Page 1

i

OPERATORS GUIDE

MODEL 1610A

LOGIC STATE ANALYZER

*

-7

L.’ ;

‘I

”

@COPYRIGHT

1900 GARDEN OF THE GODS ROAD, COLORADO SPRINGS, COLORADO, U.S.A.

-.

,.

,.’

”

/

_

F’

Manual Part Number 0161 o-90903

Microfiche Part Number 0161 o-90803

HEWLETT-PACKARD COMPANY/COLORADO SPRINGS DIVISION

ALL RIGHTS RESERVED

PRINTED: AUG 1977

1977

Page 2

SAFETY SUMMARY

The following general

and repair of this instrument. Failure to comply with these precautions or with specific warnings

elsewhere in this manual vioiafes safety standards of design, manufacture, and intended use of the

instrument. Hewlett-Packard Company assumes no i/ability

with these requirements.

GROUND THE INSTRUMENT.

To

mrnrmrze

ground The

rnust

to two-contact adapter

(safety

lnternarronal Elt:lctrotechnrcal Commrssion

shock hazard, the instrument chassis and cabinet must be connected to an electrical

tnstrument

etther

be plugged

groundi

at the power outlet, The power jack and

satefy

precautions must be observed during all phases of operation, service,

for

the customer’s failure to comply

IS equipped

Into

an approved three-contact

with

the grounding wire (green) firmly connected to an electrical ground

with

a three-conductor ac power cable. The power cable

elEctrical

(IEC) safety standards.

outlet or used with a three-contact

mating

plug of the power cable meet

7

t

i

P

-I

r

.J

-.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any

electrrcal

KEEP AWAY FROM LIVE CIRCUITS.

OperatIn!]

adjustments must be made by qualified maintenance personnel.

power cable connected. Under certain conditions, dangerous voltages may exist even with the

power cable removed To avoid Injuries,

touching them

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person,

and

USE CAUTION WHEN EXPOSING OR HANDLING THE CRT.

Breakage of

To prevent CRT Implosion,

be done only by qualified maintenance personnel using approved safety mask and gloves.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install

any

Sales and

instrument In such an environment constitutes a definite safety hazard.

personnel must not remove instrument covers. Component replacement and internal

Do not replace components with

always disconnect power and discharge circuits before

capable of rendering first aid

resu:;cttation

unauthorized modifrcatron

IS present.

the

Cathode-ray Tube (CRT) causes a high-velocity scattering of glass fragments (implosion).

avoid

rough handling or jarring of the instrument. Handling of the CRT shall

Service

substrtute

to the instrument. Return the instrument to a Hewlett-Packard

Office for service and repair to ensure that safety features are maintained.

parts or perform

I.

“I

I;

.I

‘1

I

I

DANGEROUS PROCEDURE WARNINGS.

Warnings

manual Instructions contained In the

such as the example below, precede potentially dangerous procedures throughout this

warntngs

Dangerous voltages, capable of causing death, are present in this instrument.

Use ex’treme caution when handling, testing, and adjusting.

must be followed

pzz--l

ss-2-l f76

,

1:

i

i’

i,

i:

Page 3

TABLE OF CONTENTS

PAGE

PREFACE

CHAPTER I:

General

The Keyboard

.....................................................................

tNTRODUCTlON

TO HP MODEL 1610A LOGIC ANALYZER

..................

.....................................................................

................................................................

Current

/Measurement

Display Group ............................................

Entry Group ...............................................................

Edit

Group ................................................................

Execute

Group

ProbeThreshold

The

Front

Probe Pod Cable Connectors

The

Rear

P,anel.........

.............................................................

..............................................................

Panel

............................................................

.................................................

......................................................

Basic Information About Menu Displays ...........................................

Menu

Title

and Machine Status

................................................

Error, Warning, and Information Messages ......................................

Muftrple--choice

Entry

Fields

The Cursor

...............................................................

Fields

..............................................................

......................................................

Menu Display Sections ......................................................

CHAPTER II:

Preparing for

OPERATING

YOUR

1610A

...........................................

Operation .......................................................

Quick Run-through Procedure .................................................

Now What? ................................................................

CHAPTER

Introduction

III:

DETAILED

MENU DESCRIPTIONS

................................................................

....................................

Format Specification Menu ..................................................

Trace Specification Menu., ..................................................

Trace

List

Menu..

.........................................................

Trace Graph Menu .........................................................

Trace

Cornpare

CHAPTER IV: POSITIONING THE TRACE WINDOW IN DATA FLOW.

Example 1:

Menu .......................................................

....................

:Simple

Single-state Trace

............................................

Example 2: Single-state Trace with Delay .........................................

Example 3: Tracing Specific Data Path in a Branching Program

Example 4: Tracing Specific Path in Multiple-branch Program

Example 5: Multiple-branch Path Completed in a Single Pass

.......................

........................

.........................

Example 6: Tracing a Direct Jump in a Multiple-branch Program ......................

Example 7: Tracing Program Flow in Nested Loops

CHAPTER V: PERFORMANCE VERIFICATION

.................................

......................................

Introduction.. ..............................................................

Initiation of Performance Verification ............................................

Display Test

..............................................................

Keyboard Test ............................................................

Trace Test ...............................................................

Interrupt-rest .............................................................

Printer Test ..............................................................

APPENDIX

APPENDIX B: MESSAGES

A:

GLOSSARY.

.....................................................

......................................................

iv

1

1

1

2

3

4

5

6

6

6

8

9

9

10

10

10

11

11

13

13

14

18

19

19

21

23

25

27

29

31

32

32

33

34

35

36

37

39

39

39

40

41

42

43

43

A-l

B-l

. . .

III

Page 4

PREFACE

------- HOW TO USE THIS BOOK -------

How you use this book is largely a matter of your experience with Logic State

Analyzers.

An experienced Logic State Analyzer operator can begin using the Hewlett-Packard

1610A after getting acquainted with it in Chapter I and II.

If this

page by page so you thoroughly understand your instrument and how it works.

You may want to try something you’re not sure of, or that is not described in the

book. TRY IT! You won’t damage the 161 OA. If what you try is not acceptable to the

instrument, it will tell you why on the display.

IS,

your first opportunity to use a Logic State Analyzer, go through the book

------- WHEN TO USE THIS BOOK -------

f ’

I ,

!

i.

I *

I”7.I

?

1;

I,i

Whatever your experience level, use selected portions of the book the first time you

operate your 161 OA.

Study the material presented here whenever you have a few minutes. Some of the

machine capabilities are rather subtle; thorough understanding of them will put you

in a position of being ready when that new, complex measurement problem presents

itself.

iV

i;

I.

Page 5

Chapter I

INTRODUCTION TO YOUR

HP MODEL

Your Hewlett-Packard Model

1610A

-mm____

1610A

LOGIC STATE ANALYZER

GENERAL

Logic State Analyzer (called simply

m______

1610A

in

this book) is a general-purpose instrument which extends measurement capabilities

in the Data Domain beyond the capabilities of any previous machine.

Analysis of the most advanced state machines, and the most complex software, is

possible using the 161 OA. Yet Operating simplicity has been achieved by user-oriented

engineering design; the 161 OA performs many routine “house-keeping” chores that

the operator used to do.

As you go through this book, you may find some unfamiliar terms generated by the

unique characteristics of the 161 OA. A glossary of these terms is included in the back

of the book as Appendix A.

---THE

KEYBOARD

-------

The 1610A keyboard contains 39 keys divided into four functional groups. A fold-

out illustration of the keyboard is at the back of this book for easy reference as you

work.

1

Page 6

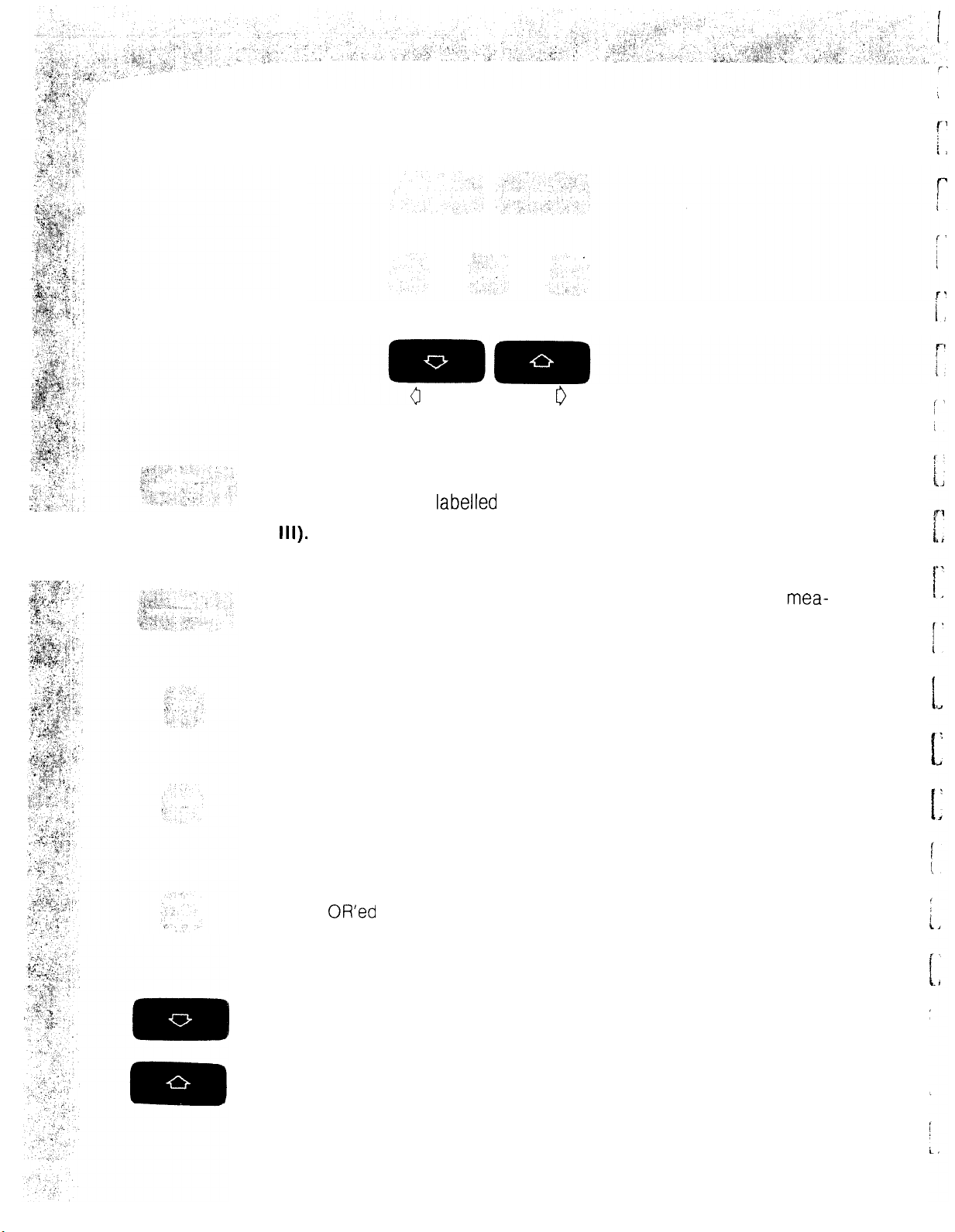

Current Measurement Display Group:

CURRENT MEASUREMENT

DISPLAY

ROLL DISPLAY

GRAPH GRAPH

0

Calls up a display menu which allows you to select clock slope, logic

polarity, and number base parameters. Also permits formatting 32

input channels into

labelled

groups (see FORMAT MENU, Chapter

III).

Calls up a display menu in which you specify state and count

mea-

surements (see TRACE SPECIFICATION MENU, Chapter Ill).

Calls up display menu in which current measurement and count data

are displayed (see TRACE LIST MENU, Chapter Ill).

Calls up graphed display of current measurement data for any speci-

fied label (see GRAPH MENU, Chapter Ill).

Calls up display menu in which current measurement data is EXCLU-

SIVE

OR’ed

with valid stored data; also selection of COMPARED

TRACE mode (see COMPARED TRACE MENU, Chapter Ill).

Rolls trace display in the indicated direction to view all 64 memory

states. The 20 states displayed are represented by intensified dots

in GRAPH MENU. Intensified dots on the graph shift left or right as

the trace is rolled,

Page 7

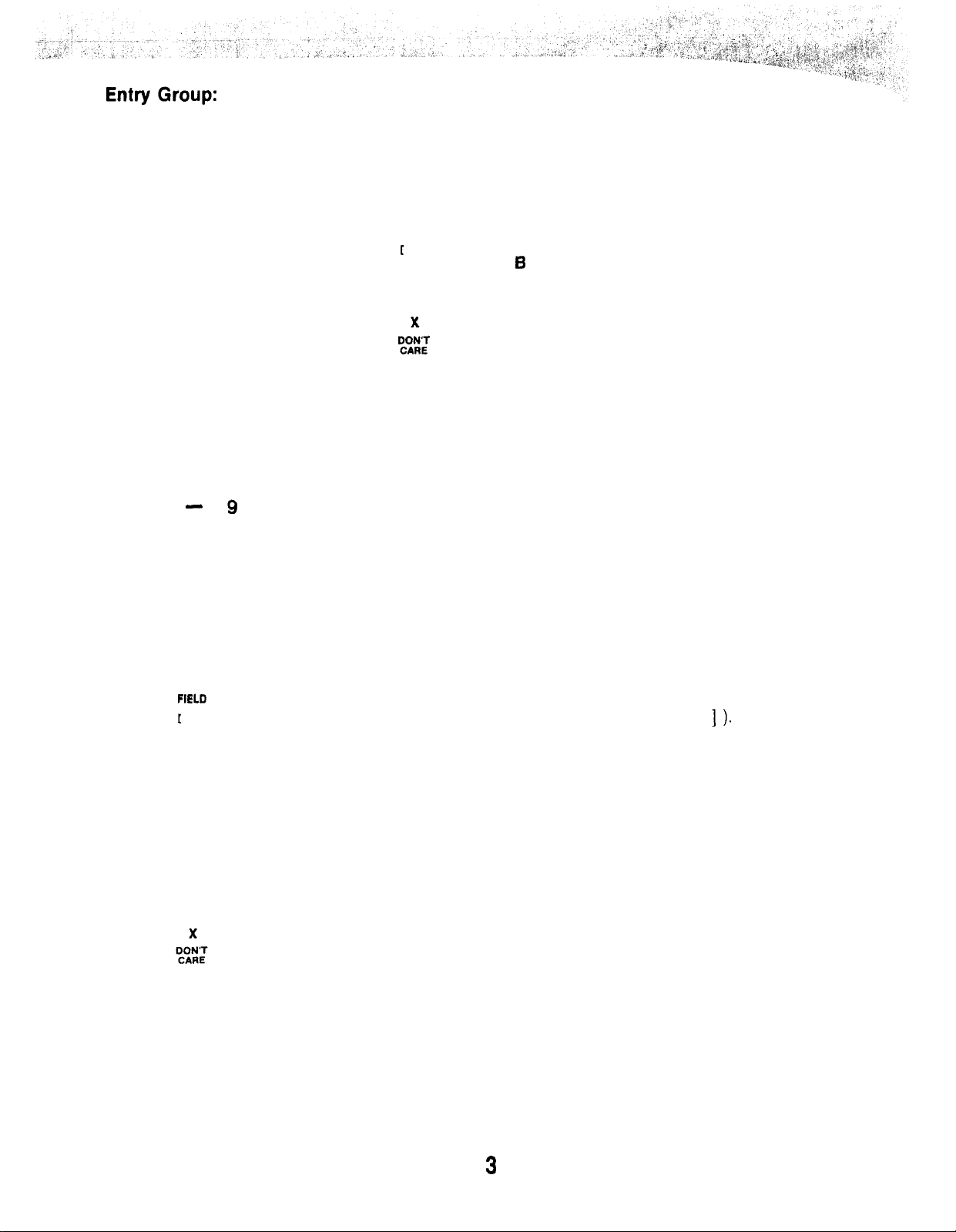

ENTRY

0

-

‘9

or

A-F

FIELD

SELECT

1

I

0

D E

A

6

7 8

4 5

1

2

F

c

9

6

3

Alphanumeric keys for entering information into all entry fields on

the displays.

FfELD

SELECT

1

I

Permits selection among field content variables. This key is used to

change inverse fields which contain brackets ( [

] ).

In entry fields:

“X” indicates that all allowed digit values are acceptable. In

octal fields allowed values of “X” are 0 through 7 (3 bits). In

hexadecimal fields allowed values for “X” are 0 through F (4 bits).

In label assignment fields:

“X” indicates that the channel is not used. An used channel is not

included in any other label reference.

3

Page 8

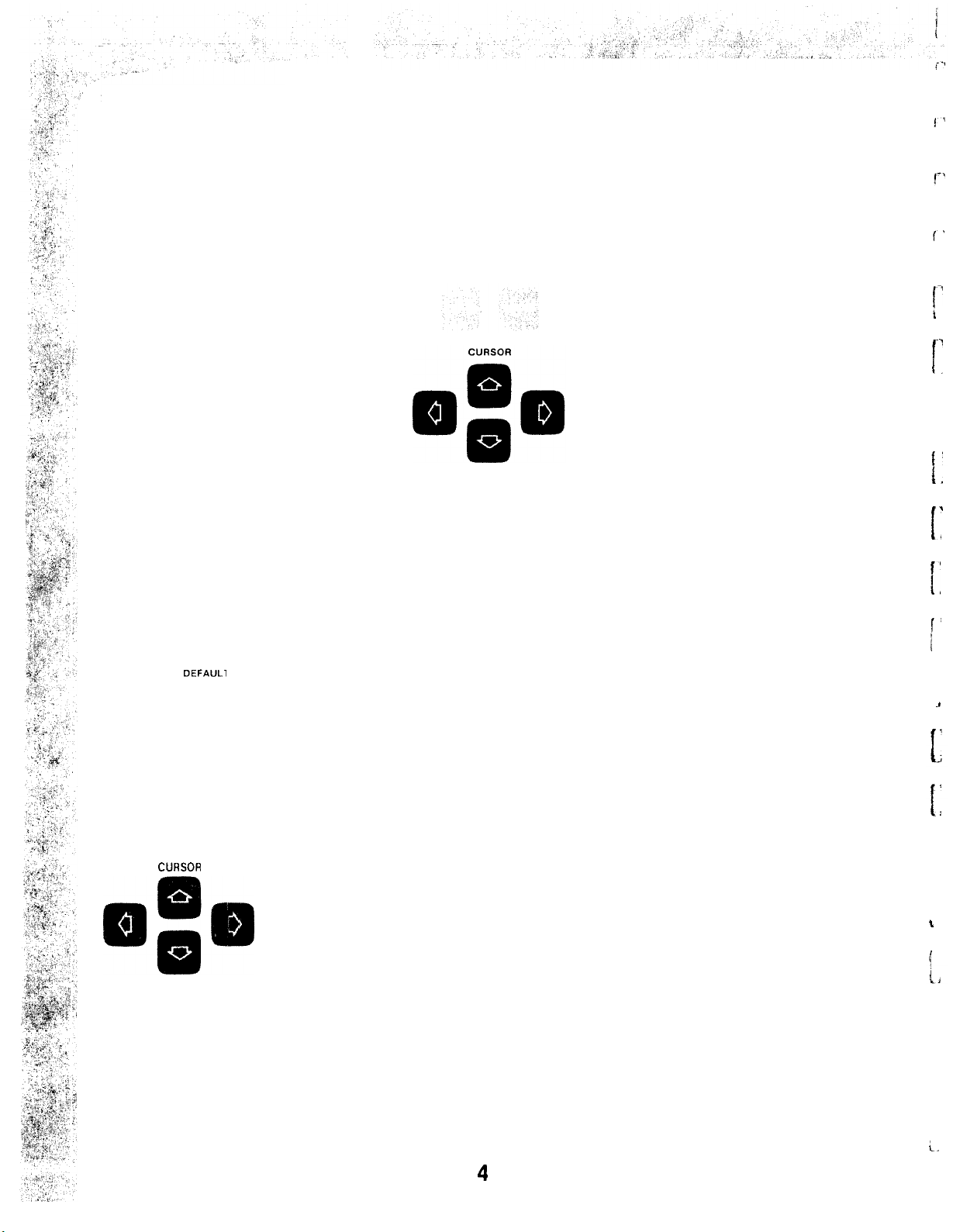

Edit Group:

EDIT

DEFAULT

GRAPH LIMITS

I’

i

.

aD+a

EDIT

DEFAULl

GRAPH LIMITS

CURSOR

1)

v

lb

Insert or delete lines which allow further definition of trace location

in program flow; or which selectively “TRACE ONLY STATES”

which meet any of several conditions.

Returns the currently displayed menu to its simplest form.

Used in TRACE GRAPH MENU only. Automatically changes upper

or lower graph limit.

Used to move blinking cursor in indicated direction.

I.

i,

I’

i

i

3

,

\

i.

4

Page 9

Execute Group:

,I.

.,,, ‘,

EXECUTE

STORE

CURRENTMEASUREMENT

..

,‘,

,,,:f;‘i/s, ”

’

,,

_.

,,.,’

“i,

‘1.” .*,

‘,I”,

,,,I

:

‘Q’S _,

Transfers current measurement data (with FORMAT and TRACE

SPECIFICATIONS) into separate storage memory; does NOT alter

current measurement information.

Performs an V-exchange between current measurement data and

data in stored memory (see COMPARED TRACE, Chapter III).

Initiates a print-out of the current display (except GRAPH) on an

interfaced HP Model

9866A/B

Printer.

Initiates a search in data flow to find and trace data that corresponds

to the parameters defined in the specification menus then displays

resultant data. Pressing the key one time initiates a single trace;

holding the key down places the 161 OA in the CONTINUOUS TRACE

mode, permitting observation of dynamic program flow.

Stops any “CONTINUOUSTRACE,““COMPAREDTRACE,””TRACE,”

or “PRINT” which remains “IN PROCESS.”

5

Page 10

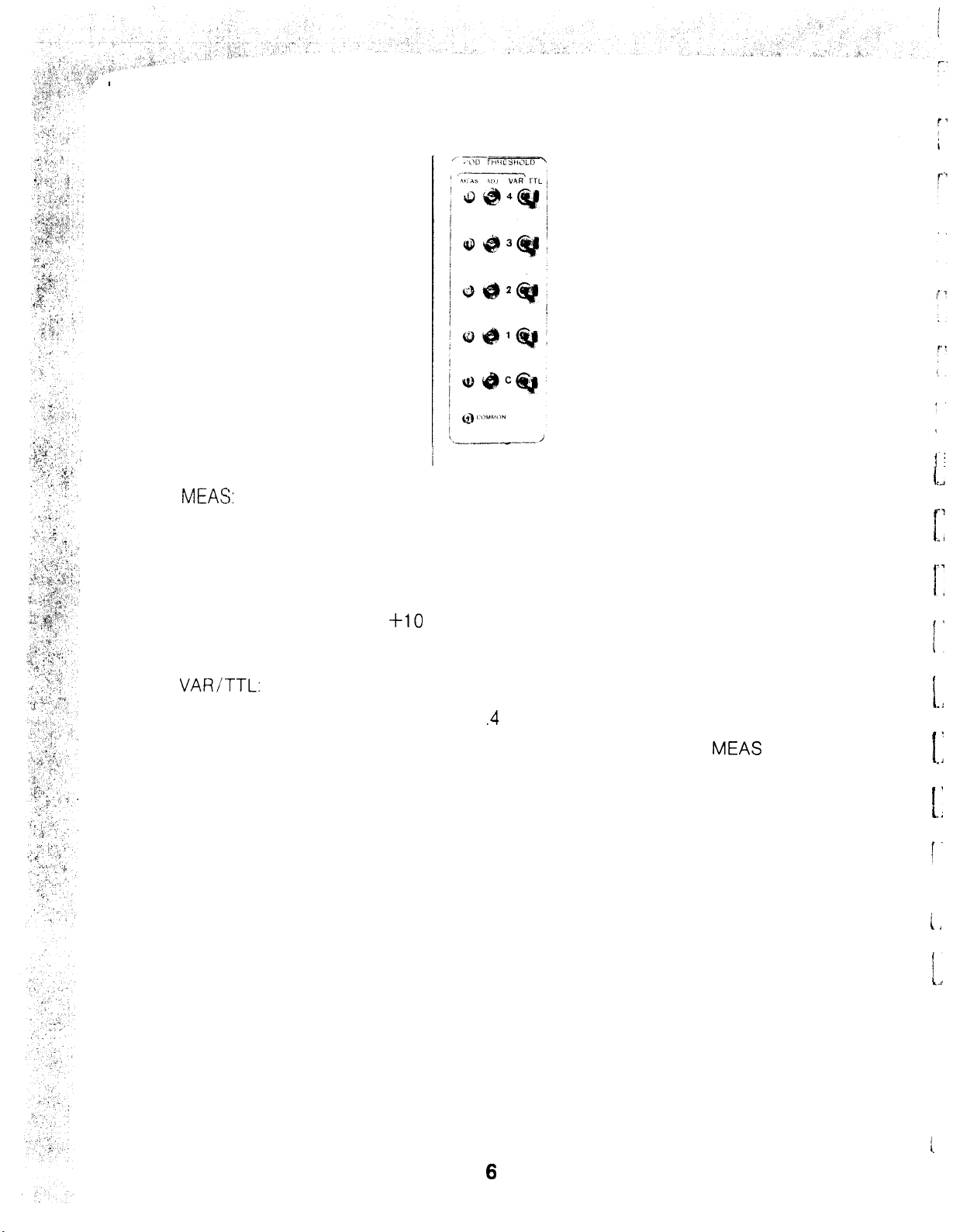

Probe Threshold:

------- THE FRONT PANEL -------

MEAS:

A point of attachment for a voltage measuring device when adjusting

threshold level.

ADJ: Adjustment for setting threshold level to the desired amplitude in a

range of -10 V to

VAH/TTL:

When this switch is set to TTL, the corresponding probe pod is

+lO

V.

set to operate at TTL (1 .4 V) threshold levels. In the VAR position, the probe pod is adjusted to required voltage at

COMMON: A grounding point

for measuring threshold voltage levels for

MEAS

point.

any probe pod.

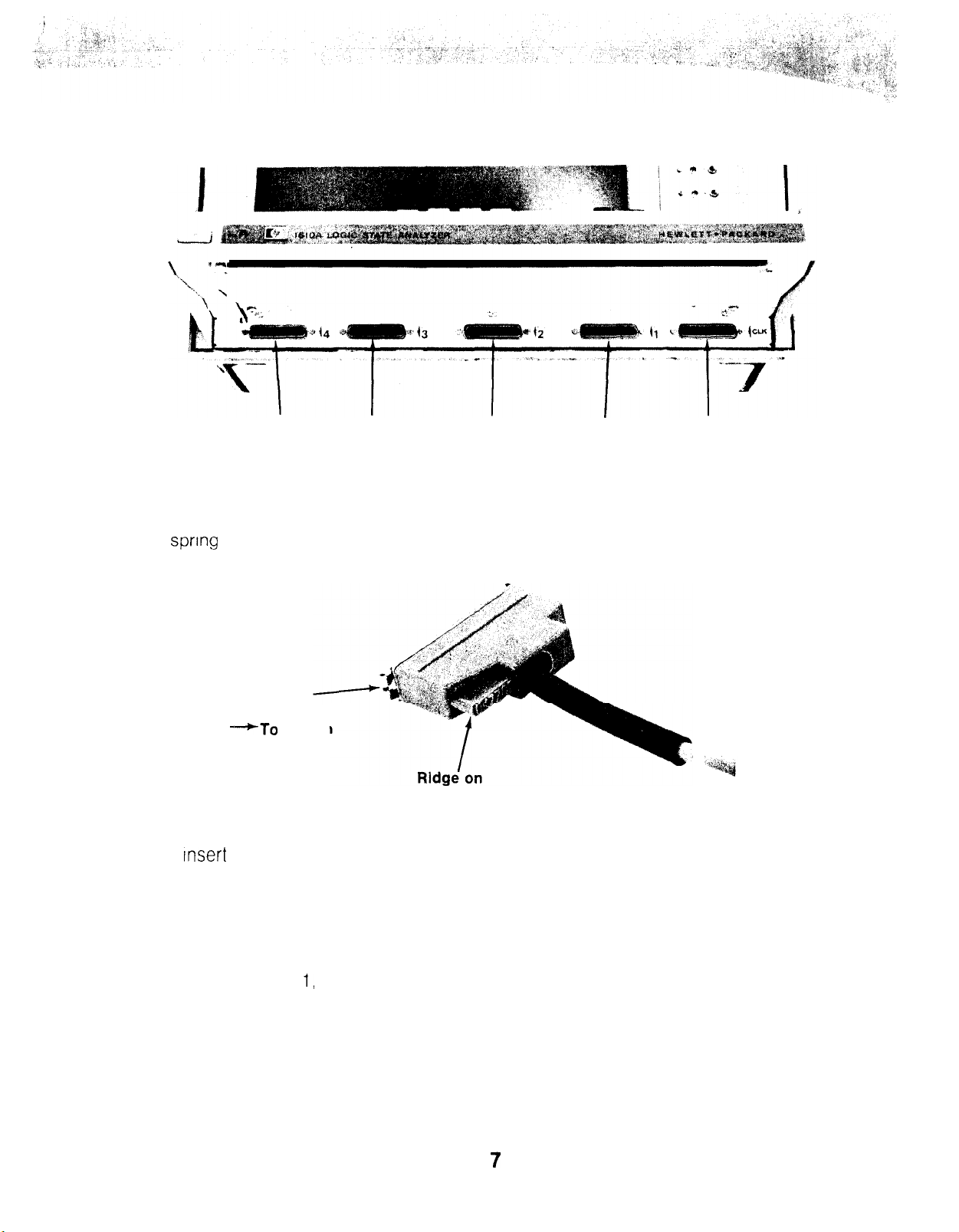

------- PROBE POD CABLE CONNECTORS -------

i,

Directly under the keyboard are sockets for connecting the probe pod cables. These

cables are not numbered and will operate interchangeably, except for the Clock pod.

Pod numbers in the photograph relate pod location to the FORMAT SPECIFICATION

6

i.

Page 11

POD

4

POD

3

POD

2

POD

1

CLK

menu display (see Chapter III). Each connector is keyed to the socket; the

ridge in the molded plug should be on the left when being inserted in the socket.

A

sprtng

clip on the connector locks it in position when it is pushed to the left as shown.

Spring Clip

-+-To lock

To

--To

Insert

plug into socket, slide spring clip to the right, insert plug in socket, slide

plug in

Molded Plug

spring clip to the left to lock in position,

There are eight data lines and a ground lead in each pod. These lines are identified by

wire colors, The white/black line represents data bit 0, the white/brown line represents data bit 1, and so on to the white/violet line which represents data bit 7,

following the standard resistor value color code. A black lead indicates “ground.” For

purposes of the FORMAT SPECIFICATION menu (Chapter Ill), line 0 represents the

least significant bit and line 7 represents the most significant bit.

7

Page 12

,

I

:

:

‘1’ ..,

,, ”

‘,

,,’

:,1,

‘,

,,,L,“

1.

1

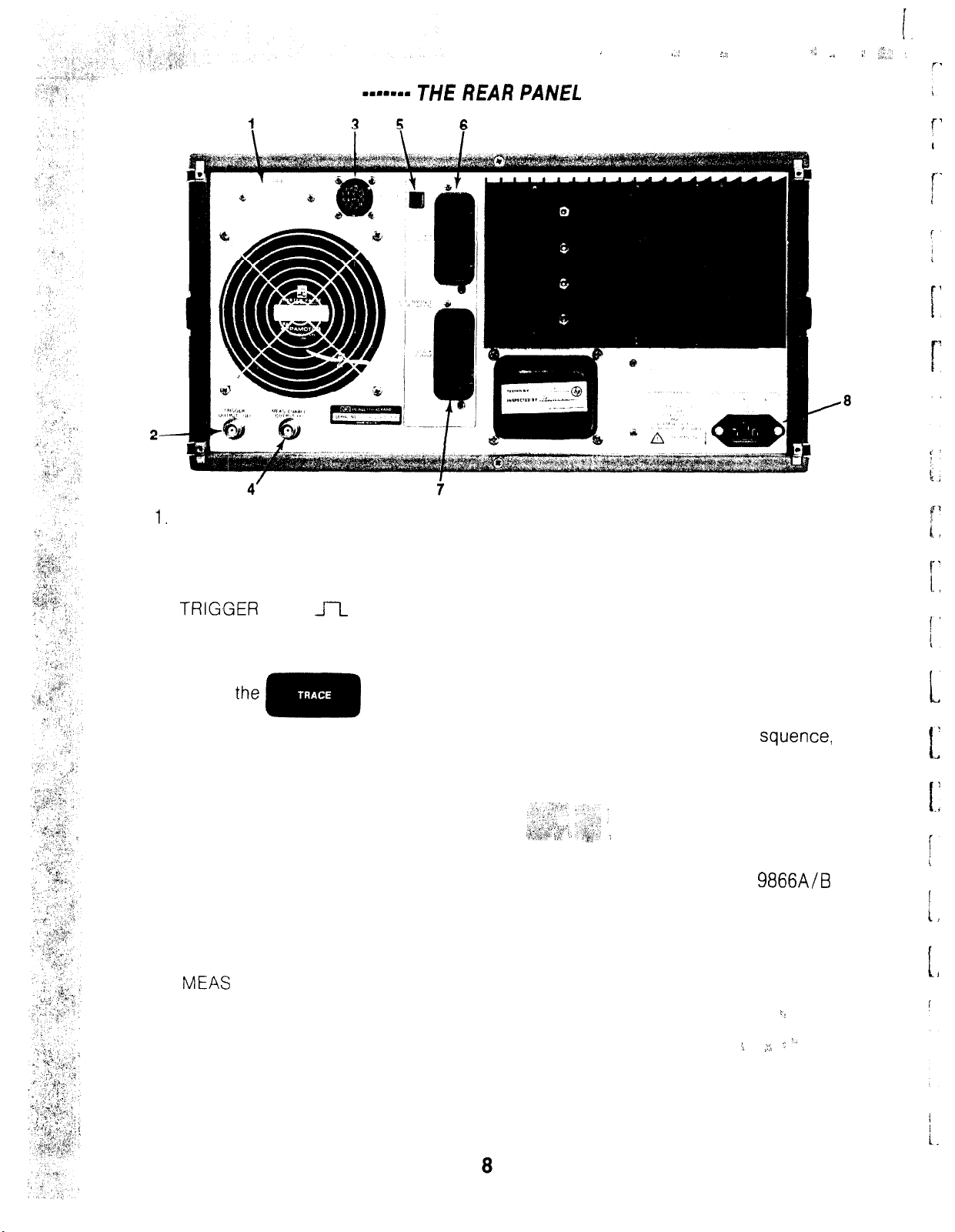

-----mm THE REAR PANEL

1.

For installation of a future Option which will permit use of the 161 OA with the HP

-s---m-

Interface Bus (HP IB).

2.

TRIG~GER

OUT

JI

connector provides high repetition rate pulses useful for

triggering external instrumentation such as oscilloscopes. Pulse output begins

when

the trace specification is satisfied. If the trace position includes a state

them

key is pressed, and a 50 ns pulse is generated each time

squence,

the pulse occurs when the last valid state is found; pulse output continues until

a new specification is traced, or until the

3.

PRINTER connector permits interfacing the 161 OA with an HP Model

L~~j$“‘- “.~~,I :

,

..;~.,‘:y

‘!,.I ‘t

,$:*<g*

p* :..tp

key is pressed.

i

9866A/B

Printer for obtaining hard copy of all display menus except GRAPH.

4.

MEAS ENABLE provides a low logic level when the 161 OA begins trace execution;

level remains low until the trace state is recognized or until

IS

pressed.

”

key

2 ^

>./r

‘1

:

Page 13

START

5.

m

pushbutton initiates internal performance verification routines. Perform-

ance verification destroys current specifications and data.

6. DATA POD connected to this socket provides a continuous 8-bit count at

10 MHz rate; also tests the data pod for accurate operation during performance

verification.

7.

CLOCK POD connected to this socket uses internally generated 10 MHz clock

signal for performance verification routines.

8. Line power socket.

-.------

BASIC INFORMATION ABOUT MENU DISPLAYS -------

Some features are common to all menu displays. These features are described here

so you

1.

Menu Title and Machine Status.

wiill

recognize them in the following pages.

The first line of all menus gives the name of the menu on the left. Machine status

is on the right and indicates the last machine operation initiated and whether the

operation is COMPLETED, FAILED, ABORTED, or IN PROCESS. When the 161 OA

is in continuous or compared trace modes, status condition will continue to flash

these possible conditions.

9

Page 14

2. ERROR, WARNING, and Information Messages.

Model

for communication between the 161 OA and the operator. Some of the messages,

ERROR and WARNING, imply a sense of urgency, but they do not in any way

mean damage to the machine or injury to the operator. ERROR is only to alert

the operator that he should make an immediate correction. WARNING cautions

the operator that a current entry may lead to an ERROR, or that a limit of execution has been reached. Appendix 6 lists and describes these messages in

more

3. Multiple-Choice Fields.

An inverse video field which contains brackets ( [

a choice among two or more variables in defining the parameter for that

ular field. Your choice is made by pressing the

1610A

‘detail.

is a conversational machine. Line two of each menu is reserved

]

) indicates that you have

partic-

&Fk&

key until the proper field

[

I

content is displayed. The 161 OA remembers the choice you made and carries it

into ali

IMPORTANT: If the COMPARED TRACE MODE selectable field is left in

[STOP=] or

single or continuous trace operation in any menu.

4. Entry Fields.

Inverse video fields without brackets indicate areas where you enter alpha-

numeric characters which define labels, states of interest, or state occur-

rences

other menu displays where it applies.

[STOP+],

condition, it must be returned to [OFF] to restore

10

Page 15

5. The Cursor.

A blinking inverse field one character wide, called the Cursor, indicates the

field in which a selection may be made, or the location where the next

alphanumeric character will be entered. You may reposition the cursor

CUASOR

into the desired field by using the

of the keyboard. The cursor is removed when the 161 OA is operating in any

continuous mode.

6. Menu Display Sections.

Each section of the menu display is given a title describing the data parameter

which it controls. Section titles are positioned along the left margin of the display.

11/(12

blank)

Page 16

Chapter II

OPERATING YOUR 1610A

------- PREPARING FOR OPERATION -------

Naturally, you want to get your 161 OA “on the air” as soon as you can. This chapter

will help you accomplish this. Let’s get started!

1. Connect the Data Pods and the Clock Pod cables under the keyboard as

described in Chapter I.

CAUTION

‘Your 1610A can be damaged if you operate it from a voltage

source different than that for which the internal Voltage

Selector switches are set. These switches are set at the factory

for operation on

different, have qualified service personnel change the Voltage

Selector switches to agree. Probe input limit

2. Plug the 1610A into the primary power source and set the front-rail LINE

switch (see keyboard fold-out) to the ON position. The power indicator light will

come on if power is present and an audible signal will indicate that the 1610A is in

a power-up condition. If you wish to do a Performance Verification procedure, see

Chapter V.

3.

In a few seconds, a display will appear on the CRT and you are ready to start

operation.

110-120 Vat.

If your primary power source is

515

V peak.

13

Page 17

-----mm

1.

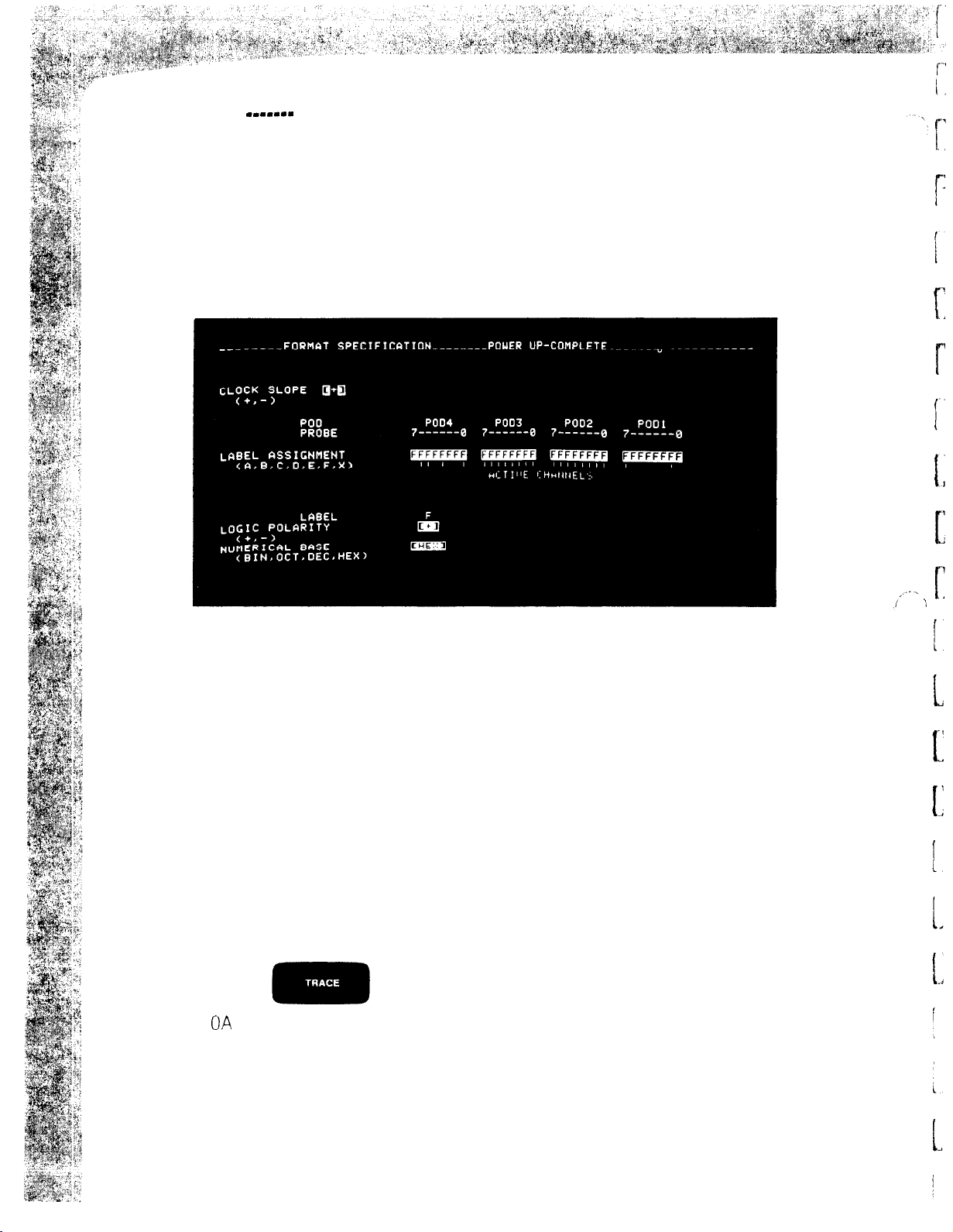

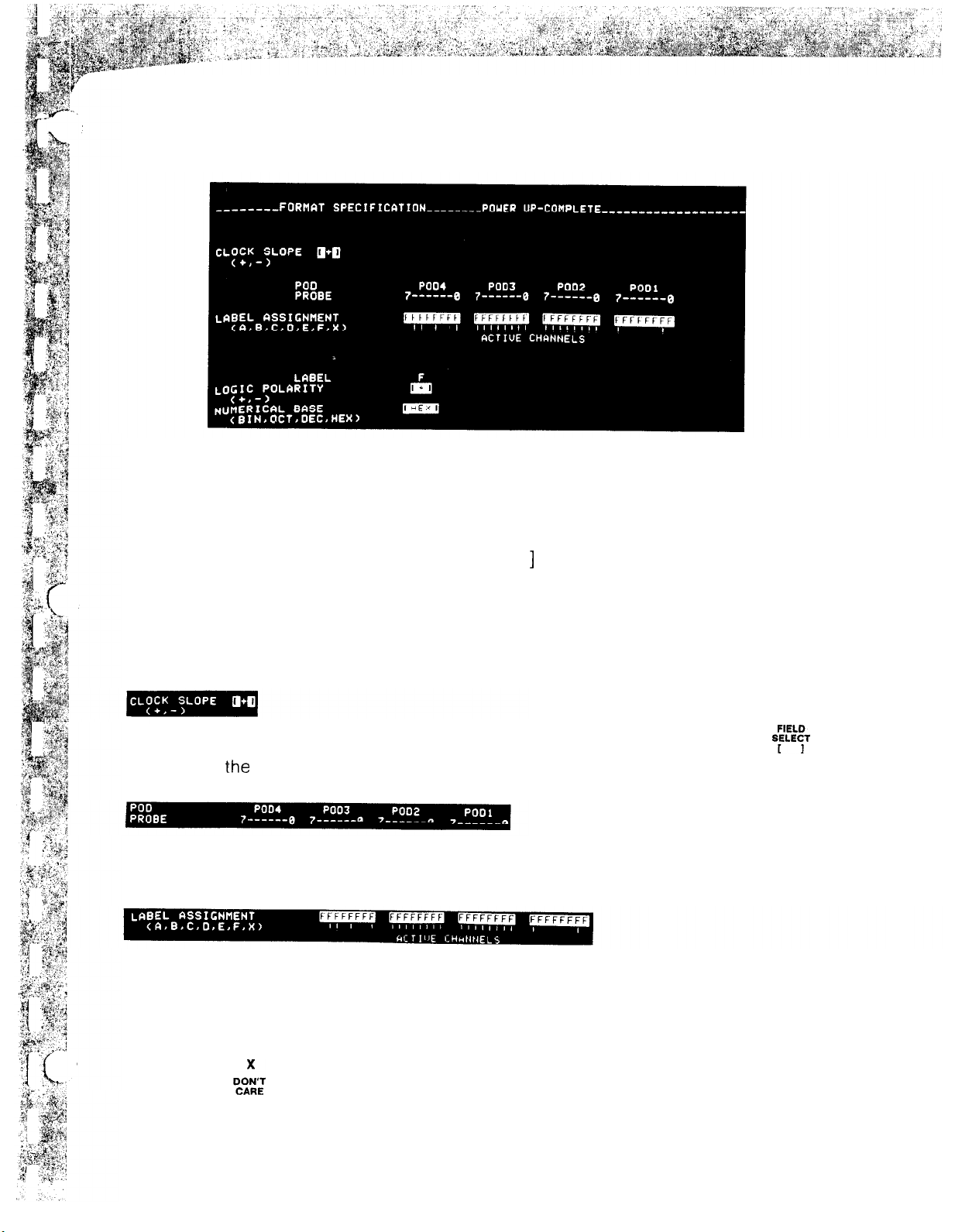

The display immediately seen on power-up is shown below. The first line shows

A QUICK RUN-THROUGH PROCEDURE -------

that this is the FORMAT SPECIFICATION menu, and the machine status shows that

the last operation initiated, Power-up, is complete.

2.

Line two shows a WARNING signal alerting you to a SLOW CLOCK condition.

This message is a good indicator during operation that a clock probe has come loose,

or that the system under test is malfunctioning. See Chapter III for a detailed discussion of the FORMAT SPECIFICATION menu.

3.

Connect probe pod 1 and the clock probe pod to their respective sockets in

the PERFORMANCE VERIFICATION section on the rear panel. These ports provide a

continuous 8-bit count at a 10 MHz rate. Notice that when this is done, the SLOW

CLOCK message disappears.

4. Press the

the 161

CIA

automatically goes to the TRACE LIST menu, and the machine status

key in the EXECUTE section of the keyboard. Notice that

reminds you that the last operation you initiated was TRACE, and the operation is

COMPLETE:.

14

Page 18

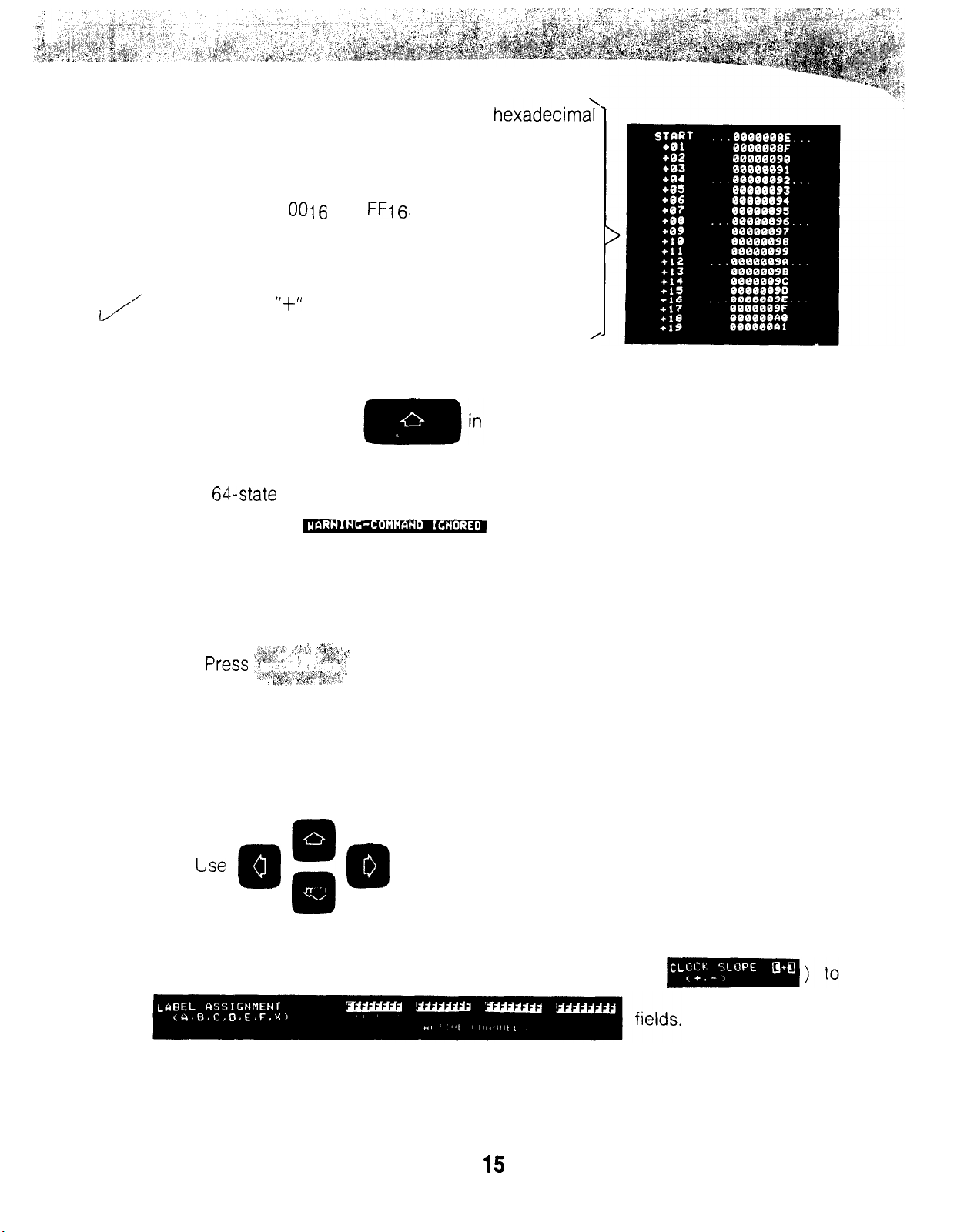

5.

The resulting trace consists of eight hexadecima?

digits representing 32 bits of data. Six of the digits are

constant (data pods not connected) and two bits are

counting from

0016

to

FFt6.

Trace starting point

is also indicated. Each successive line of memory is

numbered with a positive decimal integer for ease of

/

i

reading. The

lows the trace state in positive time.

‘I+”

sign indicates that the state fol-

/

6. Press and hold CURRENT MEASUREMENT DISPLAY

section of the keyboard. The display moves up enabling you to view any part

of the

will sound, and a

64state

memory. When the end of memory is reached, an audible signal

p

message alerts you that an operating limit

has been reached; the display will roll no further. Release the ROLL DISPLAY key and

the message will disappear.

,)< s

7

press yy,s.;,. 1” i ;:.s”?%T

.&&‘i~~ ?$+i’. ,*,r&~~: c

,;q &p ~,p;Amrr&

_ **<“‘* ~& ~~i7L’.’

““u, “<

’ in CURRENT MEASUREMENT DISPLAY section of the

-8 i,

”

keyboard. The format specification menu reappears and allows you to define state

parameters for a more useful display. See Chapter III for detailed discussion of

FORMAT SPECIFICATION menu.

8

use

Q

i

Q

(CURSOR) keys in

the EDIT section of the

(1,

keyboard to move the blinking cursor (now located at

15

Page 19

9 Use the

X

key in ENTRY section of the keyboard to enter “X” in all bit

DcobFJR;T

posrtions

to be entered continuously in each field.

10. Move the cursor to the selectable

Press

1 1. Press key. The TRACE SPECIFICATION menu allows you to

control trace and count measurements. See Chapter III for a detailed discussion of

this menu.

12. The cursor is in

in Pod 2, Pod 3, and Pod 4 columns. Holding the key down causes the “X”

field.

$&!&

II

repeatedly until the field contains

LT.

Press

m

number base.

SF

repeatedly until field reads

i

I-

I

t

13. Move cursor to open field in label F column and enter 0008. Now you

have specified that state

14. Press key in the EDIT section of the keyboard. Another line is now

available for further definition of trace position. Enter

the

16iOA: “Fiecognlze

is requested. When state

second occurrence is centered.” But that’s not all.

0008

state

0008

is to be centered in the trace.

0008

in the added open field

With these few keystrokes, you have told

0008

the first time it appears after trace

is recognized again, initiate a trace in which this

16

execution

Page 20

15. Move the cursor to

them

c OFF jselectable

field and

press FlELD

YLE7

until the field reads

the trace is initiated, the 1610A is to count elapsed time

8-bit count cycle from 0008 to

16. Press the

menu display (see Chapter III for a detailed description) now

shows the second occurrence of 0008 centered in the

trace. Data leading up to this state are designated by

negative line numbers,

have positive numbers (negative and positive time,

tively).

17. Press ROLL DISPLAY

mc

T~lIE I(

Now you have further specified that when

0008.

key. The TRACE

and data following this state

until beginning

LIST

respec-

_I

I

/

of the trace is displayed. The display shows the first

occurrence of 0008 as SEQUENCE. The TIME (in decimal

ABSolute

times are measured from the trace state, it is clear that

the elapsed time from first recognition to second

is 25.6

’ I

time) reads -25.6 microseconds. Since absolute

rc(s.

!

Page 21

‘,

,.

‘:

,,

.:

:, .%l,‘:r.

18. Press

in CURRENT MEASUREMENT DISPLAY section of the keyboard.

The resulting display shows all 64 states in memory. The first state in the trace is at

the extreme left and the last state (state 64) is at the extreme right. Vertical position

is determined by state value with respect to the UPPER LIMIT and LOWER LIMIT

values. Inl:ensified dots indicate the portion of the current valid data displayed when

‘_

!

,$p

shift to the right

you a good idea of operating methods, You begin to recognize the inter-relationships

key is pressed. Press ROLL DISPLAY

and observe intensified dots

N

-s-w--s

NOW

WHA

T?

s-----w

This procedure does not demonstrate all the features of your 161 OA, but it gives

between the keybaord and the displays, or between one display and another. Maybe

this all

Yost

need to start making meaningful measurements in your system. But if you

need more detailed information, Chapter III will give it to you.

18

Page 22

Chapter

III

DETAILED MENU DESCRIPTIONS

-w----w

/NTRODUCT/()N

----m-m

This chapter is intended to help you in two ways:

A quick reminder of the purpose

and content of each menu;

and

A detailed description of each

menu to help solve complex

measurement problems.

To do this, each menu is given a separate fold-out page. A summary of menu capabil-

ities appears first before the page is unfolded. You can glance through these sum-

maries until you find the menu with the capability you need.

When you have located the menu that seems to have what you need, unfold the

page for detailed study. Many illustrations are included to help relate the descriptions

to what you see on the display.

19/(20

blank)

Page 23

Page 24

FORMAT SPECIFICATION

MENU

l

Permits selection of desired Clock Slope.

l

Permits assignment of any of six labels to groups of input lines regardless

of Pod boundaries Unused channels may be turned off.

l

Indicates presence or absence of activity on each input channel.

l

Permits selection of logic polarity to be used in each label group.

l

Permits selection of numerical base to be used in each label group.

Page 25

THE FORMAT SPECIFICATION MENU

Headings aligned with the left margin separate the display into sections indicating

the signal parameters controlled by each section; for example, “CLOCK SLOPE”.

]

Any inverse field containing brackets ( [

select from variable field contents.

) indicates that the operator may

Parentheses enclose field content choices available to the operator.

When the blinking cursor is in this field (or any variable field), pressing

changes

Column headings are a fixed part of the display and permit quick identification of

each channel in the label assignment groups.

Entry fields in each pod column allow entry of label designations.

Parentheses enclose labels available for selection by the operator.

Label “X” %iiz

i:he

field variable

turns off channels to which it is assigned.

S/T

One label may be assigned to any number of continuous adjacent channels regard-

Page 26

Labels assigned to non-continuous channels are not allowed.

These are called SPLIT LABELS; e.g.,

In case of a split label,

1-m

appears on line 2 of the display, and an

audible signal alerts the operator. The cursor is locked into the label assignment

field until the split label condition is corrected. No EXECUTE command can be

initiated while a split label condition exists.

The symbol

‘I!”

indicates channel activity at probe line

sampled at a :I ms rate, and each bit that has changed states in

marked with

“I”.

inputs. Inputs are

100 samples will be

Each label assigned in the Label Assignment fields will automatically be entered

in this section.

Logic

polarity

and numerical base may be defined appropriately for each label

i.

group independent of Pod boundaries.

Logic Polarity and Numerical Base field content may be selected from choices shown

in parentheses under each field name.

Field content is changed by positioning the cursor in the desired field and then pressing

the

SE

key.

All FORMAT SPECIFICATION label group parameters are automatically entered in

other menus. The FORMAT SPECIFICATION may be recalled and edited at any time

by pressing

thle

key.

Page 27

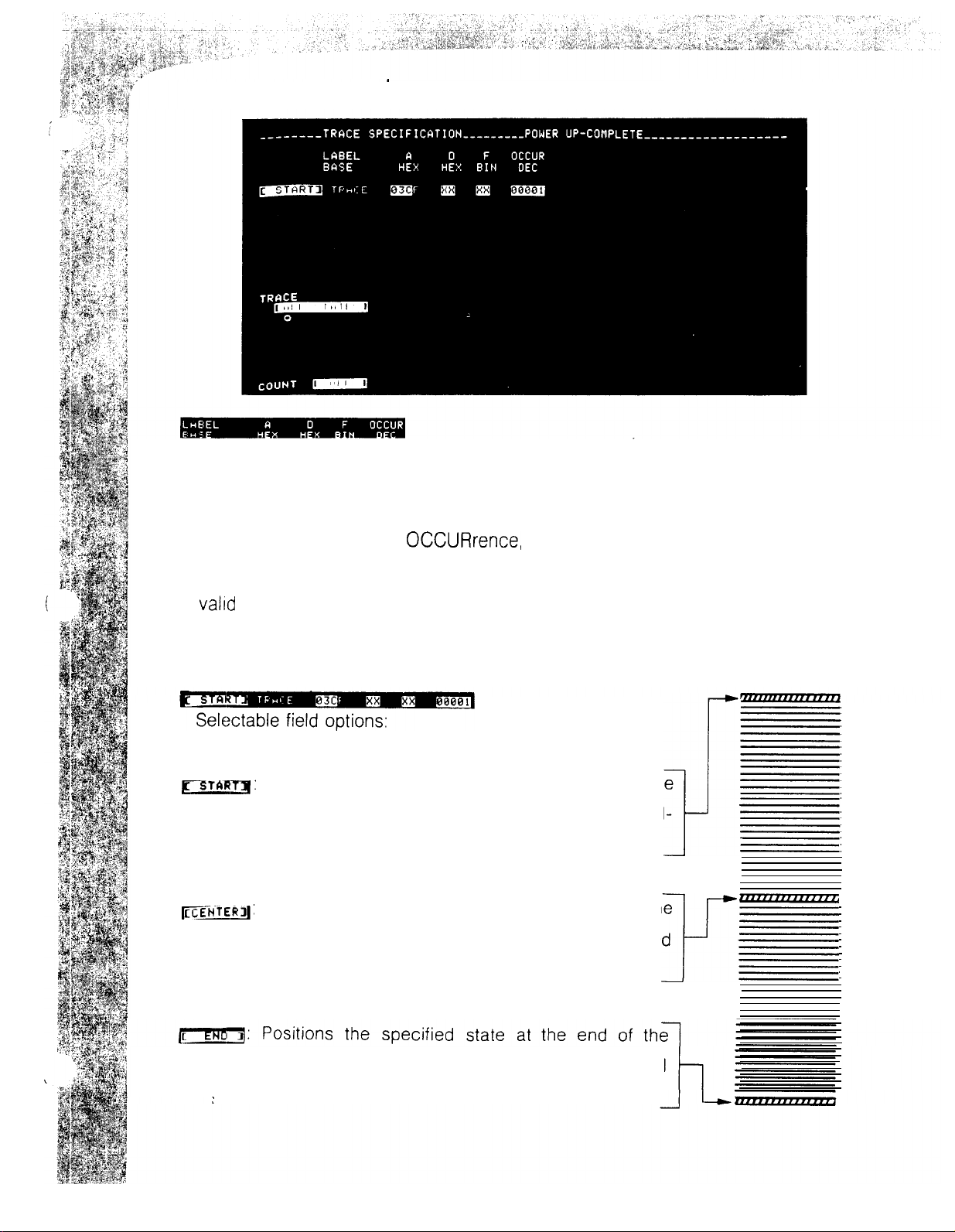

TRACE SPECIFICATION

MENU

0

IPositions

a selected state at the [START], [CENTER], or [END] of the trace

measurement.

l

ESstablishes

a state sequence condition which must be satisfied before the

trace measurement is made.

l Restricts the trace measurement to “ONLY STATES” which satisfy the

given state conditions.

l

!Specifies

a count of the occurrences of a given state; or time interval mea-

surement of each state acquired in the data trace.

Page 28

TRACE SPECIFICATION MENU

Each label and its numerical base defined in the FORMAT menu is automatically

entered in the TRACE SPECIFICATION menu.

An additional open field,

notation, the number of times a state must be recognized before it is entered as

valrd

data in memory. NOTE: a 0 in the “units” position is not allowed.

POSITIONING A GIVEN STATE IN THE DATA TRACE

FT~R~:

CENTERED:

Positions the specified state at the start of the

memory; display shows the specified state and 19 following states.

Positions the specified state at the center of the

memory; display shows 9 preceding states, specified

state, and 10 following states.

OCCURrence,

allows the operator to specify, in decimal

IJ-

T--

memory; display shows 19 preceding states and specified

state.

Page 29

Open fields permit entry of alphanumeric information that defines the desired state.

If information is entered in two or more label fields, both states must be recognized

simultaneously to initiate a trace.

Any assigned label may be used to define the trace state.

POSITIONING DATA TRACE IN PROGRAM FLOW

With the cursor located in the [

ditional lines to establish a state sequence of up to seven members.

Each member of a state sequence must be recognized in order (after occurring the

number of times specified in OCCUR field) before it is acquired into memory.

When all members of the state sequence have been recognized in order, the trace

state positions the specified state condition in memory when the trace measurement

is executed.

]

TRACE field, the

(ji,,:,-’

key will insert

_L “-

ad-

When

before the state sequence is satisfied, will restart the entire sequence search. Chapter

IV gives examples of uses.

This section of the display allows the operator to define which state(s) will be traced

into memory after the state sequence is satisfied.

SEC RESE!T

field is ON, you may specify a state which, when recognized

WHAT TO TRACE

Page 30

m

Thts

condition of the selectable field indicates that the 1610A is to trace all states

which occur after completing state sequence conditions.

key has been used to add lines. Desired states can be entered and they instruct

the 161 OA to gather only these states into memory. Additional lines may be entered

using

surement.

Entering a decimal value in the OCCUR column instructs the 161 OA to count

occurrences of each state in the TRACE section simultaneously. When any state

satisfies the count specification, it is gathered into memory and the count is restarted

on all states.

--”

:,*

key so that [ONLY STATES] may be specified in the trace mea-

STATE/TIME COUNTS

With the COUNT field in this condition, the operator may instruct the 1610A to

count occurrences of a specific state in program flow and store resultant count, along

with data, during the measurement.

With the COUNT field in this condition, the 1610A counts time intervals between

states. More information about state and time counts appears in the TRACE LIST

MENU.

mc

With the COUNT field in this condition, internal counters are not displayed.

liFr1(

Page 31

The following illustration specifies the starting addresses of three separate program

blocks which must be recognized sequentially to arrive at the block of program to be

investigated. As the program block of interest is entered at the trace state address,

a trace is initiated. The next 60 states are gathered into memory with the trace state

at the start.

Since each program block may contain many hundreds of program steps, this technique permits the operator to ignore thousands of program steps which are not pertinent to the desired measurement. You have, in effect, an apparent memory depth

which is, for all intents and purposes, limitless.

i

ll-Y--1

--i+

II r

STATE

SEOUENCE

I

I

TRACE

STATE

I

I

WHAT

TO

TRACE

II

Page 32

TRACE LIST

MENU

l Lists in memory all data in program flow and displays data according to

FORMAT and TRACE specifications.

l

Displays count of selected states.

l Displays time interval

Page 33

TRACE LIST MENU

All labels and their respective number bases defined in the FORMAT specification

are automatically entered in the TRACE LIST menu when

Data displayed in each label column shows (in this case)

address,

traced into memory, For example, at line i- 04, address 2899 shows data 96 and

control line condition low.

The dotted lines in the display appear after each four lines for convenience in

data, and control or qualifier line information for each successive state

,,;I

is pressed.

reading the display.

Page 34

DISPLAY WITH STATE COUNT OR TIME COUNT

[REL]:

Shows count value

to previous valid state; i.e.,

five

state counts between

line one and line two. Count

values always expressed in

decimal notation.

[ REL]:

Time interval values shown

are relative to previous time

interval value; i.e., 10

RELative

fls

[ABS]:

Shows absolute count value

with respect to trace state.

Count prefixed with

I,

-”

to show after trace state

or before trace state respectively; i.e.,

counts after trace state.

:ABS]:

Time interval values are shown

with respect to trace state in

terms of

“+18”

‘I-”

(before) or

“+I’

or

means 18

“f”

between first time interval

and next state. Values are

expres:sed

real time.

Pressing

recall current data at any time while examining other menus, until a new trace

measurement IS (executed.

See also TRACE COMPARE MENU or TRACE GRAPH for expanded use of this

,trace

list.

in

,YS,

ms, or s in

recalls data stored in current memory. This makes it possible to

(after) trace state occurrence;

i.e., +l .O ps after the trace

state.

Page 35

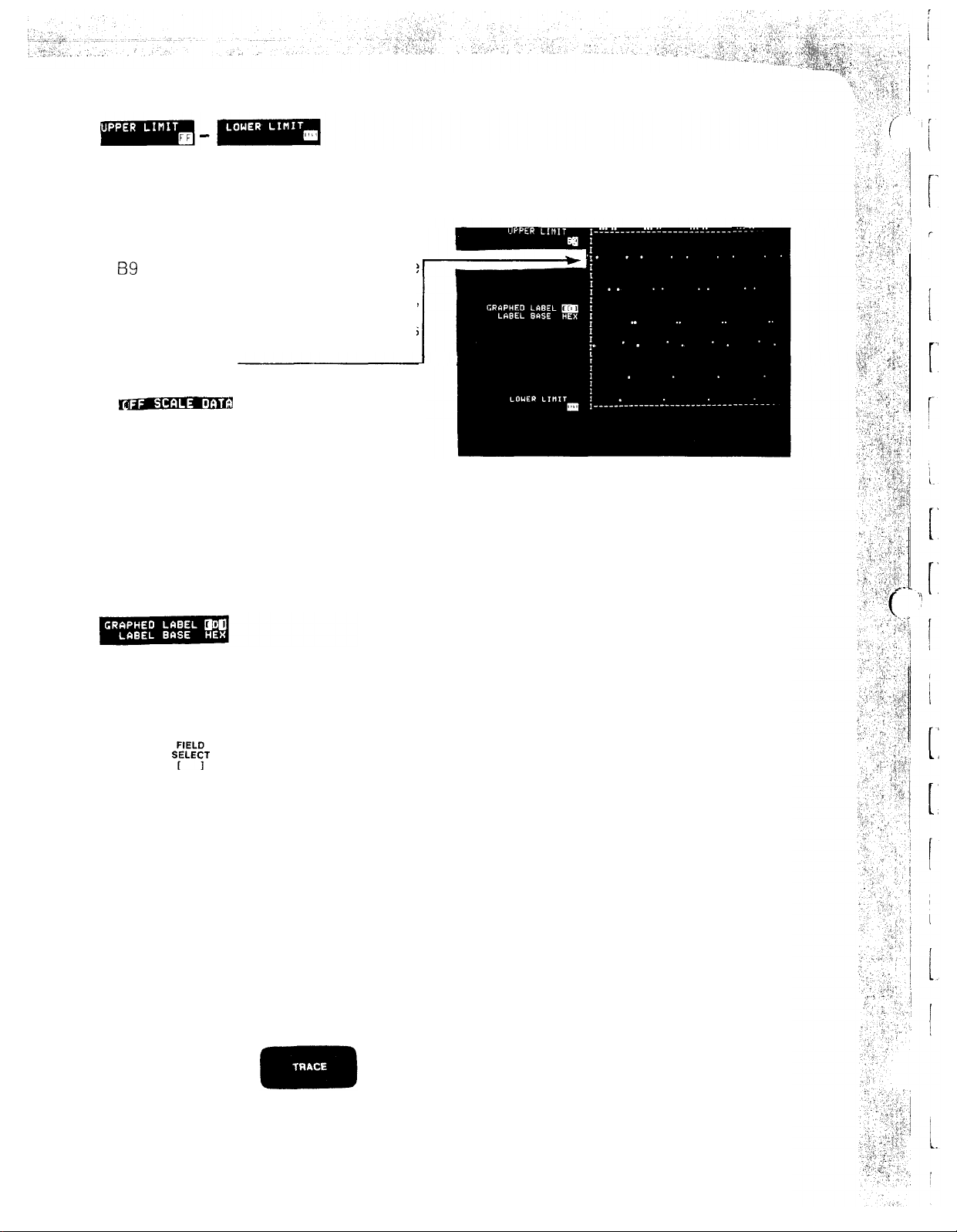

TRACEGRAPH

MENU

l Allows the operator to produce a graph of

l Any label assigned in the FORMAT

the data trace.

SPECIFICATION menu can be

graphed.

l Graph may be viewed in single or continuous TRACE.

l

Sel’ectable

upper and lower value limits for graphing.

27/(28

blank)

Page 36

GRAPH MENU

HOW THE GRAPH IS DERIVED

Each dot on the graph represents one state in the trace list.

The position of each dot is plotted on a horizontal coordinate representing the

location of the state in the trace, starting with the first state at the extreme left, and the

last state at the extreme right. The vertical coordinate represents the value of each

state with respect to the pre-selected upper and lower value limits.

Horizontal

Positioning

Dolt

r

State

#l

I

,.

*State

#64

!/I

Page 37

Vertical Dot Positioning

These open fields allow you to enter the value limits you desire within which the

states are to be graphed, e.g.:

Assuming that hexadecimal values

B9

and 00 have been assigned to the

upper and lower limit respectively,

this graph indicates that state 2 has

a value of A5.

-9

8

when one or more state values are

outside the specified value limits as in

the accompanying display.

Appearance of this message does not necessarily indicate a faulty measurement,

it is only the machine reminder to you that some data inputs are not appearing

on the graph.

This portion of the display indicates which label group is currently being graphed.

Any label assigned in the FORMAT specification may be selected for graphing,

Use the

Intensified Dots

5

message will appear

key to select the label you wish.

Intensified dots on the TRACE GRAPH represent the twenty states displayed if

you press the

as the displayed trace shifts. In this way, it is easy to use the ROLL DISPLAY keys to

locate and identify any specific dot of interest and read its actual value in TRACE

LIST.

Dynamic Graph

By pressing the

program flow on the TRACE GRAPH in a continuous TRACE mode.

key. When the trace is rolled, these intensified dots will shift

key and holding it down, you can watch dynamic

Page 38

TRACE COMPARE

MENU

l Permits “EXCLUSIVE

0R”ing

of current measurement data with a stored

standard.

l

Permiits

continuous compare of current measurement data with a known

standard with “Stop if Equal” capability.

l Permit continuous compare of current measurement data with a known

standard with “Stop if Not Equal” capability.

l Permits “Exchange” of current measurement data with stored data for visual

inspection or comparison.

Page 39

A separate rnemory in the 161 OA is provided for storing a known-standard data

trace. This standard may be derived from the trace list by pressing the

key in the EXECUTE portion of the keyboard. This key causes current measurement

data to be

Pressing the key in the CURRENT MEASUREMENT DISPLAY section of

the keyboard places the 161 OA in TRACE COMPARE mode and allows the operator

a choice of three types of comparison.

With the selectable field in this condition, pressing causes an

“EXCLUSI\/E

All states In current measurement data which are the same as corresponding states

in the stored trace are displayed as all zero’s Non-zero states differ from their

correspondrng

stlored

in the “compare” memory,

OR” comparison of current measurement data with the stored trace.

states as shown in the display.

Page 40

In

this

condition, pressing

current measurement data is equal to the stored trace. While the measurement is

in process, the instrument status message will flash “IN PROCESS” and “FAILED”

until the specification is met. At that time, an audible signal is sounded, and the

instrument stops showing a status message that reads “COMPLETE”.

is pressed, it initiates an action similar to the preceding except

that inequality between current measurement data and stored valid data is being

sought. When an inequality occurs, the instrument stops and displays a trace show-

ing where the inequality is located.

initiates a trace that continues until

NOTE

When a compared trace is in process, the blinking cursor

disappears from the selectable field; this field cannot be

changed until the search is completed or stopped.

NOTE

The selectable field must be returned to the “OFF” condi-

tion to obtain single or continuous trace operation.

This key enables the operator to exchange current valid data with a display of

stored data. Neither memory is lost unless a new trace is initiated, at which time

current measurement data in the memory is replaced.

Page 41

Chapter IV

------- POSITIONING THE TRACE WINDOW IN DATA FLOW -------

,’

Introduction

Most data programs are written in blocks, some containing loops, some containing

branches, and some containing jumps so that there is no real “continuity” of program

steps; each one may cover thousands of program steps. It can be an extremely

time-

consuming process to look backward in program flow to find a point of error.

The unique triggering capabilities of the

1610A

make it possible to open a trace

“window” on a specific location in program with pinpoint accuracy.

In the examples that follow, you will see how these triggering capabilities can be

*

,”

:

’

.,

1*

f:

used to eliminate the need for examining hundreds of program steps which do not

bear on the problem you are trying to solve.

$9

! ’

31

Page 42

EXAMPLE 1: SIMPLE SINGLE-STATE TRACE

Trace Specification

EXAMPLE 2: SINGLE-STATE TRACE WITH DELAY

States in

Display

03CF

and

next

states

Data

Flow

-?

1,

P

r

States in

Trace Specification

This technique locates the trace window in a desired block of program and con-

centrates on only that portion of the block of current interest.

Display

03CF

03E4

and

next

62

-- --

Data

Flow

--

m

-

i

32

Page 43

EXAMPLE 3: TRACING SPECIFIC DATA PATH IN A BRANCHING PROGRAM

Frequently, activity in a given program location depends on which one of several

program branches was followed to arrive at that location.

I

I

c

-.

8378

PATH

A

-l

I

, PATH

I

B

,j

/’

/’

/’

In the example given here, program address

is reached by Path A

(0378403E4).

from

03E4

is traced only when Path A is followed,

To ensure that program activity

(03CF-+03E4)

or Path B

03E4

a state recognition sequence must be set up in the

Trace Specification.

By specifying that the 161 OA must first recognize

state

lected at

03CF,

you are certain that when data is col-

03E4

Path A has been followed. If the

program flow branches through 0378, the Trace

Specification cannot be satisfied, and no data will

be gathered into memory.

33

Page 44

EXAMPLE 4: TRACING A

SPECIFIC PATH IN A MULTIPLE-BRANCH PROGRAM

More

sequential program flow

capability.

It is possible to trace program activity starting at address 286F after the

grarn has followed Path #2 by setting a Trace Specification like this:

clomplex

levels of

network branching are commonly encountered. Analyzing

in this example requires high-level sequential trigger

pro-

34

Page 45

EXAMPLE 5: MULTIPLE-BRANCH PATH COMPLETED IN A SINGLE PASS

Often tt is necessary not only to follow a specific path, but also to analyze program

flow only if the path was completed in one pass. To

use the

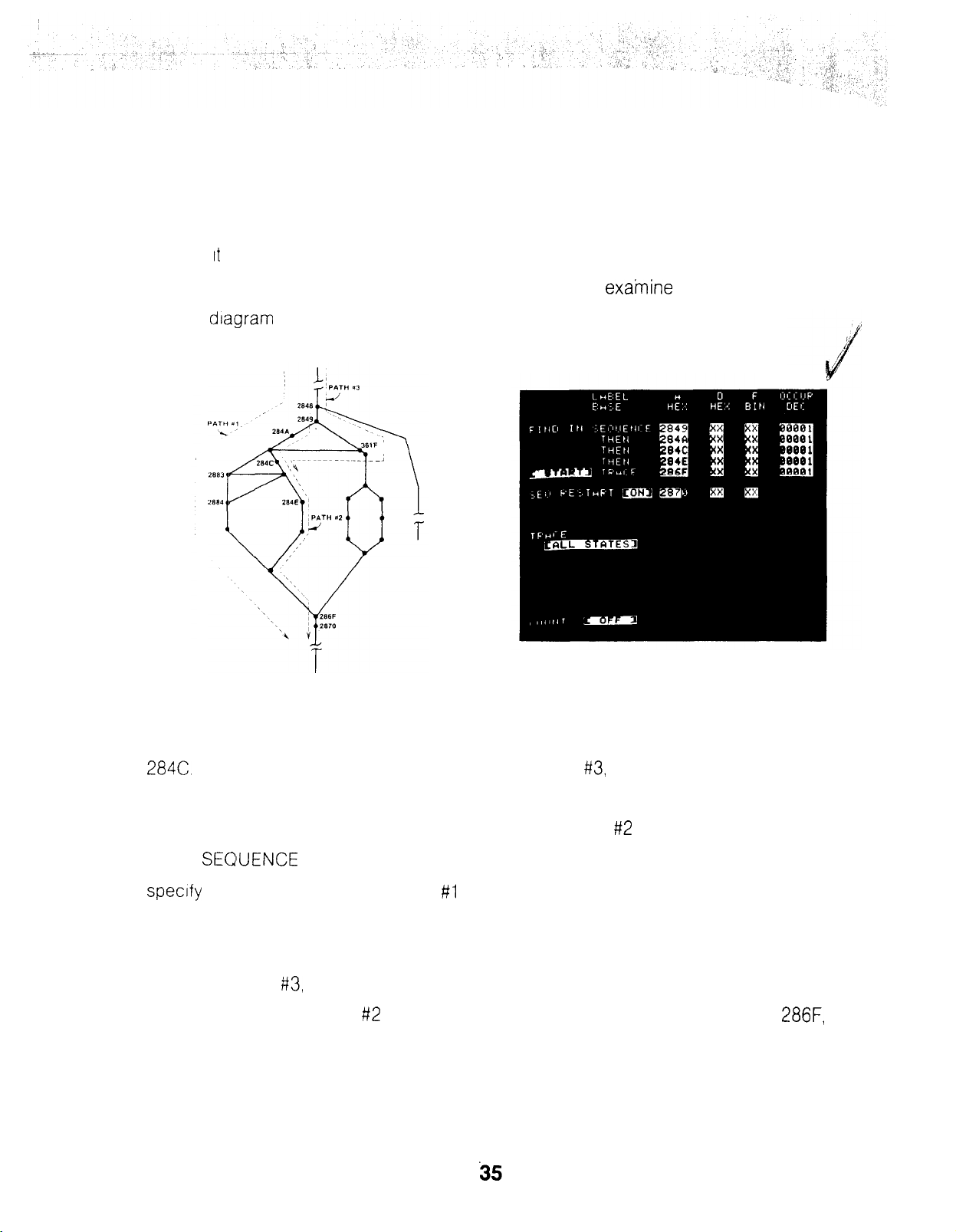

diagram

and Trace Specification of Example 5.

exa’mine

this task, we can

Specified this way, the program can satisfy sequence states 2849 and 284A and

then exit the network at 286F leaving the 161 OA looking for the next occurrence of

2846.

The program can reenter the network via Path

#3,

satisfy the remaining con-

ditions vra 361 F, and the 1610A will capture data beginning at 286F. However,

the captured data will be erroneous with regard to a Path #2 branch.

Set

specify

SECUENCE

state 2870. Now, when Path #l is followed 2849 and 284A are satisfied, but

RESTART in the Trace Specification to the ON condition and

if the network is exited at 2870, the sequence search is restarted because a restart

state was recognized before all sequence states were satisfied. If the network is

entered by Path

Only by following Path #2 is it possible to acquire data at exit address

#3,

the sequence search is restarted again for the same reason.

286F,

because only this path satisfies all sequence conditions before the restart state is

recognized.

Page 46

EXAMPLE 6: TRACING A DIRECT JUMP IN A MULTIPLE-BRANCH PROGRAM

,-

PATH I

a1

i

j PATH

a3

Three common forms of program paths appear in this program flow diagram:

Path #l is a path whose length depends on the operation being performed on a

given pass;

Path #3 is a fixed-length path because the same operation is performed each time

this path is used;

Path #2 is a zero-length, or direct jump, path.

Defining a trace on Path #l or #3 is easy using the sequential state trace specifi-

cation

However the zero-length Path #2 is not reliably defined

this way because either of the other two paths satisfy the specification.

The solution is to use the SEQUENCE RESTART function to specify the desired path:

When state 2849 is recognized, the 1610A will examine the restart condition. If

I

either Path #l or Path #3 is followed, a state after 2849, other than

287C,

is found,

the restart condition (XXXX) is satisfied, and the sequence search is restarted.

A trace is captured only when 2849 is recognized immediately followed by 2876.

36

Page 47

EXAMPLE 7: TRACING PROGRAM FLOW IN NESTED LOOPS

The 1610A is capable of examining program activity when it is working in the

Nth pass of a sub-minor loop. The three-level loop in this diagram has a major loop

that iterates 17 times, a minor loop (J) that iterates 11 times for each occurrence of

the I loop, and a sub-minor loop (K) that iterates 13 times for each occurrence of

the J loop and 143 times for each occurrence of the I loop.

f-3

28AE ---

(I)

Using the trace specification shown above you can direct the 1610A to acquire

data at state 2841 only when the program is in the 9th pass of the I loop, the 8th

pass of the J loop, and the 7th pass of the K loop.

Notice that 2887 is to be recognized first. This ensures that when you start the

measurement, the

1610A

does not start in the middle of the loop and cause an

erroneous count.

37

Page 48

r

This capability is also helpful while developing a program. Once the program is

i

written, it

is,

run to verify completion of the desired task. Sometimes the task is

eventually completed with non-desired tasks completed in addition. An example is

this nested loop. To verify that the program actually completed only the specified

number of loops, count the number of occurrences of state 2840 and compare with

what was programmed to happen:

2940

2941 K

----_--

28A5

J LOOP (11)

---------

28AE

2007

P

Loop

(13)

I LOOP (17)

TRACE 7th PASS OF K

TRACE 9th PASS OF J

TRACE 9th PASS OF I

J x

-!9x11x13=1287

8x13= 104

7=

7

X=1398

An ABSOLUTE state count will show that 1398 occurrences of state 2840 were actually

counted, and that this section of program is performing as desired.

i

38

Page 49

Chapter V

PERFORMANCE VERIFICATION

s-m---- /NTRODUCT/ON

Intricate and complex measurements made on the system you are investigating

require that you have complete confidence in the performance accuracy of your 161 OA.

To inspire this confidence, a performance verification program is built into each

161 OA. You may call up this program at any time, and by following the simple instructions

in each test display, assure yourself of accurate measurement performance by your

161 OA.

You have complete control over the flow of the tests and proceed from one test

to the next only when you are satisfied that the current test is satisfactorily

completed.

If

your 161 OA is interfaced to an HP 9866A Printer, a print-out result of each test

(except GRAPH) can be made.

-------

-‘------ INITIATlON

With 161 OA power OFF, connect the clock pod and any one data pod, say POD

to

Its

respective socket in the PERFORMANCE

panel.

OF PERFORMANCE VERIFICATION -------

VERFICATION

section of the rear

39

1,

Page 50

Turn on 161 OA power and press the START pushbutton on the rear panel. Internal

ROM and RAM tests are performed and verified then the next test is displayed. Each

test display is described on the following pages.

DISPLAY TEST

40

Page 51

Display Interpretation

As with all displays, line one shows the name of the display, and the instrument

status with respect to that test.

Beginfling

initiate each action. The

select the next test.

You can verify that various brightness levels are used and provide necessary con-

trast in the display.

Each character in the 161 OA repertoire is printed for verification that none are

missing

The blinking cursor appears in the lower right hand corner to ensure you that it

is operating properly.

Press

on line 3, you are given a choice of actions and the keys to press to

key will re-run the test. The

,,;I

SE

and go on to the next test when you are satisfied.

p+

key will

KEYBOARD TESTKEYBOARD TEST

This test determines whether keys decode properly when manipulated.

The operator is required to press each key on the keyboard in no particular sequence

except that

SF!

must be the last key pressed to validate the test.

41

Page 52

!

”

,#,,I

.,

_.

‘.

,.

i

‘,

LAST CODE indicates which key was pressed last by displaying the code for that

key. On the fold-out keyboard photograph, key codes for this test are shown in

parentheses near the key to which they apply.

MISSING CODE indicates keys that must still be pressed to obtain a complete test,

This

test cannot be regenerated by pressing

TRACE TEST

i

I‘

i.

Unplug the CLOCK and DATA pods from the rear panel.

In the first line, notice the legend: ---POD-4321 C-T--. This legend indicates that no

pods are connected to the rear panel, and the COUNT

Plug in CLOCK pod and press

that the

(CLOCK

pod is connected and also that the

m

The

1

TME

function is inoperative.

C-T-

-

will disappear to indicate

COUNT TIME function is

operating.

Piug in the DATA pod and press

then

m

The respective

pod number will disappear from the legend to indicate that this pod is connected and

operating

Repeat ‘with each data pod to verify correct operation.

Because only one date probe can be connected at a time, and each time the

button is pressed, the test verification on line 1 will show FAILED.

m

However, the procedure described above is verification of the proper operation of

i.

1,

each probe.

42

Page 53

INTERRUPT TEST

This test enables the internal Interrupt Request

that an interrupt is being received and processed by the internal microprocessor,

Pressing

Press

e

,,:d

to advance to the next test.

will cause this test to be run continuously.

halts the continuous run and readies the instrument for the

PRINTER TEST

(IRQ)

line and the test verifies

This is the final test in the PERFORMANCE VERIFICATION routine and is valid

only if your 161 OA is interfaced with an HP Model 9866A Printer.

Each time this test is initiated and completed, the printer will print the line of

characters shown at the bottom of the display.

Comloarison

accuracy of the PRINT operation.

Upon completion of this test, pressing

and returns control to the operating system via the power-up routine.

of the printed line with the character line on the display will verify

s

terminates performance verification

43/(44

blank)

Page 54

Appendix A

GLOSSARY

ABSOLUTE (STATE-TIME):

A state count or time interval measurement in which each entry is in terms with

respect to the trace state.

CLOCK

SILOPE:

I’+”

indicates that data acquisition is initiated on the positive-going portion of the

clock pulse ( 1

!,

-”

indicates that data acquisition is initiated on the negative-going portion of

the clock pulse ( 1

).

).

CONTINUOUS TRACE:

A condition under which a measurement is traced continuously in accordance

with specified limits. Memory is continuously filled with new data.

FIELD (OPEN):

An entry field in a menu whose content is made up of alphanumeric characters

from the ENTRY section of the keyboard.

FIELD (SELECTABLE):

A menu field containing brackets ([

variables. Operator selection of field content is by use of

portron

of

,the

keyboard.

1)

whose content is limited by preset

SF&

key in the ENTRY

1

LABEL:

An arbitrary character (A, B, C, D, E, or F) assigned to a group of adjacent input

lines, regardless of pod boundaries, for ease of identification and display interpretation.

LOGIC POLARITY:

In positive logic polarity

logic

polarity,,an

input high = 0, an input low =

(+),

an input high level = 1, an input low = 0. In negative

1.

MEMORY:

Consists of 64 states gathered at the input lines in accordance with the

operator-

specified parameters and conditions.

A-l

Page 55

GLOSSARY (Cont’d)

MENU:

A display on the CRT in which the operator has many choices among input signal

paramleters,

TRACE:

[RELIATIVE:

A state count or time interval measurement in which each entry is relative to the

state definition, etc. May also be a simple trace display such as

LIST.

(COUNT-TIME):

preceding valid entry.

STATE:

The logic condition at all valid probe inputs at a given clock transition.

STATE SEQUENCE:

A defined series of states which must be recognized in a given order before

becoming valid memory transactions. A valid data trace can be enabled only after

the state sequence is satisfied.

TRACE:

The

6,4

valid states gathered into memory under the constraints defined in the

trace specifications. These states may or may not be consecutive depending upon

selected specifications.

TRACE STATE:

The defined state which is positioned in the trace; i.e., the trace which is at the

[START], [CENTER], or [END] of the trace.

TRACE WINDOW:

The twenty valid states in memory that are viewed on the CRT.

CURRENT MEASUREMENT DATA:

When :a measurement trace is executed, 64 valid states are gathered into inter-

nal memory and constitute current measurement data. This valid current data will re-

main in memory, and can be recalled with the

‘, I..*

key, until the next measurement

trace is executed, or until it is exchanged into an internal store memroy.

A-2

i

Page 56

Appendix B

MESSAGES

ERROR MESSAGES

-------

INVALID ENTRY:

Check for incorrect number base; unallowed entry at this cursor position.

OVERLAPPING LIMITS:

Check TRACE GRAPH upper and lower limits.

UNASSIGNED LABLE:

Refer to FORMAT SPECIFICATION for correct

USE FIELD SELECT KEY:

Alphanumeric keys do not change a multiple-choice field.

(Machine

------- (Alerts operator that entry Is -------

Response to Unacceptable Entry) -------

lable.

WARNING MESSAGES

Incorrect In present form)

COMMAND IGNORED:

Command has reached an execution limit; command does not apply.

GRAPH NOT PRINTABLE:

TRACE GRAPH not reproducible on HP

SLOW CLOCK:

System clock is not operating, or is operating at less than approximately 10 Hz.

The 161 OA still runs and measurements are valid but may be very slow. This

message simply alerts the operator.

9866A/B

Line Printer.

B-1

Page 57

SPLIT LABEL:

Appendix B (Cont’d)

Assilgned

AAABBAA.

until corrected.

Message also appears while changing labels, but disappears when label assign-

ment conditions are satisfied.

UNALLOWED VALUE:

Magnitude of specified value exceeds size of octal or hex label field assignment;

or OCCUR value of zero not allowed; or a decimal field has mixture of digits and

X’s. Cursor locked to field until corrected.

8-LINE TRACE SPECIFICATION LIMIT:

Lines added to state sequence and states-to-be-traced must not exceed a

combined total of eight.

label must have continuous bit assignment, e.g., AAAABBBB not

Split label condition locks cursor in LABEL ASSIGNMENT

------- 0

THE!?

MESSAGES -------

field

$

MEANS X’S NOT DISPLAYABLE IN SELECTED BASE:

Digit(s) cannot be displayed in selected base; or, if a decimal field, the total

field must be all digits or all

OFF SCALE DATA:

At least one data point on the TRACE GRAPH is not within range of graph limits.

If data point is above upper graph line, its value magnitude exceeds the upper

limit. If data point is below lower graph line, its value magnitude is less than

the lower limit.

SEQUENCE RESTARTED:

Sequence restart state recognition before state sequence is satisfied causes

compllete

sequence search to be restarted.

X’s,

B-2

Page 58

CURRENT MEASUREMENT

,,_

DISPLAY

,

.,in

,.

w

ENTRY

,-

:

.,

(I)

FIELD

SELECT

1

I

D E F

fW

IE)

(F)

(4

EDIT

<

i=)

GRAPH LIMITS

DEFAULT

f-1.

EXECUTE

STORE

CVRRENTMEASUREMENT

A B C

I-)

IA) 18)

IC)

(J)

W

ROLL DISPLAY

U-J

X

DON’T

CARE

7 8 9

(7)

(0

(9)

(7) (3

CURSOR

CT)

\

Loading...

Loading...