Howe 11EFS User Manual

Rapid Freeze

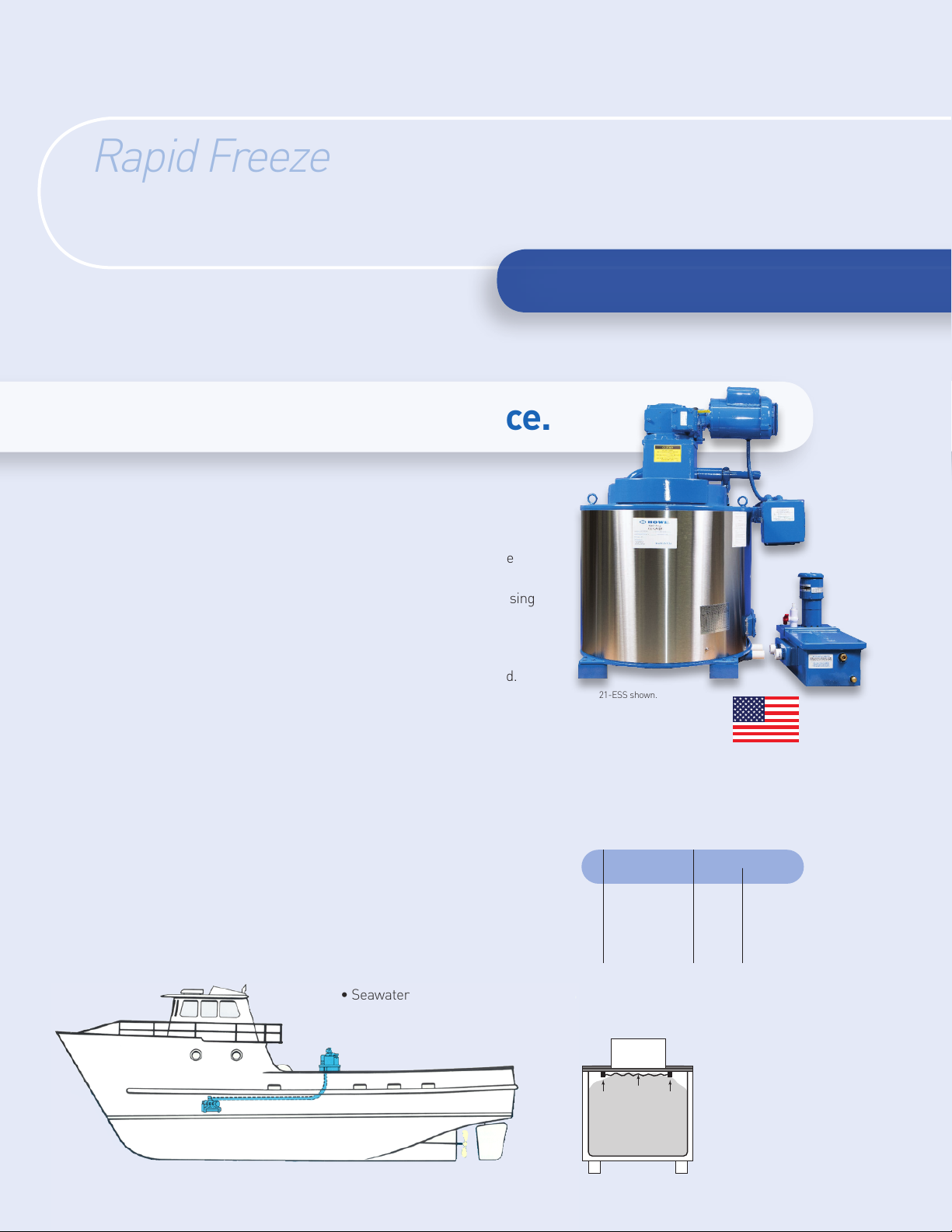

Modular Remote Low-Side Flake Ice Machines

SHIPBOARD FRESH & SEAWATER

Selective Purpose Ice Flaker

COOL SOLUTIONS SINCE 1912

HOWE Proven. Best Choice.

Rapid Freeze Shipboard ice flakers

feature unexcelled quality, reliability,

and long life. It is durable, energy

efficient and provides a high degree

of flexibility to a wide diversity of

industrial applications.

RELIABILITY An ice machine you

can always depend on. It’s backed

by over a half-century of innovation

and proven performance.

DURABILITY

• Rugged, heavy-duty design offers

years of trouble free operation

both on shore & off shore

• Weatherproof TEFC Drive motors

• Continuous ice production, no

defrost cycles ever.

• Direct expansion evaporator.

HIGH QUALITY ICE Sub-cooled

ice with exceptional cooling power.

Draws heat away quickly and

evenly for superb process cooling

applications.

FLEXIBILITY

• Freshwater & seawater

models available.

• Remote water sump, to be

field installed.

• Remote matching condensing

units available

• A diversity of refrigerants,

electrical options are

available to meet any need.

LOW MAINTENANCE

Substantially lower maintenance

requirements than most other

brands of ice equipment.

ENERGY-EFFICIENT Requires

significantly less energy per pound

of ice produced than most other

brands of ice equipment.

APPLICATIONS

FISHING VESSELS

• Freshwater

• Seawater

LANDBASED MODELS

• Freshwater

• Seawater

21-ESS shown.

MADE IN USA!

100% ICE PRODUCTION/24HRS

REMOTE*

MODEL LBS KG

11EFS, 11ESS 2,000 908

16EFS, 11ESS 3,000 1362

21EFS, 21ESS 4,000 1816

31EFS, 31ESS 6,000 2724

* All data given at 90°F (21°C) air / 70°F (21°C) water.

ICE FLAKER

INFRARED

SIGNAL

EMITTER RECEIVER

FLAKE ICE

PATENTED BIN ICE

LEVEL CONTROL

SYSTEM For maximum

bin storage, infrared

control turns machine

off when ice level

reaches chute.

SHIPBOARD FRESH & SEAWATER

MIN 2.0 "

MAX 2.5 '

6 " MIN FOR SERVICE

P-TRAP SIGHT GLASS

PORT VALVE

BALANCE

SOLENOID VALVE

REMOTE WATER

SUMP

J

D1

J

J

J

D2

LIQUID INLET

SUCTION OUTLET

DRIVE MOTOR

H1

W2

W1

H2

C

Selective Purpose Ice Flaker

DIMENSIONS (IN) CONNECTION SIZES REFRIGERATION

OD (IN) REQUIREMENT

MODEL C D1 D2 J H1 H2 W1 W2 SUCTION LIQUID WATER BTU/HR

Freshwater 11EFS 14 32½ 20¾ 10½ 39 20¾ 29¾ 15¾ 1

16EFS 14 32½ 20¾ 10½ 43½ 20¾ 29¾ 15¾ 1

21EFS 19 35 20¾ 12½ 48 20¾ 33¾ 15¾ 1

31EFS 19 35 20¾ 12½ 55 20¾ 33¾ 15¾ 1

Seawater 11ESS 14 32½ 20¾ 10½ 39 20¾ 29¾ 15¾ 1

16ESS 14 32½ 20¾ 10½ 43½ 20¾ 29¾ 15¾ 1

21ESS 19 35 20¾ 12½ 48 20¾ 33¾ 15¾ 1

31ESS 19 35 20¾ 12½ 55 20¾ 33¾ 15¾ 1

1

/

1/2 3/8 17,050*

8

3

/

5/8 3/8 25,575

8

3

/

5/8 3/8 34,100

8

5

/

7/8 3/8 51,151

8

1

/

1/2 3/8 16,000

8

3

/

5/8 3/8 25,500

8

3

/

5/8 3/8 32,000

8

5

/

7/8 3/8 48,000

8

*

*

*

**

**

**

**

* @ -5°F Evap. Temp., 70°F Water Temp.

** @ -30°F Evap. Temp., 70°F Water Temp.

ICE PRODUCTION MAKE UP DRIVE WATER

@ 70/90 WATER MOTOR PUMP

VOLTAGE MODEL LBS GPM HP FLA HP FLA APMS FUSE LBS KG

208230160 11E*S 2,000 .17 1/3 3.2 1/15 1.95 5 15 525 238

16E*S 3,000 .24 1/3 3.2 1/15 1.95 5 15 550 250

21E*S 4,000 .35 1/3 3.2 1/15 1.95 5 15 680 309

31E*S 6,000 .50 1/2 4.3 1/15 1.95 5 15 820 372

Shipboard freshwater or seawater ice flakers come with NEMA 4 control panel & TEFC drive motor as standard.

SHIPBOARD ICE FLAKER | © 2014 Howe Corporation | 9/14

1650 N. Elston Ave., Chicago, IL 60642-1585 | 773 235 0200 | Fax 773 235 0269

howecorp.com | howeinfo@howecorp.com

MIN

CIRCUIT MAX

SHIPPING WT

Loading...

Loading...