Page 1

Howard"

Rotavator" Gem

"

and Super

Gem

Operating

+

>.

Instructions

-

-

.:

Page 2

GENERAL

SAFETY

PRECAUTIONS

1.

Read and familiarise yourself with the

operating instruction book.

2. Do not allow children to operate the machine.

Do not allow adults to operate the machine

without proper instructions.

3. Clear the work area of objects which might be

picked up and thrown.

4.

Before attempting to start -the machine ensure

the gear lever

is

in neutral and the rotor drive

disengaged.

5.

Never tamper with the reverse gear mechanism,

this

is

a safety device.

6.

Disengage the rotor drive before reversing or

turning the machine.

7.

Work up and down the face of steep slopes,

never across them.

8.

Handle petrol with care

-

Use an approved petrol container.

Never remove the cap of the fuel tank or add

petrol to a running or hot engine, or fill the

tank indoors. Wipe up spilled petrol.

9.

Open doors if the engine is run in the garage

-

exhaust fumes are dangerous.

1.0.

Keep all nuts, bolts and screws tight and be

sure that the equipment is regularly lubricated

to keep

it

in a safe working condition.

11. Keep all safety guards in place.

12. Never touch the rotor with the engine

running

-

switch off first.

13. Always wear substantial footwear to provide

as much protection

as

possible.

14. The warning transfer (part number 27409)

illustrated below should always be in position

on

your machine. If, for any reason

it

is

missing

a replacement will be supplied free of charge.

WARNING

beware of rotating

blades

see

there

is

no

one

in

the

direction of driving

Page 3

Howard

Rotavator

Gem

and

Super

Gem

Operating

Instructions

CONTENTS

Aircleaner

.........................

8

Blade maintenance

......................

8

Cleaning chaincase

......................

8

Cleaning gearbox

.......................

8

Drive chain

.........................

8

Roadwheels

........................

8

Rotor flange weedcutters

....................

8

Rotor friction drive

......................

8

Attachments

.........................

10

Depth control wheel

.....................

10

Furrower

..........................

10

Pictine rotor

........................

10

............................

Controis

3

....................

Lubrication and maintenance

5

Lubrication and maintenance chart

................

6 & 7

Making the most of your Gem

....................

11

.........................

Rotor and blades

9

Serial number

..........................

2

Specifications

..........................

2

.......................

Working the machine

4

........................

Your new machine

3

The Howard Gem is

THE

heavy duty hand-controlled

Rotavator for growers. farmers and contractors

.

From seedbed making to land reclaiming. catch cropping to

weed control. mixing-in manure to breaking up pasture. the

work power and engineering quality of the Gem are

unequalled

.

The Gem has three forward gears providing the right speed

for any type of work or soil condition

.

A

reverse gear gives

ease of handling in confined areas; adjustable handlebars.

up or down. side to side. aid operator comfort and

flexibility of control

.

Simple construction and a proven design keep maintenance

to

a

minimum

.

Optional attachments include a furrower. depth control

wheel and front-end weights

.

Page 4

SPECIFICATIONS

ENGIIVE

LANDSPEEDS

(at

2800

rpm)

STANDARD

GEM

Kohler K301T 4-stroke petrol producing 11 hp

(rnax.)

at

2800 rprn governed engine speed. 22 Ib-ft

(30

Nm) torque

at

2200 rprn or

Hatz

E780 4-stroke diesel producing 9 hp (max.)

at

3000 rprn governed engine speed. 19 Ib-ft

(25.75

Nm) torque

at

2100 rpm.

SUPER GEM

Kohler

K341T 4-stroke petrol producing 15 hp

(rnax.)

at

2800 rprn governed engine speed. 28 Ib-

ft 138 Nm) torque

at

2600 rprn or

Hatz

E785 4-stroke diesel producing 11 hp (rnax.)

at

3000 rprn governed engine speed. 23 Ib-ft

(31 Nm) torque

at

2100 rpm.

FUEL

CAPACITY

9

litres (2 gallons).

TRANSMISSIQN

Three forward speeds, one reverse. Transmission by

hardened gears running in oi

I. All shafts mounted on

ball-bearings. Full differential for easy turning, with

automatic locking when rotor is engaged. Safety

clutch with slip action when under shock load.

CLUTCH

Heavy duty two-plate dry type.

CONTROLS

1. Rod-operated clutch lever with safety reverse

interlock.

2. Engine governor control by

Bowden cable.

3.

Rod-operated gear lever.

4. Rod-operated rotor engagement lever.

5.

Handlebars adjustable for height and sideswing.

6. Depth setting lever.

WHEELS

4.00

-

12 2-ply traction tread pneumatic tyres.

Tyre pressure 1.4

kg/cm2 (20 1b/in2).

ROTOR

Rotor speed 188 rprn

at

2800 rprn engine speed.

Rotor widths 51 cm (20 in) Standard GEM only.

61 cm (24 in) Standard and Super

GEM.

76 cm (30 in) Super

GEM

(diesel)

on1

y.

DEPTH

OF

CUT

Adjustable to 23 cm (9 in) maximum.

1

st

gear

1.54

km/h (0.96 mile/h).

2nd gear 2.3 km/h (1.46 milelh).

3rd gear 4.9 km/h (3.05 mile/h).

Reverse 2.9 km/h (1.85 mile/h).

OIL CAPACITY

Gearbox

-

3.4 litres (6 pints)

Chaincase - .25 litre ( ;pint)

Engine - see Engine handbook

DIMENSIONS

Length: 203 cm (80 in)

petrol:208 cm (82 in) diesel:

Height to top of handlebar: 104 cm (41 in).

Width: 63 cm (25 in)

-

51 cm (20 in) rotor.

74

cm (29

in)

-

61 cm

(24

in) rotor.

89

cm

(35

in)

-

76

cm (30

in) rotor.

WEIGHT

(Approx.)

Standard GEM - Kohler engine.

292 kg (644

Ib) - 50 cm (20 in) rotor.

305 kg (672

Ib) - 61 cm (24 in) rotor.

Standard GEM

-

Hatz engine.

296 kg (652

Ib)

-

50 cm (20 in) rotor.

306 kg (674 Ib) - 61 cm (24 in) rotor.

Super

GEM

-

Kohler engine.

312 kg (688

Ib) - 61 cm (24 in) rotor.

Super GEM

-

Hatz engine.

338 kg (746

Ib) - 61 cm (24 in) rotor.

391 kg (862

Ib) - 76 cm (30 in) rotor.

EXTRA EQUIPMENT

Depth Control Wheel; Furrower;

Pictine Rotor.

Front-end Weights.

RECOMMENDED LUBRlCAlVTS

SAE

90

-

Gearbox and chaincase.

Engine Oil

-

Rotor Dog Clutch;

rotor stub axle;

depth control wheel (if fitted).

SERIAL NUMBER

The serial number of the Gem

is

stamped on the

plate fixed to the left-hand top side of the front

shield, and on the main frame top side near the

handlebar pivot.

For future reference, record the serial number in

the space below:

..................................

Gem Serial No

Date Purchased

.................................

Page 5

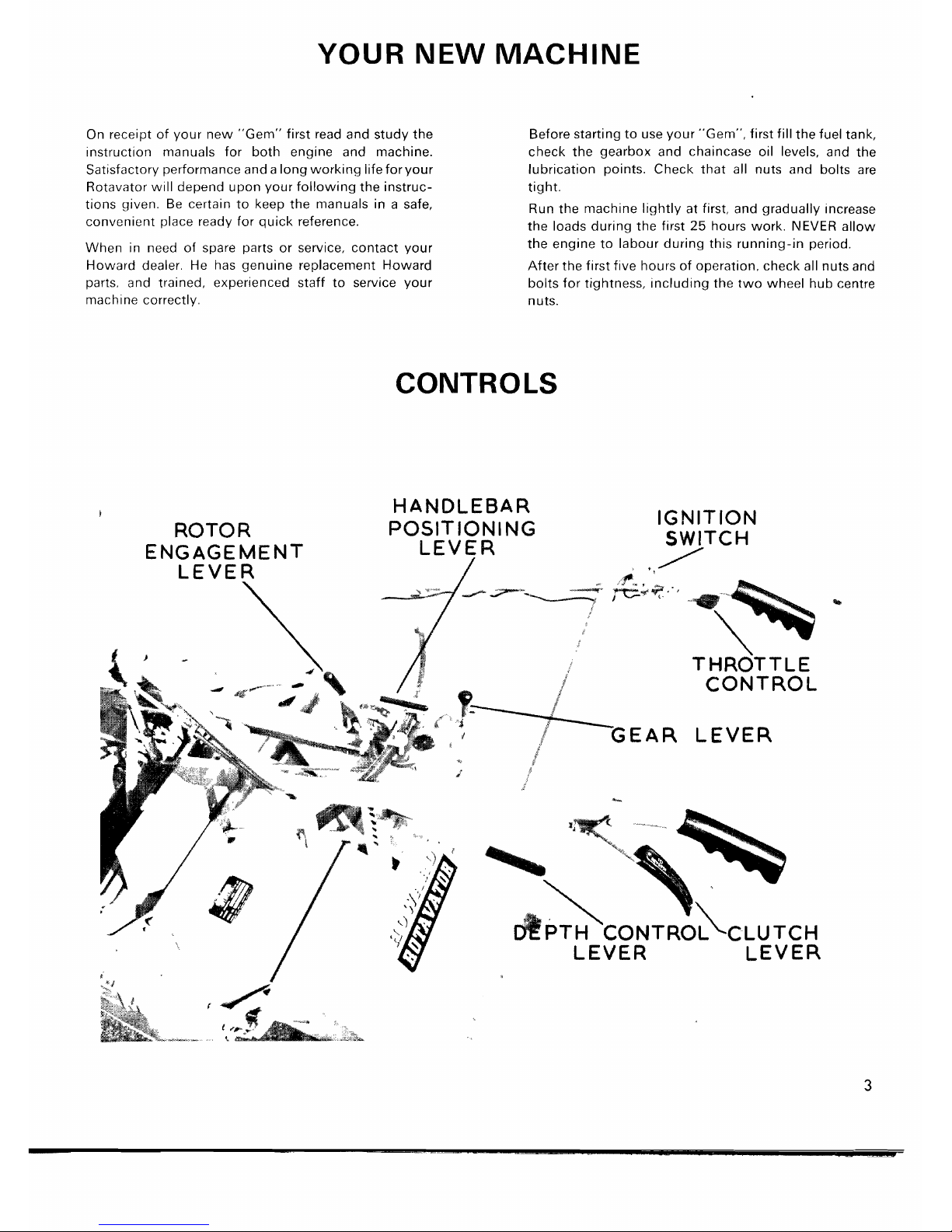

YOUR

NEW

MACHINE

On receipt of your new "Gem" first read and study the

instruction manuals for both engine and machine.

Satisfactory performance and a long working life for your

Rotavator will depend upon your following the instructions given. Be certain to keep the manuals in a safe,

convenient place ready for quick reference.

When in need of spare parts or service, contact your

Howard dealer. He has genuine replacement Howard

parts, and trained, experienced staff to service your

machine correctly.

Before starting to use your "Gem", first fill the fuel tank,

check the gearbox and chaincase oil levels, and the

lubrication points. Check that all nuts and bolts are

tight.

Run the machine lightly at first, and gradually increase

the loads during the first

25

hours work. NEVER allow

the engine to labour during this running-in period.

After the first five hours of operation, check all nuts and

bolts for tightness, including the two wheel hub centre

nuts.

CONTROLS

HANDLEBAR

ROTOR

IGNITION

ENGAGEMENT

LEVER

9a

B

THROTTLE

CONTROL

EAR

LEVER

Page 6

WORKING

THE

MACHINE

Start the engine according to the engine instruction

book. Lift the clutch lever and engage the required gear.

DO NOT FORCE THE GEARS INTO MESH. If they do

not immediately engage, release the clutch lever

momentarily.

The slight noise which may be heard when the clutch

is engaged is due to the positive action of the twin

clutch plates.

When in a position to begin Rotavating, lift the clutch

lever again, and move the rotor engagement lever to

the "IN" position. Increase the engine speed and gently

release the clutch, allowing the machine to pull itself

into the work.

The rotor engagement lever also operates the differential lock. The lever must therefore be put into the

"OUT" position for turning.

The depth is controlled by pressing the depth control

lever to the right. This releases the skid in the socket,

allowing it to be repositioned as required. The skid itself

has two alternative holes, the lower one of which permits a greater depth to be obtained.

Choose the depth to suit the crop being planted.

It this

is deeper than can be obtained in one pass without

the

engine labouring, several passes should be made at

progressively increasing depths.

First gear should be used for heavy work, and where a

fine tilth is required Second gear should be used for

average conditions, and top gear for light hoeing and

road work.

Where a coarse tilth is required, the rotor shield should

be raised as high as possible with the trailing board

folded back. The rotor should always be disengaged

when reversing as well as when turning at headlands.

To stop the machine, raise the clutch lever, and move

the gear lever to the centre (neutral) position. Move

the rotor engagement lever to the "OUT" position and

then release the clutch.

REVERSING

To reverse, pull up the clutch lever, move the gear lever

to Reverse (this simultaneously operates the safety

interlock) and release the clutch lever. No movement

occurs until the clutch lever is pushed down. Removal

of pressure automatically stops the machine. To disengage levers, pull up the clutch lever and move the

lever to neutral.

IVEVER,

UNDER ANY CIRCUMSTAIVCES, TAMPER

WlTH THE REVERSE GEAR LINKAGE. THE INTER-

LOCK MECHANISM ISASAFETY DEVICE AND MUST

NOT BE INTERFERED

WlTH OR REMOVED.

TURNING

It is often found that the machine is most easily turned

in reverse gear, especially when ground conditions are

very wet and sticky,

w~th a considerable amount of

earth adhering to the

underside

of

the shield Prov~ded

the rotor is disengaged and the blades are lifted clear of

the ground, the machine can be turned quite

eas~ly,

either

in

forward or reverse gear

If

turning appears to be

difficuit, ctieck that the differe~tial lock is fully disengaged when the rotor lever is pulled back. Adjust-

ment can be made on

tt-ie differential lock control rod,

should this not be the case.

HANDLEBAR ADJUSTMENT

The height of the handlet~ars can be adjusted to suit the

operator, by means of the alternative holes in the handle-

bar lugs.

The handlebars can also be offset to one side or the

other, by pressing down the handlebar positioning lever

to its full extent, and swinging the handlebars to whichever side is required.

A

hole is provided at each end of

the handlebar slide for positive locking in the required

position

HINTS FOR TOP PERFORMANCE

1.

The importance of correct and regular lubrication

cannot be over-stated. Study the lubrication chart on

pages

6

and

7.

2.

Do not neglect air cleaner maintenance.

3.

Always shut the throttle to the idling position when

lifting the clutch lever for engaging or disengaging

gears.

4.

Do not allow the engine to idle at slow speeds for

long periods.

5.

Do not press the handles down should the machine

jump if hitting a stump or similar obstacle; lightly resist

the movement and let the machine right itself. This

applies particularly when working on hillsides in badly

cleared land.

6.

When taking sharp corners, put the rotor out of gear,

lifting the handlebars to help in turning.

7.

Never run the "Gem" with the engine labouring.

Selection of the right gear, and correct depth of work

ensures a constant reserve of engine power.

8.

Always use the clutch in the same way as in a car,

that is, for changing gear only. DO NOT "slip the

clutch" to obtain extra engine speed.

9.

For the first

25

hours, attempt only fairly light work,

to allow the working parts to "bed down".

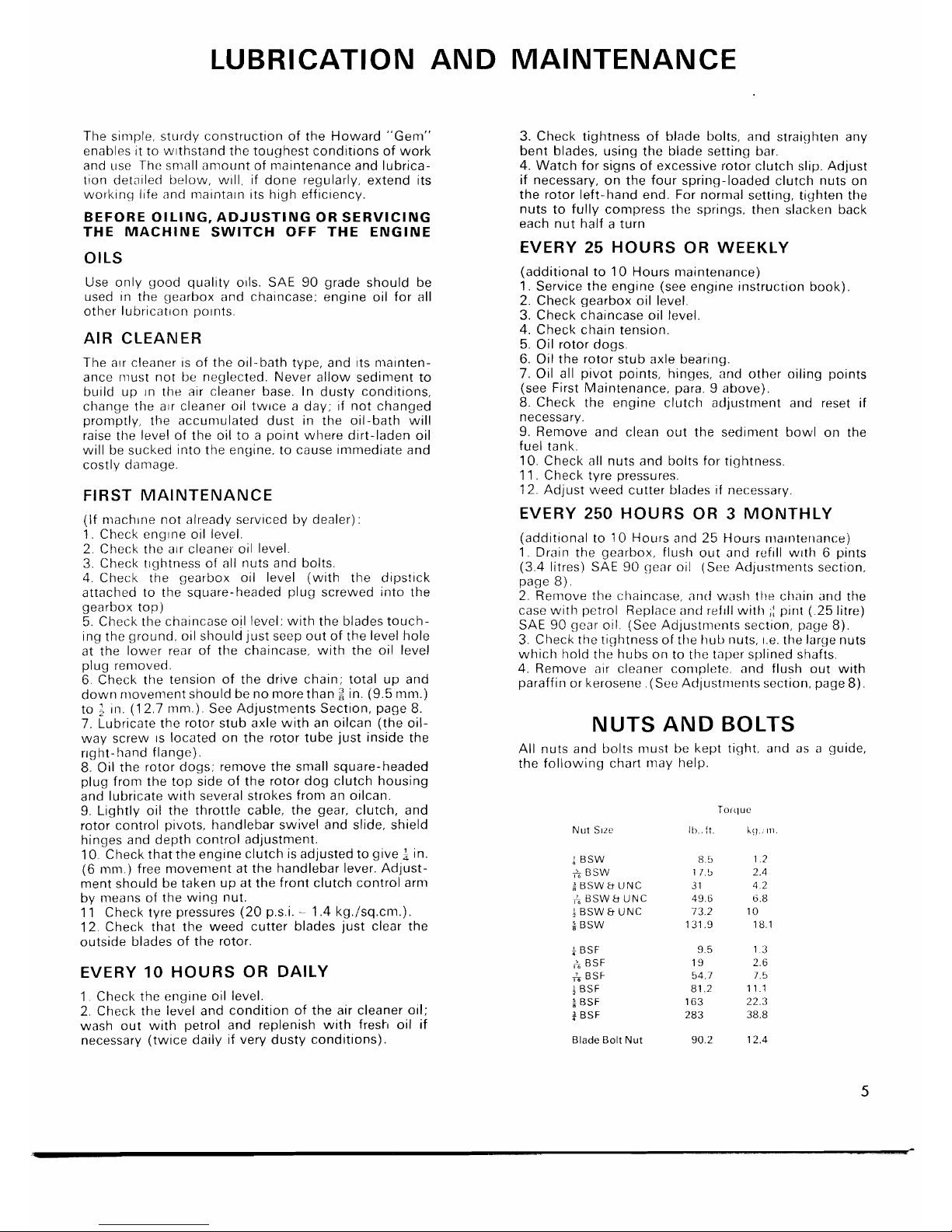

Page 7

LUBRICATION

AND

MAINTENANCE

The simple, sturdy construction of the Howard "Gem"

enables it to

w~thstand the toughest conditions of work

and

use The small aniount of maintenance and lubrica-

tion detailed below,

w~ll, if done regularly, extend its

working life and rnainta~n its high efficiency.

BEFORE OILING, ADJUSTING OR SERVICING

THE

MACHINE

SWITCH OFF THE ENGINE

OILS

Use only good quality 011s. SAE

90

grade should be

used in the gearbox and chaincase; engine oil for all

other

lubricat~on points.

AIR CLEANER

The alr cleaner is of the oil-bath type, and its niaintenance must not

be

neglected. Never allow sediment to

build up

In the air cleaner base. In dusty conditions,

change the

air cleaner oil tw~ce a day; if not changed

promptly, the accumulated dust in the oil-bath will

raise

ttie level of the oil to a point where dirt-laden oil

will be sucked into the engine, to cause immediate and

costly damage.

FIRST MAINTENANCE

(if niach~rie not already serviced by dealer)

:

1. Check engrne oil level.

2.

Check ttie alr cleaner oil level.

3. Check tightness of all nuts and bolts.

4.

Check the gearbox oil level (with the dipstick

attached to the square-headed plug screwed into the

gearbox top)

5.

Check the chaincase oil level: with the blades touch-

ing the ground, oil

should just seep out of the level hole

at the lower rear of the chaincase, with the oil level

plug removed.

6.

Check the tension of the drive chain; total up and

down

nlovenient should be no more than 2 in. (9.5 mm.)

to 4 in.

(1

2.7

rnm.). See Adjustments Section, page

8.

7.

Lubricate the rotor stub axle with an oilcan (the oil-

way screw

IS

located on the rotor tube just inside the

r~ght-hand flange).

8.

Oil the rotor dogs; remove the small square-headed

plug from the top side of the rotor dog clutch housing

and lubricate with several strokes from an

oilcan.

9. Lightly oil the throttle cable, the gear, clutch, and

rotor control pivots, handlebar swivel and slide, shield

hinges and depth control adjustment.

10.

Check that the engine clutch is adjusted to give in.

(6

rnm.)

free movement at the handlebar lever. Adjust-

ment should be taken up at the front clutch control

arm

by means of the wing nut.

11 Check tyre pressures (20

p.s.i. - 1.4 kg./sq.cm.).

12.

Check that the weed cutter blades just clear the

outside blades of the rotor.

EVERY

10

HOURS OR DAILY

1.

Check the engine oil level.

2.

Check the level and condition of the air cleaner oil;

wash out with petrol and replenish with fresh oil if

necessary (twice daily if very dusty conditions).

3.

Check tightness of blade bolts, and straighten any

bent blades, using the blade setting bar.

4. Watch for signs of excessive rotor clutch slip. Adjust

if necessary, on the four spring-loaded clutch nuts on

the rotor left-hand end. For normal setting, tighten the

nuts to fully compress the springs, then slacken back

each nut half a turn

EVERY

25

HOURS OR WEEKLY

(additional to 10 Hours maintenance)

1.

Service the engine (see engine instruction book).

2. Check gearbox oil level.

3.

Check chaincase oil level.

4. Check chain tension.

5.

Oil rotor dogs.

6.

Oil the rotor stub axle bearing.

7.

Oil all pivot points, hinges, and other oiling points

(see First Maintenance, para. 9 above).

8.

Check the engine clutch adjc~stnient and reset if

necessary.

9.

Remove and clean out the sediment bowl on the

fuel tank.

10.

Check all nuts and bolts for tightness.

1 1.

Check tyre pressures.

12.

Adjust weed cutter blades if necessary.

EVERY

250 HOURS

OR

3

MONTHLY

(additional to 10 Hours and 25 Hours nia~ntenancej

1. Drain the gearbox, flush out and ref111 w~th 6 pints

(3.4 litres) SAE 90 gear oil (See Adjustments section,

page

8).

2.

Remove the chaincase,

and

wash

the

chilin and the

case with petrol Replace and

ref111 with

;:

plr~t (.25 litre)

SAE 90

gear

oil. (See Adjustments section, page

8).

3.

Check the tightness of ttie hut) nuts, 1.e. the large nuts

which hold the hubs

or1 to the taper splined shafts.

4.

Remove air cleaner coniplete, and flush out with

paraffin or kerosene .(See

Adjustrrients section, page

8).

NUTS AND BOLTS

All nuts and bolts must be kept tight, and as a guide,

the following chart may help.

Nut

Sue

a

BSW

BSW

gBSW&UNC

BSW b UNC

,?

BSW & UNC

;

BSW

a

BSF

BSF

&

BSF

;

BSF

BSF

2

BSF

Blade

Bolt

Nut

Page 8

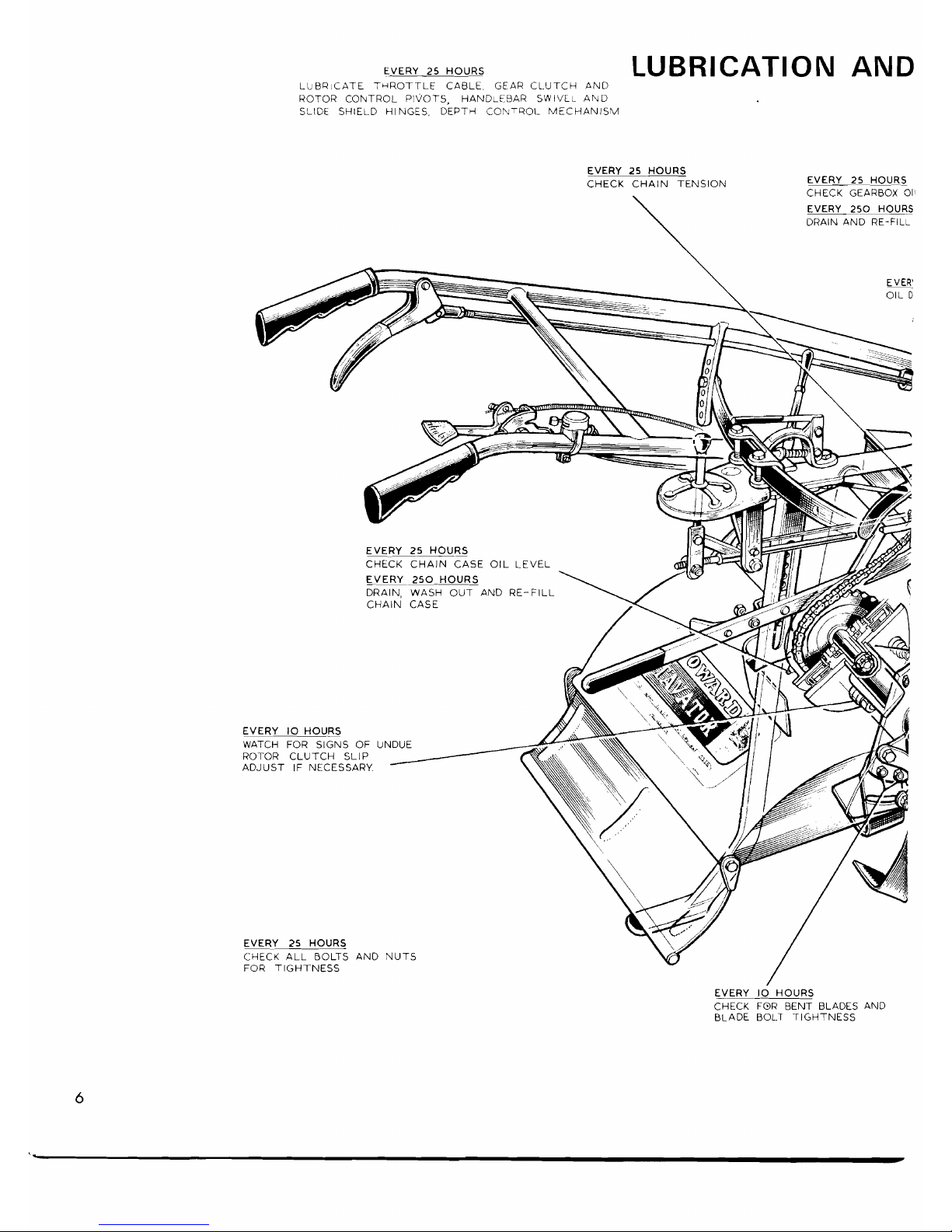

EVERY

25

HOURS

LUBRICATE THROTTLE CABLE. GEAR CLUTCH AND

LUBRICATION

AND

ROTOR COluTROL PIVOTS, HANDLEBAR SWIVEL AND

SLIDE SHIELD HINGES, DEPTH COhTQOL MECHANISM

EVERY

25

HOURS

CHECK CHAIN TENSION

EVERY

25

HOURS

CHECK GEARBOX

011

EVERY

250

HOURS

DRAIN AND RE-FILL

EVERY

25

HOURS

CHECK CHAIN CASE OIL LEVEL

\@I

I

EVERY

250

HOURS

DRAIN, WASH OUT AND

RE-FILL

CHAIN CASE

EVERY

10

HOURS

WATCH FOR SIGNS

OF

UNDUE

ROTOR CLUTCH

SLIP

ADJUST IF NECESSARY.

EVERY

25

HOURS

CHECK

ALL BOLTS AND NUTS

FOR TIGHTNESS

EVERY

I0

HOURS

CHECK FOR BENT BLADES AND

BLADE BOLT TIGHTNESS

Page 9

MAINTENANCE CHART

:;:K::2CSibnpLnvAT~~v~~)

.

LEVEL

GEARBOX

E!ERY

I0 HOURS

(OR

TWICE DAILY

IN

VERY

DUSTY

CONDITIONS.)

CHECK AIR CLEANER OIL

EVERY

25

HOURS

CLEAN OUT SEDIMENT BOWL.

LEVEL

ENGINE

SUMP

:VERY

25

HOURS

IlL

ROTOR

STUB

AXLE

\

EVERY

250

HOURS

CHECK HUB NUTS

FOR

TIGHTNESS

\

RECOMMENDED LUBRICANTS

\

EVERY

25

HOURS

CHECK

WEED

CUTTER BLADES,

ADJUST IF NECESSARY.

GEARBOX AND CHAIh CASE

.

...

.

5.A

E.

90

ROTOR DOG CLUTCH

ROTOR STUB

AXLE

)

US. ENGIME OIL

DEPTH CONTROL

WHEEL

(IF

FITTED)

Page 10

ADJUSTMENTS

ROAD

WHEELS

Each road wheel

IS

mounted on its hub by a friction

clutch device. These are adjusted so that the wheels

have sufficient

grip to pull the machine, but will slip if

they become jammed

wlth an obstruction between the

wheels and the frame.

For normal adjustment, tighten each of the four nuts to

fully compress the springs, then slacken back each nut

half a turn

Should the wheels appear not be driving, check that

the adjustment is correct.

DRIVE CHAIN

Correct drive cha~n tenslon is as Important as correct

lubrication.

Total up and down movenlent should be

no more than in

(9.5

nim.) to : in.

(1

2.5

mm.) Check

wlth a suitahle screwdriver Inserted through the oil

filler hole on the top

side

of

the

chaincase. Turn the

screwdriver to

grlp the cha~n between the links. Loosen

the locknut

on the external adiuster on

the

bottom front

of the

chaincase, and screw

In

the adjl~stln<] screw to

increase

chain tenslun Re- t~ghterl t1-i~ locknut

CLEANING CHAINCASE

After

250

hours of worh the ctlalncase should be

cleaned out

Unscrew

<]I! the bolts securlny the chain-

case to the bdckplate allovv~n<l

the

chalncase o~l to

dra~n out frorri the jolnt

no drain plug 1s fitted Remove

the cover

ensuring

that the gasket

IS

not damaged and

wash out the

lnslde of the case and the chaln wlth

petrol or kerosene Re-assemble, and

fill

wlth

,:

pint

(

25

Iltre)

SAE

90

gear

011

CLEANING GEARBOX

The gearbox must also be cleaned out after

250

hours

work Unscrew the

dra~n plug on the bottom right-hand

inner side of the gearbox and drain the box immediately

after a period of

runnlnq The

011

will be warm and free-

running and any sedlment

will

be

in suspension in the

oil. Replace the

drarn plug and ref111 the gearbox with

about

6

pints

(3.4

litres) of

flushing

011

Run the machine

for about

3

minutes wlth the rotor well clear of the

ground, then drain the flushing oil. Refill the gearbox

wlth 6 pints

(3.4

Iitres) of good quality

SAE

90

gear oil.

ROTOR

FRlCTlOlU DRIVE

The rotor to

which

the blades are bolted is driven direct

frorn the main gearbox through a friction clutch. This

clutch should only operate

when the rotor blades strike

an obstacle, when despatched from the factory the

clutch is adjusted so that no slip occurs

znder normal

working conditions. If the clutch appears

io slip too

easily, it can be adjusted by tightening the four clutch

nuts to fully compress

the

springs. then slackening back

each nut half a turn.

AIR

CLEANER

The air cleaner oilbath oil level must be checked every

10

hours, or every 5 hours In very dusty conditions.

Every

250

hours, the air cleaner lntcrior must be cleaned

out. Undo the two nuts

beh~rlcl

the air cleaner, to

separate the air cleaner from the support bracket on the

main frame, and undo the

jutjllee

clip

on the end of the

air cleaner hose to disconnect the cleaner completely.

Remove the black,

domed pre-cleaner from the top of

the air cleaner, and flush out

the interior of the air

cleaner with paraffin or kerosene, to

remove all dirt and

dust frorn the wire gauze elements

inslde.

When clean, refit the pre-cleaner and secure the air

cleaner on the support bracket. Re-connect the hose.

MAINTENANCE

OF BLADES

Only the cutting edges of the blades should rub in the

soil: the backs of the blades

should be clear

The blades are so deslgnecj that use In average so~ls

should keep them sharp. If the <]round is very stony

however,

~t

IS

recon~rnended that two

sets

of hoe blades

be used alternately, so

that

one set may be kept

sharpened

The

efficiency

of the machine is determlned largely by

the condition of the blades. If they are left bent or

dlsIorted through strlking solid obstacles in the ground,

they will requlre double the power to drlve. the quality

of the work will be poor and the blades

will

wear much

more quickly. Trouble w~ll also arise with clogging

under the shield Blades must therefore be examined

daily and any bent ones replaced

immediately

ROTOR

FLANGE

WEEDCUTTERS

Two weedcutter blades are provided, one at each side

of the machine, to prevent long grass or weeds binding

around the end rotor flanges. The blades are slotted and

secured by two setscrews each, and should be adjusted

so that they just clear the rotor flanges when the rotor

is turned BY

HAND.

Severe power losses will occur in

weedy conditions unless these blades are correctly

adjusted.

Page 11

ROTORS

AND

BLADES

BLADES

The Howard "Geri~" is normally delivered with the

blades already fitted If it

IS

necessary to fit your own

blades, this

IS

done as follows:

1.

Identify left-hand and r~ght-hand blades.

2.

The left-hand end flange carries two right-hand

blades. the right-hand end

carries two left-hand blades.

3

The centre flange (or flanges, depending on the

rnachlne width), carries two left-hand and two righthand blades leading The blades should be fitted to the

left-hand side of the centre

flange(s), with the heads

I

of the bolts against the blades and spring washers and

nuts against the flange.

PICTINE

ROTOR

In addit~on, a Pictine rotor, with flanges closer-spaced

than the standard rotor,

IS

ava~lable for use with

pic

-

tines or pasture renovating (lucerne) tines, for very hard

soil

condit~ons, or for pasture renovation. (See Attach-

ments section,

page

10).

TWISTED

BLADE

CUTTING EDGE

R.H. BLADE

How

to

identify right and left-hand blades.

Gem Rotor

(20

in. model),

24

in. and

30

in.

rotors have two centre flanges

BLADE IN CORRECT

ALlGNMENl

I

I

3"

3-2 CLEARANCE

I

L/J

STRAIGHT EDGE

DIRECTION

OF

TRAVEL

Correct blade setting showing clearance at back of blade.

Page 12

ATTACHMENTS

FURROWER

DEPTH CONTROL

WHEEL

A Depth Control Wheel

IS

standard with

24

In.

and

30

in.

models, but optional,

In place of the skid, on the

20

In.

"Gem".

The

Furrower is fitted on the depth control skid. Pivut

the depth control lever clip and move the lever sideways

to withdraw the skid engagement pin. Pull out the skid

from the socket under the rotor shield.

Assemble the

furrower on the skid leaving the furrower

bottom 4 in.

(1.25

cm.) above the foot of the skid, or

as required for the crop to be planted, then tighten the

locking nut.

Fit

the assembly into the socltet

and

connect

to the depth control lever.

For machines fitted with a depth control wheel

~nstead

of a skid, order a skid

IP

addition to the Currower.

When using the furrower, the rotor is put

Into gear so

that cultivating and furrowing are done simultaneously.

PICTINE

ROTOR

The Pict~ne Rotor w~th flanges spaced closer than on

the standard rotor can be fitted

with

PIC

tines or pasture

renovating (lucerne) tines.

The

pictines have a horizontal ch~sel po~nt, and are

used for breaking up very hard ground, old tracks, etc.

The pasture renovating tines have a vertical

kn~fe edge,

and are used to tear up and aerate old matted turf, to

encourage fresh growth of young grasses.

To fit the

pictine rotor, slacken off all the nuts and bolts

holding the support bracket which carries the stub axle,

staytube and rotor shield. Remove the four rotor clutch

nuts and springs. Spring the bracket off the stub

axle.

using a suitable bar, and slide the rotor sideways to

remove. Then reverse the sequence to fit the

pictine

rotor, ensuring that all nuts are correctly tightened and

rotor clutch adjusted.

NOT ILLUSTRATED:-FRONT-END

WEIGHTS

Page 13

MAKING

THE

MOST

OF

YOUR

"GEM"

GENERAL

As the scope of opct 3tion is so wide, and, as soil ti!lage

methods differ so gre'itly according to crop, climate and

soil condition, it is not possible to deal more than superficially with this aspect. However, it is hoped that the

following hints will help the user to obtain the best

results

from the machine.

The Howard "Gem" will cultivate

to a maximum depth

of

9

in.

(23

cm.). On certain, especially the heavier,

types of soil,

th~s depth will not be obtained in a single

pass. Where cultivation in depth is needed, a first pass

shouid be made at

3-4

in.

(7-10

cm.), followed by a

fsrther pass at full depth.

The low gear must be used when cultivating ground

which is very hard or covered with heavy growths.

Second gear is used for all ordinary cultivation, and top

gear for light cultivation. Always work

~n the highest

gear that will produce the quality of tilth necessary.

Always use top gear for running the machine between

jobs. A depth control skid or a wheel, is fitted, and by

moving this up and uown the depth of work can be

controiled in

2

in.

(19

mm.) stages down to 9 in.

(23

cm.) deep.

If the surface of the ground is very hard or baked, the

depth control should be adjusted so that the machine

just bites the surface. Further passes should then be

made until the required depth is reached.

On heavy land which is to be laid up for the winter, the

surface should be left rough. By using the ridging or

furrowing attachment during this final or late autumn

cultivation, the land can be left in ridges to promote

better drainage and to expose a greater surface area to

the weather.

If heavy land

IS

Rotavated too finely and left bare to the

winter rains, the soil may pack together, making spring

cultivations difficult.

When cultivating a ploughed field, the "Gem" should

be run across the furrows, not along them. This will

ensure complete cultivation.

On hilly ground always run the machine around the

contour, working

from the top to the bottom of the hill.

After the first cut, one road wheel can be run in the soil

just worked, so that any tendency to slip will be

countered by the wheel coming against a wall of uncut

soil.

On light soils, two courses are open. The ground may

either be left rough, or it may be Rotavated to medium

depth and sown to a green crop,

e.g. rye. The green

crop will prevent the leaching out of the nitrogen in the

soil. In the early part of the year the crop is then

Rotavated. After a week or ten days, the spring seed

bed may be prepared. This Rotavation should be

shallower than that used to work-in the green crop.

SEED

BEDS

In ground which has been cultivated properly, seed

beds should seldom exceed

2

in.

(5

cm.) in depth,

except for certain crops. Seeds require a well-aerated

soil with a firm bottom. Some small seeds require a seed

bed to be lightly consolidated. This is particularly

important on light soil, where consolidation will bring

moisture nearer to the seedling plant.

Competition from weeds is most critical when the crop

is at the seedling stage. To obtain weed-free seed beds,

the ground should be prepared a few weeks ahead of the

sowing dates. Rotavation should be carried out at a

depth of

4

In.

(1

0

cm.); this causes any weed seeds to

germinate. These weeds may be turned in by a second

Rotavation, which will prepare the seed bed at the

same time. It is most important that this second

Rotavation is shallower than the first. Remember that

the ground is now more open, so that the

machine will

tend to dig more deeply. When the seed bed has been

prepared, it should ideally be allowed to settle for

24

hours before sowing.

WEED

CON-TROL

Rotavation produces a well-aerated warm seed bed in

which germination takes place readily. Inevitably, such

conditions also favour weed seeds.

Weeds are eliminated by preventing them seeding

or by

progressive weakening

of

the deep tap roots or rhizomes.

Weeds are killed most easily and inexpensively by

Rotavating them directly they show green. Annuals will

be killed outright and perennials will be reduced until

they too, die out. This is true even of such persistent

weeds as couch or twitch.

ROW-CROP WORK

Work will be easier if rows are made as long as possible.

At least

3

ft.

(1

m.) should be allowed at each end for

turning.

Weeds between rows may be controlled by Rotavation.

Ideally, this should be done when the weeds are small,

but even a heavy growth can be turned in.

This will not prevent weeds

growing in the rows themselves; such weeds must be controlled by hand-hoeing

when small. Should land become weed-infested

because these weeds have been allowed to seed, the

Page 14

following crop should be a cleaning crop, e.g. roots or

potatoes, which will give a period of several weeks in

the early part of the year when the weed seeds will

shoot and can be killed by Rotavation.

In planning your crops to make the best use of the

"Gem", allow

2

or 3 in.

(5

or 7 cm.) over the effective

width on each side of the machine.

GREEN

MANURING

Land not immed~ately required may be sown down to

such crops as mustard or rye grass during spring and

summer, or rye during the winter. These crops should

be allowed to mature if they are to be used

as

green

manures

-

they will then have the best effect on

the

soil. A winter cover crop will preserve plant foods which

would otherwise be leached away, so it need not be

allowed to mature.

LAND

RECLAMATION

The

"Gem" may also

be

used to bring derelict land back

into cultivation. Virgin ground or soil tightly bound with

roots or grass

is

best cultivated by fjrst working at only

a shallow depth, to break up the surface. Depth can

then be gradually increased by subsequent passes made

at intervals of about a week or ten

days.

CONCLUSION

Never overtax the power of the machine. Far better

results will be obtained from working in easy stages,

rather than by forcing the machine to do work in excess

of its horsepower.

The

right to alter and/or

amend

all designs, specifications and/or prices without prior notice is strictly reserved.

Page 15

Howard

Rotavator

r

-

*'

P<-Y,-:?7

a

A

member

of

the

How

Telephone

Bury

St

E-ds

(0284

)

6326

Loading...

Loading...