Howden Roots 412 HPT Installation, Operation & Maintenance Manual

www.howden.com

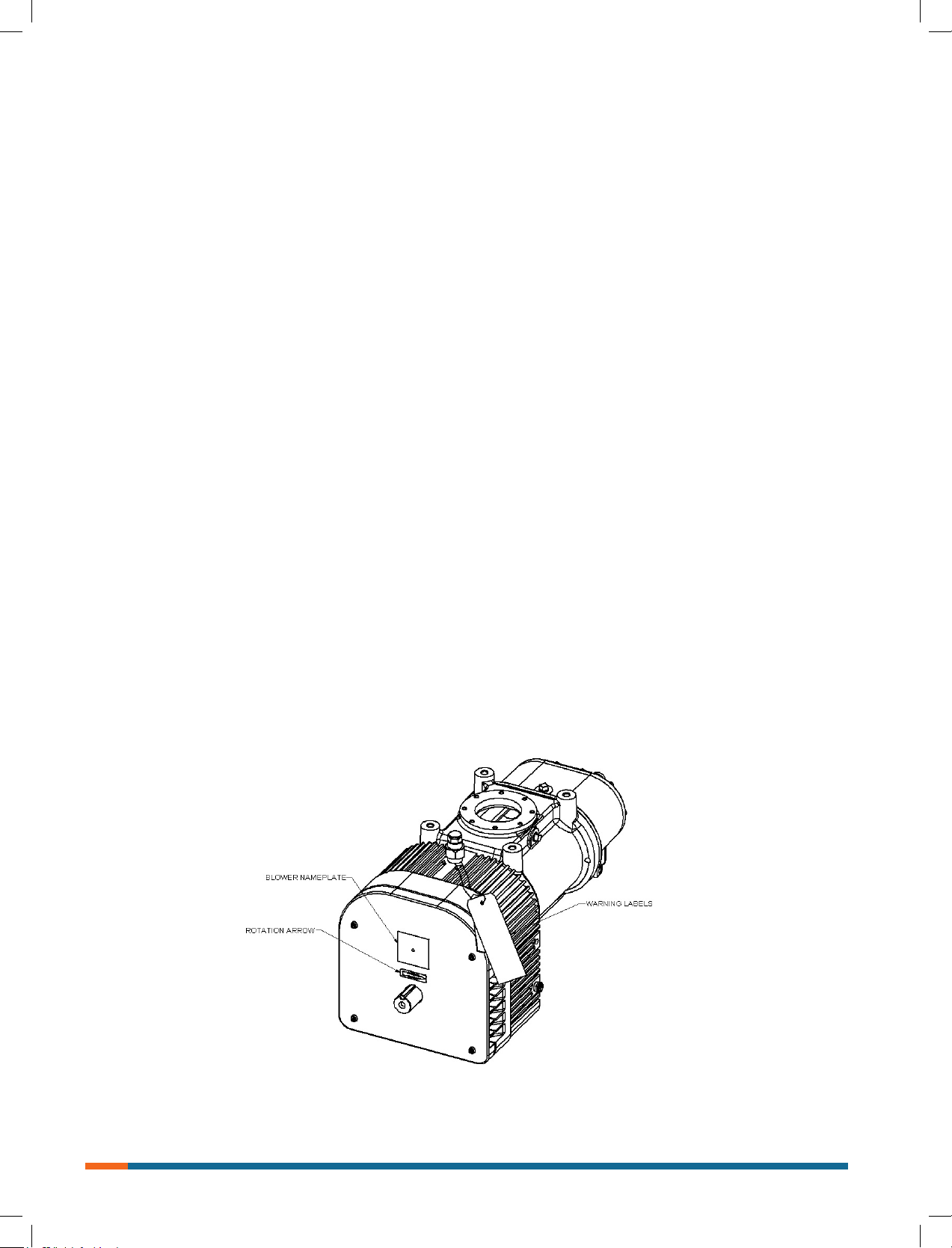

Roots® 412 HPT Blower

Installation Operation & Maintenance Manual

ISRB-2009, Rev. 02_17.

Contents

Information Summary ...............................................................2

Safety Precautions ....................................................................3

Operating Limitations ................................................................3

Installation ........................................................................... 4 - 5

Operation......................... .........................................................6

Lubrication........................ ........................................................6

Troubleshooting ........................................................................ 8

Inspection & Maintenance ........................................................9

Parts List........................................ .........................................10

Figures..................................... ......................................... 11-14

Outline Drawing........................... ...........................................15

Do these things to get the most from your Roots Blower

• Check shipment for damage. If found, le claim with

carrier and notify Howden.

• Unpack shipment carefully, and check contents against

Packing List. Notify Howden if a shortage appears.

• Store in a clean, dry location until ready for installation.

Lift by methods discussed under INSTALLATION to

avoid straining or distorting the equipment. Keep covers

on all openings. Protect against weather and corrosion

if outdoor storage is necessary.

• Read OPERATING LIMITATIONS and INSTALLATION

sections in this manual and plan the complete

installation.

• Provide for adequate safeguards against accidents

to persons working on or near the equipment

during both installation and operation. See SAFETY

PRECAUTIONS.

• Install all equipment correctly. Foundation design

must be adequate and piping carefully done. Use

recommended accessories for operating protection.

Roots products are sold subject to the current General Terms of Sale, ES104 and Warranty Policy WP-5020.

Copies are available upon request.

• Make sure both driving and driven equipment is

correctly lubricated before start-up. See LUBRICATION.

• In event of trouble during installation or operation, do

not attempt repairs of Roots furnished equipment.

Notify Roots, giving all nameplate information plus an

outline of operating conditions and a description of the

trouble. Unauthorized attempts at equipment repair

may void Roots warranty.

• Units out of warranty may be repaired or adjusted by

the owner. Good inspection and maintenance practices

should reduce the need for repairs.

NOTE: Information in this manual is correct as of the date

of publication. Howden reserves the right to make design or

material changes without notice, and without obligation to make

similar changes on equipment of prior manufacture.

For your nearest Howden Oce, dial our Customer Service

Hot Line toll free in the U.S.; 1 877 363 7668 or

direct +1 832 590 2600.

2

ISRB-2009, Rev. 02_17.

Safety Precautions

It is important that all personnel observe safety precautions

to minimize the chances of injury. Among many

considerations, the following should be particularly noted:

• Blower casing and associated piping or accessories

may become hot enough to cause major skin burns

on contact.

• Internal and external rotating parts of the blower and

driving equipment can produce serious physical injuries.

Do not reach into any opening in the blower while it is

operating, or while subject to accidental starting.

Protect external moving parts with adequate guards.

• Disconnect power before doing any work, and avoid

bypassing or rendering inoperative any safety or

protective devices.

• If blower is operated with piping disconnected, place a

strong coarse screen over the inlet and avoid standing

in the discharge air stream.

•

CAUTION: Never cover the blower inlet with your

hand or other part of body.

• Stay clear of inlet and discharge openings.

• Stay clear of the blast from pressure relief valves and

the suction area of vacuum relief valves.

• Use proper care and good procedures in handling,

lifting, installing, operating and maintaining the

equipment.

• Casing pressure must not exceed 25 PSI (1725 mbar)

gauge. Do not pressurize vented cavities from an

external source, nor restrict the vents without rst

consulting Roots.

• Do not use air blowers on explosive or hazardous

gases.

• Other potential hazards to safety may also be

associated with operation of this equipment.

All personnel working in or passing through the area

should be trained to exercise adequate general

safety precautions.

Operating Limitations

A Howden Roots blower must be operated within certain

approved limiting conditions to enable continued satisfactory

performance. Warranty is contingent on such operation.

Maximum limits for pressure, temperature and speed are

specied in TABLE 1 for this truck application blower.

These limits apply to this blower of normal construction,

when operated under standard operating conditions.

Be sure to arrange connections or taps for instruments

used to measure temperature, pressure and vacuum at

or near the inlet and discharge connections of the blower.

These, along with tachometer will enable period checks of

operating conditions.

Pressure

The pressure rise, between inlet and discharge, must not

exceed the gure listed in TABLE 1.

• The term “intermittent operation” is dened as operation

for no longer than 10 seconds at maximum pressure list

in TABLE 1, provided that the inlet restriction (lter

pressure drop, etc.) does not exceed 20” (508 mm)

of water.

• Also, in any system where the blower inlet is at a

positive pressure above atmospheric, a maximum

case rating of 25 PSI gauge (1725 mbar) should not

be exceeded. Never should the maximum dierential

pressure be exceeded.

Temperature

Blowers are approved only for installations where following

temperature limits can be maintained in service.

• Measured temperature rise must not exceed listed

values when inlet is at ambient temperature. Ambient

temperature is considered as the general temperature

of the space around the unit. This is not outdoor

temperatures unless unit is mounted outdoors.

• If inlet temperature is higher than ambient, the listed

allowable temperature rise values must be reduced by

2/3 of the dierence between the actual measured inlet

temperature and the ambient temperature. Example:

Tinlet = 150 °F and Tambient = 60 °F; Temperature rise

limit, ∆Tnew = 350 – 2/3(150-60) = 290 °F.

• The ambient temperature of the space the blower/

motor is installed in should not be higher than

120 °F (49 °C).

Speed

This blower may be operated at speeds up to the maximum

listed in TABLE 1. Blower may be direct coupled to suitable

constant or variable speed driver if pressure/temperature

conditions are also within limits. At low speeds, excessive

temperature rise may be a limiting factor.

Special Note: The listed maximum temperature rise may

occur well before its maximum pressure is reached. This

may occur at high altitude, low vacuum or at very low

speed. The blower operating limit is always determined by

the maximum rating reached rst. It can be any one of the

three: Pressure, Temperature or Speed.

3

ISRB-2009, Rev. 02_17.

Installation

Howden Roots blowers arrive without lubrication in the sump,

see lubrication section for details.

Howden Roots blowers are treated after factory assembly to

protect against normal atmospheric corrosion. The maximum

period of protection is considered to be one year under

average conditions, if shipping plugs & seals or not removed.

Protection against chemical or salt water atmosphere is not

approved. Avoid opening unit until ready to start installation,

as corrosion protection will be quickly lost due to evaporation.

If there is to be an extended period between installation and

start-up, following steps should be taken to ensure corrosion

protection.

• Coat intervals of cylinder, gearbox and drive end bearing

reservoir with Nox-Rust VCI-10 or equivalent. Repeat

once a year or as conditions may require. Nox-Rust

VCI-10 is petroleum soluble and does not have to be

removed before lubricating. It may be obtained from

Daubert Chemical Co., 2000 Spring Rd., Oak Brook,

IL. 60521.

• Paint shaft extension, inlet & discharge anges and any

other exposed surfaces with Nox-Rust X-110 or

equivalent.

• Seal inlet, discharge and vent openings. It is not

recommended that blower be set in place, piped to the

system, and allowed to remain idle for extended periods.

If any part is left open to the atmosphere, the Nox-Rust

VCI-10 vapor will escape and lose its eectiveness.

• Protect blower from excessive vibration during storage.

• Rotate shaft three to four revolutions every two weeks.

• Prior to start up, remove ange covers on both inlet &

discharge anges and covers on vent opening and

inspect internal clearances. Also, at this time, inspect

gear box intervals thru breather location for rust.

Because of the completely enclosed blower design, location

of the installation is generally not a critical matter. A clean,

dry and protected indoor location is preferred; however, an

outdoor location will normally give satisfactory service. Important requirements are that the correct grade lubricating oil be

provided for expected operating temperatures, and that the

blower be located so that routine checking and servicing can

be performed conveniently. Proper care in locating drive and

accessory equipment must also be considered.

Supervision of the installation by a Howden Roots Service

Engineer is not usually required for these units. Workmen with

experience installing light to medium weight machinery should

be able to produce satisfactory results. Handling of

equipment needs to be accomplished with care, and in

compliance with safe practices. Unit mounting must be solid,

without strain or twist, and air piping must be clean, accurately

aligned and properly connected.

Mounting

Two methods are used to handle a unit. One is to install lifting

lugs into the (4) 5/8-11 tapped holes in top of the unit. Test the

lifting lugs for tightness and potential fractures by tapping with

hammer. In lifting, keep the direction of cable pull on these

bolts as nearly vertical as possible. If unable to use the tapped

holes in top of unit for lifting, lifting slings or a special cradle

may be passed under the unit for vertical lift.

4

ISRB-2009, Rev. 02_17.

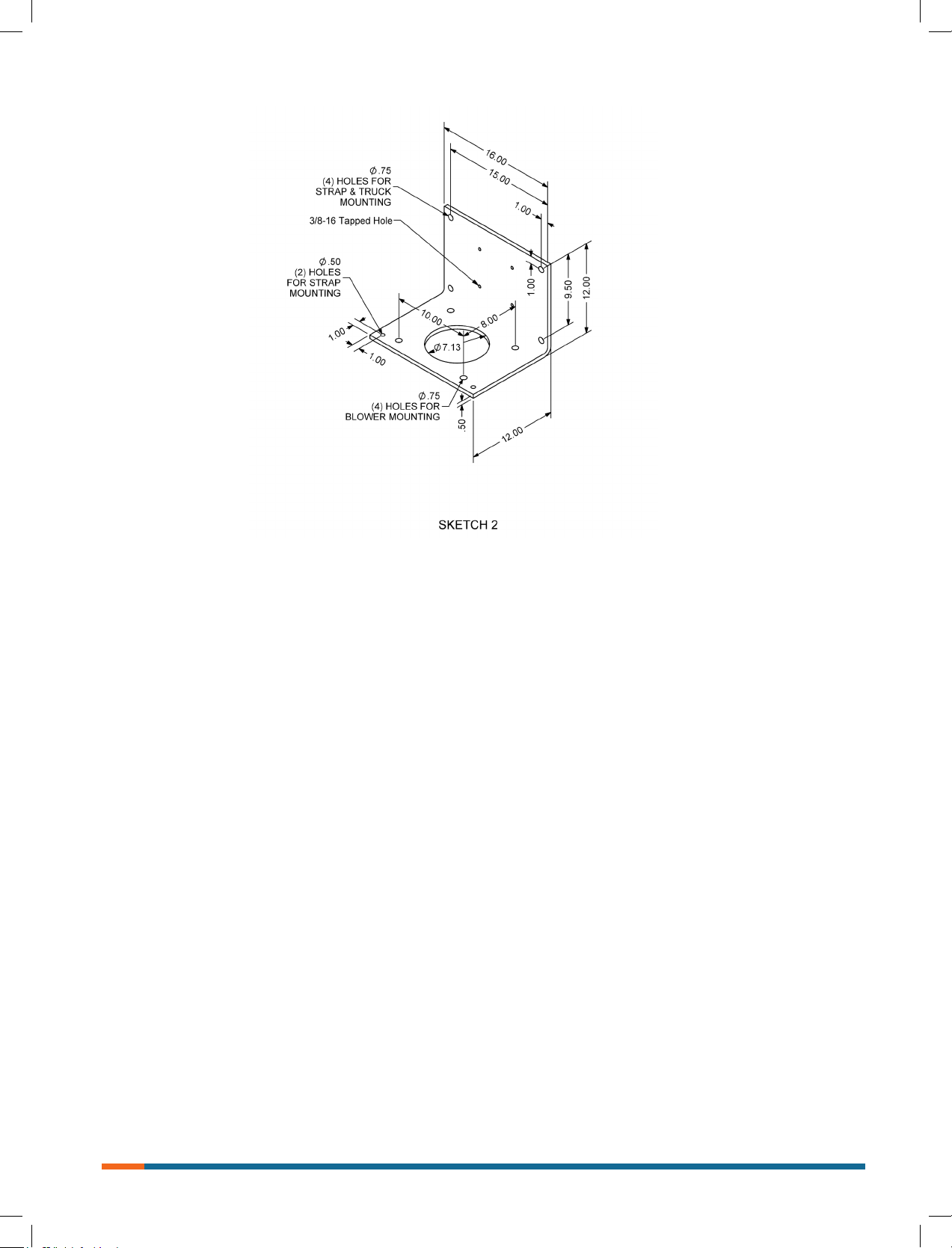

Bottom inlet, top discharge is standard orientation with CCW

rotation on input drive shaft. Blower can be mounted either

on roadside or curbside of truck chassis. Exact installation

instructions cannot be given because of the variety of truck

chassis available. See SKETCH 1 for basic details. Units are

typically held in place on truck chassis by use of “L” shaped

mounting bracket; see SKECH #2 for basic details.

Check output speed range of PTO. It must be for the

blower range.

The blower should be parallel to the truck frame to minimize

vibration.

The PTO shaft must be within the manufacturer’s angularity

limits, not to exceed 5 degrees in the horizontal plane and

3 degrees in the vertical plane.

Brace mounting securely to reduce vibration.

Be sure air lter, oil level gauge, gear case breather and oil

drain plug is not obstructed for normal maintenance.

Do not weld on the blower or base, bearings can be damaged

by the passage of current.

Piping

Install an adequate air lter on blower inlet. Servicing the air

lters is one the most important maintenance operations.

Servicing frequency of lter elements is not time predictable

and must be by the user, depending on dust and moisture

conditions but pressure drop shall never exceed 20” (508 mm)

of water before servicing. Dry lter element life is typically 50

to 300 hours before replacement is necessary. Only replace,

do not reuse dry lter elements via cleaning. Do not allow oil,

grease or solvents to contact the element. Do not operate

blower with damaged lter seals or element. Do not operate

blower without lter element.

WARNING: All piping and accessories downstream of blower

should be rated for the internal pressures being subjected

during full operation.

Insure that inlet and discharge piping are clear, clean and

air tight. Do not allow dirt to enter the blower during piping

operations.

Pressure service, install an air relief valve in discharge line as

close to blower as possible. Vacuum service, install an air relief

valve in inlet line as close to blower as possible. Do not use

any caps, covers, plugs or valves between the blower and

relief valve.

Install a check valve in the discharge line after the relief valve

to prevent back ow of material into the blower and to prevent

reverse rotation of the blower.

Provide a discharge bypass valve to the atmosphere for air

bleed o to lower pressure when too high blower speed thus

ow is present.

Pressure service, install an accurate pressure gauge at or near

the blower discharge. Vacuum service, install an accurate

vacuum gauge at or near the blower inlet.

Install an accurate vacuum gauge or indicator at inlet so able

measure pressure drop across inlet lter.

Provide an adequate sized discharge line. Use as few of

bends as possible; when bends are necessary, use long

radius bends.

Make provisions in piping to allow for expansion as near to

the blower as possible.

Use a dust cover at the nal discharge opening when hose

is removed.

Install discharge silencer after the check valve when additional

noise reduction is required.

5

Loading...

Loading...