over the full military

temperature range and can be

purchased as either standard

product or with full MIL-PRF38534 Class Level H or K testing

or from the DESC Drawing 5962-

96852. All devices are

manufactured and tested on a

MIL-PRF-38534 certified line and

are included in the DESC

Qualified Manufacturers List

QML-38534 for Hybrid Microcircuits. Minimized propagation

delay difference between devices

make these optocouplers excellent

solutions for improving inverter

efficiency through reduced

switching dead time. An on chip

20 kΩ output pull-up resistor can

be enabled by shorting output

pins 6 and 7, thus eliminating the

need for an external pull-up

resistor in common IPM applications. Specifications and

performance plots are given for

typical IPM applications.

HCPL-5300

HCPL-5301

5962-96852

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

Features

• Performance Specified Over

Full Military Temperature

Range: -55°C to 125°C

• Fast Maximum Propagation

Delays

t

PHL

= 450 ns,

t

PLH

= 650 ns

• Minimized Pulse Width

Distortion (PWD = 450 ns)

• High Common Mode

Rejection (CMR): 10 kV/µs at

VCM = 1000 V

• CTR > 30% at IF = 10 mA

• 1500 Vdc Withstand Test

Voltage

• Manufactured and Tested on

a MIL-PRF-38534 Certified

Line

• Hermetically Sealed

Packages

• Dual Marked with Device

Part Number and DESC

Drawing Number

• QML-38534, Class H and K

• HCPL-4506 Function

Compatibility

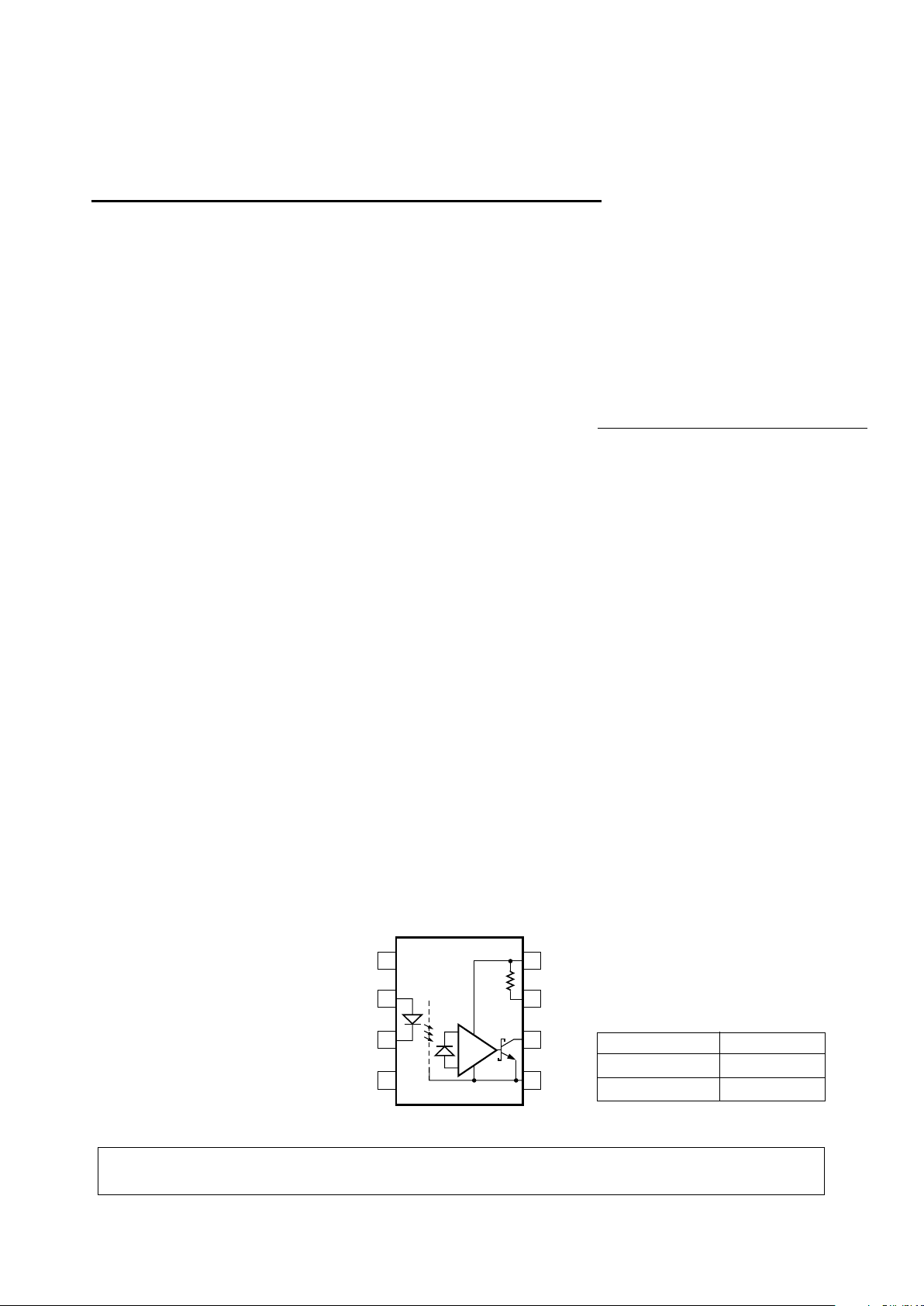

8

7

6

1

3

SHIELD

5

2

4

20 kΩ

Schematic Diagram

Truth Table

LED V

O

ON L

OFF H

5964-9648E

1-499

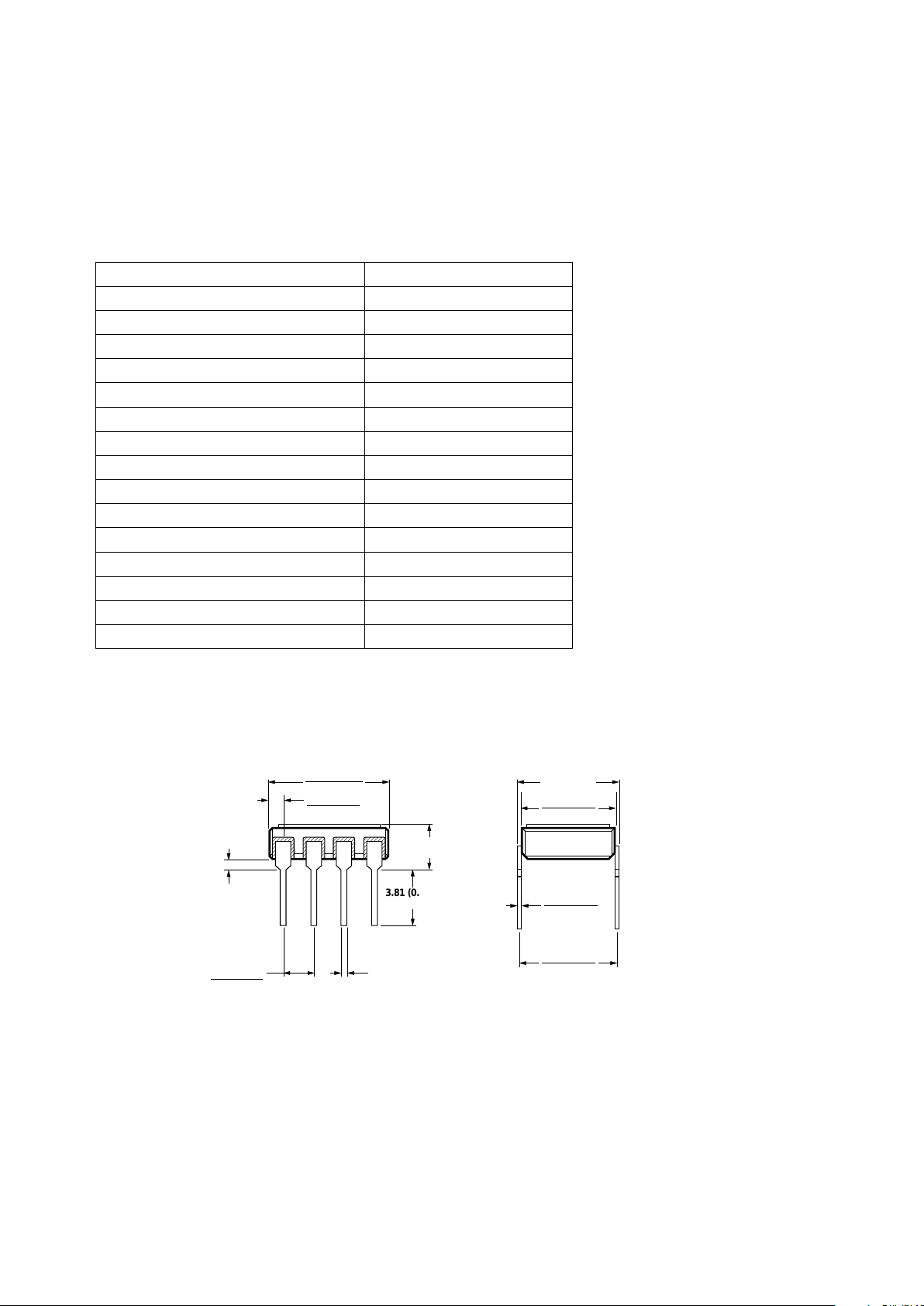

Selection Guide-Package Styles and Lead

Configuration Options

HP Part # and Options

Commercial HCPL-5300

MIL-PRF-38534, Class H HCPL-5301

MIL-PRF-38534, Class K HCPL-530K

Standard Lead Finish Gold Plate

Solder Dipped Option #200

Butt Cut/Gold Plate Option #100

Gull Wing/Soldered Option #300

SMD Part #

Prescript for all below 5962-

Either Gold or Solder 9685201HPX

Gold Plate 9685201HPC

Solder Dipped 9685201HPA

Butt Cut/Gold Plate 9685201HYC

Butt Cut/Soldered 9685201HYA

Gull Wing/Soldered 9685201HXA

Outline Drawing

3.81 (0.150)

MIN.

4.32 (0.170)

MAX.

9.40 (0.370)

9.91 (0.390)

0.51 (0.020)

MAX.

2.29 (0.090)

2.79 (0.110)

0.51 (0.020)

MIN.

0.76 (0.030)

1.27 (0.050)

8.13 (0.320)

MAX.

7.36 (0.290)

7.87 (0.310)

0.20 (0.008)

0.33 (0.013)

7.16 (0.282)

7.57 (0.298)

NOTE: DIMENSIONS IN MILLIMETERS (INCHES).

1-500

Device Marking

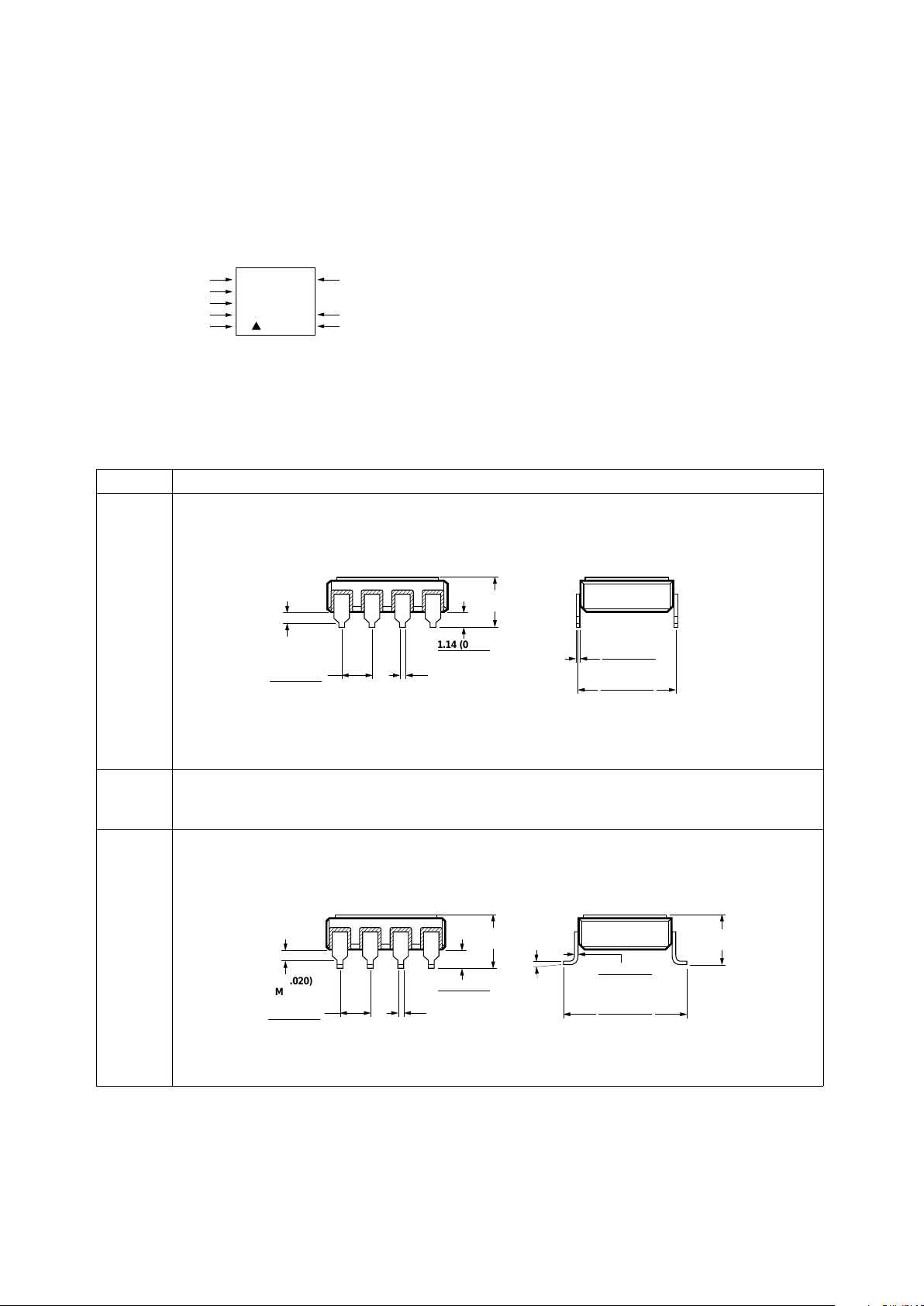

Hermetic Optocoupler Options

Option Description

100 Surface mountable hermetic optocoupler with leads trimmed for butt joint assembly. This

option is available on commercial and hi-rel product in 8 pin DIP (see drawings below for

details).

200 Lead finish is solder dipped rather than gold plated. This option is available on commercial

and hi-rel product in 8 pin DIP. DESC Drawing part numbers contain provisions for lead

finish.

300 Surface mountable hermetic optocoupler with leads cut and bent for gull wing assembly.

This option is available on commercial and hi-rel product in 8 pin DIP (see drawings below

for details). This option has solder dipped leads.

1.14 (0.045)

1.40 (0.055)

4.32 (0.170)

MAX.

0.51 (0.020)

MAX.

2.29 (0.090)

2.79 (0.110)

0.51 (0.020)

MIN.

7.36 (0.290)

7.87 (0.310)

0.20 (0.008)

0.33 (0.013)

NOTE: DIMENSIONS IN MILLIMETERS (INCHES).

COMPLIANCE INDICATOR,*

DATE CODE, SUFFIX (IF NEEDED)

HP QYYWWZ

XXXXXX

XXXXXXX

XXX USA

50434

COUNTRY OF MFR.

HP FSCN*

HP LOGO

DESC SMD*

PIN ONE/

ESD IDENT

HP P/N

DESC SMD*

* QUALIFIED PARTS ONLY

0.51 (0.020)

MIN.

5.57 (0.180)

MAX.

0.51 (0.020)

MAX.

2.29 (0.090)

2.79 (0.110)

1.40 (0.055)

1.65 (0.065)

9.65 (0.380)

9.91 (0.390)

5° MAX.

5.57 (0.180)

MAX.

0.20 (0.008)

0.33 (0.013)

NOTE: DIMENSIONS IN MILLIMETERS (INCHES).

1-501

Absolute Maximum Ratings

Storage Temperature (TS) ............................................................................................................. -65 to 150°C

Operating Temperature (TA) ......................................................................................................... -55 to 125°C

Junction Temperature (TJ) ...................................................................................................................... 175°C

Average Input Current (I

F(AVG)

) ............................................................................................................... 25 mA

Peak Input Current (50% duty cycle, ≤ 1 ms pulse width) (I

F(PEAK)

) ........................................................ 50 mA

Peak Transient Input Current (<1 µs pulse width, 300 pps) (I

F(TRAN)

) ..................................................... 1.0 A

Reverse Input Voltage (Pin 3-2) (VR)............................................................................................................ 5 V

Average Output Current (Pin 6) (I

O(AVG)

) ................................................................................................ 15 mA

Resistor Voltage (Pin 7) (V7) ......................................................................................................... -0.5 V to V

CC

Output Voltage (Pin 6-5) (VO) ........................................................................................................ -0.5 to 30 V

Supply Voltage (Pin 8-5) (VCC) ....................................................................................................... -0.5 to 30 V

Output Power Dissipation (PO)............................................................................................................. 100 mW

Total Power Dissipation (PT)................................................................................................................ 145 mW

Lead Solder Temperature (soldering, 10 seconds) .................................................................................. 260°C

ESD Classification

(MIL-STD-883, Method 3015)

HCPL-5300/5301 ......................(∆),Class 1

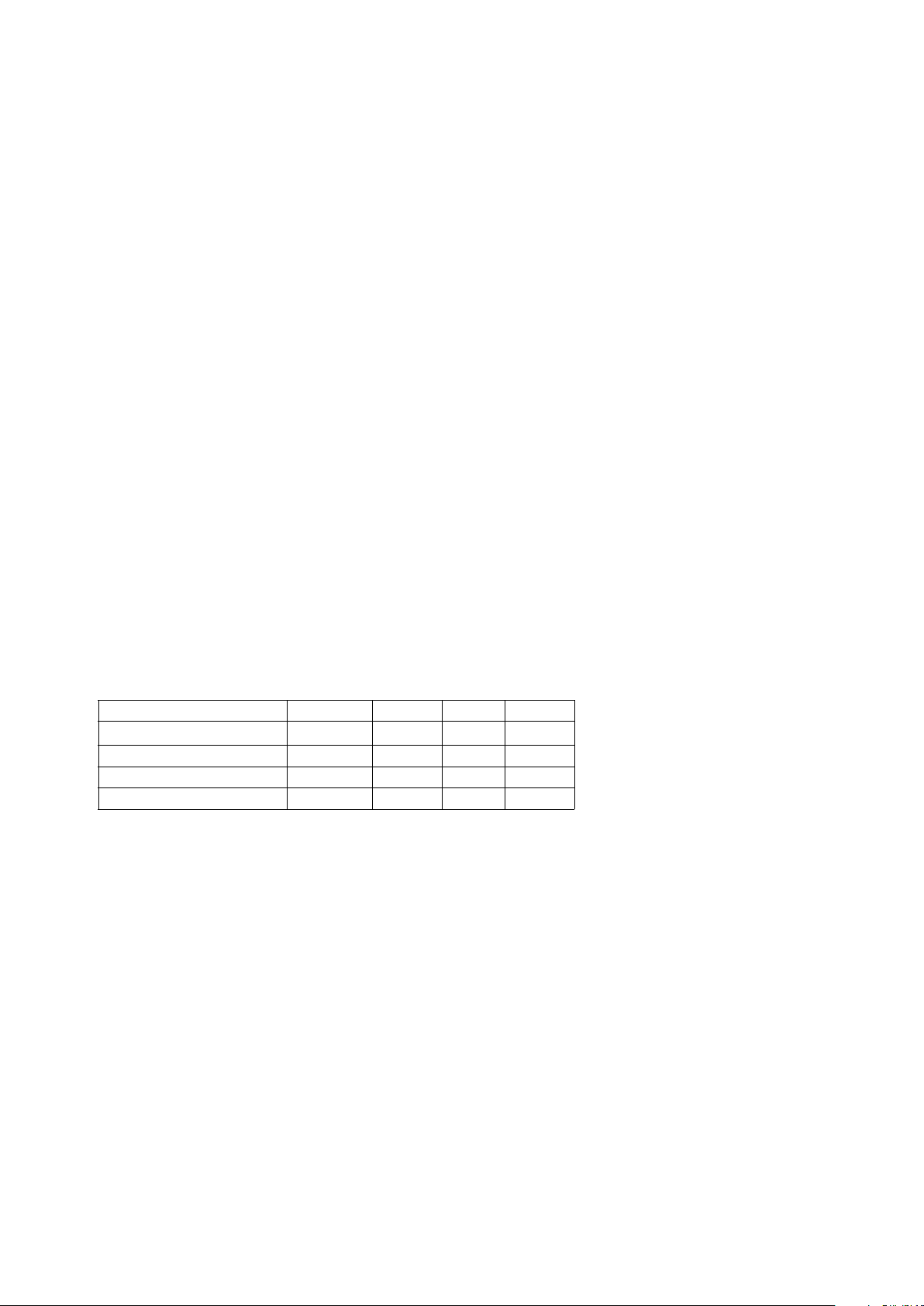

Recommended Operating Conditions

Parameter Symbol Min. Max. Units

Power Supply Voltage V

CC

4.5 30 Volts

Output Voltage V

O

0 30 Volts

Input Current (ON) I

F(ON)

10 20 mA

Input Voltage (OFF) V

F(OFF)

-5 0.8 V

1-502

Electrical Specifications

Over recommended operating conditions (TA = -55°C to +125°C, VCC = +4.5 V to 30 V,

I

F(ON)

= 10 mA to 20 mA, V

F(OFF)

= -5 V to 0.8 V) unless otherwise specified.

Group A

Sub-

Parameter Symbol groups

[12]

Min. Typ.* Max. Units Test Conditions Fig. Note

Current Transfer CTR 1, 2, 3 30 90 % IF = 10 mA, VO = 0.6 V 1

Ratio

Low Level Output I

OL

1, 2, 3 3.0 9.0 mA IF = 10 mA, VO = 0.6 V 1, 2

Current

Low Level Output V

OL

1, 2, 3 0.3 0.6 V IO = 2.4 mA

Input Threshold I

TH

1, 2, 3 1.5 5.0 mA VO = 0.8 V, 1 7

Current IO = 0.75 mA

High Level I

OH

1, 2, 3 5 75 µAVF = 0.8 V 3

Output Current

High Level Supply I

CCH

1, 2, 3 0.6 1.5 mA VF = 0.8 V, VO = Open 7

Current

Low Level Supply I

CCL

1, 2, 3 0.6 1.5 mA IF = 10 mA, VO = Open 7

Current

Input Forward V

F

1, 2, 3 1.0 1.5 1.8 V IF = 10 mA 4

Voltage

Temperature ∆VF/ -1.6 mV/°CIF = 10 mA

Coefficient of ∆T

A

Forward Voltage

Input Reverse BV

R

1, 2, 3 5 V IR = 100 µA

Breakdown Voltage

Input Capacitance C

IN

90 pF f = 1 MHz, VF = 0 V

Input-Output I

I-O

1 1.0 µA RH = 45%, t = 5 sec, 2

Insulation Leakage V

I-O

= 1500 Vdc,

Current TA = 25° C

Resistance R

I-O

10

12

Ω V

I-O

= 500 Vdc 2

(Input-Output)

Capacitance C

I-O

2.4 pF f = 1 MHz 2

(Input-Output)

Internal Pull-up R

L

1 142028kΩTA = 25° C 4, 5,

Resistor 6

Internal Pull-up ∆RL/ 0.014 kΩ/°C

Resistor ∆T

A

Temperature

Coefficient

*All typical values at 25°C, VCC = 15 V.

Voltage

1-503

Switching Specifications (R

L

= 20 kΩ External)

Over recommended operating conditions:

(TA = -55°C to +125°C, V

CC

= +4.5 V to 30 V, I

F(ON)

= 10 mA to 20 mA, V

F(OFF)

= -5 V to 0.8 V) unless

otherwise specified.

Group A

Parameter Symbol Subgrps.

[12]

Min. Typ.* Max. Units Test Conditions Fig. Note

Propagation t

PHL

9, 10, 11 30 180 450 ns CL =I

F(on)

= 10 mA, 5, 7, 3, 4,

Delay Time to 100 pF V

F(off)

= 0.8 V, 9-12 5, 6,

Low Output 100 ns C

L

=7

Level 10 pF

Propagation t

PLH

9, 10, 11 250 350 650 ns CL =

Delay Time to 100 pF

High Output 130 C

L

=

Level 10 pF

Pulse Width PWD 9, 10, 11 150 450 ns CL =11

Distortion 100 pF

Propagation t

PLH

- 9, 10, 11 -170 140 500 ns 8

Delay t

PHL

Difference

Between Any

Two Parts

Output High |CMH| 9 10 17 kV/µsIF = 0 mA, VCC = 15.0 V, 6, 17, 9, 13

Level Common V

O

> 3.0 V CL = 100 pF, 18, 21

Mode V

CM

= 1000 V

P-P

Immunity TA = 25°C

Transient

Output Low |CML| 9 10 17 kV/µsIF = 10 mA 10, 13

Level Common V

O

< 1.0 V

Mode

Transient

Immunity

*All typical values at 25°C, VCC = 15 V.

VCC = 15.0 V,

V

THLH

= 2.0 V,

V

THHL

= 1.5 V

1-504

Switching Specifications (RL= Internal Pull-up)

Over recommended operating conditions:

(TA = -55°C to +125°C, V

CC

= +4.5 V to 30 V, I

F(ON)

= 10 mA to 20 mA, V

F(OFF)

= -5 V to 0.8 V) unless

otherwise specified.

Group A

Parameter Symbol Subgrps.

[12]

Min. Typ.* Max. Units Test Conditions Fig. Note

Propagation t

PHL

9, 10, 11 20 185 500 ns I

F(on)

= 10 mA, 5, 8, 3, 4,

Delay Time to V

F(off)

= 0.8 V, 5, 6,

Low Output V

CC

= 15.0 V, 7

Level C

L

= 100 pF,

Propagation t

PLH

9, 10, 11 220 415 750 ns

Delay Time to

High Output

Level

Pulse Width PWD 9, 10, 11 150 600 ns 11

Distortion

Propagation t

PLH

- 9, 10, 11 -225 150 650 ns 8

Delay t

PHL

Difference

Between Any

Two Parts

Output High |CMH|10kV/µsIF = 0 mA, VCC = 15.0 V, 6, 21 9

Level Common V

O

> 3.0 V CL = 100 pF,

Mode Transient V

CM

= 1000

Immunity T

A

= 25°C

Output Low |CML|10kV/µsIF = 16 mA 10

Level Common V

O

< 1.0 V

Mode Transient

Immunity

Power Supply PSR 1.0 V

P-P

Square Wave, t

RISE

, t

FALL

7

Rejection > 5 ns, no bypass

capacitors.

*All typical values at 25°C, VCC = 15 V.

Notes:

1. CURRENT TRANSFER RATIO in percent is defined as the ratio of output collector current (IO) to the forward LED input current

(IF) times 100.

2. Device considered a two-terminal device: Pins 1, 2, 3 and 4 shorted together and Pins 5, 6, 7 and 8 shorted together.

3. Pulse: f = 20 kHz, Duty Cycle = 10%

4. The internal 20 kΩ resistor can be used by shorting pins 6 and 7 together.

5. Due to the tolerance of the internal resistor, and since propagation delay is dependent on the load resistor value, performance can

be improved by using an external 20 kΩ 1% load resistor. For more information on how propagation delay varies with load

resistance, see Figure 8.

6. The RL = 20 kΩ, CL = 100 pF represents a typical IPM (Intelligent Power Module) load.

7. Use of a 0.1 µF bypass capacitor connected between pins 5 and 8 can improve performance by filtering power supply line noise.

8. The difference in t

PLH

and t

PHL

between any two parts under the same test condition. (See IPM Dead Time and Propagation Delay

Specifications section.)

9. Common mode transient immunity in a Logic High level is the maximum tolerable dVCM/dt of the common mode pulse, VCM, to

assure that the output will remain in a Logic High state (i.e., VO > 3.0 V).

10. Common mode transient immunity in a Logic Low level is the maximum tolerable dVCM/dt of the common mode pulse, VCM, to

assure that the output will remain in a Logic Low state (i.e., VO < 1.0 V).

11. Pulse Width Distortion (PWD) is defined as the difference between t

PLH

and t

PHL

for any given device.

12. Standard parts receive 100% testing at 25°C (Subgroups 1 and 9). Hi-Rel and SMD parts receive 100% testing at 25°C, +125°C,

and -55°C (Subgroups 1 and 9, 2 and 10, 3 and 11 respectively).

13. Parameters are tested as part of device initial characterization and after design and process changes. Parameters are guaranteed

to limits specified for all lots not specifically tested.

V

THLH

= 2.0 V

V

THHL

= 1.5 V

1-505

LED Drive Circuit

Considerations For Ultra

High CMR Performance

Without a detector shield, the

dominant cause of optocoupler

CMR failure is capacitive

coupling from the input side of

the optocoupler, through the

package, to the detector IC as

shown in Figure 14. The HCPL5300/5301 improves CMR

performance by using a detector

IC with an optically transparent

Faraday shield, which diverts the

capacitively coupled current away

from the sensitive IC circuitry.

However, this shield does not

eliminate the capacitive coupling

between the LED and the optocoupler output pins and output

ground as shown in Figure 15.

This capacitive coupling causes

perturbations in the LED current

during common mode transients

and becomes the major source of

CMR failures for a shielded

optocoupler. The main design

objective of a high CMR LED

drive circuit becomes keeping the

LED in the proper state (on or

off) during common mode

transients. For example, the

recommended application circuit

(Figure 13), can achieve 10 kV/µs

CMR while minimizing component complexity. Note that a

CMOS gate is recommended in

Figure 13 to keep the LED off

when the gate is in the high state.

Another cause of CMR failure for

a shielded optocoupler is direct

coupling to the optocoupler

output pins through C

LEDO1

and

C

LEDO2

in Figure 15. Many factors

influence the effect and magnitude of the direct coupling

including: the use of an internal

or external output pull-up

resistor, the position of the LED

current setting resistor, the

connection of the unused input

package pins, and the value of

the capacitor at the optocoupler

output (CL).

Techniques to keep the LED in

the proper state and minimize the

effect of the direct coupling are

discussed in the next two

sections.

CMR With The LED On

(CMRL)

A high CMR LED drive circuit

must keep the LED on during

common mode transients. This is

achieved by overdriving the LED

current beyond the input

threshold so that it is not pulled

below the threshold during a

transient. The recommended

minimum LED current of 10 mA

provides adequate margin over

the maximum ITH of 5.0 mA (see

Figure 1) to achieve 10 kV/µs

CMR. Capacitive coupling is

higher when the internal load

resistor is used (due to C

LEDO2

)

and an IF= 16mA is required to

obtain 10 kV/µs CMR.

The placement of the LED

current setting resistor affects the

ability of the drive circuit to keep

the LED on during transients and

interacts with the direct coupling

to the optocoupler output. For

example, the LED resistor in

Figure 16 is connected to the

anode. Figure 17 shows the AC

equivalent circuit for Figure 16

during common mode transients.

During a +dV

CM/dt

in Figure 17,

the current available at the LED

anode (I

TOTAL

) is limited by the

series resistor. The LED current

(IF) is reduced from its DC value

by an amount equal to the current

that flows through C

LEDP

and

C

LEDO1

. The situation is made

worse because the current

through C

LEDO1

has the effect of

trying to pull the output high

(toward a CMR failure) at the

same time the LED current is

being reduced. For this reason,

the recommended LED drive

circuit (Figure 13) places the

current setting resistor in series

with the LED cathode. Figure 18

is the AC equivalent circuit for

Figure 13 during common mode

transients. In this case, the LED

current is not reduced during a

+dV

CM/dt

transient because the

current flowing through the

package capacitance is supplied

by the power supply. During a

-dV

CM/dt

transient, however, the

LED current is reduced by the

amount of current flowing

through C

LEDN

. But better CMR

performance is achieved since the

current flowing in C

LEDO1

during

a negative transient acts to keep

the output low.

Coupling to the LED and output

pins is also affected by the

connection of pins 1 and 4. If

CMR is limited by perturbations

in the LED on current, as it is for

the recommended drive circuit

(Figure 13), pins 1 and 4 should

be connected to the input circuit

common. However, if CMR

performance is limited by direct

coupling to the output when the

LED is off, pins 1 and 4 should

be left unconnected.

CMR With The LED Off

(CMRH)

A high CMR LED drive circuit

must keep the LED off

(VF≤ V

F(OFF)

) during common

mode transients. For example,

during a +dV

CM/dt

transient in

Figure 18, the current flowing

through C

LEDN

is supplied by the

parallel combination of the LED

and series resistor. As long as the

voltage developed across the

resistor is less than V

F(OFF)

the

LED will remain off and no

1-506

common mode failure will occur.

Even if the LED momentarily

turns on, the 100 pF capacitor

from pins 6-5 will keep the

output from dipping below the

threshold. The recommended

LED drive circuit (Figure 13)

provides about 10 V of margin

between the lowest optocoupler

output voltage and a 3 V IPM

threshold during a 10 kV/µs

transient with VCM= 1000 V.

Additional margin can be

obtained by adding a diode in

parallel with the resistor, as

shown by the dashed line connection in Figure 18, to clamp the

voltage across the LED below

V

F(OFF)

.

Since the open collector drive

circuit, shown in Figure 19,

cannot keep the LED off during a

+dV

CM/dt

transient, it is not

desirable for applications

requiring ultra high CMR

H

performance. Figure 20 is the AC

equivalent circuit for Figure 16

during common mode transients.

Essentially all the current flowing

through C

LEDN

during a +dV

CM/dt

transient must be supplied by the

LED. CMRH failures can occur at

dv/dt rates where the current

through the LED and C

LEDN

exceeds the input threshold.

Figure 21 is an alternative drive

circuit which does achieve ultra

high CMR performance by

shunting the LED in the off state.

IPM Dead Time and

Propagation Delay

Specifications

These devices include a

Propagation Delay Difference

specification intended to help

designers minimize “dead time” in

their power inverter designs.

Dead time is the time period

during which both the high and

low side power transistors (Q1

and Q2 in Figure 22) are off. Any

overlap in Q1 and Q2 conduction

will result in large currents

flowing through the power

devices between the high and low

voltage motor rails.

To minimize dead time the

designer must consider the

propagation delay characteristics

of the optocoupler as well as the

characteristics of the IPM IGBT

gate drive circuit. Considering

only the delay characteristics of

the optocoupler (the characteristics of the IPM IGBT gate drive

circuit can be analyzed in the

same way) it is important to

know the minimum and maximum

turn-on (t

PHL

) and turn-off (t

PLH

)

propagation delay specifications,

preferably over the desired

operating temperature range.

The limiting case of zero dead

time occurs when the input to Q1

turns off at the same time that the

input to Q2 turns on. This case

determines the minimum delay

between LED1 turn-off and LED2

turn-on, which is related to the

worst case optocoupler propagation delay waveforms, as shown

in Figure 23. A minimum dead

time of zero is achieved in Figure

23 when the signal to turn on

LED2 is delayed by (t

PLH max

-

t

PHL min

) from the LED1 turn off.

This delay is the maximum value

for the propagation delay

difference specification which is

specified at 500 ns for the HCPL5300/5301 over an operating

temperature range of -55°C to

+125°C.

Delaying the LED signal by the

maximum propagation delay

difference ensures that the minimum dead time is zero, but it

does not tell a designer what the

maximum dead time will be. The

maximum dead time occurs in the

highly unlikely case where one

optocoupler with the fastest t

PLH

and another with the slowest t

PHL

are in the same inverter leg. The

maximum dead time in this case

becomes the sum of the spread in

the t

PLH

and t

PHL

propagation

delays as shown in Figure 24. The

maximum dead time is also

equivalent to the difference

between the maximum and

minimum propagation delay

difference specifications. The

maximum dead time (due to the

optocouplers) for the HCPL5300/5301 is 670 ns (= 500 ns (-170 ns)) over an operating

temperature range of -55°C to

+125°C.

1-507

I

O

– OUTPUT CURRENT – mA

0

IF – FORWARD LED CURRENT – mA

6

4

2

5

10

10 15 20

VO = 0.6 V

8

0

125 °C

25 °C

-55 °C

Figure 5. Propagation Delay Test Circuit.

Figure 1. Typical Transfer

Characteristics.

Figure 2. Normalized Output Current

vs. Temperature.

Figure 3. High Level Output Current

vs. Temperature.

0.1 µF

V

CC

= 15 V

20 k

Ω

I

F(ON)

=10 mA

V

OUT

CL*

+

–

*TOTAL LOAD CAPACITANCE

+

–

I

f

V

O

V

THHL

t

PHL

t

PLH

t

f

t

r

90%

10%

90%

10%

V

THLH

8

7

6

1

3

SHIELD

5

2

4

5 V

20 kΩ

I

F

– FORWARD CURRENT – mA

1.10

0.001

VF – FORWARD VOLTAGE – VOLTS

1.60

10

1.0

0.1

1.20

1000

1.30 1.40 1.50

TA = 25°C

I

F

V

F

+

–

0.01

100

Figure 4. Input Current vs. Forward

Voltage.

NORMALIZED OUTPUT CURRENT

TA – TEMPERATURE – °C

0.8

0.7

0.5

IF = 10 mA

V

O

= 0.6 V

0.9

1.0

0

0.6

0 40 60 100-60 -20 20 80-40 120 140

I

OH

– HIGH LEVEL OUTPUT CURRENT – µA

TA – TEMPERATURE – °C

20

10

5

25

0

VF = 0.8 V

V

CC

= VO = 30 V

15

0 40 60 100-60 -20 20 80-40 120140

1-508

t

P

– PROPAGATION DELAY – ns

TA – TEMPERATURE – °C

500

300

200

600

t

PLH

t

PHL

IF = 10 mA

V

CC

= 15 V

CL = 100 pF

RL = 20 kΩ

(INTERNAL)

100

0 40 60 100-60 -20 20 80-40 120140

400

Figure 11. Propagation Delay vs.

Supply Voltage.

Figure 10. Propagation Delay vs. Load

Capacitance.

t

P

– PROPAGATION DELAY – ns

0

CL – LOAD CAPACITANCE – pF

800

600

400

100

1400

200 300 400

IF = 10 mA

V

CC

= 15 V

RL = 20 kΩ

T

A

= 25°C

200

1000

t

PLH

t

PHL

1200

0 500

t

P

– PROPAGATION DELAY – ns

0

V

CC

– SUPPLY VOLTAGE – V

800

600

400

10

1400

15 20 25

IF = 10 mA

CL = 100 pF

RL = 20 kΩ

T

A

= 25°C

200

1000

t

PLH

t

PHL

530

1200

t

P

– PROPAGATION DELAY – ns

RL – LOAD RESISTANCE – K Ω

600

400

200

30 50

800

010

20

40

t

PLH

t

PHL

IF = 10 mA

V

CC

= 15 V

CL = 100 pF

T

A

= 25 °C

Figure 7. Propagation Delay with

External 20 kΩ RL vs. Temperature.

Figure 8. Propagation Delay with

Internal 20 kΩ RL vs. Temperature.

Figure 9. Propagation Delay vs. Load

Resistance.

Figure 6. CMR Test Circuit. Typical CMR Waveform.

V

CM

∆t

OV

V

O

V

O

SWITCH AT A: IF = 0 mA

SWITCH AT B: I

F

= 10 mA

V

CC

V

OL

V

CM

∆t

δV

δt

=

t

P

– PROPAGATION DELAY – ns

TA – TEMPERATURE – °C

500

300

200

600

t

PLH

t

PHL

IF = 10 mA

V

CC

= 15 V

CL = 100 pF

RL = 20 kΩ

(EXTERNAL)

100

0 40 60 100-60 -20 20 80-40 120140

400

0.1 µF

V

CC

= 15 V

20 kΩ

A

I

F

V

OUT

100 pF*

+

–

*100 pF TOTAL

CAPACITANCE

+

–

+

–

B

V

FF

V

CM

= 1000 V

8

7

6

1

3

SHIELD

5

2

4

20 kΩ

1-509

Figure 12. Propagation Delay vs. Input

Current.

t

P

– PROPAGATION DELAY – ns

100

IF – FORWARD LED CURRENT – mA

300

10

500

15

VCC = 15 V

CL = 100 pF

RL = 20 kΩ

T

A

= 25°C

200

400

t

PLH

t

PHL

5020

Figure 15. Optocoupler Input to

Output Capacitance Model for

Shielded Optocouplers.

Figure 16. LED Drive Circuit with Resistor Connected to LED Anode (Not

Recommended).

8

7

6

1

3

SHIELD

5

2

4

C

LEDP

C

LEDN

C

LED01

C

LED02

20 kΩ

0.1 µF

V

CC

= 15 V

20 kΩ

CMOS

310 Ω

+5 V

V

OUT

100 pF

+

–

*100 pF TOTAL

CAPACITANCE

8

7

6

1

3

SHIELD

5

2

4

20 kΩ

Figure 13. Recommended LED Drive Circuit. Figure 14. Optocoupler Input to

Output Capacitance Model for

Unshielded Optocouplers.

0.1 µF

V

CC

= 15 V

20 kΩ

CMOS

310 Ω

+5 V

V

OUT

100 pF

+

–

*100 pF TOTAL

CAPACITANCE

8

7

6

1

3

SHIELD

5

2

4

20 kΩ

8

7

6

1

3

SHIELD

5

2

4

C

LEDP

C

LEDN

20 kΩ

1-510

Figure 21. Recommended LED Drive

Circuit for Ultra High CMR.

+5 V

8

7

6

1

3

SHIELD

5

2

4

20 kΩ

20 kΩ

* THE ARROWS INDICATE THE DIRECTION OF CURRENT

FLOW FOR +dV

CM

/dt TRANSIENTS.

300 Ω

V

OUT

100 pF

+

–

I

TOTAL*

V

CM

8

7

6

1

3

SHIELD

5

2

4

20

kΩ

C

LEDN

C

LED01

C

LED02

I

CLEDP

I

F

C

LEDP

I

CLED01

20 kΩ

* THE ARROWS INDICATE THE DIRECTION OF CURRENT

FLOW FOR +dV

CM

/dt TRANSIENTS.

** OPTIONAL CLAMPING DIODE FOR IMPROVED CMH

PERFORMANCE. V

R

< V

F (OFF)

DURING +dVCM/dt.

V

OUT

100 pF

+

–

V

CM

8

7

6

1

3

SHIELD

5

2

4

20

kΩ

C

LEDP

C

LEDN

C

LED01

C

LED02

I

CLEDN*

300 Ω

+ VR** –

Figure 17. AC Equivalent Circuit for

Figure 16 During Common Mode

Transients.

Figure 18. AC Equivalent Circuit for Figure 13 During

Common Mode Transients.

Figure 19. Not Recommended Open Collector LED Drive

Circuit.

Q1

+5 V

8

7

6

1

3

SHIELD

5

2

4

20 kΩ

20 kΩ

* THE ARROWS INDICATE THE DIRECTION OF CURRENT

FLOW FOR +dV

CM

/dt TRANSIENTS.

V

OUT

100 pF

+

–

V

CM

8

7

6

1

3

SHIELD

5

2

4

20

kΩ

C

LEDP

C

LEDN

C

LED01

C

LED02

I

CLEDN*

Q1

Figure 20. AC Equivalent Circuit for Figure 19 During

Common Mode Transients.

1-511

0.1 µF

20 kΩ

CMOS

310 Ω

+5 V

V

OUT1

I

LED1

V

CC1

M

HCPL-5300

HCPL-5300

HCPL-5300

HCPL-5300

HCPL-5300

Q2

Q1

-HV

+HV

IPM

8

7

6

1

3

SHIELD

5

2

4

20 k

Ω

HCPL-5300

0.1 µF

20 kΩ

CMOS

310 Ω

+5 V

V

OUT2

I

LED2

V

CC2

8

7

6

1

3

SHIELD

5

2

4

20 k

Ω

HCPL-5300

Figure 22. Typical Application Circuit.

Figure 24. Waveforms for Dead Time Calculations.

V

OUT1

V

OUT2

I

LED2

t

PLH

MIN.

MAXIMUM DEAD TIME

(DUE TO OPTOCOUPLER)

= (t

PLH MAX.

-

t

PLH MIN.

) + (t

PHL MAX.

-

t

PHL MIN.

)

= (t

PLH MAX.

-

t

PHL MIN.

) - (t

PLH MIN.

-

t

PHL MAX.

)

= PDD* MAX. - PDD* MIN.

t

PHL

MIN.

I

LED1

Q1 ON

Q2 OFF

Q1 OFF

Q2 ON

*PDD = PROPAGATION DELAY DIFFERENCE

t

PLH

MAX.

t

PHL

MAX.

PDD*

MAX.

MAX.

DEAD TIME

NOTE: THE PROPAGATION DELAYS USED TO CALCULATE THE MAXIMUM

DEAD TIME ARE TAKEN AT EQUAL TEMPERATURES.

Figure 23. Minimum LED Skew for

Zero Dead Time.

V

OUT1

V

OUT2

I

LED2

t

PLH MAX.

PDD* MAX. =

(t

PLH-tPHL) MAX. = tPLH MAX. - tPHL MIN.

t

PHL

MIN.

I

LED1

Q1 ON

Q2 OFF

Q1 OFF

Q2 ON

*PDD = PROPAGATION DELAY DIFFERENCE

NOTE: THE PROPAGATION DELAYS USED TO CALCULATE

PDD ARE TAKEN AT EQUAL TEMPERATURES.

MIL-PRF-38534 Class H,

Class K, and DESC SMD

Test Program

Hewlett-Packard’s Hi-Rel Optocouplers are in compliance with

MIL-PRF-38534 Classes H and K.

Class H devices are also in

compliance with DESC drawing

5962-96852.

Testing consists of 100% screening and quality conformance

inspection to MIL-PRF-38534.

Loading...

Loading...