Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

FOR

BOTTOM MOUNT REFRIGERATORS AND FREEZERS

INSPECTION

When the equipment is received, all items should be carefully checked against the Bill of Lading

to insure all crates and cartons have been received. Do not sign the freight bill clear until the

freight has been properly inspected for damage. All units should be inspected for damage

including concealed damage by uncrating immediately. If any damage is found, it should be

reported to the carrier at once, noted on the Bill of Lading and a claim should be filed with the

carrier. This equipment has been inspected and tested in the manufacturing facility and has been

crated in accordance with transportation rules and guidelines. The manufacture is not

responsible for freight loss or damages.

INSTALLATION

The unit has been secured to the shipping base with four bolts. Remove these bolts and separate

the unit from the shipping base. Locate the casters or legs found inside the unit. Attach the

casters or legs to the unit base by screwing them into the threaded fittings that were used to

secure the shipping base. Use the wrench provided to tighten the casters to the unit. The casters

with the brakes should be installed on the front of the unit. For proper drainage of condensate,

the unit should be level when placed in its permanent location. Leveling shims are in cluded in

the accessories package in the cabinet. Loosen the casters and insert shims between caster and

bottom of the unit. Retighten the caster.

The exterior of the cabinet and doors have been protected by a plastic covering. Peel this

protective covering before installation. After removing the covering, clean the interior and

exterior surfaces of the unit with soap and water and a rinse with clean water. Do not use

chlorinated cleaners on the surfaces as they can cause corrosion.

If the door(s) have come out of alignment during shipping they will need to be adjusted. This

can be accomplished by opening the door(s) and loosening the screws that hold both the top and

bottom hinges to the cabinet. After adjusting the door so it is aligned correct, tighten the screws

to securely hold the hinges and door(s) in place.

The shelves and self clips are packaged inside the unit. Install the shelf clips on the pilasters

inside the unit and set the shelves on the clips. The shelves are adjustable in ½” increments.

The refrigeration system located at the bottom of the unit requires free air access for proper

operation. Allow a minimum of seven inches between the back of the cabinet and the wall. Do

not locate the unit next to heat generating equipment or in direct sunlight.

Confirm that the proposed electrical outlet has the correct voltage, frequency and current

carrying capacity for the requirements of the unit. This information is noted on the data plate on

the inside left wall of the unit. The unit should be isolated on a circuit. Do not use an extension

cord to get power to the unit. Improper electrical installations will void the compressor

warranty.

1

Page 2

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR) ■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

GR26/GR48/GR70(MERCHANDISERS)

GR26/GR48/GR70(MERCHANDISERS)

GR26/GR48/GR70(MERCHANDISERS) GR26/GR48/GR70(MERCHANDISERS)

A. COMMERCIAL FREEZER, REFRIGERATOR GENERAL

1. SPECIFICATION - - - - - - - - - - - - - - - - - - - - - - A2

1. SPECIFICATION - - - - - - - - - - - - - - - - - - - - - - A2

1. SPECIFICATION - - - - - - - - - - - - - - - - - - - - - - A2 1. SPECIFICATION - - - - - - - - - - - - - - - - - - - - - - A2

1) GENERAL

1) GENERAL

1) GENERAL 1) GENERAL

2) MAIN COMPONENTS

2) MAIN COMPONENTS

2) MAIN COMPONENTS 2) MAIN COMPONENTS

2. REFRIGERATION CYCLE - - - - - - - - - - - - - - - - - - - A6

2. REFRIGERATION CYCLE - - - - - - - - - - - - - - - - - - - A6

2. REFRIGERATION CYCLE - - - - - - - - - - - - - - - - - - - A6 2. REFRIGERATION CYCLE - - - - - - - - - - - - - - - - - - - A6

3. TROUBLE SHOOTING - - - - - - - - - - - - - - - - - - - - - A8

3. TROUBLE SHOOTING - - - - - - - - - - - - - - - - - - - - - A8

3. TROUBLE SHOOTING - - - - - - - - - - - - - - - - - - - - - A8 3. TROUBLE SHOOTING - - - - - - - - - - - - - - - - - - - - - A8

1) CHECKING THE POWER SUPPLY

1) CHECKING THE POWER SUPPLY

1) CHECKING THE POWER SUPPLY 1) CHECKING THE POWER SUPPLY

2) CHECKING THE POWER SUPPLY OF CONTROL BOARD

2) CHECKING THE POWER SUPPLY OF CONTROL BOARD

2) CHECKING THE POWER SUPPLY OF CONTROL BOARD 2) CHECKING THE POWER SUPPLY OF CONTROL BOARD

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE 3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

4) CHECKING THE DEFROST PART

4) CHECKING THE DEFROST PART

4) CHECKING THE DEFROST PART 4) CHECKING THE DEFROST PART

5) WHEN THE UNIT DOES NOT COOL

5) WHEN THE UNIT DOES NOT COOL

5) WHEN THE UNIT DOES NOT COOL 5) WHEN THE UNIT DOES NOT COOL

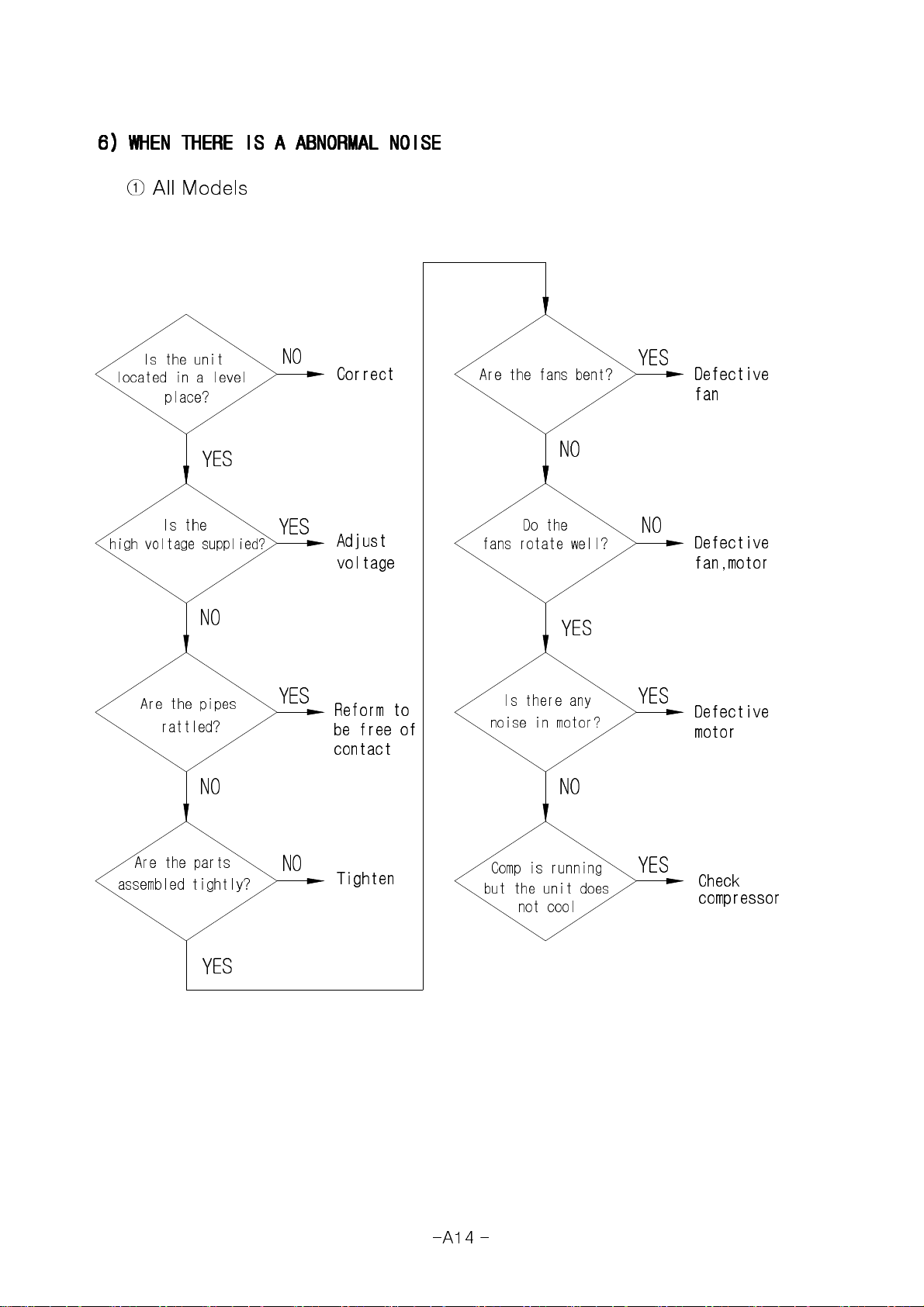

6) WHEN THERE IS A ABNORMAL NOISE

6) WHEN THERE IS A ABNORMAL NOISE

6) WHEN THERE IS A ABNORMAL NOISE 6) WHEN THERE IS A ABNORMAL NOISE

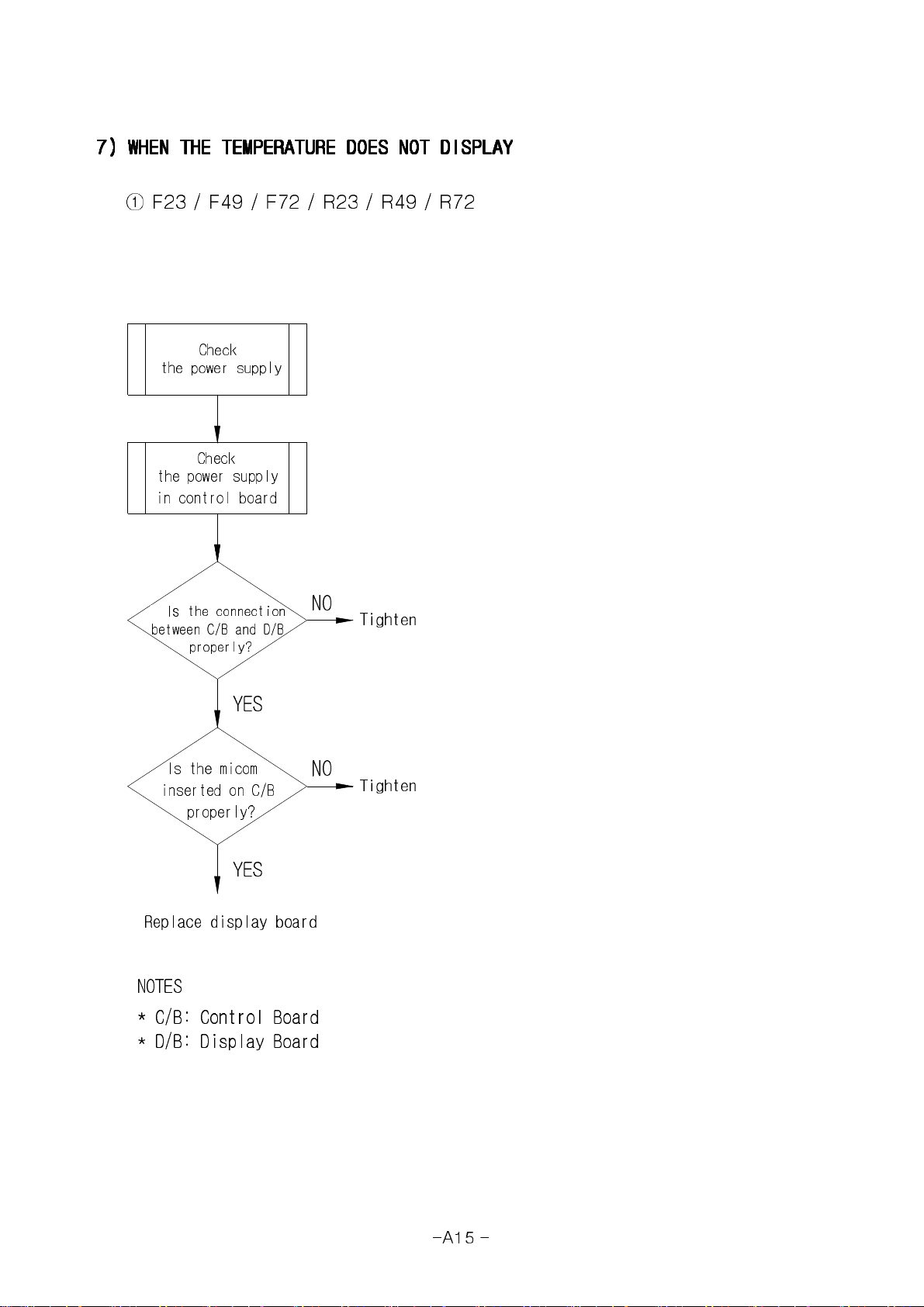

7) WHEN THE TEMPERATURE DOES NOT DISPLAY

7) WHEN THE TEMPERATURE DOES NOT DISPLAY

7) WHEN THE TEMPERATURE DOES NOT DISPLAY 7) WHEN THE TEMPERATURE DOES NOT DISPLAY

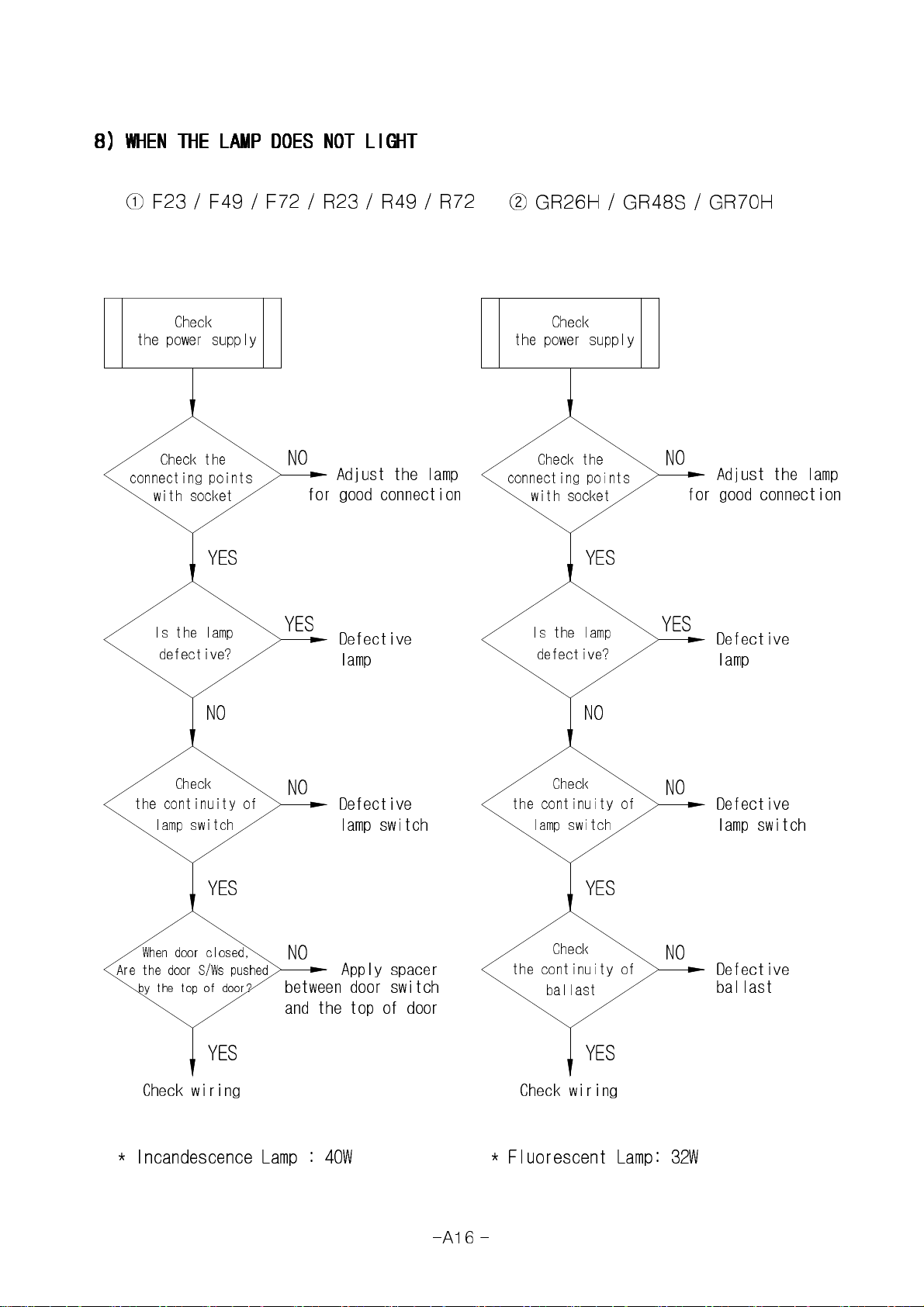

8) WHEN THE LAMP DOES NOT LIGHT

8) WHEN THE LAMP DOES NOT LIGHT

8) WHEN THE LAMP DOES NOT LIGHT 8) WHEN THE LAMP DOES NOT LIGHT

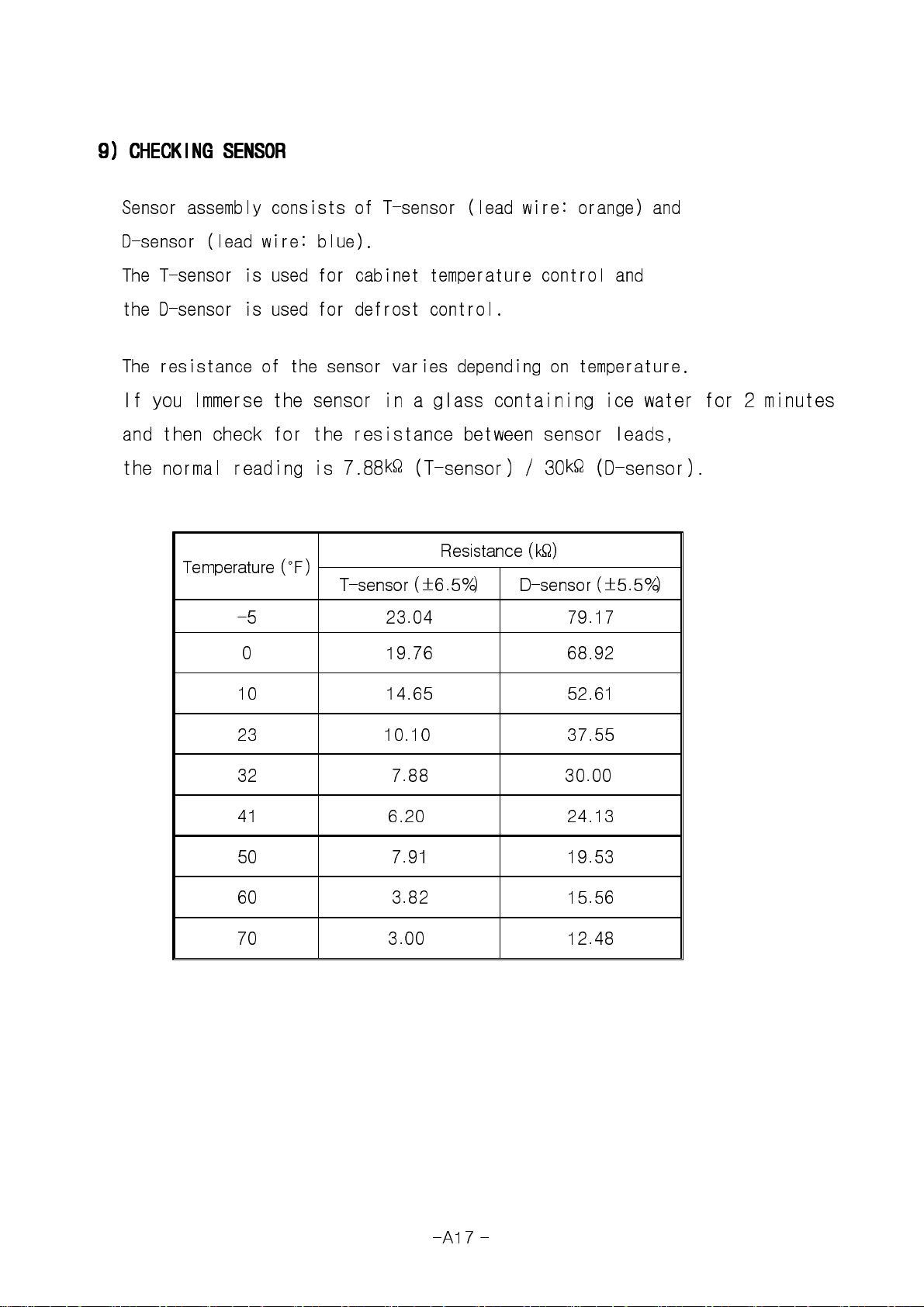

9) CHECKING SENSOR

9) CHECKING SENSOR

9) CHECKING SENSOR 9) CHECKING SENSOR

4. FEATURE CHART - - - - - - - - - - - - - - - - - - - - - - - A18

4. FEATURE CHART - - - - - - - - - - - - - - - - - - - - - - - A18

4. FEATURE CHART - - - - - - - - - - - - - - - - - - - - - - - A18 4. FEATURE CHART - - - - - - - - - - - - - - - - - - - - - - - A18

5. WIRING DIAGRAM - - - - - - - - - - - - - - - - - - - - - - A30

5. WIRING DIAGRAM - - - - - - - - - - - - - - - - - - - - - - A30

5. WIRING DIAGRAM - - - - - - - - - - - - - - - - - - - - - - A30 5. WIRING DIAGRAM - - - - - - - - - - - - - - - - - - - - - - A30

6. REPLACEMENT OF COMPONENTS - - - - - - - - - - - - - - - - - A35

6. REPLACEMENT OF COMPONENTS - - - - - - - - - - - - - - - - - A35

6. REPLACEMENT OF COMPONENTS - - - - - - - - - - - - - - - - - A35 6. REPLACEMENT OF COMPONENTS - - - - - - - - - - - - - - - - - A35

-A1 -

Page 3

1. SPECIFICATION

AC 115V

60Hz

1. SPECIFICATION

1. SPECIFICATION 1. SPECIFICATION

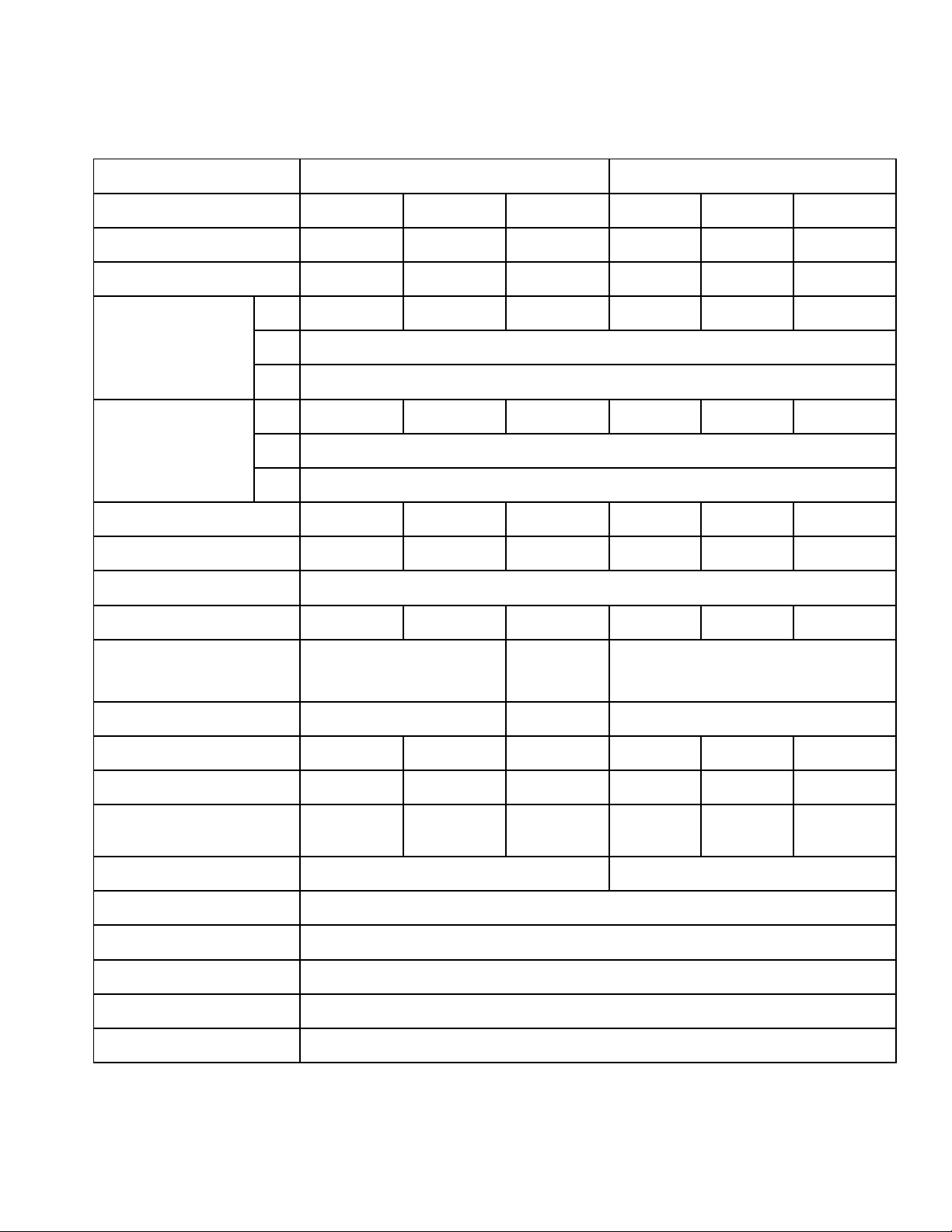

1) GENERAL - COMMERCIAL FREEZERS AND REFRIGERATORS

1) GENERAL - COMMERCIAL FREEZERS AND REFRIGERATORS

1) GENERAL - COMMERCIAL FREEZERS AND REFRIGERATORS1) GENERAL - COMMERCIAL FREEZERS AND REFRIGERATORS

PRODUCT

MODEL

Capacity (Cu,Ft)

Net Capacity (Cu,Ft)

Exterior Dimension

(Including casters)

(in)

Interior Dimension

(Including casters)

(in)

Net Weight (lbs)

Door Type

Door Material

Shelves

SOLID DOOR FREEZER SOLID DOOR REFRIGERATOR

F23 F49 F72 R23 R49 R72

23 49 72 23 49 72

20.8 45.2 65.3 20.8 45.2 65.3

(W) 27.4 55.1 78 27.4 55.1 78

(D)

(H)

(W) 23.6 51.4 74.2 23.6 51.4 74.2

(D)

(H)

295 499 622 288 475 609

Swing 1EA Swing 2EA Swing 3EA Swing 1EA Swing 2EA Swing 3EA

Stainless steel (STS)

4EA 8EA 12EA 4EA 8EA 12EA

31.3

83.9

25

60.8

Power Voltage

Plug in - Installation

Amps

Compressor

Refrigerant

Range of Temperature

Door auto-close equipment

Door stop equipment

Air suction equipment

Condensing unit

AC 115V/60Hz

NEMA 5-15P

8.5A 9.5A 9.0A 7.5A 7.5A 10.0A

1/2HP 3/4HP 1.1HP 3/8HP 3/8HP 1/2HP

R-404A

(12.0 oz)

R-404A

(22.2 oz)

Below 0 ℉

/208-230V

NEMA 14-20P

R-404A

(23.6 oz)

Auto-close Spring

120˚ Stop

Air damper

4in × 4EACaster

Sliding Type

R-134A

(8.5 oz)

AC 115V/60Hz

NEMA 5-15P

R-134A

(11.3 oz)

32 ~ 40 ℉

◈ Above specifications are subjected to change without prior notice for quality improvement.

◈ The nameplate(includes Serial Number) is located on the upper left of the cabinet interior.

R-134A

(14.1 oz)

-A2 -

Page 4

2) MAIN COMPONENTS - COMMERCIAL FREEZERS AND REFRIGERATORS

2) MAIN COMPONENTS - COMMERCIAL FREEZERS AND REFRIGERATORS

2) MAIN COMPONENTS - COMMERCIAL FREEZERS AND REFRIGERATORS2) MAIN COMPONENTS - COMMERCIAL FREEZERS AND REFRIGERATORS

PRODUCT

MODEL

Compressor

(Manufacture)

Compressor Capacity(kcal/h)

Type of Compressor motor

Compressor O.L.P

Compressor Relay

Starting Capacitor

Running Capacitor

Type of Evaporator

Evaporator pipe Dimensions

Cooling Fan Motor

SOLID DOOR FREEZER SOLID DOOR REFRIGERATOR

F23 F49 F72 R23 R49 R72

CAE2420Z(A)

(Tecumseh)

CAJ2432Z(A)

(Tecumseh)

CAJ2446Z(H)

(Tecumseh)

LBP 571 LBP 808 LBP 1219 LBP 1586

CSIR CSR CSR CSIR

MST16AHN GA3PJU00 MST00AHN GA3SJU81

3ARR3*5R* 3ARR3*3A* 3ARR18A100B

315㎌/160V 315㎌/160V 88㎌/160V 250㎌/160V

- 30㎌/400V 15㎌/160V -

SK6A1C-H2Y

(Samsung)

HBP 1120

RSIR

4TM811XHBZZ-53

MTRP0052-02

-

-

CAJ4476Y(A)

(Tecumseh)

Cu pipe + Al fin + Blue color coating

3/8"

IS3225LTSA, 120V/60Hz

Type of Condenser

Condenser pipe Dimensions

Condenser Fan Motor

Drier

Temperature Control

Running Indication

Interior Temp. Indication

Interior Lamp

Defrost for evaporator

Defrost sheath heater

Defrost pan heater

Drain heater

Cu pipe + Al fin

3/8"

MA7425W1, 120V/60Hz

OD 1", XH-9, 1.06oz

Thermistor

Digital Display

Digital Display

40W × 1EA 40W × 1EA

Heated defrost

(Control of thermistor)

40W × 2EA 40W × 2EA

Off cycle

450W 670W 944W - - -

60W 90W 128W - - -

9W

- - -

Door switch

Power switch

SP201R-7DR, AC125V

SL112A, AC125V/12A

-A3 -

Page 5

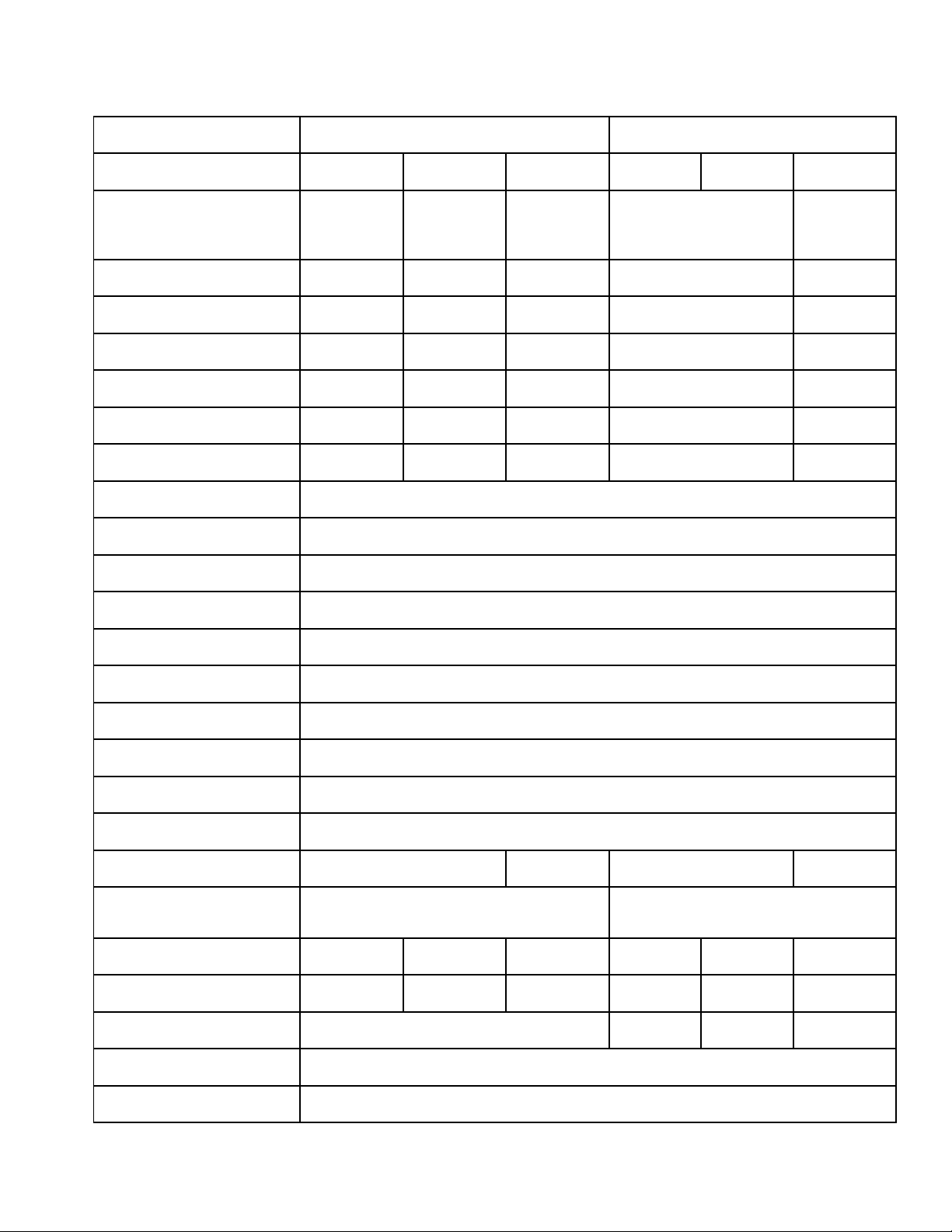

3) GENERAL - MERCHANDISERS

3) GENERAL - MERCHANDISERS

3) GENERAL - MERCHANDISERS3) GENERAL - MERCHANDISERS

PRODUCT

MODEL

Capacity (Cu,Ft)

Net Capacity (Cu,Ft)

Exterior Dimension

(Including casters)

(in)

Interior Dimension

(Including casters)

(in)

Net Weight (lbs)

Door Type

Door Material

Shelves

(W)

(D)

(H)

(W)

(D)

(H)

MERCHANDISERS

GR26 GR48

26 48

24.4 45.3 65.3

28.4

31.3

78.7

25

27

62.5

287

4EA 8EA 12EA

53.2

29.9

78.7

50

25.5

61.4

474 716

Glass + Al

GR70

70

78

31.3

83.9

74.2

25

60.8

Swing 3EASwing 1EA Sliding 2EA

Power Voltage

Plug in - Installation

Compressor

Refrigerant

Range of Temperature

Door auto-close equipment

Door stop equipment

Air suction equipment

Caster Adjust foot 4EA

Condensing unit

Door switch

Power(or Lamp) switch

3.9AAmps

1/4 HP 1/2 HP

R-134A

(10.6 oz)

120˚ Stop - 120˚ Stop

-

AC 115V/60Hz

NEMA 5-15P

10.0A

R-134A

(16.2 oz)

32 ~ 40℉

Auto-close Spring

Air damper

Adjust foot 6EA

Sliding Type

-

SL112A, AC125V/12A

Adjust foot 6EA

◈ Above specifications are subjected to change without prior notice for quality improvement.

11.9A

1/2 HP

R-134A

(17.6 oz)

-

◈ The nameplate(includes Serial Number) is located on the upper left of the cabinet interior.

-A4 -

Page 6

4) MAIN COMPONENTS - MERCHANDISERS

Ballast Name

DY232 IS120

32W × 1EA

B232I120RH-A

17W/32W

B232I120RH-A

32W × 2EA

32W(Double)×1EA /

4) MAIN COMPONENTS - MERCHANDISERS

4) MAIN COMPONENTS - MERCHANDISERS4) MAIN COMPONENTS - MERCHANDISERS

PRODUCT

MODEL

Compressor

(Manufacture)

Compressor Capacity(kcal/h)

Type of Compressor motor

Compressor O.L.P

Compressor Relay

Starting Capacitor

Running Capacitor

Type of Evaporator

Evaporator pipe Dimensions

Cooling Fan Motor

Type of Condenser

MERCHANDISERS

SK182C-L2U

(SAMSUNG)

LBP 256 LBP 1946

RSCR CSIR

4TM444NHBYY

J531Q32E4R7M1802

-

12㎌/250V -

IS3225LTSA, 120V/60Hz

CAJ4476Y(A)

(Tecumseh)

CRA38014

GE3ARR3

250㎌/160V

Cu pipe + Al fin

1/2"

Cu pipe + Al fin

GR70HGR48SGR26H

CAJ4476Y(A)

(Tecumseh)

HBP 1946

CSIR

CRA38014

3ARR3*2M*

250㎌/160V

-

Condenser pipe Dimensions

Condenser Fan Motor

Drier

Temperature Control

Running Indication

Interior Temp. Indication

Interior Lamp

Ad. Panel Fluorescent Lamp

Ballast

(Manufacture)

Defrost for evaporator

Defrost sheath heater

Thermostat

GNF-250L

(Fluorescent lamp)

32W × 1EA

17W×1EA

(ADVANCE)

-

3/8"

MA7425W1, 120V/60Hz

OD 1", XH-9, 1.06oz

Thermostat

(GNF-240L)

-

-

(Fluorescent lamp)

32W × 1EA

32W(Double)×1EA

(ADVANCE)

Off cycle

-

Thermostat

(GNF-246L)

(Fluorescent lamp)

32W × 1EA

32W(Double)×2EA

(DOYOUNG)

-

Defrost pan heater

Drain heater

-

-

-

-

-

-

-A5 -

Page 7

2. REFRIGERATION CYCLE

2. REFRIGERATION CYCLE

2. REFRIGERATION CYCLE 2. REFRIGERATION CYCLE

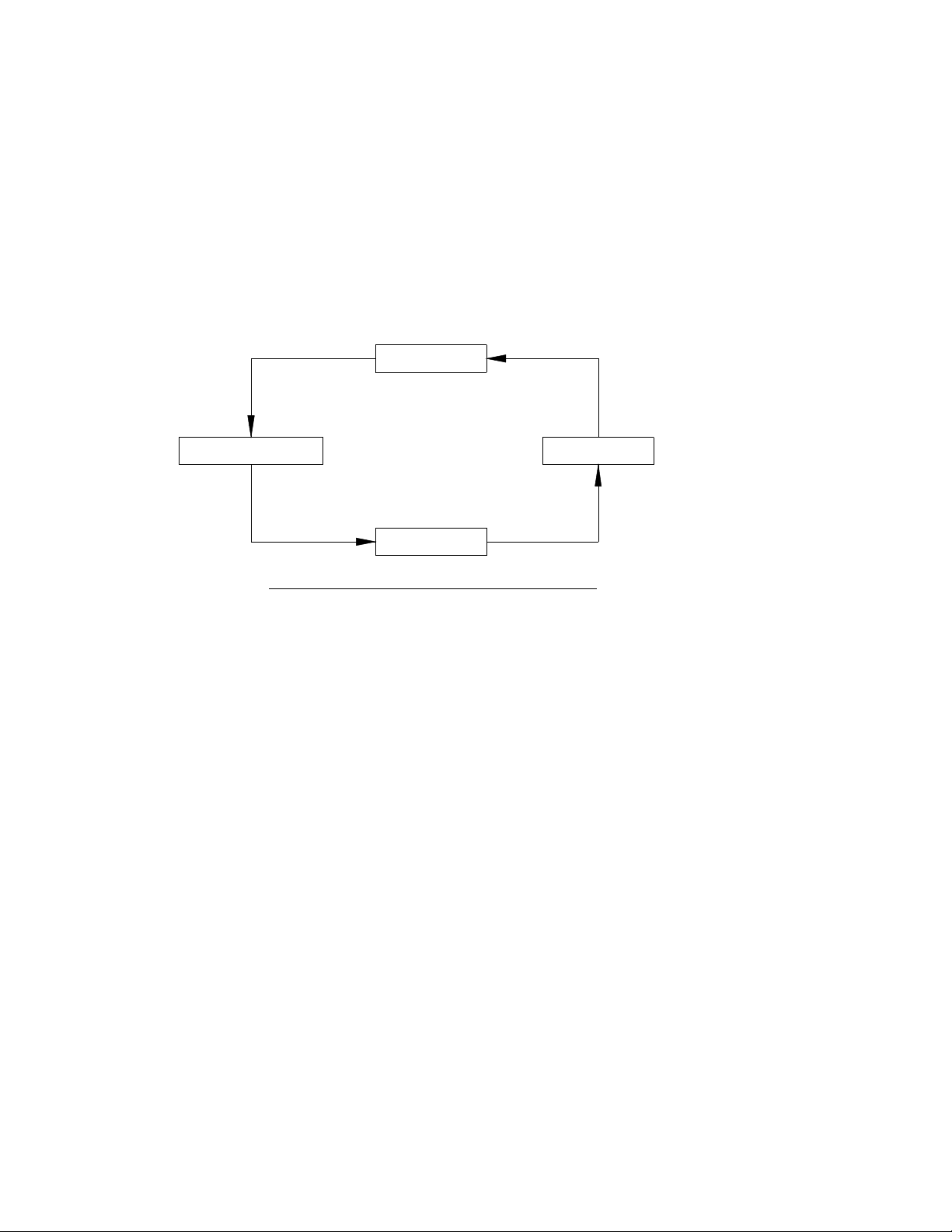

Mechanical refrigeration is accomplished by continuously circulating, evaporating, and condensing

a fixed supply of refrigerant in a closed system. Evaporation occurs at a low temperature and

pressure while condensation occurs at high temperature and pressure. Thus it is possible to

transfer heat from an area of low temperature(i.e., refrigerated compartment) to an area of high

temperature(i.e., surrounding of refrigerator).

CONDENSER

COMPRSSORCAPI LLARY TUBE

EVAPORATOR

THE BASE REFRIGERATION CYCLE

THE BASE REFRIGERATION CYCLE

THE BASE REFRIGERATION CYCLETHE BASE REFRIGERATION CYCLE

Beginning the cycle at the evaporator inlet the low pressure liquid expands, absorbs heat

(so refrigerator inner-cabinet is cooled), and evaporates, changing to a low pressure gas at the

evaporator outlet.

The compressor pumps this gas from the evaporator, increases its pressure, and discharges the

high pressured- temperature gas to the condenser.

The condenser lets high pressured- temperature gas emit the heat(so surrounding of the

condenser is warmed) in order to make it condense.

The capillary tube prevents high pressured- temperature gas from entering the evaporator

in order to lower the pressure in the evaporator and control the flow of refrigerant into the

evaporator automatically.

Eventually the desired air temperature in refrigerator inner-cabinet is reached, the thermostat

(temperature controller) will break the electrical circuit to the compressor motor and stop

the compressor.

-A6 -

Page 8

As the temperature of the air rises, the thermostat(or controller) remakes the electrical circuit.

SUCTION PIPE (INNER-CABINET)

The compressor starts, and cycle continues.

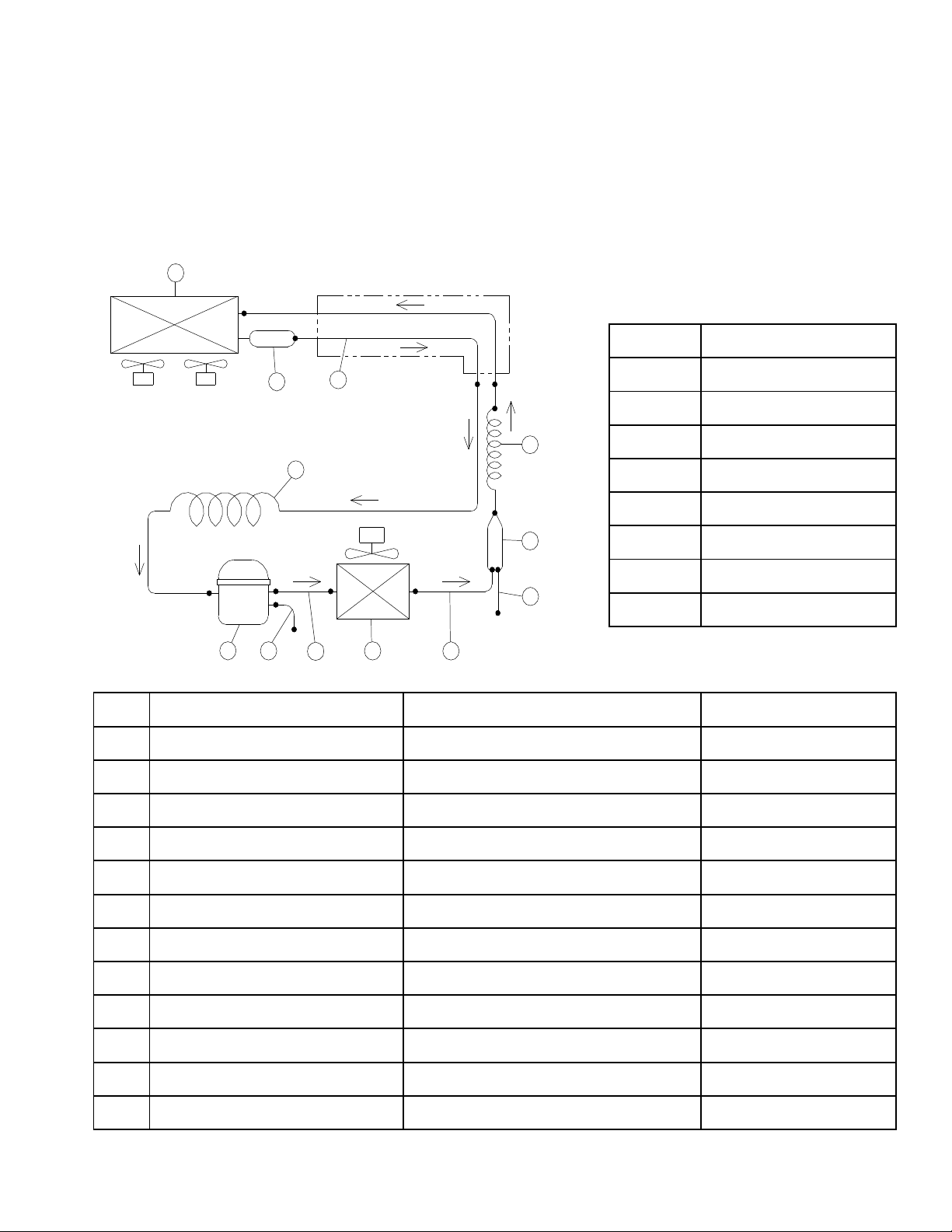

The schematic refrigeration(or freezing) cycle of F23/F49/F72/R23/R49/R72/GR26/GR48/GR70

is like below.

3

Heat Exchange

10

9

6

2

7

5

11

1

No.

COMPRESSOR

1

CONDENSER C1220TS-O,H

2

Part Name Description

12

MODEL

F23

F49

8

F72

R23/R49

R72

4

GR26H

GR48S

GR70H

COMPRESSOR

CAE2420Z(A)

CAJ2432Z(A)

CAJ2446Z(H)

SK6A1C-H2Y

CAJ4461Y(A)

SK182C-L2U

CAJ4476Y(A)

CAJ4476Y(A)

Remark

EVAPORATOR C1220TS-O,H

3

DRIER C1220T-H

4

ACCUMULATOR C1220T-1/4H

5

DISCHARGE PIPE C1220T-O

6

DRIER CONNECT PIPE C1220T-O

7

CAPILLARY TUBE C1220T-H

8

9

SUCTION PIPE (COMPRESSOR) C1220T-O

10

CHARGE PIPE (COMPRESSOR) C1220T-O

11

CHARGE PIPE (DRIER) C1220T-O

12

C1220T-O

-A7 -

Page 9

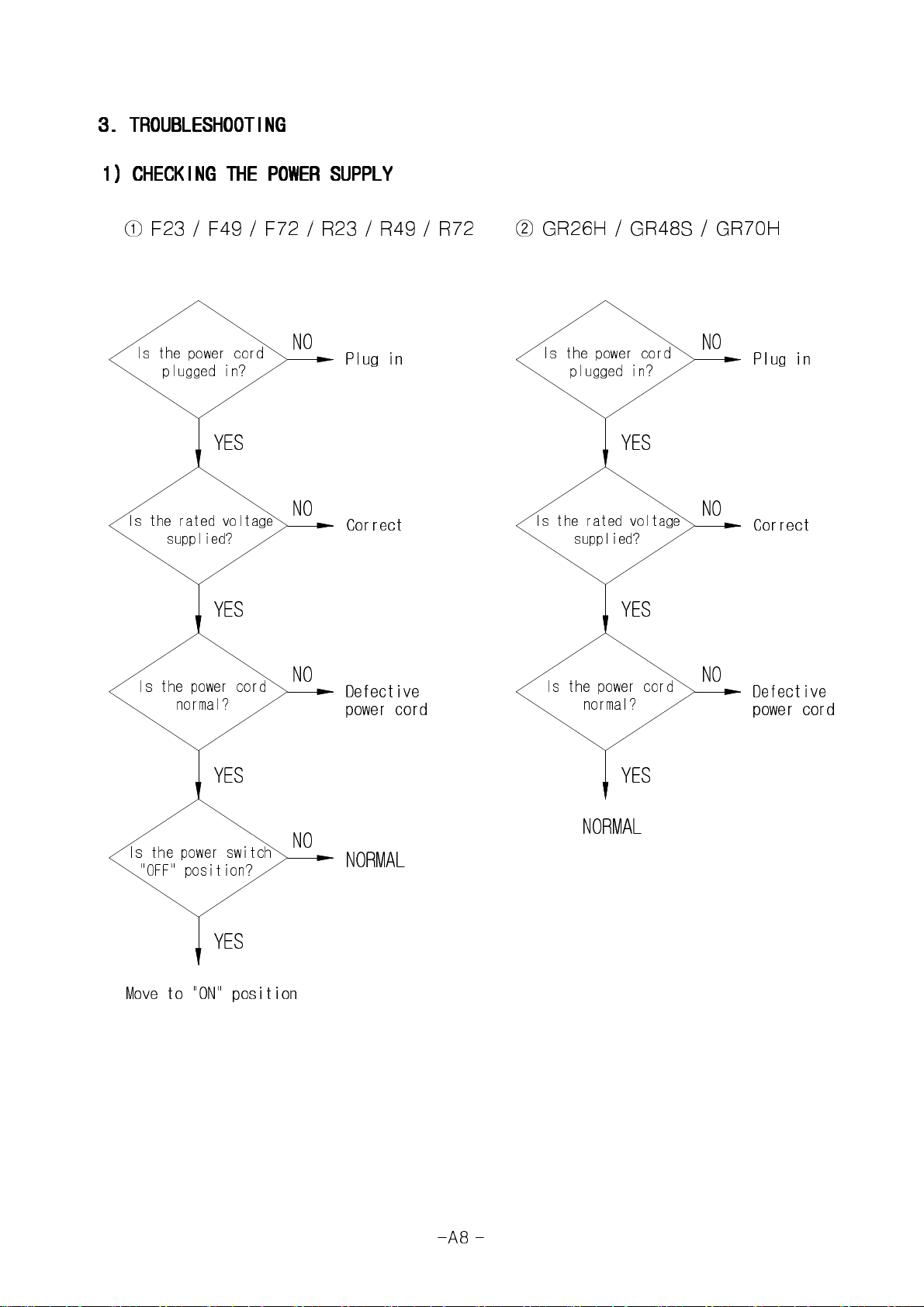

3. TROUBLESHOOTING

3. TROUBLESHOOTING

3. TROUBLESHOOTING 3. TROUBLESHOOTING

1) CHECKING THE POWER SUPPLY

1) CHECKING THE POWER SUPPLY

1) CHECKING THE POWER SUPPLY

1) CHECKING THE POWER SUPPLY1) CHECKING THE POWER SUPPLY

① F23 / F49 / F72 / R23 / R49 / R72

① BASF1/BASF2/BASF3/BASR3 Models ② BASR1/BASR2/BAGR72 Models

Is the power cord

plugged in?

NO

Plug in

YES

Is the rated voltage

supplied?

NO

Correct

YES

Is the power cord

normal?

NO

Defective

power cord

② GR26H / GR48S / GR70H

Is the power cord

plugged in?

NO

Plug in

YES

Is the rated voltage

supplied?

NO

Correct

YES

Is the power cord

normal?

NO

Defective

power cord

YES

Is the power switch

"OFF" position?

YES

Move to "ON" position

YES

NORMAL

NO

NORMAL

-A8 -

Page 10

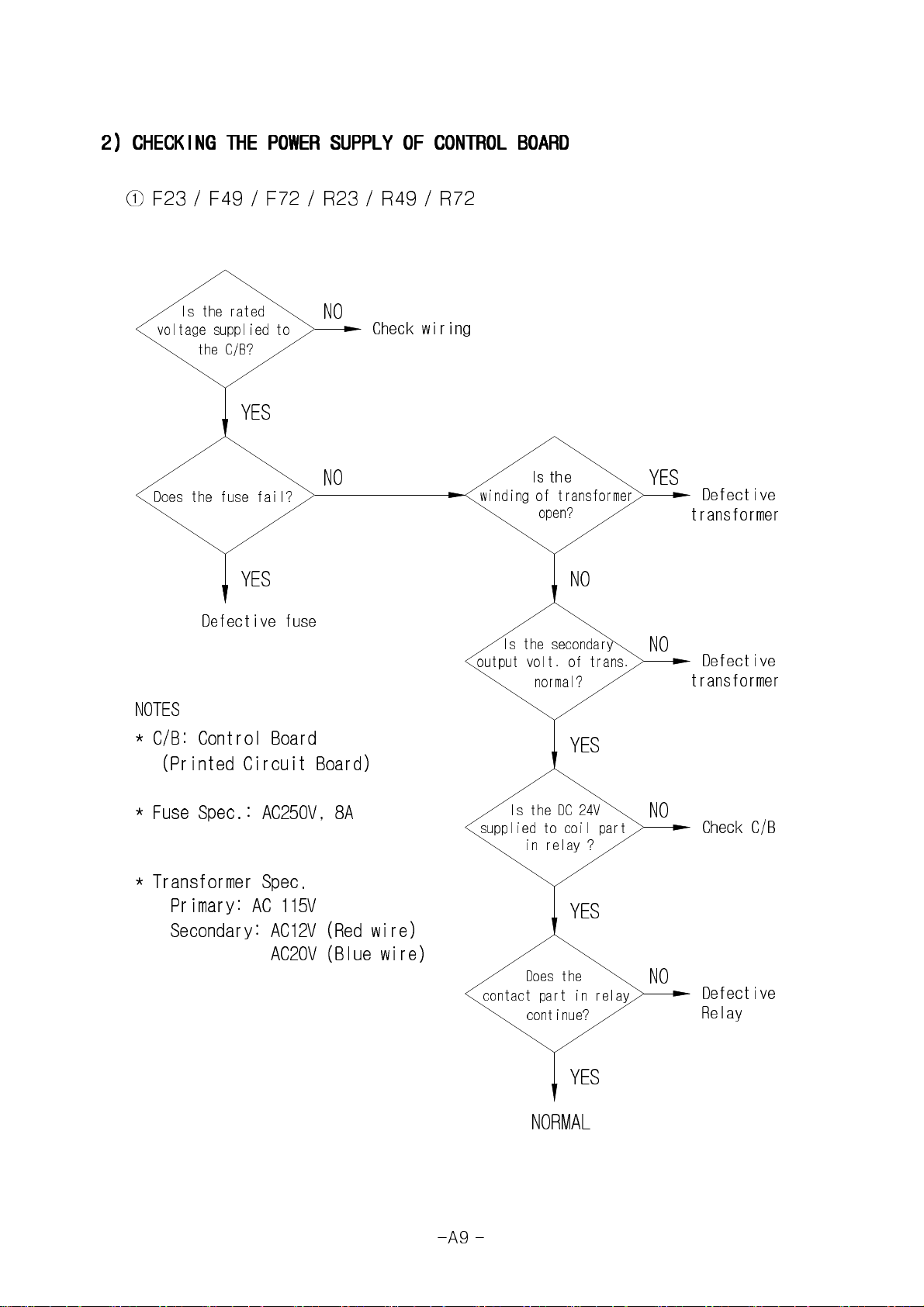

2) CHECKING THE POWER SUPPLY OF CONTROL BOARD

Secondary: AC12V (Red wire)

Primary: AC 115V

Is the

2) CHECKING THE POWER SUPPLY OF CONTROL BOARD

2) CHECKING THE POWER SUPPLY OF CONTROL BOARD

2) CHECKING THE POWER SUPPLY OF CONTROL BOARD2) CHECKING THE POWER SUPPLY OF CONTROL BOARD

① F23 / F49 / F72 / R23 / R49 / R72

① BASF1/BASF2/BASF3/BASR3 Models

Is the rated

voltage supplied to

the C/B?

YES

Does the fuse fail?

YES

Defective fuse

NOTES

* C/B: Control Board

NO

NO

Check wiring

Does the coil

winding of transformer

open?

NO

Is the secondary

output volt. of trans.

normal?

YES

YES

Defective

transformer

NO

Defective

transformer

* Fuse Spec.: AC250V, 8A

(BASF1/BASF2/BASR3)

* Transformer Spec.

AC20V (Blue wire)

Is the DC 24V

supplied to coil part

in relay ?

Does the

contact part in relay

continue?

-A9 -

NO

Check C/B

YES

NO

Defective

Relay

YES

NORMAL

Page 11

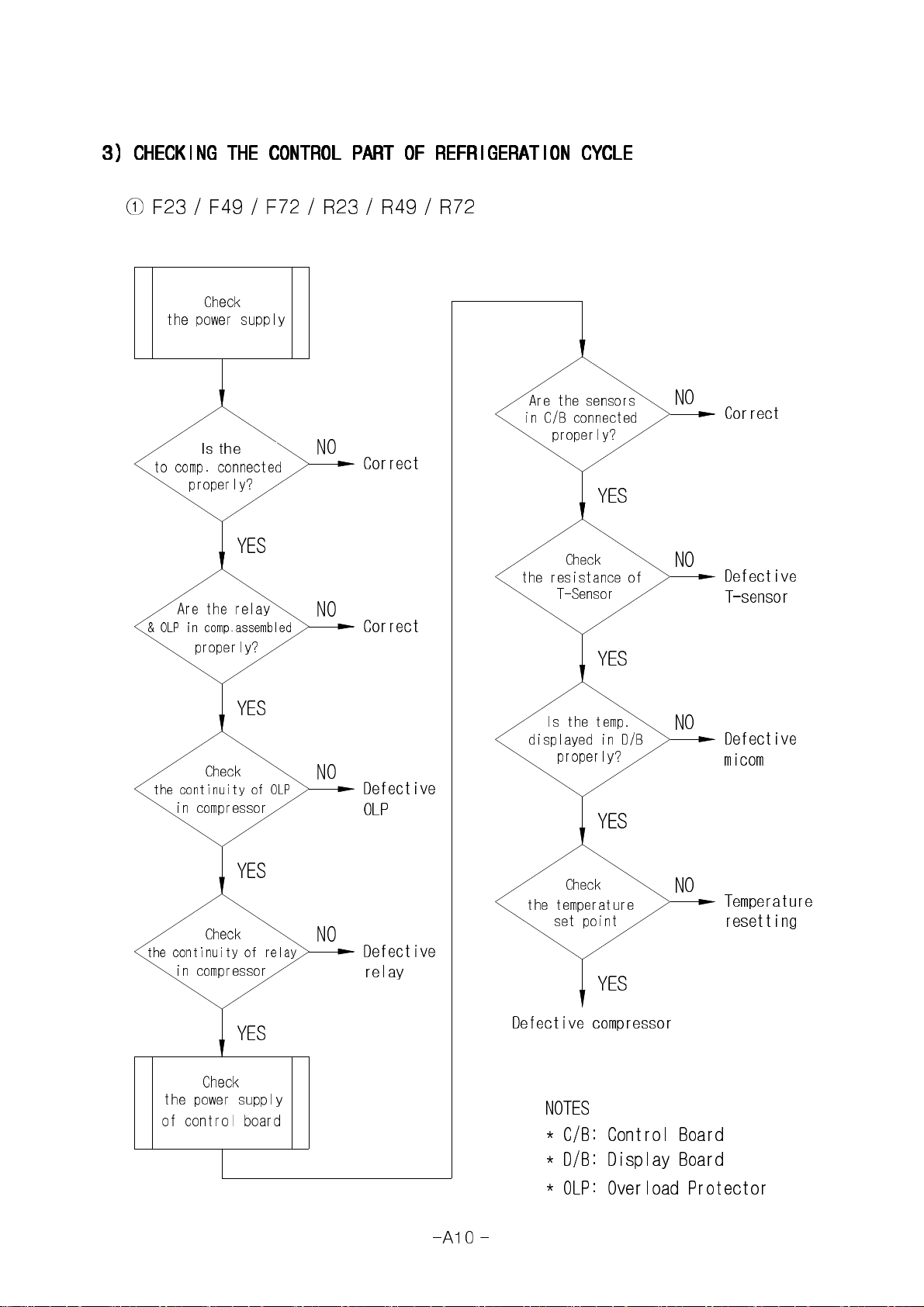

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

① F23 / F49 / F72 / R23 / R49 / R72

① BASF1/BASF2/BASF3/BASR3 Models

Check

the power supply

Is the

Does the wiring

to comp. connected

properly?

YES

Are the relay

& OLP in comp.assembled

properly?

YES

Check

the continuity of OLP

in compressor

NO

NO

NO

Correct

Correct

Defective

OLP

Are the sensors

in C/B connected

properly?

YES

Check

the resistance of

T-Sensor

YES

Is the temp.

displayed in D/B

properly?

YES

NO

Correct

NO

Defective

T-sensor

NO

Defective

micom

YES

Check

the continuity of relay

in compressor

YES

Check

the power supply

of control board

NO

Defective

relay

-A10 -

Check

the temperature

set point

NO

YES

Defective compressor

NOTES

* C/B: Control Board

* D/B: Display Board

* OLP: Overload Protector

Temperature

resetting

Page 12

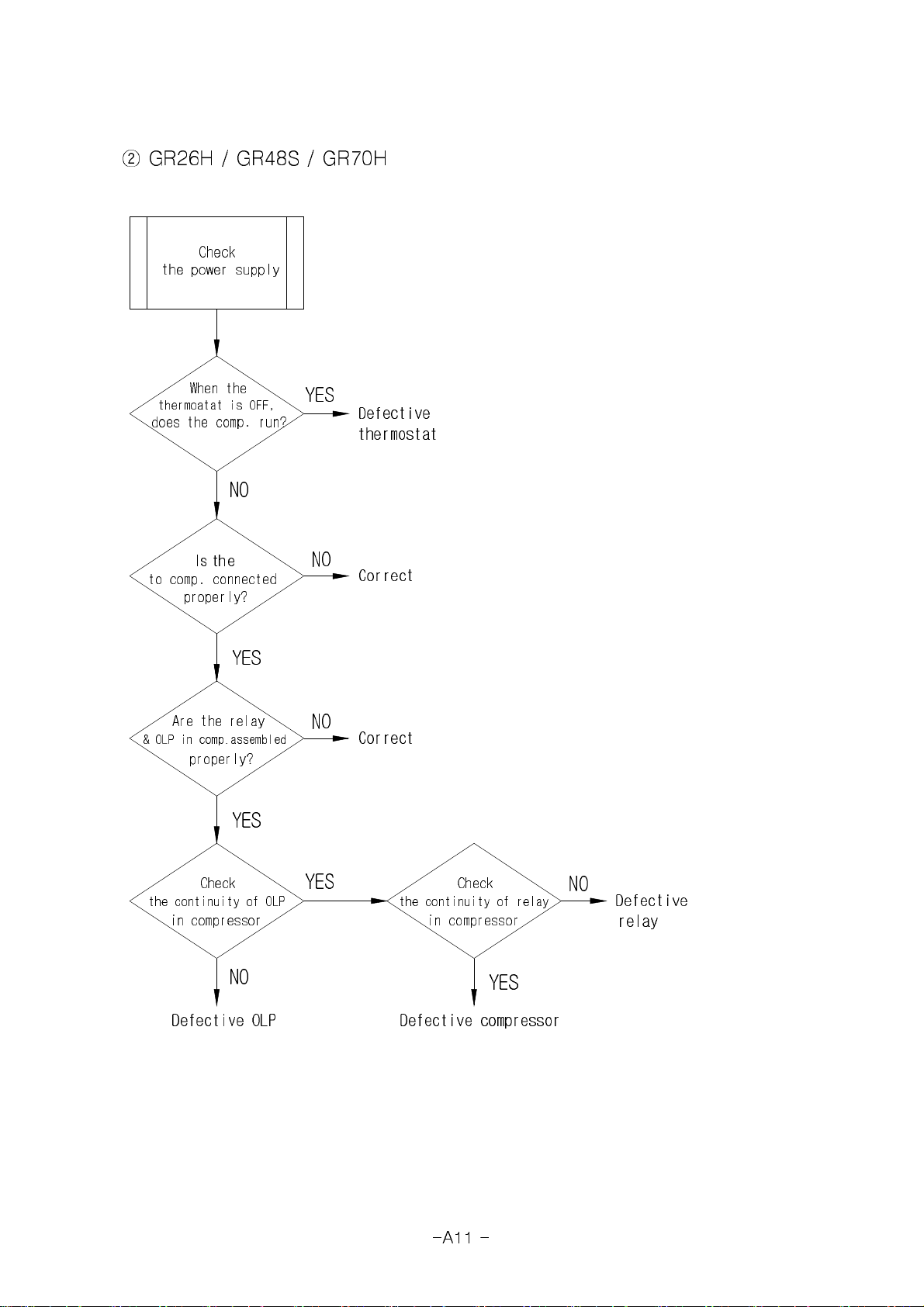

② BASR1/BASR2/BAGR72 Models

Is the

② GR26H / GR48S / GR70H

Check

the power supply

When the

thermoatat is OFF,

does the comp. run?

NO

Does the wiring

to comp. connected

properly?

YES

Are the relay

& OLP in comp.assembled

properly?

YES

YES

Defective

thermostat

NO

Correct

NO

Correct

Check

the continuity of OLP

in compressor

NO

Defective OLP

YES

Check

the continuity of relay

in compressor

YES

Defective compressor

-A11 -

NO

Defective

relay

Page 13

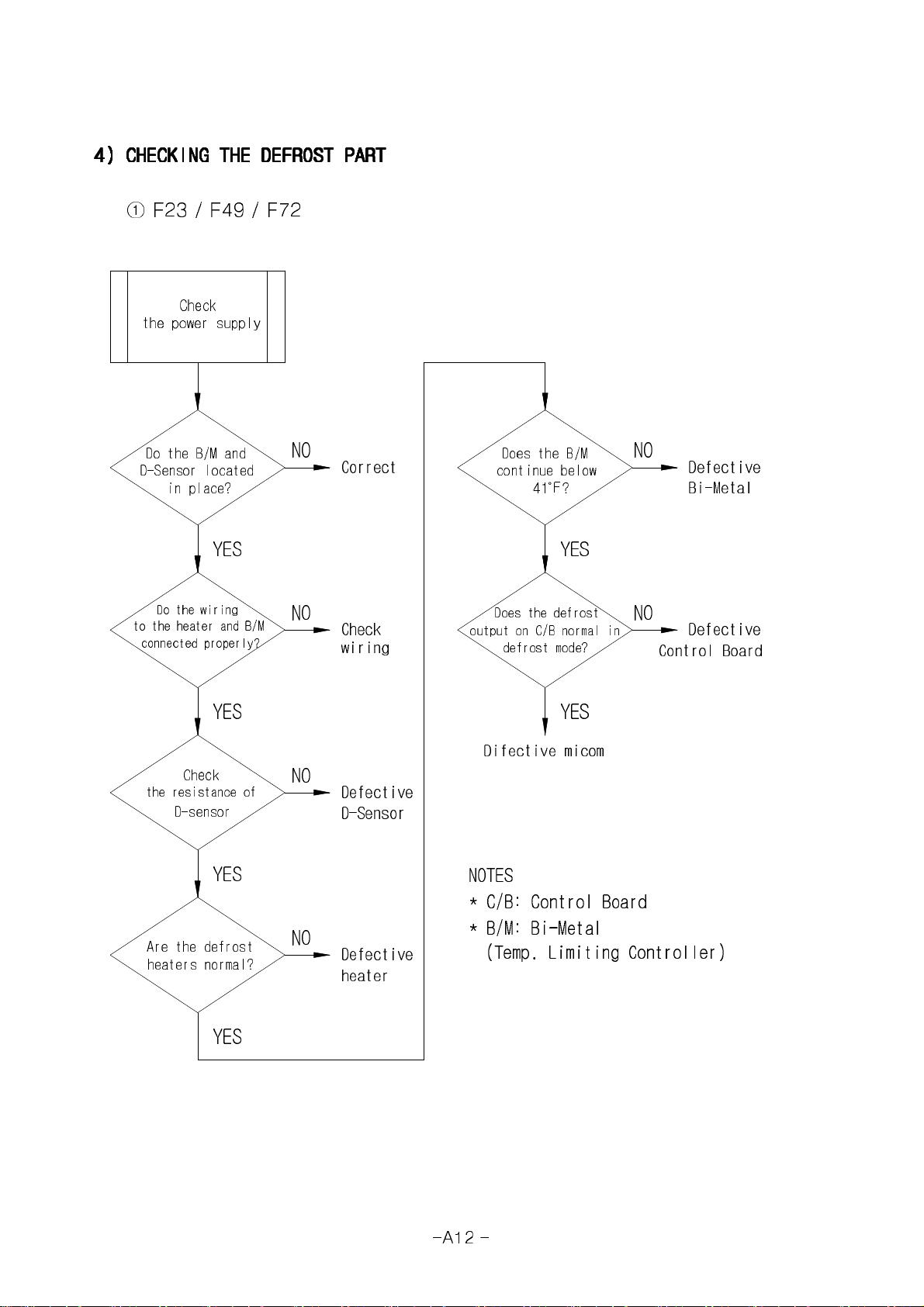

4) CHECKING THE DEFROST PART

4) CHECKING THE DEFROST PART

4) CHECKING THE DEFROST PART4) CHECKING THE DEFROST PART

4) CHECKING THE DEFROST PART

① F23 / F49 / F72

① BASF1/BASF2/BASF3 Models

Check

the power supply

Do the B/M and

D-Sensor located

in place?

YES

Do the wiring

to the heater and B/M

connected properly?

YES

Check

the resistance of

D-sensor

YES

NO

NO

NO

Correct

Check

wiring

Defective

D-Sensor

Does the B/M

continue below

41℉?

YES

Does the defrost

output on C/B normal in

defrost mode?

YES

Difective micom

NOTES

NO

Defective

Bi-Metal

NO

Defective

Control Board

Are the defrost

heaters normal?

YES

NO

Defective

heater

* C/B: Control Board

* B/M: Bi-Metal

(Temp. Limiting Controller)

-A12 -

Page 14

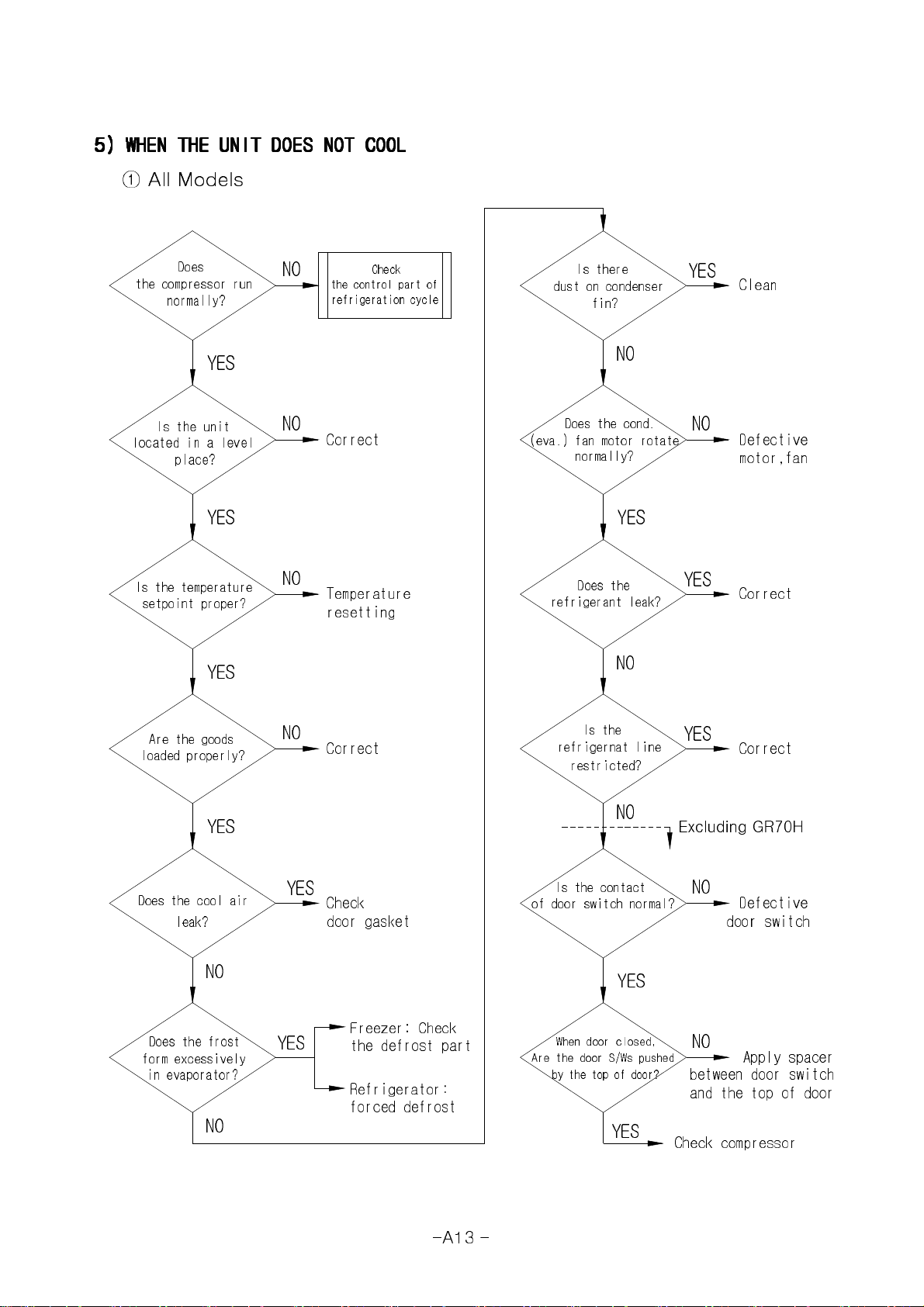

5) WHEN THE UNIT DOES NOT COOL

5) WHEN THE UNIT DOES NOT COOL

5) WHEN THE UNIT DOES NOT COOL

5) WHEN THE UNIT DOES NOT COOL5) WHEN THE UNIT DOES NOT COOL

① All Models

① BASF1/BASF2/BASF3/BASR1/BASR2/BASR3/BAGR72 Models

Does

the compressor run

normally?

YES

Is the unit

located in a level

place?

YES

Is the temperature

setpoint proper?

YES

NO

NO

NO

Check

the control part of

refrigeration cycle

Correct

Temperature

resetting

Is there

dust on condenser

fin?

NO

Does the cond.

(eva.) fan motor rotate

normally?

YES

Does the

refrigerant leak?

NO

YES

Clean

NO

Defective

motor,fan

YES

Correct

Are the goods

loaded properly?

YES

Does the cool air

leak?

NO

Does the frost

form excessively

in evaporator?

NO

NO

YES

YES

Correct

Check

door gasket

Freezer: Check

the defrost part

Refrigerator:

forced defrost

Is the

refrigernat line

restricted?

NO

Is the contact

of door switch normal?

YES

When door closed,

Are the door S/Ws pushed

by the top of door?

YES

YES

Correct

Excluding GR70H

Excluding BAGR72

NO

Defective

door switch

NO

Apply spacer

between door switch

and the top of door

Check compressor

-A13 -

Page 15

6) WHEN THERE IS A ABNORMAL NOISE

6) WHEN THERE IS A ABNORMAL NOISE

6) WHEN THERE IS A ABNORMAL NOISE6) WHEN THERE IS A ABNORMAL NOISE

6) WHEN THERE IS A ABNORMAL NOISE

① All Models

① BASF1/BASF2/BASF3/BASR1/BASR2/BASR3/BAGR72 Models

Is the unit

located in a level

place?

YES

Is the

high voltage supplied?

NO

Are the pipes

rattled?

NO

NO

YES

YES

Correct

Adjust

Reform to

be free of

contact

Are the fans bent?

NO

Do the

fans rotate well?

YES

Is there any

noise in motor?

NO

YES

Defective

fan

NO

Defective

fan,motorvoltage

YES

Defective

motor

Are the parts

assembled tightly?

YES

NO

Tighten

-A14 -

Comp is running

but the unit does

not cool

YES

Check

compressor

Page 16

7) WHEN THE TEMPERATURE DOES NOT DISPLAY

Is

7) WHEN THE TEMPERATURE DOES NOT DISPLAY

7) WHEN THE TEMPERATURE DOES NOT DISPLAY

7) WHEN THE TEMPERATURE DOES NOT DISPLAY7) WHEN THE TEMPERATURE DOES NOT DISPLAY

① F23 / F49 / F72 / R23 / R49 / R72

① BASF1/BASF2/BASF3/BASR3 Models

Check

the power supply

Check

the power supply

in control board

Does the connection

between C/B and D/B

properly?

NO

YES

Is the micom

inserted on C/B

properly?

NO

YES

Replace display board

NOTES

* C/B: Control Board

* D/B: Display Board

Tighten

Tighten

-A15 -

Page 17

8) WHEN THE LAMP DOES NOT LIGHT

8) WHEN THE LAMP DOES NOT LIGHT

8) WHEN THE LAMP DOES NOT LIGHT8) WHEN THE LAMP DOES NOT LIGHT

8) WHEN THE LAMP DOES NOT LIGHT

① BASF1/BASF2/BASF3 Models ② BAGR72 Model

① F23 / F49 / F72 / R23 / R49 / R72

② GR26H / GR48S / GR70H

BASR1/BASR2/BASR3 Models

Check

the power supply

Check the

connecting points

with socket

YES

Is the lamp

defective?

NO

NO

Adjust the lamp

for good connection

YES

Defective

lamp

Check

the power supply

Check the

connecting points

with socket

YES

Is the lamp

defective?

NO

NO

Adjust the lamp

for good connection

YES

Defective

lamp

Check

the continuity of

lamp switch

NO

Defective

lamp switch

the continuity of

lamp switch

YES

When door closed,

Are the door S/Ws pushed

by the top of door?

NO

Apply spacer

between door switch

and the top of door

the continuity of

ballast

YES YES

Check wiring Check wiring

* Incandescence Lamp : 40W

* Fluorescent Lamp: 32W

Check

Check

NO

Defective

lamp switch

YES

NO

Defective

ballast

-A16 -

Page 18

9) CHECKING SENSOR

9) CHECKING SENSOR

9) CHECKING SENSOR 9) CHECKING SENSOR

Sensor assembly consists of T-sensor (lead wire: orange) and

D-sensor (lead wire: blue).

The T-sensor is used for cabinet temperature control and

the D-sensor is used for defrost control.

The resistance of the sensor varies depending on temperature.

If you Immerse the sensor in a glass containing ice water for 2 minutes

and then check for the resistance between sensor leads,

the normal reading is 7.88㏀ (T-sensor) / 30㏀ (D-sensor).

Resistance (㏀)

Temperature (℉)

T-sensor (±6.5%) D-sensor (±5.5%)

-5 23.04 79.17

0 19.76 68.92

10 14.65 52.61

23 10.10 37.55

32 7.88 30.00

41 6.20 24.13

50 7.91 19.53

60 3.82 15.56

70 3.00 12.48

-A17 -

Page 19

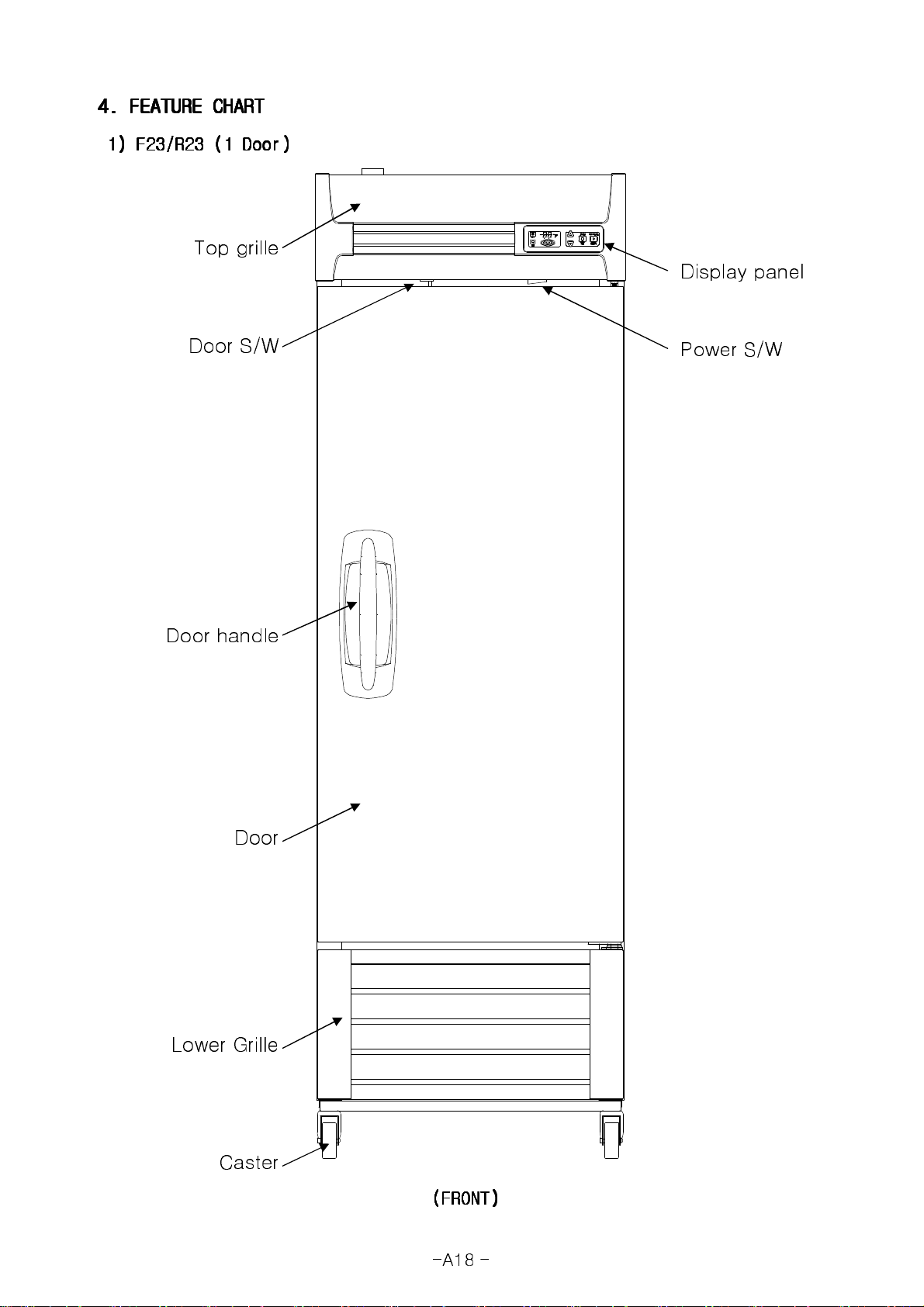

4. FEATURE CHART

4. FEATURE CHART

4. FEATURE CHART 4. FEATURE CHART

1) F23/R23 (1 Door)

1) F23/R23 (1 Door)

1) F23/R23 (1 Door) 1) F23/R23 (1 Door)

Top grille

Display panel

Door S/W

Door handle

Power S/W

Door

Lower Grille

Caster

(FRONT)

(FRONT)

(FRONT) (FRONT)

-A18 -

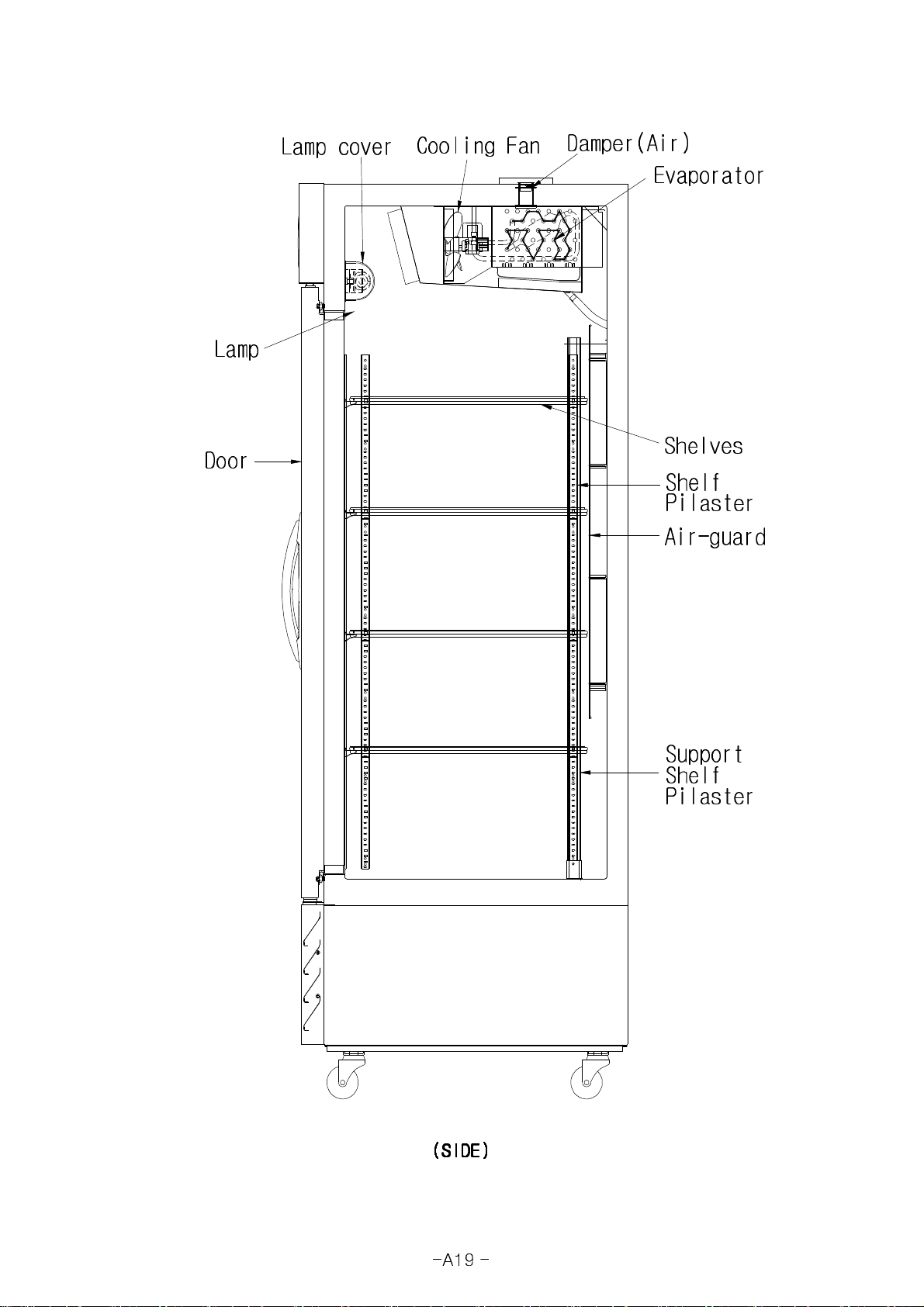

Page 20

Lamp

Lamp cover

Cooling Fan

Damper(Air)

Evaporator

Door

Shelves

Shelf

Pilaster

Air-guard

Support

Shelf

Pilaster

(SIDE)

(SIDE)

(SIDE) (SIDE)

-A19 -

Page 21

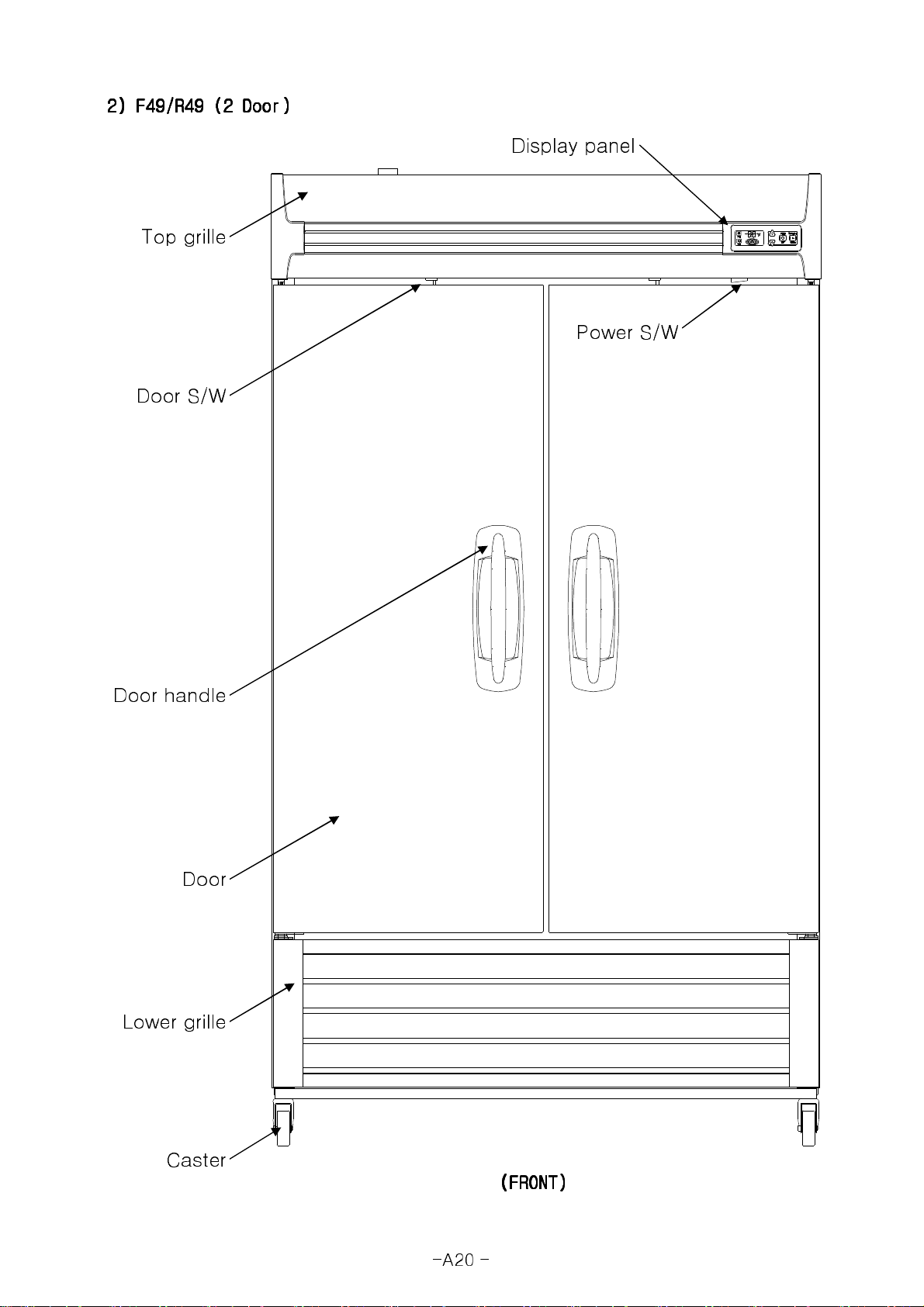

2) F49/R49 (2 Door)

2) F49/R49 (2 Door)

2) F49/R49 (2 Door) 2) F49/R49 (2 Door)

Top grille

Door S/W

Display panel

Power S/W

Door handle

Door

Lower grille

Caster

(FRONT)

(FRONT)

(FRONT) (FRONT)

-A20 -

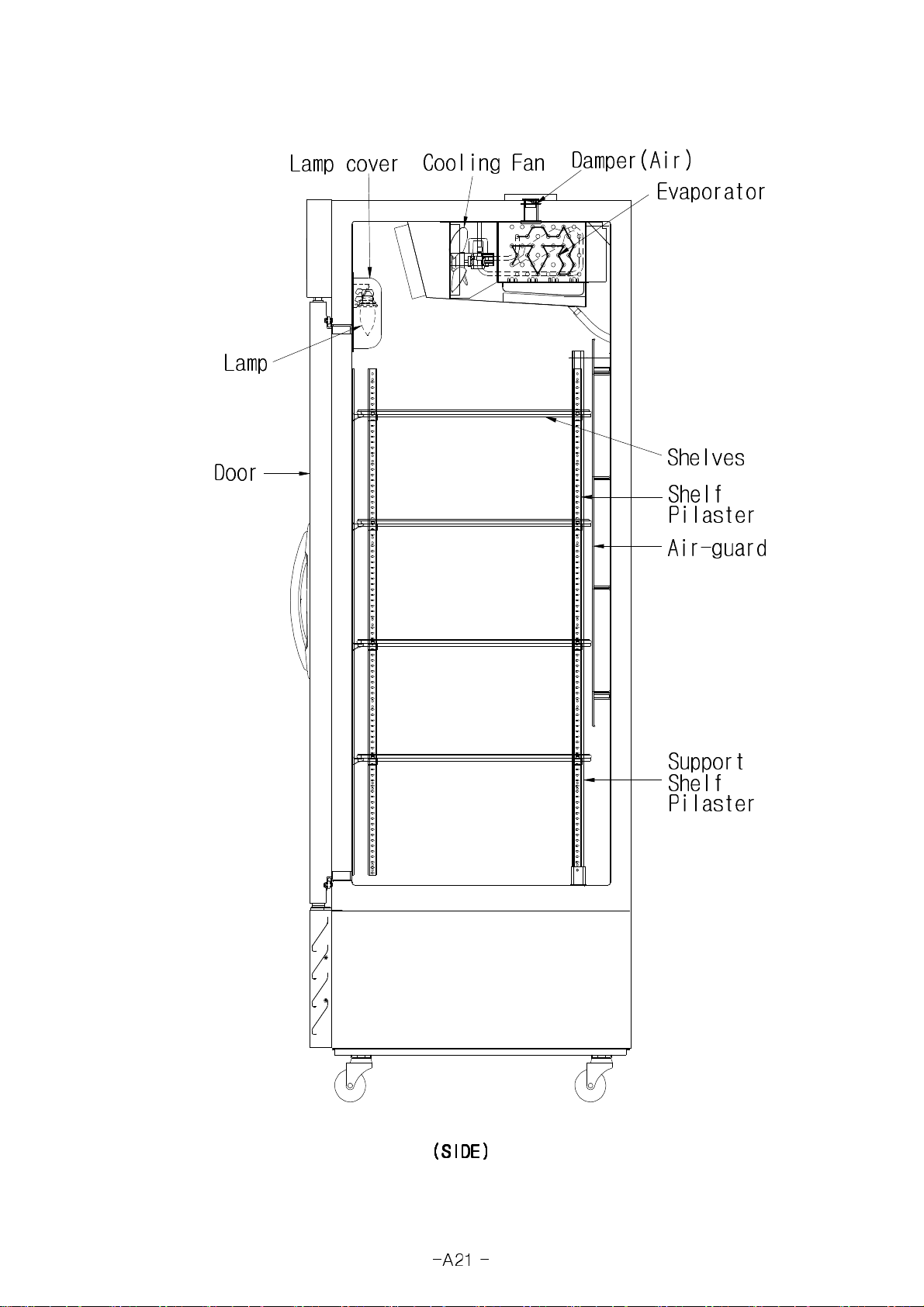

Page 22

Lamp

Lamp cover

Cooling Fan

Damper(Air)

Evaporator

Door

Shelves

Shelf

Pilaster

Air-guard

Support

Shelf

Pilaster

(SIDE)

(SIDE)

(SIDE) (SIDE)

-A21 -

Page 23

3) F72/R72 (3 Door)

3) F72/R72 (3 Door)

3) F72/R72 (3 Door) 3) F72/R72 (3 Door)

Top grille

Door S/W

Display panel

Power S/W

Lower grille

Door handle

Door

Caster

(FRONT)

(FRONT)

(FRONT) (FRONT)

-A22 -

Page 24

Lamp

Lamp cover

Cooling Fan

Damper(Air)

Evaporator

Door

Shelves

Shelf

Pilaster

Air-guard

Support

Shelf

Pilaster

(SIDE)

(SIDE)

(SIDE) (SIDE)

-A23 -

Page 25

4) GR26H (Glass 1 Door)

4) GR26H (Glass 1 Door)

4) GR26H (Glass 1 Door) 4) GR26H (Glass 1 Door)

AD. Panel

Door(Glass)

Door

Lower grille

Adjust foot

(FRONT)

(FRONT)

(FRONT) (FRONT)

-A24 -

Page 26

BALLAST

AD. PANEL

LAMP

FAN COVER

COOLING FAN

COOLING FAN MOTOR

EVAPORATOR

COVER LAMP

DOOR FRAME

LAMP

DOOR HANDLE

WATER COLLECTOR

DRAIN HOSE

SHELF SUPPORT

SHELF

LOWER GRILLE

CONDENSER

CONDENSER FAN MOTOR

MOTOR BRKT

(SIDE)

(SIDE)

(SIDE) (SIDE)

-A25 -

DRYER

SUCTION PIPE

COMPRESSOR

Page 27

5) GR48S (Glass 2 Door)

5) GR48S (Glass 2 Door)

5) GR48S (Glass 2 Door) 5) GR48S (Glass 2 Door)

Door(Glass)

AD. Panel

Door handle

Lower grille

(FRONT)

(FRONT)

(FRONT) (FRONT)

-A26 -

Adjust foot

Page 28

COOLING FAN COVER

COOLING FAN

BALLAST

AD. PANEL

LAMP

LAMP

LAMP TUBE

DOOR HANDLE

COOLING FAN MOTOR

EVAPORATOR

WATER COLLECTOR

DRAIN HOSE

SHELF SUPPORT

SHELF

DOOR FRAME

CENTER POST

LOWER GRILL

CONDENSER

CONDENSER FAN MOTOR

DRIER

SUCTION PIPE

COMPRESSOR

MOTOR BRKT

(SIDE)

(SIDE)

(SIDE) (SIDE)

-A27 -

Page 29

6) GR70H (Glass 3 Door)

6) GR70H (Glass 3 Door)

6) GR70H (Glass 3 Door) 6) GR70H (Glass 3 Door)

Door(Glass)

AD. Panel

Door handle

Lower grille

Adjust foot

(FRONT)

(FRONT)

(FRONT) (FRONT)

-A28 -

Page 30

Lamp

Door(Glass)

Evaporator Fan Motor

Evaporator

Shelves

Shelf

Pilaster

Door handle

Support

Shelf

Pilaster

(SIDE)

(SIDE)

(SIDE) (SIDE)

-A29 -

Page 31

5. WIRING DIAGRAMS

5. WIRING DIAGRAMS

5. WIRING DIAGRAMS 5. WIRING DIAGRAMS

1) F23

1) F23

1) F23 1) F23

2) F49

2) F49

2) F49 2) F49

-A30 -

Page 32

3) F72

3) F72

3) F72 3) F72

4) R23

4) R23

4) R23 4) R23

-A31 -

Page 33

5) R49

5) R49

5) R49 5) R49

6) R72

6) R72

6) R72 6) R72

-A32 -

Page 34

7) GR26H

7) GR26H

7) GR26H 7) GR26H

8) GR48S

8) GR48S

8) GR48S 8) GR48S

-A33 -

Page 35

9) GR70H

9) GR70H

9) GR70H 9) GR70H

-A34 -

Page 36

6. REPLACEMENT OF COMPONENTS

6. REPLACEMENT OF COMPONENTS

6. REPLACEMENT OF COMPONENTS 6. REPLACEMENT OF COMPONENTS

1) CONDENSING UNIT

1) CONDENSING UNIT

1) CONDENSING UNIT 1) CONDENSING UNIT

(F49/F72/R49/R72)

(F49/F72/R49/R72) (F23/R23/GR26H)

(F49/F72/R49/R72) (F49/F72/R49/R72)

DisassembleDisassemble

Disassemble

(GR48S/GR70H)

(GR48S/GR70H)

(GR48S/GR70H) (GR48S/GR70H)

(F23/R23/GR26H)

(F23/R23/GR26H) (F23/R23/GR26H)

a) Unplug the power cord before

service.

b) Remove screw securing the

lower grille.

* Remove screw securing the

reinforce angle.

(GR48S/GR70H)

(F49/F72/R49/R72)

(F49/F72/R49/R72) (F23/R23/GR26H)

(F49/F72/R49/R72) (F49/F72/R49/R72)

(F23/R23/GR26H)

(F23/R23/GR26H) (F23/R23/GR26H)

c) Separate the compressor har-

ness out of the terminal block.

d) Remove screws securing the

unit base plate and pull out

condensing unit with care.

e) Replace the necessary com-

(GR48S/GR70H)

(GR48S/GR70H)

※ CAUTION

※ CAUTION

※ CAUTION ※ CAUTION

(GR48S/GR70H) (GR48S/GR70H)

ponent.

1. Please pull out or push in the unit base plate carefully to prevent capillary tube, pipes

and wires from demaging.

2. It is recommend to arrange wires after you push in the unit base plate.

-A35 -

Page 37

2-1) LAMP

) Remove screw securing the Ad. Panel Frame and pull out the Ad. Panel Frame with care.

2-1) LAMP

2-1) LAMP 2-1) LAMP

AD. PANEL

AD. PANEL FRAME

(GR26H)

(GR26H)

(GR26H)(GR26H)

LAMP HOLDER

LAMP CAP

LAMP

a) Unplug the power cord before service.

b

c) Separate the Ad. Panel.

d) Separate the Lamp from the Lamp Holder.

e) Separate the Lamp Cap and replace the Lamp with care.

a) Unplug the power cord before

service.

b) Separate the Lamp from the

LAMP CAP

SOCKET

Lamp Holder.

c) Separate the Lamp Socket and

LAMP COVER

the Cap Lamp.

d) Replace the Lamp with care.

LAMP

LAMP TUBE

♠ Lamp Description : AC115V, F17T8/TL950

♠ Lamp Description : AC115V, F17T8/TL950

♠ Lamp Description : AC115V, F17T8/TL950 ♠ Lamp Description : AC115V, F17T8/TL950

-A36 -

Page 38

2-2) LAMP

2-2) LAMP

2-2) LAMP 2-2) LAMP

(GR48S)

(GR48S)

(GR48S)(GR48S)

LAMP HOLDER

LAMP CAP

1

2

3

4

5

6

7

1

2

LAMP

a) Unplug the power cord before service.

b) Remove screw securing the Ad. Panel Side.

c) Separate the Ad. Panel.

d) Separate the Lamp from the Lamp Holder.

AD. PANEL FRAME SIDE

7

1

2

3

AD. PANEL

e) Separate the Lamp Cap and replace the Lamp with care.

a) Unplug the power cord before

service.

b) Separate the Lamp from the

Lamp Holder.

c) Separate the Lamp Socket and

the Lamp Cap.

d) Replace the Lamp with care.

♠ Lamp Description : AC115V, FHF32SSEX-D-5

♠ Lamp Description : AC115V, FHF32SSEX-D-5

♠ Lamp Description : AC115V, FHF32SSEX-D-5 ♠ Lamp Description : AC115V, FHF32SSEX-D-5

-A37 -

Page 39

2-3) LAMP

2-3) LAMP

2-3) LAMP 2-3) LAMP

(GR70H)

(GR70H)

(GR70H)(GR70H)

Lamp Holder

Ad. Panel Frame (R)

Cap Lamp

a) Unplug the power cord before service.

b) Remove screw securing the Ad. Panel Frame (R).

c) Separate the Ad. Panel.

d) Separate the Lamp from the Lamp Holder.

e) Separate the Cap Lamp and replace the Lamp with care.

Lamp

Ad. Panel

Lamp Cap

Cap Lamp

Thin Screw

Lamp Base

Lamp

Lamp Tube

Socket

♠ Lamp Description : AC115V, 32W, F32T8/TL860

♠ Lamp Description : AC115V, 32W, F32T8/TL860

♠ Lamp Description : AC115V, 32W, F32T8/TL860 ♠ Lamp Description : AC115V, 32W, F32T8/TL860

a) Unplug the power cord before

service.

b) Separate the Lamp from the

Lamp Holder.

c) Separate the Lamp Socket and

the Lamp Cap.

d) Replace the Lamp with care.

-A38 -

Page 40

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR) ■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

GR26/GR48/GR70(MERCHANDISERS)

GR26/GR48/GR70(MERCHANDISERS)

GR26/GR48/GR70(MERCHANDISERS) GR26/GR48/GR70(MERCHANDISERS)

B. OPERATION AND ELECTRONIC CONTROLLER FUNCTION

1. OPERATION FOR F23, F49, F72, R23, R49, R72 MODELS - - - - - B2

1. OPERATION FOR F23, F49, F72, R23, R49, R72 MODELS - - - - - B2

1. OPERATION FOR F23, F49, F72, R23, R49, R72 MODELS - - - - - B2 1. OPERATION FOR F23, F49, F72, R23, R49, R72 MODELS - - - - - B2

1) BASIC OPERATION

2) ELECTRONIC CONTROLLER SETING MODE

3) NORMAL CONTROL PROCESS

4) ERROR CODE

2. OPERATION FOR GR26H, GR48S, GR70H MODELS - - - - - - - - - B9

2. OPERATION FOR GR26H, GR48S, GR70H MODELS - - - - - - - - - B9

2. OPERATION FOR GR26H, GR48S, GR70H MODELS - - - - - - - - - B9 2. OPERATION FOR GR26H, GR48S, GR70H MODELS - - - - - - - - - B9

1) BASIC OPERATION

2) ELECTRONIC CONTROLLER SETING MODE

3) NORMAL CONTROL PROCESS

4) ERROR CODE

4. INSTRUCTION FOR RE-HINGING DOOR - - - - - - - - - - - - - B10

4. INSTRUCTION FOR RE-HINGING DOOR - - - - - - - - - - - - - B10

4. INSTRUCTION FOR RE-HINGING DOOR - - - - - - - - - - - - - B10 4. INSTRUCTION FOR RE-HINGING DOOR - - - - - - - - - - - - - B10

....

- B1 -

Page 41

1. OPERATION FOR F23/F49/F72(FREEZER), R23/R49/R72(REFRIGERATOR)

1. OPERATION FOR F23/F49/F72(FREEZER), R23/R49/R72(REFRIGERATOR)

1. OPERATION FOR F23/F49/F72(FREEZER), R23/R49/R72(REFRIGERATOR) 1. OPERATION FOR F23/F49/F72(FREEZER), R23/R49/R72(REFRIGERATOR)

1) BASIC OPERATION

1) BASIC OPERATION

1) BASIC OPERATION 1) BASIC OPERATION

① Plug in the power cord and turn on the power switch located on the bottom of the top grille

right side.

[ The unit should be plugged into a

[ The unit should be plugged into a

② Display panel will be lightened for 2 seconds with buzzer then displays cabinet interior

temperature (T-sensor) and running conditions.

* Freezer : If cabinet interior temperature is higher than 14℉ compressor will run without

delay, and lower than 14℉, compressor will run after 3 minutes.

* Refrigerator : If cabinet interior temperature is higher than 50℉ compressor will run

without delay, and lower than 50℉, compressor will run after 3 minutes.

③ The default OPERATING TEMPERATURE SETTING

* Freezer : Temperature set point (setting mode sign [st]) is –5℉

Temperature differential set point (setting mode sign [di]) is 8℉.

(Operating Temperature : -14℉ ~ -4℉)

Range of adjustable set point: -22℉ ~ 8℉

* Refrigerator : Temperature set point (setting mode sign [st]) is 36℉

115V±10%, 60Hz

115V±10%, 60Hz

115V±10%, 60Hz 115V±10%, 60Hz

115V/208~230V, 60Hz

115V/208~230V, 60Hz

115V/208~230V, 60Hz115V/208~230V, 60Hz

(F23, F49, R23, R49, R72 models) ]

(F72 model) ]

Temperature differential set point (setting mode sign [di]) is 8℉.

(Operating Temperature : 34℉ ~ 44℉)

Range of adjustable set point: 25℉ ~ 50℉

④ Defrost frequency

* Freezer : It is controlled by MICOM and the default defrost frequency is 6 hours.

* Refrigerator : It is controlled by MICOM and the default defrost frequency is 12 hours.

⑤ The light inside the cabinet comes on when the door is opened.

The cabinet interior cooling fan has 3 seconds delay when the door is closed.

⑥ If door is opened, door open warnign sign (LED) will turn on.

If door is opened more than 30 seconds, the sound alarm beeps 3times,

if open more than 60 seconds, the sound alarm beeps 5 times and if open more than 5 minutes,

the sound alarm will beep continuously.

⑦ Cabinet interior temperature

* Freezer : If it is higher than 14℉(F23, F49, F72), the panel displays [Hi] and

- B2 -

Page 42

lower than -50℉(F23, F49, F72), the panel displays [Lo].

* Refrigerator : If it is higher than 68℉(F23, F49, F72), the panel displays [Hi] and

lower than 14℉(F23, F49, F72), the panel displays [Lo].

2) ELECTRONIC CONTROLLER SETTING MODE

2) ELECTRONIC CONTROLLER SETTING MODE

2) ELECTRONIC CONTROLLER SETTING MODE 2) ELECTRONIC CONTROLLER SETTING MODE

- B3 -

Page 43

No Setting Mode

Mode

Sign

How to Setting

Temperature

TemperatureTemperature

1

Temperature

Setting

Setting

SettingSetting

Mode

Mode

ModeMode

"St"

"St"

"St""St"

1. To enter this mode, press

until

2. Then press

[St]

[St]

is displayed.

[St][St]

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

3. To change the set point, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

and

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

to see current temperature set point.

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

until the desired value

is displayed.

4. At the end of the sequence, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

to set the value.

5. To display the cabinet temperature again, press

[th]

[th]

is displayed and then press

[th][th]

6. Range of adjustable set point :

Range of adjustable set point :

[VERIFY]

[VERIFY]

[VERIFY][VERIFY]

-22℉ to 8℉

-22℉ to 8℉

-22℉ to 8℉ -22℉ to 8℉

25℉ to 50℉

25℉ to 50℉

25℉ to 50℉ 25℉ to 50℉

.

(Freezer)

(Refrigerator)

simultaneously

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

until

Temperature

Temperature

TemperatureTemperature

Differential

Differential

DifferentialDifferential

2

Setting

Setting

SettingSetting

Mode

Mode

ModeMode

"di"

"di"

"di""di"

1. To enter this mode, press

until

2. Then press

[di]

[di]

is displayed.

[di][di]

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

3. To change the set point, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

and

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

to see current temperature differential.

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

until the desired value

is displayed.

4. At the end of the sequence, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

to set the value.

5. To display the cabinet temperature again, press

[th]

[th]

is displayed and then press

[th][th]

6. Range of adjustable set point :

Range of adjustable set point :

[VERIFY]

[VERIFY]

[VERIFY][VERIFY]

4℉ to 16℉

4℉ to 16℉

4℉ to 16℉4℉ to 16℉

6℉ to 16℉

6℉ to 16℉

6℉ to 16℉6℉ to 16℉

.

(Freezer)

(Refrigerator)

simultaneously

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

until

(The Unit of Setting : 2℉)

- B4 -

Page 44

No Setting Mode

Mode

Sign

How to Setting

3

Defrost

Defrost

DefrostDefrost

Frequency

Frequency

FrequencyFrequency

Setting

Setting

SettingSetting

Mode

Mode

ModeMode

"dt"

"dt"

"dt""dt"

1. To enter this mode, press

until

2. Then press

[dt]

[dt]

is displayed.

[dt][dt]

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

3. To change the defrost frequency, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

and

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

to see current defrost frequency.

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

value is displayed.

4. At the end of the sequence, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

to set the value.

5. To display the cabinet temperature again, press

[th]

[th]

is displayed and then press

[th][th]

6. Range of adjustable defrost frequency :

[VERIFY]

[VERIFY]

[VERIFY][VERIFY]

.

4Hr to 12Hr

4Hr to 12Hr

4Hr to 12Hr4Hr to 12Hr

(The Unit of frequency : 2Hr)

simultaneously

until the desired

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

until

4

Cancelation

CancelationCancelation

5

6

Forced

Forced

ForcedForced

Defrost

Defrost

DefrostDefrost

Mode

Mode

ModeMode

Cancelation

of

of

ofof

Forced

Forced

ForcedForced

Defrost

Defrost

DefrostDefrost

Mode

Mode

ModeMode

Rapid

Rapid

RapidRapid

Freeze

Freeze

FreezeFreeze

Mode

Mode

ModeMode

(Freezer)

(Freezer)

(Freezer)(Freezer)

"dF"

"dF"

"dF""dF"

Flash

Flash

FlashFlash

"dF"

"dF"

"dF""dF"

"tb"

"tb"

"tb""tb"

1. To enter this mode, press

until

2. Then press

3. During defrosting,

[dF]

[dF]

is displayed.

[dF][dF]

[MANUAL DF]

[MANUAL DF]

[MANUAL DF][MANUAL DF]

[dF]

[dF]

[dF][dF]

1. During forced defrost, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

more than

and

2 seconds

2 seconds

2 seconds2 seconds

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

simultaneously

to start forced defrost.

is displayed instead of the cabinet temperature.

[MANUAL DF]

[MANUAL DF]

[MANUAL DF][MANUAL DF]

more than

2 seconds to stop forced defrost.

2. The [dF] will be flash 5 times and then return to normal display mode.

1. To enter this mode, press

until

2. Then press

[tb]

[tb]

is displayed.

[tb][tb]

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

more than

and

2 seconds

2 seconds

2 seconds2 seconds

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

simultaneously

to start rapid freeze mode.

3. During rapid freeze,

- B5 -

[tb]

[tb]

is displayed instead of the cabinet temperature.

[tb][tb]

Page 45

No Setting Mode

Mode

Sign

How to Setting

Cancelation of

Cancelation of

Cancelation ofCancelation of

Rapid

Rapid

RapidRapid

Freeze

Freeze

7

8

8

FreezeFreeze

Mode

Mode

ModeMode

(Freezer)

(Freezer)

(Freezer)(Freezer)

Cabinet

Cabinet

CabinetCabinet

Temperature

Temperature

TemperatureTemperature

Verification

Verification

VerificationVerification

Mode

Mode

ModeMode

Cabinet

Cabinet

CabinetCabinet

Temperature

Temperature

TemperatureTemperature

Verification

Verification

VerificationVerification

Mode

Mode

ModeMode

Flash

Flash

FlashFlash

"tb"

"tb"

"tb""tb"

"th"

"th"

"th""th"

"th"

"th"

"th""th"

1. During rapid freeze, press

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

more than

2 seconds to stop rapid freeze.

2. The

1. To enter this mode, press

until

2. Then press

[tb]

[tb]

will be flash 5 times and then return to normal display mode.

[tb][tb]

[MODE/SET]

[th]

[th]

is displayed.

[th][th]

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

to see F-sensor, D-sensor temperature in turn.

and

[UP or DOWN]

[UP or DOWN]

[UP or DOWN][UP or DOWN]

simultaneously

3. To check only the F-sensor or D-sensor temperature, press

again.

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

4. Press

(return to normal display mode)

3) NORMAL CONTROL PROCESS

3) NORMAL CONTROL PROCESS

3) NORMAL CONTROL PROCESS 3) NORMAL CONTROL PROCESS

No FUNCTION

1. After Power ON, Display panel will be lightened for 2 seconds with buzzer then

1

Initial

Initial

InitialInitial

Operating

Operating

OperatingOperating

displays cabinet interior temperature.

2. If cabinet interior temperature is higher than 14℉, compressor will run

without delay, and lower than 14℉, compressor will run after 3 minutes.

1. Compressor and condenser fan motor is controlled by T-sensor and MICOM program.

displays cabinet interior temperature.

2. Compressor ON/OFF Temperature

Normal

Normal

2

NormalNormal

Operating

Operating

OperatingOperating

Compressor ON : Temperature Setting Value + (Temperature Differential Setting Value/2)

Compressor OFF : Temperature Setting Value - (Temperature Differential Setting Value/2)

[VERIFY]

[VERIFY]

[VERIFY] [VERIFY]

to see current cabinet temperature.

FUNCTION SPEC

ex) st: -9℉, di: 10℉ ⇒ Compressoer ON: -9+(10/2) = -4℉,Compressoer OFF: -9-(10/2) = -14℉

st: 39℉, di: 10℉ ⇒ Compressoer ON: 39+(10/2) = 44℉,Compressoer OFF: 39-(10/2) = 34℉

- B6 -

Page 46

No FUNCTION

It prevent exceed temperature rise during defrosting,

Rapid

Rapid

RapidRapid

3

Freeze

Freeze

FreezeFreeze

(Freezer)

(Freezer)

(Freezer)(Freezer)

FUNCTION SPEC

1. Compressor and cabinet interior cooling fan is running continuously for

120 minutes without control by sensor.

2. It is impossible to set the other modes during Rapid Freeze Mode.

It is necessary to cancel the Rapid Freeze Mode before setting the other modes.

3. If Defrost Mode become in the Rapid Freeze Mode duration,

Defrost Mode will start after the Rapid Freeze Mode finished.

4. Rapid Freeze Mode will be start after Defrost Mode finished not during

Defrost Mode. [tb] is displayed from startng the Rapid Freeze Mode.

1. Defrost process is like below

Process

Process Controlled Part

ProcessProcess

Controlled Part Description

Controlled PartControlled Part

Description

DescriptionDescription

(Freezer)

(Freezer)

(Freezer)(Freezer)

4

(Refrigerator)

(Refrigerator)

(Refrigerator)(Refrigerator)

Defrost

Defrost

DefrostDefrost

Defrost

Defrost

DefrostDefrost

Pre

Pre----Cool

Cool

PrePre

CoolCool

Defrost

Defrost

DefrostDefrost

Pause

Pause

PausePause

Evaporator

Evaporator

Evaporator Evaporator

Fan Delay

Fan Delay

Fan DelayFan Delay

Compressor

Evaporator Fan

Condenser Fan

Defrost Heater

Compressor

Evaporator Fan

Condenser Fan

Defrost Heater

Compressor

Evaporator Fan

Condenser Fan

Defrost Heater

Compressor

Evaporator Fan

Condenser Fan

Defrost Heater

On

On

OnOn

Off

Off

OffOff

Off

Off

OffOff

On

On

OnOn

①

On

On

OnOn

② Cycle is run continuously until current compressor

On

On

OnOn

cut-out temperature reach.

Off

Off

OffOff

③ Maximum time: 30minutes

① Preprogrammed frequency interval

Off

Off

Off Off

② If D-sensor is higher than 50℉, defrost heater off

Off

Off

OffOff

③ Maximum time: 40minutes

On

On

OnOn

OOOOff

ff

ff ff

① Time: 3minutes

Off

Off

OffOff

Off

Off

OffOff

① If D-sensor is lower than -4℉, Fan delay

Off

Off

Off Off

terminated

On

On

On On

② Maximum time: 10minutes

Off

Off

OffOff

On

On

OnOn

5minutes

1. Defrost Frequency : Preprogrammed frequency interval

2. Defrost time : 22 minutes

3. Defrost mode Operation

1) Compressor OFF, Condenser Fan OFF

2) Evaporator Fan ON

(Freezer)

(Freezer)

(Freezer)(Freezer)

5

(Refrigerator)

(Refrigerator)

(Refrigerator)(Refrigerator)

Default

Default

DefaultDefault

Setting

Setting

SettingSetting

Default

Default

DefaultDefault

Setting

Setting

SettingSetting

3)

1. Temperature Setting :

2. Operating Temperature :

3. Defrost Frequency Setting :

1. Temperature Setting :

2. Operating Temperature :

[dF]

[dF]

is displayed

[dF][dF]

3. Defrost Frequency Setting :

-5℉

-5℉,

-5℉-5℉

36℉

36℉

36℉36℉

Temperature Differential Setting :

-14℉

-14℉

(compressor off)

-14℉-14℉

6Hr

6Hr

6Hr6Hr

~ -4℉

~ -4℉

~ -4℉ ~ -4℉

, Temperature Differential Setting :

44℉

44℉

(compressor on)

44℉44℉

6Hr

6Hr

6Hr6Hr

~ 34℉

~ 34℉

~ 34℉ ~ 34℉

(compressor off)

- B7 -

8℉

8℉

8℉ 8℉

(compressor on)

8℉

8℉

8℉ 8℉

Page 47

No FUNCTION

FUNCTION SPEC

Setting

Setting

6

7

4) ERROR CODE

4) ERROR CODE

4) ERROR CODE 4) ERROR CODE

SettingSetting

Back UP

Back UP

Back UPBack UP

Error

Error

ErrorError

Display

Display

DisplayDisplay

Error

Code

During normal mode (not defrost mode),

C1

D-sensor sensing is higher than 23℉ and

Compressor does not run for 60min after

compressor off

1. In case of unexpected power failure or power off, does not require resetting.

2. The setting is memorized.

1. If cabinet interior temperature is higher than 14℉ the panel displays

and lower than -50℉ the panel displays

[Lo]

[Lo]

[Lo][Lo]

.

[Hi]

[Hi]

[Hi][Hi]

,

2. Press [down] button 5 times with pressing and holding [up] button, the Error

display mode is activated and it displays errors.

3. When there are more than 2 errors, the errors are displayed alternately.

4. If you press

Condition Possible Cause

[MODE/SET]

[MODE/SET]

[MODE/SET][MODE/SET]

button, the error display mode will be finished

When error occurring,

operation

●

Ambinet Temperature

too low (below -5℉)

T-sensor defective

1) Register "C1"

2) Compressor ON:20Minutes

3) Compressor OFF:5Minutes

4) Operate 2),3) three times

5) Operate Normal Mode

Entering defrost mode, D-sensor

C2

sensing is higher than 50℉ and

T-sensor sensing is lower than 14℉

After defrost mode elapsed for

C3

40minutes, D-sensor sensing is lower than

23℉

C4

T-sensor sensing is more than 18℉

higher than temperature set point for

4hours

C- No error code

Additionnal Possible Cause: Too

many hot goods loaded!!

D-sensor defective

D-sensor defective

Defrost heater defective

Refrigerant leak

Control board defective

Door not sealing

Not enough defrosts

Condenser dirty

Sensor defective

N/A N/A

1) Register "C2"

2) Operate Pre-Cool step :

30Minutes

3) Defrost Heater ON :

20Minutes

4) Operate the rest Defrost

Mode

1) Register "C3"

2) Operate the rest Defrost

Mode

1) Register "C4"

2) Compressor ON:20Minutes

3) Compressor OFF:5Minutes

4) Operate 2),3) three times

5) Operate Normal Mode

- B8 -

Page 48

2. OPERATION FOR GR26H, GR48S, GR70H MODELS

2. OPERATION FOR GR26H, GR48S, GR70H MODELS

2. OPERATION FOR GR26H, GR48S, GR70H MODELS 2. OPERATION FOR GR26H, GR48S, GR70H MODELS

1) BASIC OPERATION

1) BASIC OPERATION

1) BASIC OPERATION 1) BASIC OPERATION

① Plug in the power cord and turn on the lamp switch located on the left of the temperature

controller.

[ The unit should be plugged into a

③ The controller(Thermostat) has been preset "3" position at the factory

2) DEFROST

2) DEFROST

2) DEFROST 2) DEFROST

115V±10%, 60Hz

115V±10%, 60Hz

115V±10%, 60Hz115V±10%, 60Hz

]

This unit uses an off cycle defrost. No needs any programming.

3) CONTROL TEMPERATURE

3) CONTROL TEMPERATURE

3) CONTROL TEMPERATURE 3) CONTROL TEMPERATURE

① The temperature controller is mounted on top of the cabinet interior.

② The controller has been preset "3" position at the factory to maintain the average

cabinet temperature of 38℉

1

1

F

F

F

F

O

ON

ON

OFF

OFF

LAMP S/W Only

LAMP S/W Only

O

7

7

TEMP. CONTROLLER

TEMP. CONTROLLER

2

2

3

3

46

46

5

5

4) LAMP

4) LAMP

4) LAMP 4) LAMP

① The light comes on when the lamp switch is on.

- B9 -

Page 49

3. INSTRUCTION FOR RE-HINGING DOOR (F23/R23)

3. INSTRUCTION FOR RE-HINGING DOOR (F23/R23)

3. INSTRUCTION FOR RE-HINGING DOOR (F23/R23) 3. INSTRUCTION FOR RE-HINGING DOOR (F23/R23)

Top Grille

1

Top Grille

Top Grille

Top Grille

Top Grille

1

2

2

3

3

4

4

Re

Re

Re

Re

ReRe

ReRe

Re

Re

Re

Re

ReRe

ReRe

----

hinging

hinging

----

hinging

hinging

hinginghinging

hinginghinging

----

hinging

hinging

----

hinging

hinging

hinginghinging

hinginghinging

*

*

7

7

2

2

8

8

4

4

CABINET

CABINET

CABINET

CABINET

Lower Grille

Bottom Grille

Bottom Grille

Bottom Grille

Bottom Grille

Figure 1.

Figure 1.

Figure 1.

Figure 1.

*

*

84

84

DOOR

DOOR

DOOR

DOOR

*

5

5

6

6

7

7

*

*

*

9

9

10

10

1

1

180˚

180˚

Figure 2.

Figure 2.

Figure 2.

Figure 2.

Turn the hinge in

Turn the hinge in

Turn the hinge in

Turn the hinge in

A counterclockwise

A counterclockwise

A counterclockwise

A counterclockwise

direction

direction

direction

direction

Figure 3.

Figure 3.

Figure 3.

Figure 3.

- B10 -

Figure 4.

Figure 4.

Figure 4.

Figure 4.

Page 50

▣ To change the door mounting from right hand to left hand hinges you will need the following;

▣ Medium to large size Phillips Screwdriver

146413 Door Hinge Kit - Lower Left

146442 Door Hinge Kit - Top Left

STEP1. Remove the door (Figure 1)

STEP1. Remove the door (Figure 1)

STEP1. Remove the door (Figure 1) STEP1. Remove the door (Figure 1)

a) Remove the Top Grille (seven screws)

b) Remove the Lower Grille (four screws)

c) Remove the Top Hinge (#1) (four screws)

d) Lift and remove the Door

e) Remove the Bottom Hinge (#7) (four screws)

STEP2. Convert the Door

STEP2. Convert the Door

STEP2. Convert the Door STEP2. Convert the Door

a) Replace the Spring Guide (#4) with Bushing (#9)-(SEE 146413 HINGE KIT)

b) Replace the Bushing (#5) with the Spring Guide (#4).

STEP3. Reinstall the Door (figure 2)

STEP3. Reinstall the Door (figure 2)

STEP3. Reinstall the Door (figure 2) STEP3. Reinstall the Door (figure 2)

a) Install Bottom Left Hinge (#1) with Bushing (#10)-(SEE 146413 HINGE KIT)

b) Set Door in place on Bottom Hinge

c) Insert Spring (#8) (silver) into Spring Guide (#4) as shown in figure 3-(SEE 146442 HINGE KIT)

d) Install the Top Hinge (#7) as shown in figure 4-(SEE 146442 HINGE KIT)

(confirm that spring ends are engaged in the spring guide and hinge)

e) Replace the Top and Lower Grilles

Note:

Note:

Note: Note:

The silver colored spring (#8) is for left hand hinged door and the yellow color spring (#3)

is for right hand hinged doors.

The letter "L" is marked on the left hand bushings (#9 and 10)

- B11 -

Page 51

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR) ■ MODEL : F23/F49/F72(FREEZER) R23/R49/R72(REFRIGERATOR)

GR26/GR48/GR70(MERCHANDISERS)

GR26/GR48/GR70(MERCHANDISERS)

GR26/GR48/GR70(MERCHANDISERS) GR26/GR48/GR70(MERCHANDISERS)

C. EXPLODED VIEW AND LIST

1. COMMERCIAL FREEZERS AND REFRIGERATORS - - - - - - - - - - C2

1. COMMERCIAL FREEZERS AND REFRIGERATORS - - - - - - - - - - C2

1. COMMERCIAL FREEZERS AND REFRIGERATORS - - - - - - - - - - C2 1. COMMERCIAL FREEZERS AND REFRIGERATORS - - - - - - - - - - C2

1) SERVICE LIST

1) SERVICE LIST

1) SERVICE LIST1) SERVICE LIST

2) F23 EXPLODED VIEW

2) F23 EXPLODED VIEW

2) F23 EXPLODED VIEW2) F23 EXPLODED VIEW

3) F49 EXPLODED VIEW

3) F49 EXPLODED VIEW

3) F49 EXPLODED VIEW3) F49 EXPLODED VIEW

4) F72 EXPLODED VIEW

4) F72 EXPLODED VIEW

4) F72 EXPLODED VIEW4) F72 EXPLODED VIEW

5) R23 EXPLODED VIEW

5) R23 EXPLODED VIEW

5) R23 EXPLODED VIEW5) R23 EXPLODED VIEW

6) R49 EXPLODED VIEW

6) R49 EXPLODED VIEW

6) R49 EXPLODED VIEW6) R49 EXPLODED VIEW

7) R72 EXPLODED VIEW

7) R72 EXPLODED VIEW

7) R72 EXPLODED VIEW7) R72 EXPLODED VIEW

2. MERCHANDISERS - - - - - - - - - - - - - - - - - - - - - - C10

2. MERCHANDISERS - - - - - - - - - - - - - - - - - - - - - - C10

2. MERCHANDISERS - - - - - - - - - - - - - - - - - - - - - - C10 2. MERCHANDISERS - - - - - - - - - - - - - - - - - - - - - - C10

1) SERVICE LIST

1) SERVICE LIST

1) SERVICE LIST1) SERVICE LIST

2) GR26H EXPLODED VIEW

2) GR26H EXPLODED VIEW

2) GR26H EXPLODED VIEW2) GR26H EXPLODED VIEW

3) GR48S EXPLODED VIEW

3) GR48S EXPLODED VIEW

3) GR48S EXPLODED VIEW3) GR48S EXPLODED VIEW

4) GR70H EXPLODED VIEW

4) GR70H EXPLODED VIEW

4) GR70H EXPLODED VIEW4) GR70H EXPLODED VIEW

-C1 -

Page 52

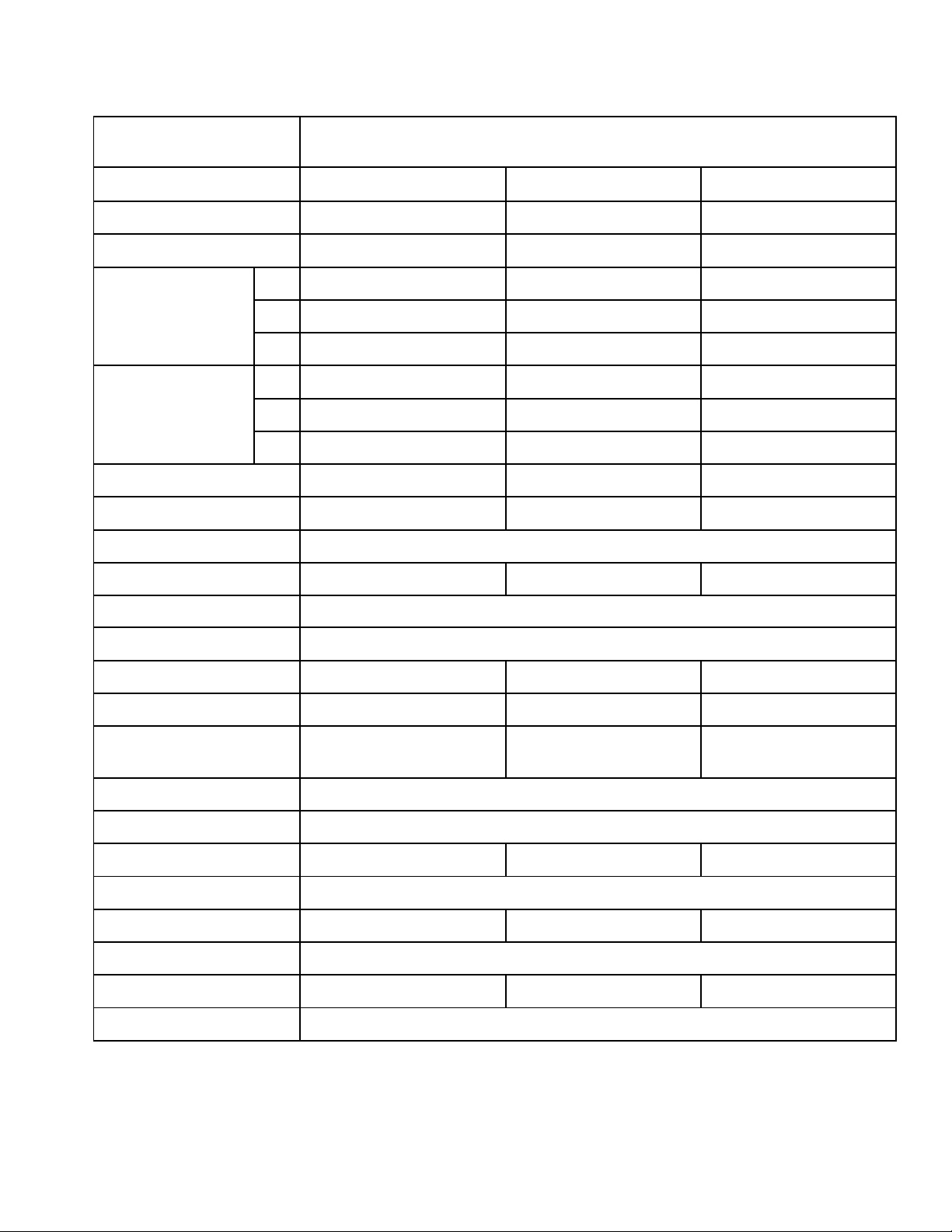

1. COMMERCIAL FREEZERS AND REFRIGERATORS

1. COMMERCIAL FREEZERS AND REFRIGERATORS

1. COMMERCIAL FREEZERS AND REFRIGERATORS 1. COMMERCIAL FREEZERS AND REFRIGERATORS

1) SERVICE LIST

1) SERVICE LIST

1) SERVICE LIST 1) SERVICE LIST

No. PART NAME

F23

Door Hinge Kit - Top Right 146441 146441 146441 146441 146441 146441

1

Door Hinge Kit - Top Left NA 146442 146442 NA 146442 146442

2

Door Hinge Kit - Lower Right 146412 146412 146412 146412 146412 146412

3

Door Hinge Kit - Lower Left NA 146413 146413 NA 146413 146413

4

Door Hinge Kit - Lower Center NA NA 146414 NA NA 146414

5

Control PCB Assembly (115V) 146416 146417 146418 146415 146415 146415

6

Main Transformer (115V) 146420 146420 146420 146420 146420 146420

7

PART No.

F49 F72 R23 R49 R72

8

9

10

11

12

13

14

15

16

17

18

19

20

21

DC Relay 146421 146421

Relay Wire Harness 146423 146423 146423 146423 146423 146423

Front PCB Wire Harness 146424 146424 146424 146424 146424 146424

Temperature Sensor 146426 146428 146430 146425 146427 146429

Pilaster 146411 146411 146411 146411 146411 146411

Shelf Clip 001585 001585 001585 001585 001585 001585

Door Assembly - Right Hand 146436 146437 146439 146436 146437 146439

Door Assembly - Left Hand NA 146438 146440 NA 146438 146440

Door Gasket 146444 146444 146445 146444 146444 146445

Lamp (115V) 146408 146408 146408 146408 146408 146408

Lamp Socket 146409 146409 146409 146409 146409 146409

Lamp Cover 146410 146410 146410 146410 146410 146410

Top Grille Assembly (115V) 146433 146434 146435 146433 146434 146435

Top Grill Cover - Right 146431 146431 146431 146431 146431 146431

146422

146421 146421 146421

22

23

24

25

26

27

28

29

Front PCB Assembly 146419 146419 146419 146419 146419 146419

Control Decal 146432 146432 146432 146432 146432 146432

Light Switch 146449 146449 146449 146449 146449 146449

Door Lock& Key 146443 146443 146443 146443 146443 146443

Power Switch 146450 146450 146450 146450 146450 146450

Condensate Pan w/paper 146386 146387 146387 146386 146387 146387

Lower Grille Assembly 146388 146389 146390 146388 146389 146390

Caster Kit 100436 100436 100437 100436 100436 100437

-C2 -

Page 53

146446

146446

146448

146448

146516

146516

146518

146518

No. PART NAME

F23

PART No.

F49 F72 R23 R49 R72

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Power Cord (115V) 138533 138533 138657 138533 138533 138533

Evaporator Coil 146392 146394 146396 146391 146393 146395

Defrost Limit Switch 146404 146404 146404 NA NA NA

Defrost Heater (115V) 146397 146398 146399 NA NA NA

Drain Heater (115V) 146403 146403 146403 NA NA NA

Drain Pan Heater (115V) 146400 146401 146402 NA NA NA

Evaporator Fan Guard 146405 146405 146405 146405 146405 146405

Evaporator Fan Blade 146406 146406 146406 146406 146406 146406

Evaporator Fan Motor (115V) 146407 146407 146407 146407 146407 146407

Condenser Coil 146373 146375 146375 146372 146374 146375

Condenser Fan Blade 146371 146371 146371 146371 146371 146371

Condenser Fan Motor (115V) 146370 146370 146370 146370 146370 146370

Suction pipe(B) Assembly 146377 146379 146381 146376 146378 146380

Capillary Tube 146383 NA NA 146382 NA NA

44

45

46

47

48

* Shelf Set : F(R)72 - 146446 (ENDS), 146448 (CENTER)

* Shelf Kit : F(R)72 - 146516 (ENDS), 146518 (CENTER)

Drier 146384 146384 146385 146384 146384 146385

Compressor (115V) 146361 146507 146364 146505 146360 146363

Compressor Electrical Kit 146366 146512 146369 146510 146365 146368

Shelf Set 146446 146447

Shelf Kit(1Shelf + 4 Clips) 146516 146517

146446 146447

146516 146517

-C3 -

Page 54

2) F23 EXPLODED VIEW

2) F23 EXPLODED VIEW

2) F23 EXPLODED VIEW 2) F23 EXPLODED VIEW

0

1

1

9

1

7

2

9

2

1

3

7

6

8

9

1

7

1

8

1

1

2

6

2

2

2

5

4

2

2

0

2

3

2

4

1

2

3

3

1

2

1

0

3

8

2

6

1

6

4

5

4

t

e

S

f

l

e

h

S

7

4

3

1

3

8

3

7

3

6

3

3

4

4

4

3

t

i

5

3

3

4

1

4

2

4

9

3

K

f

l

e

h

S

8

4

0

4

-C4 -

Page 55

3) F49 EXPLODED VIEW

3) F49 EXPLODED VIEW

3) F49 EXPLODED VIEW 3) F49 EXPLODED VIEW

0

1

7

2

1

3

9

2

7

1

9

1

6

8

0

7

9

1

8

1

1

3

1

2

1

2

6

1

2

6

2

4

2

2

2

3

2

5

2

1

4

1

2

3

4

8

2

6

4

6

1

5

1

3

0

2

1

3

8

3

7

3

6

3

3

3

2

4

4

3

5

3

4

4

9

3

5

4

t

e

S

f

l

e

h

S

t

i

K

f

l

e

h

S

t

e

S

f

l

e

h

8

4

1

4

S

7

4

0

4

-C5 -

Page 56

4) F72 EXPLODED VIEW

4) F72 EXPLODED VIEW

4) F72 EXPLODED VIEW 4) F72 EXPLODED VIEW

0

1

7

2

1

3

9

2

7

1

9

1

6

5

8

0

7

9

1

8

1

0

2

1

3

1

2

1

1

2

6

2

2

2

3

2

4

2

5

2

2

6

1

4

1

2

3

4

6

1

5

1

8

2

6

4

5

4

t

i

K

f

l

e

h

S

8

4

3

t

e

S

f

l

e

h

S

t

e

S

f

l

e

h

S

t

e

S

4

3

1

3

8

3

7

3

6

3

3

3

2

4

4

4

5

3

1

4

9

3

f

l

e

h

S

7

4

0

4

-C6 -

Page 57

5) R23 EXPLODED VIEW

5) R23 EXPLODED VIEW

5) R23 EXPLODED VIEW 5) R23 EXPLODED VIEW

0

1

1

9

1

7

2

9

2

1

3

7

6

8

9

1

7

1

8

1

1

2

6

2

4

1

2

2

5

4

2

2

0

2

3

2

3

1

2

1

0

3

8

2

6

1

6

4

5

4

t

e

S

f

l

e

h

S

t

i

K

f

l

e

h

S

7

4

1

3

3

4

8

3

7

3

6

3

4

4

2

4

8

4

1

4

0

4

9

3

-C7 -

Page 58

6) R49 EXPLODED VIEW

6) R49 EXPLODED VIEW

6) R49 EXPLODED VIEW 6) R49 EXPLODED VIEW

0

1

7

2

1

3

9

2

7

1

9

1

6

8

0

7

9

1

8

1

1

3

1

2

1

2

6

1

2

6

2

4

2

2

2

3

2

5

2

1

4

1

4

8

2

6

1

5

1

3

6

4

5

4

0

2

t

e

S

f

l

e

h

t

i

K

f

l

e

h

S

1

3

8

3

7

3

6

3

2

4

4

4

9

3

8

4

1

4

S

t

e

S

f

l

e

h

S

7

4

0

4

-C8 -

Page 59

7) R72 EXPLODED VIEW

7) R72 EXPLODED VIEW

7) R72 EXPLODED VIEW 7) R72 EXPLODED VIEW

0

1

7

2

1

1

3

9

2

7

1

9

1

6

3

8

0

7

9

1

7

1

0

2

1

3

1

2

1

6

4

2

1

2

6

2

2

2

3

2

4

2

5

2

2

6

1

4

1

4

6

1

5

1

8

2

5

4

t

i

K

f

l

e

h

S

3

t

e

S

f

l

e

h

S

t

e

S

f

l

e

h

S

8

4

t

e

S

f

l

e

h

S

7

1

3

8

3

7

3

6

3

2

4

4

4

9

3

4

1

4

0

4

-C9 -

Page 60

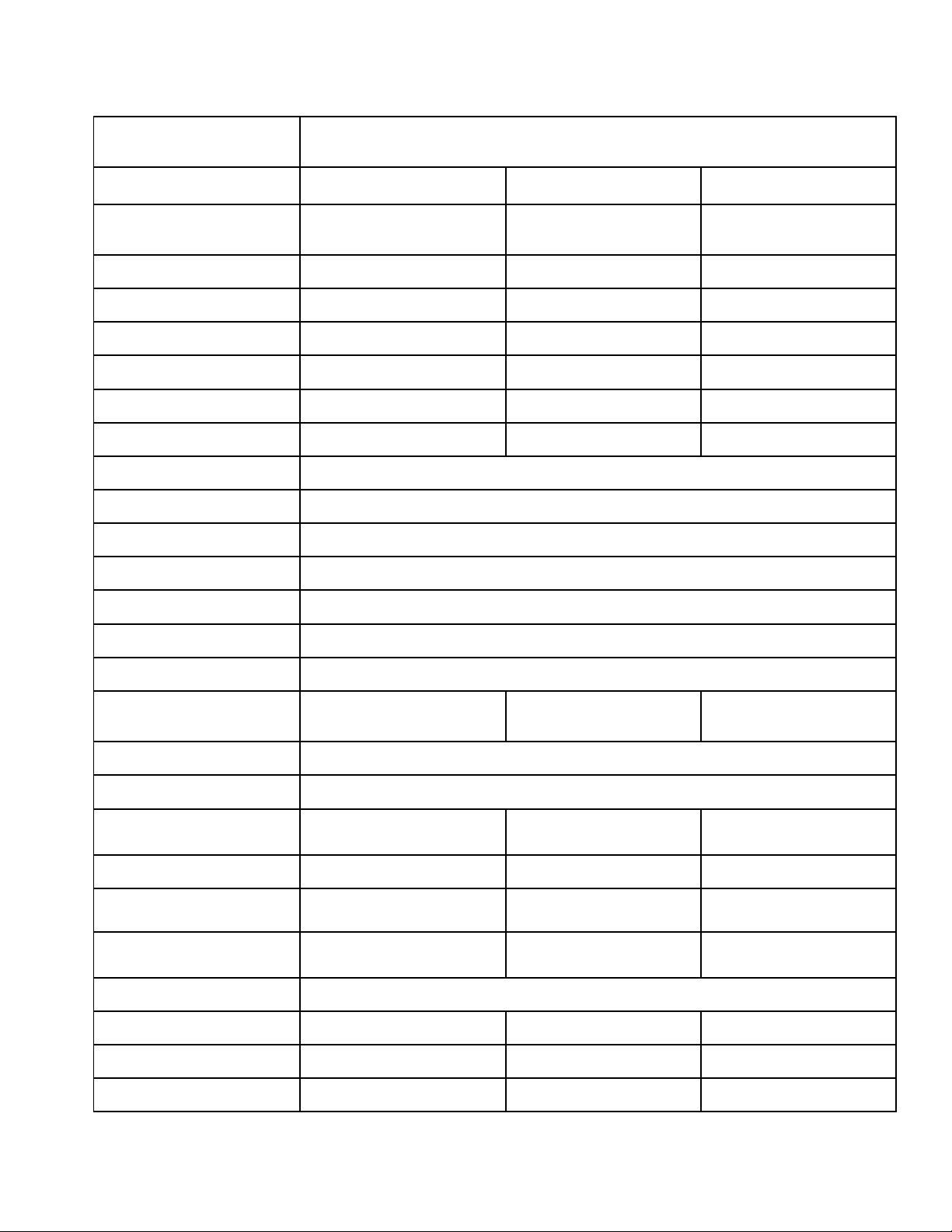

2. MERCHANDISERS

Advertising Panel Frame-Bottom

2. MERCHANDISERS

2. MERCHANDISERS 2. MERCHANDISERS

1) SERVICE LIST

1) SERVICE LIST

1) SERVICE LIST 1) SERVICE LIST

No. PART NAME

PART No.

GR26H GR48S GR70H

1 Door Hinge Kit - Top Right

2 Door Hinge Kit - Top Left

3 Door Hinge Kit - Lower Right

4 Door Hinge Kit - Lower Left

5 Door Hinge Kit - Lower Center

6 Ballast

7 Pilaster

8 Shelf Clip

9 Door Assembly - Right Hand

10 Door Assembly - Left Hand

11 Door Gasket

12 Lamp (115V)

13 Lamp Socket

14 Lamp Cover

146481

NA

146471

NA

NA

146492

146470

146489

146478

NA

146483

146466~7

146468

146469

NA

NA

NA

NA

NA

146491

146470

146489

146477

146480

NA

146466

146468

146469

146441

146442

146412

146413

146414

146490

146470 / 146411

146489

146476

146479

146482

146466

146468

146469

15 Advertising Panel - Blank

16 Advertising Panel Frame

17 Advertising Panel Frame-Left

18 Advertising Panel Frame-Right

19

20 Advertising Panel Frame-Top

21 Condensate Pan w/paper

22 Lower Grille Assembly

23 Foot Kit

24 Power Cord

25 Evaporator Coil

26 Evaporator Fan Guard

27 Evaporator Fan Blade

28 Evaporator Fan Motor

146495

NA

NA

NA

NA

146386

146463

143502

146475

146465

146405

146406

146407

146494

NA

146460

146462

143502

146475

146464

146405

146406

146407

146493

NA

146500

146501

146498

146499

146459

146461

146502

138533

146395

146405

146406

146407

29 Temperature Control