Howe 101-RLA User Manual

Rapid Freeze

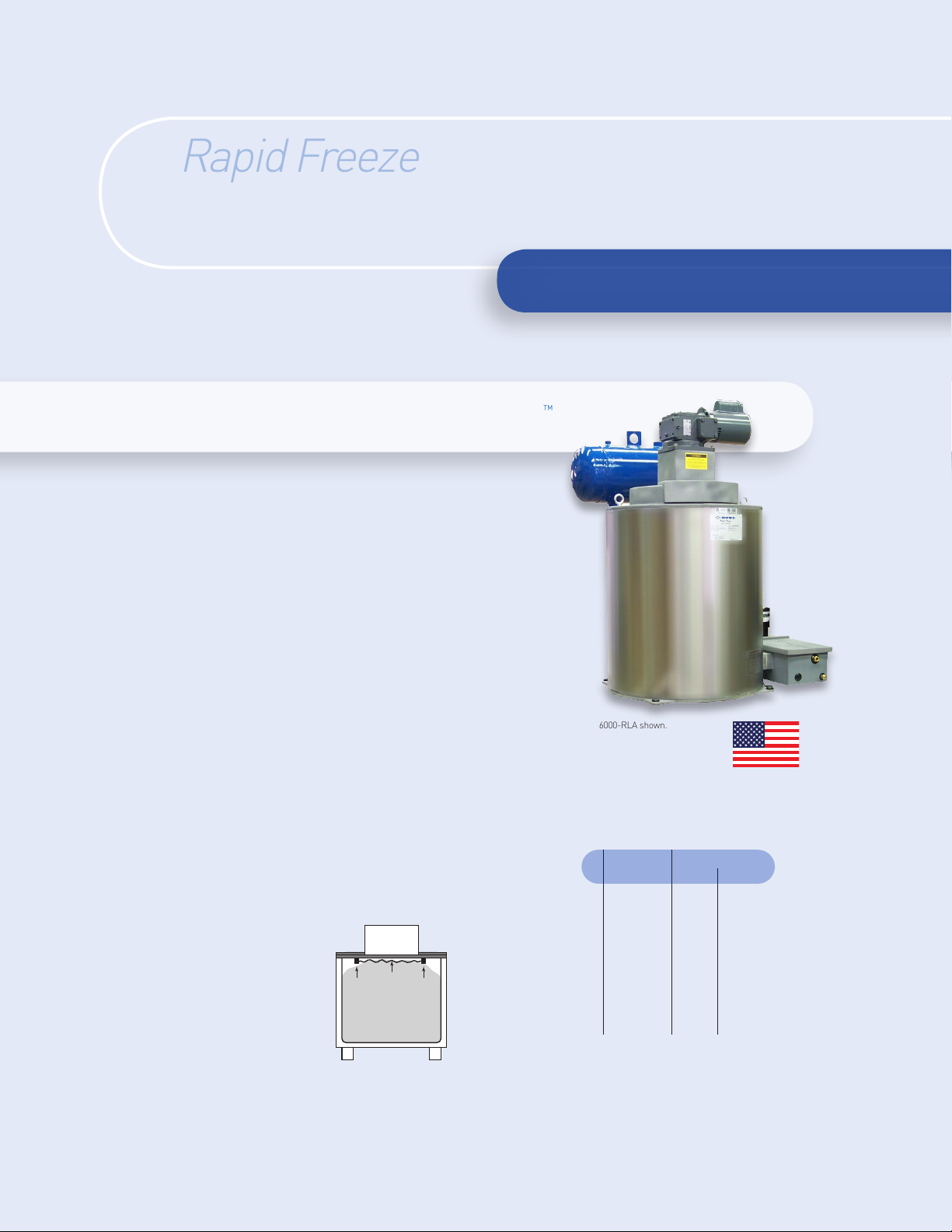

Modular Remote Low-Side Flake Ice Machine

FLOODED AMMONIA

Selective Purpose Ice Flaker

COOL SOLUTIONS SINCE 1912

HOWE Proven. Best Choice.

™

Rapid Freeze Flooded Ammonia

ice flakers feature unexcelled

quality, reliability, and long life. It

is durable, energy efficient and

provides a high degree of flexibility

to a wide diversity of industrial

applications.

RELIABILITY An ice machine you

can always depend on. It’s backed

by over a half-century of innovation

and proven performance.

DURABILITY All internal

components come as standard,

in stainless steel, shaft, ice blade,

deflector, deflector brackets,

squeegee wrapper & brackets.

NO Galvanized parts inside ice

flaker.

HIGH QUALITY ICE Super-cold,

dry, crisp, 100% sub-cooled

ice with greater surface area

and exceptional cooling power.

Draws heat away quickly and

evenly for superb process cooling

applications.

FLEXIBILITY A diversity of

refrigerants, electrical options

and condenser configurations are

available to meet any need.

LOW MAINTENANCE

Substantially lower maintenance

requirements than most other

brands of ice equipment.

ENERGY-EFFICIENT Requires

significantly less energy per pound

of ice produced than most other

brands of ice equipment.

APPLICATIONS

• Produce Harvesters

• Produce Wholesalers

• Produce Markets

• Industrial Bakeries

• Seafood Processors

• Seafood Distributors

• Meat Processors

• Sausage Processors

• Poultry Processors

• Concrete Cooling

• Amusement Parks

• Industrial Catering

ICE FLAKER

INFRARED

SIGNAL

EMITTER RECEIVER

FLAKE ICE

PATENTED BIN ICE LEVEL

CONTROL SYSTEM For

maximum bin storage, infrared

control turns machine off when

ice level reaches chute.

6000-RLA shown.

MADE IN USA!

100% ICE PRODUCTION/24HRS

REMOTE*

MODEL LBS KG

2000-RLA 2,000 908

3000-RLA 3,000 1,362

4000-RLA 4,000 1,816

6000-RLA 6,000 2,724

51-RLA 10,000 4,540

76-RLA 15,000 6,810

101-RLA 20,000 9,080

201-RLA 40,000 18,160

* All data given at 90°F (21°C) air / 70°F

(21°C) water.

FLOODED AMMONIA

S

H

A

F

T

R

O

T

A

T

I

O

N

J J

D

MOUNTING HOLE

1/2" SCREWS

RELIEF

H

W

1

W

OPENING TO ICE BIN

C DIA.

LIFTING HOLE

OPTIONAL

SUPPORT

SHIPPING

BASE

OIL

DRAIN

OIL POT

10" MINIMUM FOR SERVICE

AMMONIA LIQUID

FLOAT VALVE

See table below

for orifice size

WATER PUMP

WATER DRAIN

WATER INLET

WATER SUMP

D

1

SURGE DRUM

L

AMMONIA SUCTION

TO COMPRESSOR

AMMONIA LIQUID

INLET EITHER SIDE

1" TYP

Ω

FLOODED AMMONIA

ICE FLAKER

Selective Purpose Ice Flaker

DIMENSIONS APPROX SHIPPING SURGE FLOAT CONNECTION SIZES ICE REFRIGERATION

(IN) WEIGHT (LB) DRUM VALVE PRODUCTION REQUIREMENT*

MODEL B C D H J W FLAKER DRUM D x L ORIFICE LBS KG BTU/HR TEMP

SURGE EVAP

SUCTION

LIQUID

OIL

DRAIN

RELIEF

VALVE

WATER

WATER

G.P.M.

2000-RLA 23 14 41 34 8½ 29½ 400 125 8

3000-RLA 23 14 41 38½ 8½ 29½ 450 135 8

4000-RLA 27½ 18 45 43 10¼ 31½ 550 150 8

6000-RLA 27½ 18 47 50 10¼ 35½ 720 200 10¾ x 24 3/32 1¼ 1/2 1/2 1/2 3/8 6,000 2,724 .50 51,500 -5

51-RLA 43 30 52 60 16¼ 60 1500 425 18 x 40 7/64 1½ 1/2 1/2 1/2 1/2 10,000 4,540 .85 85,250 -5

76-RLA 43 30 64 72 16¼ 60 2100 475 20 x 40 9/64 2 1/2 1/2 1/2 1/2 15,000 6,810 1.25 128,000 -5

101-RLA 43 30 68 79 16¼ 60 2500 525 24 x 40 9/64 2 1/2 1/2 1/2 1/2 20,000 9,080 1.65 170,500 -5

201-RLA 60 48 88 100 22

* @ 70°F (21°C) Water Temperature

ELECTRICAL

230/1/60 460/3/60 380/3/50**

DRIVE WATER

MOTOR PUMP

MODEL HP FLA HP FLA AMPS FUSE HP FLA HP FLA AMPS FUSE HP FLA HP FLA AMPS FUSE

2000-RLA 1/3 3.2 — .7 5 15 1/3 1.2 — .7 3 15

3000-RLA 1/3 3.2 — .7 5 15

4000-RLA 1/3 3.2 — .7 5 15 1/3 1.2 — .7 3 15

6000-RLA 1/2 4.3 — .7 8 15 1/2 1.5 — 1.95 5 15

51-RLA 1 6.8 1/8 1.05 15 20 1 1.8 1/6 .35 5 15 1 2.4 1/8 1.1 7 15

76-RLA 1 6.8 1/8 1.05 15 20 1 1.8 1/6 .35 5 15 1 2.4 1/8 1.1 7 15

101-RLA 1 6.8 1/8 1.05 15 20 1 1.8 1/6 .35 5 15 1 2.4 1/8 1.1 7 15

201-RLA 1 4 1/3 2.8 15 20 1 2 1/3 1.4 5 15 1 4.2 1/3 .7 8 15

Standard NEMA 1 control panel is shipped loose for field installation. (Optional NEMA4 enclosure is available with NEMA4/TEFC kit) Drive motor is standard ODP (open drip proof) (TEFC motor is available

with optional NEMA4/TEFC kit). Rapid Freeze ice flakers require a condensation drip pan to be fabricated and installed under flaker, but above the storage bin. Drip pan shall be constructed to prevent

condensation from entering ice storage bin.

** 380/3/50 drive motor, 220/1/50 water pump

FLOODED AMMONIA | © 2014 Howe Corporation | 9/14

230/3/60

5

/

x 24 3/32 1 1/2 1/2 1/2 3/8 2,000 908 .17 17,050 -5

8

5

/

x 24 3/32 1 1/2 1/2 1/2 3/8 3,000 1,362 .24 25,525 -5

8

5

/

x 24 3/32 1¼ 1/2 1/2 1/2 3/8 4,000 1,816 .35 34,100 -5

8

1

/

80 4800 900 24 x 80 3/16 3 3/4 1/2 1/2 1/2 40,000 18,160 3.33 346,500 -10

8

DRIVE WATER

MIN

CIRCUIT MAX

MOTOR PUMP

NOT AVAILABLE

MIN

CIRCUIT MAX

DRIVE WATER

MOTOR PUMP

1/3 1.2 — .7 3 15

MIN

CIRCUIT MAX

1650 N. Elston Ave., Chicago, IL 60642-1585 | 773 235 0200 | Fax 773 235 0269

howecorp.com | howeinfo@howecorp.com

Loading...

Loading...