Page 1

ST 400

ST 400

HOWARD

Operating Instructions

Page 2

ST 400

CONTENTS

Safety precautions........................................ 14-18

Specification & description ........................... 19-20

New maschine ....................................................21

Attaching machine to the tractor.........................21

Depth control ......................................................21

Rotors.................................................................22

Lubrication + maintenance .................................22

Operating instructions ........................................23

Operational advice .............................................24

Introduction

Howard would like to thank you for purchasing this machine and offer their support and assistance

throughout its productive life.

This machine has been designed and manufactured as a tractor driven, ground cultivator - no other use

is intended.

Please read and understand this manual before operating the machine.

Warranty

The warranty applicable to your machine is detailed on separate documentation which should accompany

this manual. If this is missing, please contact your dealer.

Serial Number

The Serial Number and Model are stamped on the Identification Plate attached to your machine.

For future reference record this information below. Always quote them when ordering spare parts.

MODEL ________________

SERIAL No. ________________________

Date Purchased: ________________

14

Page 3

ST 400

SAFETY PRECAUTIONS

PLEASE READ. IT MAY SAVE A LIFE.

!

SAFETY IS YOUR RESPONSIBILITY.

The safety of operators and any other connected personnel

is a major component of; machine design, manufacture,

retailing, commissioning, operation and maintenance.

Howard have designed and manufactured this

machine with as many safety features as possible. The

retailer’s responsibility is to ensure you have selected the

correct machine for your tractor/application and to

commission this machine.

Your responsibilities as owner or operator are to ensure

the safety of any personnel in connection with; the operation,

transport, maintenance or storage of this machine. Be

aware of your responsibilities and carry them out. The owner

or an appropriately designated officer, if the owner is a

company or corporation, is responsible for all safety issues

related to this machine.

The most important safety device attached to this machine

is a Safety Conscious Operator whose training and

experience must include:

• Correct and complete installation and commissioning of

the machine to ensure safe and reliable operation in the

intended application.

• Training in safety issues, operation and maintenance of

this machine in its application prior to beginning work.

This training is to be reviewed or repeated annually.

• Being aware of their environment to the extent that

unforeseen safety issues that may arise are dealt with to

ensure the safety of all personnel (including operators,

maintenance personnel and bystanders).

This is the SAFETY ALERT symbol and means:

ATTENTION ! SAFETY ISSUE !

!

Failure to comply with the given instruction could result in

severe injury or death.

If you have questions not answered in this manual please

contact your dealer or distributor.

IF YOU REQUIRE MORE COPIES OF THIS MANUAL PLEASE CONTACT YOUR DEALER.

ALTERNATIVELY YOU ARE WELCOME T O COPY

AND DISTRIBUTE THIS MANUAL TO THE

OPERAT ORS AND MAINTENANCE PERSONNEL.

SAFETY DECAL CARE

• Keep safety decals clean and legible at all times. Replace

any missing safety decals or any that have become

illegible. Safety decals can be purchased from you dealer

or distributor.

• If any part is replaced that supports a safety decal ensure

that a decal is affixed to the replacement part.

ATTACHING SAFETY DECALS

1.Clean and dry the area where the decal is to be affixed.

Warm soapy water is the best as some cleaning agents

leave an oily film which may prevent the decal adhering.

2.Remove/fold back a small portion of the backing and affix

the exposed portion of the decal in the desired position.

3. Peel back the remaining backing paper from under the

decal and smooth down the decal with a rag, working

any bubbles towards the edge of the decal.

4. Any bubbles that remain trapped can be pierced with a

pin and smoothed down.

ENGLISH

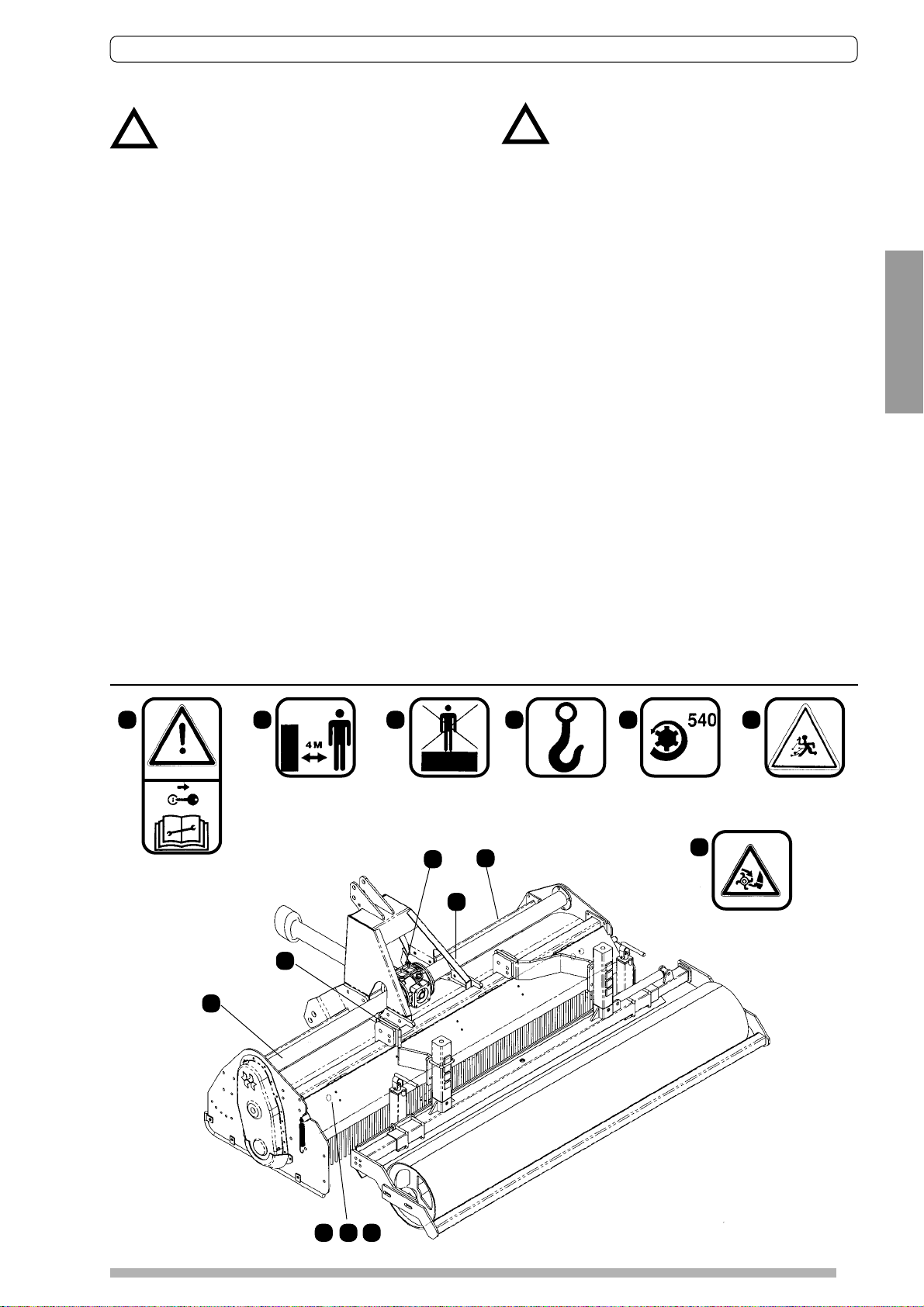

1 65432

WARNING!: READ

CAREFULLY THE

INSTRUCTIONS.

BEFORE HANDLING OR

REPAIRING THE MACHINE

REMOVE THE TRACTOR

IGNITION KEY

7

STA Y AT LEAST A T A

DISTANCE OF 4 METERS

WHEN THE ROTAVATOR IS

RUNNING.

4

DO NOT STAY ON THE

ROTAVATOR WHEN

TRANSPORTING

NEITHER WORKING

5

1

4

LIFTING

POINT

THE DRIVE IS BY A

PTO FROM A 540

TPM TRACTOR PTO

DANGER!

OBJECTS

PROJECTION.

7

MAINTAIN HANDS AND FEET AWAY WHEN

ROTAVATOR IS WORKING

Fig. 1

6

32

15

Page 4

ST 400

A T ALL TIMES

• Use the machine only for the purpose for which it has

been designed, and in accordance with the instructions

in this operators manual.

• Ensure that only responsible, properly instructed people

operate this machinery. Inexperienced operators will

require training, followed initially by careful supervision.

• Children are not permitted to operate this machinery.

• Keep children well clear and appropriately supervised

when connecting/disconnecting the tractor, operating or

maintaining this machinery.

• Do not wear clothes that are loose fitting or with drawstring

ties which can catch in moving parts.

• Wear appropriate protective clothing and equipment.

Boots are a minimum, however if your tractor is not fitted

with a controlled environment cab you may also need

protection from prolonged exposure either to noise, dust

or sunlight.

• Interpret ‘Left’ and ‘Right’ as if seated in the operators

seat and facing forward.

BEFORE OPERATION

• Read and understand this manual.

• The tractor to be connected to the machine:

- Must be the tractor that the machine has been

commissioned to operate with. Check that it has been

correctly maintained and has not been re-configured

(for example front weights removed etc) which may

reduce stability and control.

- Consult the Tractor Manufacturers Manual for

instructions on mounting implements and safe working

methods.

- Is recommended to be fitted with a Roll Over Protection

System (ROPS).

- Must be one the operator is familiar with.

• Prior to starting the tractor ensure the PTO is disengaged

and the tractor is in neutral.

• Do not allow anyone to stand between the tractor and

machine while backing the tractor up to attach it.

- Quick hitch systems are recommended for both Safety

and convenience.

- Before attempting to connect the universal drive shaft

to the tractor, lower the machine to the ground, stop

the tractor, apply the park brake and remove the key.

• Visually inspect the machine and check:

- Hitch pins and drive shaft are secure.

- No components are excessively worn, cracked or

otherwise defective and all bolts are tight.

- Guards, covers, warning labels and safety devices are

all correctly fitted and operative.

- Maintenance as per schedule has been carried out.

- No tools or other unsecured items have been left on

the Rotavator.

• Practice operation of the tractor and machine

combination.

- T ake sufficient time to become completely familiar with

all controls, particularly those required to bring both

tractor and machine to an emergency stop if so

required.

- Progress slowly initially and check stability, steering and

braking are satisfactory.

• Ensure the work area is clear, especially of children or

animals.

• Inspect the work area for hidden obstructions which may

constitute a hazard.

DURING OPERATION

• Ensure the work area is clear, especially of children or

animals.

• Do not attempt to start the tractor or engage the PTO

until correctly seated in the driver’s seat.

• Never leave the tractor running unattended.

• Do not allow passengers on the machine. [Or on the tractor unless approved seating is available.]

• Never attempt to make adjustments or perform

maintenance functions while the machine is operating.

• Observe all safe driving procedures:

- Reduce speed when working on sloping ground or

during sharp turns.

- Do not attempt to work on steeply sloping ground where

there is a risk of the tractor overturning.

- Do not attempt to work near the edge of drop-offs or

banks.

- Avoid sudden starts and stops.

• After striking an obstacle, stop the tractor and implement

and inspect it for damage. Repair as necessary before

continuing.

• Disengage the PTO when transporting the implement or

when not in use.

• When halting operation, even temporarily, lower the

machine to the ground, stop the tractor, apply the park

brake and remove the key.

• Allow the machine sufficient time to cool down before

performing any maintenance, or changing gears in the

Selectaspeed gearbox. [Oil and other transmission

components may be hot enough to inflict burns.]

• Note:

- By virtue of its mode of operation it is not possible to

totally enclose a machine with guards.

- Contact with the blades while operating can result in

severe injury or death.

- Do not allow anybody (operators, maintenance

personnel, bystanders or especially children) anywhere

near the blades whilst the implement is operating. Note

that children will often be attracted to placing objects

into the blades if you leave it running - this machine is

not a toy.

- Be aware that machine blades will not only cut, but

drag limbs etc. into further danger.

- Ensure that all shielding is in place before operating. If

guards are removed for maintenance work, ensure they

are replaced correctly upon completion. Repair or

replace any damaged guards.

- NEVER place hands or feet under the machine, nor

endeavour to make any repairs or adjustments while

the blades are rotating; they are capable of inflicting

serious injury.

- NEVER touch the blades or attempt to free any jammed

obstacle while the tractor engine is running. The clutch

may be slipping and removal of any obstruction may

allow the blades to rotate, the result possibly being

serious injury.

16

Page 5

ST 400

FOLLOWING OPERATION

• Visually inspect the machine and check:

- All bolts are tight.

- That no components are excessively worn, cracked,

damaged or otherwise defective.

• Note and organise any maintenance required.

• Allow the machine sufficient time to cool down before

performing any maintenance. The gearboxes, lubricant

and other transmission components may be hot enough

to inflict burns.

• Refer to TRANSPORT SAFETY and STORAGE SAFETY

for issues related to travel to/from operation and

disconnection of the machine from the tractor.

STORAGE SAFETY

• When unhitching the machine and before leaving the tractor to disconnect the universal drive shaft and remove

hitch pins:

- Check that the PTO drive has been disengaged.

- Stop the tractor, apply the park brake and remove the

key.

• Store the machine away from human activity and in particular do not permit children to play around, or on, stored

equipment.

• Store the machine in a dry level area and ensure

parkstands and wheels/roller are securely positioned to

prevent it tipping, falling over or rolling onto any personnel

(particularly children).

MAINTENANCE SAFETY

• Maintain the machine as detailed in the given schedule

and check for any damage after use. Poor maintenance

is an invitation to trouble.

• Ensure that all shielding is correctly in place when

maintenance is completed. Repair or replace any

damaged guards. Warning or instruction decals are to

be kept in a readable condition; unreadable decals must

be replaced.

• NEVER place hands or feet under the machine nor

endeavour to make any repairs or adjustments, while the

blades are rotating; they are capable of inflicting serious

injury.

• If working on the implement whilst it is raised on the

tractor’s three-point linkage, ensure:

- That the tractor is turned off and the ignition key is re-

moved to prevent accidental starting.

- The park brake is engaged and the wheels chocked to

prevent the tractor moving.

- The PTO drive is disengaged.

- The machine is properly supported by blocks or stands.

DO NOT rely on the tractor’s hydraulic system to

support the implement.

• Modifications or fitment of non genuine replacement parts.

- If the equipment is modified in any way from the origi-

nal design, the manufacturer will not accept any liability

for any injury or warranty as a result of their use or

attempted fitment.

• Fasteners.

- Fit only the correct replacement fasteners and tighten

fasteners to the torque specified in the manual.

Incorrect (too weak) fasteners may break when torqued

to the required setting or, if too strong, may induce

failures in other components.

• Follow safe workshop practices during any maintenance:

- Keep working area clean, dry and in particular free of

oil spills.

- Ensure the workshop is adequately ventilated. Do not

run the tractor engine inside a closed building. The

exhaust fumes can reduce mental alertness initially and

will progressively cause death by asphyxiation.

- Use tools, lifting or jacking equipment suitably capable

of the intended task.

- Ensure electrical equipment is safe to use before

operating.

- A fire extinguisher and first aid kit should be readily

accessible during maintenance.

- Tools, parts and other service equipment must be removed to appropriate storage locations prior to any test

running.

- Do not wear baggy, ill-fitting or frayed clothing when

working around transmission components.

- Wear suitable gloves when handling or working with

sharpened cutting elements.

- Ensure bystanders, especially small children, are kept

clear during maintenance or while making any

adjustments.

• Hydraulic fluid can be dangerous.

- When disconnecting any hydraulic fluid line, shut off

the hydraulic supply and relieve the hydraulic pressure.

- Never use hands to locate hydraulic fluid leaks.

Escaping hydraulic fluid is capable of cutting and

penetrating skin. Use a small piece of cardboard or

wood.

- Minor cuts are susceptible to infection from hydraulic

fluid. Gangrene can result. If injured by escaping

hydraulic fluid or you suspect you have been infected,

seek medical treatment immediately.

TRANSPORT SAFETY

• When transporting the implement on a tractor on public

roads ensure that you comply with the relevant

regulations.

- Class of roads permitted for travel may be restricted.

- Transport may restricted to daylight or, off peak traffic

hours.

- Signs indicating width may be required.

- Lights indicating vehicle width if transported within the

hours of darkness may be required.

If in doubt, contact your government department responsible

for road transport.

• Secure the machine for transport.

- Disengage the PTO when transporting.

- Ensure all hitch pins are correctly fitted with retaining

pins.

- Mechanically secure hydraulic cylinders to prevent

cylinders creeping.

• Observe the tractor manufacturers regulations and

recommendations - specifically those relating to:

- Maximum transport loads.

- Maximum speed.

• Passengers

ENGLISH

17

Page 6

ST 400

- Do not allow passengers to ride on the tractor unless a

specific seat is provided.

- Do not allow anyone to ride on the implement when it

is being transported.

• Consider other road users.

- Plan your route to avoid heavy traffic and peak traffic

periods.

- Be a safe and courteous driver. Give way to oncoming

traffic in all situations, including narrow bridges,

intersections etc.

• Adopt safe driving practices:

- Lock tractor brake pedals together. Never use

independent breaking at transport speeds.

- Drive at a safe speed to ensure control and ability to

stop in an emergency. Ensure the additional weight of

the machine on the linkage does not compromise

steering and braking - for example front weights or

repairs to the brakes may be required if the tractor is

not safe to drive.

- Reduce speed during turns. Tractors have not been

designed for fast cornering.

- Use engine braking when going down hills - do not

coast.

- Do not drink alcohol and drive.

• Watch for obstructions, particularly if over-width.

• Observe any load ratings applicable on bridges.

IDENTIFICATION OF HAZARDS

• Owners and operators must be prepared to assess their;

equipment, operators, maintenance procedures and

applications to identify safety hazards.

• Appropriate methods to reduce the hazards identified

must then be applied.

MACHINE SUITABILITY TO APPLICATION

Machine have been designed and manufactured as a tractor driven, ground cultivator - no other use is intended.

• Before beginning work it is necessary to assess the effect

of the machine on the safety of both the operator and

any potential bystanders. It is reccomended that you

contact the manufacturer or distributor for assistance in

this area.

AUTHORISED OPERATORS & TRAINING

If you are an employer, do not assume an operator is trained

for use of this equipment, (you would not let an unlicensed

driver borrow your car !).

• Ask to see licences if applicable, and record numbers

and validity dates.

• Request details of previous experience, in writing and

check them out if appropriate and ensure such records

are retained.

• Devise a suitable training course for operators if

appropriate, and ensure records of their completion are

retained.

MAINTENANCE RECORDS

Recommended maintenance is detailed in the Lubrication

& Maintenance section. Failure to follow these may

jeopardise safety as well as economic operation.

Records of periodic maintenance are important as they

detail when and who carried out the last maintenance and

inspection. Appropriate checklists should include

maintenance as detailed and in particular the following

safety aspects:

- SAFETY DECALS AFFIXED & LEGIBLE.

- GUARDING - All fitted and secure.

- CRITICAL FASTENERS SECURE

Fit all safety guards before operating. Operation is not permitted without safety guards

!

fitted. These are not fitted at the factory due to freight limitations.

18

Page 7

ST 400

NEVER

- Touch any moving parts of the machine or parts

which may be hot from opertaion.

Check oil levels whilst the machine is running.

- Carry out adjustments or repairs to a mounted

machine unless the tractor engine is stopped and the

machine firmly supported or lowered to the ground.

- Leave the tractor seat unless the machine is lowered,

the pto drive disengaged, the gear shift in neutral,

the brake applied, the engine stopped and the ignition

key removed

BE A SAFE OPERATOR BY THINKING –

BEFORE ACTING

PTO DRIVE SHAFT GUARDS

HOWARD PRODUCTS are supplied with non-rotating PTO

Drive Shaft which must be correctly fifted and well

maintained.

Before and after each use PTO driven implements should

be examined to ensure the Drive Shaft rotates freely in the

guards, the guards are undamaged, securely fifted, correctly

seated on the shaft grooves and the restraining chains

attached to the tractor and implement.

Should the guards be broken, damaged or badly fitted the

implement must no be used damaged parts habe been

replaced and/or bad fitting corrected.

Always ensure the guard tubes do not separate at tthe PTO

Drive Shaft’s longest working or transport lengh, or at it’s

shortest.

Avoid damage to guards when the PTO Drive Shaft is being

connected or disconnected from the tractor by resting it on

a suport.

Never allow PTO Drive Shaft Guards to fall into the

implement or drop to the ground: damage will almost

certainly occur.

Always ensure the sliding surfaces of the guard tubes are

clean and the guard bearings lubricated.

When replacing worn or damaged sections of the Guard,

use special tools available from the makers.

Always follow the fitting, lubrication and maintenance

instructions supplied by the makers of the PTO Drive Shaft

Guard.

UNLESS CORRECTLY GUARDED

PTO DRIVE SHAFTS CAN KILL

!

ENGLISH

Minimum overlap in straight position

19

Page 8

ST 400

Model

ST400S-130M 130 152 480 30 40-75

ST400S-155M 155 177 560 36 40-75

ST400S-165M 165 187 251 600 39 45-75

ST400S-180M 180 202 640 42 45-75

ST400S-205M 205 227 720 48 50-75

Fig. 1

A

Working Transport Rotor speed Weight Number of Tractor engine

width cm width cm rpm kg blades HP

E

F

A

B

C

F

E

L

D

I

G

G

H

K

B

C

D

DESCRIPTION

Fig. 1 indicates assemblies refered to in the

text of this manual which are named bellow:

A: PTO drive shaft

B: Gerabox

C: Side drive

D: Rotor

E: Frame

F: Top mast

ST-400 is a Stone burier designed to prepare perfect seed

beds, both for flat field crops (grass, turf, vegetables ) or for

vegetable planting in beds (tomato, strawberries, vegetables

in general.)

The reverse rotating rotor, lifts the soil in the front of the

machine and the rear sieve is separating stones and clods

from the fine soil. The result is a structured seed bed with

two separate layers that are ensuring:

• Perfect operation of the seed drill or planter

• Better crop implantation: The first growing phase is crucial

• Trouble free operation of the following operations: mower,

harvester.

G: Rubber hull

H: Sieve

I: Depth control

J: Bed former

K: Roller

L: Levelling board

I

H

J

• For turf plantations: even surface for sport practice (golf,

football etc)

The new ST-400 receive the benefit of a flexible rubber top

with variable geometry (pat. Pending). This feature helps

the machine to avoid the most common disadvantages that

usually appear on this kind of machines:

1.Work in wet soils: The rubber top is avoiding soil sticking

and longer free operation than metal shield machines

2. Noise level: The machine works in a substantial lower

noise level than a conventional machine even in fields

with high stone content

3.Frame deformation: No permanent deformations of the

top are expected due to stone impacts. The rubber

absorbs the energy of the impacts from the stones and

this is not transmitted to the frame.

After long service, just changing the rubber hull as a

wearing part, and the machine is maintained as if it was

new.

4.Loads on transmission: The machine is protected by a

friction clutch, but even though, if a severe blockage

happens with a stone, the rubber top is reducing the loads

on the transmission elements, protecting them.

WARNING! THE MACHINE CAN ONLY WORK IN SOILS

WITH STONES NOT BIGGER THAN 12 CM.

OTHERWISE THE MACHINE CAN HAVE A SEVERE

OBSTRUCTION.

20

Page 9

ST 400

Fig. 2 Fig. 3

NEW MACHINE

PTO shaft

For transport purposes, the PTO shaft is dismantled and

must be refitted.

Lubrication and general

With the machine standing level ensure the following

preparatory

work has been done:

1.The gearcase filled to the level plug (A) (fig. 2) Capacity:

2l. Use SAE 90 oil.

2.The gearbox filled up to the level mark in the inside rod

(A) (fig. 3). Capacity 1,5 l.

3.All oil and grease points as indicated on p. 22 (Lubrication)

4.All nuts and bolts tightened. (Re-tighten after first hour’s

work)

SERIOUS DAMAGE CAN RESULT

FROM FAILURE TO CARR Y OUT THE

!

ABOVE PROCEDURES

PTO, lift the machine on the hydraulic lift linkage until the

PTO dirve shaft attains an angle of 40 º and set the limit

stop on the hydraulic lift control quadrant. (fig. 5)

A TTENTION! : THE PTO DRIVE SHAFT

!

ANGLE MUST NEVER EXCEED 40º.

Finally check that during transport and use the PTO drive

shaft does not “bottom“ or separte and that the maximum

angle of 40 º is not exceeded. Should it not be possible to

obtain the aforementioned setting with your tractor, SEEK

ADVICE, it may be necessary to reduce the length of the

PTO drive shaft by cutting.

B

E

A

Fig. 6

A

C

ENGLISH

Fig. 5

Fig. 6

ATTACHING THE MACHINE TO THE

TRACTOR

The PTO drive shaft must be set to a safe working length to

ensure the male shaft does not “bottom“ or separate from

the female tube under all conditions of use and transport.

To determine the correct mounting position: with the

machine on a firm level surface the Depth Control equipment

should be adjusted until the gearbox input shaft is horizontal (fig.5). Position the tractor at a distance from the machine

to give 150 mm (6“) minimum engagement of the male half

of the PTO drive shaft in the female tube when connected

to the tractor. This establishes the safe working length of

PTO drive shaft for connection to the tractor.

Position the tractor lower link ball joints in line with the

mounting pins. Connect the tractor lower links. Fit the tractor upper link and secure. Attach the PTO dirve shaft to the

pressure plate by the studs and tighten the nuts. Attach the

PTO drive shaft guard chains to the tractor and machine.

Attach stabilizer bar or check chains to limit sway to 50 mm

(2”). Adjust tractor linkage to level machine laterally and

longitudinally (fig. 5 and 6). Before engaging the tractor

D

Fig. 7

Depth control

Machines with roller (fig 6):

Adjust the roller height by means of the spindle (A) until the

required position.

It is also necessary to adjust the height of the levelling board

by means of the spindles (B) in order to get a correct and

regular soil flow.

In order to obtain a good result the machine should be

adjusted in horizontal position. By adjusting the length on

the 3rd point linkage, ensure that the lower profile in the

side plates is horizontal.

It is possible to offset the position of the roller, ensuring a

good overlap between the passes, without marking in the

field. Optionally the offset is made by means of a hydraulic

ram.

Machines with bed former (Fig.7):

On these machines the adjustment is made by adjusting

the height and the working angle of the bed former.

Modify the height by means of the spindle (A). In order to

make the correct adjustment it might be necessary to modify

the working angle. By moving the adjusting plate (C) the

working angle is changed and is possible to modify the

pressure on the soil. The plate (D) is then regulated in order

to close the bed former sides.

Is also possible to change the height of the side skimmers

(E) to regulate the incoming soil flow.

21

Page 10

ST 400

X

ROTOR AND BLADES

ST400 are fitted with original HOWARD BLADES model

9900/9901. See fig. 8 where the left blade is marked with

X. Use always only ORIGINAL HOWARD BLADES and

HOWARD.blade bolts. As an option it can be fitted

wiht»speed» blades model 9953/54 ( Fig.9 )

Fig. 10

Fig. 8

The blades must form a «scroll» patern (fig. 10). This ensure

that they enter the soil at regular intervals to even out the

load on the transmission.

When replacing worn blades, remove one blade and fit the

new one in its place before proceeding to the next. This will

ensure that the blade «scroll» patern is mantained.

D = right

I = left

Fig. 11

Rotacadet

ST400 can optionally be is fitted with a special rotor with

four blades per flange type ROTACADET (9941/9942)

When replacing worn blades take special attention to the

following instructions in order to get the correct mounting

and maintain the «scroll patern·». (Fig. 11)

LUBRICATION + MAINTENANCE

D

A

S

A

S

ATTENTION! IN ORDER TO OBTAIN A CORRECT MAINTENANCE AND FUNCTION OF

!

YOUR MACHINE IS IMPERATIVE TO FOLLOW THE ENCLOSED INSTRUCTIONS:

A

S

S

D

D

D

• (D) DAILY:

1.Lubricate with grease gun PTO spiders.

2.Lubricate with grease gun right hand stub axle bearing

3. Lubricate with grease gun roller bearings

•

(S) WEEKLY:

1.Top up with oil SAE W85-140 The gearbox.

2.Top up with oil SAE W85-140 The side drive gearcase.

3.Tighten fasteners.

22

• (A) EVERY 500 WORKING HOURS:

1.Drain flush and fill with oil SAE W85-140 the gearbox.

2. Drain flush and fill with oil SAE W85-140 the side drive

gearcase.

3. Lubricate with oil the spindles

Page 11

ST 400

Operational advice

Insufficient Depth Obtained

(a) adjust depth control equipement

(b) insufficient power : use lower tractor gear

(c) chaincase on hard soil. Further passes required

(d) blades “trowelling” (rolling over ground), use lower tractor gear

(e) blades incorrectly mounted

Tilth too fine

(a) use a faster tractor gear

(b) raise levelling board

ENGLISH

Tilth too coarse

(a) use lower tractor gear

(b) wait until soil is drier if sticks

(c) lower the levelling board

Blades “Ballinq up” with soil

(a) ground too sticky for working

(b) raise levelling board

(c) decrease tractor speed

Excessive Blade Wear

(a) reduce rotor speed

(b) replace loose or bent blades

Machine “Bumping” on Ground

(a) obstacles entangled in blades

(b) blades incorrectly mounted with no scroll effect or blades fitted with blunt edge leading or broken

blades

Obvious Points

(a) Machine not level - cutting too deep on right side. Shorten right hand tractor lift rod or adjust

depth control wheel (b) Not overlapping - drive closer to last run

(c) Working on hillsides. Work up the slope if possible. If lateral work cannot be avoided, work from

the top to the bottom in order to limit any terracing effect.

Advice

1. When operating the machine the most suitable practice is to work in “lands”

2. The worked ground should always be to the right of the driver.

3. Working on the field headlands should not be carried out until the “lands” have been completed.

4. Always raise the machine before turning.

THE MACHINE SHOULD NEVER BE

!

LOWERED WHILST THE TRACTOR IS TURNING.

23

Loading...

Loading...