Page 1

Service Manual

HP LaserJet 4V / 4MV

(C3141A / C3142A)

Page 2

© Copyright

Hewlett-Packard Company

1994

All Rights Reserved.

Reproduction, adaptation, or

translation without prior

written permission is

prohibited, except as

allowed under the copyright

laws.

Publication number

C3141-90929

First edition, July 1994

Printed in USA

Warranty

The information contained

in this document is subject

to change without notice.

Hewlett-Packard makes no

warranty of any kind with

regard to this material,

including, but not limited to,

the implied warranties or

merchantability and fitness

for a particular purpose.

Hewlett-Packard shall not

be liable for errors contained

herein or for incidental or

consequential damaged in

connection with the

furnishing, performance, or

use of this material.

WARNING

Electrical Shock Hazard

To avoid electrical shock,

use only supplied power

cords and connect only to

properly grounded (3-hole)

wall outlets.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714

Page 3

Conventions

This manual uses the following conventions:

Color is used to emphasize it ems which are important to the material under

discussion.

The names of major printer parts and assemblie s are Cap it alize d.

Bold is used for emphasis, particularly in situatio ns whe re italic type would

be confusing.

Italic type is used to indicate related documents or emphasis.

COMPUTER type indicates text as seen on a computer monitor.

[Keyface] indicates keys on a computer keyboard or on the printer control

panel. Examples include [Form Feed] , [Enter] and [On Line].

NOTE

CAUTION Caution messages alert you to the possibilit y of damage to equipm ent or

WARNING!

Notes contain important information set off from the text.

loss of data.

Warning messages alert you to the possibility of personal injury.

i

Page 4

Chapter Descriptions

1 Product Information

Orientation to th e print er , as well as the ser vice and rep air philos o ph y is

discussed. Information on obtaining assistance and warrant y is also here.

2 Site Requirements

Here are recommendations pertaining to installation requ irements.

3 Operating Overview

This chapter has detailed inf ormatio n abo ut the Cont rol Pane l. Sample self

tests and printer reset information are also included.

4 Maintenance

Turn to this chapter for information about printer cleaning.

5 Functional Overview

Here you will find the basic theory-of-operation informa tion required to

understand the various printer systems and how they function together.

6 Removal and Replacement

This chapter contains the step-by-step procedures for replacing printer field

replaceable units (FRUs). Assemblies are group ed by locat ion in the pr inter.

7 Troubleshooting

Diagnose printer problems here. Preliminary troubleshooting table is

followed by error messages, image defect samples, and diagnostic tools.

8 Parts and Diagrams

Look here to find any field replaceable unit (FRU) in the printer. Exploded

view drawings are accompanied by complete part number tables.

A Parts Index

All parts are sorted and cross-referenced here by part number and name .

B I/O Information

This appendix contains cabling and pin-o u t informat io n for paralle l and

LocalTalk interfaces which are supported by the printer.

C Regulatory Information

Here are required statement s regard ing RFI and lase r saf ety.

Subject Index

Use the subject index to quickly locate any informat ion in the man ual.

ii

Page 5

List of Figures

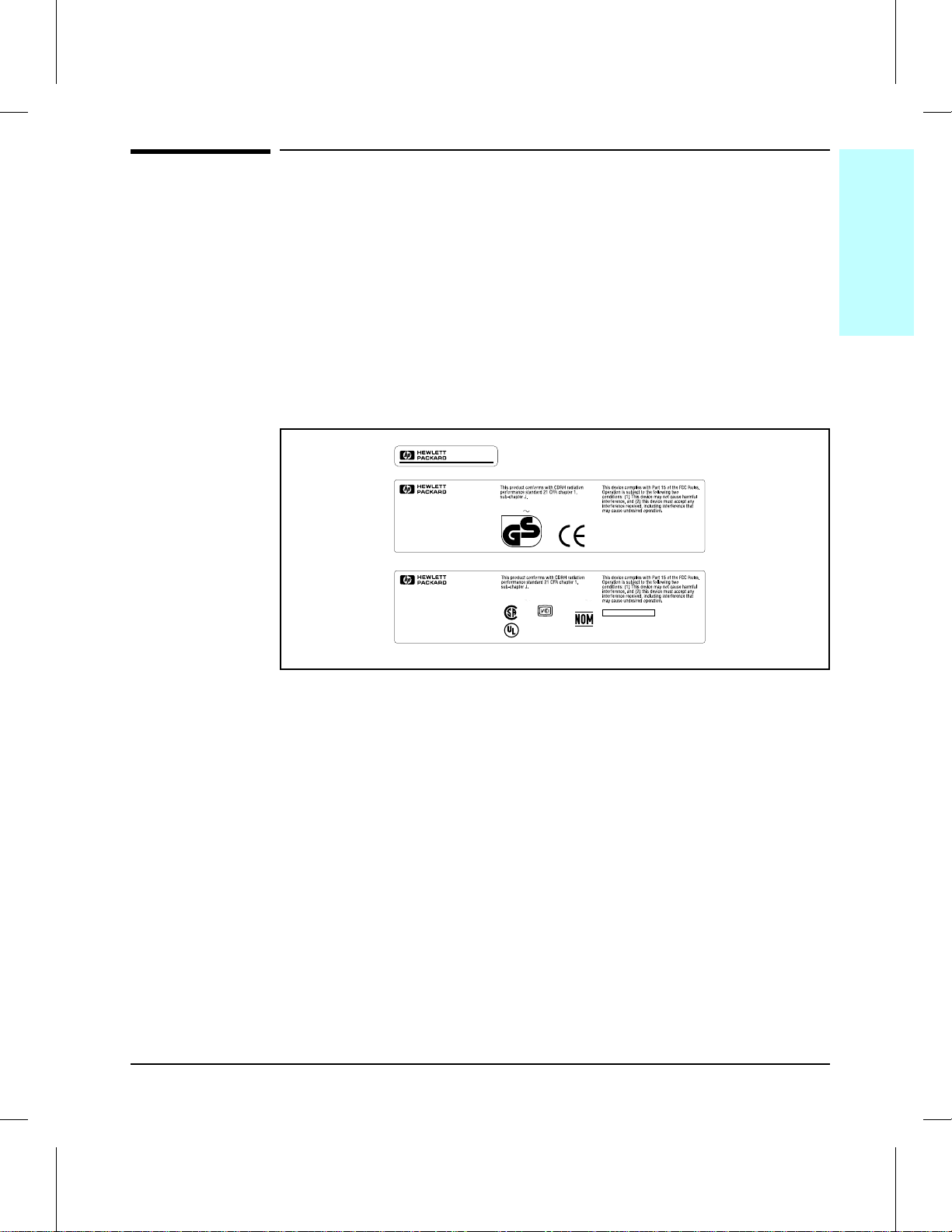

Figure 1-1 Sample Model and Serial Number Labels . . . . . . . . . . 1-5

Figure 1-2 Front and Rear Side View . . . . . . . . . . . . . . . . . . 1-11

Figure 1-3 Rear and Left Side View . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-4 Front View with Front Cover Open . . . . . . . . . . . . . 1-13

Figure 1-5 Internal Assembly Locations (1 of 2) . . . . . . . . . . . . . 1-14

Figure 1-6 Internal Assembly Locations (2 of 2) . . . . . . . . . . . . . 1-15

Figure 1-7 Sample 5% Page Coverage . . . . . . . . . . . . . . . . . . 1-17

Figure 2-1 Printer Space Requirements . . . . . . . . . . . . . . . . . 2-4

Figure 3-1 Control Panel Layout . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-2 Service Mode Menus . . . . . . . . . . . . . . . . . . . . . 3-16

Figure 3-3 Self Test Printout (printed in Service Mode) . . . . . . . . 3-21

Figure 3-4 Engine Test . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Figure 5-1 Printer Functional Block Diagram . . . . . . . . . . . . . . 5-3

Figure 5-2 Power Supply/Power Distribution . . . . . . . . . . . . . . 5-4

Figure 5-3 Formatter PCA Block Diagram . . . . . . . . . . . . . . . 5-10

Figure 5-4 EconoMode vs Normal Mode . . . . . . . . . . . . . . . . . 5-12

Figure 5-5 Image Formation Block Diagram . . . . . . . . . . . . . . 5-17

Figure 5-6 Photosensitive Drum . . . . . . . . . . . . . . . . . . . . . 5-18

Figure 5-7 Drum Cleaning . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Figure 5-8 Primary Charging Roller . . . . . . . . . . . . . . . . . . . 5-20

Figure 5-9 Image Writing . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Figure 5-10 Image Development . . . . . . . . . . . . . . . . . . . . . . 5-22

Figure 5-11 Image Transferring . . . . . . . . . . . . . . . . . . . . . . 5-23

Figure 5-12 Image Fusing . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Figure 5-13 Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Figure 5-14 Clutches and Sensors . . . . . . . . . . . . . . . . . . . . . 5-26

Figure 5-15 General Timing Diagram . . . . . . . . . . . . . . . . . . . 5-29

Figure 6-1 Phillips vs. Posidriv Screwdrivers . . . . . . . . . . . . . . 6-4

Figure 6-2 Removing the Control Panel . . . . . . . . . . . . . . . . . 6-8

Figure 6-3 Upper Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Figure 6-4 Static Charge Eliminator . . . . . . . . . . . . . . . . . . . 6-10

Figure 6-5 Removing Side Covers . . . . . . . . . . . . . . . . . . . . 6-11

Figure 6-6 Removing Rear Cover . . . . . . . . . . . . . . . . . . . . . 6-12

Figure 6-7 Exhaust Fan . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Figure 6-8 High Voltage Power Supply PCA . . . . . . . . . . . . . . 6-14

Figure 6-9 Cassette Size Sensor Assembly . . . . . . . . . . . . . . . 6-15

Figure 6-10 Card Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Figure 6-11 Rear Exhaust Fan . . . . . . . . . . . . . . . . . . . . . . 6-17

Figure 6-12 Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . 6-18

Figure 6-13 DC Controller PCA . . . . . . . . . . . . . . . . . . . . . . 6-19

Figure 6-14 Laser/Scanner Assembly . . . . . . . . . . . . . . . . . . . 6-20

Figure 6-15 Main Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Figure 6-16 Main Drive Assembly Removal (1 of 2) . . . . . . . . . . . 6-22

iii

Page 6

Figure 6-17 Main Drive Assembly Removal (2 of 2) . . . . . . . . . . . 6-23

Figure 6-18 Drum Drive Assembly . . . . . . . . . . . . . . . . . . . . 6-24

Figure 6-19 Transfer Roller Assembly . . . . . . . . . . . . . . . . . . 6-25

Figure 6-20 Fusing Assembly . . . . . . . . . . . . . . . . . . . . . . . 6-26

Figure 6-21 Fuser Inlet Guide . . . . . . . . . . . . . . . . . . . . . . . 6-27

Figure 6-22 Paper Guide Plate Assembly . . . . . . . . . . . . . . . . . 6-28

Figure 6-23 MP Guide Plate . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Figure 6-24 MP Drive Gears . . . . . . . . . . . . . . . . . . . . . . . 6-30

Figure 6-25 Fuser Door . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Figure 6-26 MP Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Figure 6-27 Front Door Assembly . . . . . . . . . . . . . . . . . . . . . 6-33

Figure 6-28 Upper and Lower Delivery Roller Assemblies . . . . . . . 6-34

Figure 6-29 Delivery Gear Assembly . . . . . . . . . . . . . . . . . . . 6-35

Figure 6-30 Cartridge Guide . . . . . . . . . . . . . . . . . . . . . . . 6-36

Figure 6-31 Cassette Picku p Roller Assem bly . . . . . . . . . . . . . . 6-37

Figure 6-32 Separation Pad . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Figure 6-33 Registr atio n Roller (1 of 2) . . . . . . . . . . . . . . . . . . 6-39

Figure 6-34 Registr atio n Roller (2 of 2) . . . . . . . . . . . . . . . . . . 6-40

Figure 6-35 Registr atio n Roller Guid e Plate . . . . . . . . . . . . . . . 6-41

Figure 6-36 Anti-Static Brush . . . . . . . . . . . . . . . . . . . . . . . 6-42

Figure 6-37 Paper Guide . . . . . . . . . . . . . . . . . . . . . . . . . 6-43

Figure 6-38 Left Side Foot . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

Figure 7-1 Paper Path and Components . . . . . . . . . . . . . . . . 7-4

Figure 7-2 Engine Test Button and Printout . . . . . . . . . . . . . . 7-3 1

Figure 7-3 Repetitive Image Defect Ruler . . . . . . . . . . . . . . . . 7-36

Figure 7-4 DC Controller Inputs . . . . . . . . . . . . . . . . . . . . . 7-38

Figure 7-5 DC Controller Outputs (1 of 2) . . . . . . . . . . . . . . . . 7-39

Figure 7-6 DC Controller Outputs (2 of 2) . . . . . . . . . . . . . . . . 7-40

Figure 7-7 Main Wiring Diagram . . . . . . . . . . . . . . . . . . . . 7-41

Figure 8-1 Major Assembly Locations . . . . . . . . . . . . . . . . . . 8-9

Figure 8-2 Covers and Doors . . . . . . . . . . . . . . . . . . . . . . . 8-10

Figure 8-3 Foot Assemblies . . . . . . . . . . . . . . . . . . . . . . . 8-12

Figure 8-4 Front Door Components (Page 1 of 2) . . . . . . . . . . . . 8-14

Figure 8-5 Front Door Components (Page 2 of 2) . . . . . . . . . . . . 8-16

Figure 8-6 Output Components . . . . . . . . . . . . . . . . . . . . . 8-18

Figure 8-7 Internal Components (Page 1 of 4) . . . . . . . . . . . . . 8-20

Figure 8-8 Internal Components (Page 2 of 4) . . . . . . . . . . . . . 8-22

Figure 8-9 Internal Components (Page 3 of 4) . . . . . . . . . . . . . 8-24

Figure 8-10 Internal Compon ents (Pag e 4 of 4) . . . . . . . . . . . . . 8-26

Figure 8-11 Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . 8-28

Figure B-2 Connecting to the END of a LocalTalk Network . . . . . . B-2

Figure B-3 Connecting to the MIDDLE of a LocalTalk Network (1 of 2) B-3

Figure B-4 Connecting to the MIDDLE of a LocalTalk Network (2 of 2) B-3

Figure B-5 I/O Connector Locations . . . . . . . . . . . . . . . . . . . B-4

Figure C-1 VCCI Statement (Japan) . . . . . . . . . . . . . . . . . . . C-4

iv

Page 7

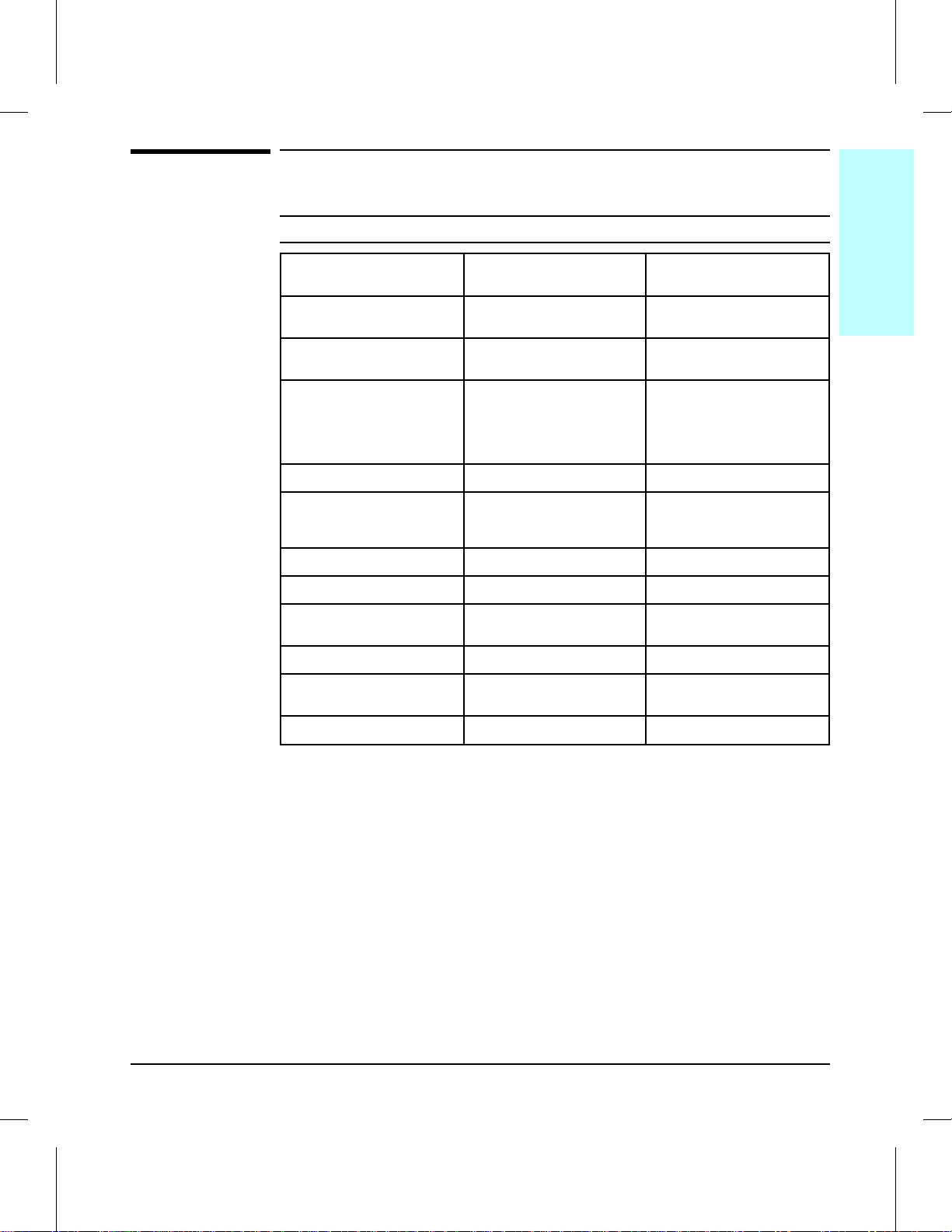

List of Tables

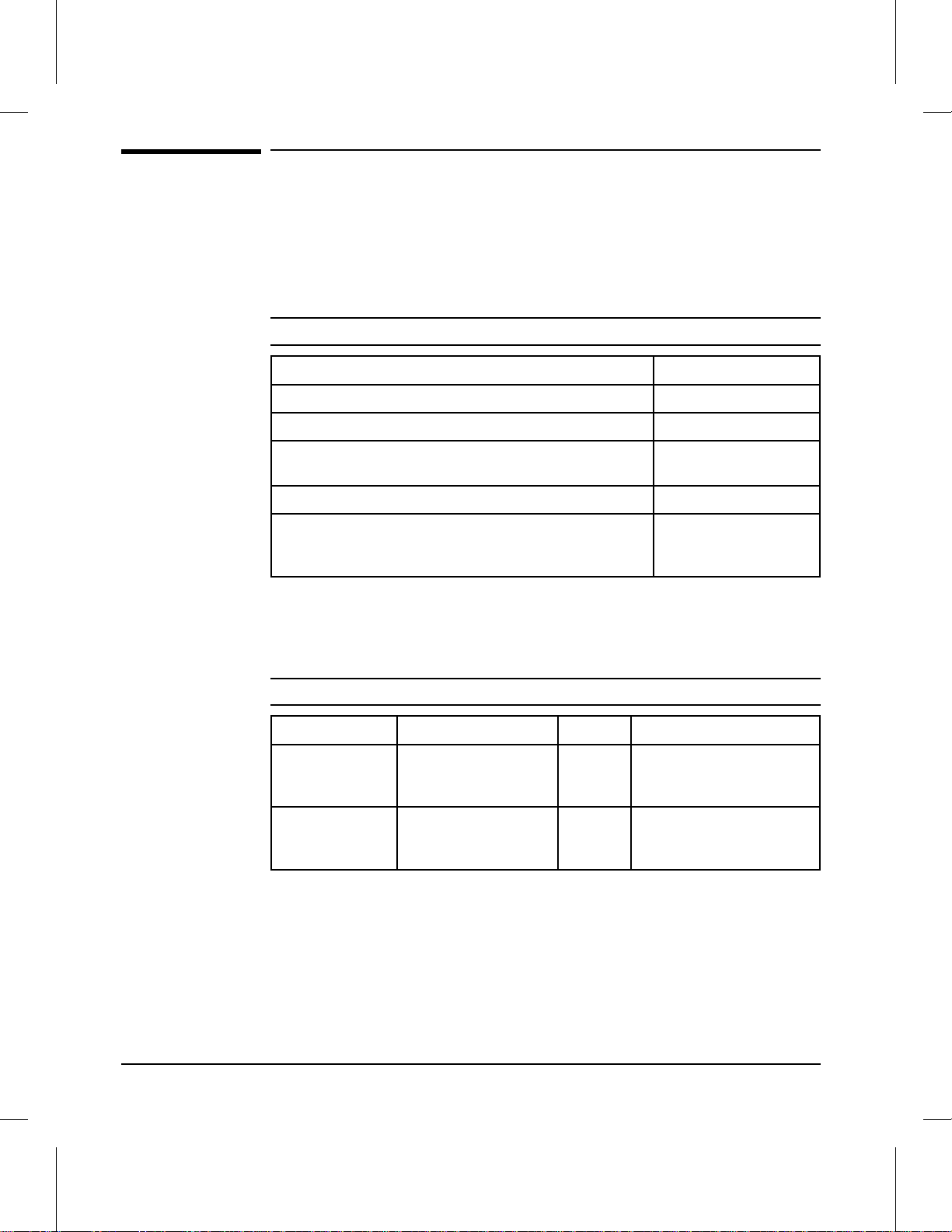

Table 1-1 Printer Features . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-2 Paper Capacitie s and Size s . . . . . . . . . . . . . . . . . . 1-4

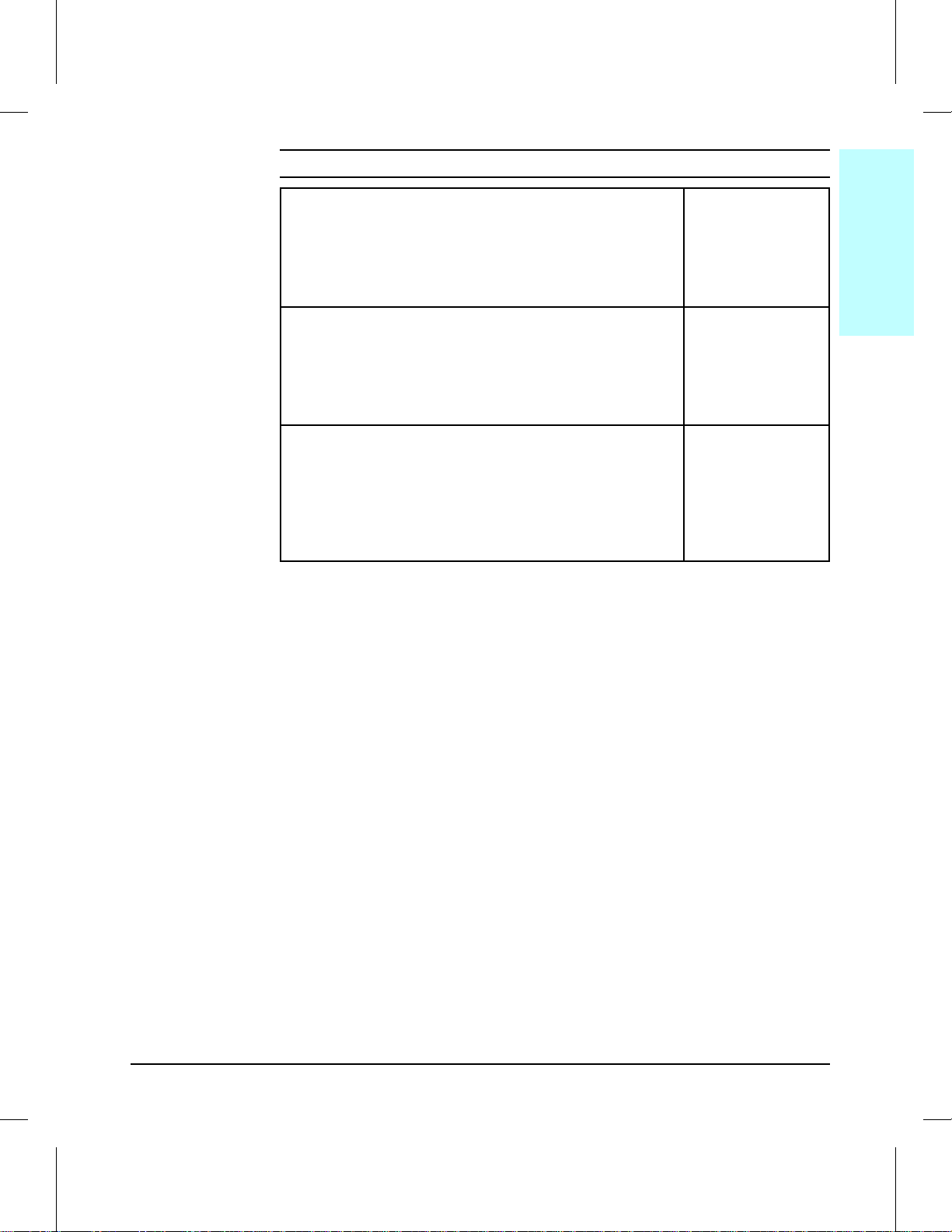

Table 1-3 Printer Dimensions . . . . . . . . . . . . . . . . . . . . . . 1-6

Table 1-4 Electrical Specifications . . . . . . . . . . . . . . . . . . . 1-6

Table 1-5 Acoustic Emissions . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-6 Related Documentation . . . . . . . . . . . . . . . . . . . . 1-19

Table 2-1 Printer and Toner Cartridge Environmental Conditions . . 2-4

Table 3-1 Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-2 Control Panel Keys . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-3 Settings and Defaults . . . . . . . . . . . . . . . . . . . . . 3-6

Table 3-4 Control Panel Menu Map . . . . . . . . . . . . . . . . . . 3-7

Table 3-5 Printing Menu Items . . . . . . . . . . . . . . . . . . . . . 3-8

Table 3-6 PCL Menu Items . . . . . . . . . . . . . . . . . . . . . . . 3-9

Table 3-7 Job Menu Items . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Table 3-8 Configuration Menu Items . . . . . . . . . . . . . . . . . . 3-11

Table 3-9 Memory Configurat io n Items . . . . . . . . . . . . . . . . 3-12

Table 3-10 Parallel Menu Items . . . . . . . . . . . . . . . . . . . . . 3-13

Table 3-11 Test Menu Items . . . . . . . . . . . . . . . . . . . . . . . 3-14

Table 3-12 Other Service Menu Items . . . . . . . . . . . . . . . . . . 3-18

Table 3-13 Menu of Resets . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Table 5-1 Clutches and Sensors . . . . . . . . . . . . . . . . . . . . . 5-26

Table 7-1 Status Messages . . . . . . . . . . . . . . . . . . . . . . . 7-6

Table 7-1 Status Messages — continued . . . . . . . . . . . . . . . . 7-7

Table 7-1 Status Messages — continued . . . . . . . . . . . . . . . . 7-8

Table 7-1 Status Messages — continued . . . . . . . . . . . . . . . . 7-9

Table 7-1 Status Messages — continued . . . . . . . . . . . . . . . . 7-10

Table 7-2 Service and Error Messages . . . . . . . . . . . . . . . . . 7-11

Table 7-2 Service and Error Messages — continued . . . . . . . . . . 7-12

Table 7-2 Service and Error Messages — continued . . . . . . . . . . 7-13

Table 7-2 Service and Error Messages — continued . . . . . . . . . . 7-14

Table 7-2 Clearable Warning Mes sage s . . . . . . . . . . . . . . . . 7-15

Table 7-4 Blank (White) Page . . . . . . . . . . . . . . . . . . . . . . 7-21

Table 7-5 Black Page . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Table 7-6 Faded Print . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Table 7-7 White Stripes (parallel to path) . . . . . . . . . . . . . . . 7-24

Table 7-8 Black Lines (perpendic ular to path) . . . . . . . . . . . . . 7-24

Table 7-9 Black Lines (parallel to pat h) . . . . . . . . . . . . . . . . 7-25

Table 7-10 Repetitive Defects . . . . . . . . . . . . . . . . . . . . . . . 7-25

Table 7-11 Bubble Print . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Table 7-12 Dropout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Table 7-13 Character Voids . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Table 7-14 Background Scatter (or Lead ing Ed ge Halo) . . . . . . . . 7-28

Table 7-15 Partial Blank Page . . . . . . . . . . . . . . . . . . . . . . 7-28

v

Page 8

Table 7-16 Faulty Registration . . . . . . . . . . . . . . . . . . . . . . 7-29

Table 7-17 Smeared Print . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Table 7-18 Compressed Print . . . . . . . . . . . . . . . . . . . . . . 7-30

Table 7-19 Image Skew . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Table 7-20 High Voltage System Checks . . . . . . . . . . . . . . . . 7-34

Table 7-21 Causes of Paper Curl . . . . . . . . . . . . . . . . . . . . . 7-35

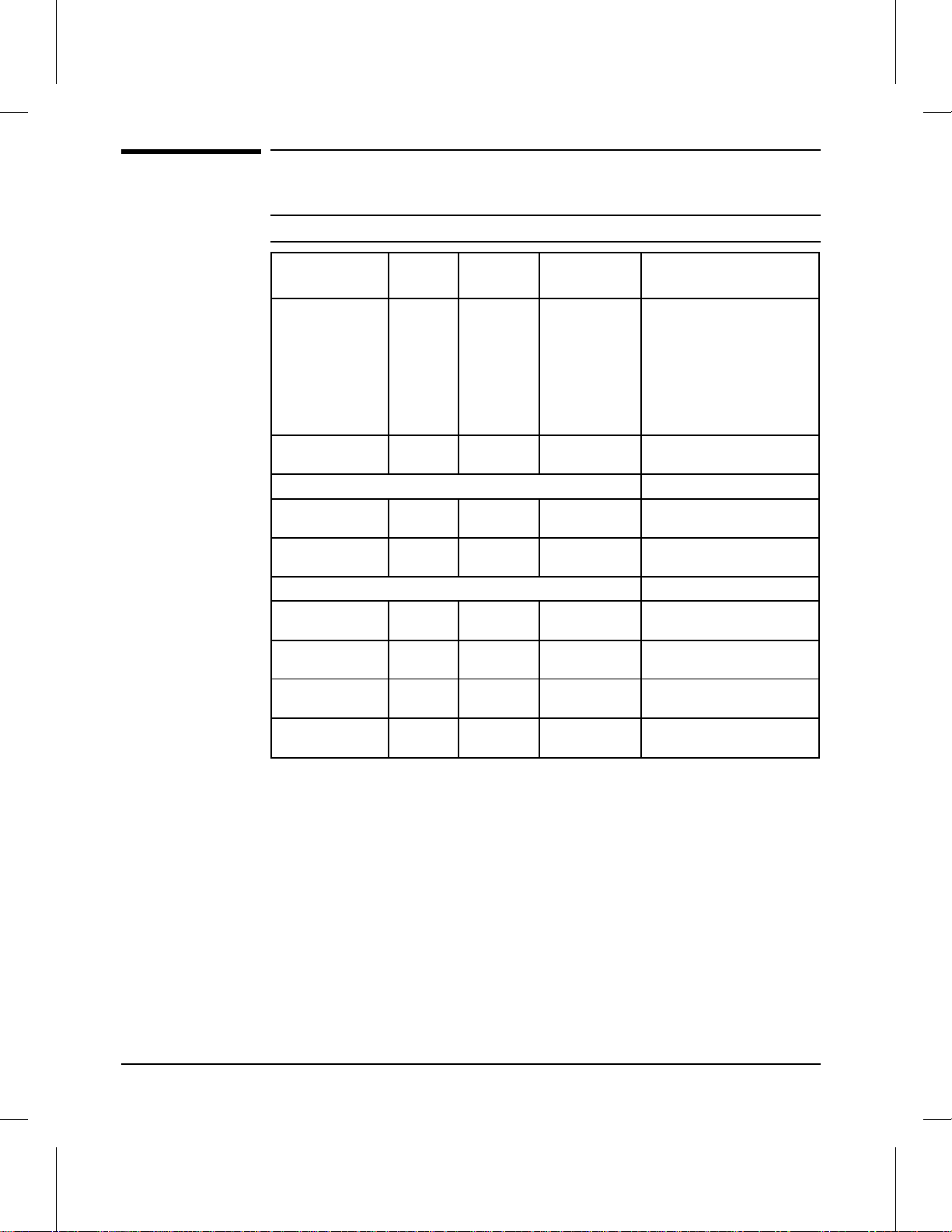

Table 8-1 Accessories and Supplies . . . . . . . . . . . . . . . . . . . 8-5

Table 8-1 Accessories and Supplies - continued . . . . . . . . . . . . 8-6

Table 8-A Common Fasteners Used in the Printer . . . . . . . . . . . 8-7

Table 8-A Common Fasteners Used in the Printer - continued . . . . 8-8

Table 8-B Replaceable Cables . . . . . . . . . . . . . . . . . . . . . . 8-8

Table 8-2 Covers and Doors . . . . . . . . . . . . . . . . . . . . . . . 8-11

Table 8-3 Foot Assemblies . . . . . . . . . . . . . . . . . . . . . . . 8-13

Table 8-4 Front Door Components (1 of 2) . . . . . . . . . . . . . . . 8-15

Table 8-5 Front Door Components (2 of 2) . . . . . . . . . . . . . . . 8-17

Table 8-6 Output Components . . . . . . . . . . . . . . . . . . . . . 8-19

Table 8-7 Internal Components (1 of 4) . . . . . . . . . . . . . . . . 8-21

Table 8-8 Internal Components (2 of 4) . . . . . . . . . . . . . . . . 8-23

Table 8-9 Internal Components (3 of 4) . . . . . . . . . . . . . . . . 8-25

Table 8-10 Internal Components (4 of 4) . . . . . . . . . . . . . . . . 8-27

Table 8-11 Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . 8-29

Table 8-12 Optional Lower Cassette Assembly . . . . . . . . . . . . . 8-30

Table B-1 Novell NetWare Frame Types . . . . . . . . . . . . . . . . B-6

vi

Page 9

Product Information

Chapter Contents

Printe r Feature s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Paper Capacities and Size s . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Model and Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . 1-5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Media Selection Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Adhesive Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Transparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Storing Print Media . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Shipping Print Medi a . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Produc t Overv i ew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

External Assembly Locations (1 of 2) . . . . . . . . . . . . . . . . . . 1-11

External Assembly Locations (2 of 2) . . . . . . . . . . . . . . . . . . 1-12

Front Door Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Internal Assembly Locations (1 of 2) . . . . . . . . . . . . . . . . . . 1-14

Internal Assembly Locations (2 of 2) . . . . . . . . . . . . . . . . . . 1-15

Service Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Phone numbers for the various sources are: . . . . . . . . . . . . . . 1-16

Exchange Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Toner Cartrid ge Life . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Refilled Toner Cartridges . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Recycling Toner Cart rid ges . . . . . . . . . . . . . . . . . . . . . . . 1-18

Related Documenta tion and Tr aining Media . . . . . . . . . . . . . . 1-19

1

Product Information 1-1

Page 10

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

HP AUDIO-TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

HP FIRST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

HP FIRST, U.S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

HP FIRST, Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

HP CompuServe Forum . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

North American Response Center (NARC) . . . . . . . . . . . . . . . 1-21

Other Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

One Year Return to HP Authorized Repair Station . . . . . . . . . . 1-22

Exclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

1-2 Product Information

Page 11

Printer Features

1

Product

Information

Table 1-1 Printer Features

Features LaserJet 4V

Print Speed 16 ppm letter or A4

Text & Graphics Resolution 600 dpi; plus Resolution

Printer Language(s)

Standard

Optional

Monthly Usage (pages) Up to 35,000 Up to 35,000

Memory:

Standard

Optional (maximum)

Internal Typefaces 45 PCL 45 PCL, 35 PostScript

Cartridge Slots 00

Standard Interfaces Bi-Tronics Parallel (IEEE 1284) Bi-Tronics Parallel (IEEE 1284)

Power Control Power Save Mode Power Save Mode

Control Panel 8 Keys,

1

2

8 ppm ledger (11x17) or A3

Enhancement technology (REt)

Enhanced PCL 5

Adobe PostScript Level 2

4 Mbyte

68 Mbyte total

16 Character VFD Display

(C3141A)

16 ppm letter or A4

8 ppm ledger (11x17) or A3

600 dpi; plus Resolution

Enhancement technology (REt)

Enhanced PCL 5

Adobe PostScript Level 2

None

12 Mbyte

44 Mbyte total

JetDirect MIO

8 Keys,

16 Character VFD Display

LaserJet 4MV

(C3142A)

EconoMode (toner saving) Yes Yes

1

Printer memory is optimized with Memory Enhancement Technology (MEt).

2

SIMMS available for use include 1, 2, 4, 8, and 16 Mbtye Modules. See “Accessories & Supplies”

in Chapter 8 for option product numbers.

Product Information 1-3

Page 12

Paper Capacities and Sizes

Table 1-2 Paper Capacities a nd Sizes

Name Product

Number

MP Tray N/A 100 sheets 17 to 28 pounds

Paper Output Bin N/A 250 sheets 17 to 28 pounds

Standard Cassettes

Letter/A4 C3160A 250 Sheets 17 to 28 pounds

11X17/A3 C3161A 250 Sheets 17 to 28 pounds

Optional Cassettes

Legal C3162A 250 Sheets 17 to 28 pounds

B4 C3163A 250 Sheets 17 to 28 pounds

B5 C3164A 250 Sheets 17 to 28 pounds

Lower Cassette C3760A 500 Sheets 17 to 28 pounds

Capacity Basis

Weight

(64 to 105 g/m2)

(64 to 105 g/m2)

(64 to 105 g/m2)

(64 to 105 g/m2)

(64 to 105 g/m2)

(64 to 105 g/m2)

(64 to 105 g/m2)

(64 to 105 g/m2)

Size Range

Maximum 11.7 x 17.7 in.

(297 x 450 mm)

Minimum 3.9 x 5.8 in.

(100 x 148 mm)

Standard sizes: A3, A4,

B/Ledger, B4, B5, Letter,

Legal, Executive

N/A

Selectable between letter

and A4

Selectable between ledger

and A3

Legal only

JIS B4 only

JIS B5 only

Adjustable for letter, legal,

ledger, A4, A3, and JIS B4

1-4 Product Information

Page 13

Identification

1

Product

Information

Model and Serial Numbers

The model number and serial numbers are listed on ident if icat ion la bels

located on the rear of the prin t er . The model nu mbe r is alph a nume ric , suc h

as C3141A for the HP LaserJet 4V printer.

The serial number contains informatio n about the Count ry of Origin, t he

Revision Level, th e Produc tio n Co d e, and prod uct io n numbe r of the pri n ter.

The rear labels also contain power rating and regulatory informat ion as

shown in Figure 1-1.

Figure 1-1

C3141A

C3141A

RS5-8403

C3141A

RS5-8402

POWER RATING:

220-240V 50 Hz, 2.8A

2

geprüfte

Sicherheit

CE1

POWER RATING:

100-120V 50-60 Hz, 5.7A 127V

®

CE1

51742

LISTED

ITE

660F

®

HEWLETT-PACKARD

11311 CHINDEN BLVD.

BOISE, IDAHO 83714 U.S.A.

MANUFACTURED:

XXXXXXXX

SERIAL NO.:

Made in Japan

HEWLETT-PACKARD

11311 CHINDEN BLVD.

BOISE, IDAHO 83714 U.S.A.

MANUFACTURED:

XXXXXXXX

SERIAL NO.:

Made in Japan

Sample Model and Serial Number Labels

60 Hz, 5.7A

FCC ID: B94C3141A

C3141A

Product Information 1-5

Page 14

Specifications

This section contains inf ormat io n on phy sic al and electr ical char ac t eristics

of the printer. For information on printer site requirements (such as

operating temperature and humid it y, ventilation, et c.) see Chapter 2.

Table 1-3 Pri nter Dimensions

Width 18 in. (46 cm)

Depth 23 in. (59 cm)

Description Dimension

Height (standard)

(with Optional Lowe r Cassett e)

Weight (with toner cartridge) 52 lbs. (23.5 kg)

Toner cartridge weight* 70.5 oz. (2000 g) ful l

* Some quantity of toner will reside in the waste toner area of a toner cartridge when the toner

supply is exhausted. Therefore, using toner cartridge weight may be an unreliable indication of

remaining toner supply.

Table 1-4 Electrical Specifications

Volts Freq Amps Watts (typical)

120 V ac ± 10%

100 V ac ± 10%

220 V ac ± 10%

240Vac ± 10%

*Operating current requirements.

50/60 Hz ± 2 Hz

50/60 Hz ± 2 Hz

50/60 Hz ± 2 Hz

50/60 Hz ± 2 Hz

12.4 @

120v

5.4 @

220v

12 in. (30 cm)

17.3 in. (44 cm)

56.4 oz. (1600 g)

empty

printing = 385

standby = 115

Power Save Mode = 31

printing = 400

standby = 120

Power Save Mode = 3 8

1-6 Product Information

Page 15

Table 1-5

1

Product

Information

Acoustic Emissions

Operation position (per ISO 9296)

Printing L

Standby

Power Save

dB(A) 55 db

PA

dB(A)

L

PA

L

dB(A)

PA

Bystander 1m (per ISO 9296)

Printing L

Standby

Power Save

dB(A) 51 db

PA

dB(A)

L

PA

L

dB(A)

PA

Sound Po wer (per ISO 9296)

Printing L

Standby

Power S ave

WAD

L

WAD

L

WAD

38 db

33 db

34 db

29 db

6.6 bels (A)

4.9 bels (A)

4.4 bels (A)

Product Information 1-7

Page 16

Media Selection Guidelines

NOTE

More detailed specifications are in the HP LaserJet Printer Family Paper

Specification Guide, HP Part No. 5002-1801 (See “R elate d Docum en t at ion

and Training Media” later in this chapter).

Paper

To achieve the bes t po ssible p rint quality and avoid pape r jams , follow these

guidelines for selecting paper:

• Use only copier grade paper that meets all specificat io ns in the pap er

specification guide. Avoid paper with embossed lettering, perforations, or

texture that is too smooth or too rough.

• Colored paper should be of the same high quality as white photocopy paper.

The pigments must withstand the fusing temperature of 392°

0.1 second with out det er ioration. Do not use pap er with a colo r ed co at in g

that was added after the paper was produced.

F (200° C) for

• Pre-printed forms must be print ed wit h no n- flam mable , heat- resis t ant inks

that do not melt, vaporize, or release hazardous emissions when subjected

to the fusing temperature of 392° F (200° C) for 0.1 second.

•

A small sample of a new print media should be tested before purchasing

large quantities.

Envelopes

CAUTION To prevent severe printer damage, do not use envelopes having windows,

clasps, snaps, or synthetic materials.

Envelopes can be print ed only from the MP Tray. Choose envelope s that

are well-constructed. They shou ld lay flat and be shar p ly c rease d. They

should not be wrinkled, nicked, or otherwise damaged. Envelope adhesive

must be compatible with the heat and pressure of the fusing process.

1-8 Product Information

Page 17

Adhesive Labels

1

Product

Information

Use the following guidelines when selecting labels:

CAUTION

This printer does not support use of labels with any exposed spaces.

Previous LaserJet family printers could safely print on label stock with

exposed spaces running lengthwise down the sheet.

Do not attempt to print on label she ets af ter any of the labels have be en

removed from the sheet . Damage t o the pri n ter may res ult .

• Labels must be arranged on the carrier sheet so that there are no exposed

spaces on the sheet. Using label stock with spaces between rows or columns

of labels can often result in labels peeling off during printing, causing

serious jamming and possible printer damage.

• The top sheet (printing surface) must be of copier quality and provide good

toner adhesion.

• The carrier sheet (bac k ing she et) mus t be c omp at ible wit h t he tem per at u r es

and pressure of the fusing process, and must be coat ed for easy rele ase of

the top sheet.

• The adhesive must be stable at the 392° F (200° C) temperatures

encountered for 0.1 second in the fusing process, and must not produce

emissions that exceed exposur e le ve ls or thre s hold limits establis he d by

OSHA and other safety agencies. Adhesives must not come into direct

contact with any part of the printer.

NOTE The MP Tray is recommended for printing adhesive labels.

A wide selection of suitable labels is available through Hewle t t-Pa ckar d. A

list of available sizes is located in the HP LaserJet Printer Family Paper

Specification Guide, HP Part No. 5002-1801.

Transparencies

Overhead transparencies used in HP LaserJe t printers must be able to

withstand the 392° F (200° C) temperatures encountered in the printer’s

fusing process for 0.1 second. Suitable transparency film is available

through Hewlett-Packard. Refer to the HP LaserJet Printer Family Paper

Specification Guide, HP Part No. 5002-1801 for details.

NOTE The MP Tray is recommended for printing transparencies.

Product Information 1-9

Page 18

Storing Print Media

Follow these guidelines when stacking and storing print med ia:

• Store paper in its ream wrapper until ready to use.

• DO NOT store cartons or reams directly on the floor where they will absorb

a higher moisture content. Instead , place cart ons on a pallet or on shelv es.

• DO NOT store individual reams in a manner that causes them to curl or

warp along the edges.

• Re-wrap partially used packages of media before storing.

• DO NOT stack more than six cartons on top of each other.

• Stack each carton upright and squarely on top of the one underneath.

• DO NOT place anything on top of media, regard less of whet he r the paper is

packaged or unpackaged.

• Store envelopes in a protective box to avoid damaging the envelope edges.

• Keep stored media away from temperature and humidity extremes.

• DO NOT store printed documents in vinyl folders (which may contain

plasticizers) or expose the docu ment s to petrole um base d solvent s.

Shipping Print Media

When shipping prin t media th rough dif ferent envir onm ents, plastic wrap all

cartons on the shipping palle t. When shipp ing media across bod ies of

water, wrap individual car ton s as well. Pac kagin g mus t protect the medi a

from physical damage.

1-10 Product Information

Page 19

Product Overview

1

Product

Information

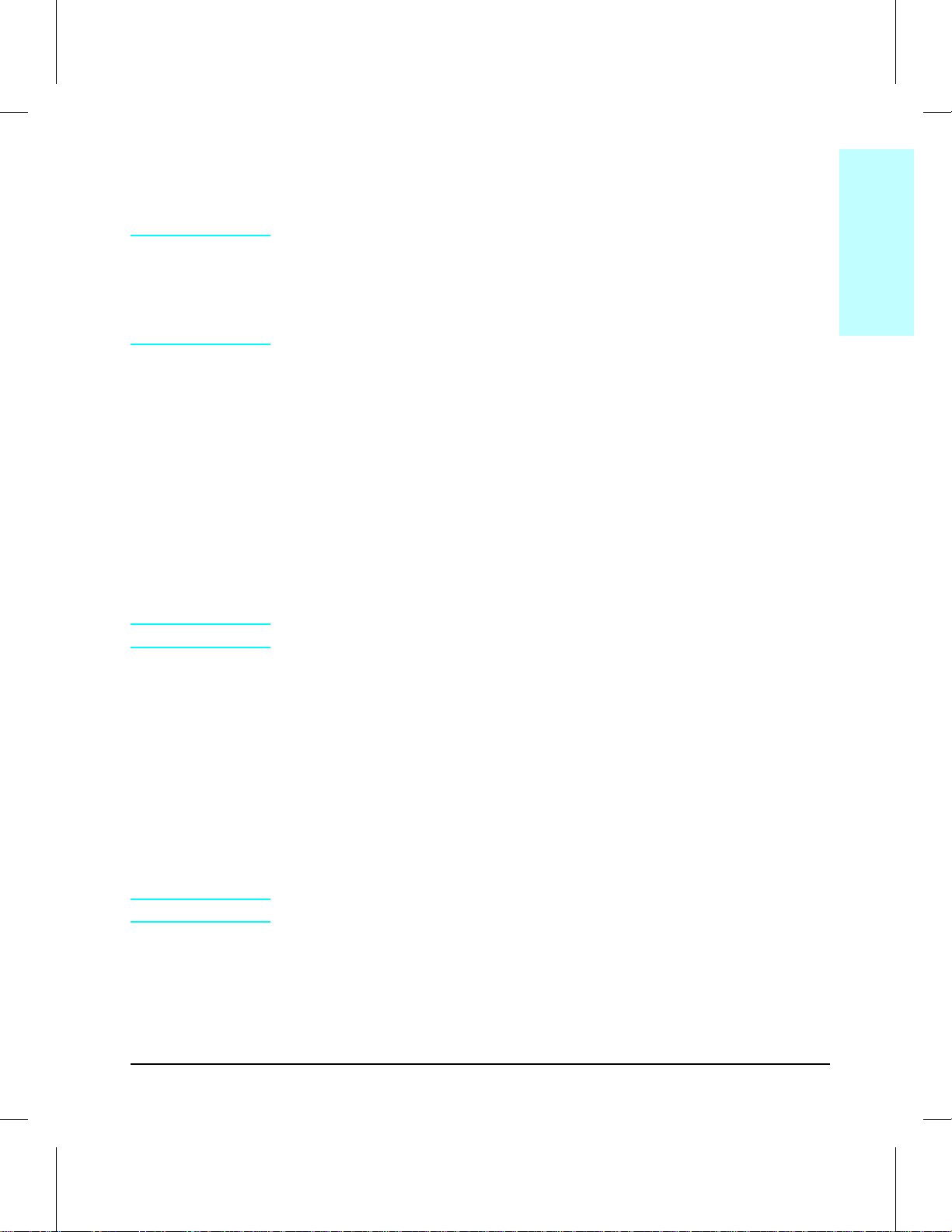

External Assembly Locations (1 of 2)

32

1

4

12

11

10

Figure 1-2 Front and Right Side View with MP Tray Ope n

1 Front Cover

2 Control Panel

3 Output Bin

4 Adjustable Paper Stop

5 250 sheet ledger (11x17) or A3 Paper Cassette

6 ON/OFF Switch

7 250 sheet Letter or A4 Paper Cassette

8 Front Cover Re lease Button

9 Multipurpose (MP) Tray

10 MP Tray Extension

11 MP Tray Paper Width Guides

12 Fuser Door

9

8

5

6

7

Product Information 1-11

Page 20

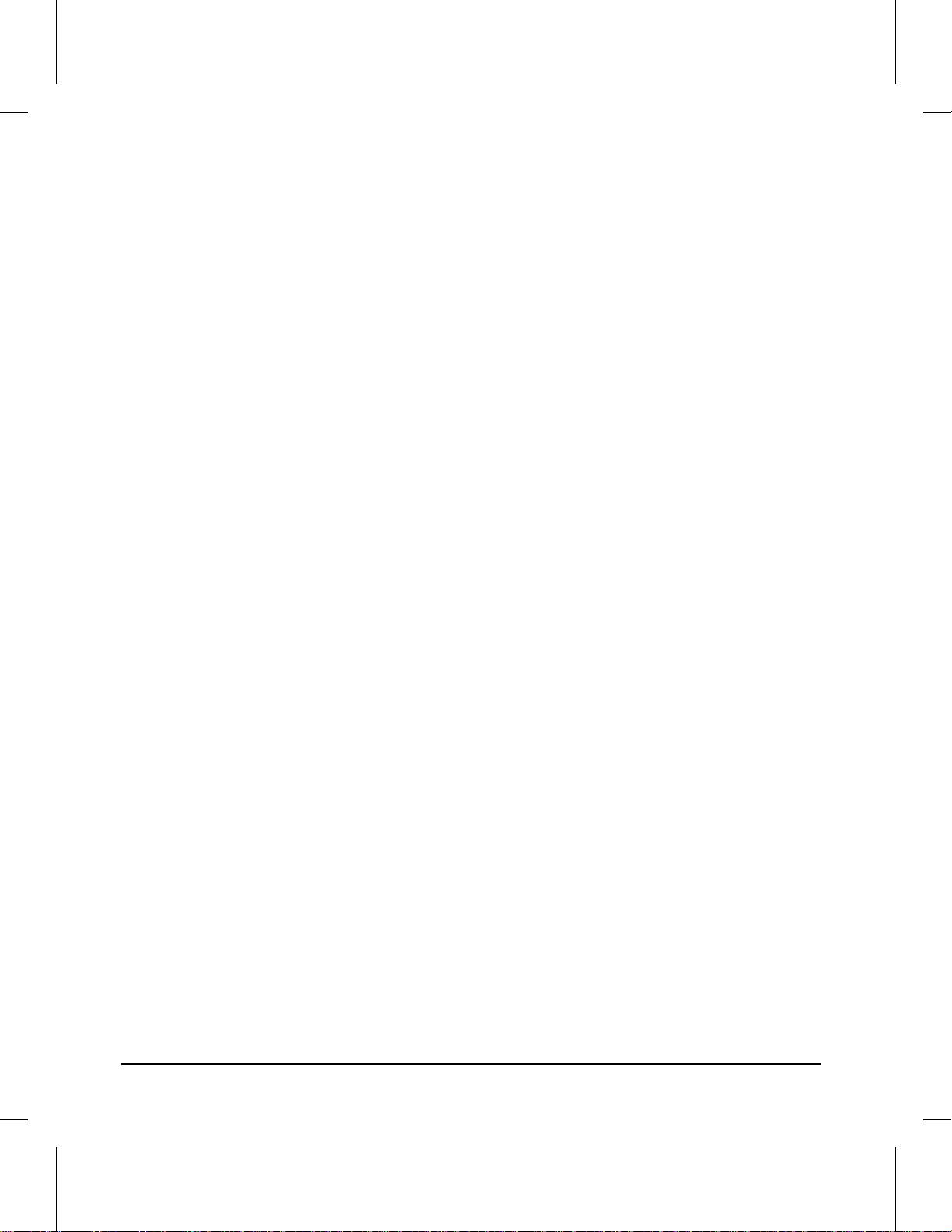

External Assembly Locations (2 of 2)

1

3 4

Figure 1-3 Rear and Left Side View

1 Optional 42.8 Mbyte Disk Accessory Location

2 Parallel Bi-Tronic s Int e rfa c e

3 SIMM Slots

4 Multiple I/O (MIO) slot

5 Power Supply Connector

6 Dust Cover for 250 sheet ledger (11x17) or A3 Paper Cas sett e

7 Serial Number Plate

8 Optional Universal Lower Cassette Connector Access

2

5678

1-12 Product Information

Page 21

Front Do or As sembli e s

1

Product

Information

1

2

3

4

5

6

7

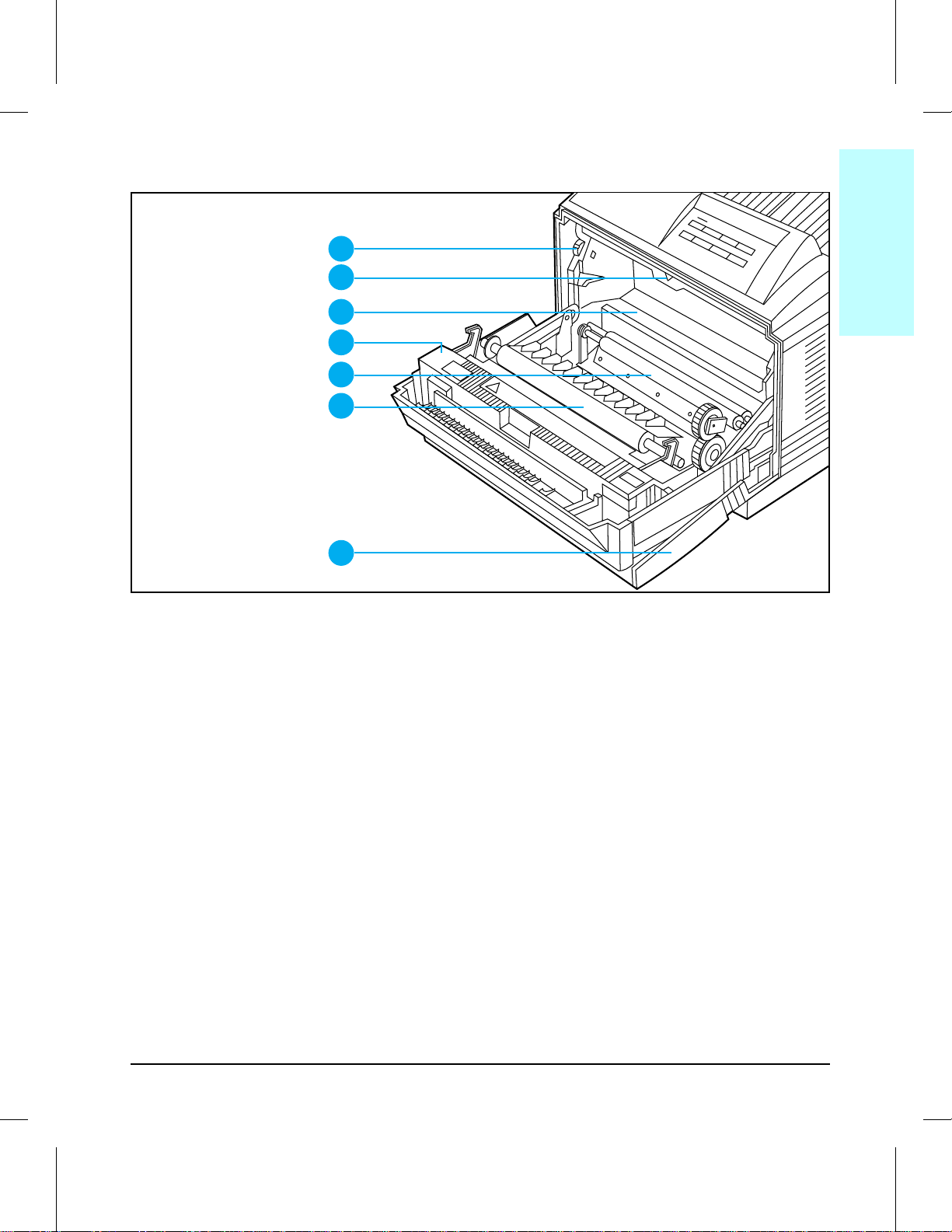

Figure 1-4 Front View with Front Cover Open (wit h toner cartridge re m oved)

1ASYDOOR

1 Print Density Dial

2 Arrow guide for installing toner cartridge in printer

3 Toner cartridge cavity

4 Fusing Assembly

5 Registratio n Roller

6 Transfer Roller

7 Multipurpose (MP) Tray

Product Information 1-13

Page 22

Internal Assembly Locations (1 of 2)

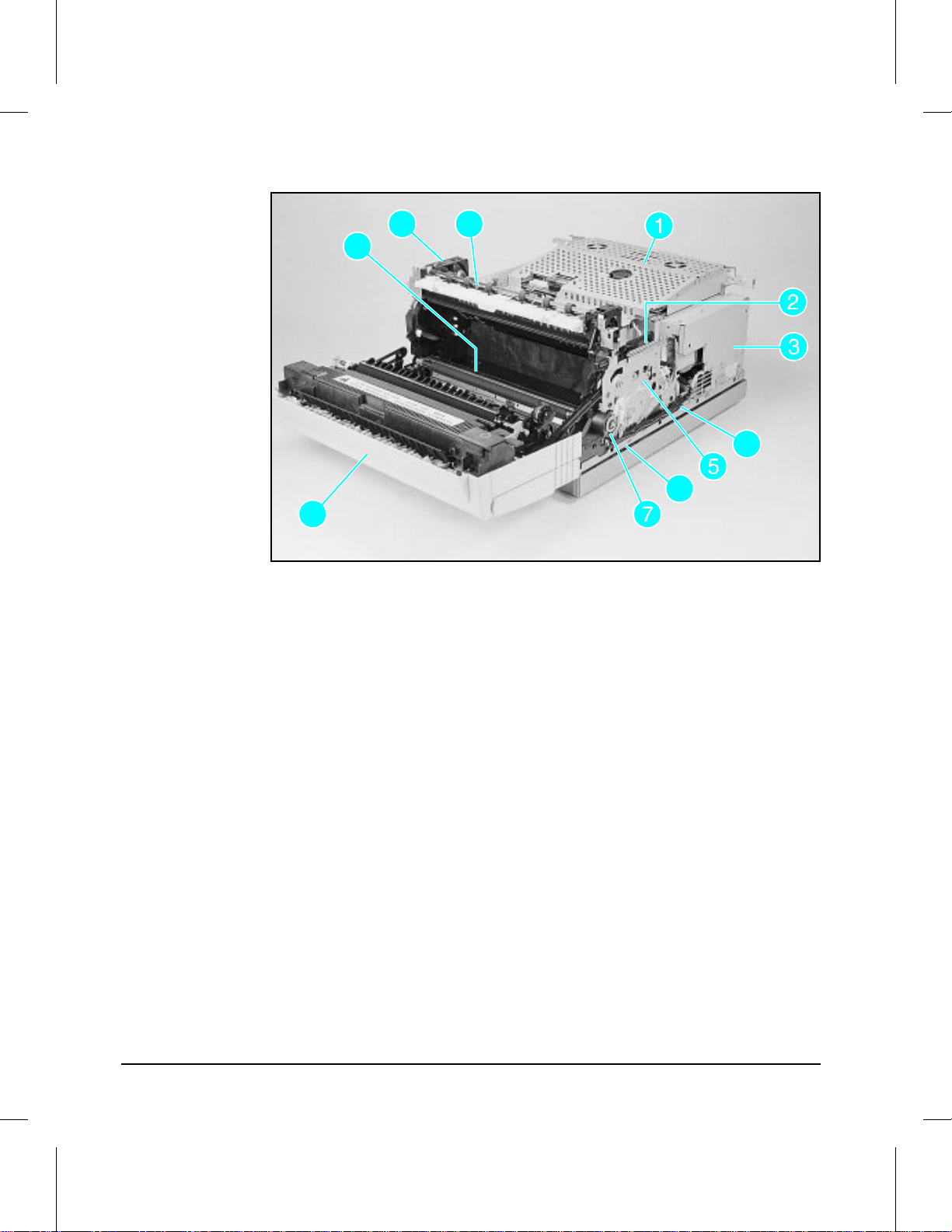

Figure 1-5I

Internal Assembly Locat ions (1 of 2)

1 Card Cage Assembly

2 Main Motor

3 Power Supply Unit

4 Fusing Assembly Cable

5 Main Drive Assembly

6 Cassette Pickup Roller Clutch

7 Registration Roller Clutch

8 Front Door

9 Cassette Pickup Roller (under plate)

10 Exhaust Fan (FM1)

11 Delivery Assembly

1-14 Product Information

Page 23

Figure 1-6

1

Product

Information

1ASSYSEC

Internal Assembly Locati ons (2 of 2)

1

2

8

7

Internal Assembly Loc ati ons (2 of 2)

1 Output Bin

2 Delivery Assembly

3 Fusing Rollers

4 Transfer Roller

5 Standard Paper Casse tt e

6 Optional Lower Paper Cassette

7 Cassette Pickup Roller

8 Toner Cartridge

3

4

5

6

Product Information 1-15

Page 24

Service Approach

Repair of the printer normally beg ins wit h us e of the printer ’s int ern al

diagnostics in conjunction with the troubleshooting procedures in Chapter 7.

Once a faulty part is located, repair is generally accomp lished by assembly

level replacement of Field Replaceable Unit s (FRUs). Some mechanic al

assemblies may be repaired at the subassembly level. PCA compone nt

replacement is not supported by Hewlett-Packard.

Ordering Parts

Field replaceable part numbers are found in Chap ter 8 of this manual.

Replacement parts may be ordered from HP’s Service Materials

Organization (SMO), or Support Materials Europe (SME).

Phone numbers for the various sources are:

• SMO (Service Materials Organization)

1-800-227-8164 (U.S. only)

• SME (Support Materials Europe)

(49 7031) 142253

• HP’s Distribution Center (HPD)

1-303-353-7650

Exchange Program

HP offers remanufactured assemblies for some parts. These are ident ified

in Chapter 8 and can be ordered through Parts Direct Ordering (PDO), or

Support Materials Europe (SME).

Consumables

The printer has no consumables other than the toner cart ridge, which may

be ordered directly from Hewlett-Packard. Refer to Chapter 8 for ordering

information.

1-16 Product Information

Page 25

Figure 1-7

1

Product

Information

Toner Cartridge Life

The toner cartridge (C3900A) is designed to simplify replacement of the

major “consumable” parts. The toner cartridge contains the printing

mechanism and a supply of toner.

At 5% page coverage, a toner cartrid ge will pri n t approximat ely 7500 p ages

(see Figure 1-7).

Sample 5% Page Coverage

When regularly printin g pag es wit h less cover age , such as sho rt memo s, a

toner cartridge should print more th an 7 500 page s . However, the cart rid ge

may print less than 7500 pages if routinely printing very dense print.

NOTE For best results, always use a toner cartrid ge be fore the expir at io n d at e

stamped on the toner cartridge box.

Product Information 1-17

Page 26

Refilled Toner Cartridges

While Hewlett-Pack ar d does not prohibit the use of refilled toner car trid ge s

during the warranty period or while under a maintenance contract, their

use is not recommended for the following reasons:

• Repairs resulting from the use of refilled tone r car trid ges ar e not covered

under the Hewlett-Packard warranty or maintenance contract.

•

Hewlett-Packard has no control or process to ensure that a refilled toner

cartridge functions at th e high lev el of reliability of a new HP LaserJet

toner cartridge. Hewlett-Packard also cannot predict what the long term

reliability effect on the printer is from using different toner formulations

found in refilled cartrid ges.

• The print quality of HP LaserJet toner cartridges influences the customer’s

perception of the printer. Hewlett-Packard has no control over the actual

print quality of a refilled toner cartridge.

Recycling Toner Cartridges

In order to reduce waste, Hewlett -Pac kar d ut ilize s a recycling progr am fo r

used toner cartridges. Cartridge components that do not wear out are

recycled. Plastics and other materials are recycled. Hewlett-Packard pays

the shipping costs from the user to the recycling plant. For each cartrid ge

returned, HP don a te s one U .S. d ollar t o be shared by the Nature

Conservancy and the National Wildlife Federation. To join this recycling

effort, follow the instructions inside the toner cartridge box.

1-18 Product Information

Page 27

Related Documentation and Training Media

1

Product

Information

Table 1-6 lists where to order related documentation. See “Ordering Parts”

earlier in this chapter.

Table 1-6 Related Documentation

Description Part Number SMO SME HPD

HP LaserJet Family Quick Ref er enc e

Service Guide

HP LaserJet 4V and 4MV Printers

User’s Manual

HP PCL5 Printer Langua ge Technic al

Reference Information Package

HP LaserJet Printer Family Paper

Specifications Guid e

Introduction to Netw ork Printing,

Network Printi ng for the Enterprise,

LaserJet Basic Hardwar e Training Course

Solutions Connectivity Guide

(Ava il abl e f r o m L D C 1-800-544-9976)

Specific Application Drivers

1

Shipped with printer. (English version part number is shown. Other translations are available

see your local HP Sales Office.)

1

Book 5961-0649 X X

Video 5961-0650 X X

5961-0531 X X

C3141-90901 X X

5961-0601 X X

5002-1801 X

5961-0880 X X

5962-8536E

X

Product Information 1-19

Page 28

Technical Assist ance

HP ASAP (Automated Support Access Program) provid es free technica l

support infor mat io n 24 h our s a da y , 7 days a week. The ASA P syst e m

includes HP AUDIO-TIPS and HP FIRST, both explained below . The ASAP

service requires a touchtone phone.

HP AUDIO-TIPS

HP AUDIO-TIPS is an interactive voice response system providing

prerecorded answers to the most frequently asked questions by HP LaserJet

printer users. Helpful “Sys t em Map s” t o the HP AU DIO- TIPS r ecor din gs

are available by fax through HP FIRST.

HP FIRST

HP FIRST (Fax Information Retrieval Support Technology) is a phone-in

fax service providing technical informat ion f or HP LaserJe t users as well as

service personnel. Receiving a fax requires a group 3 facsimile mac hine or

fax card. Service related information includes:

• Service notes (HP Authorize d deale r s)

• Application notes

• Product Data Sheets

• Material Safety Data Sheets (MSDS)

•

Typeface and accessory information

• Printer support software information

•

Toner information

• Driver request form and Software Matrix.

HP FIRST, U.S.

Call the HP ASAP system (1-800-333-1917) and follow the voice prompt s to

enter HP FIRST.

HP FIRST, Europe

Call HP FIRST at one of the following numbers:

U.K., 0800-96-02-71 Netherlands, 06-0222420

Belgium (Dutch), 078-111906 Germany, 0130-810061

Switzerland (German), 155-1527 Austria, 0660-8128

For English service outside the above countries, (31) 20-681-5792.

1-20 Product Information

Page 29

HP CompuServe Forum

1

Product

Information

CompuServe members can download a variety of support materials

including product data sheets, software application notes, and printer

drivers for many popular software app licat ion s. Membe rs may also post and

reply to questions in an interact ive form at . To access the HP Fo rum, type

GO HP at any prompt. For more information, or to join CompuServe, call

1-800-524-3388.

North American Response Center (NAR C)

The North American Response Center (NARC) is available for technical

support to assist service technicians. The NARC can be reached at

1-800-544-9976 between 7:00 A.M. and 6:00 P.M. Mountain Standar d Time,

Monday, Tuesday, Thursday and Fr iday. On Wedne sdays the office clos es

at 4:00 P.M.

Other Areas

Outside of North Ame ric a and Eur op e, co ntac t your local HP sale s offic e for

assistance in obtaining technical support .

Product Information 1-21

Page 30

Warranty Statement

Warranty

This warranty give s spec ific legal rights. There may also be other rights

which vary from area to area. Refer to Appendix E in the User’s Manual for

further warranty inf ormation.

One Year Return to HP Authorized Repair Station

Hewlett-Packar d war ra n ts th e LaserJet 4V/ 4MV pr int er against de fects in

materials and workmanship for a period of one year from receipt by the

customer. During the warranty p er iod, HP will, at its option , either repair

or replace products which prove to be defective.

NOTE

User maintenance components are not covered under the

HP LaserJet 4V/4MV printer factory warranty. A separate maintenance

agreement may be written to cover these components.

Exclusions

The warranty on printers shall not apply to defects resulti n g from:

• Improper or inadequate maintenance by customer.

• Customer supplied software or interfacing.

• Unauthorized modification or misuse.

• Operation outside of the environmental specifications for the product.

• Operation of non-supported printing media.

• Duty cycle abuse maximum (printing more than the equivalent of 35,000

single-sided page s p er mon th) .

• Operating the printer from a mechanical switchbox wit hout a design ated

surge protector.

• Improper site preparation and maintenance.

• Use of non-HP toner cartridges (see the following explanation), SIMM

memory boards, or interface boards.

The use of non-He wle t t-Packard toner cartridges doe s not aff ec t eithe r th e

warranty or any maintenance contrac t p urchas ed from HP. However, if an

HP LaserJet printer failure or if printer damage is found to be directly

attributa ble t o the use o f any non- HP product, the r e pair will not be covered

under the warranty or HP main ten anc e contr ac t. Hewlet t-Packard cannot

recommend use of non-HP cartridges, either new or remanufactured,

because they are not HP products and HP cannot influence or control their

quality.

1-22 Product Information

Page 31

Site Requirements

Chapter Contents

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . 2-4

2

Site Requirements 2-1

Page 32

2-2 Site Requirements

Page 33

Operating Environment

2

Site

Requirements

The environmental specifications (listed in the “Specifications” section of

Chapter 1) must be maintained to ensur e the proper op eratio n of this

printer. Consider the following points before installing the print er:

• Install in a well-vent ilated, dust-free area.

• Install on a hard, flat and continuous surface, with all four printer feet

level. Do not install on carp et or other soft sur f ac es.

• Ensure adequate power is supplied . Printer power requir ement s are listed

under “Specifications,” in Chapter 1.

• Install where there is stable temperature and humidity, away from water

sources, humidifie rs, air cond it io ne r s, r efri g er at ors , or othe r maj or

appliances.

• Install away from direct sunlight, open flames, or ammonia fumes. If the

printer is placed near a window, make sur e t he wind ow has a cu rt ain or

blind to block any direct sunlight.

• Install with enough space around the printer for proper access and

ventilation (see Figure 2-1).

• Install printer away from the direct flow of exhaust from air ventilation

systems.

Site Requirements 2-3

Page 34

Space Requirements

49.2 in (1250mm)

3.94 in (100mm)

3.35 in (85mm)

Optional Lower Cassette

Figure 2-1 Printer Space Requirements

3.54 in

(90mm)

25.35 in (644mm)

(340mm)

13.38 in

(440mm)

17.3 in

Environmental Req uirements

Keep the printer within the following environmental conditions for optimum

performance.

Table 2-1

2-4 Site Requirements

Printer and Toner Cartridge Environm ental Condi tions

Temperature 10° to 32.5° C

Humidity 20 to 80% RH

Item Operating Storage

0° to 40° C

(50° to 90.5° F)

(32° to 105° F)

10 to 95% RH

(with no condensation)

(with no condensation)

Page 35

Operating Overview

Chapter Contents

Using the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Control Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Control Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Settings and Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting the Display Language . . . . . . . . . . . . . . . . . . . . . . 3-6

Control Panel Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Printing Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

PCL Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Job Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Memory Configur at ion Men u . . . . . . . . . . . . . . . . . . . . . . 3-12

Parallel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Power Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting the Page Count and Serial Number . . . . . . . . . . . . . . 3-17

Setting the Cold Reset Default Paper Size . . . . . . . . . . . . . . . 3-18

Other Service Mode Items . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Testing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Printing a Self Test Page . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Understanding the Self Te st Pr int out . . . . . . . . . . . . . . . . . . 3-20

Self Test Printout Key . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Engine Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Resetting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Simple Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Cold Re se t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Menu of Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3

Operating Overview 3-1

Page 36

3-2 Operating Overview

Page 37

Figure 3-1

3

Operating

Overview

Using the Control Panel

Control Panel Layout

The control panel consists of a 16-charac t er disp lay pane l, t hree indicator

lights, and eight keys, three of which have alternate functio ns.

Ready

On Line Form Feed MP Paper Size Enter

Menu Item

Shift Reset Continue

+

-

Control Panel Layout

Operating Overview 3-3

Page 38

Indicator Lights

The control panel indicator lights are described in the following table. The

column labeled “Do this:” includes an action only whe n an ac tion is

required.

Table 3-1

When this

indicator:

Ready On

On Line On

Form Feed On

Looks like this: It means this: Do this:

Flashing

Off

Flashing

Off

Flashing

Off

Indicator Lights

Ready to print.

Print job in progress.

Not ready to print.

Ready to receive data.

Going off line.

Printer is off line. Access other ke y s or pres s [On Line]

Data still in print buffer.

Buffered data is

printing.

No buffered data in

printer.

Let job finish printing.

See display panel message.

to place printer back on line .

Take printer off line; press

[Form]Feed]; press [On Line] to place

printer back on line.

Control Panel Keys

You must take the printer off line to use con trol pane l keys , excep t for the

MP Paper Size and keys related to its operatio n.

Each key in the top row has a single function. Three keys in the bottom row

have more than one function. The primary function name of each key

appears above the key. The alternate function name of each key appears

below the key. These alternate function names are color-coded to match the

[Shift] key, which you must hold down while selecting an alternate function.

You can rapidly scroll through some selections by holding down the [+/-] key.

3-4 Operating Overview

Page 39

Table 3-2

3

Operating

Overview

Key Explanation

[On Line] Switches the state of communicati on betw een comput er and printer either on

[Form Feed] Prints any data remaining in the page buf fer. Does not send a b l ank sheet of

[MP Paper Size] Only activ e when MP Tray is set to ca sset te (s elec t MP TRAY=CASS in the

[Enter] Saves a sel ect ed co ntr ol panel key setting. An asterisk (*) appears next to the

[Shift] Accesses color coded alternate functions of bot tom -ro w cont rol panel k eys.

[Menu] Cycles through menus, returning to 00 OFFLINE at the end of the cycle unless a

Control Panel Keys

(on line) or off (off line). For the printer to receive data, both the On Lin e an d

Ready indicator lights must be lit.

paper through the printer.

Configuration Menu). Selects size of paper loaded in MP Tra y. Pressing [Enter]

saves your se lecti on.

saved selection, indicating that it is now the default. Default settings remain in

place when the printer is reset or switched OFF.

Hold down while pressing an assoc iated k ey.

problem is encounter ed. When an option is added to the printer (P os t Script, f or

example), a menu for that option appears in the sequence (see “Control P an el

Menus” in this chapter).

Reset

[Shift] + [Reset]

[Item] Cycles through the selected menu items. Menu items vary depending on

Continue

[Shift] + [Continue]

[+] or [-] Press [+] to step through menu items. Hold down [+] to scroll through items.

Resets the printer (displays 07 RESET). Clears the page and active I/O buffers

and makes the current cont rol panel values the defaults (see “Menu of Resets”

at the end of this chapter).

options installed and configur ation of other menu choices.

Allows the printer to resum e print i ng after a print er mes sage ( su ch as

20 MEM 0V ERFLOW) has placed it off line. Clears most printer messages (such

as manual f eed reques t s) and plac es the print er bac k on lin e .

Press or hold down [Shift] + [-] to move through items in reverse order.

Operating Overview 3-5

Page 40

Settings and Defaults

The printer makes most printing decisions based on either temporary

settings or permanent defaults.

NOTE

Table 3-3

Settings you send from software applications override printer d efaults .

Settings and Defaults

Setting or Default Explanation

Temporary setting A value set for the current print job by your software

application. For example , a request from your

software to print three copies i nstead of t he cont rol

panel default val ue of one co py is a temporary

setting. The printer continues to use the temporary

setting until you send another software request or

reset the print er.

Control panel defaul t A value you set at the control panel by selecting a

menu item, then pressing [Enter]. An asterisk

appears followi ng the item name to in dicat e that it is

now the defaul t. The printer retains this def aul t

when it is switched off.

Fac tory defaul t The value set for each menu ite m at the factory.

Factory defaults are marked with an asterisk in the

menu tables on the pages that follow.

Setting the Display Language

1 Press and hold [Enter] while powering on. Hold [Enter] until CONFIG

LANGUAGE appears.

2 Releas e [Enter]. 05 SELF TEST appears briefly. Wait for LANG=ENGLISH to

appear.

3 Click [+] repeatedly until the desired language appears.

4 Click [Enter] to save your choice . An asterisk (*) will appear beside your

language selection.

3-6 Operating Overview

Page 41

Control Panel Menus

3

Operating

Overview

Pressing [Menu] gives you access to the menus, one after another. Each

menu is described in a separate table in this sectio n. When option s (suc h as

the PostScript language) are inst alle d in the pri n ter , new menus or menu

items automatically ar e add ed in th e appropriat e menus .

Table 3-4 Cont rol Panel Menu Map

PRINTING MENU PCL MENU PS MENU JOB MENU CONFIG MENU MEM CONFIG

COPIES FONT SOURCE PRT PS ERRS RESOLUTION MP TRAY IO BUFFER HIGH SPEED SELF TEST

P APER FONT NUMBER JAM RECOVER PERSONALITY LOCK** IO SIZE ADV FNCTNS CONT SELF TEST

ORIENT ATION PITCH or

FORM SYM SET IO TIMEOUT AUTO CONT PCL MEM P CL DEMO PAGE

MANUAL FEED LOW TO NER PS MEM PS CONFIG P A GE

RET PS TYPEFA CE

ECONOMODE PS DEMO PAGE

You can change these menu items either from a software

application or from the control panel.

Shaded items appear when the PostScript option is installed.

Additional menu items may appear if options are installed (such as MIO cards).

* These items will appear if sufficient memory is available.

** The Lock function is only available if MP Tray = Cassette.

PT SIZE

PWR SAVE CLR WARN RESRCSAVE PCL TYPEFACE

You can change these menu items only from the control panel.

MENU*

PARALLEL MENU TEST MENU

LIST

LIST

To select a menu item:

1 Press [On Line] to take the printer off line.

2 Press [Menu] repeatedly until the menu you want app ear s .

3 Press [Item] repeatedly until the item you want appears.

4 Press [+] repeatedly (or hold down [+] to scroll) until the setting you want

appears.

5 Press [Enter] to save your selection. An asterisk appears next to your

selection, indicating that it is now the default.

6 Press [On Line] to place the printe r back on line.

Operating Overview 3-7

Page 42

Printing Menu

You can override or change any Print ing Menu set ting t hro ugh most

software applications. When you change a setting from the printer control

panel, the new setting becomes the printer default value.

Table 3-5 Printing Menu Items

Item Options Explanation

COPIES 1* to 999 Select any number from 1 to 999.

PAPER

ORIENTATION P*, L P means portrait

FORM 5 to 128 LINES

MANUAL FEED OFF*, ON Av ailab le only through MP Tra y. When Manual Feed i s

RET OFF, LIGHT, MEDIUM*, DARK Refines print quality by smoothing the fine gradations

ECONOMODE OFF*, ON EconoMode substantially reduces the amount of toner

*Factory default. **Factory default for 110V printers. ***Factory default for 220V printers.

LETTER**, LEGAL, A4***,

EXEC, 11x17, A3, JIS B 4,

JIS B5, CUSTOM, COM10,

MONARCH, C5, DL, B5,

JPOST, JPOSTD

(60** and 64***)

Sets default image size at which print er formats page

unless a software setti ng o v er rides i t.

Sets vertical spacing, from 5 to 128 lines, for default

paper size. Scrolls in increments of 1 line.

on and the MP Tray is empt y, the printer goes off lin e

when it receives a print job and displays MF FEED

paper size

a sheet in the MP Tray, the printer goes bac k on li n e

and prints the sheet.

along the angles and curves of the printed ima g e.

on the printed page; the resul t is similar to draf t mode

on some dot matrix printers.

or ME FEED

envelope size

. Whe n you place

3-8 Operating Overview

Page 43

PCL Menu

3

Operating

Overview

PCL Menu items allow you to choose the pr inter def ault font and symbo l

set. Printer Control Language (PCL) is HP print er languag e. You can also

change such PCL Menu items as the FONT SOURCE through your so ftware

application.

Table 3-6 PCL Menu Items

Item Options Explanation

FONT SOURCE I*

S

Mn

FONT NUMBER 0 to 999 The printer assigns a number to each typeface and lists them on the

PITCH

or

PT. SIZE

SYM SET ROMAN-8*

Range

Pitch:

10.00*

Point:

12.00*

Many others

Internal fonts*

Permanent soft f ont s

SIMM Module: n=s l ot n umber. Typef ac es stored in one of the f our

ROM SIMM slots ( M1=s lot 1, for example).

PCL Typeface List, accessed under the Test Menu (see Table 3-4 ).

The font number appears in the F o n t # column of the printout.

You must select a FONT SOURCE in order for FONT NUMBER to appear.

Defaults and other conditions are as follows:

I*

0* is the default.

S

1* is the default. You can select from the control panel

only a permanent soft font that is currently in the printer.

Mn

The pitch or point size item avai la b le depends on the FONT SOURCE

and FONT NUMBER you select.

Pitch:

Point:

A symbol set is a unique grouping of all the charact ers in a font.

PC-8 or PC-850 is recomme nded for line draw char ac ter s . Symbol

set charts appear in the

SIMM Module; n=SI MM slot (1- 4). Typefaces stored in

one of the four ROM SIMM slots (M 1=s lot 1, f or example).

For fixed-pitch outline typefaces, select pitch sizes from

.44 to 99.99.

For proportionally-spaced outline typefaces, select point

sizes from 4.00 to 999.75 in .25-point incr ement s .

PCL 5 Technical Reference M anual

.

*Factory default.

Operating Overview 3-9

Page 44

Job Menu

The items available in the Job Menu can also be changed through soft war e

applications if an app r opr iate p r int er driv er is insta lled .

Table 3-7 Job Menu Items

Item Options Explanation

RESOLUTION 300 or 600* For most purposes, 600 dpi is recommended.

PERSONALTY A U TO*

PCL

PS

PWRSAVE OFF, 15 MIN,

30 MIN*, 1 HR,

2 HRS, 3 HRS

IO TIMEOUT 5 to 300

15*

Per so nality

from its standard personality, PCL, to other personalities,

such as P os tScript. When PERSONA LTY is set to AUTO, the

printer analyzes each print j ob it rec eives and switches

personalities automatically.

When you make ano ther personal i ty the default, the printer

stops switching person a lities autom at icall y unles s a softw ar e

command specifically instructs it to do so. If the PostScript

option is not install ed, PERSONALTY will not display in the Job

Menu.

If you select PS as the default, you may want to set

ADV FNCTNS in the Parallel Menu to OFF.

Sets the amount of time the printer is idle bef or e the fus er

shuts down. The printer automatically starts warming the

fuser when you send a print job to the printer, press a control

panel key, load or remove paper, or open the top door.

NOTE: A ten second interval is also availab l e in Service Mode

(see “Service Mode” later in this chapter ).

I/O timeout refers to the time, measured in seconds, that the

printer waits before ending an incomplete pri nt jo b (it scrol l s in

increments of 10). This setting allows you to adjus t tim eout for

best performance. If data from other ports appears in the

middle of the print job, increase the timeout va lue .

means printer language. The print er can switch

PAGEPRO TCT AUTO*

ON

*Factory default.

3-10 Operating Overview

You will not see this item unless the er ror 21 PRINT OVERRUN

has occurred. (See Chapter 7 for error message

troubleshooting.)

Page 45

Configuration Menu

3

Operating

Overview

Configuration Menu items cannot be chan ged from softwar e app lic at ions .

Table 3-8 Configuration Menu Items

Item Options Explanat ion

MP TRAY FIRST* Draws paper from the MP Tray regardless of paper si ze

(this setting not recommended for shared environment s).

CASS The MP Tray operates as a paper cas set te . Paper feeds

automatically. Paper size must be selected with the

[MP[Paper]Size] key because the MP Tra y can not sens e th e siz e

of the paper . The [MP [Paper] Size] key works only when the MP

Tray is set to CASS.

MANUAL Operates only as a manual f eed tray.

LOCK NONE*

MP

PC

LC

and combinations

CLR WARN ON* Clearable warnings are displayed until ackn o wledged by

JOB Clearable warnings are displayed from the time they are

AUTO CONT ON* When an error message is displa yed, printer goes offline for ten

OFF When an error message is displayed, printer goes offline and

LOW TO NER CONT* Printer remains on-line and continue s to print on encou nteri n g

Locks out a tra y or a com bi nati on of tr ays so the printer will not

draw paper. Lock-out options depend on h ow t he MP Tray is

configured and whether an optional 500-sheet Low er Cassett e

(LC) is installed. When the MP Tray = MANUAL or FIRST or no

optional Lower Cassett e is install ed, no paper sources are

available to be locked out. All possible options are:

NONE

MP

PC

LC

PC MP

LC MP

LC PC

pressing [Continue].

detected until the start of the next job.

seconds, then returns to on-line state .

remains offline until op er ator pres ses [Continue].

a 16 TONER LOW me ssage.

No trays or cassettes lock ed out.

The MP Tray i s l ocked out.

The Paper Cassette is locked out.

The optional Lower Casset te is l oc ked out.

Only the optional Low er Cas sett e is a vailable.

Only the Paper Cassett e is a v ai l a bl e .

Only the MP Tray is available.

STOP Printer stops and goes offline until oper ator changes the toner

cartridge , presses [On Line], or [Continue].

*Factory default.

Operating Overview 3-1 1

Page 46

Memory Configuration Menu

This menu contains the items for personality Resource Saving and I/O

Buffering. Depending on how the printer memory is configur ed , any

combination of menu items and possible values can appear . When you

change an item in this menu, the printer automatically resets, and all fonts,

macros and downloaded data in the printer are lost (except data stored on

the optional Disk Accessory) . Mem ory Co nfigur at io n Men u items can be

selected only from the printer control panel.

Table 3-9 Me m ory Conf igur at io n Items

Item Options Explanation

IO BUFFER AUTO*

The I/O buffer is a portion of the printer memory set aside

to hold incoming data. When this item is set to AUTO, the

OFF**

memory set aside for I/O buff eri ng is autom ati call y

determined by the printer b ased on available memory.

ON

When it is set to ON, the size can be manually adjusted.

When it is set to OFF, no memory is set aside.

IO SIZE 10K and up When IO BUFFER is set to ON, I/O SIZE appears in the

menu. Use this item to add or reduce I/O buff er memory in

increments of 10 KBytes up to 100 KBytes, then in

100 KByte increments.

RESRCSA VE A UTO*

This item appears when a certain amount of memory and

a personality SIMM are ins tal led i n the printer. If it is set to

OFF**

AUTO, the printer automatically determines the amount of

memory to allocate to ins ta lled pers onal iti es ( languages ) .

ON

When it is set to ON, additional memory management item

selections appear for each inst alled per sonal ity (see next

item). When it is set to OFF, no memory is allocated and

personality-dependent resources (such as fonts) are lost

when personality changes.

PCL MEM

PS MEM

0 KBytes and up When Resource Saving is set to ON, each installed

personality (for exam pl e, PCL and PostScript) is added as

a menu item. You can increase memory in increments of

100 KBytes up to the maximum.

*Factory default.

**The HP LaserJet 4MV printer is set to OFF at the factory.

3-12 Operating Overview

Page 47

Parallel Menu

3

Operating

Overview

Parallel Menu items can be selected only from the pr int er control p ane l. You

cannot change or override them from your software application.

Table 3-10 Parallel Menu Items

Item Option s Explanation

HIGH SPEED YES*

NO

ADV FNCT NS ON*

OFF

*Factory default.

The speed at which data is transmitted to the printer. YES sets

the Bi-Tronics parallel i nter face to run at a higher data rate

supported by newer computers . NO sets the Bi-Tronics parallel

interface to run at a slower speed compati b le with older

computers.

Choosing ADV FNCTNS=ON enables bi-directional parallel

communication, which all o ws the print er to send status readbac k

messages to the comput er. Setting adv anc e func t ions to ON ma y

slow personality switching.

Operating Overview 3-1 3

Page 48

Test Menu

Test Menu items can be selected only from the printer control panel. You

cannot change or overr id e th em fro m your so ft war e ap plication. See

“Testing the Printer” later in this chapt er for detaile d inform at io n abou t

running printer tests and interpreting their results.

Table 3-11

Item Explanation

SELF TEST When SE LF TEST is displayed, and you p ress [Enter], the printer

CONT SELF TEST

(Continuous Self Test)

PCL TYPE LIST

PS TYPE LIST

PCL DEMO PAGE

PS DEMO PAGE

PS CONFIG PAGE Prints PostScript-specific information, including cur rent settings,

Test Menu Items

runs a self test during which it displays the message 05 SELF

TEST and all cont rol panel li ghts are li t. During the printing portion

of the self test, the messa g e 06 PRINTING TEST is displayed.

Prints continuous self-test pages unti l you press [On Line] or

[Shift] + [Continue]. Then the 04 portion of the display blinks and

sever al m ore pages print until the buf fer clears. Press [On Line]

when pages stop printing.

Prints a list of the typefaces and bitmapped fonts currently

available in the printer (both internal and accessory) for PCL or

Adobe Post Script print jobs .

Prints a page that illustrates printer f eatures (PCL or Adobe

Po stScript).

printable area, and memory configurati on.

3-14 Operating Overview

Page 49

Service Mode

3

Operating

Overview

The Service Mode should be us ed only by aut ho rize d servic e pers onne l.

While in Service Mode, you can:

• Print a Service Mode Self Test.

• Verify and set the Page Count and ser ial nu mbe r. These are disp laye d on

the standard self test.

• Set the Cold Reset Default. (This sets the factory default paper size to either

Letter or A4).

• Set the Demo Page=True/False. Used t o remove the Demo Page optio n from

the self test menu.

• Set the Diagnostic Functions ON or OFF (for software developers use only).

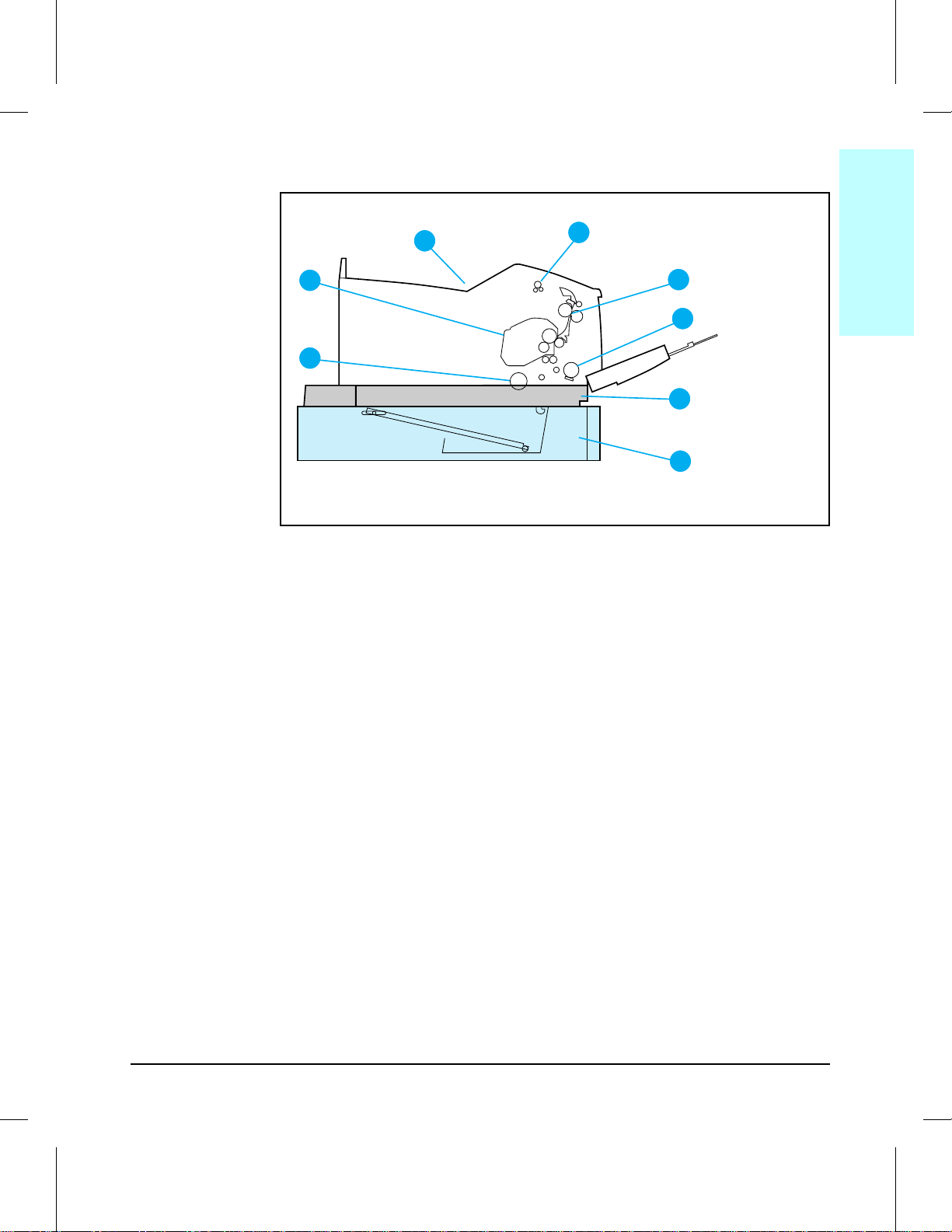

The following procedure is used to initiate the Service Mode (refer to Figure

3-2).

1 Hold down the [On Line], [Form Feed], and [Enter] keys while powering ON

the printer, until all lights are illuminated and the Display Window is

blank. (If the Display Window reads 05 SELF TEST at this point, the keys

were release d too soon. Repeat this step unt il suc c es sf ul.)

2 Press the [Form Feed] key, then the [Enter] key. The message SERVICE MODE

is displayed briefly, then the printer automatically begins a 05 SELF TEST.

After several seconds, both Control Panel Indicators turn OFF. (The printer

may display 02 WARMING UP if it has not warmed up completely.) After the

printer has warmed up and pass ed the self t est, SERVICE MODE is displayed.

To exit the Service Mode press the [On Line] key.

Power Save

An additional 10 second tim e inter v al is ad de d to the Po we r Save function

in Service Mode.

With Service Mode displayed, press MENU until Job Menu is displayed.

1 Press [Item] until PWRSAVE= is displayed.

2 Press [+/-] until the desired time interval is d isp laye d.

3 Press [Enter] to save your selection.

4 Press [On Line] once to return to the Service Mode. Press [On Line] again to

place the printer back on-line.

Operating Overview 3-1 5

Page 50

3SERVMOD

On Line Form Feed Enter

Wait 5 seconds

Form Feed

Enter

Menu

Item

Figure 3-2 Service Mode Menus

Menu

3-16 Operating Overview

Page 51

Setting the Page Count and Serial Number

3

Operating

Overview

The page count and serial numbers are stored in Non-Volatile Memory. If it

is necessary to replace the Formatter PCA, the page count should be set to

the current value to reflect the age of the print engine. The procedure for

setting the serial number is similar to setting the page count. Use the

following procedure to set the page count:

Before removing the old Formatter PCA, print a control panel self test to

verify the current page count and serial number of the printer, if possible.

NOTE If it is not possible to print a self test, try to verify the values before

replacing the Formatter PCA by follow ing step s 3 throu gh 5, be lo w.

After verifying the page count from the old Fo rmat ter PCA, replac e it wit h

the new PCA as described in Chapter 6.

1

Enter the Service Mode as previously describe d in this chap ter.

2 When SERVICE MODE is displayed, press [Menu] to access the Service Menu.

3 Press [Item to step through the menu. PAGES=XXXX XX is displayed. (XXXXXX

represents the page count currently stored in Non-Volatile Memory. The

underlined character den otes the cur sor p osit io n.)

4 Press [Enter] to scroll the cursor to underline the desired dig it .

5 Press [+/-] to select the correct value.

6 Press [Enter] to store the new value in NV R AM.

7 Set each digit in the same manner. Press [On Line] to return the dis p lay t o

SERVICE M ODE. Use the procedure described above to set the serial number

in the printer memory.

8 Press [On Line] a second time to exit Service Mode.

Operating Overview 3-1 7

Page 52

Setting the Cold Reset Default Paper Size

When replacing a Formatter PCA with a default paper size setting of A4, set

the Customization Var iable to A4.

To set the Customization Variable:

1 Enter the Servic e Mode as pre v iou sly d esc ribe d in this chapter.

2

Press [Menu] to access the Service Menu.

3 Press [Item to step through the menu until CR PAPER=LETTER* is displayed.

4 Press [+/-] to toggle between Letter and A4 paper.

5 Press [Enter] to save your selectio n.

6 Press [On Line] to return the display to SERVICE MODE.

7 Press [On Line] a second time to exit Service Mode.

Other Service Mode Items

If any of the following items need to be chan ge d from the ir def ault settin gs,

the procedure is similar to that used for setting the page count or cold reset

default, described above.

Table 3-12

Item Default Description

SKIP DEMO FALSE Inhibits printing of PCL Demo Page when set to TRUE

BIG DATA OFF For factory test purposes. Do not change.

DIAGNOSTI CS OFF For factory test purposes. Do not change.

ERR LOG N/A Contains a list of the ten most recent errors with the related page count.

PRT ERR LOG N/A Prints the error log.

CLR ERR LOG N/A Clears the er ror log b uffer.

Other Service Menu Items

3-18 Operating Overview

Page 53

Testing the Printer

3

Operating

Over v i e w

When you run a self test, the printer checks its internal controller and I/O

interface, then prints a test page. You can review the self test printout to

verify proper installation of such options as paper cassettes or personalities .

Printing a Self Test Page

1 Press [On Line] to take the printer off line.

2 Press [Menu] until TEST MENU appear s .

3 Press [Item] until the test you want to print appears.

4 Press [Enter] to print the test.

5 Press [On Line] to place the print er back on line.

NOTE

When you select CONT SEL F TEST, the printer prints self test pages

continuously until you press [Shift] + [Continue] or [On Line].

Operating Overview 3-1 9

Page 54

Understanding th e Self Test Printout

Figure 3-3 is a sample self test printout ( run from Service Mod e). Numbers

in the sample prin t ou t matc h n umbe rs in the ke y to the pri n tou t belo w.

The appearance of the self test printout varies depending on the options

currently installed in the printer.

Self Test Printout Key

1 Menu selections: Lists selections in the order in which they ap pear in the

control panel display. Also includes options su ch as Post Script and Modular

I/Os.

2 MIO information: Reserved for MIO and ne t wor k stat is tic s. For some

installed MIO options, this block of inform at io n can be as lo ng as 20 lines

and three columns.

3 Serial Number and Formatter Number: Shows version number of internal

code

4 RAM size: Shows total installed printer memory.

5 Page Count: Shows the number of pages the printer has print ed.

6 Firmware Datecode: Eight-digit date (YYY YM MD D) and version numbe r of

formatter firmware.

7 Control Panel options status: Shows status of control panel Lo ck and

Password functions.

8 Other installed options: Lists optional paper cassettes, personalities, and

other installed options .

9 Disk Accessory: Appear s whe n th e option is inst alle d and dis pla ys ac cess

status.

10 I/O Buffering and Resource Saving: Information about the current

configuration appe ar s here. If the printer does not have en ough memory

installed to enable I/O Buff ering o r Re sour ce Sav ing, the amo unt o f

additional memory needed appears here.

11 Print Pattern: Illustrates print d ensit y and qu alit y.

12 Resolution Enhancement : When pr int res olu tion is set to 600 dpi, th e REt

block appears here. The REt block illust rat es current pri nt resolu tion

enhancement.

13 PCL Memory Information: Shows the total amount of installe d memor y, an d

also indicates the amount available for PCL applicatio ns (such as font

downloading software).

3-20 Operating Overview

Page 55

3SELFTST

3

Operating

Overview

1

13

2

3

4

5

6

7

8

C3295A

9

10

11

Figure 3-3 Self Test Printout (printed in Service Mode)

12

Operating Overview 3-2 1

Page 56

3ENGTEST

Figure 3-4

Engine T est

The engine test print can be used to verify that the print engine is