Howden Roots Tri-RAM 416, Roots Tri-RAM 413, Roots Tri-RAM 722, Roots Tri-RAM 728, Roots Tri-RAM832 Installation, Operation & Maintenance Manual

...

www.howden.com

Roots

TM

Tri-RAM

TM

Tri-lobe

Blowers

Installation Operation & Maintenance Manual

Contents

Information Summary ...............................................................2

Safety Precautions

Operating Limitations

Installation

........................................................................... 4 - 6

Lubrication

Operation

..................................................................................8

....................................................................3

................................................................3

................................................................................7

Troubleshooting

Inspection & Maintenance

Figures

............................................................................ 11 - 12

Tables

.....................................................................................13

Parts List

.................................................................... 14, 17, 19

Assembly Drawings

Do these things to get the most from your Roots Blower

........................................................................9

......................................................10

...........................................15 - 16, 18, 20

• Check shipment for damage. If found, file claim with

carrier and notify Howden.

• Unpack shipment carefully, and check contents against

Packing List. Notify Howden if a shortage appears.

• Store in a clean, dry location until ready for installation.

Lift by methods discussed under INSTALLATION to

avoid straining or distorting the equipment. Keep covers

on all openings. Protect against weather and corrosion

if outdoor storage is necessary.

• Read OPERATING LIMITATIONS and INSTALLATION

sections in this manual and plan the complete

installation.

• Provide for adequate safeguards against accidents

to persons working on or near the equipment

during both installation and operation. See SAFETY

PRECAUTIONS.

• Install all equipment correctly. Foundation design

must be adequate and piping carefully done. Use

recommended accessories for operating protection.

• Make sure both driving and driven equipment is

correctly lubricated before start-up. See LUBRICATION.

• In event of trouble during installation or operation, do

not attempt repairs of Roots furnished equipment.

Notify Roots, giving all nameplate information plus an

outline of operating conditions and a description of the

trouble. Unauthorized attempts at equipment repair

may void Roots warranty.

• Units out of warranty may be repaired or adjusted by

the owner. Good inspection and maintenance practices

should reduce the need for repairs.

NOTE: Information in this manual is correct as of the date

of publication. Howden reserves the right to make design or

material changes without notice, and without obligation to make

similar changes on equipment of prior manufacture.

For your nearest Howden Office, dial our Customer Service

Hot Line toll free in the U.S.; 1 877 363 7668 or direct +1

Roots products are sold subject to the current General Terms of Sale, ES104 and Warranty Policy WP-5020.

Copies are available upon request.

2

GEA19684 ISRB_2008 rev._11.15

Safety Precautions

It is important that all personnel observe safety precautions

to minimize the chances of injury. Among many considerations, the following should be particularly noted:

• Blower casing and associated piping or accessories

may become hot enough to cause major skin burns on

contact.

• Internal and external rotating parts of the blower and

driving equipment can produce serious physical injuries.

Do not reach into any opening in the blower while it is

operating, or while subject to accidental starting. Protect external moving parts with adequate guards.

• Disconnect power before doing any work, and avoid

bypassing or rendering inoperative any safety or protective devices.

• If blower is operated with piping disconnected, place a

strong coarse screen over the inlet and avoid standing

in the discharge air stream.

Operating Limitations

A Roots blower or exhauster must be operated within

certain approved limiting conditions to enable continued

satisfactory performance. Warranty is contingent on such

operation.

Maximum limits for pressure, temperature and speed are

specified in TABLE 1, page 13 for various models & sizes

of blowers & exhausters. These limits apply to all units

of normal construction, when operated under standard

atmospheric conditions. Be sure to arrange connections or

taps for instruments such as thermometers and pressure or

vacuum gauges at or near the inlet and discharge connections of the unit. These, along with a tachometer, will enable

periodic checks of operating conditions.

PRESSURE – The pressure rise, between inlet and discharge, must not exceed the figure listed for the specific unit

frame size concerned. Also, in any system where the unit

inlet is at a positive pressure above atmosphere a maximum

case rating of 25 PSI gauge (1725 mbar) should not be

exceeded without first consulting Roots. Never should the

maximum allowable differential pressure be exceeded.

On vacuum service, with the discharge to atmospheric pressure, the inlet suction or vacuum must not be greater than

values listed for the specific frame size.

TEMPERATURE – Blower & exhauster frame sizes are approved only for installations where the following temperature

limitations can be maintained in service:

CAUTION: Never cover the blower inlet with your hand

or other part of body.

• Stay clear of inlet and discharge openings.

• Stay clear of the blast from pressure relief valves and

the suction area of vacuum relief valves.

• Use proper care and good procedures in handling, lifting, installing, operating and maintaining the equipment.

• Casing pressure must not exceed 25 PSI (1725 mbar)

gauge. Do not pressurize vented cavities from an external source, nor restrict the vents without first consulting

Roots.

• Do not use air blowers on explosive or hazardous

gases.

• Other potential hazards to safety may also be associated with operation of this equipment. All personnel working in or passing through the area should be trained to

exercise adequate general safety precautions.

• Measured temperature rise must not exceed listed values when the inlet is at ambient temperature. Ambient

is considered as the general temperature of the space

around the unit. This is not outdoor temperature unless

the unit is installed outdoors.

• If inlet temperature is higher than ambient, the listed

allowable temperature rise values must be reduced by

2/3 of the difference between the actual measured inlet

temperature and the ambient temperature.

• The average of the inlet and discharge temperature

must not exceed 250°F. (121°C).

• The ambient temperature of the space the blower/

motor is installed in should not be higher than 120°F

(48.8°C).

SPEED – These blowers & exhausters may be operated

at speeds up to the maximum listed for the various frame

sizes. They may be direct coupled to suitable constant

speed drivers if pressure/temperature conditions are also

within limits. At low speeds, excessive temperature rise may

be a limiting factor.

Special Note: The listed maximum allowable temperature

rise for any particular blower & exhauster may occur well

before its maximum pressure or vacuum rating is reached.

This may occur at high altitude, low vacuum or at very low

speed. The units’ operating limit is always determined by the

maximum rating reached first. It can be any one of the three:

Pressure, Temperature or Speed.

GEA19684 ISRB_2008 rev._11.15

3

Installation

Roots blowers & exhausters are treated after factory assembly

to protect against normal atmospheric corrosion. The maximum period of internal protection is considered to be one year

under average conditions, if shipping plugs & seals are not

removed. Protection against chemical or salt water atmosphere

is not provided. Avoid opening the unit until ready to start

installation, as corrosion protection will be quickly lost due to

evaporation.

If there is to be an extended period between installation and

start up, the following steps should be taken to ensure corrosion protection.

• Coat internals of cylinder, gearbox and drive end

bearing reservoir with Nox-Rust VCI-10 or equivalent.

Repeat once a year or as conditions may require. NoxRust VCI-10 is petroleum soluble and does not have to

be removed before lubricating. It may be obtained from

Daubert Chemical Co., 2000 Spring Rd., Oak Brook, Ill.

60521.

• Paint shaft extension, inlet and discharge flanges, and

all other exposed surfaces with Nox-Rust X-110 or

equivalent.

• Seal inlet, discharge, and vent openings. It is not

recommended that the unit be set in place, piped to

the system, and allowed to remain idle for extended

periods. If any part is left open to the atmosphere, the

Nox-Rust VCI-10 vapor will escape and lose its effectiveness.

• Protect units from excessive vibration during storage.

• Rotate shaft three or four revolutions every two weeks.

• Prior to start up, remove flange covers on both inlet and

discharge and inspect internals to insure absence of

rust. Check all internal clearances. Also, at this time, remove gearbox and drive end bearing cover and inspect

gear teeth and bearings for rust.

Because of the completely enclosed unit design, location of

the installation is generally not a critical matter. A clean, dry

and protected indoor location is preferred. However, an outdoor location will normally give satisfactory service. Important

requirements are that the correct grade of lubricating oil be

provided for expected operating temperatures, and that the

unit be located so that routine checking and servicing can be

performed conveniently. Proper care in locating driver and

accessory equipment must also be considered.

Supervision of the installation by a Roots Service Engineer is

not usually required for these units. Workmen with experience

in installing light to medium weight machinery should be able

to produce satisfactory results. Handling of the equipment

needs to be accomplished with care, and in compliance with

safe practices. Unit mounting must be solid, without strain or

twist, and air piping must be clean, accurately aligned and

properly connected.

Bare-shaft Units: Two methods are used to handle a unit

without base. One is to use lifting lugs bolted into the top of

the unit headplates. Test them first for tightness and fractures

by tapping with a hammer. In lifting, keep the direction of

cable pull on these bolts as nearly vertical as possible. If lifting

lugs are not available, lifting slings may be passed under the

cylinder adjacent to the headplates. Either method prevents

strain on the extended drive shaft.

Packaged Units: When the unit is furnished mounted on a

baseplate, with or without a driver, use of lifting slings passing

under the base flanges is required. Arrange these slings so

that no strains are placed on the unit casing or mounting feet,

or on any mounted accessory equipment. DO NOT use the

lifting lugs in the top of the unit headplates.

Before starting the installation, remove plugs, covers or seals

from unit inlet and discharge connections and inspect the interior completely for foreign material. If cleaning is required, finish

by washing the cylinder, headplates and impeller thoroughly

with a petroleum solvent. Turn the drive shaft by hand to

make sure that the impellers turn freely at all points. Anti-rust

compound on the connection flanges and drive shaft extension may also be removed at this time with the same solvent.

Cover the flanges until ready to connect piping.

Mounting

Care will pay dividends when arranging the unit mounting. This

is especially true when the unit is a “bare-shaft” unit furnished

without a baseplate. The convenient procedure may be to mount

such a unit directly on a floor or small concrete pad, but this generally produces the least satisfactory results. It definitely causes

the most problems in leveling and alignment and may result in a

“Soft Foot” condition. Correct soft foot before operation to avoid

unnecessary loading on the casing and bearings. Direct use of

building structural framing members is not recommended.

For blowers without a base, it is recommended that a well

anchored and carefully leveled steel or cast iron mounting

plate be provided. The plate should be at least 1 inch (25 mm)

thick, with its top surface machined flat, and large enough to

provide leveling areas at one side and one end after the unit is

mounted. It should have properly sized studs or tapped holes

located to match the unit foot drilling. Proper use of a high

quality machinist’s level is necessary for adequate installation.

With the mounting plate in place and leveled, set the unit

on it without bolting and check for rocking. If it is not solid,

determine the total thickness of shims required under one foot

to stop rocking. Place half of this under each of the diagonallyopposite short feet, and tighten the mounting studs or screws.

Rotate the drive shaft to make sure the impellers turn freely.

If the unit is to be direct coupled to a driving motor, consider

the height of the motor shaft and the necessity for it to be

aligned very accurately with the unit shaft. Best unit arrangement is directly bolted to the mounting plate while the driver

is on shims of at least 1/8 inch (3mm) thickness. This allows

adjustment of motor position in final shaft alignment by varying

the shim thickness.

Aligning

When unit and driver are factory mounted on a common

baseplate, the assembly will have been properly aligned and is to

be treated as a unit for leveling purposes. Satisfactory installation can be obtained by setting the baseplate on a concrete

slab that is rigid and free of vibration, and leveling the top of the

base carefully in two directions so that it is free of twist. The slab

must be provided with suitable anchor bolts. The use of grouting

under and partly inside the leveled and shimmed base is recommended.

4

GEA19684 ISRB_2008 rev._11.15

It is possible for a base-mounted assembly to become

twisted during shipment, thus disturbing the original alignment. For this reason, make the following checks after the

base has been leveled and bolted down. Disconnect the drive

and rotate the unit shaft by hand. It should turn freely at all

points. Loosen the unit foot hold-down screws and determine

whether all feet are evenly in contact with the base. If not,

insert shims as required and again check for free impeller rotation. Finally, if unit is direct coupled to the driver, check shaft

and coupling alignment carefully and make any necessary

corrections.

In planning the installation, and before setting the unit,

consider how piping arrangements are dictated by the unit

design and assembly. Drive shaft rotation must be established

accordingly and is indicated by an arrow near the shaft.

Typical arrangement on vertical units has the drive shaft at the

top with counterclockwise rotation and discharge to the left.

Horizontal units are typically arranged with the drive shaft at

the left with counterclockwise rotation and discharge down.

See Figure 4 for other various unit arrangements and possible

conversions.

When a unit is DIRECT COUPLED to its driver, the driver

RPM must be selected or governed so as not to exceed the

maximum speed rating of the unit. Refer to Table 1, page 13

for allowable speeds of various unit sizes.

A flexible type coupling should always be used to connect the

driver and unit shafts.

When direct coupling a motor or engine to a blower you must

ensure there is sufficient gap between the coupling halves and

the element to prevent thrust loading the blower bearings.

When a motor, engine or blower is operated the shafts may

expand axially. If the coupling is installed in such a manner

that there is not enough room for expansion the blower shaft

can be forced back into the blower and cause the impeller

to contact the gear end headplate resulting in damage to the

blower. The two shafts must be in as near perfect alignment

in all directions as possible, and the gap must be established

with the motor armature on its electrical center if end-play exists. Coupling manufacturer’s recommendations for maximum

misalignment, although acceptable for the coupling, are

normally too large to achieve smooth operation and maximum

life of the blower.

The following requirements of a good installation are

recommended. When selecting a coupling to be fitted to the

blower shaft Roots recommends a taper lock style coupling

to ensure proper contact with the blower shaft. Coupling

halves must be fitted to the two shafts with a line to line thru

.001” interference fit. Coupling halves must be warmed up

per coupling manufacturer’s recommendations. Maximum

deviation in offset alignment of the shafts should not exceed

.005” (.13 mm) total indicator reading, taken on the two

coupling hubs. Maximum deviation from parallel of the inside

coupling faces should not exceed .001” (.03 mm) when

checked at six points around the coupling.

When a unit is BELT DRIVEN, the proper selection of sheave

diameters will result in the required unit speed. When selecting

a sheave to be fitted to the blower shaft Roots recommends

a taper lock style sheave to insure proper contact with the

blower shaft. This flexibility can lead to operating temperature

problems caused by unit speed being too low. Make sure

the drive speed selected is within the allowable range for the

specific unit size, as specified under Table 1, page 13.

Belt drive arrangements should employ two or more V-belts

running in grooved sheaves. Installation of the driver is less

critical than for direct coupling, but its shaft must be level and

parallel with the unit shaft. The driver should be mounted

on the inlet side of a vertical unit (horizontal piping) and

on the side nearest to the shaft on a horizontal unit. The

driver must also be mounted on an adjustable base to permit

installing, adjusting and removing the V-belts. To position the

driver correctly, both sheaves need to be mounted on their

shafts and the nominal shaft center distance known for the

belt lengths to be used.

CAUTION: Drive couplings and sheaves (pulleys) should have

an interference fit to the shaft of the blower (set screw types

of attachment generally do not provide reliable service.) It is

recommended that the drive coupling or sheave used have a

taper lock style bushing which is properly sized to provide the

correct interference fit required. Drive couplings, that require

heating to fit on the blower shaft, should be installed per

coupling manufacturer recommendations. A drive coupling or

sheave should not be forced on to the shaft of the blower as

this could affect internal clearances resulting in damage to the

blower.

Engine drive applications often require special consideration to drive coupling selection to avoid harmful torsional vibrations. These vibrations may lead to

blower damage if not dampened adequately. It is often

necessary to install a fly-wheel and/or a torsionally soft

elastic element coupling based on the Engine manufacturer recommendations.

The driver sheave should also be mounted as close to its

bearing as possible, and again should fit the shaft correctly.

Position the driver on its adjustable base so that 2/3 of the

total movement is available in the direction away from the unit,

and mount the assembly so that the face of the sheave is

accurately in line with the unit sheave. This position minimizes

belt wear, and allows sufficient adjustment for both installing

and tightening the belts. After belts are installed, adjust their

tension in accordance with the manufacturer’s instructions.

However, only enough tension should be applied to prevent

slippage when the unit is operating under load. Excessive

tightening can lead to early bearing concerns or shaft breakage.

Before operating the drive under power to check initial belt

tension, first remove covers from the unit connections. Make

sure the interior is still clean, then rotate the shaft by hand.

Place a coarse screen over the inlet connection to prevent

anything being drawn into the unit while it is operating, and

avoid standing in line with the discharge opening. Put oil in the

sumps per instructions under LUBRICATION.

Piping

Before connecting piping, remove any remaining anti-rust

compound from Unit connections. Clean pipe should be no

smaller than unit connections. In addition, make sure it is

free of scale, cuttings, weld beads, or foreign material of any

kind. To further guard against damage to the unit, especially

when an inlet filter is not used, install a substantial screen

GEA19684 ISRB_2008 rev._11.15

5

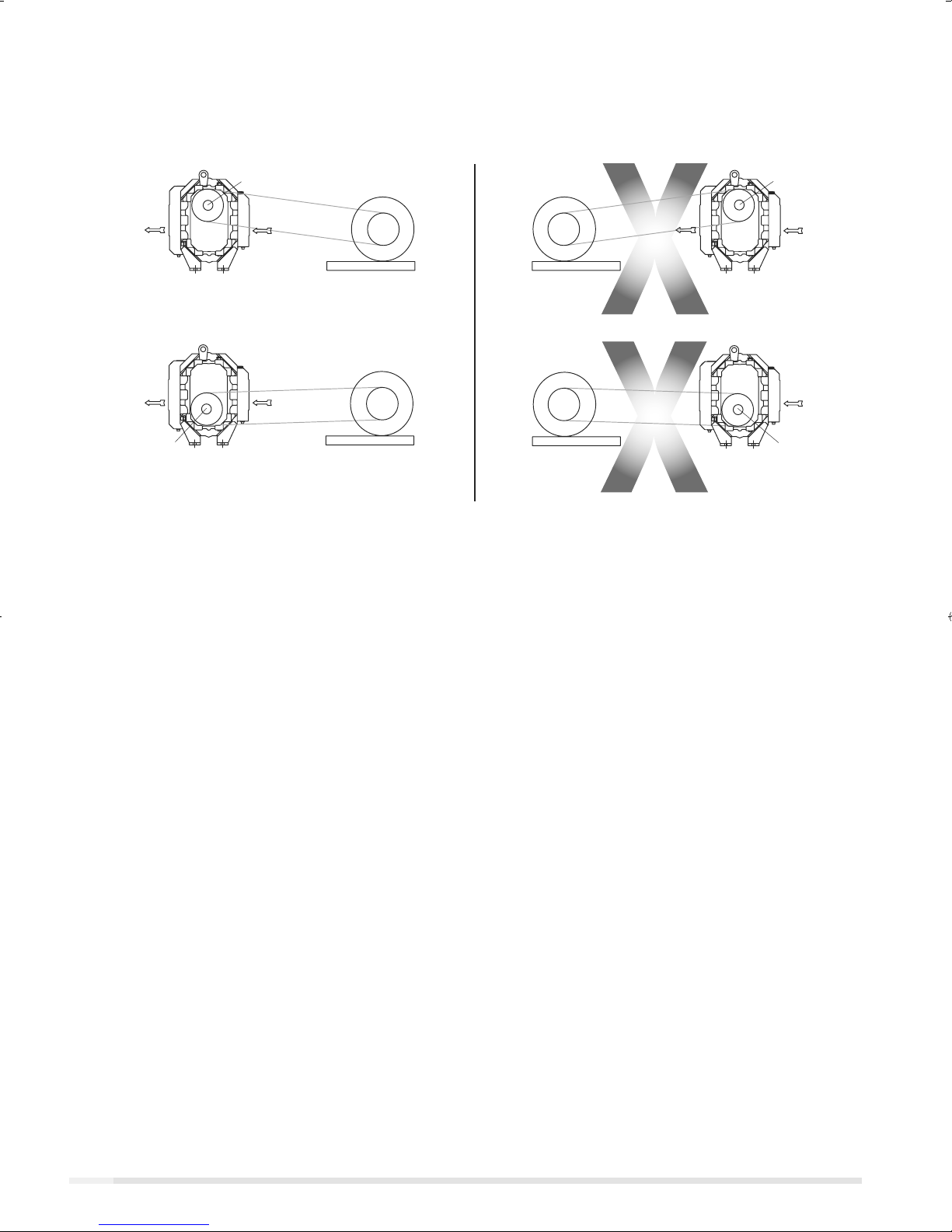

Fig. 1 - Acceptable Blower Drive Arrangement Options

Acceptable Unacceptable

Top Shaft

INLETDISCHARGE

Motor on Inlet Side of Blower (Top Shaft)

DISCHARGE

Bottom Shaft

INLET

Motor on Inlet Side of Blower (Bottom Shaft)

Above are suggested locations for available accessories.

of 16 mesh backed with hardware cloth at or near the inlet

connections. Make provisions to clean this screen of collected

debris after a few hours of operation. It should be removed

when its usefulness has ended, as the wire will eventually

deteriorate and small pieces going into the unit may cause

serious damage.

Pipe flanges or male threads must meet the unit connections

accurately and squarely. DO NOT attempt to correct misalignment by springing or cramping the pipe. In most cases this

will distort the unit casing and cause impeller rubbing. In severe cases it can prevent operation or result in a broken drive

shaft. For similar reasons, piping should be supported near

the unit to eliminate dead weight strains. Also, if pipe expansion is likely to occur from temperature change, installation of

flexible connectors or expansion joints is advisable.

Figure 3, page 11 represents an installation with all accessory

items that might be required under various operating conditions. Inlet piping should be completely free of valves or other

restrictions. When a shut-off valve can not be avoided, make

sure a full size vacuum relief is installed nearest the unit inlet.

This will protect against unit overload caused by accidental

closing of the shut-off valve.

Need for an inlet silencer will depend on unit speed and pressure, as well as sound-level requirements in the general

surroundings. An inlet filter is recommended, especially in

dusty or sandy locations. A discharge silencer is also normally

suggested, even though Whispair units operate at generally

Top Shaft

DISCHARGE

INLET

Motor on Discharge Side of Blower (Top Shaft)

INLETDISCHARGE

Bottom Shaft

Motor on Discharge Side of Blower (Bottom Shaft)

lower noise levels than conventional rotary blowers. Specific

recommendations on silencing can be obtained from your

local Roots distributor.

Discharge piping requires a pressure relief valve, and should

include a manual unloading valve to permit starting the unit

under no-load conditions. Reliable pressure/vacuum gauges

and good thermometers at both inlet and discharge are

recommended to allow making the important checks on unit

operating conditions. The back-pressure regulator shown in

Figure 3, page 11 is useful mainly when volume demands

vary while the unit operates at constant output. If demand is

constant, but somewhat lower than the unit output, excess

may be blown off through the manual unloading valve.

In multiple unit installations where two or more units

operate with a common header, use of check valves is

mandatory. These should be of a direct acting or free swing-

ing type, with one valve located in each line between the

unit and header. Properly installed, they will protect against

damage from reverse rotation caused by air and material

back-flow through an idle unit.

After piping is completed, and before applying power, rotate

the drive shaft by hand again. If it does not move with uniform

freedom, look for uneven mounting, piping strain, excessive

belt tension or coupling misalignment.

DO NOT operate the unit at this time unless it has been

lubricated per instructions.

6

GEA19684 ISRB_2008 rev._11.15

Lubrication

Due to sludge build-up and seal leakage problems,

Roots recommendation is DO NOT USE Mobil SHC

synthetic oils in Roots blowers.

LUBRICATION: For Units with Splash Lubrication on

Both Ends.

• The specified and recommended oil is Roots Synthetic

oil of correct viscosity per Table 2, page 13.

• The proper oil level should be half way or middle of the

sight gauge when the blower is not operating. DO NOT

OVERFILL OIL SUMP/S as damage to the blower may

occur.

• Oil level may rise or fall in the gauge during operation to

an extent depending somewhat on oil temperature and

blower speed.

• It is recommended that the oil be changed after initial

100 hours of operation.

• Proper service intervals of the oil thereafter are based

on the discharge air temperature of the blower. Please

refer to the information below to properly determine the

oil service intervals.

• If you choose to use another oil other than the specified

and recommended Roots Synthetic, use a good grade

of industrial type non-detergent, rust inhibiting, antifoaming oil and of correct viscosity per Table 2, page

13.

• Roots does NOT recommend the use of automotive

type lubricants, as they are not formulated with the

properties mentioned above.

Normal life expectancy of the specified and recommended

Roots Synthetic oil is approximately 6000 hours with an oil

temperature of 180°F (82°C) or less. As the oil temperature

increases by increments of 15°F (8°C), the oil life is reduced

by half for each 15°F (8°C) increase. Example: Oil temperatures of 195°F (90.5°C) will produce a life expectancy

reduced by half or 3000 hours oil service life.

Normal life expectancy of petroleum based oils is about

2000 hours with an oil temperature of about 180°F (82°C).

As the oil temperature increases by increments of 15°F

(8°C), the life is reduced by half for each 15°F (8°C) increase.

Example: Oil temperatures of 195°F (90.5°C) will produce life

expectancy reduced by half or 1000 hours oil service life.

NOTE: To estimate oil temperature, multiply the discharge

temperature of the blower by 0.88. Example: if the discharge

air temperature of the blower is 200° F, it is estimated that

the oil temperature is 176° F.

High ambient temperatures contribute to increased lubrication

sump temperatures. In situations such as blowers in a enclosure, blowers exposed to radiant heat from other sources,

blowers installed in areas with poor air circulation or ambient

temperatures above 80°F the lubrication sump temperature

should be measured rather than fully rely on the calculation.

Bearings and oil seals are lubricated by the action of the

timing gears or oil slingers which dip into the main oil sumps

causing oil to splash directly on gears and into bearings

and seals. A drain port is provided below each bearing to

prevent an excessive amount of oil in the bearings. Seals

located inboard of the bearings in each headplate effectively

retain oilwithin the sumps. Any small leakage that may occur

should the seals wear passes into a cavity in each vented

headplate and is drained downward. Oil sumps on each end

of the blower are filled by removing top vent plugs, Item (21),

and filling until oil reaches the middle of the oil level sight

gauge, Item (37).

Initial filling of the sumps should be accomplished with the

blower not operating, in order to obtain the correct oil level.

Approximate oil quantities required for blowers of the various

models and configurations are listed in Table 3, page 13.

The oil level should not fall below the middle of the site

gauge when the blower is idle.

Proper lubrication is usually the most important single

consideration in obtaining maximum service life and satisfactory operation from the unit. Unless operating conditions are

severe, a weekly check of oil level and necessary addition of

lubricant should be sufficient. During the first week of operation, check the oil levels in the oil sumps about once a day,

and watch for leaks. Replenish as necessary. Thereafter, an

occasional check should be sufficient.

More frequent oil service may be necessary if the blower is

operated in a very dusty location.

*Roots Synthetic oil is superior in performance to petroleum

based products. It has high oxidation stability, excellent corrosion protection, extremely high film strength and low coefficient of friction. Typical oil change intervals are increased

2-3 times over petroleum based lubricants. Also, Roots

Synthetic oil is 100% compatible with petroleum based oils.

Simply drain the oil in the blower and refill the reservoirs with

Roots Synthetic oil to maintain optimum performance of

your Roots blower.

GEA19684 ISRB_2008 rev._11.15

7

Loading...

Loading...