Page 1

Howard Industries, Inc.

ISO-9001 Certi ed

Catolog Section

94-10

Network Transformers

Introduction

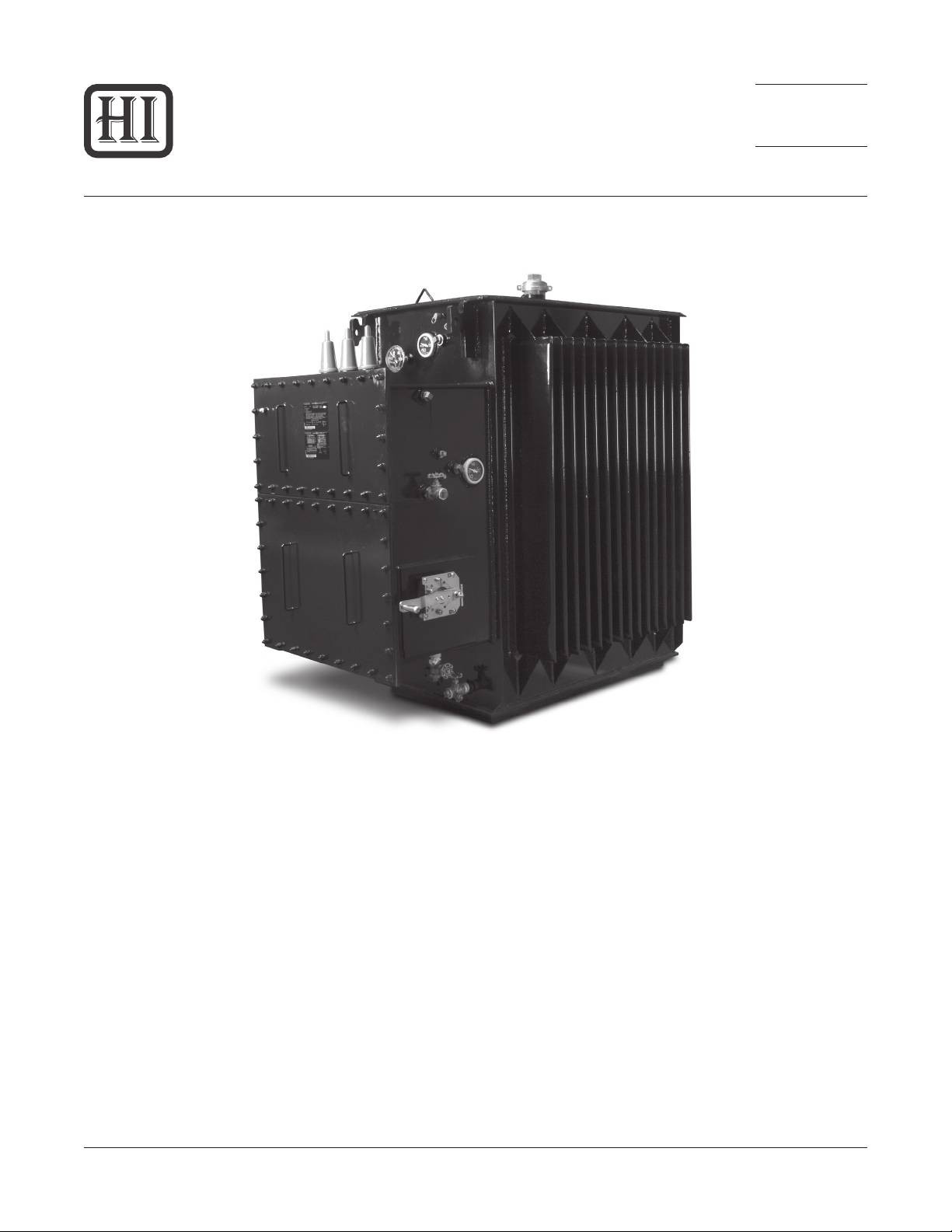

Howard network transformers are designed and built

according to the most exacting engineering standards to

provide many years of outstanding performance and reliability in the most demanding utility network applications.

Product scope includes capacities from 300 kVA through

2,500 kVA with high-voltage ratings from 2.4 kV through

34.5 kV and low-voltage ratings through 600 Volts.

Network transformers are typically used to supply

power to grid-type secondary distribution systems in

areas of high load density, such as are found in large

cities and are designed for either vault-type or subway-

Catalog Section 94-10

Network Transformers

Issued: April 9, 2010

Copyright © 2010 Howard Industries, Inc.

Figure 1: Network Transformer

type applications. Vault-type network transformers are

designed for installation in above-ground dry vaults, where

occasional submersion may occur. Subway-type network

transformers are designed for installation in subsurface

vaults, where frequent or continuous submerged

operation is likely. Subway designs may also be used in

vault-type applications.

Howard Industries, Inc.

1

www.howardtransformers.com

Laurel, MS 39440

Page 2

Design and Manufacturing

Network Transformer94-10

Transformer Design

Howard network transformers are designed with conservative mechanical and electrical margins to withstand

the harsh environments encountered in today’s network

distribution systems. Core-and-coil designs are optimized

for the lowest procurement cost or lowest total owning

cost according to each customer’s specic requirements.

All designs are guaranteed to meet the U.S. Department of

Energy’s minimum efciency standards. General industry

standards applicable to Howard network transformer designs include IEEE C57.12.00 Standard General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers, ANSI C57.12.40 American National

Standard for Secondary Network Transformers, Subway

and Vault Types (Liquid Immersed)—Requirements, IEEE

C57.12.90 Standard Test Code for Liquid-Immersed Distribution, Power and Regulating Transformers and Guide for

Short Circuit Testing of Distribution and Power Transformers, IEEE C57.93 Guide for Installation of Liquid-Immersed

Power Transformers, IEEE C57.98 Guide for Transformer

Impulse Tests, IEEE C57.100 Standard Test Procedure for

Thermal Evaluation of Oil Immersed Distribution Transformers, 10 CFR Part 431, Department of Energy, Energy

Conservation Program for Commercial Equipment: Distribution Transformers Energy Conservation Standards; Final

Rule, and 10 CFR Part 431, Department of Energy, Energy

Conservation Program: Test Procedures for Distribution

Transformers; Final Rule.

Core-and-Coil Design

Howard’s ve-legged core-form design provides excellent

mechanical strength that has been proven through rigorous design verication testing and years of eld service.

Mechanical strength is achieved through the use of a rugged steel mounting frame that provides solid support for

core/coil assembly.

Core-and-coil designs are optimized to provide the lowest

total owning cost or lowest purchase price according to

each customer’s specications. In addition, all network

transformer ratings, where applicable, are designed to

satisfy the minimum efciency standards set by the U.S.

Department of Energy.

Core Construction

Cores are fabricated using high-efciency grain-oriented

silicon steel that has been precision slit and edge conditioned by the supplier. Step-lap joints are used to

minimize losses and exciting current, and to insure quiet

operation. Cores are designed to operate at ux densities

well below saturation. Stress-relief annealing is employed

to maximize efciency and establish the required rectangular shape of each core loop. Prior to assembly each

core is carefully tested to ensure it meets dimensional, exciting current and no-load loss specications. Amorphous

metal cores are available for those applications requiring

ultra-low excitation losses.

Coil Construction

High-voltage coil windings are constructed of copper

or aluminum magnet wire. Automatic wire tensioners,

computer-controlled traverse mechanisms and laser

alignment systems ensure that coils are wound tightly and

accurately. Low-voltage coil windings are constructed of

edge-conditioned full-width sheet conductor, available in

either copper or aluminum. Low-voltage sheet windings

provide the advantage of virtually eliminating axial forces

during short circuit.

Turn-to-turn insulation in the high-voltage winding is Formvar® or extruded polymer coating. Main barrier and layer

insulation in both low-voltage and high-voltage windings is

thermally-upgraded craft, providing exceptional insulation

life. Insulation paper is coated with a thermoset epoxy

adhesive throughout the coil to produce excellent layerto-layer bonding. Strategically placed oil ducts provide

oil ow and adequate cooling throughout the windings.

The insulation system is designed to provide exceptional

impulse withstand capability.

Tank Construction

Network transformer tanks are of sealed construction,

including a sub-base and a welded main cover with

bolted (standard) or welded hand-hole cover. The subbase consists of steel bars parallel to the long axis of the

transformer with jacking areas located along the length

and width of the tank bottom. The copper-bearing steel

plate used to construct the tank is reinforced with side

wall braces, and all tank seams are continuously welded.

The completely sealed tank is capable of withstanding a

pressure of 7 psig without permanent deformation and

15 psig without rupture. Four lifting lugs are supplied and

arranged for lifting of the complete transformer including the network protector, if attached. Tank grounding

provisions consist of copper-faced or stainless-steel pads

welded to the tank. Fastening hardware is composed of

corrosion-resistant steel. The tank exterior nish is in accordance to the requirements of ANSI C57.12.40.

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Copyright © 2010 Howard Industries, Inc.

2

Catalog Section 94-10

Network Transformers

Issued: April 9, 2010

Page 3

Network Transformer 94-10

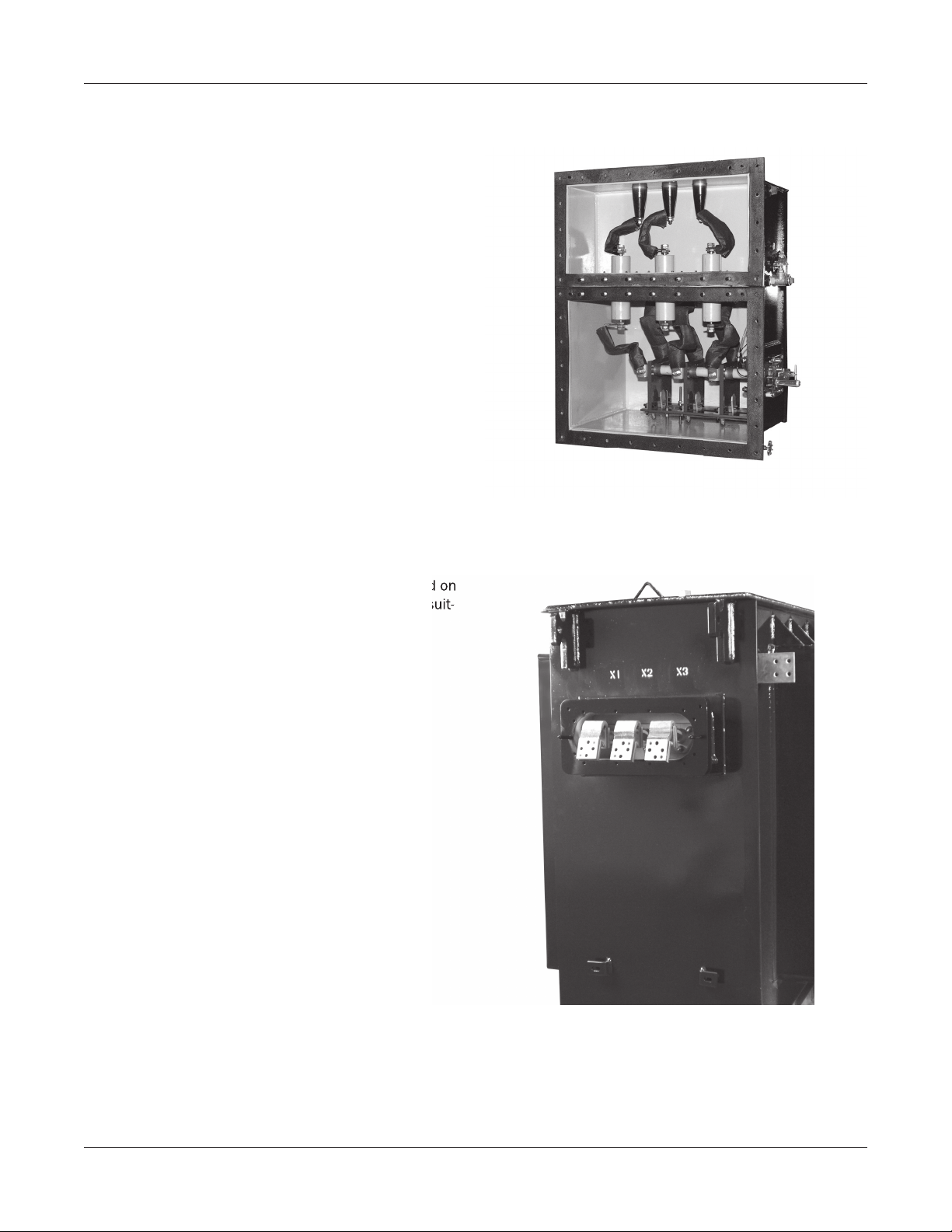

High-Voltage Switch and Terminal Chamber

The high-voltage switch is a uid-immersed rotary type

switch located in the high-voltage switch chamber, with

an adjacent terminal chamber located above. An optional

single-chamber design is available. The switch has three

operating positions, OPEN, CLOSED, and GROUND, clearly

indicated on the switch indicator plate. A mechanical

stop is provided to prevent unintentional operation of the

switch and to allow an electrical interlock to prevent operation if the transformer is energized. Several different

types high-voltage cable entrances are available.

Figure 2: High-Voltage Switch and Terminal Chamber

Network Protector Provisions

A secondary throat and support brackets are provided on

the low-voltage termination side of the tank that are suit-

able for mounting a low-voltage network protector.

Table 1: Factory Testing

Catalog Section 94-10

Network Transformers

Issued: April 9, 2010

Figure 3: Network Protector Provisions

Copyright © 2010 Howard Industries, Inc.

3

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Page 4

Network Transformer94-10

Factory Testing

In addition to numerous quality inspections throughout

the manufacturing process, nal tests are conducted on

the completed network transformer to ensure proper function of all systems. All tests are conducted in accordance

with applicable industry standards. Test equipment is

state-of-the-art and capable of extremely accurate and

reliable test measurements, meeting all the industry loss

measurement standards. All test systems are calibrated

regularly according to industry standards. Calibration of

loss-measuring equipment is NIST traceable.

The following standard and optional production-line tests

are performed. Standard tests are performed on each

completed transformer. Optional tests are performed

upon customer request and at customer expense. Customers may arrange to witness factory testing. All tests

will be made in accordance with the latest revisions of

IEEE C57.12.00 Standard General Requirements for

Liquid-Immersed Distribution, Power, and Regulating

Transformers and IEEE C57.12.90 Standard Test Code for

Liquid-Immersed Distribution, Power and Regulating Transformers and Guide for Short Circuit Testing of Distribution

and Power Transformers.

Quality Assurance

Howard employees understand the importance of quality,

particularly as it relates to network transformer applications. Emphasis on quality begins at design and follows

throughout the manufacturing and delivery processes.

Only the highest quality components and materials are

used in Howard network transformers. Attention to detail

during manufacture, and careful inspection and testing

ensure that a high level of quality is maintained.

Howard’s quality management system is designed to

ensure that all of the company’s products and services

meet or exceed our customers’ requirements and is certi ed by DQS-UL as being compliant with ISO-9001:2008.

The ISO-9001:2008 standard covers design, manufacturing, and servicing systems, and is the most stringent and

comprehensive standard in the internationally recognized

ISO-9000 series of quality standards.

Production-Line Tests

Winding resistance •

Winding insulation resistance (Megger) •

Ratio •

Polarity and phase relation •

Insulation power factor •

No-load losses and excitation current •

Impedance voltage and load losses •

Zero-phase sequence impedence

voltage

Temperature rise •

Low frequency dielectric tests •

Applied potential •

Induced potential •

Lightning impulse •

Front-of-wave impulse •

Audible sound level •

Leak test •

Partial discharge (RIV) •

ANSI impulse test •

Standard

Test

Optional

Test

•

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Copyright © 2010 Howard Industries, Inc.

4

Catalog Section 94-10

Network Transformers

Issued: April 9, 2010

Page 5

Network Transformer

Features and Accessories

94-10

Howard network transformers are available with a wide

range of features and accessories in order to satisfy the

requirements of even the most demanding applications.

Contact the factory or your area sales representative for

the availability of other design options not listed.

Standard Features and Accessories

Howard network transformers are supplied with the following standard features and accessories:

• Self-cooled power ratings (ONAN)—300 kVA through

2,500 kVA, three-phase

• High-voltage rating—from 2.4 kV through 34.5 kV

• High-voltage taps—Per ANSI C57.12.40.

• Low-voltage ratings—through 600 Volts

• BIL levels—Per ANSI C57.12.40

• Excitation limit—Per ANSI C57.12.00

• Average temperature rise—55ºC/65ºC

• Frequency—60 Hertz

• Impedance and impedance tolerance—Per ANSI

C57.12.40

• Audible sound levels—Per ANSI C57.12.40

• Service location—vault-type network transformers are

suitable for installation in above-ground dry vaults

where occasional submersion is possible. Subwaytype network transformers are suitable for installation

in subsurface vaults where frequent or continuous

submersion is likely. Subway type designs are suitable for subway or vault applications.

• Cooling/insulating uid—Type II mineral oil with oxidation inhibitor

• Fluid preservation system—sealed tank

• Main tank—copper-bearing steel construction, with

sub-base, main cover, and the following standard accessories:

− Dial-type magnetic liquid-level indicator (without

alarm contacts) welded to tank

− Dial-type thermometer (without alarm contacts)

− Combination drain and bottom lter valve

− Filling plug and upper lter press connection

− Top liquid sampling plug

− Air test provision

− Grounding pad welded to tank

− Lifting provisions for complete unit

− Lifting provisions for main tank cover

− Cover-mounted, pad-lockable tap changer switch

under protective pipe cap for de-energized operation (on units supplied with high-voltage taps)

− Bolted hand hole cover

− Corrosion-resistant steel fastening hardware

− Secondary throat suitable for mounting network

protector, with mounting holes, guide pins, gasket, and steel plate shipping guard

− Subway-type radiator panels (when required by

design)

− Pressure-relief valve (subway type)

• Primary terminal chamber—sealed enclosure welded

to main tank above the primary switch chamber, with

the following standard accessories:

− Bolted cover with, gasket, guide pins, and lifting

provisions

− Drain plug

− Liquid lling plug

− Liquid level and vent plug

− Three replaceable primary bushings between

terminal chamber and switch chamber, with terminals

− Primary entrance consisting of one of the following two methods: 1) wiping sleeves or 2) deadfront bushing bushings

• Primary switch chamber—sealed enclosure welded to

main tank beneath the primary switch chamber, with

the following accessories:

− Bolted cover with, gasket, guide pins, and lifting

provisions

− Three-pole, three-position, 200 Ampere, noninterrupting high-voltage switch and external

operating handle with latch

− Electrical interlock on switch

− Dial-type magnetic liquid level indicator welded to

chamber (without alarm contacts)

− Liquid lling plug

− Air test provision

− Drain valve

− Mineral oil insulating uid

• Low-voltage termination consisting of the following:

− Three externally replaceable bushings bolted to

the tank within the secondary throat

− Three exible connectors for electrical connection

to a network protector

− Low-voltage neutral connection welded to the

tank

• Paint nish—catalyzed epoxy primer plus catalyzed

urethane enamel topcoat; 3.0 mils nominal dry thickness

• Nameplate—non-corrosive diagrammatic nameplate,

permanently attached with non-corrosive hardware

Catalog Section 94-10

Network Transformers

Issued: April 9, 2010

Copyright © 2010 Howard Industries, Inc.

5

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Page 6

Network Transformer94-10

Optional Features and Accessories

The following optional features and accessories are available. Check with the factory for the availability of other

features and accessories not listed.

• Series-multiple high-voltage winding

• Delta-wye connection

• Special high-voltage taps

• Special low-loss high efciency designs

• Design optimization to lowest total owning cost

• 50 Hertz operating frequency

• Special impedance

• Special sound level

• Special phase relationship

• Special BIL level

• Over excitation capability

• 65° C average temperature rise

• Special ambient temperature

• Operation at altitudes above 3300 feet

• Copper windings

• Core ground test point located inside tank accessible

from bolted handhole

• Electrostatic shields

• Optional tank features and accessories

− Special hardware

− Welded handhole cover

− Additional bolted or welded hand-hole

− Special tank design pressure (up to 15 psig)

− Ground connectors

− Special tank dimensions

− Tank undercoating

− Omit pressure-relief valve

• Optional gauges and ttings

− Dial-type magnetic liquid-level gauge (with alarm

contacts)

− Dial-type thermometer (with alarm contacts)

− Pressure-vacuum gauge (with or without alarm

contacts)

− Automatic pressure-relief device (with or without

alarm contacts)

− Drain valve with liquid sampling valve

− Additional drain valve on tank or switch chamber

− Spare gaskets for secondary throat, bolted hand-

holes, high-voltage terminal chamber, and switch

chamber

− Sight gauge for high-voltage terminal chamber

− Other options (check with factory)

• Optional high-voltage switch features and accessories

− Interrupting switch or other special switches

− Provisions for phase sequence identication

(phasing tubes)

− Phase sequence indication (sequential grounding), including 3 internal grounding contacts,

5-position switch to indicate phase when switch is

moved from transformer positions to ground position

− Additional electrical interlocks

− Viewing windows for observation of switch blades

(with hinged protective cover)

• Optional high-voltage entrance features and accessories

− Single-conductor or multi-conductor wiping

sleeves, or pothead entrance

− Six universal bushing wells for loop feed with or

without loadbreak inserts (HV switch must be

omitted)

− Three integral loadbreak bushings

− Three non-Ioadbreak bushings

− Six non-Ioadbreak bushings for loop feed (HV

switch must be omitted)

− Six integral loadbreak bushings for loop feed (HV

switch must be omitted)

− Three molded bushings mounted on front of

terminal chamber in lieu of the standard wiping

sleeve

− Potheads, one 3-conductor or three 1-conductor,

instead of the standard terminal chamber

− Bottom entrance of HV cable, including wiping

sleeves

− Packing gland or stufng box

− Phase separation barriers in compartment (when

switch is omitted)

− Dielectric uid or compound for terminal chamber

• Optional low-voltage air terminations

− Welded low-voltage bushings

− Fully insulated low-voltage neutral bushing

− Other low-voltage termination options (check with

factory)

• Optional network protector provisions (check with factory)

• Optional dielectric uids

− Silicone uid

− FR3 natural ester-based uid

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Copyright © 2010 Howard Industries, Inc.

6

Catalog Section 94-10

Network Transformers

Issued: April 9, 2010

Page 7

Network Transformer 94-10

Warranty Service and Maintenance

Warranty Service

Should product defects be discovered during the warranty period, immediately contact the factory or your area sales

representative. A warranty claim will be processed, so that any problem can be resolved quickly.

Replacement Parts

Replacement parts can be obtained by contacting the factory or your area sales representative. Be prepared to provide

the transformer serial number, which is located on the transformer’s diagrammatic nameplate.

Catalog Section 94-10

Network Transformers

Issued: April 9, 2010

Copyright © 2010 Howard Industries, Inc.

7

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Page 8

Network Transformer94-10

Network Transformers

Catalog Section 94-10

Document 2.4.85, Revision 0, April 9, 2010

Copyright © 2010 Howard Industries, Inc.

Laurel, Mississippi

Telephone: 601-425-3151

Fax: 601-649-8090

E-mail: mkt@howard.com

Web: howardtransformers.com

Loading...

Loading...