Installation and operating instruction

ABRA 6

CONTENT

INTRODUCTION

Page 3

DESCRIPTION OF THE DEVICE

Electronical control unit Page 4

Display Page 5

Door sensor Page 5

Air inlet flap Page 5

Hightemperature sensor Page 5

Power source adapter Page 5

INSTALL ATION

Door sensor intallation Page 6

Hightemperature sensor installation Page 6

Air inlet flap installation Page 7

Electronical unit connection Page 7

SETTINGS

Setting of device and communication channel Page 8

Setting for UNI-product Page 9

OPERATING

Informations on display Page 10

Alarms and warnings Page 11

Power source shortage Page 11

TROUBLESHOOTING Page 12

LIST OF PRODUCTS Page 13

WARRANTY Page 14

2

We would like to thank you for purchasing electronical fireburning

control ABRA 6.

Based on the temperature in the burning chamber this fireburning

control optimizes combustion by precise dosage of inlet air.

The installation of this product must be carried out by specialist

– stove maker – only.

Before you start using the device we would like to invite you to read

this manual and follow the instruction inside.

INTRODUCTION

3

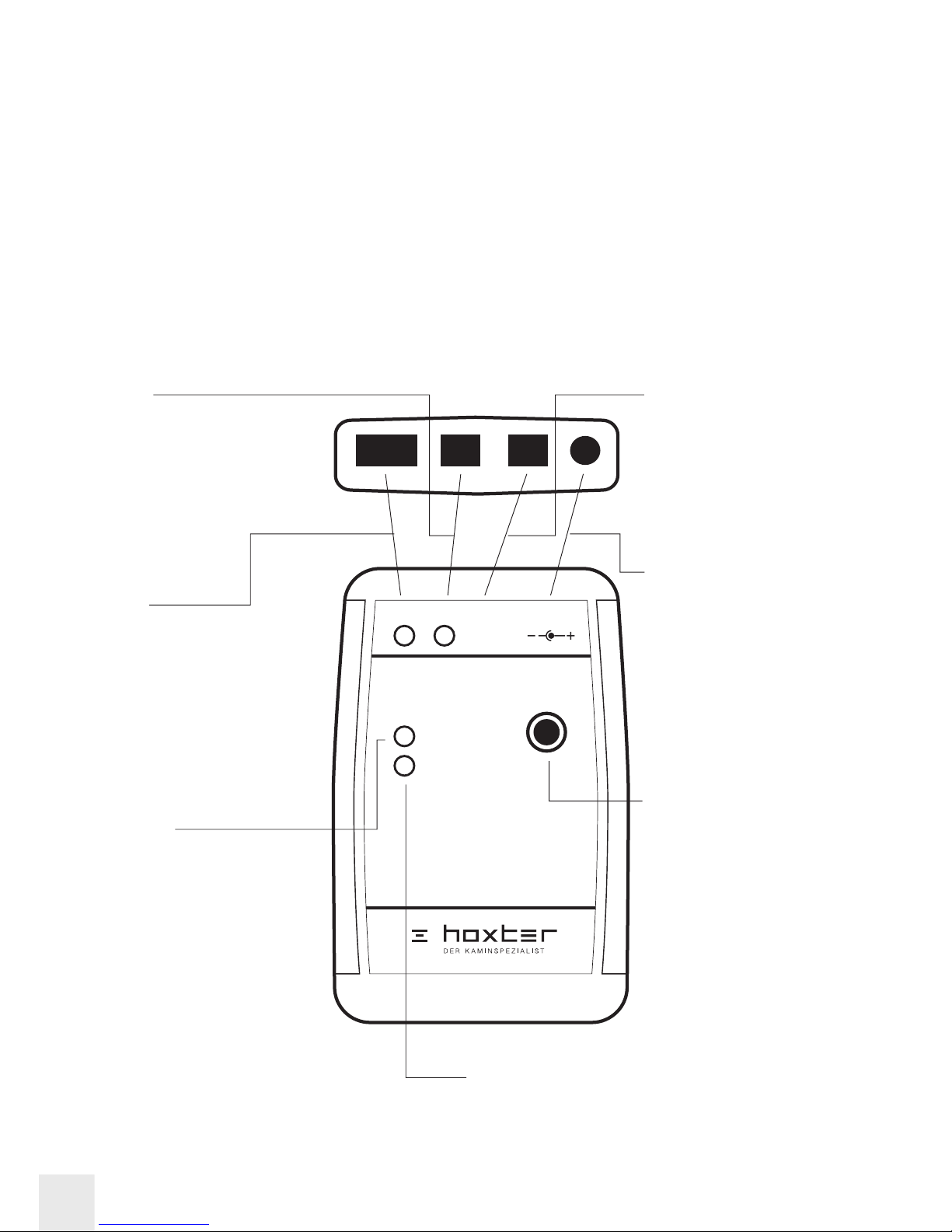

RUN

SET

S1

TK

T1

12V DC

PWR

ELECTRONICAL FIREBURNING CONTROL UNIT

• Power source adapter 12V

• Electronical unit includes 9V backup battery

• Heat resistance max 40°C / 104°F

Description of inputs and control diode

S1

• Connector input

for air inlet flap

• Control diode signals

when flap is changing

its position

RUN

• Operation

control diode

• Flashing signals

ongoing burning

process

• If switches off

during set-up

process, it confirms

the current step

TK

• Connector input

for door sensor

• Control diode signals

closed position

of the door

T1

• Connector input

for hightemperature

sensor

12V DC

• Connector input

for power supply

adapter

DESCRIPTION OF THE DEVICE

SET

• Functional button

used for set-up

• Browse through

choices by short

pressing

• Confirm choice

by holding (5 sec)

PWR

• Control diode signals

power supply 12V

4

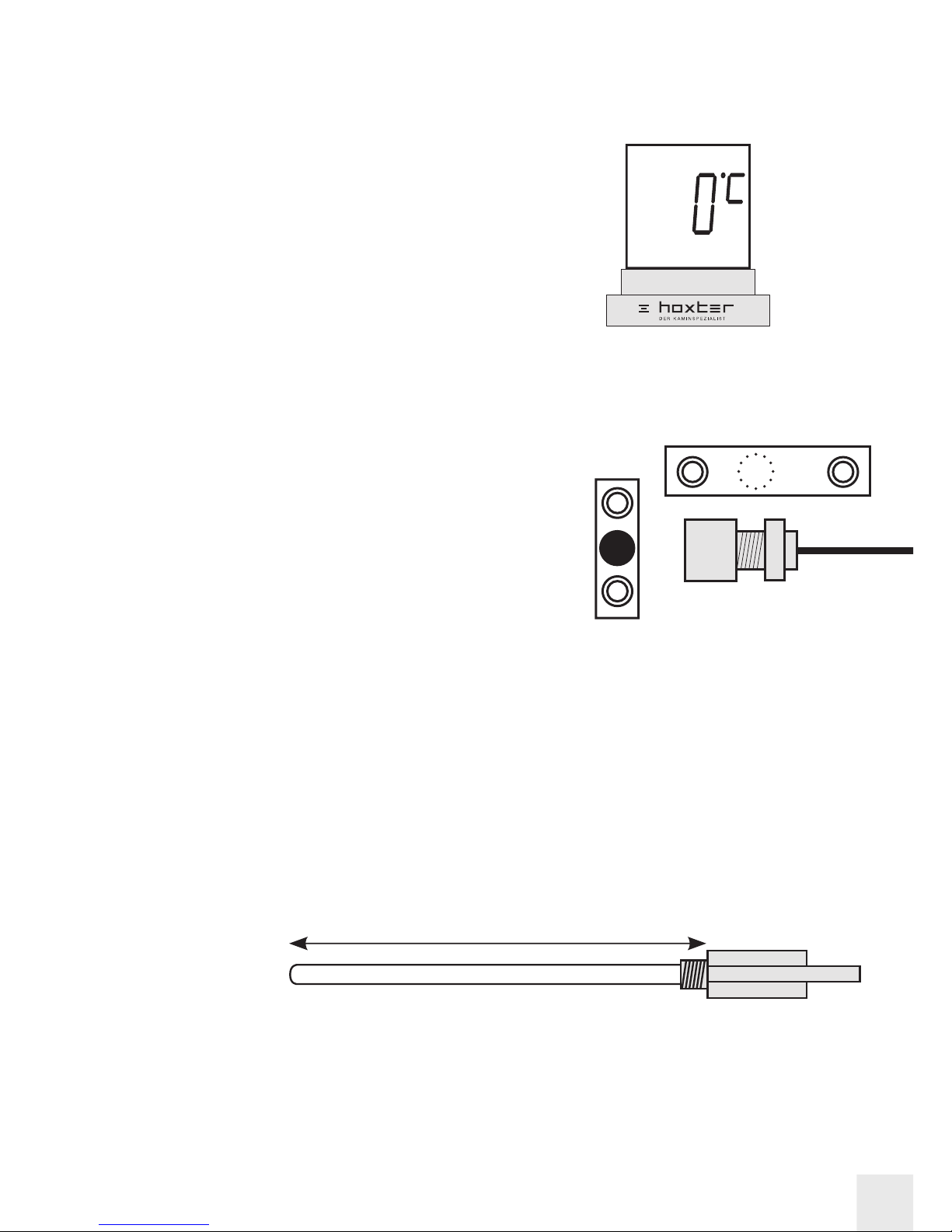

DIS PLAY

• Display shows information from

the control unit through FM waves

• Power supply – 3pcs of 1,5V AAA battery

• Heat resistence - max 40°C / 104°F

• Signal range between electronical control

unit and display max 50m / 164 ft.

• (more instruction for display unit in chapter

„OPERATION“ on page 10)

DOOR SENSOR

• Sensor with connecting cable, lenght 4 m / 13 ft.,

heat resistence of the cable 180°C / 356°F (A)

• Magnetic counterpart (B)

• Steel hitch (only compatible

with HOXTER products) (C)

AIR INLET FLAP

• Heat resistence of the stainless steel flap and its components max 50 °C / 122 °F

• Lenght of the cable 4m / 13 ft., heat resistence of the cable 180 °C / 356 °F

HIGHTEMPERATURE SENSOR

• Range 0°C - 1200°C / 32°F - 2192°F

• Heat resistence of the hightemperature sensor and ceramical cover max 1200 °C / 2192°F

• Heat resistence of the cable 400 °C / 752°F, lenght of the cable 5 m / 16,4 ft.

• Assembly lenght of the sensor is adjustable 140-160mm / 5.5 – 6.3 In.

POWER SUPPLY ADAPTER

• Input 110-230V

• Output 12V DC

• Heat resistance max 40 °C / 104 °F, lenght of the cable 2 m / 6.5 ft

140 - 160 mm

5

A

B

C

DOOR SENSOR INSTALLATION

Break out the indicated opening in the steel

hitch (B), pull the door sensor through this hole

(A) and fasten with the distance barrel (C)

and a nut (D).

Fasten the steel hitch with the door sensor

on designed place at the frame (E).

Enclose the magnetic counterpart on the

bottom edge of the doors.

Both the door sensor and the magnetic

counterpart must be placed in the common

axis. The distance between those parts

must be 2-12mm / 0.08-0.47 in. (F) In case

the distance between these part is too big,

underlay the magnetic counterpart with the

distance barrel.

The magnetic counterpart is strong enough

to held on place. For the fixation use

enclosed screws (G).

A

B

C

D

E

INSTALLATION

1

2

3

4

5

2-12 mm

F

6

G

HIGHTEMPERATURE SENSOR INSTALLATION

Screw the hightemperature sensor on fireplace

insert or stove doors to the designed place.

Minimal lenght for correct measurment

is 20mm / 0.8 in at its end (H).

AIR INLET FLAP INSTALLATION

Connect the air inlet flap by alu pipe with the fireplace insert or stove doors.

The connection between the air inlet flap and the product must be tight enough.

When installing into closed-in build, the air inlet flap must be placed

outside the hightemperature place. The heat resistence of the air inlet

flap is max 50°C / 122°C.

CONTROL UNIT CONNECTION

Connect all the components and power supply adapter with the control unit.

After that plug the power supply adapter to the power feed.

For complete instruction

how to set-up the control

unit follow the instruction

stated in the chapter

„SET-UP“

RUN SET

S1 TK T1 12V DC

PWR

1

1

1

2

2

2

min.

20 mm

H

7

SETTING UP THE PRODUCT AND COMMUNICATING CHANNEL

There is a red control diode RUN flashing.

Press the SET button on the control unit until the red control diode turns off.

Remove the strip between the battery and the contact in the display. It prevents

the batteries to power the display. In case, the display is already powered,

remove and after short moment put back inside all the batteries.

The first number from the product codes appears on the

display (list of product codes on page 13).

Scroll to the required number by short presses of the SET

button. To confirm the selection hold the SET button for 5 sec.

Now the last two numbers from the product codes are active. Scroll to the

required number by short presses of the SET button. To confirm the selection

hold the SET button for 5 sec.

Now the number of the communicating channel is active.

Confirm by holding the SET button. In case there is another

fireburning control installed or another source interfering the

communication, repeat the SET-UP process and choose

different channel.

Set message appears on the display to confirm the set-up

proces was finished succesfully. After a while the fireburning

control turns itself into operating mode.

SET-UP

SHORT PRESS TO CHANGE VALUE.

HOLD TO CONFIRM THE CHOICE.

1

2

3

4

5

6

7

8

RUN SET

S1 TK T1 12V DC

PWR

8

UNI PRODUCTS SETTING

This settings is defined for individual fireplaces or to adjust the time of active

burning out phase. UNI setting is available in three different options for

starting temperatures (T

start

) - pro 80°C, 250°C or 400°C. The choice for the

correct starting temperature depends on the place where the hightemperature

sensor is installed – in burning chamber, or in the accumulating system.

When setting the UNI system, follow the step 1-5 as in the chapter

„Setting up the product and communicating channel“.

After confirmation of the UNI product code, the option for temperature T5

appears on the display. When this temperature is reached, the air inlet flap

is closing completely, the phase of active burning ends and phase of hot

coal is starting. By default the temperature T5 is set on the 65% value of the

temperature T4.

For adjusting applies:

Values higher than 65% shortens the phase of active burning

Values lower than 65% extends the phase of active burning

To confirm the choice hold the SET button. After that continue with the

option for communicating channel.

St1

T

3

T

4

T

5

T

start

T

max

St2

St3 St4

St5

time

temperature

1

2

3

COMBUSTION CURVE

9

Stage or phase of the burning

Because of different conditions of each burning (humidity, firewood quantity,

thrust of the chimney) the fireburning control unit ABRA 6 doesn’t control the

combustion by fixed time intervals for each phase. The period and process of

the combustion are always derived from maximal reached temperature (T

ma x

)

in the second phase of burning.

INFORMATIONS ON DISPLAY

Informations on the display are beeing updated

each 8 second. For instant update or to activate

the backlight push the display in the upper part.

During common operation the display

shows four basic values:

Current temperature in the burning chambre

Temperature measured by the hightemperature sensor

Time of burning

The period starts when the doors sensor contact

is interrupted (opened doors) and ends when the

combustion stops . The fireburning control is now

in phase 0, the hightemperature sensor measures

temperature lower than 50°C.

Strenght of signal

The marks in the lower part of the display are showing

the strenght of the signal between the display and the

electronical control unit. It shows seven marks when

the signal is full, when the signal is too weak,

the display shows SIG warning message.

OPERATING

St1

T

start

T

max

St2 St3 St4 St5

time

temperature

10

ALARMS AND WARNING MESSAGES

SiG warning message - the signal strenght beween display

and control unit is too weak.

bAt warning message - the voltage of the batteries in the

display is too low. Replace the batteries.

Alarm - Alarm is signaled by beeps and flashing of the display.

AL-1 Power supply of the electronical control unit failure. For security reason the

backup battery allows to open the air inlet flap and the fireburning controls turns

itself off. Check the power supply feed.

AL-2 Power supply of the electronical control unit failure

and also weak backup battery in the electronical control unit.

Replace the backup battery in the electronical control unit

and check the power supply feed.

AL-3 Bad heating. All of following conditions occured. The time period of the first

burning phase was longer than 30min, the temperature in the burning chamber

didn’t reach 90°C and decreased of more than 10°C. The fireburning control

automatically ends the combustion proces and when the temperature drops bellow

50°C it closes the air inlet flap.

St1 - first phase. This stage begins with opening and closing of the doors and

ends when the starting temperature

tstart

is reached. Starting temperature is

determined with the choice of product during the set-up process.

St2 - second phase. Second phase starts after the temperature

tstart

is reached

and continues for at least 15 min. During this stage the maximal temperature

tmax

is reached.

St3 - third phase is the stage of active burning.

St4 - fourth phase is the stage of active burning out, the air inlet flap lets in only

minimal possible air required for combustion.

St5 - fifth phase is the stage of hot coals, the air inlet flap is closed completelly.

St0 phase zero - non-active phase, when the temperature in the burning chamber

is lower than 50°C. Fireburning control automatically wents in saving mode.

11

Failure Cause Solution

Control diode RUN

doesn’t flash.

Electronical fireburning

control unit is in set-up

mode.

Remove and put back

batteries from the

display. Finish the set-up

process.

Sig is showing on the

display, control diode

PWR is off.

Electronical fireburning

control unit is not feeded

from the power supply

feed.

Check the connection

between electronical

fireburning control unit

and the power supply

feed.

Display is showing SiG,

control diode PWR is

on, control diode RUN is

not flashing.

Electronical fireburning

control unit is in set-up

mode.

Remove and put back

batteries from the

display. Finish the set-up

process.

Display is showing SIG,

control diode PWR

is on, control diode

RUN is flashing.

Display is out of reach

from the electronical

fireburning control unit.

Put the display closer

to the electronical

fireburning control unit.

Display and electronical

fireburning control unit

are not on the same

channel.

Repeat the whole proces

described in chapter

„Setting up the product

and communicating

channel“.

The communication

between display and

electronical unit is

interfered.

Repeat the whole proces

described in chapter „

Setting up the product

and communicating

channel“. Change the

communication channel

as described in point

7 of this chapter.

TROUBLESHOOTING

12

HOXTER

1.01 HAKA 37/50

1.02 HAKA 63/51

1.03 HAKA 67/51h

1.04 HAKA 89/45h

1.05 ECKA 67/45/51h

1.06 ECKA 90/40/40h

1.07 HAKA 37/50W

1.08 HAKA 63/51W

1.09 HAKA 63/51WT

1.10 HAKA 67/38W

1.11 HAKA 67/51W

1.12 HAKA 89/45Wh

1.13 ECKA 67/45/51Wh

UNIVERSAL

2.01 UNI - 80°C

2.02 UNI - 250°C

2.03 UNI - 400°C

LIST OF PRODUCTS

13

14

Warranty for the electronical fireburning control ABRA 6 and its componenst is

24 months. The warranty doesn’t apply on mechanical damage. The warranty

also doesn’t apply if the damaged products were exposed to temperatures

higher than the defined maximal values.

Installation of the electronical fireburning control ABRA 6 must be done by

specialist – stove maker. For warranty and post-warranty service contact

please the company that installed the product.

Date of the installation:

Company / Stove maker:

Address:

Phone:

WARRANTY

NOTES

15

HOXTER gmbh

Kirchgasse 1

91217 Hersbruck

Germany

Tel.: +49 (0)9151 8659 163

info@hoxter.de

www.hoxter.de

HOXTER a.s.

Mlýnská 326/13

602 00 Brno

Czech republic

Tel.: +420 518 777 701

info@hoxter.eu

www.hoxter.eu

Loading...

Loading...