Howden ENF, ELF, ELFA, E-series Service Manual

Service Manual

Howden 24-07.030r04E 1/25

Warning

Failure to comply with these instructions

could cause serious bodily harm or

property damage and will void the

warranty.

Installation and Maintenance

E-series Axial Flow Cooling Fans

Howden 24-07.030r04 2/25

E-series Axial Flow Cooling Fans

Service Manual

INDEX

I. General Information ........................................................................................................................ 3

Introduction ........................................................................................................................................ 3

Description ......................................................................................................................................... 3

Options / Accessories (at extra cost) ................................................................................................. 3

Field Service ...................................................................................................................................... 3

II. Receiving / Handling / Storage / Disposal .................................................................................... 4

Fan identification ............................................................................................................................... 4

Receiving and unloading ................................................................................................................... 5

Handling ............................................................................................................................................. 5

Storage .............................................................................................................................................. 5

De-commissioning ............................................................................................................................. 6

Exploded view and part list ................................................................................................................ 7

III. Installation ..................................................................................................................................... 8

Required Tools .................................................................................................................................. 8

Rotation and flow direction ................................................................................................................ 8

Preparation ........................................................................................................................................ 8

Coupling flange with parallel bore ..................................................................................................... 9

Coupling flange with tapered bushing ............................................................................................... 9

Hub-plate installation ....................................................................................................................... 10

Blades installation..........................................................................................................................12

Minimum tip-clearance .................................................................................................................... 14

Impeller diameter reduction ............................................................................................................. 15

Retaining plate ................................................................................................................................. 15

Balancing ......................................................................................................................................... 16

IV. Commissioning ............................................................................................................................ 16

V. Preventive Maintenance .............................................................................................................. 18

VI. Contact Howden ......................................................................................................................... 19

VII. Trouble Shooting ....................................................................................................................... 20

VIII. Overview Tightening Torques ................................................................................................. 23

IX. Hardware Overview .................................................................................................................... 24

X. Guideline for acceptable vibration levels of cooling fans in application category BV-3

(according ISO 14694) ...................................................................................................................... 25

XI. Document Version Control ........................................................................................................ 25

Howden 24-07.030r04 3/25

E-series Axial Flow Cooling Fans

Service Manual

Allowable operating temperature

Min.

Max.

All diameters

- 20°C

+ 65°C

- 4°F

+ 149°F

Allowable incidental upset temp. (<12 h)

Max.

Max.

All diameters

+ 80°C

+ 176°F

Maximum tip speed

(As well depends on duty point)

m/s

ft/min

ENF

70

13780

ELF

60

11811

ELFA

46

9055

I. GENERAL INFORMATION

Introduction

This manual provides information necessary to

install, operate and maintain E-series axial

flow cooling fans. Maintenance guidelines and

procedures are given so that your equipment

will operate efficiently, with a minimum of repair or replacement requirements.

Description

Howden E-series fans are most widely used

and are available in three different blade profiles, ENF, ELF & ELFA. Whether you are

looking for a highly efficient impeller and/or a

low noise solution, the E-series offers you a

choice. The fibreglass reinforced polyester

blades have an integral shaft, which eliminates

concentration of stress at mechanical joints.

The FRP blade material offers superior damping of mechanical vibrations and of structure

borne noise compared with metal blades, pro-

longing the fan‟s lifetime. The fan blades are

connected to a polyurethane coated steel hub

with aluminium clamping pieces and A2

stainless steel or ST8.8 galvanised steel Ubolts, nuts and washers for an easy installation

and manual blade pitch variation. The

impellers are connected to the drive shaft by

means of a polyurethane coated cast iron coupling flange, with a cylindrical bore and electrogalvanised hardware.

Howden E-series impellers are in compliance

with EC directive 94/9EC (ATEX 100) for the

equipment of level group II, Category 2, potentially explosive environment class 01. Also respect the instructions in paragraph IV commissioning.

Note: The nomenclature is ‘cooling fans’,

however Howden supplies impellers only. Impellers are components in the sense of European Machinery Directive 98/37/EC.

Table 1: Description table E-series

Options / Accessories (at extra cost)

Coupling flange with tapered bushing

connection, instead of standard cylindrical

bore connection.

Epoxy coating.

A4 stainless steel hardware.

Baked epoxy coating on aluminium

clamping pieces.

Polyurethane leading edge protection for

wet applications or stainless steel leading

edge protection for severe erosion.

Retaining plates to secure the impeller to

the drive shaft.

Bolted clamping piece fastening instead

of location pins, for horizontal drive shaft

applications.

Special impellers for fan selections out-

side the standard design range.

Tools (torque wrench or an inclinometer

for blade pitch adjustment).

Field Service

Howden Service maintains a staff of experi-

enced field service personnel. Their expert

knowledge may be of great assistance at inspection, installation, or to get your fan unit

back in service with a minimum of delay.

Service Manual

Howden 24-07.030r04E 4/25

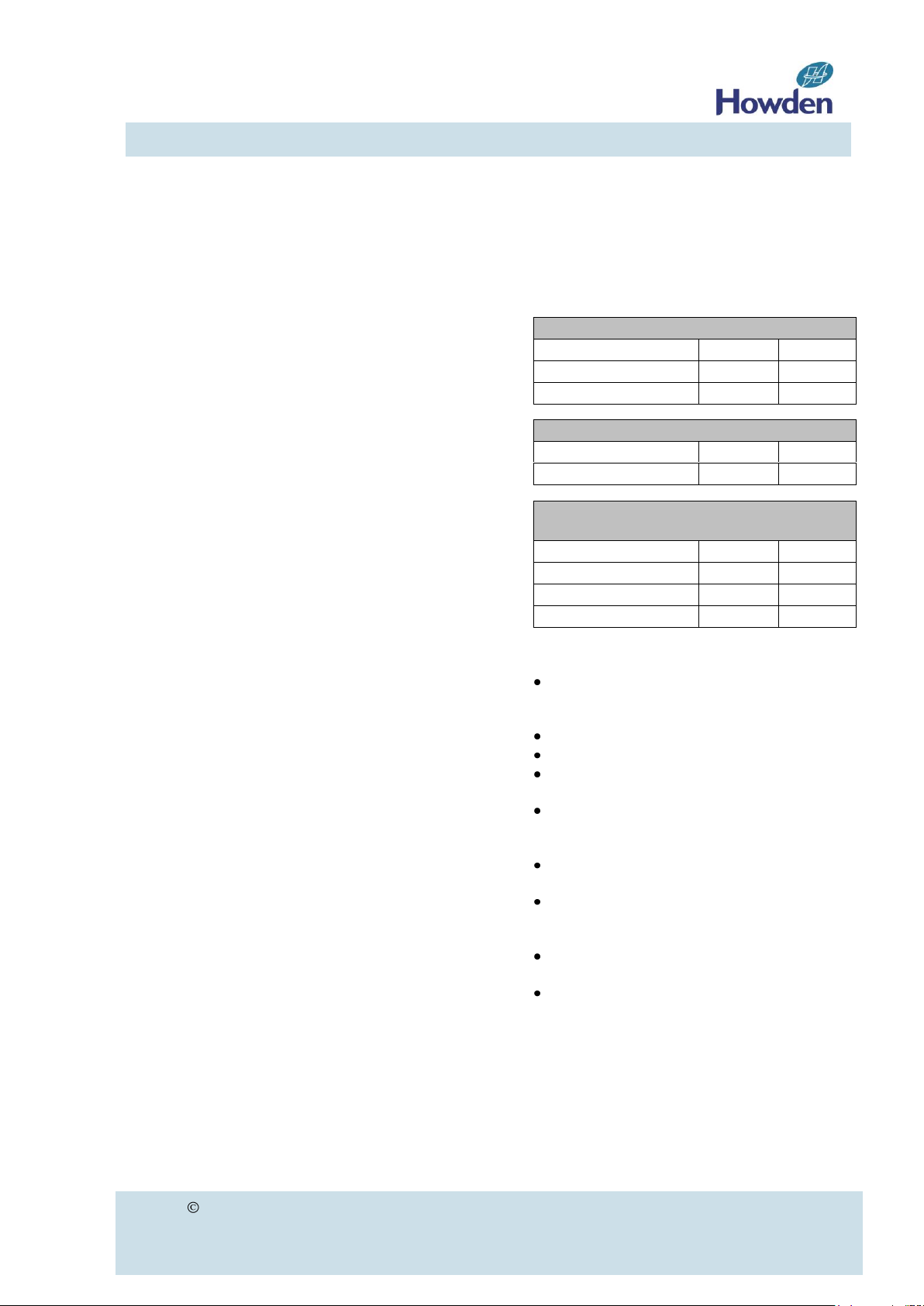

Leading edge protection for wet cooling tower applications

Number of blades: 3,4,5,6,7,8,9

Impeller type: ENF, ELF, ELFA

Fan diameter: metric or imperial (>100 = mm, <100 = feet)

HOWDEN COOLING FANS

Hengelo, The Netherlands

Phone +31-74 2556000

Fax +31-74 2556060

Order No. 103459

Fan type 30ENF6 EP

II. RECEIVING / HANDLING / STORAGE / DISPOSAL

Fan identification

The fan identification code allows identification of the main characteristics of the fan. You can find

this code on the order acknowledgement and packing list included with the shipment.

FAN 30ENF6 EP

Another example:

FAN 8910ELF8

Identifies an ELF fan with a diameter of 8910 mm, 8 blades and without leading edge protection (EP)

The impellers are provided with a product identification plate fixed to the hub plate according the

example below. The unique order number permits future identification of the fan supplied.

Howden 24-07.030r04 5/25

E-series Axial Flow Cooling Fans

Service Manual

Receiving and unloading

Upon unloading this equipment, inspect it for

damage. If damage occurred, file a claim immediately against the carrier and mark the bill

of lading accordingly.

Superficial transport damages like scratches

or small holes may be repaired with touch-up

material (PU filler, e.g. Sikaflex 252).

All consignments are accompanied by a

packing list with the following data:

Order number of the Customer and of

Howden.

Impeller type (fan identification code)

Parts supplied by Howden.

The delivered goods shall be checked upon

arrival for full compliance with the order

and/or the parts count and description stated

on the packing list.

Shortages should be reported to your Howden Contract Engineer within 2 weeks from

receipt of shipment at destination.

Handling

to allow easy container loading / unloading.

Through these hoist eyes, one can pull the

bunk beds from the container without damaging the fan blades or the crates.

Figure 2

The fan blades can be lifted from the packing

by placing a single sling around the blade.

Position the sling as such that the blade tip is

somewhat hanging down which makes it

easier to move the blades around.

Fan blades of impellers smaller than 26 ft.,

are packed in strong wooden cases or crates.

Fan blades of E-series impellers larger than

26 ft. are packed in so-called “bunk beds” or

specially developed transport frames.

Figure 1

The width of these crates suits standard container dimensions. Fan blades that will be

transported by container sea-freight, are

equipped with and hoist eyes (see figure 2),

Storage

If not installed immediately, it is recommended to store the impeller in a dry and

shaded area.

For long-term storage (in excess of 6 months)

it is necessary to check the condition of the

corrosion protection agent on all machined

surfaces.

Reapply or repair where necessary, using an

acid-free corrosion protection agent (e.g.

Esso Rust ban 397 or equivalent).

You may stack the “bunk beds” to a maximum

of 3 high. Do not allow any heavy materials of

any kind to be stored on top of the blades.

Howden 24-07.030r04 6/25

E-series Axial Flow Cooling Fans

Service Manual

De-commissioning

In accordance with our ISO14001 certified

environmental management system, our

cooling fans can easily be disassembled after

de-commissioning. Their metal components

and polyethylene fan casings are highly

suitable for recycling. Since no viable

recycling procedure for reinforced plastics

exists, fan blades need to be shredded and

incinerated or used as land-fill. The inert

nature of the materials used will prevent

chemical pollution of soil and ground water in

case of in land-fill.

Howden 24-07.030r04 7/25

E-series Axial Flow Cooling Fans

Service Manual

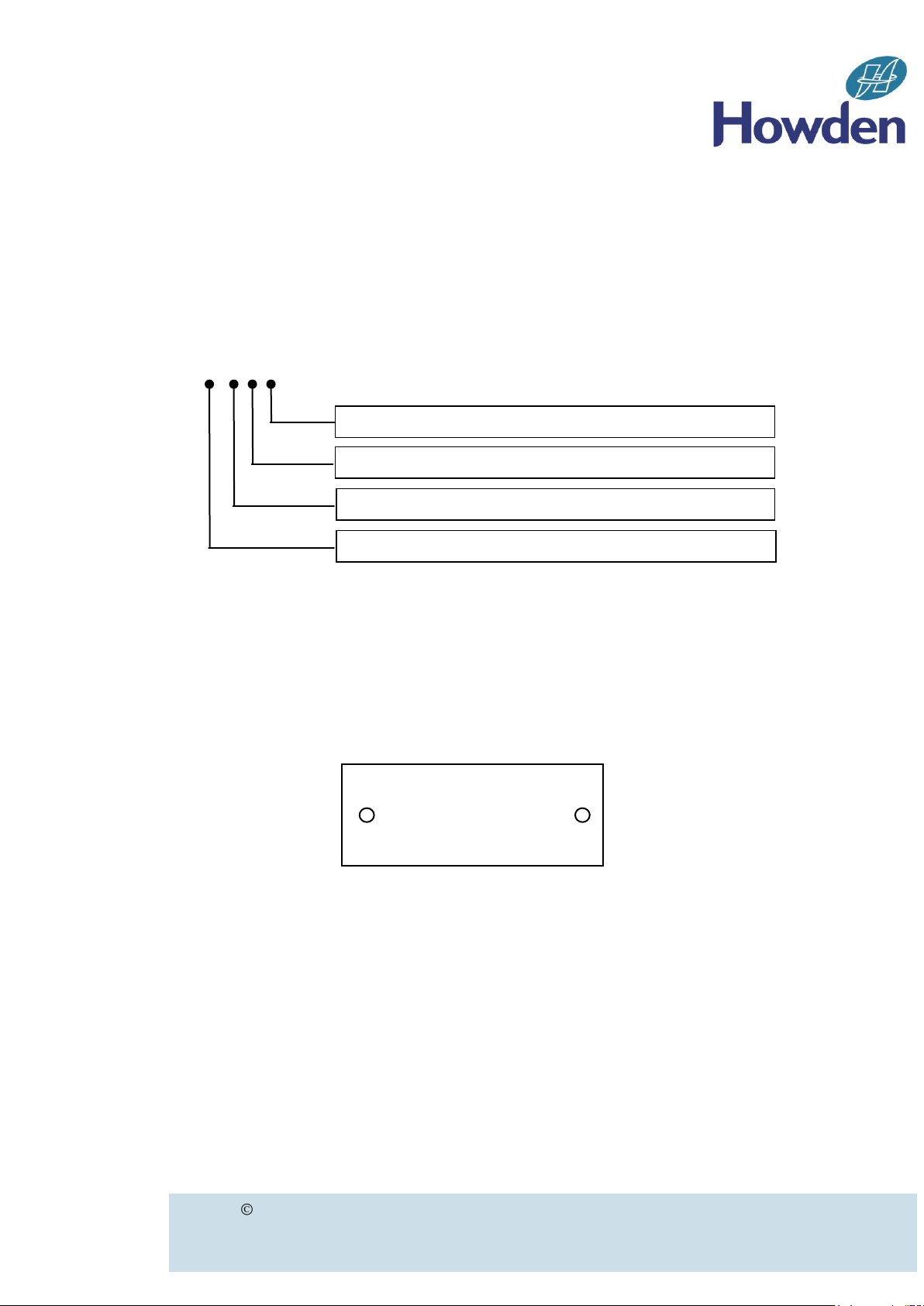

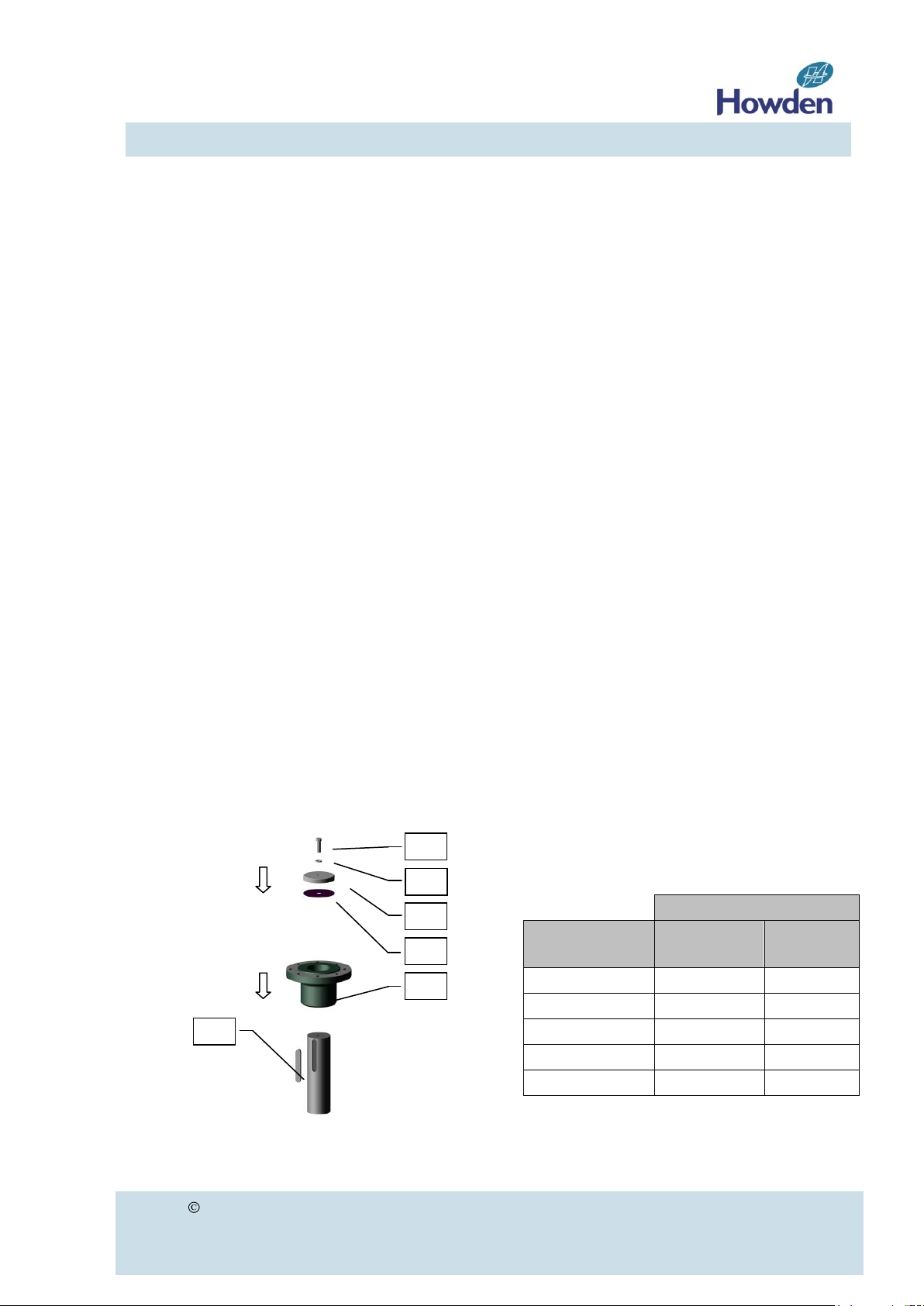

Item

Description

Material (standard construction)

Quantity

1

U-bolt

Stainless steel A2/ steel 8.8

2 / blade

2

Upper clamping piece

Aluminium

2 / blade

3

Lower clamping piece

Aluminium

1 / blade

4

Washer

Stainless steel A2/ steel 8

4 / blade

5

Nut

Stainless steel A2/ steel 8

4 / blade

6

Blade

Fibreglass reinforced polyester

-

7

Hub plate

Polyurethane coated mild Steel

1

8

Coupling flange bolt

Steel class 8.8 electro-galvanised

8 9 Washer

Electro-galvanised

16

10

Nut

Electro-galvanised

8

11

Coupling flange

Nodular cast iron polyurethane coated

1

12

Split tapered bushing

Manufacturers standard

1 (optional)

13

Bolt

Manufacturers standard

3 (optional)

14

Retaining plate

Polyurethane coated steel

1 (optional)

15

Central bolt M16 or M20 or M24

Steel class 8.8 electro-galvanised

1 (optional)

16

Washer

Electro-galvanised

1 (optional)

17

Gasket

Rubber

1 (optional)

18

Key - 1 (optional)

19

Key

Not supplied by Howden

1

2

16

3

4 5 6

15

14

9

8

12

10 9 11

13 7 18

19

17

Exploded view and part list

Figure 3 Figure 4

Table 2

Howden 24-07.030r04 8/25

E-series Axial Flow Cooling Fans

Service Manual

Flow

III. INSTALLATION

Required Tools

Torque wrench (check tightening torques

for the correct model)

Socket and wrench

Inclinometer

Straight edge:

Minimum length > blade width

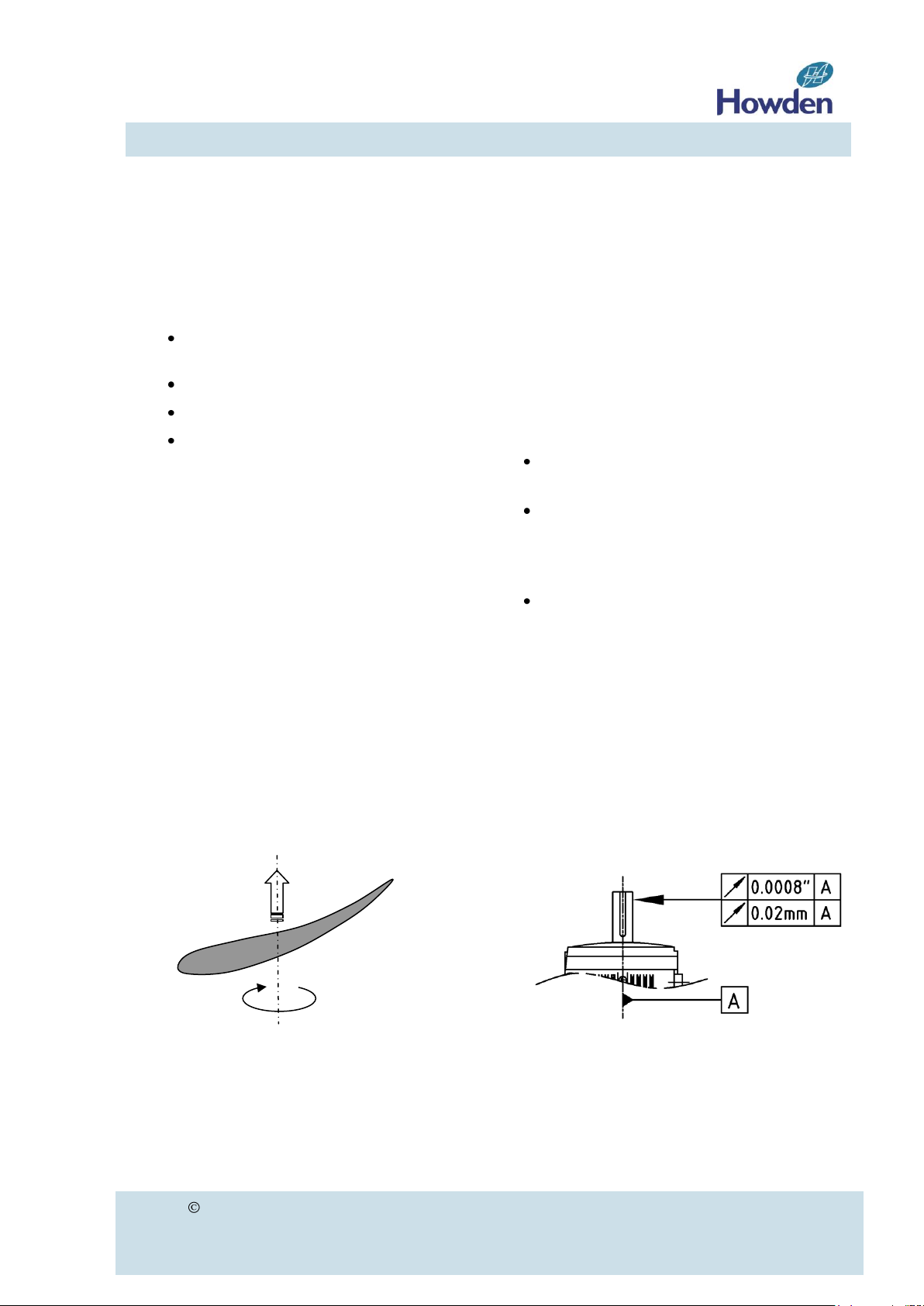

Rotation and flow direction

Standard rotation is clockwise when viewed

into the air-stream. See figure 5.

Preparation

Clean all mating surfaces between shaft, tapered bushing (if applicable) and fan hub. All

corrosion preventive coatings should be removed.

Check the following before parts shall be assembled:

Drainage hole at the blade tip and blade

shoulder shall be open

Make sure the drive shaft is properly cen-

tred with respect to the fan casing. Also

check if the shaft is vertical within the prescribed tolerance.

Check the concentricity of the driver shaft

end before mounting the impeller. The impeller should not be mounted if the con-

centricity error exceeds 0.02 mm (0.0008”)

see figure 6.

Figure 5

Figure 6

Howden 24-07.030r04 9/25

E-series Axial Flow Cooling Fans

Service Manual

Class 8.8 (A3B)

Bolt size

(bushing type)

Torque

(Nm)

Torque

(lb.ft)

5/16” (P2)

22

16

3/8” (Q2, R2)

39

29

½” (S1)

95

70

5/8” (U1)

190

140

3/4” (W1, W2)

339

250

14

19

11

15

16

17

Coupling flange with parallel bore

a) Check if the shaft and bore diameters are

according to specification. The standard

execution has a H7 fit.

b) Slightly lubricate the shaft, the key, and

the bore of the hub with grease.

c) Locate the key (19) into the drive shaft

(figure 7).

d) To slip the coupling flange over the shaft

we advise you to uniformly heat up the

coupling flange up to maximum 120 °C

(248 °F) by means of a hot plate, electric

induction or oil bath, until a 0.15mm difference in diameter is reached. Wear

protective gloves during this operation.

e) Slip the coupling flange (11) onto the

drive shaft and check the key for proper

fit. Be sure the coupling flange is completely through the shaft against the shaft

shoulder.

f) For reverse coupling flange configuration:

(e.g. impeller hanging below the driver)

Install the retaining plate (14) with gasket

(17) and secure it to the shaft with the

lock washer (16) and the central bolt

(15). Supply of retaining plate items 14,

15, 16 and 17 by Howden is optional.

Item 19 (key) is not supplied by Howden.

For torque values of the retaining plate

bolts see table 7 on page 22.

Coupling flange with tapered bushing

(Supply of coupling flange with tapered

bushing is optional).

a) Do not lubricate bushing, coupling flange

bore or hardware. Use of lubricants can

cause coupling flange damage.

b) Slip the bushing onto the drive shaft and

check the key (19) for proper fit (figure 8

on page 10). Be sure the shaft is completely through the bushing. Keep a bolt

length as minimum distance X between

bolts (13) and flange of the drive (figure 9

on page 10).

c) Lock the bushing on the shaft by tighten-

ing the setscrew in the flange. Support

the bushing with a sleeve to prevent it

from sliding down during assembly.

d) Install the coupling flange onto the bush-

ing. Start bolts (13) by hand turning just

enough to engage threads.

e) Keep tightening them as equally as

possible, in several steps, while drawing

the hub onto the bushing until the bushing tightly grips the shaft.

f) Tighten the bolts to the torque shown in

table 3. Do not over-torque. Excessive

torque can cause coupling flange or

bushing damage. Some gap must remain

between the flange of the bushing and

coupling flange in properly tightened assembly.

Torque value for bolts

tapered bushing to coupling flange

Table 3

Figure 7

Loading...

Loading...