?

aquaforce

6000, 8000, 12000 &

15000

2823

1583

1584

1585

1586

Hozelock Ltd.

Midpoint Park,

Birmingham B76 1AB. England

Tel: +44 (0) 121 313 1122

info@hozelock.com

www.hozelock.com

43386-001

1

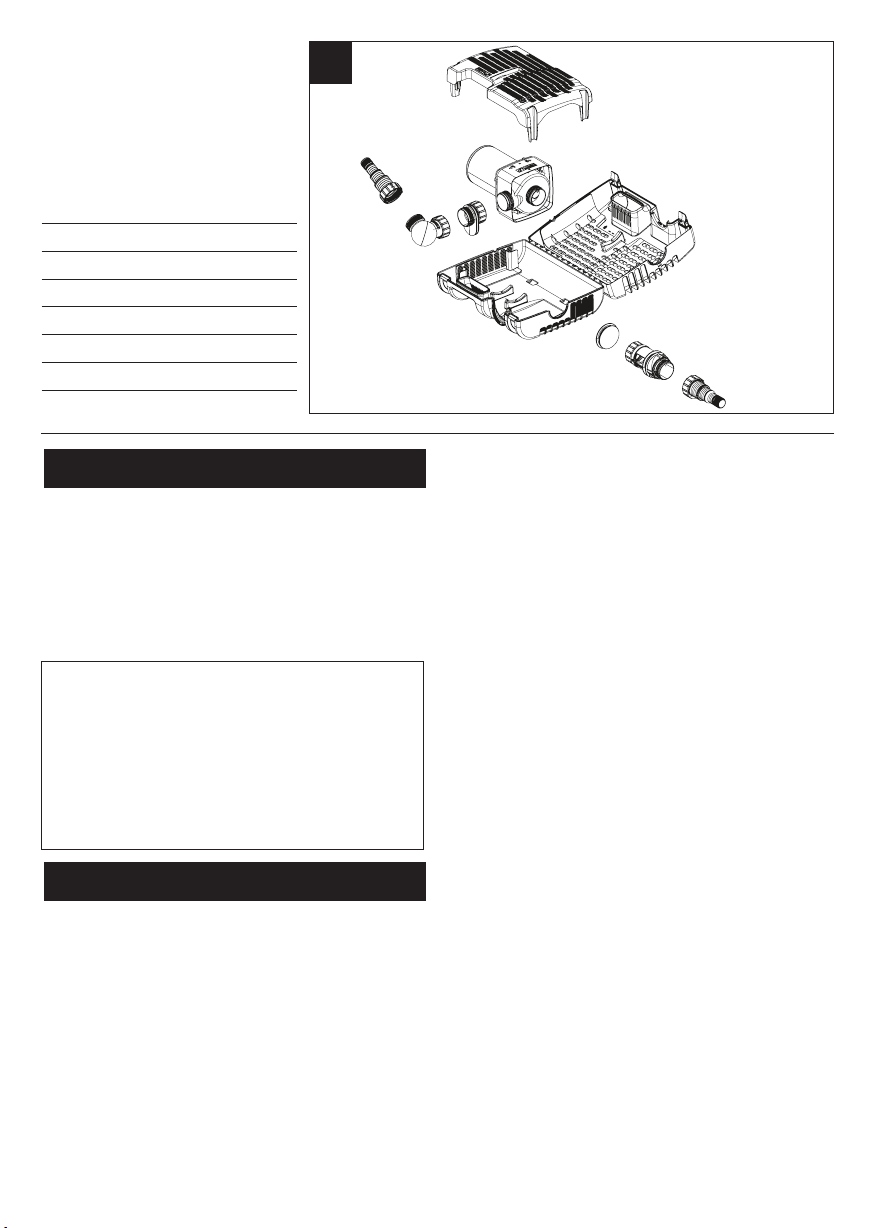

A

E

A. Wildlife Protection System

B. Pump

C. Outlet adaptor

D

D. Ball Joint

E. Hosetail & Nut

F. Strainer Cage

G. End Cap

H. Flow Control

Introduction

The pump is electrically operated and is designed to pump

solid particles up to 10mm in diameter with minimal prestrainer maintenance. These types of pumps are particularly

suitable for pumping water to external filters or for use in

high flow waterfalls or watercourse applications where low

maintenance is important. The pump does not use oil or

grease for lubrication and can be used safely in ponds

containing fish or plants. The motor consists of a sealed

stator and water-cooled rotor. All electrical components are

isolated from the water.

ATTENTION

AUTOMATIC CUT-OUT

To help ensure your pump’s long life and to prevent

damage, it is fitted with automatic thermal overload

protection. This switches off the pump if it overheats. If

this occurs, switch off the power at the mains supply to

the pump. Check for the cause. Usually it will be debris

blocking the inlets of the pump or obstructing the

impeller. Remove the obstruction and wait for the pump

to cool down. Then switch on the pump again.

General Safety Guidelines

Failure to observe the following notices may result in

injury, product damage or loss of fish.

1. This pump has been designed for the use with ponds

only. Only use this pump for the operation of pond

filter systems, water displays, waterfalls etc. Do not use

this pump for any other use (i.e. do not use this pump

in swimming pools, bathrooms, central heating systems

etc). Using the product for any other application may

result in injury or product damage.

2. This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person

responsible for their safety. Children should be

supervised to ensure that they do not play with the

B

F

C

G

EH

appliance. (Australia & NZ only) This appliance is not

intended for use by young children or infirm persons

unless they have been adequately supervised by a

responsible person to ensure that they can use the

appliance safely. Young children should be supervised

to ensure that they do not play with the appliance.

3. WARNING: Always unplug or disconnect all appliances

in the pond from the electricity supply before putting

your hands in the water whilst equipment is being

installed, repaired, maintained or handled.

4. Never use the mains supply cable to lift the pump, as

this may cause damage. We recommend fitting a lifting

cord to the handle on the strainer cage when the pump

is installed in deep water.

5. Do not operate or leave the pump in freezing

conditions.

6. Protect the pump from direct sunlight. Direct sunlight

may overheat the motor.

7. Never allow the pump to run dry.

8. Do not operate this pump without the strainer cage

properly attached. Using the pump without the strainer

cage may invalidate your guarantee.

9. ATTENTION: This product is not suitable for water

temperatures above 35ºC.

10. ATTENTION: Do not operate this product if the mains

supply cable or the motor has become damaged in any

way. The supply cable cannot be replaced as it is

permanently encased in the motor housing and should

therefore be disposed of according to local regulations.

11. If you live in a hard water area (water with high

calcium or limescale content), the pump, rotor assembly

and inside of motor should be cleaned at regular

intervals (See MAINTENANCE).

12. Only use accessories which have been designed for use

with this product. The use of any other accessories may

invalidate your guarantee.

Installing this product in the garden is classed as

'notifiable' in the revised Building Regulations for

England and Wales. The Regulations require you to tell

your local authority building control department that

you intend to install this product before installation.

Your local authority will let you know how you can get

your installation approved.

Electrical Connections

1. WARNING: Always unplug or disconnect all appliances

in the pond from the electricity supply before putting

your hands in the water whilst equipment is being

nstalled, repaired, maintained or handled.

i

2. Check that the voltage marked on the unit corresponds

o the mains supply.

t

3. The pump is supplied with 10m of 3 core electric cable

which is permanently connected and sealed to the

otor.

m

he supply cable cannot be replaced. If the cable is

T

amaged, the pump should be discarded.

d

This product is designed to be permanently wired to the

mains supply in a dry weatherproof enclosure through a

ouble-Pole Switched Fused Spur - (Disconnector) to BS

D

3676 – with a minimum contact gap of 3mm in each

pole. Fitted with a 3 or 5 Amp fuse. The installation

must conform to the National and Local wiring

regulations which could include the use of plastic or

metal conduit to protect the cable.

4. A 10mA or 30mA Residual Current Device (RCD) Must

be fitted to the mains supply.

5. WARNING: This appliance must be earthed and it is

essential that the connections are made using the

following code;

Typical Installation

rown – Live

B

Blue – Neutral

Green/Yellow – Earth

The BROWN lead should be connected to the LIVE

erminal which may be marked with an ‘L’ or coloured

t

brown or red.

he BLUE lead should be connected to the NEUTRAL

T

terminal which may be marked with an ‘N’ or coloured

blue or black.

he GREEN/YELLOW lead should be connected to the

T

ARTH terminal which may be marked with an ‘E’ ( ) or

E

oloured green or green/yellow.

c

6. If an extension cable is required, this should be

onnected to the end of the pump cable using a

c

weatherproof cable connector.

he joint must be positioned in a suitable dry housing.

T

The extension cable should be of 3 core 0.75mm2

Polychloroprene rubber insulated cable (ref: HO5 RN-F)

and permanently wired to the mains supply with a 3 or

5 Amp fuse.

7. The pump cable (and extension cable) should be

positioned and adequately protected against damage

especially where contact with gardening equipment,

(lawn mowers, forks etc..) children and domestic

animals may occur.

8. Consult a qualified electrician or local authority if in any

doubt about wiring to the mains supply.

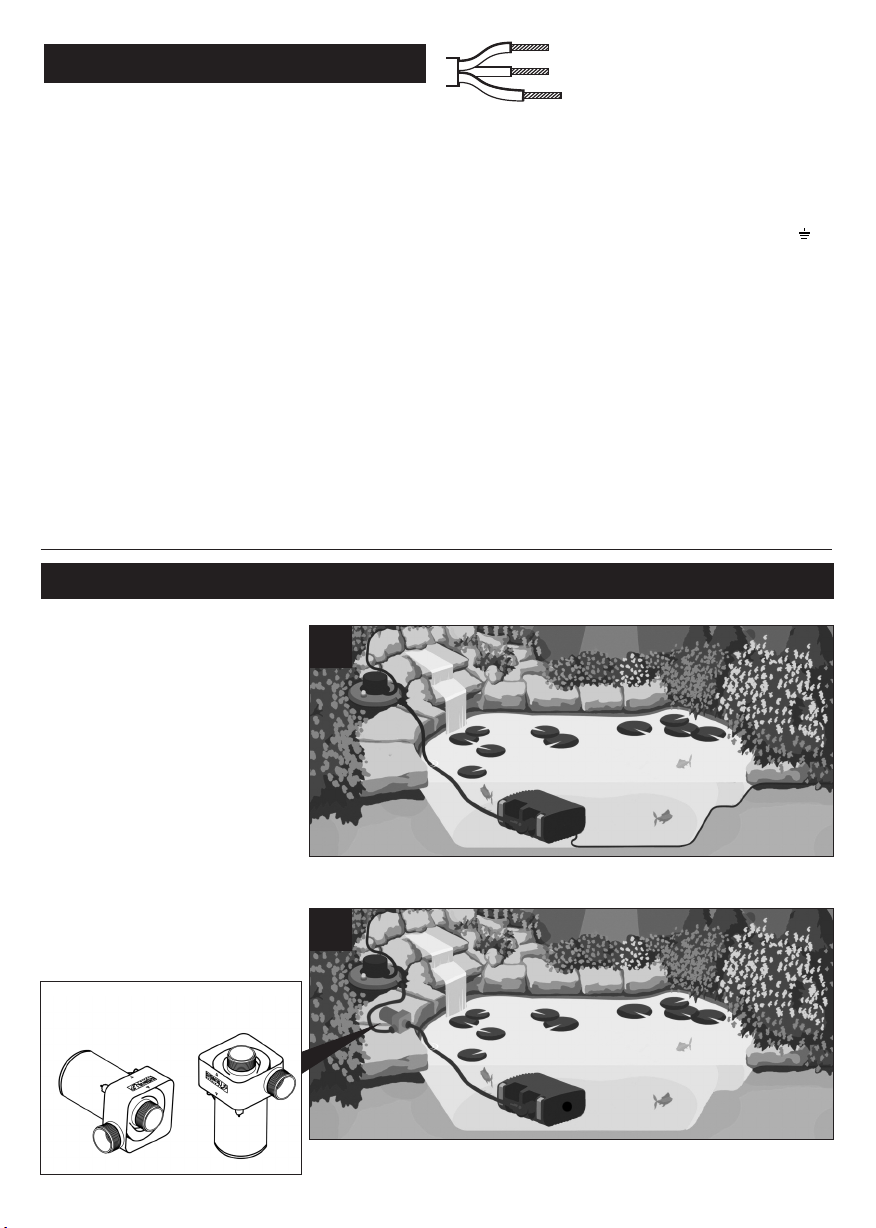

NOTE: When running amphibiously,

the dry sited pump MUST be

positioned horizontally, as shown.

✓

✗

2

Most common Aquaforce set up

3

Amphibious operation

Pump Assembly & Installation

- Submerged Operation

ASSEMBLY

1. Open the clips at either end of the

trainer cage (Fig 1 – f) and open the

s

cage.

2. Remove the Wildlife Protection

ystem (Fig 1 – a).

s

3. Remove & unpack the ball joint,

hosetails & Flow control (Fig 1–d, e &

h).

4.Remove the mains supply cable and

ote:

N

For the 6000 & 8000 pump the adaptor

should be orientated with the outlet

at the bottom of the cage (fig 5).

For the 12000 & 15000 pumps, the

adaptor should be orientated with the

outlet towards the top of the cage (Fig

5).

6. Locate the mains supply cable into

the recess on the side of the cage.

Ensure it is seated in the correct

position so that the cable does not get

trapped when the cage is closed. (Fig

6).

nwind.

u

5. Ensure that the outlet of the pump

is secured to the outlet adaptor (Fig 1

– c). Locate the pump onto its

mounting area ensuring that the

daptor piece slots into the location

a

ribs in the front of the lower cage (Fig

).

4

4

5

6000/8000

12000/15000

6

7. Close the cage lid ensuring that the

end cap (Fig 1 – g) is in its correct

position and secure by pressing in the

centre of the clips (Fig 7).

8. Checking that the ball joint’s inlet

and outlet bosses are in line, firmly

screw the nut on to the screw thread

on the outlet adaptor (Fig 8).

7

8

300mm

9. Using small bore hoses leads to

xcessive restriction of the water flow.

e

The larger the diameter of hose that

ou use the better the performance of

y

the pump will be, especially over long

ose runs. The hosetail supplied with

h

this unit will accommodate 25mm (1"),

2mm (1.25") and 40mm (1.6") hose as

3

well a ¾” BSP screw thread for

ttaching fountain accessories. We

a

ould always recommend that on

w

pumps of this size, that the 40mm

0. Screw the hosetail directly onto the

1

utlet boss of the ball joint (Fig 10).

o

The ball joint can be rotated to allow

the hose to be directed away from the

pump.

diameter hose should be used when

sing the pump as a waterfall pump or

u

in combination with a filter (Fig 2 & 3).

nce you have selected the hose

O

diameter you wish to use, cut the steps

ff the hosetail which are smaller than

o

the hose diameter to eliminate

estriction (Fig 9). Attach a suitable

r

length hose to the hosetail and secure

ith a suitable hose clip and position

w

he outlet end of the hose in the

t

desired position.

9

10

Position

11. For the best results, the pump

should be positioned in the deepest

part of the pond at least 200mm under

the surface. This will ensure the best

circulation of water in the pond and

when being used as a filtration pump,

its solids handling capability will be

maximised.

For best results, the pump should not

be placed directly on the bottom of

the pond. We recommend that the

pump be installed on a flat level

Wildlife Protection System (WPS)

12. If you have fish or other wildlife in

your pond, there are periods in the

year during which they may breed. At

this time the fish ‘fry’ are small and

can be sucked into the pump. To

minimise this possibility, the Aquaforce

range of pumps has a unique Wildlife

Protection System (WPS), which

reduces the inlet strainer hole size

down to 2mm at this critical time in

fishes’ life cycle. To use this feature,

locate the WPS’s 4 legs into the

corresponding area in the lower cage

as shown in Fig 12 ensuring that the

WPS is the correct way round. Close

platform which is raised approximately

300mm from bottom of pond. This will

prevent the pump sucking dirt directly

from the bottom of the pond and will

also ensure that sufficient water

remains in the pond in the event of

accidental leakage of pond water (See

fig 11).

the top of the cage and secure the

clips. Whilst the WPS is in use, you may

need to unblock the Strainer Cage

more frequently. Once the fish or

other wildlife have grown to a

sufficient size you can then remove the

WPS from your pump’s cage and

return the strainer size to its maximum

10mm size.

11

12

Using The Flow Control

he flow Control (Fig 1 - h) can vary

T

the amount of water entering the

ump. Alternatively, it can be used to

p

connect a second inlet to the pump

uch as a satellite filter or a skimmer.

s

Do not use the flow control when the

ump is being used amphibiously.

p

1. Open the cage and remove the end

ap (Fig 1 - g).

c

. Close the flow control by rotating

2

the outer part until the arrows are

ligned.

a

. To use as a flow control, screw the

5

end cap to the free end of the flow

control.

6. Rotate the grip to the desired

position. This varies the opening size

on the flow control. The arrow on the

grip aligns with the pointer on the

outside of the top cage.

When the pointed end of the arrow is

aligned with the pointer on the

outside of the filter cage, this indicates

9. To use a second inlet connect a

suitable length of hose to a hosetail

which has been cut to a suitable

diameter and screw to the free end of

the flow control in place of the end

cap (Fig 15).

. Firmly screw the flow control to the

3

inlet of the pump aligning the arrows

n the flow control with the arrow in

o

the centre of the top of the pump

hamber (Fig 13).

c

4. Locate the pump into the cage.

Ensure that the slots in the outlet

adaptor align with the ribs in the

ower cage and that the grip of the

l

ow control is on the outside of the

fl

cage (Fig 4).

inimum flow. When the wide end of

m

the arrow is aligned with the pointer,

this indicates maximum flow (See fig

14).

7. Locate the cable into its recess (See

point 6 under Submerged Operation),

close the cage lid and secure the clips.

8. This allows you to reduce the flow

of water to your filter and control the

waterfall size.

13

14

15

10. The other end of the hose can be

connected to a satellite filter (Fig 16)

(available as a spare from Hozelock) or

to a skimmer (Fig 17).

11. By rotating the grip of the flow

control, the amount of water coming

through the satellite filter or skimmer

can be varied.

16

17

- AMPHIBIOUS

This pump can be used amphibiously

(i.e. it can be used whilst not

ubmerged).

s

WARNING! Ensure that the unit does

ot take in air or run dry otherwise

n

your pump will be damaged!

NOTE: This pump does not self prime.

. Place the pump under the surface of

3

the water near the side of the pond to

allow water to flow into the pumping

chamber (Fig 19).

4. Cut 2 hosetails to the required size

(See point 9 under Submerged

Operation). Attach a suitable length

hose to each hosetail and secure with

suitable hose clips.

5. Submerge the inlet hose under the

surface of the water ensuring that the

complete hose fills. Screw the hosetail

to the inlet of the pump ensuring a

watertight seal using the washer

provided (Fig 20).

Pump Installation

he suction hose and pump must be

T

filled with water before switching on.

1. Open the clips at either end of the

strainer cage, open the cage, and

remove all the contents.

. Unscrew the outlet adaptor from

2

the pump outlet and locate it into the

ibs in the lower cage (Fig 18)

r

18

19

20

6. Fix the outlet hose to the pump

outlet by screwing on the hosetail.

Ensure a watertight seal using the

washer provided (Fig 21).

7. Check that the pump chamber and

hose are full of water and switch on

the pump. The pump can now be

removed from the water to it’s

amphibious operating location

ensuring that the inlet end of the hose

remains submerged.

8. To prevent the pump becoming

clogged, connect the cage to the inlet

end of the inlet hose using another

hosetail.

9. When using the pump amphibiously,

protect the pump from direct sunlight.

Direct sunlight may overheat the

motor.

10. The ball joint is not designed to be

used out of water.

21

The Hozelock Cyprio range of

quaforce pumps have been designed

A

to allow fast and easy maintenance. To

rolong the life of your pump and

p

keep your pump in peak condition,

ou should follow these maintenance

y

guidelines.

aution: Always unplug or disconnect

C

LL appliances in the pond from the

A

electricity supply before putting your

hands in the water or starting

maintenance.

1. When the pump is newly installed,

ou should check your pump daily that

y

it is performing correctly.

2. If you notice a drop in performance

(low flow) you should clean the

strainer cage. Cleaning intervals will

vary depending on the condition of

your pond’s water. This could be as

often as weekly in the summer

months. To clean the strainer cage,

open the clips and remove the pump.

The cage can then be wiped clean of

debris blocking the strainer holes and

washed in clean water. You should

also check that the pump chamber &

rotor are not blocked with debris.

3. At least once a year you should

completely disassemble the pump

including the rotor assembly as

described below and wash all

components in clean, fresh water.

Replace worn or broken parts.

Pump Dismantling & Assembly

(6000 & 8000) - Fig 22

1. Switch off the pump and remove

the strainer cage as described above

and remove the pump.

2. Ensure the pump is cool before

dismantling it.

3. Unscrew the 3 posidrive screws in

the chamber.

4. Gently pull the pump chamber (d)

squarely away from the motor body

(a).

5. Pull the rotor assembly (c) out of

the motor body. Important! Take

extra care so as to not drop the

rotor assembly.

6. Wash out all of the components in

clean water. Do not use detergents

or other chemical cleaners.

7. Ensure the o-ring (b) is on it’s seat

(fig 29). Replace the rotor assembly

into the motor body, ensuring that

the holes in the plate behind the

impeller locate onto the pins on the

motor body. Refit the pump

chamber and screws and return the

pump to the strainer cage.

Pump Dismantling & Assembly

(12000 & 15000) - Fig 23

1. Switch off the pump and remove

the strainer cage as described above

and remove the pump.

2. Ensure the pump is cool before

Maintenance

22

a

b

000/8000

6

23

a

b

12000/15000

dismantling it.

3. Unscrew the 4 posidrive screws in

the chamber.

4. Rotate the pump chamber (d) as

far as it will go and gently pull the

chamber squarely away from the

motor body (a).

5. Pull the rotor assembly (c) out of

the motor body.

Important! Take extra care so as to

not drop the rotor assembly.

6. Wash out all of the components in

clean water. Do not use detergents

or other chemical cleaners.

7. Ensure the o-ring (b) is on it’s seat

(fig 24). Replace the rotor assembly

into the motor body, ensuring that

the holes in the plate behind the

impeller locate onto the pins on the

motor body. Refit the pump

24

c

d

c

d

chamber and screws and return the

pump to the strainer cage.

4. If you live in a hard water area

(water with high levels of calcium or

limescale content), the pump, rotor

assembly and steel can should be

cleaned at regular intervals. The

cleaning interval required will vary

depending on the hardness of your

water, so you should inspect for signs

of calcium build up regularly.

To clean off calcium or limescale

deposits a small nylon bristled brush

(such as a toothbrush) may be used.

Dismantle the pump as described

above and remove the rotor. Clean the

limescale deposits from the rotor using

fresh clean water

If excessive calcium deposits build up,

the thermal overload protection may

be activated (See INTRODUCTION).

Winter Care

. Your pump should be removed from your pond during

1

the autumn.

2. Clean the pump as described above.

3. During winter, we recommend storing the pump in a

bucket of water. This is to prevent the bearings from

drying out and potentially seizing. This is especially

mportant if you have been using your pump in a hard

i

water area. The bucket of water containing the pump

hould be stored in a frost protected area.

s

Troubleshooting/Fault Finding

Important - Please keep this section for reference.

LOW FLOW FROM PUMP

1. Ensure that the strainer cage is clean.

2. A small diameter outlet pipe will restrict outlet flow.

3. Ensure that there is no blockage within the pump

chamber.

4. If using the pump amphibiously, ensure that the ball

joint is not being used and check that the washers

provided are used when fixing the hosetail to the pumps.

NO FLOW FROM PUMP

1. Check the power supply is on.

2. Check the fuse, RCD and wiring.

3. Check that the rotor assembly is not jammed, blocked,

damaged or showing signs of excessive wear.

4. Ensure that the strainer cage is clean.

5. The thermal overload protection has tripped. (see

NTRODUCTION).

I

Hozelock Cyprio 3 Year

Guarantee

To activate your warranty please go to

http://register.hozelock.com.

f this pump, excluding the rotor assembly, becomes

I

unserviceable within 3 years of the date of purchase it

ill be repaired or replaced at our option free of charge,

w

unless in our opinion it has been damaged or misused.

Liability is not accepted for damage due to accident,

mproper installation or use. Liability is limited to

i

eplacement of a faulty pump.

r

This guarantee is not transferable. It does not affect your

statutory rights. To obtain the benefits of the guarantee,

firstly contact Hozelock Cyprio Consumer Services who

may request that the pump is sent along with proof of

purchase directly to the address below.

Hozelock Cyprio Ltd.

Midpoint Park, Birmingham

B76 1AB. England

Telephone: 0121 313 1122

www.hozelock.com

SPARE PARTS

Contact the Consumer Services Helpline on 0121 313 1122.

All spare parts can be purchased at www.hozelockservice.com

Model no. 6000 8000 12000 15000

Spares

1. Pump Chamber Assembly and Seal. Z10008 Z10009 Z10010 Z10010

2. Rotor Assembly. Z10001 Z10002 Z10003 Z10004

3. Outlet Adaptor Z10011 Z10011 Z10011 Z10011

4. Strainer Cage Assembly/Satellite Filter 1683 1683 1683 1683

5. Ball Joint Z10013 Z10013 Z10013 Z10013

6. Stepped Hosetail, Washer & Nut Z10012 Z10012 Z10012 Z100012

7. Flow Control Valve & End Cap Z100014 Z100014 Z100014 Z100014

Part No

Performance*

Aquaforce 1000 2500 4000 6000 8000 12000 15000

Saleable Part number 1580 1581 1582 1583 1584 1585 1586

Volts (V)

Power (w) 25 30 50 65 95 130 180

Max Flow, QMax, (l/hr) 1000 2500 4000 6000 8000 12000 15000

Max Head, HMax, (m) 1.5 2.1 2.5 3.5 4.0 5.0 5.7

IP Rating IPX8 IPX8 IPX8 IPX8 IPX8 IPX8 IPX8

Max submersion depth, (m) 2.5 2.5 2.5 2.0 2.0 2.0 2.0

Max Water Temperature

TMax, (°C) 35°C 35°C 35°C 35°C 35°C 35°C 35°C

Amphibious use

*

Measured under controlled conditions

230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz

✗ ✗ ✗ ✓ ✓ ✓ ✓

Hozelock Cyprio

Midpoint Park, Birmingham B76 1AB. England.

Tel: +44 (0)121 313 1122

www.hozelock.com

The Aquatics Division of Hozelock Group

43386-001

Do not dispose of electrical appliances as

unsorted municipal waste, use separate

collection facilities. Contact your local

government for information regarding

the collection systems available. If

electrical appliances are disposed of in

landfills or dumps, hazardous substances

can leak into the groundwater and get

into the food chain, damaging your

health and well-being. In the EU, when

replacing old appliances with new ones,

the retailer is legally obligated to take

back your old appliance for disposal at

least free of charge.

Loading...

Loading...