Page 1

Howard Industries, Inc.

ISO-9001 Certied

Distribution Transformer Division

INTRODUCTION

Howard Industries’ SVR-1 single-phase

step voltage regulators are tap-changing

autotransformers designed to automatically regulate distribution line voltages in

a range of plus or minus 10% in thirty-two

steps of approximately 5/8% each. The

following ratings are available:

• Voltage: 2500 Volts (60 kV BIL)

through 19920 Volts (150 kV BIL)

• Current: 50 through 1665 Amps

• KVA: 38.1 through 1000

• Frequency: 50 or 60 Hertz

Internal potential winding taps and/or

an external ratio correction transformer

are provided on all ratings so that each

regulator may be applied within a range

of system voltages.

Catalog Section

Single-Phase Step

28-10

Voltage Regulators

A digital control system automatically

operates the tap changer mechanism to

maintain system voltage within desired

limits. The control system is externally

programmable to allow precise setting of

control limits and provides sophisticated

capabilities for special control requirements, communication, and data logging.

Overhead type voltage regulators are

supplied with support brackets for pole

mounting and have bolt-down provisions

for pad-mounted applications. Substation

type voltage regulators are provided with

rectangular substation bases. Elevating

platforms are available as an option.

SVR-1 voltage regulators are designed for

reliable operation and ease of maintenance and are supplied with a full array of

standard features for routine applications.

Optional accessories are available to accommodate special applications.

FIGURE 1: SVR-1 single-phase voltage regulator

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Copyright © 2011 Howard Industries, Inc.

1

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Page 2

28-10

SVR-1 Single-Phase Step Voltage Regulators

The SVR-1 features sealed-tank

construction and a 65°C rise insulation

system, which allows 55°C rise rated

designs to provide an additional 12%

capacity above nameplate rating

without loss of normal insulation

life. The HI-AMP™ feature provides

capability for additional load capacity,

as long as the regulator’s maximum

current rating is not exceeded.

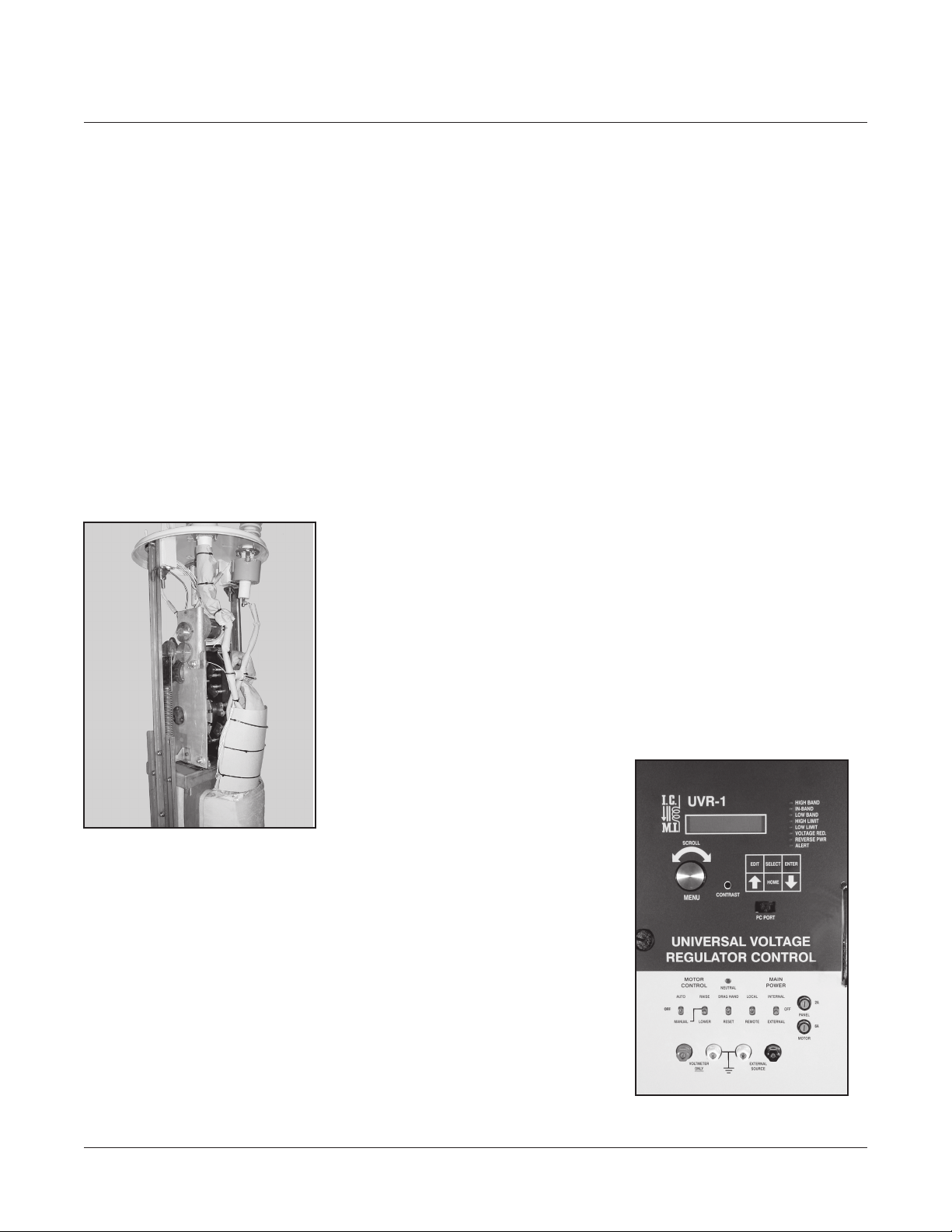

The regulator’s complete internal

assembly (including tap-changer

switch, motor, core-and-coil assembly,

and reactor coil-and-coil assembly) is

mounted to the cover (Figure 2). This

construction simplies removal of

the internal assembly for inspection,

maintenance, and repair.

FIGURE 2: Internal Assembly

_______________________________

SVR-1 voltage regulators are designed,

manufactured, and tested in

accordance with the requirements of

ANSI Standard C57.15.

STANDARD REGULATOR FEATURES

All SVR-1 voltage regulators are

supplied with the following standard

accessories and features:

• Gear-driven tap-changer switch with

motor and power supply

• Motor capacitor mounted in control

enclosure for ease of replacement

• Mechanical tap position indicator

with externally adjustable HI-AMP™

limit switches

• Laser-etched nameplates (two)

• Lifting lugs

• Oil drain valve with sampling device

• Upper lter press connection

• Oil sight gauge

• High-creep porcelain bushings

• Bolt-down provisions (overhead type

regulators)

• Pole mounting brackets (overhead

type regulators)

• Rectangular substation base

(substation type regulators)

• Externally mounted series arrester

(MOV type)

• Mounting provisions for shunt

arresters

• Automatic pressure relief device

• Powder coated mild steel tank, cover,

clamp ring, and control enclosure

• HI/ICMI UVR-1 digital regulator

control (refer to description below)

OPTIONS

The following optional features and

accessories are available for the SVR-1

voltage regulator:

• Externally mounted shunt arresters

(MOV type)

• Wildlife protection for high-voltage

bushing terminals and lightning

arresters

• Extra-length control cable

• PTs and CTs for external metering

• Elevating platform

• Control enclosure heater

• 4-hole NEMA H-spade connectors

• Cooling fans

• Powder coated stainless steel

tank, cover, clamp ring, and control

enclosure

• HI/ICMI USC-1 simplied regulator

control

• Beckwith digital regulator control

• SEL digital regulator control

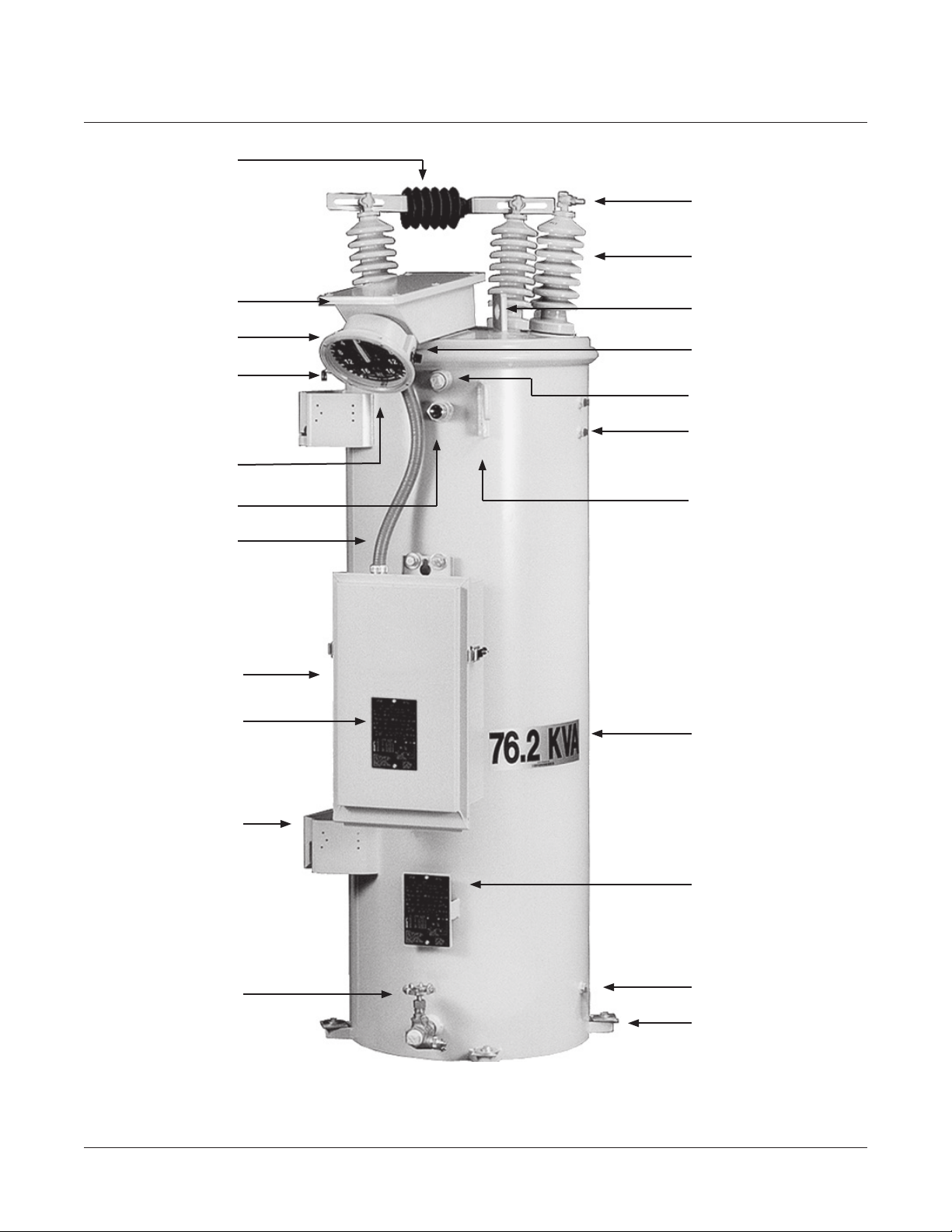

HI/ICMI UVR-1 CONTROL

The HI/ICMI UVR-1 digital regulator

control (Figure 3) has the following

standard features and options:

• Digital processing and nonvolatile

ash technology data storage with

Motorola 32-bit processor

• Mil-spec modular design with Mil-std

I-46085 conformal coated circuit

boards

• Solid-state tap-changer relays

• Corrosion resistant panel/shield

• Bright white/blue LCD high-visibility

display

• Super-bright LED indicators, including

High Band, In Band, Low Band, High

Limit, Low Limit, Voltage Reduction,

Reverse Power, Neutral Position, and

Alert

• DNP 3.0 Level 2, report-by-exception

communications protocol with ACS

worldwide certication

• Multiple, interoperable

communications ports, including

RS-232, IEEE-485 two and four-wire,

front panel serial program port, ber

optic interface, ethernet capable,

TCP/IP (optional), Bluetooth wireless

(optional), and eight-port input/output

board (optional)

• Certications: radio frequency

interference withstand capability per

ANSI/IEEE C37.90.2, electrostatic

(continued on Page 4)

FIGURE 3: HI/ICMI UVR-1 Control

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Copyright © 2011 Howard Industries, Inc.

2

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Page 3

SVR-1 Single-Phase Step Voltage Regulators

Series arrester (MOV)

28-10

High-voltage terminals (3)

High-voltage bushings (3)

Cover-mounted terminal

block enclosure

™

HI-AMP

lower limit

switch (hidden)

Automatic

pressure relief device

Tap position indicator

Oil level sight gauge

Control cable

Control enclosure

Laser-engraved nameplate

(mounted on control

enclosure)

Internal assembly

lifting eyes (2)

™

HI-AMP

upper limit switch

Upper lter press and

oil ll connection

Shunt arrester mounting

provisions (3)

Regulator lifting lugs

(2 or 4)

KVA label

Pole mounting brackets (2)

Drain valve and oil

sampling device

FIGURE 4: SVR-1 single-phase step voltage regulator standard features and accessories (overhead type as shown)

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Copyright © 2011 Howard Industries, Inc.

3

Laser-engraved nameplate

(tank-mounted)

Tank grounding provisions

(2)

Bolt-down provisions (4)

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Page 4

28-10

SVR-1 Single-Phase Step Voltage Regulators

discharge withstand capability

per IEC 61000-4-2 (1995-2001),

oscillatory surge and fast transient

surge withstand capabilities per ANSI

C37.90.1 (2002), metering accuracy

per IEEE C57.15 of 0.3% from -40°C

to +85°C (excluding VT/CT errors)

• User-friendly scrolling control

navigation with complete menu chart

(minimizes obsolescence)

• Comprehensive controller programs

on CD-ROM including Quick Start,

Control Congure, DNP Point

Congure, Data Log, Tap Contact Log,

and Program Loader, with customer

upgradeable expansion capability

• Front panel serial port

• Comprehensive control self-test

capability and protection safeguards

• Front panel controls including

automatic/manual motor control

switch, manual raise/lower switch,

drag-hand reset switch, local/remote

control switch, and internal/external

voltage source switch

• Panel-mounted fuses

• External voltage source terminals

• Voltage test terminals

• Line drop compensation R, X

• Temperature controller with settable

levels for high and low temperature,

-40°C to +85°C

• Sequential and time-integrating

regulation algorithms

• Reverse power capability without

need for internal potential

transformer

• Multiple modes of operation

including Locked Forward, Locked

Reverse, Idle Reverse, Bi-directional,

Neutral Reverse, and Co-generation

• Adjustable high and low-voltage limits

with automatic runback (rst house

protection)

REGULATOR CONSTRUCTION

SVR-1 regulators are designed and

built to provide reliable service, long

life, and ease of maintenance. The

entire internal assembly is mounted to

the regulator cover and can be easily

removed for inspection, repair, and

maintenance.

Tank

SVR-1 regulators feature sealed-tank

construction to prevent moisture and air

from entering the internal environment.

Tanks are constructed of mild steel

or stainless steel and electrostatically

coated with a tough polyester powder

nish.

Core and Coil Assembly

The use of a 65°C rise insulation

system in 55°C rated designs provides

an extra 12% capacity for the SVR-1

regulator without loss of insulation life.

The series coil is wound with fullwidth aluminum strip conductor and

compression-bonded thermosetadhesive insulation paper to provide

exceptional protection from potentially

damaging through-fault conditions.

Cores are manufactured from high

quality grain-oriented silicon steel.

Laminations are cut and assembled

using a distributed-gap process to

produce a low reluctance joint. A sturdy

clamping assembly effectively secures

the core and coils.

FIGURE 5: Tap changer mechanism

FIGURE 6: Tap position indicator

Tap Changer

All SVR-1 regulators feature rugged

gear-driven tap changers (Figure 5).

The tap-changing mechanism and

current-carrying contacts are designed

to provide exceptional reliability

and long service life exceeding one

million mechanical operations. The

tap changer uses an electric motor,

gear train, and spring drive to provide

quick, reliable operation. The switch is

mechanically coupled to the external

tap position indicator (Figure 6) to

provide visual indication of the switch

position.

Tap Position Indicator

The tap position indicator (Figure

6) is located on the cover-mounted

terminal block enclosure and is directly

connected to the tap changer by a

exible drive shaft. The indicator dial

plate is marked in 32 steps, 16 each

on the RAISE and LOWER segments of

the dial. The “zero” mark designates

the neutral position. Drag hands follow

the pointer and indicate the pointer’s

maximum and minimum positions since

the last reset. Drag hands can be reset

using the drag hand reset switch on the

front panel of the control unit. HI-AMP™

limit switches are mounted on either

side of the position indicator.

HI-AMP™ Feature

The HI-AMP™ Feature allows SVR-1

regulators to handle increased current

capacity by reducing the regulation

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Copyright © 2011 Howard Industries, Inc.

4

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Page 5

SVR-1 Single-Phase Step Voltage Regulators

28-10

range. This is accomplished by setting

the raise (boost) and lower (buck) limit

switches (Figure 7) located on the tap

position indicator to prevent the tap

changer from traveling above or below

the desired settings. Scales on the

limit switches are graduated in percent

regulation, including 5%, 6-1/4%m

7-1/2%, 8-3/4% and 10% regulation

settings. Table 2 (Page 7) lists the load

current and regulation ranges available

with the HI-AMP™ feature. At each

setting, a detent stop provides positive

adjustment. Upper and lower limits

need not be the same.

Upper and lower limits can also be

implemented with the digital control

unit.

SURGE ARRESTERS

Series Arrester

Each SVR-1 regulator is equipped

with an appropriately sized MOV-type

surge arrester connected between the

source and load bushings (Figure 4).

This series arrester (also known as a

bypass arrester) is provided to protect

the series winding of the regulator from

damage due to line surges, such as can

result from lightning, switching surges,

and line faults. The series arrester

alone does not provide complete

lightning protection. For more complete

protection, option shunt arresters

should be installed.

Shunt Arresters

MOV surge arresters are available as an

option on the SVR-1 regulator to provide

protection for the shunt winding. Shunt

arresters are mounted on the regulator

tank adjacent to the load bushing and

the source bushing. Each arrester

is connected between the bushing

terminal and ground.

FIGURE 7: HI-AMP™ limit switches

(one located on each side of tap

position indicator)

_________________________________

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Copyright © 2011 Howard Industries, Inc.

5

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Page 6

28-10

Table 1:

Load Current and KVA Ratings, 60 Hz

Voltage

(kV)

2.5 kV

60 kV BIL

5.0 kV

75 kV BIL

7.62 kV

95 kV BIL

13.8 kV

95 kVBIL

14.4 kV

150 kV BIL

19.92 kV

150 kV BIL

Load Current

(Amperes)

200

300

400

500

668

1000

1332

1665

100

150

200

250

334

500

668

833

50

75

100

150

219

328

438

546

656

875

1093

50

100

150

200

300

400

483

604

50

100

200

231

300

400

463

578

50

100

167

200

335

418

502

SVR-1 Single-Phase Step Voltage Regulators

kVA

50

75

100

125

167

250

333

416

50

75

100

125

167

250

333

416

38

57

76

114

167

250

333

416

500

667

833

69

138

207

276

414

552

667

833

72

144

288

333

432

576

667

833

100

200

333

400

667

833

1000

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Copyright © 2011 Howard Industries, Inc.

6

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Page 7

SVR-1 Single-Phase Step Voltage Regulators

Table 2:

HI-AMP™ Capabilities, 60 Hz

Rated

Volts

2.5 kV

5.0 kV

7.62 kV

13.8 kV

14.4 kV

19.92 kV

Rated

kVA

50

75

100

125

167

250

333

416

50

75

100

125

167

250

333

416

38.1

57.2

76.2

114.3

167

250

333

416

500

667

833

69

138

207

276

414

552

667

833

72

144

288

333

432

576

667

833

50

100

200

333

400

667

833

±10% ±8-3/4% ±7-1/2% ±6-1/4% ±5%

200

300

400

500

668

1000

1332

1665

100

150

200

250

334

500

668

2

2

2

2

2

2

2

2

2

2

2

833

50/53

75/79

100/106

150/159

219/232

328/347

438/464

548/580

656/668

875/926

1093/1157

50

100

150

200

300

400

483

604

50

100

200

231

300

400

463

578

25

50

100

167

200

335

418

220

330

440

550

668

1000

1332

1665

110

165

220

275

367

550

668

833

55/58

83/88

110/116

165/175

241/255

361/382

482/510

603/638

668

875/926

1093/1157

55

110

165

220

330

440

531

664

55

110

220

254

330

440

509

636

28

55

110

184

220

369

460

Load Current (Amperes)

Regulator Range

240

360

480

600

668

1000

1332

1665

120

180

240

300

401

600

668

833

60/63

90/95

120/127

180/190

263/278

394/417

526/557

658/668

668

875/926

1093/1157

60

120

180

240

360

480

580

668

60

120

240

277

360

480

556

668

30

60

120

200

240

402

502

1

270

405

540

668

668

1000

1332

1665

135

203

270

336

451

668

668

833

68/72

101/95

135/143

203/215

296/313

443/469

591/625

668

668

875/926

1093/1157

68

135

203

270

405

540

652

668

68

135

270

312

405

540

625

668

34

68

135

225

270

452

564

28-10

320

480

640

668

668

1000

1332

1665

160

240

320

400

534

668

668

833

80/85

120/127

160/169

240/254

350/370

525/556

668

668

668

875/926

1093/1157

80

160

240

320

480

640

668

668

80

160

320

370

480

640

668

668

40

80

160

267

320

536

668

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Copyright © 2011 Howard Industries, Inc.

7

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Page 8

SVR-1 Single-Phase Step Voltage Regulators

Catalog Section 28-10

Document 2.4.132, Revision 0, October, 2011

Copyright © 2011 Howard Industries, Inc.

Laurel, Mississippi

Telephone: 601-425-3151

Fax: 601-649-8090

E-mail: mkt@howard.com

Web: howardtransformers.com

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Copyright © 2011 Howard Industries, Inc.

8

Document No. 2.4.132

Revision: 0

Issued: October, 2011

Loading...

Loading...