Page 1

Reference Manual

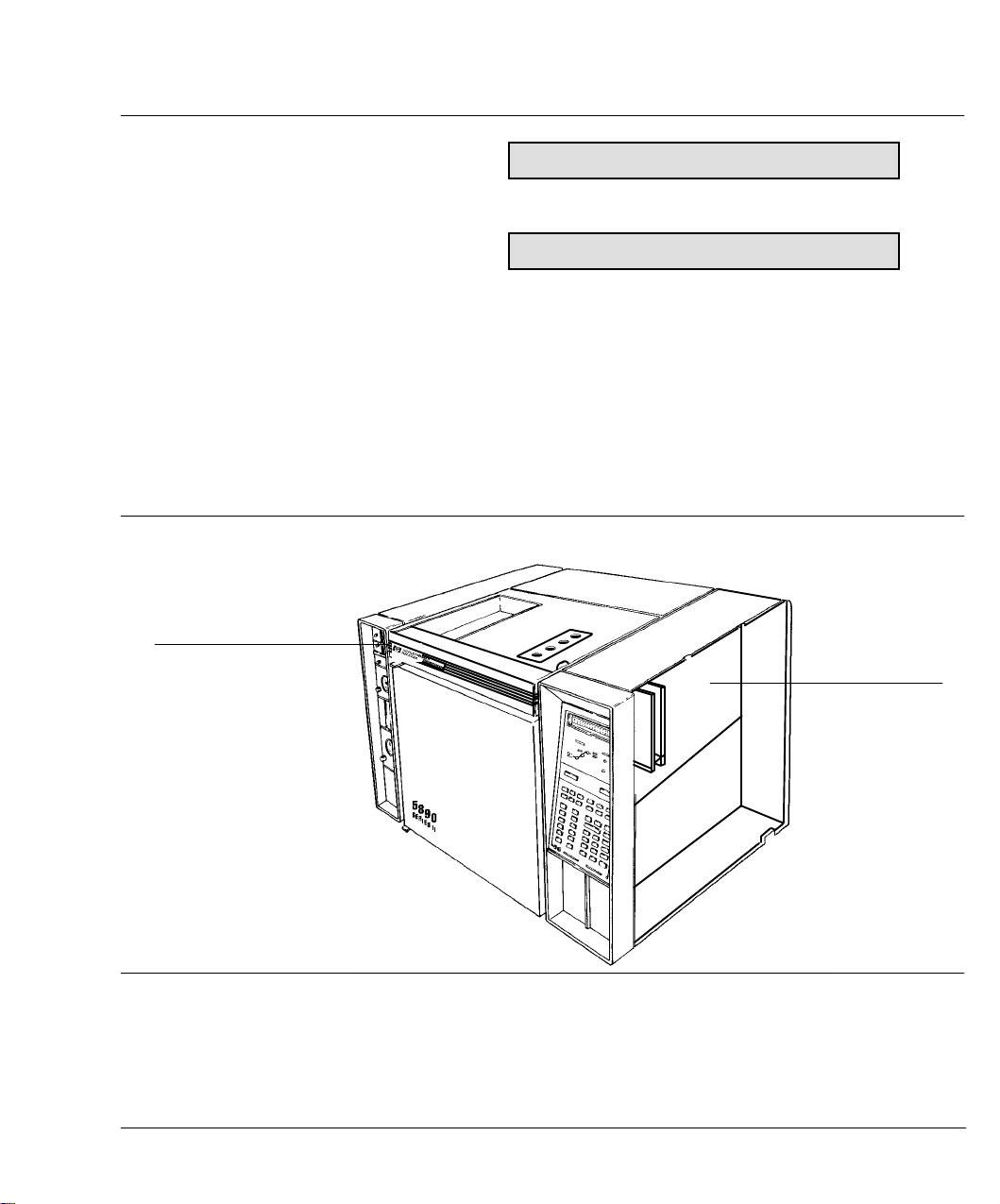

HP 5890 Series II and

HP 5890 Series II Plus

Page 2

D

Hewlett-Packard

Company 1989,1990, 1991,

1993, 1994

All Rights Reserved.

Reproduction, adaptation,

or translation without

permission is prohibited,

except as allowed under

the copyright laws.

HP part number

05890-90271

First edition—Jun 1989

Printed In U.S.A.

Second edition—Oct 1989

Printed In U.S.A.

Third edition—Jan 1990

Printed In U.S.A.

Fourth edition—Oct 1990

Printed In U.S.A.

Fifth edition—Oct 1991

Printed In U.S.A.

Fifth edition—Mar 1993

Printed In U.S.A.

Sixth edition—Jul 1994

Printed In U.S.A.

Printed in USA

Warranty

The information contained

in this document is subject

to change without notice.

Hewlett-Packard makes no

warranty of any kind with

regard to this material,

including, but not limited

to, the implied warranties

of merchantability and

fitness for a particular

purpose. Hewlett-Packard

shall not be liable for errors

contained herein or for

incidental or consequential

damages in connection with

the furnishing,

performance, or use of this

material.

Safety Information

The HP 5890 Series II and

HP 5890 Series II Plus are

IEC (International

Electrotechnical

Commission) Safety Class 1

instruments. This unit has

been designed and tested in

accordance with recognized

safety standards. Whenever

the safety protection of the

HP 5890 Series II has been

compromised, disconnect

the unit from all power

sources and secure the unit

against unintended

operation.

Safety Symbols

This manual contains

safety information that

should be followed by the

user to ensure safe

operation.

WARNING

A warning calls attention

to a condition or possible

situation that could cause

injury to the user.

CAUTION

A caution calls attention to

a condition or possible

situation that could

damage or destroy the

product or the user’s work.

Important User

Information for In Vitro

Diagnostic Applications

This is a multipurpose

product that may be used

for qualitative or

quantitative analyses in

many applications. If used

in conjunction with proven

procedures (methodology)

by qualifiedoperator, one

of these applications may

be In Vitro Diagnostic

Procedures.

Generalized instrument

performance characteristics

and instructions are

included in this manual.

Specific In Vitro Diagnostic

procedures and

methodology remain the

choice and the

responsibility of the user,

and are not included.

Sound Emission

Certification for Federal

Republic of Germany

If Test and Measurement

Equipment is operated with

unscreened cables and/or

used for measurements in

open set-ups, users have to

assure that under these

operating conditions the

Radio Interference Limits

are still met at the border

of their premises.

The following information

is provided to comply with

the requirements of the

German Sound Emission

Directive dated January 18,

1991

Sound pressure Lp <

70db(A)

During normal operation

At the operator position

According to ISO 7779

(Type Test)

When operating the HP

5890 Series II with cryo

valve option, the sound

pressure

cryo valve operation for

short burst pulses.

78 db(A) during

Schallemission

Werden Meß- und

Testgeräte mit

ungeschirmten Kabeln

und/oder in offenen

Meßaufbauten verwendet,

so ist vom Betreiber

sicherzustellen, daß die

Funk-Entströbedingungen

unter Betriebsbedingungen

an seiner

Grundstücksgrenze

eingehalten werden.

Diese Information steht im

Zusammenhang mit den

Anforderungen der

Maschinenl

sverordnung vom 18

Januar 1991.

Schalldruckpegel LP < 70

dB(A)

Am Arbeitsplatz

Normaler Betrieb

Nach DIN 45635 T. 19

(Typpr

Bei Betrieb des HP 5890

Serie II mit Cryo Ventil

Option treten beim Oeffnen

des Ventils impulsfoermig

Schalldrucke Lp bis ca. 78

dB(A) auf.

ärminformation

üfung)

Little Falls Site

Page 3

Contents

Chapter 1 — Columns and Fittings 9.................

Column oven 11..........................................................

Column placement 12.................................................

Packed column 12....................................................

Hewlett•Packardcapillary columns 13..................................

Fittings 14...............................................................

Liners/adapters and inserts, general 17....................................

Inlet/detector liners/adapters 20...........................................

Packed column inlet liners 20..........................................

Detector liners/adapters 22............................................

ECD and TCD adapters 23............................................

Liner/adapter installation 24..........................................

Inlet inserts 25...........................................................

Packed column inlet inserts 25.........................................

Split/splitlessor split•onlycapillary inlet inserts 27......................

Jet replacement, FIDs or NPDs 30.........................................

Metal capillary columns 30................................................

Chapter 2 — Keyboard and Displays 31...............

Displaying setpoints 33...................................................

Entering setpoints 34.....................................................

Keyboard operation, INET control 37......................................

Protecting setpoints 38...................................................

Loading default setpoints 39..............................................

Chapter 3 — Temperature Control 43.................

Valid setpoint ranges 46..................................................

Cryogenic (sub•ambient)oven control 47...................................

Programming oven temperature 49........................................

Oven status 50...........................................................

Oven safety 51...........................................................

Fault: messages 52.......................................................

After a power failure . . . 53...............................................

Oven temperature calibration 54..........................................

Page 4

Contents

Chapter 4 — Electronic Flow Sensing 57...............

Displaying gas flow rate 58...............................................

Designating gas type 59..................................................

Electronic flow sensor (EFS) calibration 60.................................

Preparation 61.......................................................

Setting the zero calibration value 61...................................

Setting the GAIN calibration value 63..................................

Entering specific ZERO and GAIN values 65............................

Chapter 5 — Signal Output 67........................

Zeroing signal output 68..................................................

Displaying current setpoint 69........................................

Self• setpoint 70......................................................

User•defined setpoint 72..............................................

Signal attenuation 72.....................................................

Displaying current

RANGE 2!()

Entering / setpoints 76..............................................

Switching off the +1 mV output 76.....................................

Test signal output 77.....................................................

Instrument network (INET) 79............................................

The controller 79.....................................................

An instrument 81.....................................................

Active workspace 82..................................................

HP 5890 INET states 82...............................................

INET operation 83....................................................

Automatic INET reconfiguration 85....................................

INET configuration 85....................................................

Switching between Global and Local 86.................................

INET/HP•ILaddresses 87.............................................

HP•ILloopback test 90...................................................

Warn: and fault: messages 92.............................................

File compatibility with data handling devices 94............................

What are the modes? 94...............................................

What is the proper mode for my data handling device? 94................

How do I know in which mode my GC is configured now? 94..............

How do I change modes? 95............................................

How to convert HP 339X Integrator workfiles from 5890A

to SERIES II mode: 97.............................................

ATTN 2!()

/

setpoints 75..............

Page 5

Contents

Chapter 6 — Inlet Systems 99.........................

Packed column inlet 100...................................................

Electronic flow sensor 102..............................................

Septum•purgedpacked column inlet 103.................................

Problems at high inlet temperatures 104.................................

A thermally optimized high•temperatureinlet 104........................

Septum purge 105.....................................................

Electronic flow sensor 106..............................................

Split/splitlesscapillary inlet 107............................................

Carrier gas considerations 108..........................................

Initial column head pressure 110........................................

Split sampling 111.....................................................

Splitless sampling 114.................................................

Injection technique, split/splitless sampling 121..........................

Chapter 7 — Detector Systems 123.....................

Capillary makeup gas flow rate 124.........................................

FID and NPD jets 125.....................................................

Flame ionization detector (FID) 126.........................................

FID flameout problems 128.............................................

Nitrogen•phosphorusdetector (NPD) 129....................................

Performance considerations 132.........................................

Electron capture detector (ECD) 135........................................

Requirements for USA owners 135......................................

Temperature 140......................................................

Background level 141..................................................

Thermal conductivity detector (TCD) 143....................................

Optimizing performance 146............................................

Analyzing for hydrogen, special considerations 148.......................

TCD•to•FIDseries connection 149.......................................

Filament passivation 149...............................................

Capillary column considerations 150....................................

Flame photometric detector (FPD) 151......................................

Optimizing FPD sensitivity and selectivity 151...........................

Flame ignition problems 153............................................

Page 6

Contents

Chapter 8 — Preventive Maintenance 155..............

Conditioning columns 156..................................................

(Re)Packing columns 158..................................................

Packed column inlet 159...................................................

Changing septa 159....................................................

Insert/liner care 160...................................................

Leaks 160.............................................................

Cleaning 162..........................................................

Split/splitlesscapillary inlets 163...........................................

Changing septa 163....................................................

Insert care 164........................................................

Leaks 165.............................................................

Cleaning 168..........................................................

Liner and/or insert care 169................................................

Glass inserts 169......................................................

Repacking a split insert 170............................................

Metal inserts and/or liners 171..........................................

Flame ionization detector (FID) 171.........................................

Jet exchange/replacement 172..........................................

Cleaning 173..........................................................

Ignition problems 177..................................................

Nitrogen•phosphorusdetector (NPD) 178....................................

Cleaning 178..........................................................

Removing/replacing the NPD collector 181...............................

Type B NPD transformer/collector assembly 184..........................

Reinstallation 186.....................................................

Electron capture detector (ECD) 188........................................

Frequency test 188....................................................

Carrier gas evaluation 188.............................................

Leaks 189.............................................................

Thermal cleaning 190..................................................

Packed column: 191....................................................

Capillary column: 191..................................................

Radioactivity leak test (wipe test) 192...................................

Thermal conductivity detector (TCD) 192....................................

Cleaning 192..........................................................

Flame photometric detector 193............................................

Cleaning/replacing FPD windows, filters, seals 193.......................

Cleaning/replacing the FPD jet 197.....................................

FPD leak testing (GC with electronic flow sensor) 198....................

FPD leak testing (GC without electronic flow sensor) 199.................

Conditioning chemical traps 200............................................

Page 7

Contents

Chapter 9 — Chromatographic Troubleshooting 201......

Introduction 202..........................................................

Baseline symptoms 202....................................................

Position 202...........................................................

Wander and drift 203..................................................

Noise 204.............................................................

Spiking 206...........................................................

Retention time symptoms 207..............................................

Retention time drift 207................................................

Retention time wander (reproducibility) 207.............................

Peak symptoms 209.......................................................

No peaks 209..........................................................

Inverted peaks 209....................................................

Extra peaks 209.......................................................

Deformed peaks 211...................................................

Troubleshooting valve systems 214..........................................

Chromatographic symptoms 214........................................

Locating leaks 216........................................................

Pressure check 217........................................................

Electronic pressure control 218.............................................

Safety shutdown 219...................................................

Proper configuration 220...............................................

Switch setting examples 221............................................

Chapter 10 — Test Sample Chromatograms 223........

Test sample chromatograms 225............................................

Index 241.............................................

Page 8

This page intentionally left blank.

Page 9

1

Columns and Fittings

Page 10

Columns and Fittings

The HP 5890 SERIES II (hereafter referred to as HP 5890) provides

flexibility in choices among inlets, columns, and detectors through use of

liners and adapters, allowing any standard column to be used without

sacrificing performance. Additionalflexibility is gained through positions

of inlets and detectors relative to each other and through the large

internal volume of the oven.

This section provides information for the following:

C

The column oven.

C

Fittings.

C

Liners and inserts.

C

ECD and TCD capillary makeup gas adapters.

The first three items must be considered before a column may be

installed properly at either an inlet or a detector. In addition, for an FID

or NPD, and depending upon the column to be installed (packed versus

capillary), the correct jet must be installed before installing the column.

Jet installation is described in Chapter 8, Preventive Maintenance.

10

For specific information on ordering fittings, liners, and inserts, see

Hewlett•Packard's analytical supplies catalog.

Page 11

Columns and Fittings

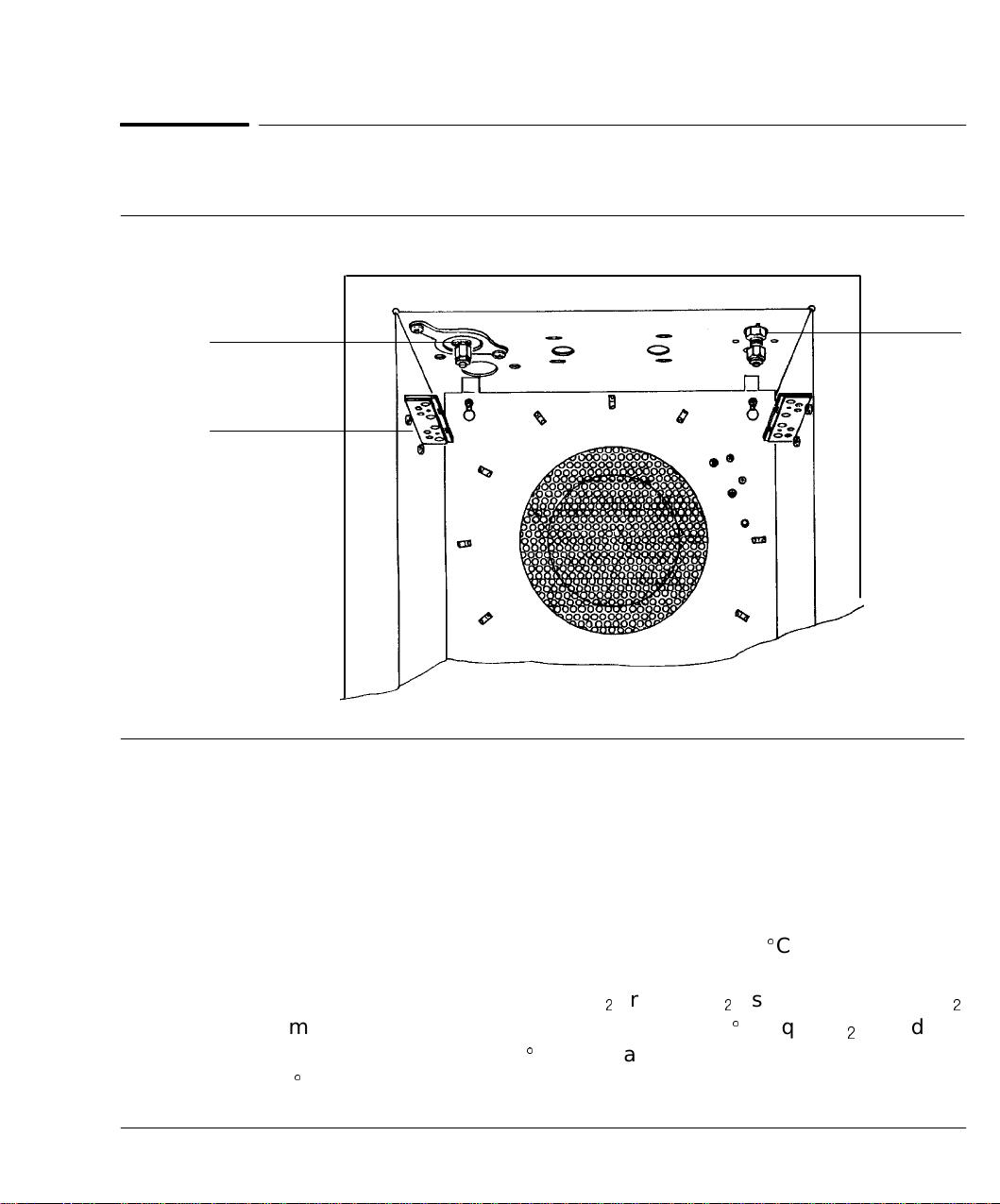

Column oven

Column oven

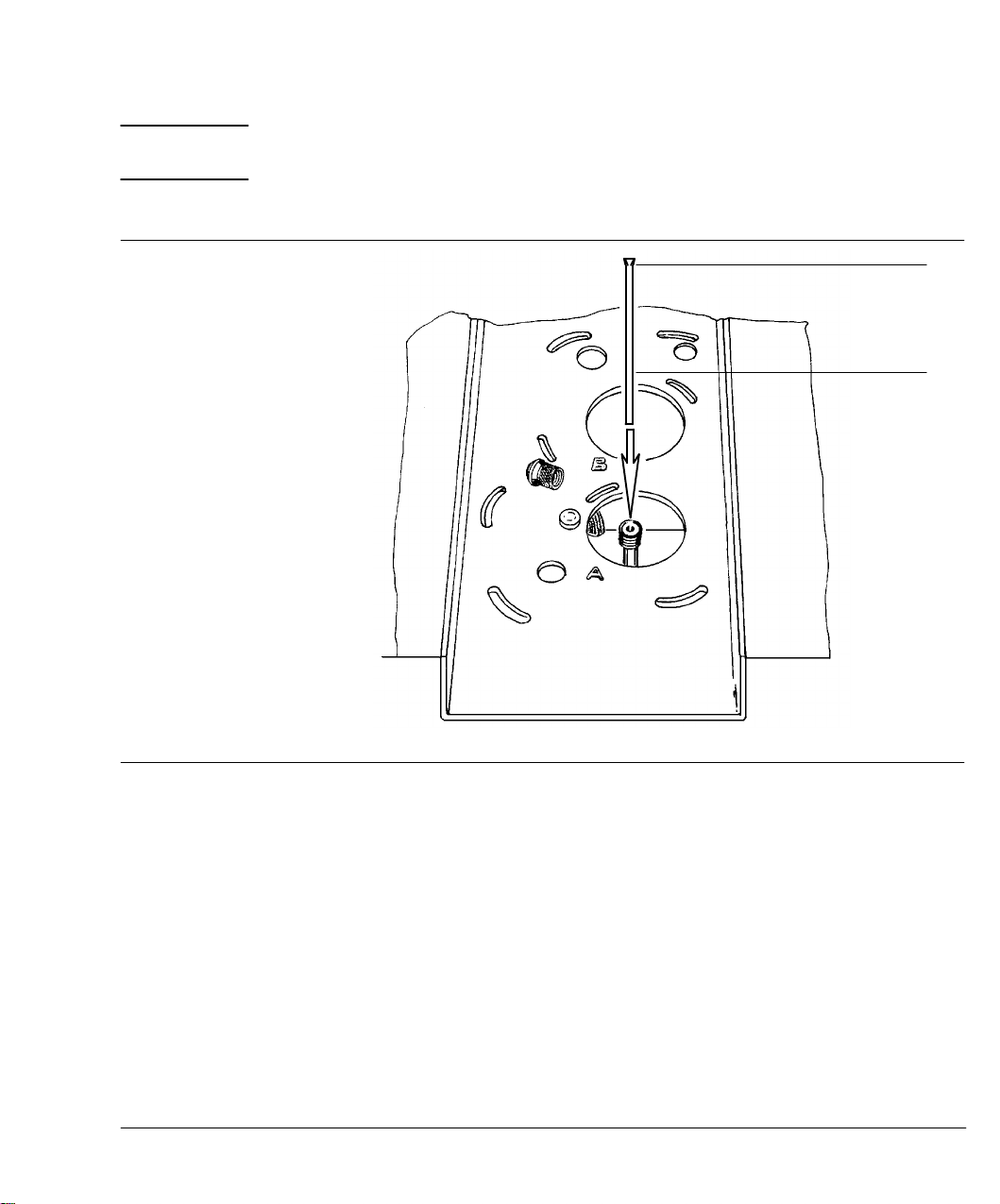

Figure 1-1

Inlet Ftg

Nut Plate

The Column Oven

The oven door latch, located beneath the lower right corner of the door, is

pressed upward to open the door.

Motor•drivenflapsat the rear of the oven admit room air for cool down or

near•ambientoperation, so the door is kept closed except for access to

columns (the oven cools most efficiently with its door closed).

Det Ftg

The oven can maintain temperature down to about 7

^

C above ambient

without auxiliary cooling. If lower temperatures are required, a

cryogenic valve (for either liquid CO

1

or liquid N1) is needed. Liquid CO

permits reliable temperature control down to -50^C; liquid N1provides

reliable control down to -80

450

^

C.

^

C. The maximum oven temperature is

1

11

Page 12

Columns and Fittings

Column oven

Column placement

Generally, a column may be installed between any inlet and detector.

A rigid1/4•inchpacked glass column, however, if installed in the B

(rear•most)inlet, can only be installed in the B (rear•most)detector.

Distance relationships among inlets and detectors are shown in

Figure 1•2.

Figure 1-2

Top View

(showing relationshipof inlets to detectors)

B

A

Front

Installation Restrictions, Rigid Columns

1mm

228 +

B

A

12

Packed column

Packed columns require no physical support other than that provided by

proper installation at inlet and detector fittings.

Page 13

Columns and Fittings

Column oven

Hewlett-Packard capillary columns

Hewlett•Packardcapillary columns are wound on wire frames which

mount on a pair of brackets which slip into slots at the top of the oven

interior.

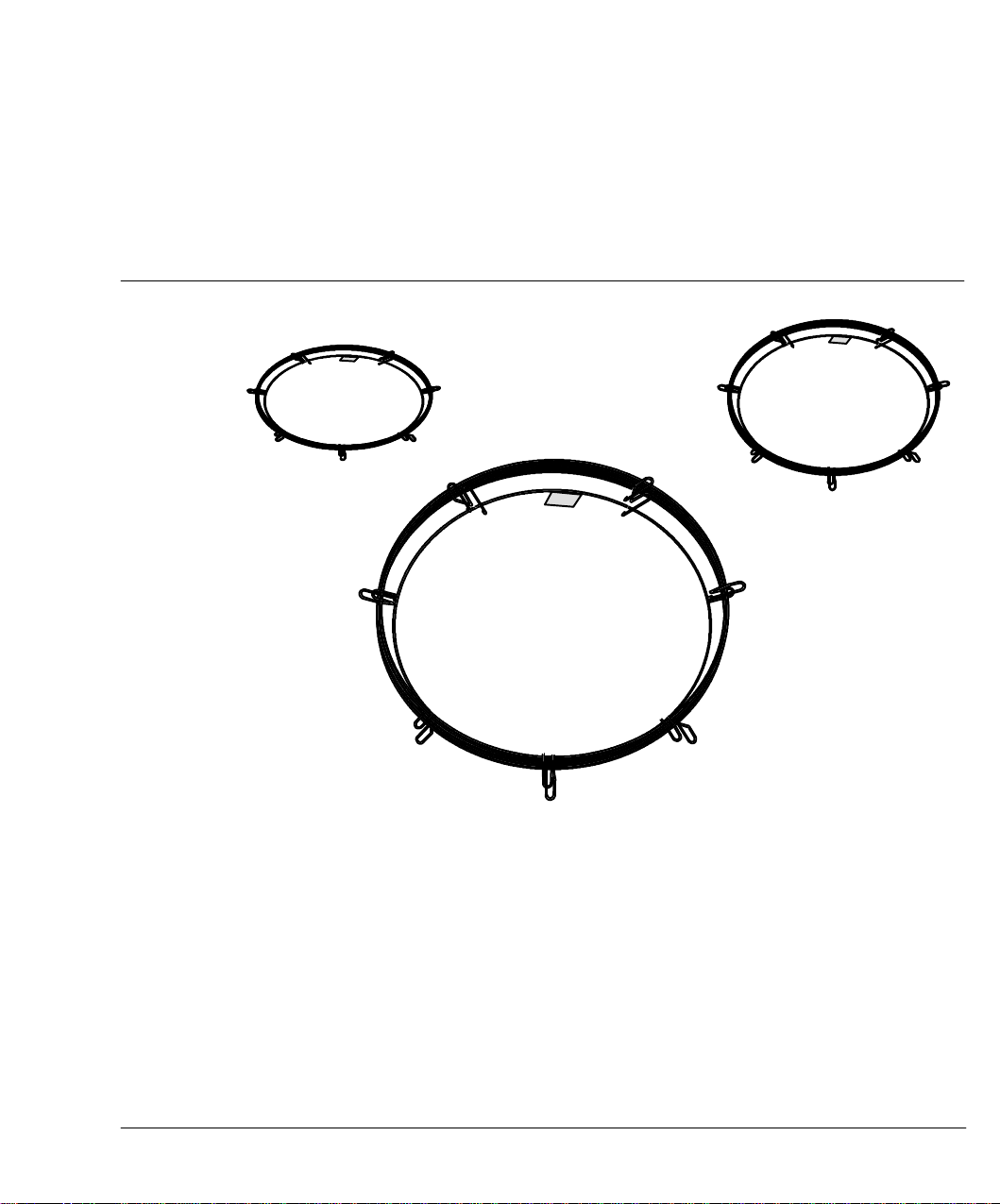

Figure 1-3

Typical Hewlett-Packard Capillary Columns

13

Page 14

Columns and Fittings

Fittings

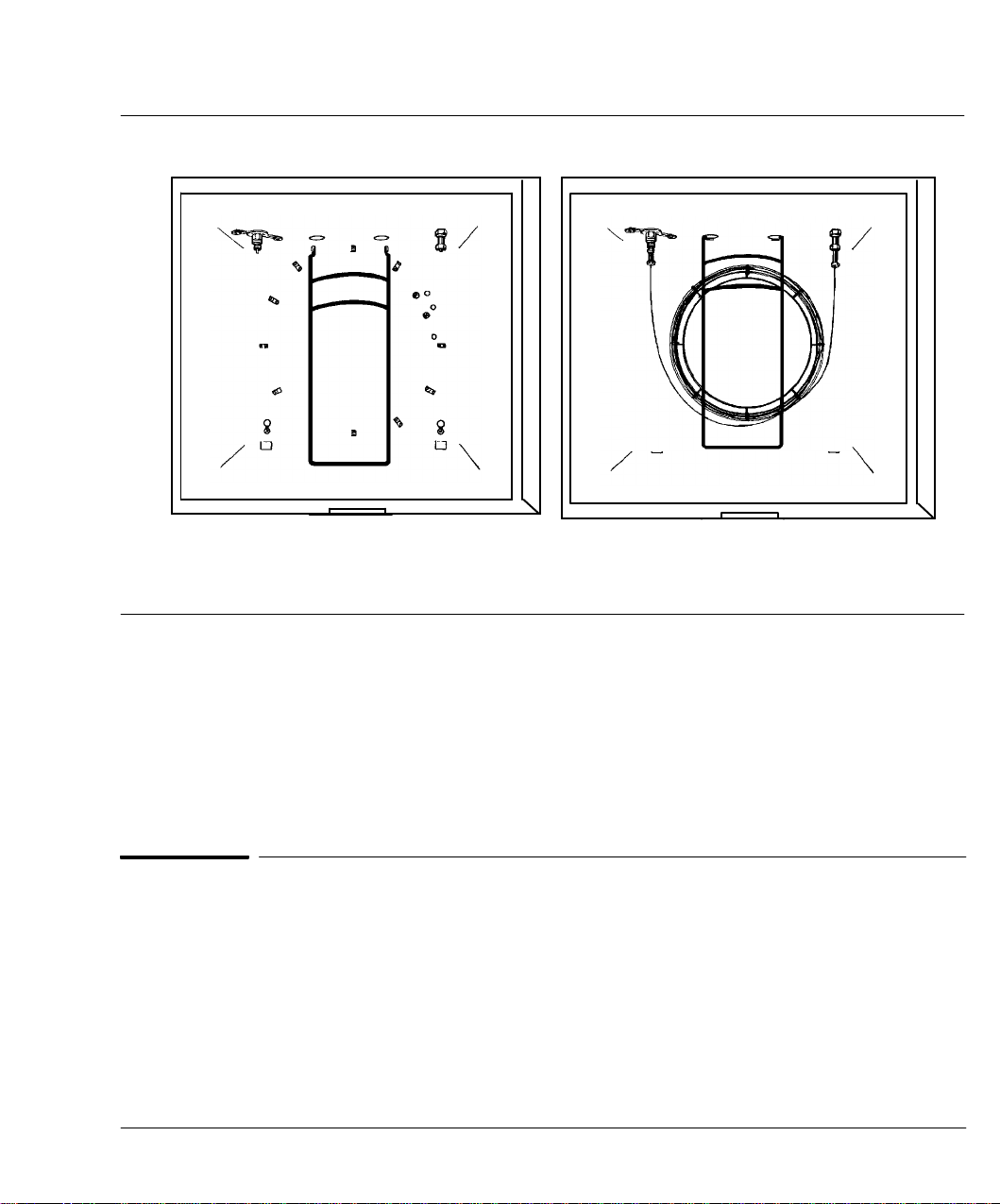

Figure 1-4.

Column Hanger

Part No. 1460-1914

Installed Bracket for Hewlett-Packard Capillary Columns

Column Installed

The bracket has two positions from which to hang the column wire frame.

Depending upon frame diameter, use the position which best centers the

column in the oven. Column ends should come off the bottom of the

frame, making smooth curves to inlet and detector fittings. Avoid

allowing any section of the column itself to come in contact with oven

interior surfaces.

Fittings

The following is a brief comparison of common types of fittings (nuts,

ferrules, O•rings)used to install columns, and to install inlet and detector

liners and/or inserts. Each type has its own set of advantages and

disadvantages:

14

Page 15

Columns and Fittings

Fittings

C

C

C

Graphite O•ringsor ferrules have excellent sealing quality and long

service life, can be used continuously to 400

^

C, and are generally

recommended for most applications, particularly capillary and glass

columns. They are also recommended for inlet and detector liners, and

for split/splitlesscapillary inlet inserts.

Since they do not adhere permanently to glass or metal, they can be

removed easily without damage to the column, tubing, liner, or insert.

A rear metal ferrule may be needed if recommended by the

manufacturer.

Commonly used with metal columns and tubing, brass nuts and

ferrules on the column prevent damage to inlet and detector liners,

but may develop leaks above 250

^

C or with temperature

programming.

Also commonly used with metal columns and tubing, stainless steel

fittings minimize possibility of leakage at high temperature, but

require care in installing columns; overtightening may damage the

column end or inlet/detector fitting.

C

Teflon ferrules may be used to 250^C but are recommended only for

isothermal work, because they develop leaks when

temperature•programmed.

C

Commonly used with glass columns, Vespel (or graphite•filledVespel)

ferrules are reusable and work well to 350

^

C. These ferrules may

leak or crack if tightened when cold.

C

Glass columns can be installed using silicone O•rings. For O•ring

installation, a back metal ferrule, reversed, is necessary to provide a

flat surface to seal against.

Silicone O•ringsare useful to about 250

^

C, but, due to bleed, interfere

in high•sensitivitywork. They also gradually lose elasticity and crack,

so they must be replaced fairly often.

15

Page 16

Columns and Fittings

Fittings

Table 1-1. Typical Fittings for Columns and Inlet/Detector Liners, Adapters, and Inserts

Type Description Typical Use Part No.

1/4-inch swage, nut 1/4-inch packed metal columns 5080-8753

stainless steel, front ferrule

pkg, 20 of each back ferrule

1/8-inch swage, nut 1/8-inch packed metal columns 5080-8751

stainless steel, front ferrule

pkg, 20 of each back ferrule

1/4-inch swage, nut 1/4-inch packed metal columns 5080-8752

brass, pkg, front ferrule

20 of each back ferrule

1/8-inch swage, nut 1/8-inch packed metal columns 5080-8750

brass, pkg, front ferrule

20 of each back ferrule

Vespel, 1/4-inch ferrule inlet/detector liners, 5080-8774

pkg of 10 1/4-inch glass packed columns

Vespel, 1/8-inch ferrule metal columns 0100-1107

pkg of 10

graphite, 1.0-mm ferrule capillary columns 5080-8773

pkg of 10

graphite, 0.5-mm ferrule capillary columns 5080-8853

pkg of 10

graphite 6.35-mm O-ring inlet/detector liners, 0905-0767

1/4-inch glass packedcolumns,

split capillary inlet insert

graphite 6.52-mm O-ring splitless capillary inlet insert (use) 0905-1004

silicone 6.0-mm O-ring inlet/detector liners 0905-0322

1/4-inch glass packedcolumns,

split/splitless capillaryinlet inserts

silicone 1.0 mm O-ring capillary columns 0905-0759

Note: Dimensions given are id’s of the O-ring or ferrule.

16

Page 17

Columns and Fittings

Liners/adapters and inserts, general

Liners/adapters and inserts, general

A liner/adapter is installed from below, inside the oven; it serves both as

an adapter to mate the particular column to the inlet or detector and to

provide correct internal volume for proper operation.

Inserts are used with inlets only, and, when required, are installed from

above, at the top of the inlet; these are discussed specificallylater in this

section (see Inlet inserts).

In general, the analysis to be performed determines the column to be

used. The column then dictates hardware required for the inlet and

detector (liner, insert, adapter, jet (FID or NPD)).

Note:

C

A correctly designed 1/4•inchpacked glass column requires no liners

since the column ends themselves serve this purpose.

C

The appropriate liner/adapter, and insert if required, must be

installed prior to installing a column.

Tables 1•2and 1•3summarize hardware required for various

combinations of inlets, columns, and detectors.

17

Page 18

Columns and Fittings

Liners/adapters and inserts, general

Table 1-2. Hardware and Recommended Fittings for Packed Column Installation

Packed Columns

1/8-inch Metal 1/4-inch Metal 1/4-inch Glass

Recommended 1/8-inch 1/4-inch 1/4-inch swage-

Column Fittings swage-type nut swage-type nut type nut and

and ferrules

3

and ferrules

3

graphic ferrule or

silicone O-ring(s)

Packed Column 19243-80510

1

19243-80520

1

Inlet Liners or or

19243-80530

1

19243-80540

1

(requires glass insert) (requires glass insert)

FID/NPD

2

19231-80521

1

19231-80530

1

Liners/Adapters

TCD Liners/Adapters None 19302-80020

ECD Liner/Adapters 19301-80530

1

Use 1/4-inch swage-typenut and Vespel or graphite ferrule to install liner/adapter.

2

See Chapter8 for details regardingjet exchange(if necessary).

3

See information later in this chapter regarding proper installation of swage-type fittingson packed

metal columns.

1

None None

1

None

None

19302-80020

(may require

altering the

column)

1

18

Page 19

Columns and Fittings

Liners/adapters and inserts, general

Table 1-3. Hardware and Recommended Fittings for Capillary Column Installation

Capillary Columns

HP Series 530

¿

320¿m ID 200¿m ID Metal/

Glass

Recommended Capillary column Capillary column Same as 320¿m Same as

Column Fittings nut and 1.0-mm nut and 0.5-mm HP Series

graphite ferrule, or graphite or 530

¿

silicone O-ring(s) silicone O-ring(s)

Packed Column 19244-80540

1

Not Not Not

Inlet Liners (requires glass Recommended Recommended Recom-

insert) mended

Split/Splitless & 18740-60840 Same Same Same

Split-Only with graphiteor

Capillary Inlet silicone O-ring

Split Sampling

Split/Splitless 18740-80220 Same Same Same

Capillary Inlet with graphite or

Insert: Splitless silicone O-ring

Sampling

Programmable 19245-20580

3

19245-20520 19245-20510 19245-

On-Column 20550

Capillary Inlet

Insert

FID/NPD

2

19244-80550

1

Same Same Same

Liners/Adapters

TCD 18740-20950 19232-80550

1

Same Same

Liners/Adapters and

18740-20960

ECD 19244-805501,

3

3

19233-80530 Same Same

Liners/Adapters

1

Use 1/4-inch swage-typenut (if a nut is notsuppliedas part ofthe adapter) and graphite or Vespel ferrule to

install liner/adapter.

2

0.11-inch jet must beused; see Chapter8 for informationregarding jet exchange (if necessary).

3

Use only if detector is not configured with capillary makeupgas adapter. If makeup adapter is provided,it is

used instead (usually with makeup gas turnedoff).

19

Page 20

Columns and Fittings

Inlet/detector liners/adapters

Inlet/detector liners/adapters

Interchangeable stainless steel liners/adapters, installed from inside the

oven, are used with the packed column inlet, and with all detectors,

depending upon the column to be installed.

Packed column inlet liners

Figure 1-5

20

Liner

Installed Liner, Packed Column Inlet

Liners for the packed column inlet are available in three sizes: one for

1/8•inchcolumns, one for 1/4•inchcolumns, and one for HP Series 530

capillary columns.

¿

Page 21

Columns and Fittings

Inlet/detector liners/adapters

In addition, liners for the packed column inlet are available to accept

glass inserts (discussed later) for reduced reactivity, to trap nonvolatile

residues, or for use with an HP Series 530

C

No liner is used with 1/4•inchpacked glass columns. The long leg of

the column fits into the inlet body, replacing the liner. Packing and

glass wool plug must be below the tip of the needle for best results.

C

Metal columns are installed with a liner appropriate for the column

diameter.

C

If necessary, glass columns can be installed using a metal liner

(preferably those accepting a glass insert), but this is not

recommended. There may be problems with dead volume in

connections, and preventing contact of sample with metal surfaces.

¿

capillary column.

21

Page 22

Columns and Fittings

Inlet/detector liners/adapters

Detector liners/adapters

Figure 1-6

Liner/Adapter

22

Typical Installed Detector Liner/Adapter

Detectors require a liner/adapter to be installed when used with packed

metal columns (either 1/8•or 1/4•inch),and with any type of capillary

column. Normally, no liner is required with 1/4•inchpacked glass

columns, since the leg of the column itself serves as the liner.

For the FID or NPD, the correct detector jet must be installed prior to

installation of the liner. (If jets must be exchanged, see Chapter 8,

Preventive Maintenance.)

Page 23

Columns and Fittings

Inlet/detector liners/adapters

ECD and TCD adapters

A makeup gas adapter must be installed in the ECD or TCD base to

install a capillary column, and to augment carrier flow through the

column with additional gas flow needed for optimal detector operation.

The adapter must be removed for packed column applications.

In addition, to install an HP Series 530

¿

capillary column in an ECD or

TCD having no capillary makeup gas adapter, the following adapters are

used: Part No. 19244•80550for the ECD, and Part No. 18740•20950and

18740•20960for the TCD.

Finally, to use a 1/4•inchcolumn with the TCD (having a base designed

for 1/8•inchcolumns), a 1/8•to 1/4•inchadapter is required (Part No.

19302•80020). For the ECD (having a base designed for 1/4•inch

columns), to use a 1/8•inchcolumn, a 1/4•to 1/8•inchadapter is required

(Part No. 19301•80530).

23

Page 24

Columns and Fittings

Inlet/detector liners/adapters

Liner/adapter installation

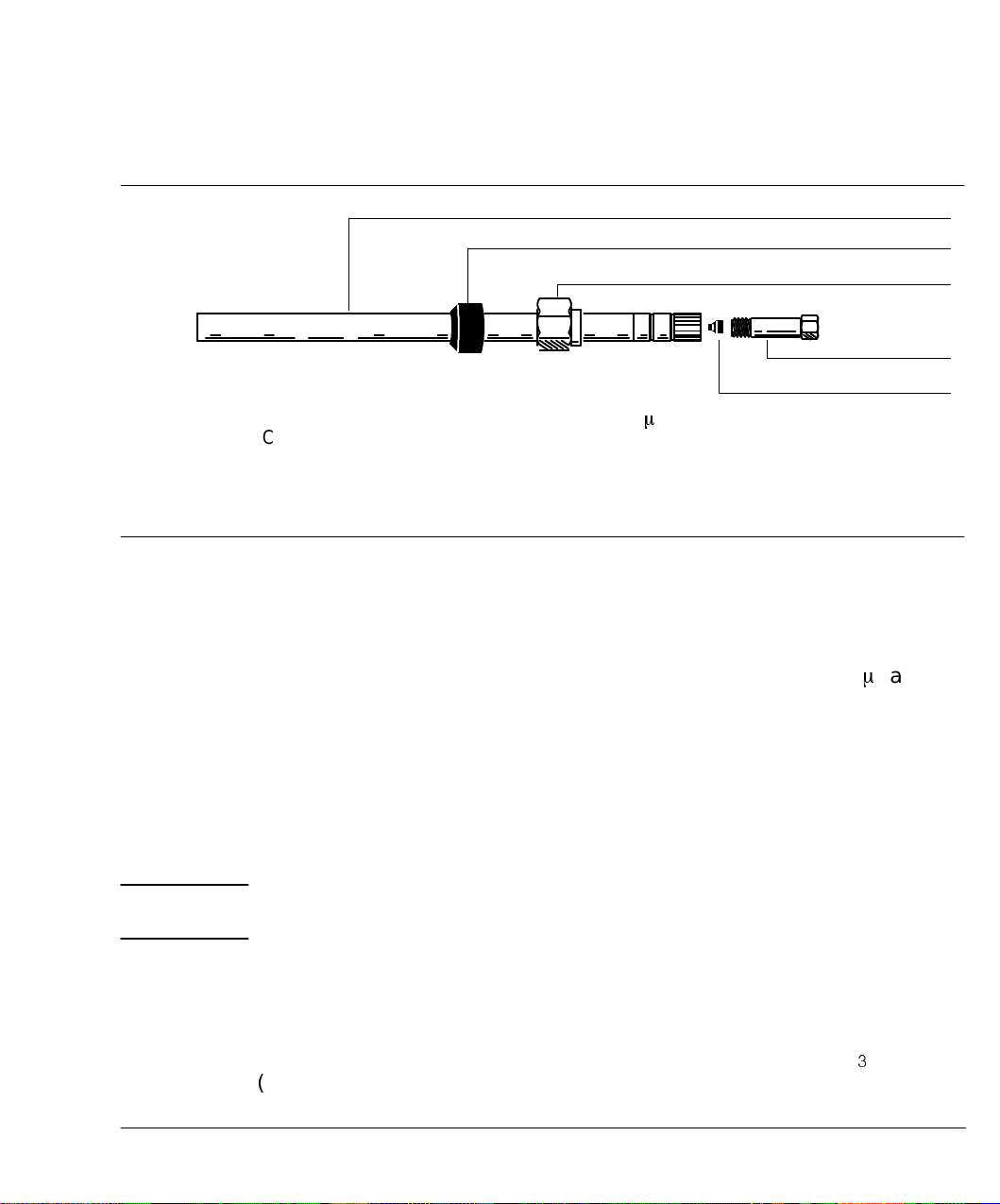

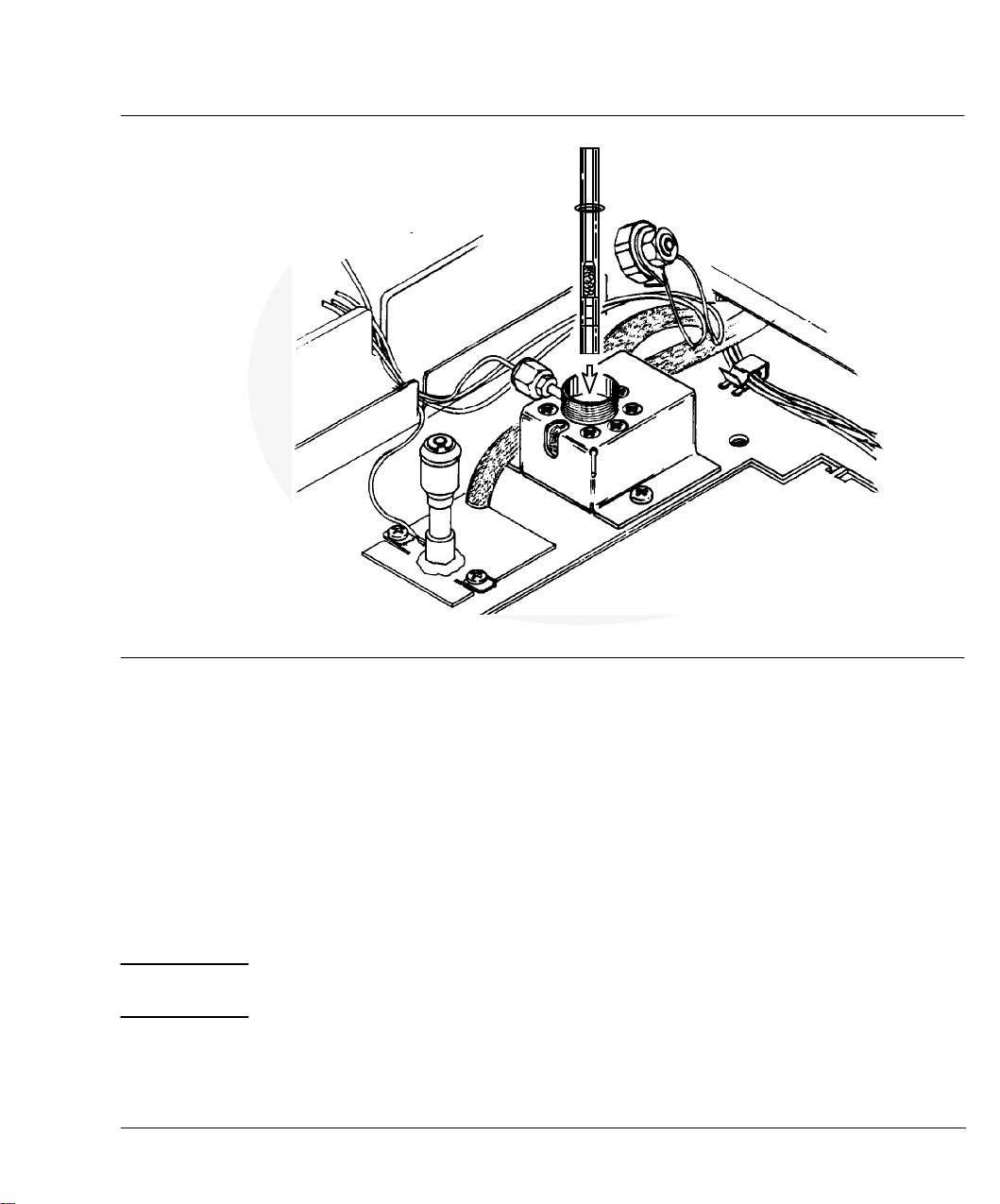

Figure 1-7

Liner

1/4-inch Ferrule

Liner Retainer Nut

Capillary Column Nut

WARNING

Packed Column Inlet Liner for HP Series 530

Capillary Column Use

Nut and Ferrule Installed on a Liner/Adapter

¿

1-mm Graphite Ferrule

With one exception, liners/adapters are installed in the same manner;

if the liner/adapter has not been used before, a new ferrule must be

installed.

¿

The single exception is the adapter to install an HP Series 530

capillary

column in a TCD without provision for capillary makeup gas (Part No.

18740•20950and 18740•20960). In this case, no ferrule is required to

form a seal with the detector base.

Note: A graphite ferrule is strongly recommended; since metal ferrules

tend to lock permanently onto the liner/adapter, their use may require

replacing the entire liner/adapter, should a permanent leak develop.

Exercise care! The oven, and/or inlet or detector fittings may be hot

enough to cause burns.

24

Note: The liner/adapter must be kept as clean as possible to prevent

introducing contamination into the inlet or detector. Use a clean,

lint•freecloth to remove fingerprints, etc., from the end of the

liner/adapter to be inserted into the inlet or detector base. CH

2

OH

(methanol) may be used as a solvent.

Page 25

Columns and Fittings

Inlet inserts

1. Assemble a brass nut and graphite ferrule onto the liner/adapter.

2. Insert the liner/adapter straight into the detector base as far as

3. Holding the liner/adapter in this position, tighten the nut finger•tight.

4. Use a wrench to tighten the nut an additional 1/4 turn.

5. Install the column; then heat the oven, inlet, and detector to desired

Inlet inserts

Inserts are used in inlets, and can be installed from the top of the

particular inlet.

Packed column inlet inserts

possible.

operating temperatures and, only if necessary to stop leaks, tighten

fittings further.

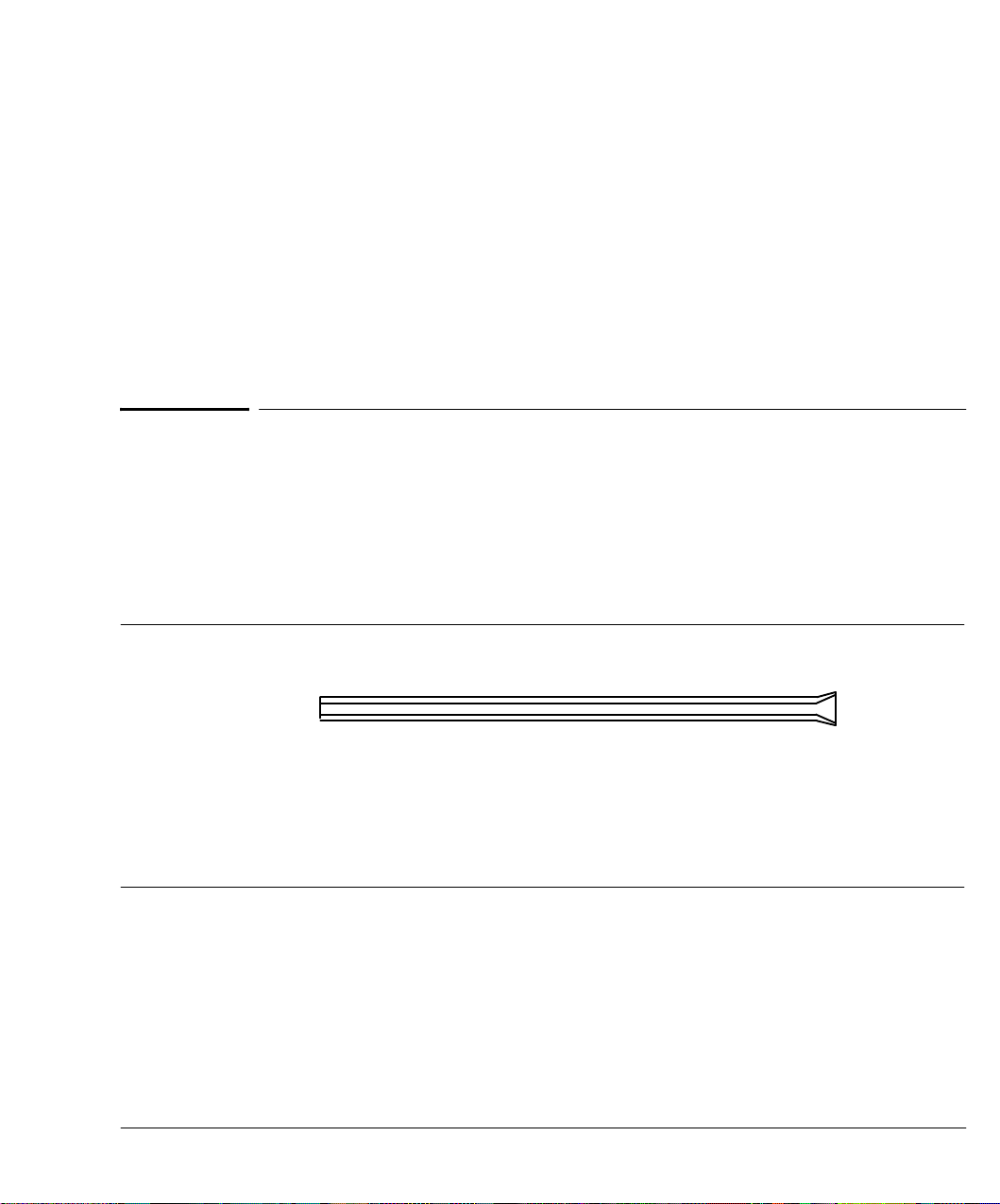

Figure 1-8

Flared End

Glass Insert for Packed Column Inlet Liner

Assuming the correct inlet liner is installed, a glass insert is installed as

described on the next page.

25

Page 26

Columns and Fittings

Inlet inserts

WARNING

Figure 1-9

Exercise care! the oven, and/or inlet, or detector fittings may be hot

enough to cause burns.

Flared End

Insert

26

Installing a Glass Insert in a Packed Column Inlet

1. In handling the insert, avoid contaminating its surface (particularly

its interior).

2. Remove the septum retainer nut and septum.

3. Carefully remove the old insert (if present) by withdrawing it straight

up. A match stick or similar fibrous item may be used as an aid in

lifting the insert from the inlet.

4. Install the new insert by dropping it carefully, straight into the inlet

liner, flared end up.

Page 27

Columns and Fittings

Inlet inserts

Note: For the liner and insert for an HP Series 530¿capillary column, if

the column is already installed, a new insert may not seat properly in the

liner; the column may prevent it from dropping completely into the liner.

If the insert does not drop completely into the liner, do not force it

(either the liner or the column may shatter); instead, remove the column,

seat the insert, and then replace the column.

5. Replace the septum and septum retainer nut.

Split/splitless or split-only capillary inlet inserts

Figure 1-10

Viton O-ring (Preferred)

Viton O-ring

Split Use Splitless Use

Split/Splitless and Split-Only Capillary Inlet and Inserts

A specific inlet insert is required, depending upon the particular

sampling mode. Specific sampling modes include:

C

Split, for major•componentanalyses

C

Purged splitless, for trace•componentanalyses

27

Page 28

Columns and Fittings

Inlet inserts

The split insert contains packing material (10% OV•1on 80/100 High

Performance Chromosorb•W),held in place by silanized glass wool plugs,

located immediately above a mixing chamber. This ensures proper

volatilization and homogeneous mixing of the sample prior to its entry

into the column.

WARNING

Caution

Exercise care! The oven, and/or inlet, or detector fittings may be hot

enough to cause burns.

If operating in split mode, carrier gas pressure must be reduced before

opening the inlet. If not done, pressure may blow insert packing out of

the inlet, altering its characteristics. Pressure is reduced at the

backpressure regulator for the inlet.

1. In handling the insert, avoid contaminating its surface (particularly

its interior).

2. Remove the insert retainer nut. The septum retainer nut need not be

removed from the insert retainer nut assembly.

28

Page 29

Columns and Fittings

Inlet inserts

Figure 1-11

Caution

Installation, Split/Splitless Capillary Inlet Insert

3. Using tweezers, forceps, or similar tool, remove any insert already in

place.

4. Inspect the new insert to be installed: For a split mode insert, the end

with the mixing chamber and packing is inserted first into the inlet.

5. Place a graphite or silicone O•ringon the insert, about 2 to 3 mm from

its top end.

6. Install the insert, pressing it straight down, as far as possible, into

the inlet.

Do not add any seal either at the bottom of the inlet or at the bottom of

the insert; to do so will damage the inlet and/or shatter the insert.

7. Replace the insert retainer nut, tightening it to firm finger•tightness

to form a leak•freeseal. Do not overtighten.

29

Page 30

Columns and Fittings

Jet replacement, FIDs or NPDs

Jet replacement, FIDs or NPDs

Depending upon the column type (packed versus capillary) to be used,

and/or analyses to be performed, exchanging the jet in an FID or NPD

may be necessary. This must be done prior to column installation, and is

particularly important in optimizing FID performance.

Exchanging the jet in either an FID or an NPD is described in Chapter 8,

Preventive Maintenance.

Metal capillary columns

Most metal capillary columns (0.6 to 1.0 mm od) can be connected

directly. Some metal capillaries have a large•diametersleeve soldered on

each end; this must be removed. Use a small triangular file to score the

tubing behind the sleeve; then bend the sleeve back and forth until it

breaks.

30

It is important to have fresh ends of the column, free of burrs, jagged

edges, and/or loose particles of column, stationary phase, and/or material

from a sealing ferrule or O•ring.

Therefore, whenever the column must be cut to provide fresh ends, use

a suitable file to first score the column at the point at which it is to be

broken. This is done normally after installing on the column the column

nut and ferrule (or O•ring)required for installation.

Page 31

2

Keyboard and Displays

Page 32

Keyboard and Displays

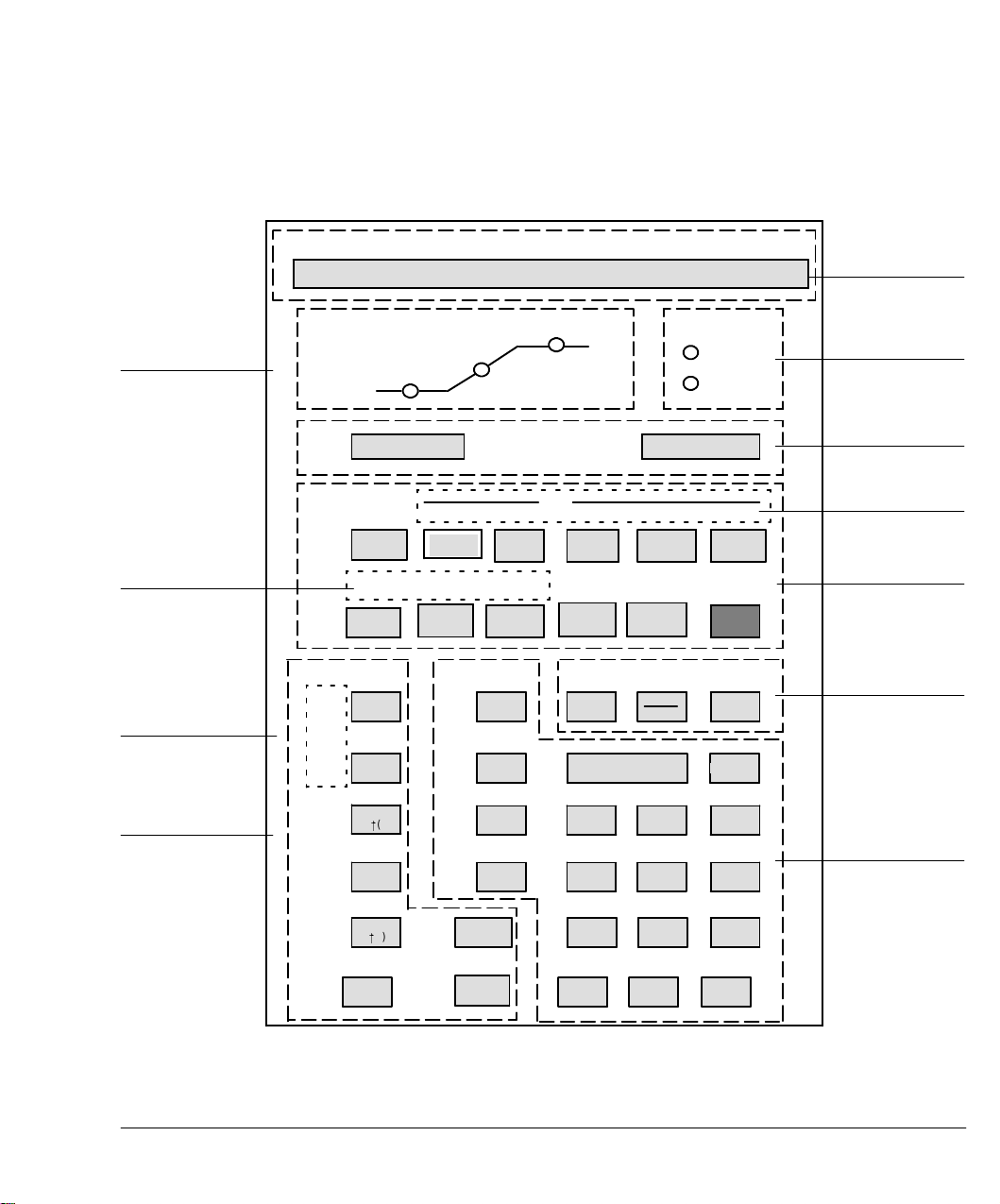

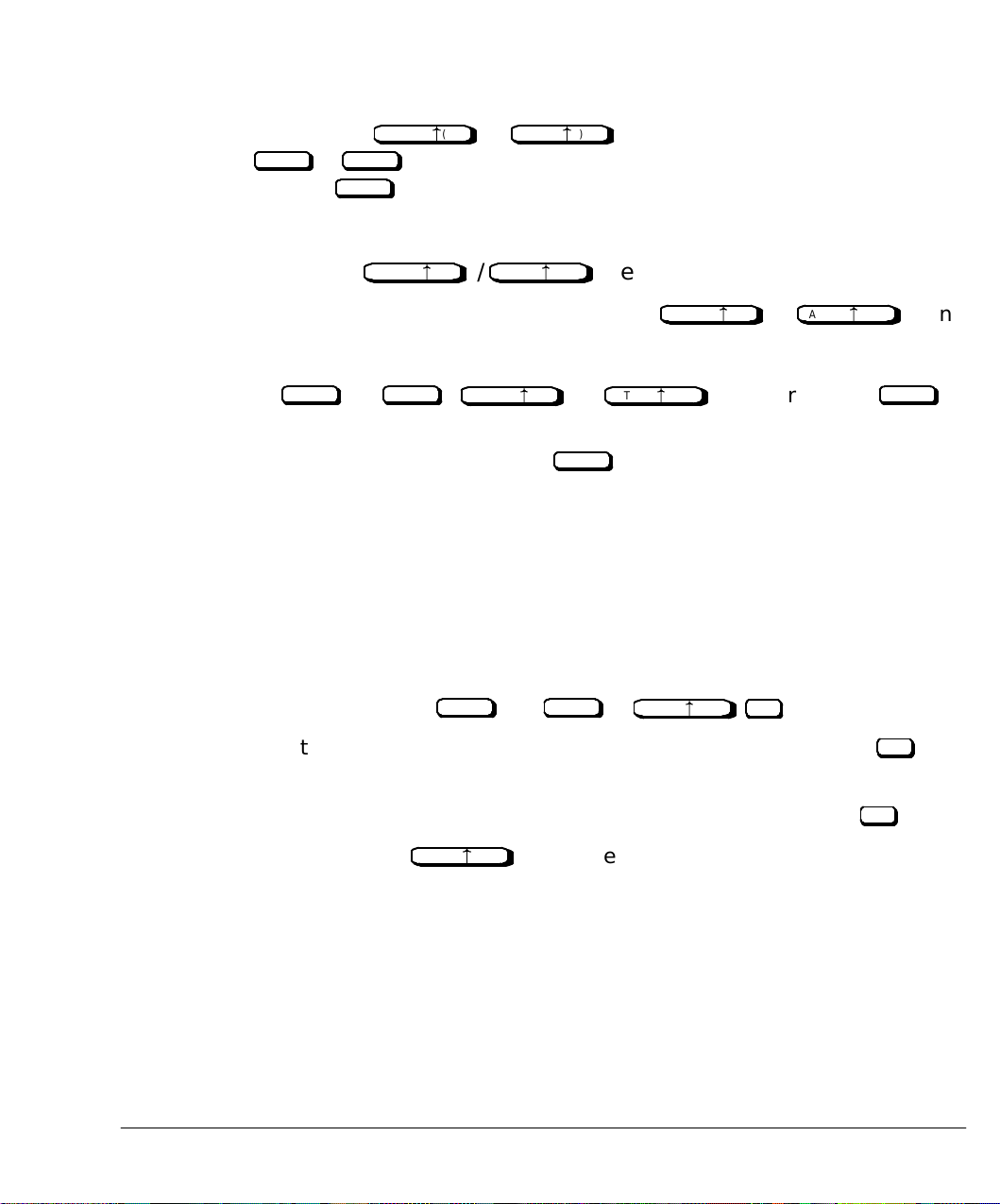

Figure 2-1

HP 5890 SYSTEM READY

OVEN

RATE

Oven Status

INITIAL

TIME

ACTUAL SETPOINT

STATUS

FINAL

TIME

RUN

NOT

READY

Alphanumeric

Display

Instrument

Status

Programmable

Cool on Column

Control

Setpoint

Storage

Control

Signal Definition

and Control

STORE

LOAD

TCD

SENS

STOP START

ON

OFF

A

B

IINIT

TIME

OVEN

TRACK

DET A

TEMP

TIME

RATE

AUX

TEMP

DET B

TEMP

FLOW CRYO

PARAM PARAM

FLOW TIME

ENTER

7 8 9

4

1 2 3

0

TABLE ADD DELETE PREVIOUS NEXT

OVEN

TEMP

PRES PRES

INJ A

TEMP

SIG 1

SIG 2

RANG

E2!()

ZERO

ATTN

2!()

DET

INIT

VALUE

INJ BINJ A

INJ B

TEMP

COL

COMP1

COL

COMP2

FINAL

VALUE

OVEN

MAX

EQUIB

TIME

PURGE

VALVE

.

FINAL

TIME

CLEAR

65

-

Run Control

Timetable

Control

Temperature

Control

Miscellaneous

Functions

Numeric and

Modifier Keys

32

HP 5890 SERIES II Keyboard and Display Panel

Page 33

Keyboard and Displays

Displaying setpoints

HP 5890 SERIES II (hereafter referred to as HP 5890) operation is

monitored and controlled through its front panel keyboard, and

alphanumeric and LED displays.

Some instrument functions are monitored continuously: signal levels,

temperatures, carrier gas flow rates (if electronic flow sensing is

installed), and inlet purge valve status (if a split/splitlesscapillaryinlet

is installed).

There are two general display areas:

C

Alphanumeric Display. Echoes keys pressed at the HP 5890

keyboard show current setpoint values for instrument functions;

actual values of continuously monitored instrument functions; and

warning, error, information, and diagnostic messages.

C

LED Display. Consists of two parts: the left half (OVEN) displays

oven status during a run; the right half (STATUS) gives overall

instrument status at any given time.

Figure 2-2

Displaying setpoints

Any particular instrument current value and/or setpoint is displayed at

the alphanumeric display simply by pressing the appropriate instrument

function key followed possibly by additional modifier" keys necessary to

further define the function (i.e.,

TIME

). For example, pressing

A

OVEN MAX

OVEN MAXIMUM 400

Example, a Typical Alphanumeric Setpoint Display

The name of the function key pressed is always displayed, along with the

current setpoint and/or measured values.

B

or

SIG 1

,

or

might give the display:

ACTUAL SETPOINT

SIG 2,ON

or

OFF

,

33

Page 34

Keyboard and Displays

Entering setpoints

Examples of possible displays are provided where appropriate throughout

the manual.

If a particular function is not installed in your instrument, an

appropriate message is displayed when the key corresponding to the

function is pressed. For example, if no heated zone controlled by

DET B TEMP

Figure 2-3

Typical Display, a Function NOT Installed in the Instrument

Entering setpoints

is installed, pressing

DET B TEMP

ACTUAL SETPOINT

DET B NOT INSTALLED

gives the display:

34

To enter a setpoint value for a particular instrument function, the

function is first displayed by pressing the appropriate key(s).

Once the chosen HP 5890 function is displayed, a new setpoint value can

be entered at any time by pressing appropriate keys

.

-

,

, or possibly

A

,

B,ON

,or

OFF

. For a numeric value,

0

through

9

ENTER

,

is pressed to terminate the entry. Figure 2•4summarizes the two steps

involved.

Page 35

Keyboard and Displays

Entering setpoints

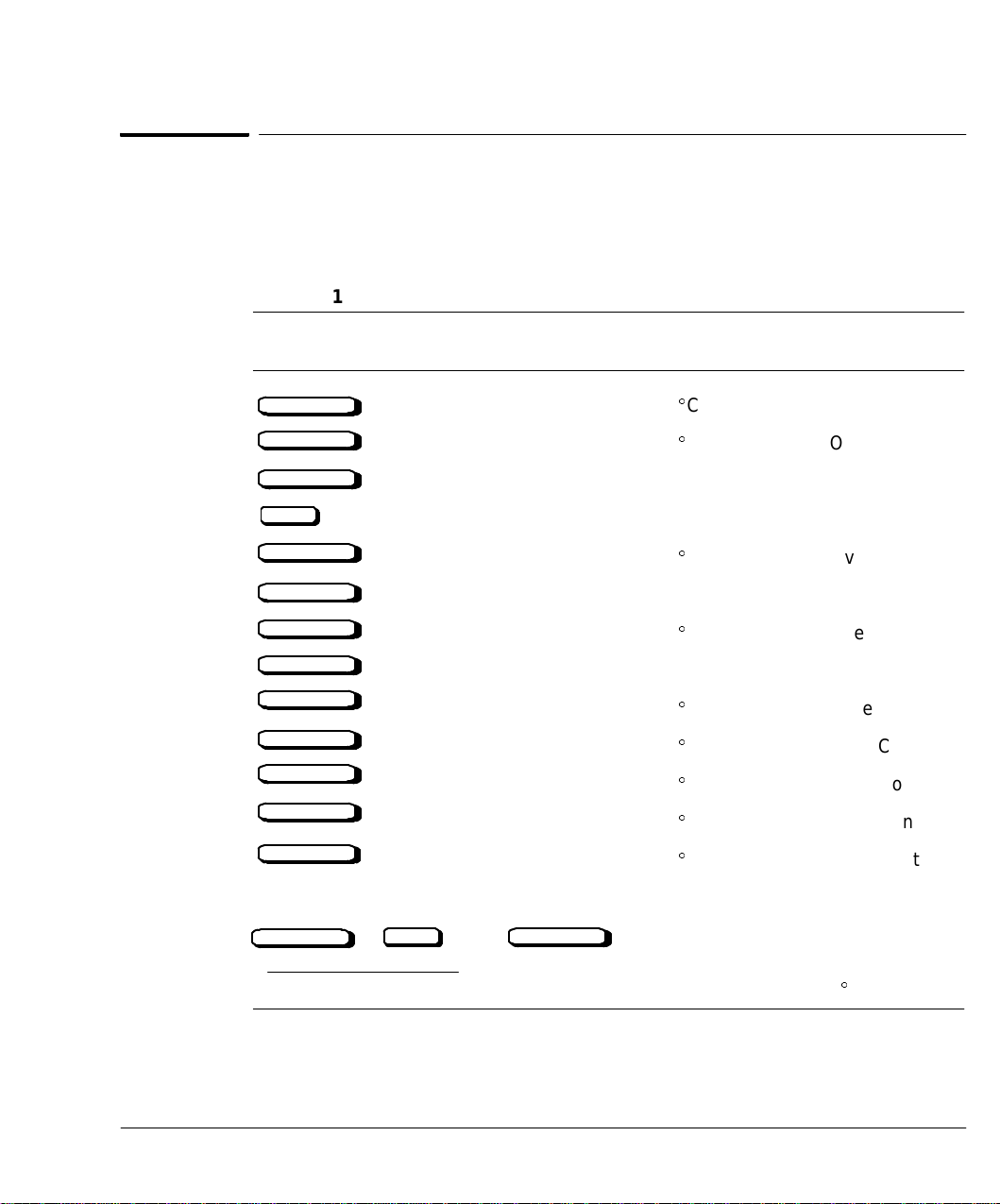

To display the function and its setpoint:

Figure 2-4

(Instrument Function Key) ( or )

A B

necessary for a few

instrument functions

then, EITHER

0 9

( through , , )

-

.

ENTER

to enter a new setpoint value

OR, for a few functions,

ON

(or)

OFF

to switch the function on or off

Steps in Entering a Setpoint Value

For example, to set the A detector zone to 250^C, the following sequence

of keys is pressed:

DET A TEMP

2

5

0

ENTER

function key numeric key(s)

Once detector A temperature is displayed by pressing

DET A TEMP

, the

new setpoint value may be entered at any time thereafter.

Note that the display shows a flashing * (asterisk) while the new

setpoint is entered, disappearing when

When

ENTER

is pressed, the setpoint value is verified and, if satisfactory,

ENTER

is pressed.

becomes the new setpoint for the function. If the entered value is not

satisfactory (out of range, or inconsistent with other, related setpoints),

an appropriate message is displayed. A different value may be entered

immediately, without again pressing the particular function key.

35

Page 36

Keyboard and Displays

Entering setpoints

CLEAR

can be used anytime during an entry, prior to pressing

ENTER

,to

erase the entry in progress. The * disappears, and the original setpoint

display is restored.

Rules regarding keyboard usage are summarized below:

C

An instrument function key, when pressed, is shown in the display

along with its current setpoint value, and actual value for

continuously monitored functions: signal levels, temperatures, flow

rates.

- A displayed function is also ready for entering a new setpoint

value simply by pressing appropriate keys.

C

An * (asterisk) is flashed as the new value is entered, indicating an

entry in progress.

ENTER

C

must terminate a numeric entry. It is also required in

terminating a sequence to assign a particular detector to a given

output signal channel.

In general, any display showing the flashing * must be terminated

ENTER

using

.

36

ENTER

Upon pressing

, the value is verified to ensure it is within the

range permitted for the particular function, and/or that the value is

internally consistent with previously defined setpoint values for other,

related functions.

- If the value is accepted, * disappears from the display indicating

the new value is stored and implemented. For functions whose

values are continuously monitored, * is replaced by the actual

value.

- If the value is out of range, or inconsistent with another setpoint

value, an appropriate message is displayed. Another setpoint

value may be entered immediately without again pressing the

particular instrument function key.

The original setpoint value remains in force until an acceptable entry

is made.

Page 37

Keyboard and Displays

Keyboard operation, INET control

CLEAR

C

is used anytime during setpoint entry, prior to pressing

ENTER

,

to erase the entry in progress.

CLEAR

C

, if pressed when no setpoint entry is in progress, displays

HP 5890 readiness .

C

Run Control Key

START

, if pressed while a setpoint entry is in

progress, causes the entry to be aborted.

C

If a particular key is not valid, it is simply ignored if pressed during

setpoint entry.

C

While an entry is in progress, other instrument function keys are

ignored if pressed, until the current entry is terminated and stored

(

ENTER

) or erased (

CLEAR

).

Keyboard operation, INET control

In general terms, HP 5890 operation is the same whether the instrument

is under local control or INET control (controlled by a separate device). If

the HP 5890 is to be controlled through INET, the following should be

noted:

C

In the event communication is lost (e.g., by power lost at one or more

devices on the loop, a disconnected INET cable, etc.), HP 5890

STOP

and

C

Should the HP 5890 keyboard exhibit problems (keys inactive) while

keys will be disabled.

under INET control, disconnect INET cables at their HP 5890

receptacles; then switch power to the HP 5890 off, and then on. The

keyboard should behave normally (assuming the HP 5890 itself has

no problems).

C

To restore INET control, check that all devices on the loop are

powered on, and that all INET cables are installed properly. The

system should return to normal operation automatically.

START

37

Page 38

Keyboard and Displays

Protecting setpoints

Additional information regarding INET control is available in Chapter 5,

Signal Output. Servicing may be required for one or more devices on the

INET loop if communication cannot be established.

Protecting setpoints

The HP 5890 provides a keyboard lock feature to minimize possibility of

stored setpoints being altered unintentionally. When the HP 5890

keyboard is locked, setpoint values (numeric values, A, B, OFF, and

ON) may only be displayed; they cannot be altered.

remain functional, so runs may be started or stopped.

To lock instrument setpoints, first enter the key sequence:

START

and

STOP

Figure 2-5

CLEAR

Then press

.

ON

ENTER

-

to lock the keyboard, or

OFF

to unlock the keyboard.

Figure 2•5shows displays occurring during this process.

ACTUAL SETPOINT

CALIB AND TEST [0-0]

ACTUAL SETPOINT

KEYBOARD LOCK ON

ACTUAL SETPOINT

KEYBOARD LOCK OFF

Keyboard Lock Displays

38

Page 39

Keyboard and Displays

Loading default setpoints

With the keyboard locked, Figure 2•6shows the display occurring if a

setpoint entry is attempted:

Figure 2-6

KEYBOARD LOCKED Message Display

If the HP 5890 keyboard is locked while the instrument is under INET

control, a setpoint file may be loaded into HP 5890 memory from the

controller, but the loaded setpoints cannot then be edited at the HP 5890

keyboard until it is unlocked.

After locking or unlocking the keyboard, return to operation by pressing

any function key (e.g.,

KEYBOARD LOCKED

OVEN TEMP

).

ACTUAL SETPOINT

Loading default setpoints

This function permits resetting HP 5890 operating setpoints to a

standard set of values. Only the following information is retained:

C

Calibration constants for oven temperature control

C

All gas flow rate monitoring information (gas types and calibration

constants)

C

Column compensation data, including detector assignments

Note: Since user•definedsetpoints are lost in the process, any critical

HP 5890 setpoints should be recorded for later reentry before proceeding.

Through the keyboard, select CALIB AND TEST mode, function 6:

CLEAR

.

6

39

Page 40

Keyboard and Displays

Loading default setpoints

Upon pressing

ENTER

, default setpoints are loaded into memory, erasing

setpoints already present. Table 2•1lists resulting HP 5890 default

setpoints.

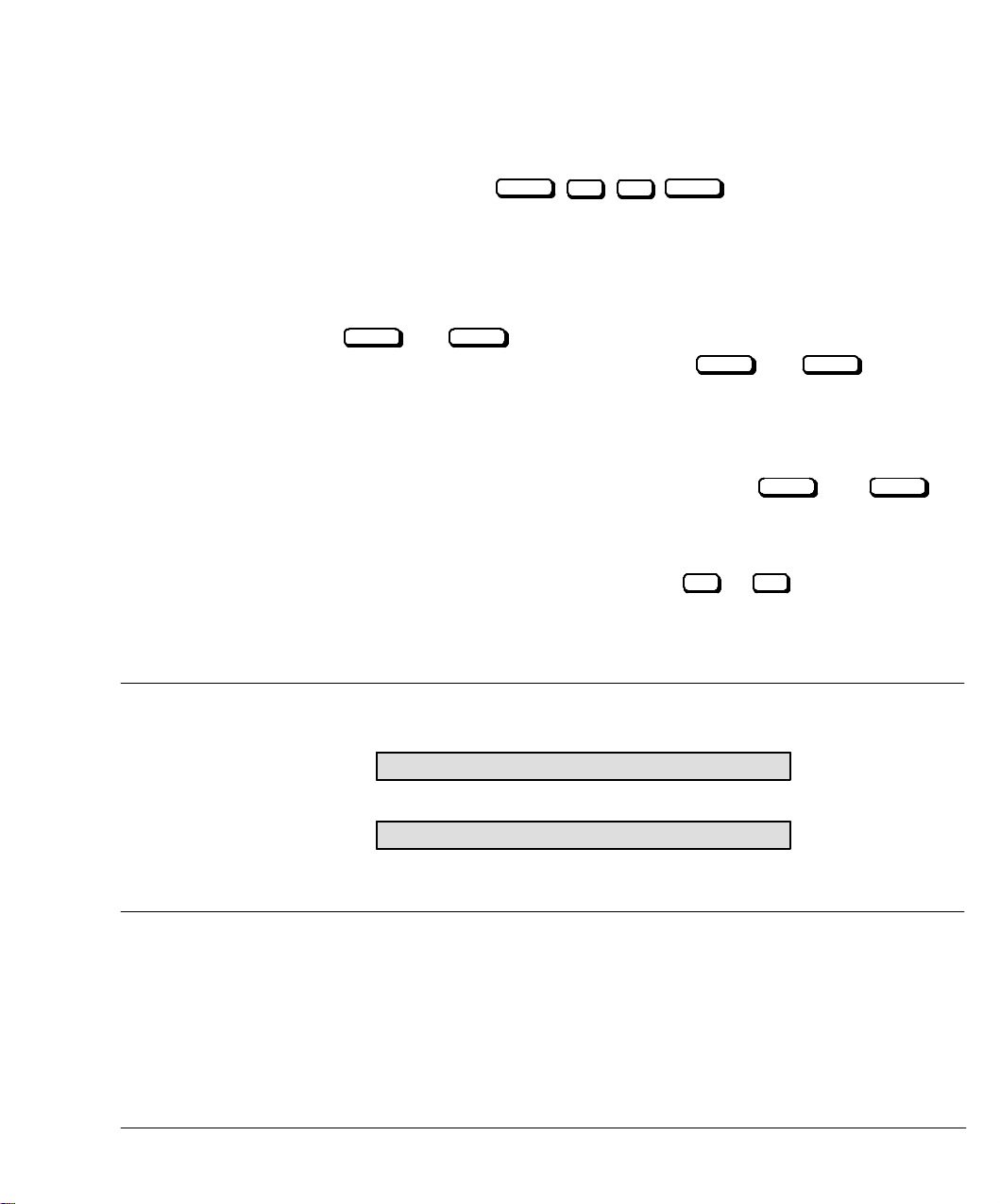

Table 2-1. HP 5890 Default Setpoints

Function Default Setpoint

^

Inj Temp (A & B): 50

Det Temp (A & B): 50

Oven Temp: 50

Oven Max Temp: 400

Cryo Cooling: OFF

Cryo Blast OFF

Equib Time: 3 min

Init Temp: 50

Init Time: 650 min

Oven Prog Rates: 0

Final Temp: 0

Final Time: 0 min

Inlet Purge: ON

Purge Time: 0 min

Detector (A & B): OFF

Signal 1 Det: Detector A

Signal 2 Det: Detector B if BOTH detectors A and

Range (1 & 2): 0

Attn (1 & 2): 0, ON

Zero (1 & 2): 0, ON

HP-IL (INET): Address- 31

INET: Global (unconfigured)

Keyboard Lock: OFF

Timetable Empty

Inj A Pres OFF

Inj B Pres OFF

TCD Sens HIGH

Oven Track ON

Constant Flow OFF

C, OFF

^

C, OFF

^

C, OFF

^

C

^

C

^

C/min

^

C

B are installed; otherwise,detector A.

40

Page 41

Keyboard and Displays

Loading default setpoints

Note that if the battery protecting memory should fail when main power

is turned off, the default setpoints are loaded into memory when the

battery is replaced. In addition, calibration constants for oven

temperature control and gas flow rate monitoring are also reset to default

values.

41

Page 42

This page intentionally left blank.

Page 43

3

Temperature Control

Page 44

Temperature Control

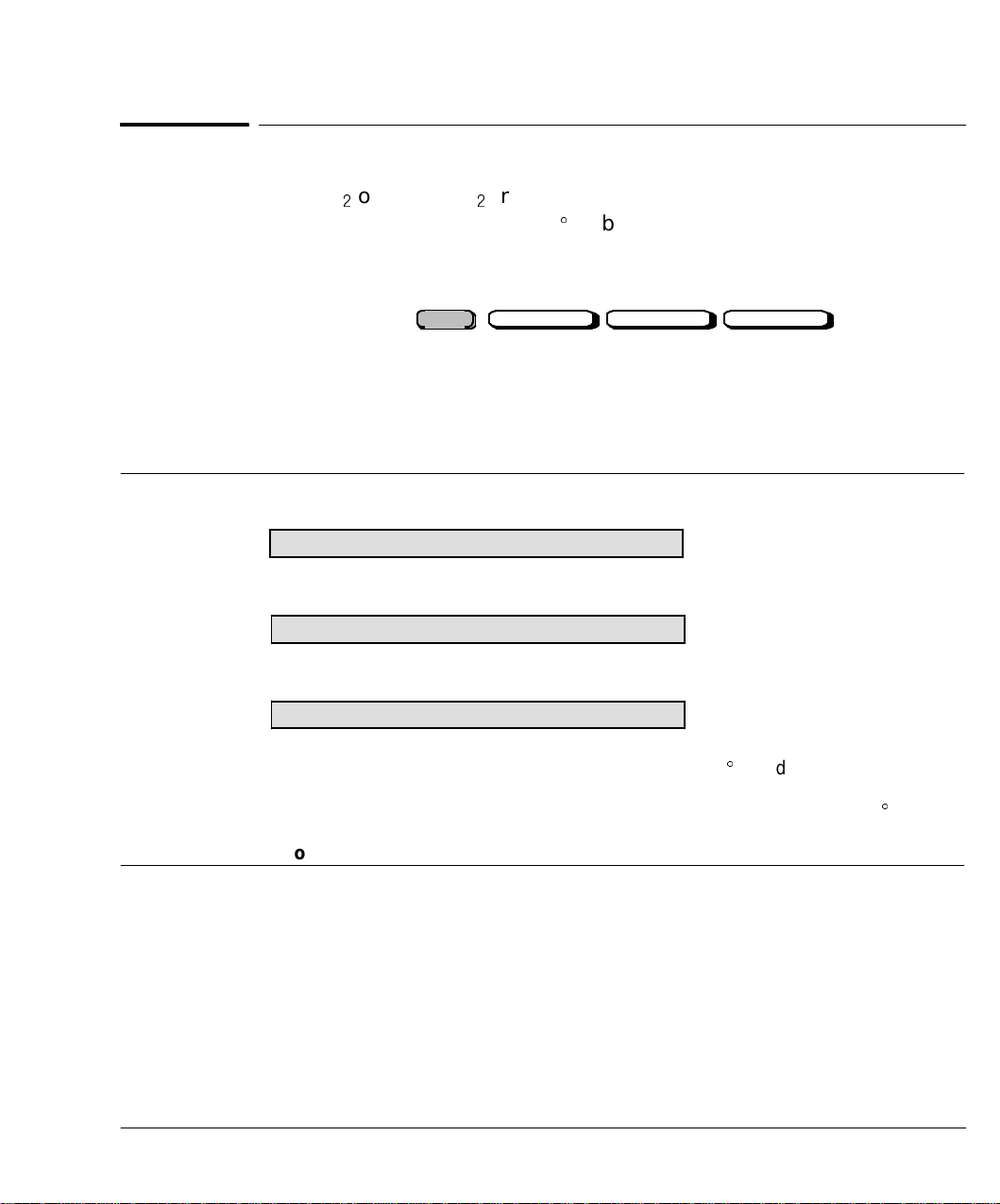

Oven temperature, and temperatures of up to five separate heated zones

(detectors, inlets, and/or heated valves), are controlled through keys

shown in Figure 3•1.

Figure 3-1

Oven Control

Figure 3-2

OVEN

TEMP

INJ A

TEMP

INIT

VALUE

INJ B

TEMP

INIT

TIME

DET A

TEMP

RATE

AUX

TEMP

DET B

TEMP

FINAL

VALUE

OVEN

MAX

EQUIB

TIME

FINAL

TIME

Heated Zone Control

Temperature Control Keys

In these cases, both current setpoint value and current monitored value

are displayed by pressing the appropriate temperature control key. For

example, Figure 3•2shows typical displays obtained by pressing

OVEN TEMP

.

ACTUAL SETPOINT

OVEN TEMP 279 350

44

Typical Display, Setpoint and Current Value

Page 45

Temperature Control

Note that the ACTUAL value is a measured quantity, while the

SETPOINT value is user•defined:in this example, the setpoint value for

oven temperature might recently have been changed from 250 to 350

and the oven is now heating to the new setpoint. Given sufficient time for

equilibration, ACTUAL and SETPOINT values become equal.

In addition to keys

defining setpoint values,

specific key sequences:

0

through

ON,OFF,A

^

C,

.

-

9

,

,

, and

CLEAR

,

B

, and

are used in certain

ENTER

used in

ON

C

and

OFF

add convenience in being able to switch on or off the

oven, and/or heated zones, without losing their current setpoint

values.

A

C

and

temperature program:

parameters for the second ramp;

B

are used in key sequences defining a multiple•rampoven

A

as part of key sequences defining

B

as part of key sequences

defining parameters for the third ramp.

45

Page 46

Temperature Control

e

Valid setpoint ranges

Valid setpoint ranges

Table 3•1lists valid setpoint ranges for the 13 keys controlling oven and

heated zone temperatures.

Table 3-1. Valid Setpoint Ranges For Temperature Control Keys

Key

OVEN TEMP

INIT TEMP

INIT TIME

RATE

FINAL TEMP

FINAL TIME

OVEN MAX

EQUIB TIME

INJ A TEMP

INJ B TEMP

DET A TEMP

DET B TEMP

AUX TEMP

Valid

Setpoint Range

In

Increments Of Function

-80 to 450 1^C Oven Control

-80 to 450 1

^

C Oven Control

0 to 650.00 0.01 minute Oven Control

0 to 70 0.1 /minute Oven Control

-80 to 450 1

^

C Oven Control

0 to 650.00 0.01 minute Oven Control

70 to 450 1

^

C Oven Control

0 to 200.00 0.01 minute Oven Control

0 to 400 1

0 to 400 1

^

C Zone Control

^

C Zone Control

0 to 400* 1^C Zone Control

0 to 400* 1

^

C Zone Control

0 to 400 1^C Zone Control

NOTE: TOTAL run time will not exceed 650.00 minutes regardless of values enter

INIT TIME

RATE FINALTIME

, , and .

*The valid setpoint range for a Flame Ionization Detector is 0 to 450^C.

46

Page 47

Temperature Control

Cryogenic (sub-ambient) oven control

Cryogenic (sub-ambient) oven control

Liquid N1or liquid CO1cryogenic options are for operation at

temperatures less than about 7

operation of a valve which opens when coolant is demanded and closes

when the setpoint temperature is reached.

^

C above ambient. This is done through

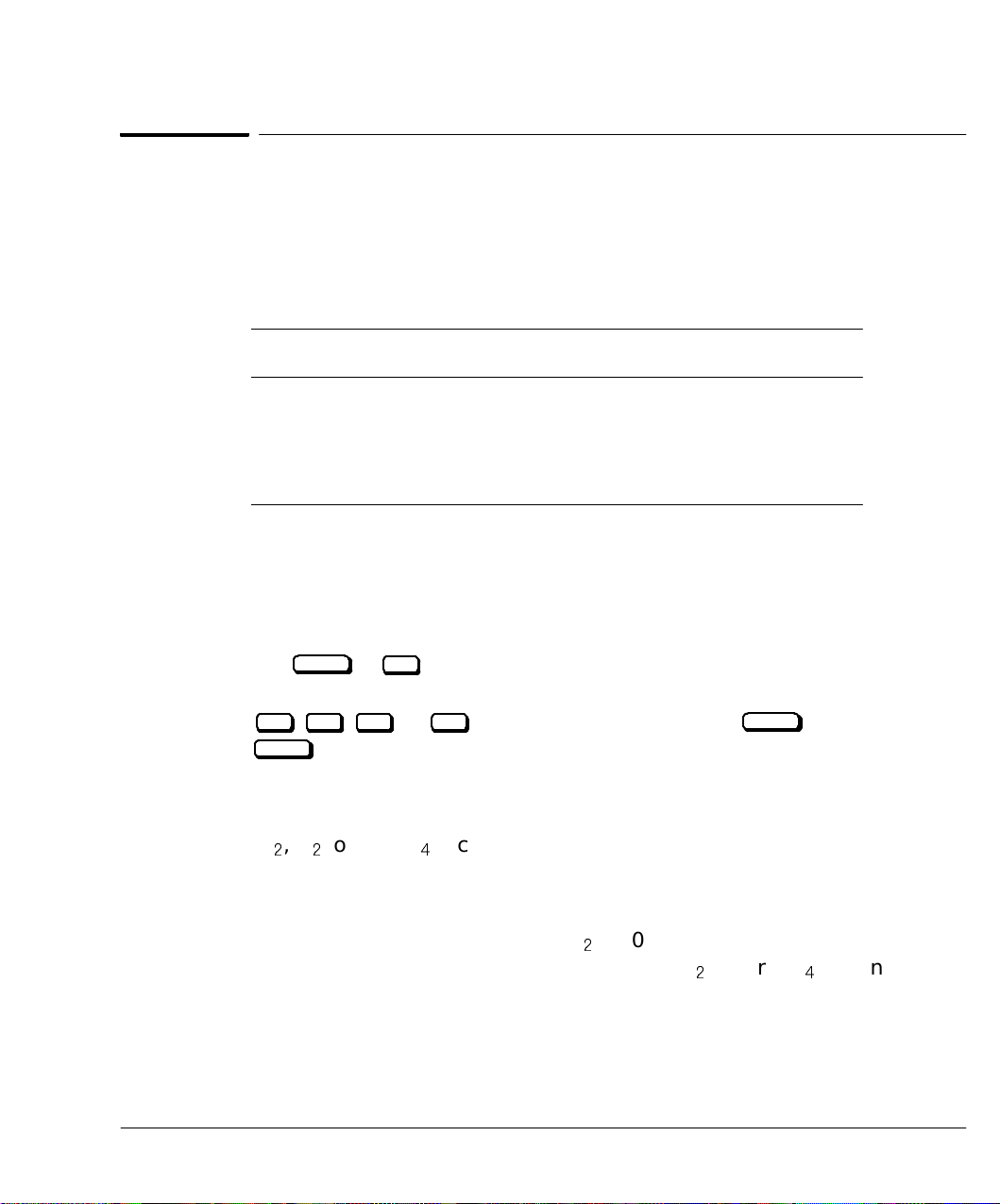

Figure 3-3

When you press

gold CRYO PARAM CRYO PARAM CRYO PARAM

you scroll

through a series of displays for choosing cryogenic options. These options

include CRYO for operation during the entire run, CRYO BLAST, for very

fast cool down between runs, and AMBIENT to regulate on and off times

to optimize coolant use.

ACTUAL SETPOINT

CRYO ON

ACTUAL SETPOINT

CRYO BLAST ON

ACTUAL SETPOINT

AMBIENT 25

Cryogenic options

For operation duringruns at

subambient temperatures.

For very fast cool down

between runs.

Lets you regulate Cryo and

Cryo Blast on and off times to

optimize coolant use. Default is

25

^

C and need not be changed

unless

ambient differs by 10

^

.

The following figures show the oven temperature profile for a typical run,

showing the on and off times for CRYO and CRYO BLAST.

47

Page 48

Temperature Control

Cryogenic (sub-ambient) oven control

Figure 3-4

75

50

25

Figure 3- 5.

120

80

40

CRYO OFF at ambient +15

^

9

(CRYO ON)

Oven profile using CRYO, for operation

during runs at subambient temperatures

9

CRYO BLAST ON

ambient + 50

9

CRYO ON

at ambient + 25

^

CRYO BLAST OFF

9

(30 sec. modulation)

^

48

Oven profile using CRYO BLAST, for very fast cool down between runs

Page 49

Temperature Control

Programming oven temperature

Programming oven temperature

HP 5890 oven temperature programming allows up to three ramps, in

any combination of heating or cooling. Keys defining an oven temperature

program include:

INIT TEMP

INIT TIME

RATE

FINAL TEMP

FINAL TIME

A setpoint temperature value at which the oven is

maintained at the beginning of a temperature•programmed

run. This is also the temperature to which the oven returns

at termination of the temperature•programmedrun.

When not in a run, the setpoint value for

equals

OVEN TEMP

.

Time for which oven temperature is held at

INIT TEMP

INIT TEMP

.

Rate at which the oven is to be heated or cooled.

Temperature the oven attains at the end of a heating or

cooling ramp.

In a multiple•ramptemperature program, final

temperature for one ramp is also the initial temperature

for the next ramp.

Time period over which oven temperature is held at

FINAL TEMP

.

In a multiple•ramptemperature program, final time for one

ramp is also the initial time for the next ramp.

total elapsed time for a run cannot exceed 650 minutes: at 650 minutes,

the run terminates and oven temperature recycles to

calculated total length of time anticipated for a run,

INIT TEMP

TIME

. To know

is pressed

repeatedly until a NEXT RUN display is obtained.

49

Page 50

Temperature Control

Oven status

In isothermal operation (

RATE

= 0 ), if

INIT TIME

is set equal to 0

(zero), the HP 5890 internally sets run time to the maximum, 650

minutes.

A

is included in key sequences defining parameters for a second ramp;

B

is included in key sequences defining parameters for a third ramp.

In isothermal operation, and in one•or two•ramptemperature programs,

rate for the next ramp must be set to 0 (zero) to prevent further

programming.

In oven temperature programming, once any one of the five temperature

programming functions (

FINAL TIME

) is displayed, pressing

INIT TEMP

INIT TIME

,

ENTER

, without entering a new

RATE

,

FINAL TEMP

,

, and

setpoint value, rolls the display successively through the entire group,

(including A and B displays for second and third ramps).

This is an efficient way in which to review and, if necessary, change oven

temperature program setpoints.

Oven status

50

During a temperature•programmedrun, the LED OVEN display provides

indication of oven status at any given time:

C

Isothermal Run: Assuming

than 0, and that

RATE

=0,only the INITIAL TIME LED is lit. It

INIT TIME

is assigned a value greater

remains lit throughout the run.

C

Single•Ramp Temperature Program: The three LEDs, INITIAL

TIME, RATE, and FINAL TIME, successively light to indicate position

in the temperature program.

C

Multiple•Ramp Temperature Program: The three LEDs, INITIAL

TIME, RATE, and FINAL TIME, successively light to indicate position

in the first temperature program ramp.

Then RATE and FINAL TIME LEDs light alternately as the program

proceeds through the second (and third) ramp(s).

Page 51

Temperature Control

Oven safety

In complex two•or three•rampoven temperature programs, information

as to the part of the program in progress is monitored by pressing

OVEN TEMP

Note that, during a ramp, the SETPOINT value displayed is that

calculated to be the correct temperature, based upon specified

heating/cooling rate, and initial and final oven temperatures.

Also, note that if the RATE LED is observed to blink during oven heating,

this indicates the particular

given operating conditions: the oven heater is operating at full power and

may not be able to deliver the desired temperature program rate. Such a

situation compromises accuracy in repeating the heating ramp from run

to run.

Oven safety

.

RATE

value entered is too aggressive for the

WARNING

Normally, the oven should be switched off (

OVEN TEMP

OFF

) prior to

accessing the oven interior (e.g., to change columns, check for leaks, etc.).

For safety, this turns off power to the oven heater, fan, and cryogenic

valve (if installed), but maintains the setpoint value in memory.

The oven is equipped with a shut•offfeature to protect against

unintentional opening of the oven door, and/or the possibility of

mechanical and/or electronic failure affecting oven operation.

At any time during normal above•ambientoperation, if the oven cannot

attain and/or maintain an entered setpoint temperature, a problem is

assumed and the oven is automatically switched off. Examples of possible

problems include the oven door open (or closed but not properly latched),

inoperative oven vent flaps, failure of the oven fan, heater, or

temperature sensor, or electronic problem.

If the oven door is opened, a time delay may be observed before the

oven shuts itself off. The closer the oven is to ambient temperature,

the longer the delay will be.

51

Page 52

Temperature Control

Fault: messages

The message displayed when this occurs is shown in Figure 3•6.

Figure 3-6

Message, Oven SHUT DOWN

The oven remains off until switched on again via the keyboard

OVEN TEMP

(

Fault: messages). Power to the instrument must be switched off, and then

on again to restore operation (setpoints are maintained).

Fault: messages

Figure 3•7shows possible FAULT: messages associated with heated zones

or the oven. In general, the following problems are indicated when a

FAULT: message appears:

ACTUAL SETPOINT

WARN: OVEN SHUT OFF

ON

), unless a FAULT: message is displayed (see below,

52

C

ADC OFFSET indicates a problem with one or more electronic

components in circuitry associated with temperature control.

C

LINE SENSE indicates a problem with AC power to the instrument

(an excessively high source voltage).

C

Any of the TEMP RDG messages indicate an inoperative temperature

sensor for the indicated zone or oven.

C

OVEN > MAX + 20 indicates oven temperature exceeds the current

OVEN MAX

setpoint value by more than 20^C. Thermal run•awayis

the likely cause.

Note: In case multiple problems exist simultaneously, press

CLEAR

roll through all message displays.

to

Page 53

Temperature Control

After a power failure . . .

Figure 3-7

Thermal Control FAULT: Messages

ACTUAL SETPOINT

FAULT: ADC OFFSET

ACTUAL SETPOINT

FAULT: LINE SENSE

ACTUAL SETPOINT

FAULT: INJA TEMP RDG

ACTUAL SETPOINT

FAULT: DETA TEMP RDG

ACTUAL SETPOINT

FAULT: OVEN TEMP RDG

ACTUAL SETPOINT

FAULT: OVEN > MAX+20

In addition to the message, the red NOT READY LED blinks. All zones

and the oven are turned off and made inoperative until power is switched

off, and then on again (setpoints are maintained).

After a power failure . . .

Setpoint values are protected during a power failure (even if intentional,

by disconnecting the power cord, or by switching off the HP 5890 at its

main power switch) by a lithium battery (10•yearnominal life) which

maintains power to HP 5890 memory.

After power is restored, a message is displayed, as shown in Figure 3•8.

53

Page 54

Temperature Control

Oven temperature calibration

Figure 3-8

ACTUAL SETPOINT

PASSED SELF TEST

INITIAL

TIME

RATE

OVEN

FINAL

TIME

STATUS

RUN

NOT

READY

Message Display, Power Failure and Recovery

Heated zones return to their respective setpoint values, after which the

oven returns to its setpoint value.

If

OVEN TEMP

is displayed after recovery from a power failure, and if

C

the oven was ON before the power failure, the oven display shows the

actual oven temperature value, and cycles between showing the

setpoint value and OFF until other zones achieve their respective

setpoint temperatures.

C

The oven can be switched ON through the keyboard at any time,

without waiting for heated zones to first come to correct temperature.

C

An analytical or column compensation run in progress at the time of a

power failure is aborted; similarly, a keyboard entry in progress is

aborted.

54

Oven temperature calibration

To maximize precision with respect to retention time information,

particularly if retention times are to be compared between

chromatographs, it may be necessary to calibrate oven temperature in the

range of interest using an independent temperature•measuringdevice.

With the factory•setcalibration difference value of 0 (zero), displayed

oven temperature is accurate to within 1% of the actual temperature,

expressed in

^

K (Kelvin).

Page 55

Temperature Control

Oven temperature calibration

The HP 5890 providesthe means to (if necessary) reset oven temperature

monitoring so the displayed ACTUAL value accurately represents the

correct temperature.

Oven temperature calibration requires entering the difference (delta)

^

value (in

C) between an independently measured temperature value

versus the corresponding displayed oven temperature value:

Correction Value =

Measured Temperature (

For example, if actual measured oven temperature were found to be

148.73

^

C, while the corresponding displayed value was 150.00, the

calibration difference value to be entered would be -1.27.

Setting the oven calibration value

An oven temperature calibration measurement should be made at a

temperature in the middle of the range of interest. Allow ample time (up

to 1/2•hour)for thermal equilibration at the selected temperature; no

drift should be observed. The temperature•sensingprobe should be placed

in the region of the oven occupied by the column(s).

^

C) - Displayed Temperature (^C)

1. Through the keyboard, select CALIB AND TEST mode, function 1:

CLEAR

.

ENTER

1

CALIB is displayed, followed by two values: the observed oven

temperature (to 0.01

^

C), and the current difference (delta)

calibration value.

Note: Record the displayed calibration delta value! If problems are

encountered in recalibration, the value may be reentered.

2. Assuming no drift in temperature, the new difference (delta) value is

then entered by pressing appropriate number keys, followed by

appropriatevalue

ENTER

ENTER

:

55

Page 56

Temperature Control

Oven temperature calibration

3. CALIB DELTA is displayed until

ENTER

is pressed; then oven

temperature recalibration occurs. Note that, after calibration, the

displayed oven temperature value should match closely the measured

value.

Any delta value within the range -10.00 through +10.00

^

C may be

entered. If a value outside this range is entered, the message

CORRECTION TOO HIGH is displayed.

Assuming the battery protecting HP 5890 memory is operational, a new

calibration constant remains in effect even if the instrument is switched

off, or disconnected from its power source, or if power fails.

56

Page 57

4

Electronic Flow Sensing

Page 58

Electronic Flow Sensing

Two channels of electronic flow rate sensing continuously monitor gas

flow rates (usually carrier) in the HP 5890 SERIES II. Proper scaling of

displayed values for different commonly used gases is defined through

keyboard entries. The two flow channels are distinguished through

and

If carrier gas flows are monitored, A implies flow through column A

(nearest the instrument front); B implies flow through column B (nearest

the instrument rear).

Displayed flow rate values are in ml/minute.

Displaying gas flow rate

Current flow rate is displayed by pressing:

B

.

A

Figure 4-1

58

FLOW A

(or

B

)

Typical gas flow rate displays are shown in Figure 4•1:

ACTUAL SETPOINT

FLOW A 25.4 N2

ACTUAL SETPOINT

NO FLOW SENSOR

Typical Electronic Flow Rate Sensor Displays

Page 59

Electronic Flow Sensing

Designating gas type

Designating gas type

To scale the displayed flow rate value properly, one of four commonly used

gases must be designated. The appropriate gas type is selected according

to Table 4•1:

Table 4-1. Defining Type of Gas to be Monitored

Number Gas Type Preferred Use

1 He (Helium) TCD

2N

3H

4 Ar/CH

(Nitrogen) General

2

(Hydrogen) Capillary

2

(Methane in Argon) ECD

4

To select one of these gases for a particular flow channel, press:

FLOW

1

2

,

ENTER

, the current flow rate is displayed, scaled appropriately for the

B

(

) to display FLOW A (or FLOW B).

3

,

,or

4

is then pressed, followed by

ENTER

. Upon pressing

chosen gas type.

If a gas other than one of the above standard four is used, select He,

N

1,H1

, or Ar/CH3according to which one is closestin thermal

conductivity to the gas being used. Under no circumstances should any

corrosive gas be passed through the EFS.

The maximum usable range for H

( >100 ml/min), where a gas other than He, N

1

is 100 ml/minute. At higher flow rates

1

, or Ar/CH3is being used,

or to ensure maximum accuracy in displayed flow rate, calibration of the

EFS may be necessary.

59

Page 60

Electronic Flow Sensing

Electronic flow sensor (EFS) calibration

Electronic flow sensor (EFS) calibration

Electronic flow sensor (EFS) calibration may be performed any time to

ensure displayed flow rate accurately represents real gas flow rate

through the sensor. The EFS is factory•calibratedfor four standard

gases, H

ml/min. This covers the majority of chromatographic applications.

Two situations where it would be appropriate to perform recalibration

would be where a nonstandard gas is to be used (e.g., something other

than H

to be used.

EFS calibration requires setting two values for a given flow

channel•first, the zero value (defined with no flow through the given

flow channel) and then the gain value (calculated, based upon a

measured flow rate value).

1

, He, N1, and Ar/CH3, within the flow rate range of 0 to 100

1

, He, N1, or Ar/CH3), or if flow rates in excess of 100 ml/min are

WARNING

60

If calibration is being performed for H2, observe proper safety

precautions to prevent fire or explosion hazard.

Prior to performing the calibration procedure, the following must be done:

C

The instrument must be on for at least one hour for thermal

equilibration of the EFS.

C

Since gas flow through the channel to be calibrated will be

interrupted, detectors should be turned off (particularly an NPD or

TCD! ), and the oven cooled to ambient temperature (to protect

columns).

C

A flow•measuringdevice is required, accurate to better than 1 ml/min.

C

The EFS is calibrated to measure volumetric flow at standard

temperature and pressure. Flows measured at ambient temperature

with a bubble flow meter will have to be converted from ambient

temperature and pressure to standard temperature and pressure.

Page 61

Electronic Flow Sensing

Electronic flow sensor (EFS) calibration

Preparation

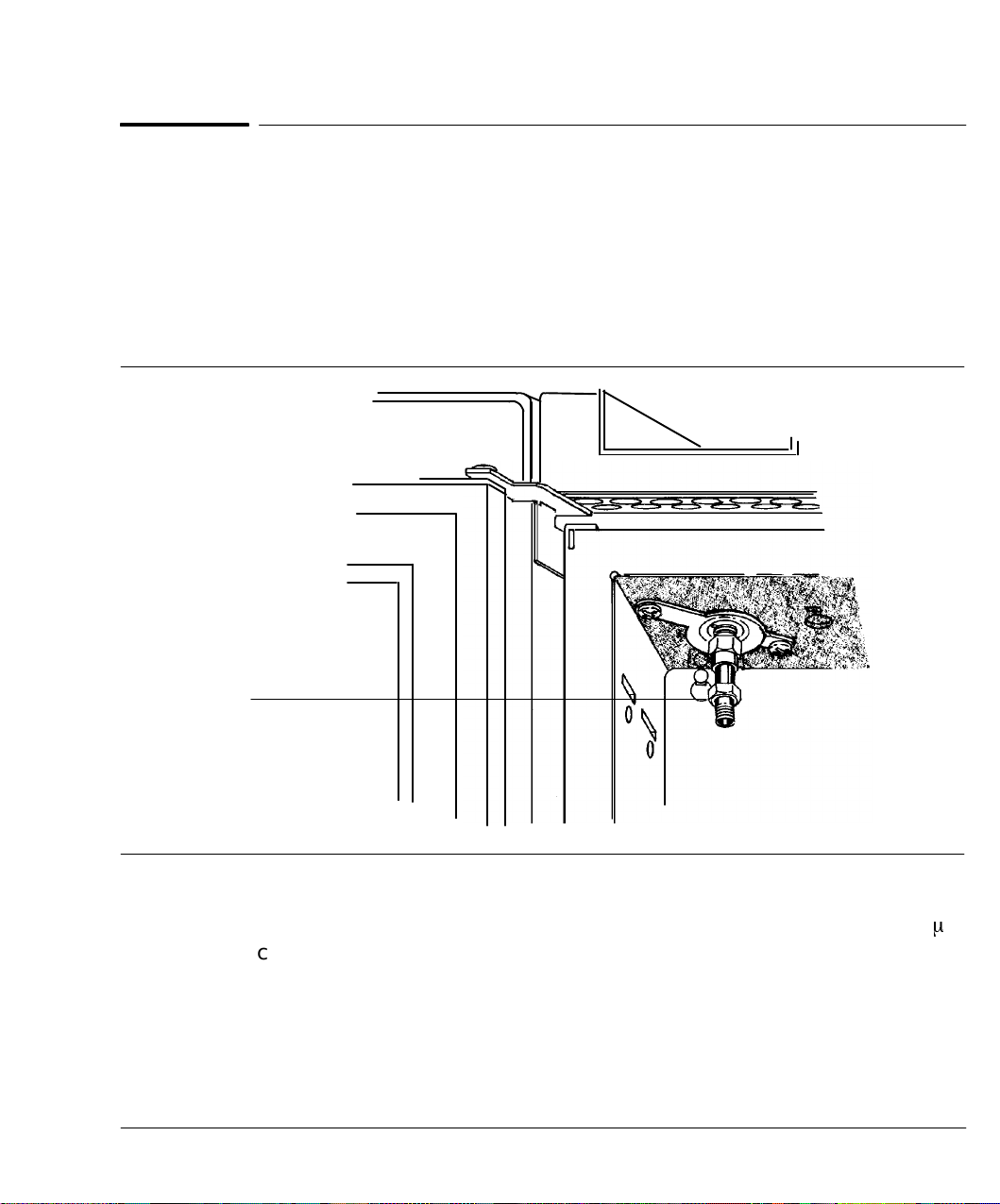

1. Access the EFS by removing the left side panel; remove two screws

along its lower edge, slide the panel toward the rear of the

instrument, and then lift.

2. Through the keyboard, select CALIB AND TEST mode, function 2:

CLEAR

.

ENTER

2

GAIN A is displayed, followed by two values: the observed flow rate

through Channel A, and the current gain calibration value for

Channel A.

Setting the zero calibration value

The zero calibration value must be set with no gas flow through the

channel being calibrated.

ZERO

1. Press

current zero calibration value for EFS Channel A). Note that

Channel A is assumed by default; if channel B is to be calibrated

instead, press

2. Disconnect the gas source to the particular flow channel being

calibrated. Do not trust an on/off valve, pressure regulator, or mass

flow controller to be an effective shutoff device; any gas flowing

through the EFS will invalidate the zero calibration value.

Disconnect the source at any convenient point (e.g., at the connection

of the supply line into the instrument).

: FLOW A ZERO is displayed, followed by a value (the

B

.

61

Page 62

Electronic Flow Sensing

Electronic flow sensor (EFS) calibration

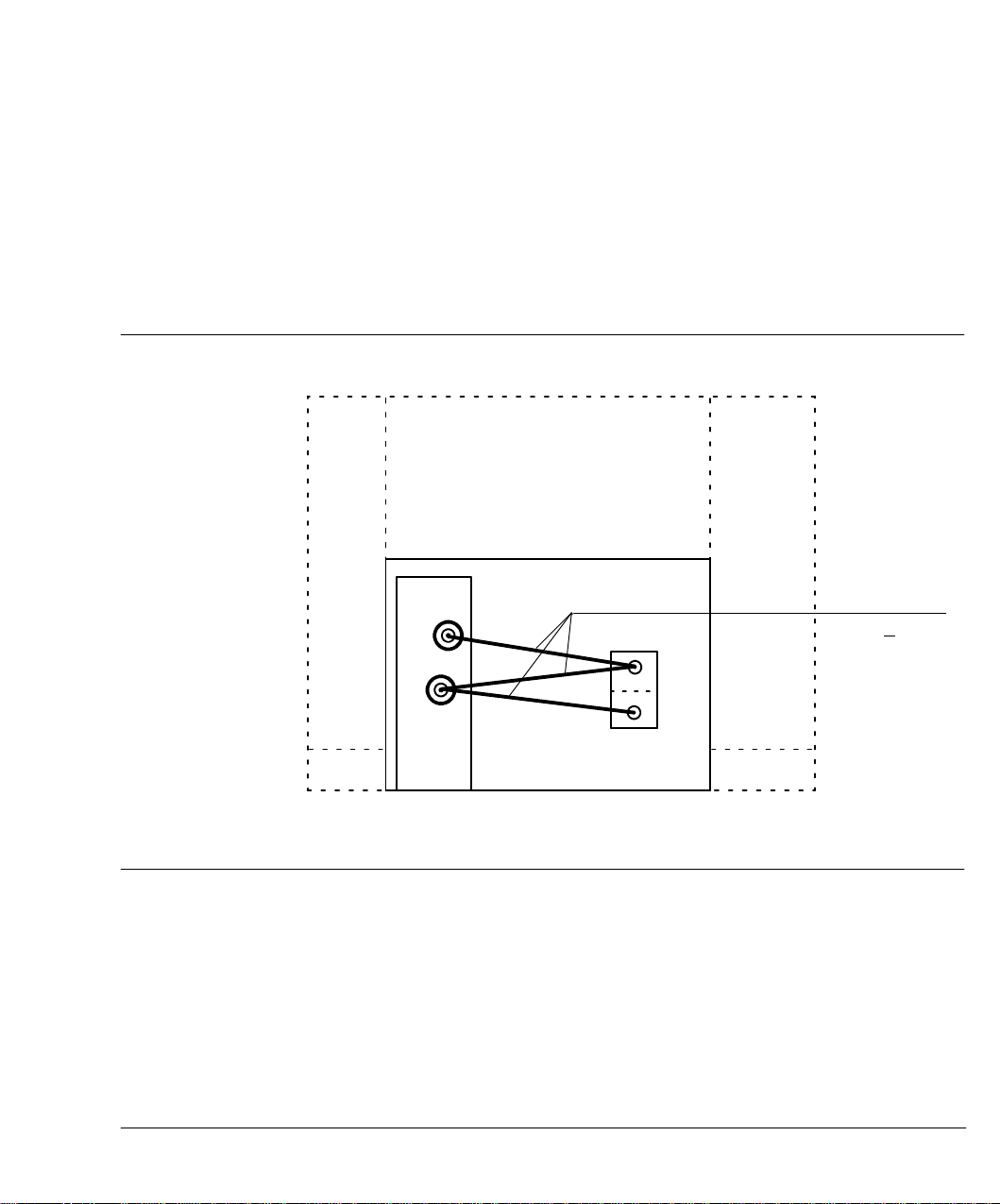

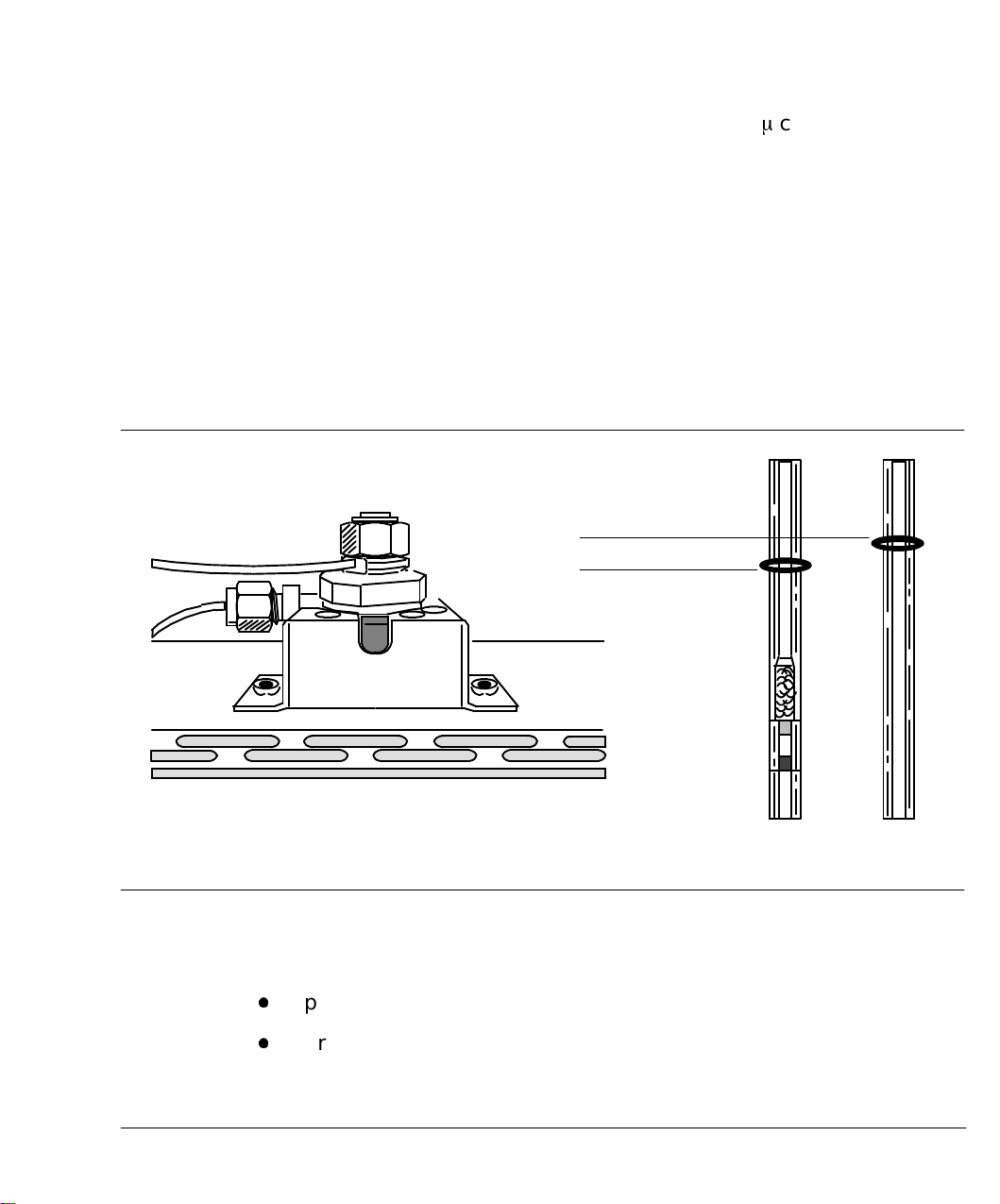

3. Locate the EFS module and note its labelling: CHANNEL A/

CHANNEL B, IN/OUT. For the channel being calibrated, locate and

disconnect its OUT fitting; use two wrenches in opposition to prevent

twisting the tubes.

Figure 4-2

Outlet Line, Channel B

EFS Module

Detail, Electronic Flow Sensor (EFS) Module

Outlet Line, Channel

A

4. Install the EFS flow•measuringadapter (Part No. 05890•80620)into

the female OUT fitting to the EFS module. Connect a bubble flow

meter to the adapter.

62

Allow ample time (up to 1/2•hour)for residual gas within connected