Page 1

HP 2566C/HP 2567C

Operator's Manual

HEWLETT

"HM PACKARD

Page 2

HP2566C/HP2567C

OPERATORS MANUAL

HEWLETT

PACKARD

HP Part No. 02566-90990

Printed in USA April 1990

1st edition

Page 3

NOTICE

HEWLETT-PACKARD MAKES NO WARRANTY OF ANY

KIND WITH REGARD TO THIS MATERIAL, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. Hewlett-Packard shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the

furnishing, performance or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its

software on equipment that is not furnished by Hewlett-Packard.

This document contains proprietary information which is protected

by copyright. All rights are reserved. No part of this document

may be photocopied or reproduced without prior written consent of

Hewlett-Packard Company.

PUBLICATION

HISTORY

Changes in text to document updates subsequent to the initial release

are supplied in new editions of the manual. The printing histoiy

(edition) of the manual is shown on the title page. The last edition date

itemized reflects the machine configuration documented in the manual.

FOR U.Sj\. ONLY

The Federal Communications (in 47 CFR 15.818) has specified that the

following notice be brought to the attention of the user of the product.

FEDERAL COMMUNICATIONS COMMISSION RADIO

FREQUENCY INTERFERENCE STATEMENT

Warning: This equipment generates, uses, and can radiate radio

frequency energy and if not installed and used in accordance with the

instructions manual, may cause interference to radion communications.

It has been tested and found to comply with the limits for Class A

computing devices pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference in which

case the user at his own expense will be required to take whatever

measures may be required to correct the interference.

©Hewlett-Packard Company 1990

Page 4

Contents

Inside This Manual

1. GENERAL INFORMATION

Introduction............................................................................................................................... 1-1

Product Description................................................................................................................. 1-2

Supplies and Accessories ........................................................................................................ 1-5

Service..................................................................................................................................... 1-6

Operator Safety ....................................................................................................................... 1-6

2. GETTING THE MOST FROM YOUR PRINTER AND PAPER

Printer Location......................................................................................................................... 2-1

Printer Installation..................................................................................................................... 2-1

Power......................................................................................................................................... 2-4

Paper Requirements................................................................................................................... 2-4

Paper Storage and Handling...................................................................................................... 2-5

3. PREPARING THE PRINTER FOR OPERATION

Ribbon Removal and Replacement........................................................................................... 3-1

Paper Loading and Adjustment ............................................................................................. 3-10

Adjusting Vertical Paper Tension.......................................................................................... 3-15

Adjusting Forms Position...................................................................................................... 3-17

Adjusting Forms Thickness................................................................................................... 3-21

Overall Print Quality.............................................................................................................. 3-24

Adjusting Forms Length ....................................................................................................... 3-25

Adjusting Top of Form.......................................................................................................... 3-30

4. USING THE POWERED PAPER STACKER

Unloading the Paper Stack ....................................................................................................... 4-7

5. PRINTER CONFIGURATION

Setting Configuration Functions

Interface Configuration............................................................................................................. 5-5

HP-IB Selection......................................................................................................................... 5-6

Test............................................................................................................................................ 5-7

...............................................................................................

Contents-1

5-1

Page 5

6. USING THE PRINTER

Printer Modes............................................................................................................................ 6-1

Printer Status Mode................................................................................................................... 6-2

Operator Controls and Indicators............................................................................................. 6-3

Power-On Parameters and Power-Fail Recovery

..................................................................

Graphics Printing .................................................................................................................. 6-12

Vertical Forms Control.......................................................................................................... 6-13

Optimizing Print Quality....................................................................................................... 6-14

Preventive Maintenance......................................................................................................... 6-16

7. IN CASE OF DIFFICULTY

General Problems .................................................................................................................... 7-2

Printer Errors............................................................................................................................ 7-4

Calling for Help..................................................................................................................... 7-8

A. PRINTER SPECIFICATIONS

Certification.............................................................................................................................. A-1

Printer Overview....................................................................................................................... A-1

Physical Specifications .......................................................................................................... A-3

Electrical Characteristics ........................................................................................................ A-3

Performance Specifications .................................................................................................... A-5

Environmental Specifications ................................................................................................ A-7

6-11

B. PAPER SPECIFICATIONS

Certification.............................................................................................................................. B-1

Standard Forms Specifications................................................................................................. B-1

Speciality Forms Specifications................................................................................................ B-3

C. RIBBON SPECIFICATIONS

Index

Self-Test Printout

User Comment Sheet

Hewlett-Packard Sales and Service Offices

Contents-2

Page 6

Figures

1- 1. HP2566C/HP2567C Printer with powered paper stacker

2- 1. Shipping Lock Bracket Locations..................................................................................... 2-2

3- 1. Opening the Ribbon Cover................................................................................................ 3-2

3-2. Removing Upper Ribbon Spool............................................................................................ 3-3

3-3. Opening the Swing-Gate ...................................................................................................... 3-3

3-4. Accessing Lower Ribbon Spool........................................................................................... 3-4

3-5. Removing Lower Ribbon Spool........................................................................................... 3-4

3-6. Removing the Ribbon........................................................................................................... 3-5

3-7. Correct Ribbon Winding Direction

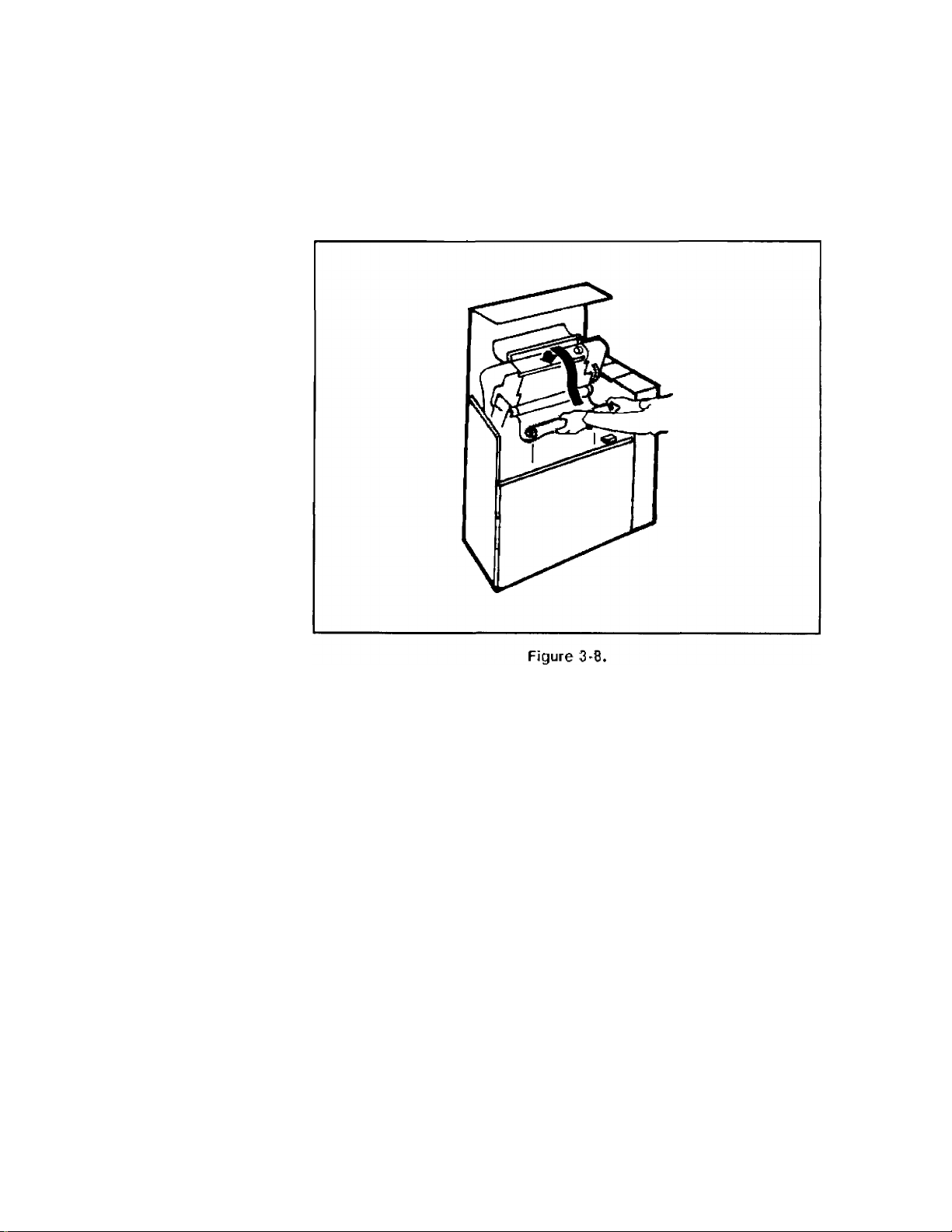

3-8. Lowering Ribbon Shield and Opening Ribbon Access Cover

3- 9. Installing Lower Ribbon Spool......................................................................................... 3-7

3-10. Closing Lower Ribbon Cover and Paper Shield................................................................... 3-8

3-11. Installing Upper Ribbon Spool............................................................................................. 3-9

3-12. Closing the Printer................................................................................................................ 3-9

3-13. Opening the Printer ............................................................................................................ 3-10

3-14. Opening the Swing-Gate ................................................................................................... 3-11

3-15. Opening the Platen.............................................................................................................. 3-12

3-16. Opening the Tractors.......................................................................................................... 3-13

3-17. Positioning the Paper.......................................................................................................... 3-14

3-18. Adjusting Vertical Paper Tension....................................................................................... 3-15

3-19. Tractor Controls.................................................................................................................. 3-17

3-20. Adjusting Forms Position................................................................................................... 3-18

3-21. Tractor Strip Distortion....................................................................................................... 3-20

3-22. Setting the Forms Thickness Lever at Maximum Thickness

3-23. Dot Slalom.......................................................................................................................... 3-22

3-24. Character Scrunch............................................................................................................... 3-24

3-25. Parts of the Form ............................................................................................................... 3-25

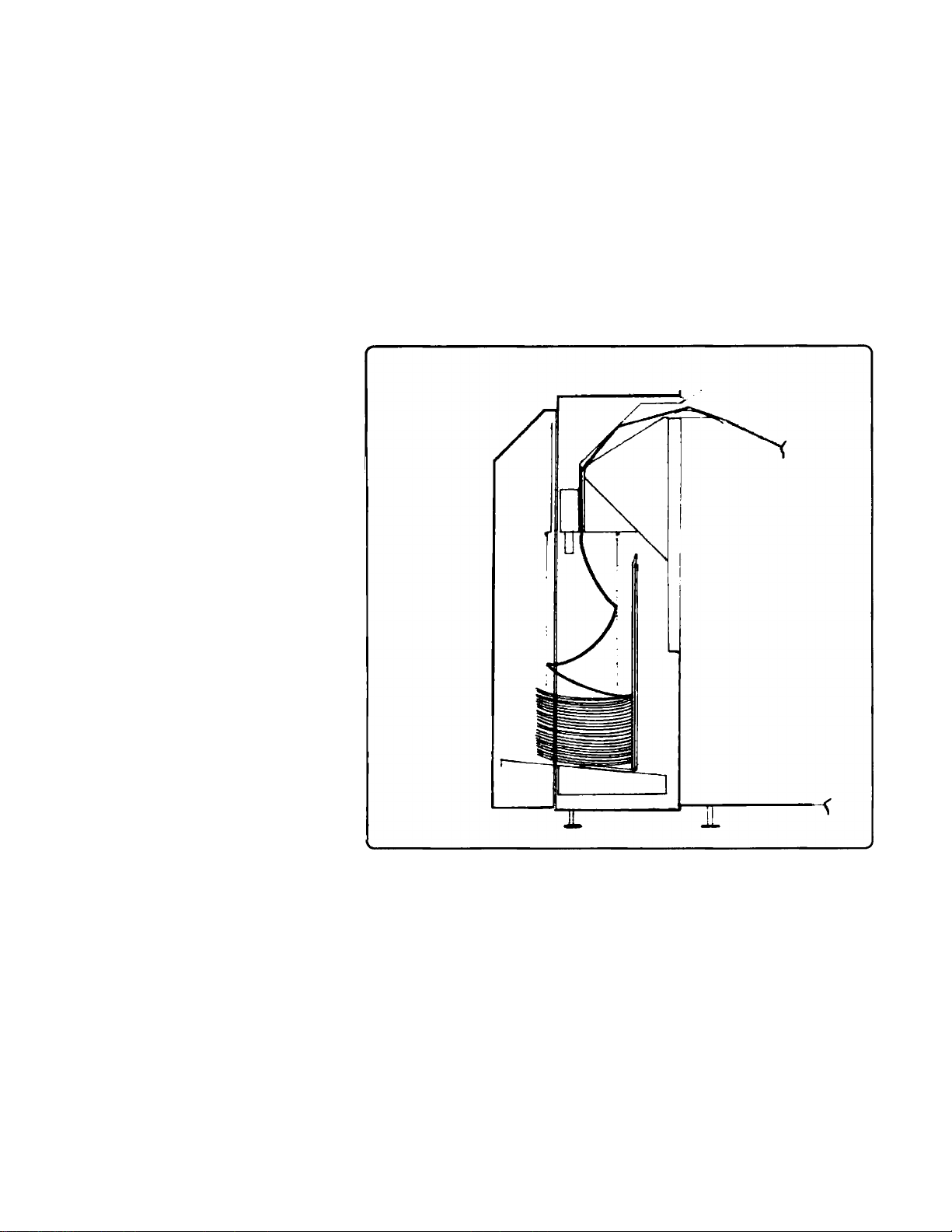

3-26. Adjusting Paper Over the Platen......................................................................................... 3-30

3-27. Lowering the Paper Shield................................................................................................. 3-31

3-28. Positioning Paper to the First Column of Print

3-29. Top of Form Alignment Guide Labels............................................................................... 3-33

3-30. Top of Form Index Label.................................................................................................... 3-34

3-31. Positioning Alignment Guide Labels

3-32. Recording Information on Index Label

4- 1. Sliding Out the Paper Tray................................................................................................ 4-1

4-2. Positioning the Backstop ..................................................................................................... 4-2

4-3. Pushing In the Paper Tray .................................................................................................... 4-3

4-4. Adjusting Door Chains......................................................................................................... 4-4

4-5. Starting the Paper Stack ....................................................................................................... 4-5

4- 6. Aligning the Paper Stack................................................................................................... 4-6

5- 1. Character Set Self-Test Example

6- 1. Display Modes.................................................................................................................. 6-1

......................................................................................

.................................................................

.................................................................................

.............................................................................

......................................................................................

.................................................

.............................................

.............................................

1-1

3-5

3-6

3-21

3-31

3-35

3-36

5-3

Contents-3

Page 7

6-2. Parts of the Printer................................................................................................................ 6-3

6-3. Operator Control Panel......................................................................................................... 6-4

6-4. Forms Loading Controls....................................................................................................... 6-9

6-5. Forms Thickness Adjustment Lever .................................................................................. 6-10

6- 6. Dot Slalom....................................................................................................................... 6-15

7- 1. Character Scrunch.............................................................................................................. 7-4

A-1. Dot-Matrix and Full-Font Print Gap Comparison

B-1. Maximum Height of Form Defects...................................................................................... B-3

B-2. Maximum Thickness Variation for All Areas of a Special Form

B-3. Maximum Thickness Variation for the Thin Areas of a Special Form................................. B-4

B-4. Maximum Allowable Form Perforation Projection......................................................... B-5

.........................................................

........................................

Tables

1-1. Character Sets....................................................................................................................... 1-5

1-2. Power Supplies..................................................................................................................... 1-6

1-3. Interface Subsystems............................................................................................................ 1-6

1-4. Convenience Options............................................................................................................ 1-6

1-5. Recommended Printer Paper................................................................................................ 1-7

4-1. Recommended Backstop Positions....................................................................................... 4-2

4- 2. Recommended Door Chain Positions................................................................................ 4-4

5- 1. Configuration Function Numbers ..................................................................................... 5-2

5- 2. Sub-Test Numbers............................................................................................................. 5-8

6- 1. Status Codes...................................................................................................................... 6-2

6- 2. VFC Channel Definitions................................................................................................ 6-13

7- 1. Run-time Errors................................................................................................................. 7-6

7-2. Self-Test Error Numbers...................................................................................................... 7-7

A-1. Print Speed and Matrix Sizes - HP2566C...................................................................... A-5

A-2. Print Speed and Matrix Sizes - HP2567C...................................................................... A-6

A-3. Dot Density.................................................................................................................... A-7

A-2

B-4

Contents-4

Page 8

What Is In This

Manual

The information in this manual is divided into the following chapters:

Chapter 1:

General Information

Chapter 2:

Getting the Most From

Your Printer and Paper

Chapter 3:

Preparing the Printer for

Operation

Chapter 4:

Setting-Up the powered

paper stacker

Chapter 5:

Configuring Printer

Features

This chapter provides a list of related documentation that may be

useful to you. This is followed by a functional description of the

HP2566C/HP2567C printer, a list of options and supplies, and a word

about service and operator safety.

To determine the best location for your printer and what kind of paper

to use, read Chapter 2.

Chapter 3 helps you begin using the printer. It explains how to load the

ribbon and paper, adjust your printer for different sizes and thicknesses

of paper, and set Top of Form.

Once your paper is loaded correctly in the printer, follow the instructions

in this chapter to set-up your powered paper stacker for optimum paper

stacking performance.

This chapter explains how to program your printer to perform various

tasks. It also describes how to set the HP-IB interface address and run

sub-tests.

Chapter 6:

Using the Printer

Chapter 7:

In Case Of Difficulty

Appendix A:

Printer Specifications

Appendix B:

Paper Specifications

Appendix C:

Ribbon Specifications

Chapter 6 discusses the use of the Operator Control Panel and explains

each control key in detail. After this there are sections on power fail

recovery and reset. Vertical Forms Control (VFC), and optimizing print

quality.

This chapter tells you what to do in case of printer fault conditions. All

printer errors are explained; even those that do not show up in the

display window.

Appendix A gives detailed printer specifications, including physical

characteristics, environmental requirements, electrical hook-up, power

consumption, and performance data.

This appendix describes paper requirements and provides information on

specialty forms.

This section lists specifications for the printer ribbon.

Page 9

lnd6X Use the index to locate primaiy sources of information.

Self-Test Printout

User Comment Sheet

Sales and Service

Offices

This is a simulated copy of a standard self-test run on an

HP2566C/HP2567C printer. You might find it useful for comparison

purposes.

A postage-paid form is available for you to give us feedback about this

manual. Please use it to relay any comments or suggestions you may

have for us.

In the back of this manual there is a listing of all of Hewlett-Packard’s

Sales and Service offices throughout the world. If you have any

questions or need information, contact the nearest office.

Page 10

GENERAL INFORMATION

1

Introduction

This manual contains information necessaty to operate the

HP2566C/HP2567C line printer. Read it before using your printer so

that you will be familiar with all its capabilities and features.

Figure 1-1, HP2566C/HP2567C Printer with powered paper stacker

GENERAL INFORMATION 1-1

Page 11

Product Description

The HP2566C/HP2567C printer is a highly reliable, heavy-duty line

printer designed for use in many printing applications. The HP2566C

model prints 1200 upper case draft lines-per-minute; the HP2567C

model prints 1600 upper case draft lines-per-minute. These printers

have several attractive features, including:

V Multiple character sets requiring no mechanical font change

■ Bar code printing capability

■ 16-channel vertical forms control (VFC)

■ Several print pitches (10, 12, 13.3, 15 and 16.7 characters-per-inch)

m Raster graphics capability (standard and high density selectable)

■ Paper jam detection

g Easy forms alignment

■ Interfacing flexibility

■ Restart/recoveiy ability following printer interrupts and power failure

(Hewlett-Packard ciper protocol only)

a powered paper stacker to stack printer paper

■ High speed draft quality character set

Related Manuals

Options The HP2566C/HP2567C line printer is available in several

HP2566/67B Service and Parts Manual (02566-90915)

HP256X Printer Family Technical Reference Manual (02564-90905)

HPLabel Card Manual (26062-90902)

HP-IB Interface Manual (26067-90901)

Parallel-Differential Interface Manual (26067-90905)

Centronics Parallel Interface Manual (26067-90906)

RS232/422 Interface Manual (26067-90921)

conftgurations to match your individual application needs. These

conftgurations are stated as options and are identified by a three digit

suffix to the model number. For example, HP2566C #001. The option

numbers are marked on an identiftcation tag which is located near the

main power ON/OFF (1/0) switch on the back of the printer.

The standard model HP2566C/HP2567C printer includes a 16-channel

Vertical Forms Control, normal and compressed printing features,

raster graphics capabilities, paper jam detection, a RomanS symbol set

(Standard ASCII plus Roman Extension), compressed and double-size

characters, and high speed draft characters.

It is configured for 120 VAC, 50/60 Hz. operation, and comes equipped

with a power cord and one ribbon.

1-2 GENERAL INFORMATION

Page 12

The following tables show the available options for the

HP2566C/HP2567C printer:

Table 1-1. Character Sets

Options #

001

002

004

005

006

008

009

012

013

026

027

028

029

030

Description

Line Draw, Math, and Block character sets

Katakana8 character set (replaces Roman8 standard

character set)

High DeJisity Romans character set

High Density Italics Roman8 character set

High Density Katakana8 character set

Bar Code Printing Capability

Adds 12, 13.3 cpi with Roman8 character set

Adds 12, 15 cpi with Roman8 character set (Line

Draw, Math and Block character sets)

Adds 13.3, 15 cpi with Roman8 character set

Cyrillic standard density (ECMA 113/86 character set)

Cyrillic high density (ECMA 113/86 character set)

Cyrillic standard density (ECMA 113/88 character set)

Cyrillic high density (ECMA 113/88 character set)

Arabics, Line draw character set

031

Arabics, (high density) character set

032 TurkishS, ASCII, Line draw cliaracter set

033

TurkishS, (high density) character set

034 Greeks, ASCII, Line draw character set

035 Greeks, (high density) character set

036

Hebrews, ASCII, Line draw character set

037 Hebrews, (high density) character set

038

039

043

Hebrew7, Line draw character set

Hebrew7, (high density) character set

East European standard density (ECMA 94/Latin2

character set)

044 East European high density (ECMA 94/Latin2

character set)

GENERAL INFORMATION 1-3

Page 13

Note

The standard printer will accept one additional normal density character

set ROM and three additional high density character set ROM’s. Contact

your Hewlett-Packard Sales or Service Representative for details.

Table 1-2. Power Supplies

Option #

015

016

017

220 VAC, 50/60 Hz Operation

100 VAC, 60/60 Hz Operation

240 VAC, 50/60 Hz Operation

Table 1-3. Interface Subsystems

Description

Option # Description

046

049

050

053

054

HP-IB interface (standard), 4 metre cable included

RS232C interface subsystem

RS422A interface suhsj^stem

Centronics Parallel interface subsystem

Dataproducts Long-Line interface subsystem

Table 1-4. Convenience Options

1-4 GENERAL INFORMATION

Option # Description

024

HP Label Card graphics enabling the printer to

print varying sizes of characters, graphics,

bar codes and lines using QMS(R)*

Magnum(R.)* language.

060

715

Delete powered paper stacker

Service Documentation (02566-90915)

"QMS and MAGNUM are registered trademarks of QMS, Inc.

Page 14

Supplies and

Accessories

The supplies and accessories recommended for use with your printer

are listed below. These are available from Hewlett-Packard’s Direct

Marketing Division (DMK) with direct phone service available to

Hewlett-Packard customers within the continental United States. Orders

may be taken from 9 am to 5 pm in all United State time zones.

To place an order call:

TOLL FREE - 800-538-8787

IN CALIFORNIA - (408) 738-4133 (Direct or Collect)

Outside the United States, however, orders may be placed with the

local Hewlett-Packard Sales and Service office listed in the back of this

manual.

Ribbon One replacement ribbon (towel-type), part number 9282-0545. (See

Appendix C, Ribbon Specifications.)

Paper

Table 1-5. Recommended Printer Paper

----

■■ 1 ■ ^1-----------------------------------------------------

Part #

92157A One-part, white, 9.5 x 8.5 in.

92157B One-part, white,9.5 x 8.5 in,

9280-0218

9280-0705 One-part, white, 8.5 x 7.5 in,

9320-1515 One-part, blue bar, 14.9 x 11 in.

See Appendix B for information on paper specifications.

L Description J Quantity

(241 X 216 mm), 18 lb.

(241 X 216 mm), 15 lb.,

3-hole punched

One-part, green bar, 9,9 x 11 in.

(251 X 279 mm), 15 lb.,

80-column

(216 X 191 mm), 15 lb.,

72 column

(378 X 279 mm), 18 lb.,

132-coiumn

2400 sheets/box

3200 sheets/box

3200 slieets/box

3200 sheets/box

2400 sheets/box

GENERAL INFORMATION 1-5

Page 15

Service

Operator Safety

Hewlett-Packard offers maintenance agreements, “time and material”

service, and other service agreements for the HP2566C/HP2567C

printer. If you need service or have questions regarding the servicing

of your printer, contact the Hewlett-Packard Sales and Service office

nearest you. A list of these offices is provided at the back of this manual.

Warning

For operator safety, close the top cover and printer cabinet door when

the printer is powered on and during operation. Keep hands, long hair,

necklaces, and articles of clothing such as long sleeves out of the

printer when operating conditions exist. DO NOT attempt to perform

troubleshooting or maintenance procedures beyond those described in

Chapter 7.

1-6 GENERAL INFORMATION

Page 16

2

GETTING THE MOST FROM YOUR PRINTER AND PAPER

Printer Location

Note

Printer Installation

The HP2566C/HP2567C printer should be located in a clean, traffic-free

environment, preferably an area not subjected to excessive mechanical

shocks, vibrations or Avide ranges of temperature. Air conditioning is

not required to ensure reliable operation of the printer; however, the

environmental specifications as outlined in Appendix A should not be

exceeded.

Make sure the printer sits level. The output paper stack will not stack

correctly if the printer does not sit evenly on the floor.

The location of your printer must provide adequate operator access to

both the front and rear of the printer. The area around the printer

should be kept clean and dust free so that the air used to cool the

printer will not contain excessive dust particles.

If the printer must be operated in either high or low humidity, read

Appendix B for ways to optimize paper handling.

Hewlett-Packard provides the original installation and testing of the

printer at your site. However, if you need to move the printer to a new

location, follow these procedures:

Moving the Printer l- Record printer configurations.

Before moving the printer, record key configuration values retained in

memory. This will allow quick restoration in the event of a batteiy

failure. Recording all configuration settings listed in Table 5-1 is

recommended, however configuration functions 20-29 are the most

critical. These could affect system performance and stability and must

be verified before connecting the printer to the operating system.

Refer to Chapter 5, “Configuring Printer Features” for information

on configuration settings. To find out which printer configuration

parameters are saved in memory when power is turned off, refer to

“Power-On Parameters and Power-Fail Recoveiy” on page 6-11.

GETTING THE MOST FROM YOUR PRINTER AND PAPER 2-1

Page 17

2. Turn the printer "OFF."

With the printer “off-line,” switch the main power ON/OFF (1/0)

switch located on the back of the printer to the “OFF” (0) position.

Unplug the power cable from both the AC outlet and the printer.

3. Disconnect the interface cable.

Unplug the printer’s interface cable from the rear of the printer.

4. Raise the levelers.

Turn the printer’s four leveling feet counter-clockwise and raise them

into the full UP position.

5. Install the shipping brackets (behind the casting).

The printer is shipped with four metal shipping lock brackets as

shown in their locations in Figure 2-1. The brackets should have

been removed when the printer was unpacked and saved for printer

relocation. Re-install them, behind the casting, for any m^jor

relocation of the printer as they provide protection from vibration

damage. New shipping brackets may be ordered through your

Hewlett-Packard Service Representative. Specify two each of part

numbers 02566-00231 and 02566-00236 (front and rear brackets)

and four each of part numbers 3020-0004 and 3020-0025 (bolts and

washers).

REAR

■SHtPPING-

Figure 2-1. Shipping Lock Bracket Locations

2-2 GETTING THE MOST FROM YOUR PRINTER AND PAPER

Page 18

(_ auiion

f

Before moving the printer, make sure that the leveling feet are fully

raised. Roll the printer from the side to minimize the possibility of

tipping.

6. Move the printer.

Move the printer from the side to its new location. The printer is

more stable when rolled in this way.

At New Location

Note

1. Remove shipping brackets (if installed).

Refer to Figure 2-1 for locations.

2. Connect the power cord.

Connect the power cord to the AC power input jack on the back of

the printer and plug the other end into the AC outlet.

3. Lower the leveler feet.

Turn the printer’s leveling feet clockwise until all four wheels are just

off the floor. Next, level the printer.

For optimum performance of the powered paper stacker, make sure the

printer sits level on the floor. The output paper stack will not stack

correctly if the printer is not level.

4. Connect the interface cable.

Connect the interface cable from the computer system to the interface

connector on the back of the printer. If you have an HP-IB interface,

use the supplied shielded cable. Failure to use the appropriate cable

could cause electrostatic discharge (ESD) problems.

5. Load the ribbon and paper.

Follow the directions starting on page 3-5 to load the ribbon and

paper.

6. Switch the printer "ON."

Switch the main power ON/OFF (1/0) switch located on the back of

the printer to the “ON” (1) position.

7. Verify the configuration parameters.

Verify printer configuration as recorded in step 1 of “Moving the

Printer” on page 2-1.

GETTING THE MOST FROM YOUR PRINTER AND PAPER 2-3

Page 19

8. Run a self-test.

Put the printer “off-line” and press the (test) key on the Operator

Control Panel. Run the standard self-test (refer to page 5-7 for

self-test information) and press the

to print out. Compare this printout with the self-test printout at

the back of this manual. (Note that the self-test in this manual is a

simulated copy of an standard printout and will not be exactly like

the one you printed. Yours will vary depending on which character

set options are instedled in your printer.) If no error numbers are

flashing in the display window, and the print quality of the characters

on the self-test is good, the printer is ready for operation.

(enter 1 key. The self-test begins

Powe.'

iJote

V

Paper Requirements

The HP2566C printer has a maximum power requirement of 550W;

the HP2567C requires 650W. One of the following power sources

must be available for operating the printer: 100, 120, 220, or 240 VAC

(-i-5%-10%). Your printer has been shipped to match the power source

specified in your order. If it becomes necessary to change to a different

power source, contact your Hewlett-Packard Service Representative.

Changing to a different power source is not covered under warranty or

Hewlett-Packard Service Agreements.

See Appendix A or more power requirement information.

Selecting the right printer paper is one of the most impoi-tant factors in

obtaining good paper stacking performance. The paper that you choose

needs to acclimate to your location and the type of printing you are

doing. The powered paper stacker is only successful if the paper falls

and folds correctly onto the paper tray. Because some variables in paper

may significantly affect print quality or the way the paper handles, it is

very important to understand the many aspects that can alter paper

performance.

The printer uses continuous fan-fold, edge-perforated paper varying in

width from 3 inches (7.6 cm) to 18 inches (45.72 cm). Although the

printer accepts paper as wide as 18 inches (45.72 cm), the farthest right

it can print is 15.2 inches (38.6 cm). It vrill handle paper weights in the

range of 15 to 100 pound (57 to 380 gra/sq metre) and multi-part carbon

forms up to six parts may be used, with a maximum pack thickness of

.024 inches (.61 mm).

2-4 GETTING THE MOST FROM YOUR PRINTER AND PAPER

Page 20

Note

Note I For best paper performance, use a higher weight paper in high humidity

Hewlett-Packard does not recommend the use of untested carbonless

multi-part forms. This is due to the varying manufacturing quality and

storage considerations associated with this type of paper.

If paper will be printed in humidity extremes (greater than 80% or less

than 20%) it should be thoroughly tested first. Paper to be used in high

humidity areas should be tested for satisfactory feeding and handling.

Paper to be used in low humidity areas should be tested for static

build-up to determine potential paper stacking problems.

In general, before you purchase large quantities of paper, test it for

satisfactoiy feeding, print quality, and stacking ability. Any special

application paper, such as multi-part forms, labels, etc., should also be

thoroughly tested prior to volume purchase.

environments.

^ Op T S oraqe and

Handii

Packaging To avoid damage during handling, top and bottom fillers should be used

Storing Do not store cartons directly on the floor, and do not stack more than six

Refer to Appendix B for additional information on paper.

The performance of the printer is dependent on the condition of the

paper it uses. Here are some recommendations for packaging, storing,

and handling your paper.

in continuous paper cartons to hold the stack firmly in place. Because

the physical condition of the paper affects printer reliability, correct

packaging ensures that the paper remains flat and is not damaged along

the edges.

high. Each carton should be set upright squarely on the one underneath.

Placing additional weight on top of the stack of cartons can damage the

paper.

GETTING THE MOST FROM YOUR PRINTER AND PAPER 2-5

Page 21

Environmental

Conditions

Since performance is affected by environmental conditions, paper should

be protected from extremes in temperature and humidity.

Paper should be stored in an environment similar to the printer’s

controlled environment for four days prior to use. This conditioning

allows moisture content in the paper to stabilize. Your printer is

intended for operation in a controlled environment where temperatures

range from 50° to 122° F (10° to 50° C) and the relative humidity is

30% to 80% non-condensing. For best results, however, the cartons

should be stored and used at 65° to 75° F (18° to 24° C), with a relative

humidity of 30% to 45% (also the best environment for your printer).

In the event the printer is in an environment subject to extremes of

relative humidity or temperature, it may be necessary to store the forms

in a controlled environment and withdraw them on an as-needed basis.

Shipping When paper is shipped through different environments, the entire stack

of cartons on the pallet should be plastic wrapped. When shipping across

large bodies of water, individual cartons should be wrapped as well.

Paper Specifications Refer to Appendix B for information.

2-6 GETTING THE MOST FROM YOUR PRINTER AND PAPER

Page 22

PREPARING THE PRINTER FOR OPERATION

This chapter will help you begin using your HP2566C/HP2567C printer.

It explains how to load the ribbon and paper, adjust your printer for

different sizes and thicknesses of paper, and set Top of Form.

Follow these instructions to install the ribbon. At this point, the

printer’s power can either be “ON” or “OFF.”

3

Ribbon Removal and

Replacement

Note

Tools are not required to remove or replace the ribbon. The printer

uses a towel-type ribbon (9282-0545) which is easily installed. Refer to

Appendix C, “Ribbon Specifications,” to verify that the ribbon being

replaced meets the recommended specification listed in this document.

Be careful not to touch the ribbon as you will get ink on your hands and

clothing. A pair of plastic gloves and a moist towelette are normally

included in each Hewlett-Packard ribbon package to help protect yourself

from the ink.

PREPARING THE PRINTER FOR OPERATION 3-1

Page 23

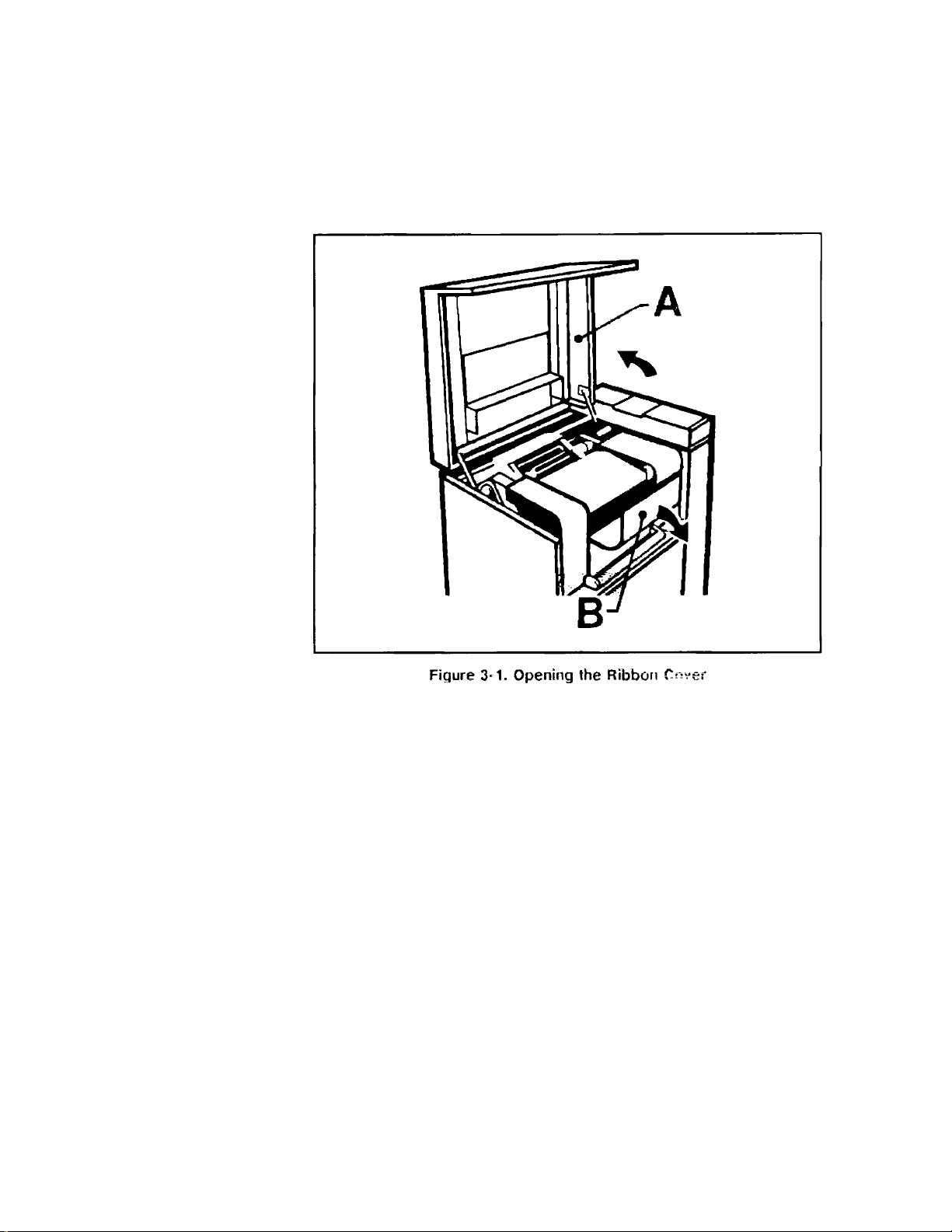

Removing the Ribbon:

1. Open the upper ribbon access cover.

Raise the printer’s top cover (Figure 3-1, A), and open the upper

ribbon access cover (Figure 3-1, B) by gently pulling it toward you.

3-2 PREPARING THE PRINTER FOR OPERATION

Page 24

2. Remove the ribbon spool.

Put on the plastic gloves. Remove the old ribbon spool from the drive

hubs by sliding it to the left (Figure 3-2, A). Roll up the slack and

place the spool in the retainer cups (Figure 3-2, B) at the rear of the

swing-gate. Close the upper ribbon access cover.

3. Open the swing-gate.

Open the swing-gate by pushing down on the release lever (Figure

3-3, A) and lifting up the handle (Figure 3-3, B) until it latches at the

top.

PREPARING THE PRINTER FOR OPERATION 3-3

Page 25

4. Lower the paper shield.

Pull downward on the paper shield to move it out of the way (Figure

3-4, A) and then open the lower ribbon access cover (Figure 3-4, B).

5. Remove the lower ribbon spool.

Remove the lower ribbon spool from its drive hubs by sliding it to the

left (Figure 3-5).

3-4 PREPARING THE PRINTER FOR OPERATION

Page 26

6. Discard the old ribbon.

Remove the upper ribbon spool from the retainer cups. Throw away

the used ribbon (Figure 3-6).

Replacing the Ribbon

When you replace a ribbon, the ribbon spools must be mounted correctly

so they wind in the right direction (Figure 3-7). If the ribbon is on

backwards it will not function properly. Also, make sure that both spools

fit solidly into the drive hubs (rotate the spool until it snaps onto the

drive hubs). If it does not fit correctly, the ribbon spool will be broken

by the drive hub.

PREPARING THE PRINTER FOR OPERATION 3-5

Page 27

1. Place spool on retainer cups.

Open the swing-gate completely until it latches at the top. Lower the

ribbon shield and open the ribbon access cover (refer to Figure 3-4,

B). Put on the plastic gloves supplied in the ribbon box and place one

of the ribbon spools on the retainer cups as shown in Figure 3-8.

Lowering Ribbon Shield and Opening Ribbon Access Cover

3-6 PREPARING THE PRINTER FOR OPERATION

Page 28

2. Install lower ribbon spool.

Route the ribbon up and over the ribbon sensing bar (Figure 3-9,

A). Install on the lower ribbon drive hubs by sliding toward the left

(Figure 3-9, B).

PREPARING THE PRINTER FOR OPERATION 3-7

Page 29

3. Close lower access cover and ribbon shield.

Pull the lower ribbon access cover toward you to close. Lift the paper

shield up to close (Figure 3-10).

Figure 3-10. Closing Lower Ribbon Cover and Paper Shield

4. Close swing-gate and open upper access cover.

Push the swing-gate handle down to close. Open the upper ribbon

access cover by gently pulling it toward you.

3-8 PREPARING THE PRINTER FOR OPERATION

Page 30

5. Install upper ribbon spool.

Lift the ribbon spool from the retainer cups (Figure 3-11, A). Install

on the upper ribbon drive hubs by sliding toward the left (Figure

3-11, B).

6. Close the printer.

Raise the upper ribbon access cover up into the closed position and

close the printer’s top cover (Figure 3-12).

PREPARING THE PRINTER FOR OPERATION 3-9

Page 31

Paper Loading and

Adjustment

The rest of this chapter explains how to load, adjust, and position your

paper in the printer. The instructions are written in sequence, and, if

followed in order, detail the correct procedure to set up your printer for

operation.

Note

IF

When the printer runs out of paper, it completes printing the last page

and goes “off-line.” At this point, the paper is at the Top of Form

position.

1. Operator Information Label.

An Operator Information Label is located on the inside of the printer

for ea^ reference to error and configuration modes, setting forms

position and Top of Form, and other printer functions.

2. Turn the printer "ON.”

On the back panel of the printer, flip the power switch to the “ON”

(1) position. The printer must be “ON” to perform set-up functions.

Raise the printer’s top cover and open the cabinet’s front door (Figure

3-13).

3-10 PREPARING THE PRINTER FOR OPERATION

Page 32

3. Open the swing-gate.

Push down on the swing gate release lever (Figure 3-14, A) and

lift up the swing-gate by the handle (Figure 3-14, B) until the gate

latches at the top.

PREPARING THE PRINTER FOR OPERATION 3-11

Page 33

4. Open the platen.

Pull out the spring plunger knob and move the paper thickness

adjustment lever to the maximum thickness setting, “N” (Figure

3-15). This will prepare the printer for the final forms thickness

adjustment later in this chapter.

Figure 3-15. Opening Ihe Platen

3-12 PREPARING THE PRINTER FOR OPERATION

Page 34

5. Open the tractors.

Flip open the tractor lids.

PREPARING THE PRINTER FOR OPERATION 3-13

Page 35

6. Position the paper.

Position the paper supply on the floor of the cabinet so that it is all

the way forward, towards the door. Then, center it under the tractors

(Figure 3-17). DO NOT RUN PAPER FROM A BOX PLACED

OUTSIDE THE PRINTER CABINET.

Note

Paper jams can occur because the sides of the box are too close to the

paper stack. Pull the sides of the box away from the stack to let the

paper move freely through the printer.

7. Continue loading paper.

Proceed to “Adjusting Vertical Paper Tension” on page 3-15.

3-14 PREPARING THE PRINTER FOR OPERATION

Page 36

Adjusting Vertical

Paper Tension

Note -,l Make sure you adjust vertical paper tension each time you load paper.

A slight paper tension aids print quality and is impoitant for proper

operation of your printer. If the paper tension is too loose, marginal

print quality occurs. If the paper tension is too tight, paper will come

out of the tractors causing a paper jam. After you make a preliminary

tension adjustment, proceed to page 3-17 to adjust the forms position

and make the rinal adjustment.

1. Position the vertical tension lever.

Pull out the spring plunger knob and place the vertical tension lever

in the “A” position (Figure 3-18, A). Place the paper in the two left

tractorti and close the tractors.

Figure 3-18. Adjusting Vertical Paper Tension

PREPARING THE PRINTER FOR OPERATION 3-15

Page 37

2. Preliminary adjustment of vertical paper tension.

Pull out the spring plunger knob again (Figure 3-18, A) and move the

lever downward until the paper is slightly taut against the platen.

(The platen is located in the curved black surface lying between the

upper and lower tractors.) To test the tension, place your hand on the

paper over the black surface and gently push the paper up and down

(Figure 3-18, B). If the paper moves freely, the vertical tension is too

loose. When the tension is correct, you will notice only slight vertical

looseness and no paper feed hole distortion.

3-16 PREPARING THE PRINTER FOR OPERATION

Page 38

Adjusting Forms

Position

Use this procedure when you change the position of the form in the

printer, or want to set the horizontal paper tension. These insti-uctions

prepare your printer for the next step, “Adjusting Forms Thickness” on

page 3-21.

Notti

I

Too little or too much horizontal tension can cause paper jams in the

cp printer.

1. Adjust the left paper path.

With the swing-gate latched in the full open position, set the tractor

control knob to FORMS ALIGNMENT POSITION (Figure 3-19, A).

Press either of the tractor control keys (Figure 3-19, B) left or right

until the left tractors (Figure 3-19, C,D) are in the desired position

for printing the left page margin. Holding the center key down while

pressing the left or right key will increase the speed that the tractors

move.

Figure 3-19. '^ractor Conti ols

PREPARING THE PRINTER FOR OPERATION 3-17

Page 39

2. Ai^ust the right tractor.

Set the tractor control knob to the FORMS WIDTH ADJUST

POSITION (Figure 3-20, A). Only the right tractors should move; the

left tractors should remain stationary. Press the right tractor control

key to increase the forms width position (Figure 3-20, B). To decrease

the forms width position, press the left tractor control key until the

tractors are narrower than the form (Figure 3-20, B, HORIZONTAL

ADJ.).

3-18 PREPARING THE PRINTER FOR OPERATION

Page 40

3. Close the right tractors.

Insert the paper into the two right tractors and close the tractors.

Adjust the horizontal tension.

With the tractor control knob still in the FORMS WIDTH ADJUST

POSITION, fine adjust the tractor positioning by touching the right

tractor control key (Figure 3-20, B) until there is a slight horizontal

tension on the paper. When the tension is correct, reset the tractor

control knob to the PRINT AND FORMS ALIGNMENT POSITION

(Figure 3-20, C).

Note Be sure the tractor control knob is reset to the PRINT AND FORMS

^ ALIGNMENT POSITION before printing or you may have form feed

problems.

5. Final vertical paper tension adjustment.

Make sure the tractors line up vertically with the holes in the paper.

If they do not, align them by pulling out the spring plunger knob and

moving the vertical paper tension lever up or down (Figure 3-18, A).

Close the tractors. (For detailed adjustment instructions refer back to

step 2, “Preliminary Adjustment of Vertical Paper Tension,” on page

3-16.)

6. Test paper motion.

Press and hold the (line feed 1 key for several seconds to advance

paper into the powered paper stacker. Press the (form feed) key two

or three times to make sure that the paper moves freely over the

platen.

PREPARING THE PRINTER FOR OPERATION 3-19

Page 41

7. Inspect paper tractor holes.

Inspect the holes in the paper’s tractor strips that have just passed

through the tractors. They should have a slight teardrop shape

(Figure 3-21, A). If the holes show an extreme distortion (Figure

3-21, B) or the paper jams, pull out the spring plunger knob (refer to

Figure 3-18) and move the vertical paper tension lever one position

toward “A.” Press the [form feed 1 key again and re-examine the

tractor holes.

8. Proceed to "A4justing Forms Thickness."

Follow the instructions on page 3-21 to adjust the thickness setting

for your form.

3-20 PREPARING THE PRINTER FOR OPERATION

Page 42

Adjusting Forms

Thickness

The forms thickness adjustment allows the printer to accommodate

various thicknesses of paper, such as when changing from single to

multi-part forms, or when using different weights of paper. The result

of setting forms thickness correctly is optimum print quality. These

procedures explain how to correctly set forms thickness and run a

sub-test to determine best print quality.

1. Position the forms thickness lever.

If the lever is not already positioned at maximum thickness setting,

“N” (as per instruction 4 on page 3-12), pull out the spring plunger

knob and set it at this time (Figure 3-22).

'"igure 3-22. Setting the Forms Thickness Lever at Maximum Thickness

PREPARING THE PRINTER FOR OPERATION 3-21

Page 43

2. Adjust the setting for print quality.

Move the lever one or two positions at a time toward the minimum

thickness setting, “A,” and then run sub-test 15 until you find

optimum print quality.

3. Run sub-test 15:

a. Enter the TEST mode.

Push the [testI key to enter the TEST mode (two decimal points

will light up). Use either [fine adj.) key to find sub-test 15 (a

pattern of horizontal and vertical lines). Press [enter ) to start the

test.

b. Examine the print.

Use the [form feed) key to eject the page out of the powered

paper stacker. Examine the vertical lines. They should be straight.

If they are somewhat jagged, with the individual dots offset to the

right and left, this is called “dot slalom” (Figure 3-23). It signifies

that the print gap is too large (the higher the letter on the knob,

the wider the print gap). To decrease the gap, turn the forms

thickness knob one position towards the smaller letters. If the ink

is smudging on the paper, the print gap is too small; increase the

setting by turning the knob one position toward the larger letters.

ONE PACE OF PRINT

3-22 PREPARING THE PRINTER FOR OPERATION

y V

GOOD SAD

COLUMN DOT POSITIONS

Figure 3-23. Dot Slalom

Page 44

c. Return to step "1."

Continue to a(^ust the thickness setting and run sub-test 15 until

the vertical lines are straight and the best print quality is obtained.

If you are having print quality problems, see “Optimizing Print

Quality” on page 6-14 for information.

Note

When printing in draft mode, tighten the paper thickness adjustment

lever up one additional position.

4. Check overall print quality.

At this point, your printer is set-up to obtain best print quality.

Follow the instructions on page 3-24 to run sub-test 9 and examine

the printed characters.

PREPARING THE PRINTER FOR OPERATION 3-23

Page 45

Overall Print Quality

Run sub-test 9 to check the overall print quality of your printer. Inspect

the upper case characters on the printout for “character scrunch.”

1. Select sub-test 9.

Press the fTEST) key to enter the TEST mode (two decimal points will

light up). Use either [fine adj. ) key to find sub-test 9. Press [enter )

to start the test.

2. Examine the characters.

Use the [form feed 1 key to eject the page. Examine the printed

characters. They should look even and well formed. If they appear

“squatty” or “scrunched,” this is called “character scrunch,” and

indicates that the paper tension is too loose (Figure 3-24).

1

•

•

A

UNEQUAL

SPACING

___

J

•

----------------------

SPACING

'

A

PAPER TENSION

rA TOO LOOSE

Figure 3-24, Character Scrunch

D PAPER TENSION

D CORRECT

3. Adjust vertical paper tension.

To correct “character scrunch,” move the vertical paper tension lever

toward “N” one position at a time. Continue to run sub-test 9 and

adjust the setting until optimum print quality is achieved.

4. Proceed to "Adjusting Forms Length."

Turn to page 3-25 for instructions on “Adjusting Forms Length.’

3-24 PREPARING THE PRINTER FOR OPERATION

Page 46

Forms length is the amount of text lines your printer can print per page.

It can be set two ways: | inch increments or text lines-per-page. Both

methods are explained below. If you are setting forms length for the

first time, or changing forms length to a new paper size, follow these

instructions.

If you do not need to adjust the forms length, continue to the next

section, “Adjusting Top of Form,” on page 3-30.

Figure 3-25 defines areas on the form you need to consider when setting

forms length.

igure 3-25. P?rts oi the Form

PREPARING THE PRINTER FOR OPERATION 3-25

No Perf

Skip

Page 47

Adjust Physical Forms

Length in ^ Inch

Increments.

The forms length can be set in | inch increments from 2 to 16 inches. If

you want to set forms length in increments other than ^ inch, turn to

page 3-27 to acUust forms length in physical text lines-per-page.

Use the keys on the control panel to set the forms length:

1. Enter the connguration mode.

Press and hold down the f CONFIG. 1 key. At the same time, press the

[fine adj. 1 keys to move to function 7 (the decimal points indicate

the CONFIGURATION mode). Release the [CONFIG.] key. A “1” or

a “0” lights up in the display window. You want setting “0.” Press

either [fine adj. ] key to move to “0” (if “0” is already displayed, press

[ENTER P.

2. Press [enter]

This programs the printer to set forms length in | inch increments.

3. Press [page l. adj.]

Note

The current page length setting is displayed in inches. A decimal

point allows the number to be a fraction. For example, a setting of

8.5 is actually 8 ^ inches. A setting of 11.0 is 11 inches.

If you do not want to change the page length, press the [page l. adj. )

key a second time to return to the STATUS mode, or press [on line) to

return the printer to the host.

4. Change the page length setting.

Use the [fine adj. 1 keys to move to the desired page length.

5. Press [enter]

The printer returns to the STATUS mode (a “0” appears in the

display window) indicating that the desired page length is entered.

6. Proceed to "A4)usting Top of Form."

Turn to page 3-30 to adjust the Top of Form position.

3-26 PREPARING THE PRINTER FOR OPERATION

Page 48

Adjust Forms Length in

Physical Text

Lines-Per-Page.

The forms length can be set in number of printable text lines-per-page.

The printer can be set at 6 LPI (lines-per-inch), to print 12 to 96 lines of

physical text per page, or 8 LPI, to print 16 to 128 lines of physical text

per page. It can also be set to operate with perforation skip “ON” or

“OFF.” To adjust forms length in physical text lines-per-page, you must

set perforation skip, LPI, and forms length in this order.

Set Perforation Skip.

Perf (perforation) skip provides a 1 inch vertical margin that, when

properly positioned via the Top of Form setting, prevents printing on the

perforated line.

Example:

When printing an 11 inch form at 6 LPI with perf skip “OFF,” 66 lines

will be printed with no margin allowed for the perforation. When perf

skip is “ON,” the text length is limited to 60 lines, thus allowing for a

1 inch vertical margin. If Top of Form is set to begin printing 1 inch

below the perf, the next perf will be centered within the 1 inch margin.

At 8 LPI, the maximum text length would be reduced from 88 to 80

lines (refer to Figure 3-25).

Turn perf skip "ON."

The perf skip default setting for your printer is “OFF.” To turn perf skip

“ON,” follow these instructions:

1. Enter connguration function 60.

Press and hold down the (config.) key. At the same time, press

either (fine adj. ] key to move to function 60 (the decimal points

indicate the CONFIGURATION mode). Release the (config.) key. A

“0” lights up in the display window.

2. Change to "1."

Use either (fine adj. ] key to move to “1.”

3. Press (enter 1

This turns perf skip “ON.”

Turn perf skip "OFF."

Follow steps 1, 2, and 3 above, but enter “0” instead of “1.’

PREPARING THE PRINTER FOR OPERATION 3-27

Page 49

With perf skip “OFF,” the printer will print whatever number you enter

for physical text lines-per-page. If the number exceeds the maximum

physical lines the printer can print per page, it will print in the perf skip

region.

For more information on perf skip, refer to the section on “Perforation

Skip Mode” in the HP256X Printer Family Technical Reference Manual,

02564-90905.

Note Perf skip mode is only applicable when using line feed instruction

“ applications fline count). If the application uses calls to Vertical Forms

Control (VFC) channels, the VFC definition Of vertical margin is used

and the state of the perf skip mode has no effect.

Set LPI (lines-per-inch).

Once you have determined the perf skip mode, the next step is to set

LPI.

1. Press (L.P.I. ADJ.l

The present LPI setting shows up in the display window (the decimal

points indicate the CONFIGURATION mode).

2. Change the LPI setting.

If you want to change the value, use either [fine adj. ) key to move to

the desired LPI setting (both keys toggle between 6 and 8). If you

do not want to change the value, press the fu.P.i. adj.) key again to

return to the STATUS mode (a “0” appears in the display window)

and proceed to set the forms Ic/igth.

3. Press [enter]

The printer returns to the STATUS mode (a “0” appears in the

display window) indicating that the desired setting is entered.

3-28 PREPARING THE PRINTER FOR OPERATION

Page 50

Set forms length.

After determining the LPI setting, use the keys on the control panel to

set the forms length:

Nok

I-;?:

If you set forms length in programmable Vertical Forms Control (VFC),

make sure the same setting is entered in the front panel. Otherwise, the

printer will continue to print when paper-out occurs.

1. Elnter the configuration mode.

Press and hold down the fcoNFiG.) key. At the same time, press

either (fine adj.1 key to move to function 7 (the decimal points

indicate the CONFIGURATION mode). Release the fcoNFiG.) key.

A “1” or a “0” lights up in the display window. You want setting

“1.” Press either (fine adj. 1 key to move to “1” (if “1” is already

displayed, press [enter]).

2. Press [enter]

This programs the printer to set forms length in lines-per-page.

3. Press [page l. adj ]

The current number of text lines-per-page is displayed.

iMOtf

I If you do not want to change the text lines-per-page, press the

[page l. adj.] key a second time to return to the STATUS mode, or press

[on line] to return the printer to the host.

4. Change the setting.

Use either [fine adj. ] key to move to the desired number of text

lines-per-page.

5. Press [enter]

The printer returns to the STATUS mode (a “0” appears in the

display window), indicating that the desired page length is entered.

6. Proceed to "Ac^usting Top of Form."

Turn to page 3-30 for instructions on “Adjusting Top of Form.’

PREPARING THE PRINTER FOR OPERATION 3-29

Page 51

Adjusting Top of

Form

Noie -.1 In order to set Top of Form, the swing-gate must be open and latched at

The Top of Form (TOF) position is an arbitrary indicator of the first

line of print. Once the Top of Form is set, any succeeding (form feed)

advances paper one page length until the same position on the next page

is reached. This enables you to move swiftly to the first print line on the

succeeding page.

Adjust Top of Form using the keys on the Operator Control Panel.

^ the top. The number 10 will flash in the display window indicating that

the swing-gate is open; however, disregard this message for now.

1. Adjust the paper.

Use the fuNE feed 1 or [fine adj.1 keys to adjust the paper so the

paper perforation is directly over the metal platen strip (Figure 3-26).

Pialen MetalStrip

3-30 PREPARING THE PRINTER FOR OPERATION

Figure 3-26. Adjusting Paper Over the Platen

Page 52

2. Lower the paper shield.

3. Ac^ust horizontal forms alignment.

The numbers on the paper shield (Figure 3-28) are indicators to

determine your first column of print. Set the tractor control knob to

the FORMS ALIGNMENT POSITION (Figure 3-19, A) and move the

left tractor control key (Figure 3-19, B) to position the paper to the

first column of print.

Figure 3-28. Positioning Paper to the First Column of Prin:

PREPARING THE PRINTER FOR OPERATION 3-31

Page 53

4. Press fSET T.O.F. 1

Three decimai points in the display window illuminate to indicate the

SET T.O.F. mode.

5. Press [enter 1

This sets the new Top of Form position and returns the printer to the

printer ready STATUS mode.

6. Close the swing-gate.

7. Verify the Top of Form position.

Use the (testI key and (print i line) key to determine if the Top of

Form setting is correct. If not, repeat step 1 on page 30 to adjust your

paper to the desired position.

If a paper-out error was in effect before the (set t.o.f. ) key was pressed,

setting the Top of Form clears the error.

3-32 PREPARING THE PRINTER FOR OPERATION

Page 54

Top of Form Alignment Guide Labels

These labels provide easy alignment of frequently used forms. They are

provided with each printer; however, additional sheets (02566-00223)

may be purchased through your Hewlett-Packard Sales offices.

ALIGNMENT GUIDE LABELS

____1__

I I I M I M I M

INDEX

TOF

"index

ig ir 3-29. "op I j in / itir (

PREPARING THE PRINTER FOR OPERATION 3-33

Page 55

Installing the Top of Form Alignment Guide Labels

1. Position the index label.

Peel off the index label from the plastic sheet (Figure 3-30) and

adhere it to the left hand print mechanism cover above the “Forms

Loading/Ribbon Replacement” label.

INDEX

A

B

c

D

E

F

G

H

1

J

K

L

M

N

RECORD "TOF*

INFORMATION

■ FOR FORMS

SEING USED.

Fióte

It is recommended that alignment guide labels be placed only on the

upper viewing surface so that paper position can be viewed with the top

cover closed. Do not place labels on the platen surface, under the paper.

3-34 PREPARING THE PRINTER FOR OPERATION

Figure 3-30. Top of Form Index Label

Page 56

2. Position the alignment guide labels.

After your form is in position, place an alignment guide label (A, B,

etc.) next to the perforation on the rear paper guide (Figure 3-31).

Make sure the label is positioned so it can be seen when using

various paper sizes.

Figure 3-31. Positioning Alignment Guide Labels

PREPARING THE PRINTER FOR OPERATION 3-35

Page 57

3. Record information.

Write down form placement information on the index label (Figure

3-32).

INDEX

A

BANK CHECKS C

9.5 X 11 INVENTORY D

B

CARD LABELS A

C

INVOICE FORMS E

D

E

F

G

■ BEING USED-

H

RFCORO -TDF*

information

~ FOR FORMS

1

_J_

K

L

M

IT

Fiaure J-3Ì'.

Noie If form alignment information changes, record the new form placement

on the index label.

3-36 PREPARING THE PRINTER FOR OPERATION

di ' = I iloi

Page 58

USING THE POWERED PAPER STACKER

For optimum performance of your powered paper stacker, follow these

instructions to correctly use the stacker and position your paper.

NotP „,i An Operator Information Label is located on the inside panel of the

y powered paper stacker to provide brief instructions on how to use your

stacking aid.

1. Open the stacker door.

Slide out the paper tray and place the chains behind the backstop

(Figure 4-1).

4

figure i. Sliding Oul Ihe P<iper Tray

USING THE POWERED PAPER STACKER 4-1

Page 59

2. Position the backstop.

The two labels on the paper tray show you where to position the

backstop for different paper sizes. Refer to Table 4-1 for the correct

placement for your paper size and then install the backstop at the

desired location on the paper tray (Figure 4-2).

Figure 4-2. Positioning the Backstop

4-2 USING THE POWERED PAPER STACKER

Table 4-1. Recommended Backstop Positions

Form Size (width x length)

14 g X 12 inches

14 1 X 11 inches

Single Part Multi-Part

E D

E E

9 g X 11 inches E

8 1x11 inches (3 hole) E

11 X 8 1 inches G F

8 1 X 7 1 inches I H

E

E

Page 60

3. Push in the paper tray.

Make sure the chains hang in front of the backstop (Figure 4-3).

Figure 4-3. Pushing In the Paper Tray

USING THE POWERED PAPER STACKER 4-3

Page 61

4. Adjust the door chains.

Refer to Table 4-2 for the recommended position of the door chains

for your paper size. (The Operator Information Label, inside the

stacker, also diagrams door chain positions.) To install the chain

assembly on the stacker door, turn the metal bar sideways to fit into

the bracket; then, insert the chain assembly into the desired slot

(Figure 4-4).

4-4 USING THE POWERED PAPER STACKER

Figui v ' Arliiiiiiirin uoor Ciiaiiis

lule 2. Rerr ;irui ndet De ■ '<

Form Size (width x length)

14 1 .\ 12 inches

14 1 X 11 inches

Single Part Multi-Part

B

C

9 1 X 11 inches B A

8 i X 11 inches (3 hole)

11 X 8 i inches

8 j X 7 1 inches

B

F D

F

A

A

A

E

Page 62

5. Advance paper into the stacker.

Start your job to advance at least 10 sheets of paper onto the paper

tray (make sure the first form feeds smoothly into the stacker without

jamming).

6. Start the paper stack.

Make sure each form folds on the tray the same way as it came out of

the input box (Figure 4-5).

•-! jn. 1-5. SI.:- ini

Sia: k

The performance of the stacker depends on the paper folding correctly.

It is extremely important for the paper to fold the same way it was

manufactured.

USING THE POWERED PAPER STACKER 4-5

Page 63

7. Align the paper stack.

Center the stack directly under the falling paper and then push it

against the backstop (Figure 4-6). The backstop guides the paper into

position and helps it fold correctly.

8. Cluso the stacker door.

Continue to peige 4-7, “Unloading the Paper Stack,” for information

on how to remove paper from the stacker.

4-6 USING THE POWERED PAPER STACKER

Figure 4-6. Aligning the Paper Stack

Page 64

Unloading the Paper

Stack

When you run out of paper in the printen

1. Advance paper into the stacker.

Put the printer “off-line” and press [form feed 1 to advance the last

sheets of paper into the stacker.

2. Remove the stack.

Slide the paper tray out and pick up the stack.

3. Close the stacker.

Push the tray back in and close the door.

When you Hnish one job and want to start anothen

1. Put the printer "off-line."

Push the fON line) button to take the printer “off-line.”

2. Pull out the paper tray.

3. Remove your job.

Tear off the last sheet from your job and remove it from the paper

tray.

4. Prepare the stacker for the next job.

Adjust the backstop and door chains for your next forms length.

5. Push the paper tray back in.

6. Push the [on line) key to put the printer turn the printer "ON."

7. Start your new job.

Return to the stacker and make sure the forms are folding and

stacking correctly.

8. Close the stacker door.

USING THE POWERED PAPER STACKER 4-7

Page 65

4-8 USING THE POWERED PAPER STACKER

Page 66

The HP2566C/HP2567C printer needs to be configured to perform

various functions. Follow the procedure below, to configure your printer

using the buttons on the Operator Control Panel.

Table 5-1 lists the configurable printer functions and their associated

numbers. Each function has two or more possible parameters that can

be selected as desired. Some of the functions can be set remotely via

escape (ESC) sequences. See the HP256X Printer Family Technical

Reference Manual, 02564-90905, for information about remote

configuration. Also, use the Operator Information label, inside your

printer, as a quick reference guide for the CONFIGURATION modes.

Follow steps 1 - 4 to atyust and set CONFIGURATION modes from the

Operator Control Panel.

5

1. Enter the CONFIGURATION mode.

Make sure the printer is “off-line.” Press and hold down the

(CONFIG. 1 key. At the same time, press either (fine adj. ) key to move

to the desired function number (two decimal points indicate the

CONFIGURATION mode).

2. Release the (config.1 key.

The parameter value for the desired function number shows up in

the display window.

If you do not want to change the parameter, press the (config. ) key a

second time, or press the [enter) key, or press the (on line] key. All

these retain the original configuration for that function.

3. Set the parameter.

Use the (fine adj ) keys to move to the desired parameter.

PRINTER CONFIGURATION 5-1

Page 67

Some configuration parameters can only be modified by a

^ Hewlett-Packard Service Representative. In these cases, the (fine adj, )

keys have no effect.

4. Press [ENTER 1

This sets the new parameter and the printer returns to the STATUS

mode.

Table 5-1. Configuration Function Numbers

Parameter

Function #

Description

Range

Comments

1

2

Select Primary Character Set 0-95 See pg. 5-3

Select Secondary Character Set 0-95

7 Select Page Length

Representation

20-29* Configure Interface

50

51

Disconnect Modem

Difficult Forms Mode

52 Horizontal Graphics Density

60 Perforation Skip 0,1

61 Display Functions

80 Enable/Disable Label Card

81 Printronix P-Series Line Feed

Emulation

85-89

Configure Label Card

See pg. 5-3

0,1

See pg, 5-4

00-FF See pg. 5-5

0.1

0,1

60,70

See pg. 5-4

See pg. 5-4

See pg. 5-4

See pg. 5-5

0,1

0,1

See pg. 5-5

See HP Label

Card Manual

26062-90902

0,1

See HP Label

Card Manual

00,FF

See HP Label

Card Manual

5-2 PRINTER CONFIGURATION

• Functions 20-29 are dependent on which interface is installed (see your

Interface manual)

Page 68

Character Set Selection

To be compatible with both 7-bit and 8-bit hosts, your

HP2566C/HP2567C has 7-bit and 8-bit character sets. The standard

7-bit sets are ASCII and Roman Extension. The standard 8-bit set is

Romans, combining ASCII plus Roman Extension characters. The

printer may contain up to 16 character sets. Your printer contains the

sets which were speciHed in your purchase order. Two character sets

(primary and secondary) may be selected at any one time and are chosen

either through the CONFIGURATION mode from the Operator Control

Panel or remotely via escape sequences.

Primary Character Set: FUNCTION 1

Select the primary character set by accessing function number “1” of

the CONFIGURATION mode and selecting the parameter associated

with the desired primary character set. The character sets and their

associated parameters are listed on your self-test print out. Figure 5-1

shows an example of the top portion of a self-test printout. The arrows

in the figure point out the assigned character set parameter value.

Note that the assigned values vary from printer to printer. Check your

printer’s self-test to find the character set values.

Secondary Character Set: FUNCTION 2

Select a secondary character set from the printer’s self-test. Access

function number “2” of the CONFIGURATION mode and enter the

parameter associated with that set (Figure 5-1).

CONTROL RONRD tCRC E7(l6t ST I 3

HR-ie INTCRRACE £33R

IL gp. ..«,» ? I n

► IT

►ai

Id Û CPI—HICH DCriStTT

►a« [)»■

► as !"**«■ {)*•

► a* iWVriim'i'.Vp'iWW'iSl.lWW.VWil'l ''Pi*<' Ci

"igurr 5-1. Chsrarirr Sc! SofJ ’"Dît rsmrip''

PRINT TINE OOOOOi HOURS

HP-19 DEVICE ADDRESS < 4.

AtttPt i t(iUd(itiD«>3i{

tsos