Hoval UltraGas 150, UltraGas 400, UltraGas 200, UltraGas 250, UltraGas 300 Installation Instructions Manual

...

Subject to modi cations |

EN

Technical information

Installation instructions

4 213 783 / 00 - 06/15

Hoval products may only be installed and commissioned

by appropriately qualied experts. These instructions

are intended exclusively for the specialist. Electrical

installations may only be carried out by a qualied

electrician.

Vertical gas condensing boilers UltraGas® (125-1000)

acc. to EN 483 and EN 677 are suitable and licensed for

use as heat generators for hot water heating systems

with a permissible ow temperature of up to 90 °C1).

They are designed for continuously controlled reduced

operation in a heating system.

1)

See technical data

UltraGas® (125 - 1000)

Condensing gas boilers

for natural gas and liqueed gas

for modulating operation

These instructions are applicable to the

following types:

Nominal output ranges at 40/30°C and

with natural gas

41-UltraGas® (125) 28 - 123 kW

41-UltraGas® (150) 28 - 150 kW

41-UltraGas® (200) 44 - 200 kW

41-UltraGas® (250) 49 - 250 kW

41-UltraGas® (300) 57 - 300 kW

41-UltraGas® (350) 58 - 350 kW

41-UltraGas® (400) 97 - 400 kW

41-UltraGas® (450) 97 - 450 kW

41-UltraGas® (500) 97 - 500 kW

41-UltraGas® (575) 136 - 575 kW

41-UltraGas® (650) 136 - 650 kW

41-UltraGas® (720) 142 - 720 kW

41-UltraGas® (850) 166 - 850 kW

41-UltraGas® (1000) 224 - 1000 kW

41-UltraGas® H (720) 142 - 720 kW

41-UltraGas® H (1000) 224 - 1000 kW

2

4 213 783 / 00

TABLE OF CONTENTS

1. Important notes

1.1 General safety instructions .................................................................................................................................................4

1.2 Explanation of the symbols ................................................................................................................................................4

1.2.1 Warnings ..........................................................................................................................................................................4

1.2.2 Icons .................................................................................................................................................................................4

1.3 On delivery ...........................................................................................................................................................................5

1.4 Warranty ...............................................................................................................................................................................5

1.5 Manuals ................................................................................................................................................................................5

1.6 Regulations, official approvals ...........................................................................................................................................6

1.6.1 Germany § ........................................................................................................................................................................6

1.6.2 Austria § ...........................................................................................................................................................................6

1.6.3 Switzerland § ....................................................................................................................................................................6

2. Installation

2.1 Set-up ...................................................................................................................................................................................7

2.2 Fitting the thermal insulation ............................................................................................................................................10

2.3 Fitting the casing ............................................................................................................................................................... 11

2.4 Fitting the pedestal casing ................................................................................................................................................14

3. Technical information

3.1 Description of the boiler ...................................................................................................................................................16

3.2 UltraGas® (125-300) technical data ...................................................................................................................................17

3.3 Dimensions space / required ............................................................................................................................................20

3.3.1 Overall unit dimensions ...................................................................................................................................................21

3.4 Boiler flow resistance ........................................................................................................................................................22

3.5 Brief description of the automatic firing device ...............................................................................................................23

4. Installation

4.1 Safety instructions ............................................................................................................................................................24

4.2 Requirements on the boilerhouse ....................................................................................................................................24

4.2.1 Room air dependent installation ......................................................................................................................................24

4.2.2 Room air independent installation ...................................................................................................................................24

4.3 Flue gas connection, flue gas conduit .............................................................................................................................25

4.4 Condensate drain ..............................................................................................................................................................25

4.4.1 Design variants ...............................................................................................................................................................25

4.5 Gas connection ..................................................................................................................................................................26

4.6 Hydraulic connection ........................................................................................................................................................26

4.6.1 To be provided on-site ..................................................................................................................................................... 27

4.6.2 Hydraulic integration .......................................................................................................................................................27

4.6.2.1 Cascades .......................................................................................................................................................................................27

4.7 Electrical connection .........................................................................................................................................................28

5. Commissioning

5.1 Safety instructions ............................................................................................................................................................29

5.2 Filling the heating system .................................................................................................................................................29

5.3 Water quality ......................................................................................................................................................................30

5.4 Venting the gas pipe ..........................................................................................................................................................31

5.5 Switch on ...........................................................................................................................................................................31

5.6 Gas inlet pressure .............................................................................................................................................................31

5.7 Setting the gas quantity, measuring the CO2 (O2) and NOx/CO content in the flue gas .................................................32

5.7.1 UltraGas® (125-720) flue gas measurement ....................................................................................................................32

5.7.2 UltraGas® (850, 1000) flue gas measurement ..................................................................................................................32

5.8 Changing to a different type of gas ..................................................................................................................................33

5.9 Type (850, 1000) setting the stabilisation damper (if required) .......................................................................................35

5.10 Handover to the operator ..................................................................................................................................................35

5.11 Activation of screed function ............................................................................................................................................36

3

4 213 783 / 00

TABLE OF CONTENTS

6. Maintenance

6.1 Safety instructions ............................................................................................................................................................38

6.2 Deaeration ..........................................................................................................................................................................38

6.3 Top up with water ..............................................................................................................................................................38

6.4 Renewing fuse ...................................................................................................................................................................38

6.5 Information for fire inspector / chimney sweep regarding emission and manual operation settings ...........................39

6.6 Cleaning .............................................................................................................................................................................40

6.6.1 Cleaning the burner cylinder (inside and out) ..................................................................................................................40

6.6.2 Cleaning the combustion chamber and burner cylinder on the outside .............................................................................41

6.6.3 Clean/adjust ignition and ionisation devices ....................................................................................................................42

6.6.4 Cleaning the gas filter HFVR050 (only applicable for UltraGas® (450-720)) (if fitted) .......................................................43

6.7 Setting the gas quantity, measuring the CO2 (O2) and NOx/CO content in the flue gas .................................................44

6.8 Cleaning the condensation trap ........................................................................................................................................44

6.9 Maintaining the neutralisation unit for type 23 and type 24 (if fitted) .............................................................................45

4

4 213 783 / 00

IMPORTANT NOTES

1. Important notes

1.1 General safety instructions

The system may only be placed in operation

if all the relevant standards and safety regula

-

tions have been complied with.

At least the following conditions must be satised for a trial operation:

- Safety valve installed (system sealed)

- Control system in operation (connected to the power

supply)

- Sensor for safety temperature limiter connected (= boiler temperature sensor)

- System lled with water

- Condensation trap lled with water

- Expansion tank connected

- Flue gas outlet with ue gas conduit connected to ue

gas system.

- Burner preset (see point 6.7).

WARNING

The heat generator can only be de-energised

by disconnection from the mains (e.g. allpole switch).

WARNING

All electric power supply circuits must be

switched off before accessing the terminals.

1.2 Explanation of the symbols

1.2.1 Warnings

!

DANGER

... indicates a situation of immediate danger

which will lead to serious or fatal injuries if

not avoided.

!

WARNING

... indicates a situation of possible danger

which can lead to serious or fatal injuries if

not avoided.

!

CAUTION

... indicates a situation of possible danger

which can lead to minor or slight injuries if

not avoided.

NOTICE

... indicates a situation of possible danger

which can lead to damage to property if not

avoided.

1.2.2 Icons

!

General warning of a danger zone.

"Warning: dangerous electrical voltage" as

a warning for accident prevention.

Ensures that people do not come into contact

with electrical voltage. The danger sign with

the black lighting symbol warns against the

danger of electrical voltage.

Warning of cutting injuries.

Warning of hot surface

Indicates dangers of injury and burns on hot

surfaces.

Danger: Substances with a corrosive effect on

skin, eyes and respiratory organs; can cause

irritation.

Handling: Do not inhale vapours and avoid

contact with skin and eyes.

Information:

Provides important information.

5

4 213 783 / 00

IMPORTANT NOTES

Follow the instructions for use.

Requirements to comply with the instructions.

Information:

Which tools and other equipment are required.

§

Provides important information.

Refers to standards and directives.

1.3 On delivery

Carry out a visual inspection immediately on receiving the

boiler. If any damage is found, take the necessary steps

as dened in the delivery contract. The respective risk

carrier bears the cost of repairs.

1.4 Warranty

The warranty does not cover defects attributable to:

• Failure to comply with these instructions

• Failure to comply with the operating instructions

• Incorrect installation

• Impermissible modications

• Incorrect handling

• Contaminated operating materials (gas, water, combustion air)

• Unsuitable chemical additives to the heating water

• Damage caused by the application of force

• Corrosion by halogen compounds (e.g. paints, adhesives, solvents)

• Corrosion caused by not observing the required water

quality

1.5 Manuals

All instructions relevant to your system can be found in

the Hoval system manual! In exceptional cases, the instructions can be found with the components!

Further sources of information:

• Hoval catalogue

• Standards, regulations

6

4 213 783 / 00

IMPORTANT NOTES

1.6 Regulations, official approvals

The standards and directives stated under points 1.6.1 to

1.6.3 must be taken into account during installation and

operation of the system.

1.6.1 Germany §

- DIN EN 12831 Heating systems in buildings – Method

for calculation of the design heat load

- DIN EN 13384 Flue gas systems – Calculation methods

in heat and ow engineering

- DIN EN 12828 Heating systems in buildings - Design of

hot water systems.

- DIN 4755 Oil-red systems. Design, construction and

safety engineering requirements.

- DIN 4756 Gas-red combustion systems: design, construction and safety engineering requirements, design

and construction (for operation with gas burners).

- DIN 18160 House chimneys; requirements, planning

and execution.

- TRD 702 Steam boiler plants with caloriers of the

group II.

- TRD 721 Safety devices against excess pressures /

safety valves / for steam boilers of Group II.

- VDI 2035 Prevention of damage by corrosion and the

formation of scale in hot water heating systems.

- DIN 57 116 / VDI 0116 Electrical equipment for ring

systems (VDE Regulation).

- For further standards applicable in Germany, see appendix N-430 020.

1.6.2 Austria §

- OENORM 12831 Heating systems in buildings - Procedure for calculation of the standard heating load

- OENORM 13384 Waste gas systems – Procedures for

heat and ow calculations

- OENORM 12828 Heating systems in buildings - Design

of hot water systems.

- ÖNorm B 8130 Open water heating systems; safety devices.

- Norm B 8131 Closed water heating systems; safety, execution and testing requirements.

- ÖNorm B 8133 Hot water production systems; technical

safety requirements.

- ÖNorm B 8136 Heating systems, space requirements

and other building requirements.

- ÖNorm M 7515 Calculations of dimensions of chimneys; terminology, calculation procedure.

- ÖNorm H 5171 Heating systems – construction engineering requirements.

- ÖVGW TR-gas (Austrian Gas and Water Confederation

- Technical Guidelines)

1.6.3 Switzerland §

- SN EN 12831 Heating systems in buildings - Procedure

for calculation of the standard heating load

- SN EN 13384 Flue gas systems - Heat and ow calculation methods

- SN EN 12828 Heating systems in buildings - Design of

hot water heating systems.

- VKF – Association of Cantonal Fire Insurers.

- Fire prevention authority regulations.

- SVGW Swiss Association for Gas and Water.

- SNV 27 10 20 Aeration and ventilation of the boiler installation room.

- SWKI BT102-01 Water quality for building services systems.

- Technical tank regulations TTV 1990.

- EKAS - Guidelines for liqueed gas Part 2

and further regulations and standards issued by CEN,

CEN ELEC, DIN, VDE, DVGW, TRD and the legislative

body. The regulations of the local building authorities, insurance companies and chimney sweeps must also be

taken into account. The regulations of the responsible

gas supply company are to be complied with if using gas.

Approval by the authorities may be required.

7

4 213 783 / 00

INSTALLATION

2. Installation

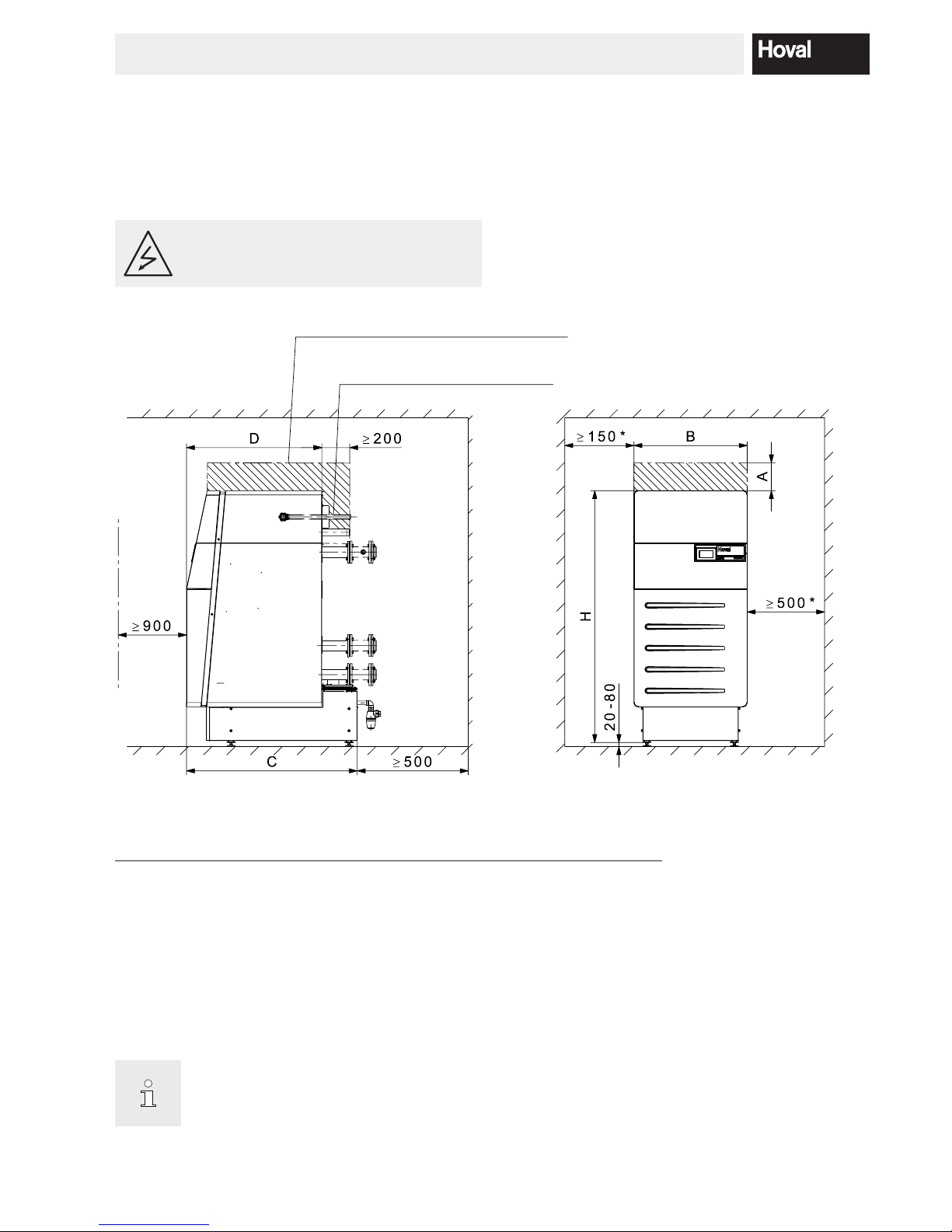

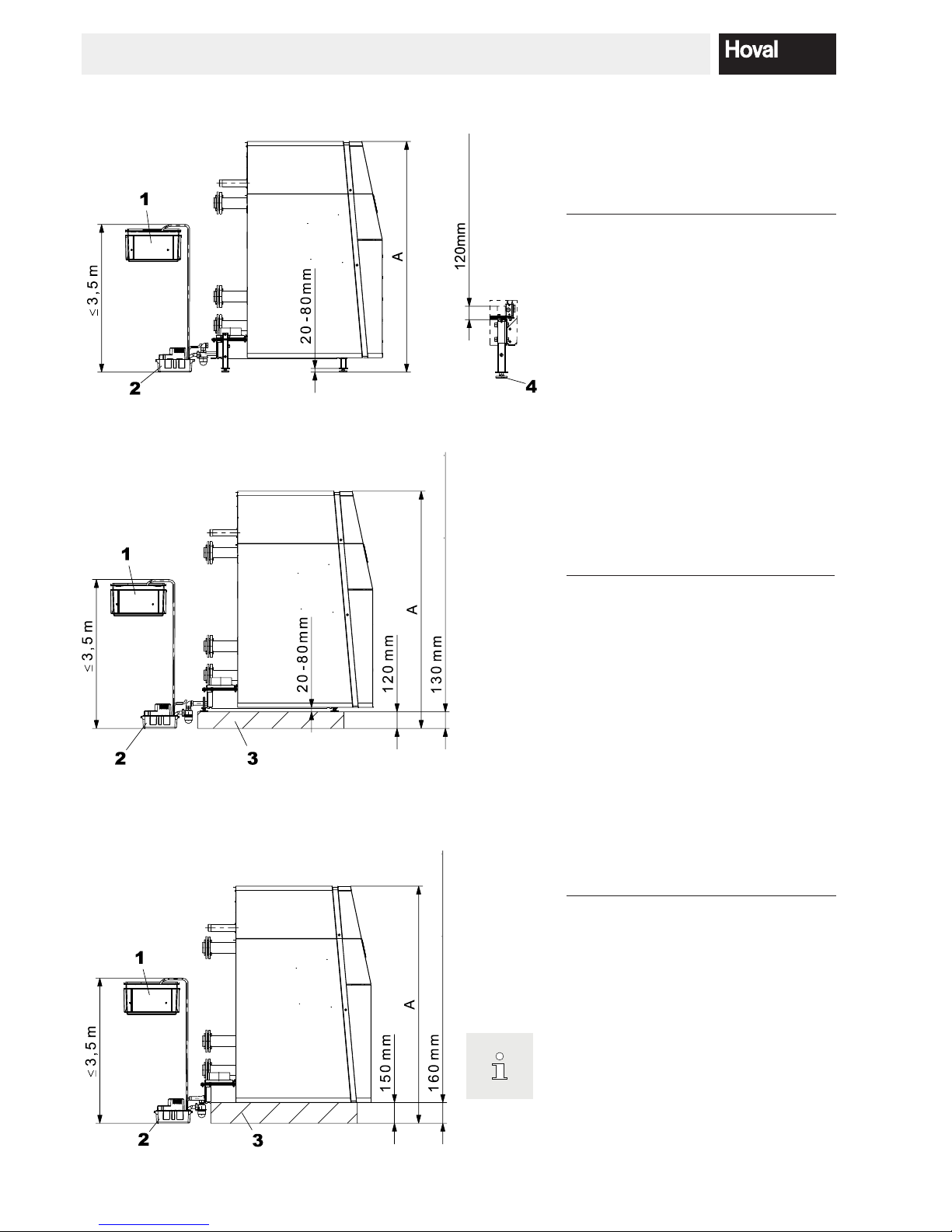

2.1 Set-up

Space requirement of UltraGas® (125-1000)

(All dimensions in mm)

CAUTION

The cables must not touch any hot parts.

Straight gas connection line route

to the rear

For swinging out the burner this area

must remain free

Fig. 01

UltraGas

®

Model

A A mini-

mum

B C D H H mini-

mum

(125, 150) 180

1

80

2

820 1237 981 1823 1711

3

(200 - 300) 360 1160

2

930 1584 1247 1923 1811

3

(350 - 500) 200 1100

2

1110 1679 1268 2070 1958

3

(575 - 720) / H (720) 200 1100 21290 1843 1438 2086 1984

3

(850, 1000) / H (1000) 420 1230 21550 2154 1703 2139 2037

3

1

If the room height is too low: the dimension can be reduced. See A

minimum.

2

Caution! At A minimum, the burner can no longer be swivelled out

completely! Cleaning is made difcult!

3

Feet can be shortened, no pedestal casing possible! For details see

next page.

The boiler can be placed with one side directly

the wall. For the casing to be installed, how

-

ever, there must be a distance of at least 100

mm from the wall.

8

4 213 783 / 00

INSTALLATION

cut off

UltraGas

®

(575 - 1000)

UltraGas

®

(575 - 1000)

UltraGas® with shortened boiler feet

(All dimensions in mm)

UltraGas® peak load boiler

Model A

(125, 150) 1723 - 1783

(200 - 300) 1823 - 1883

(350 - 500) 1970 - 2030

(575 - 720) / H (720)

1986 - 2046

(850, 1000) / H (1000)

2039 - 2099

UltraGas® peak load boiler

Model A

(125, 150) 1711 - 1771

(200 - 300) 1811 - 1871

(350 - 500) 1958 - 2018

(575 - 720) / H (720)

1984 - 2044

(850, 1000) / H (1000)

2037 - 2097

UltraGas® peak load boiler

Model A

(125, 150) 1721

(200 - 300) 1821

(350 - 500) 1968

(575 - 720) / H (720)

1994

(850, 1000) / H (1000)

2047

UltraGas

®

with walled-in pedestal and adjustable feet

UltraGas

®

with walled-in pedestal without adjustable feet

1 Neutraliser box

2 Condensate pump

3 Walled base

4 Adjustable feet 20-80 mm

No refunds for pedestal sheets and adjusting

feet!

9

4 213 783 / 00

INSTALLATION

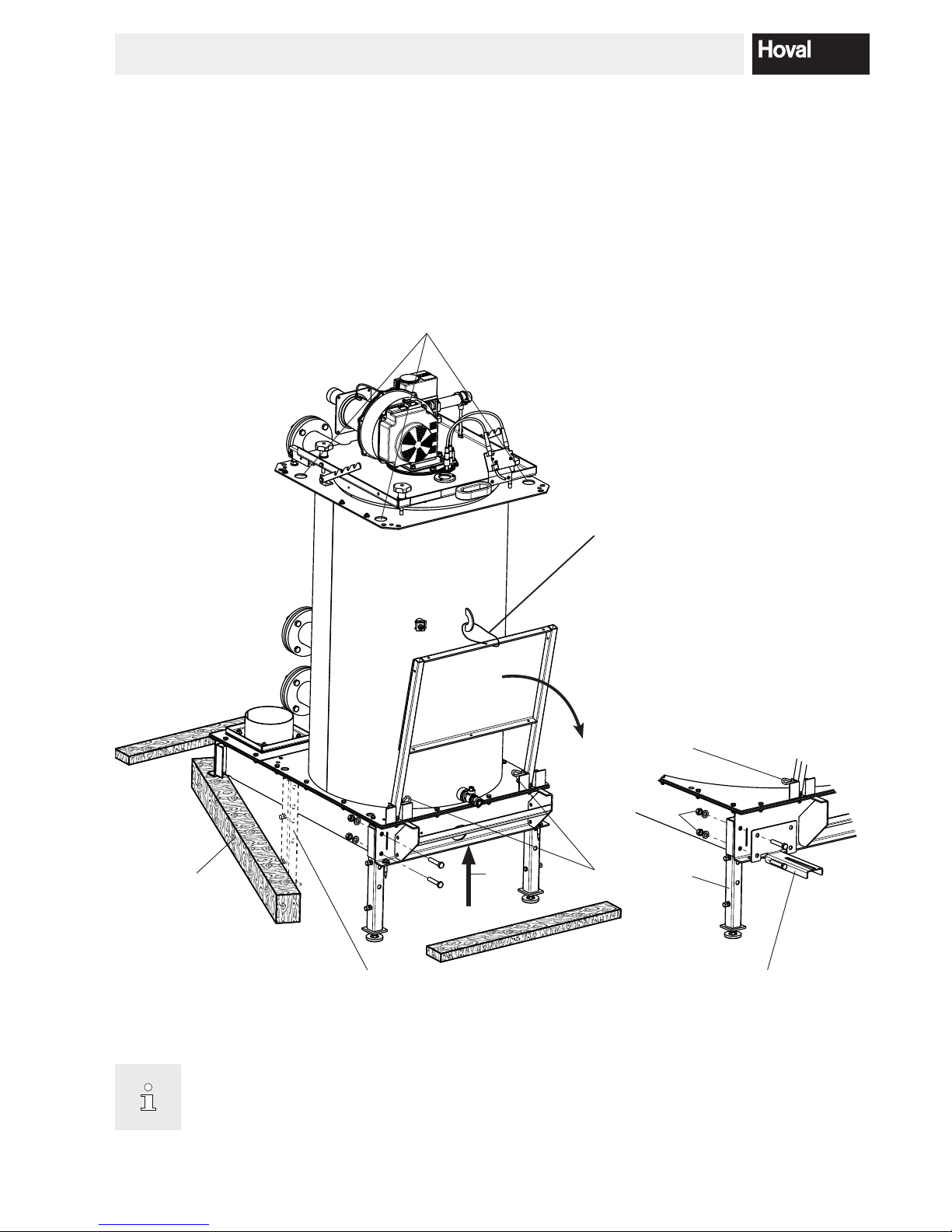

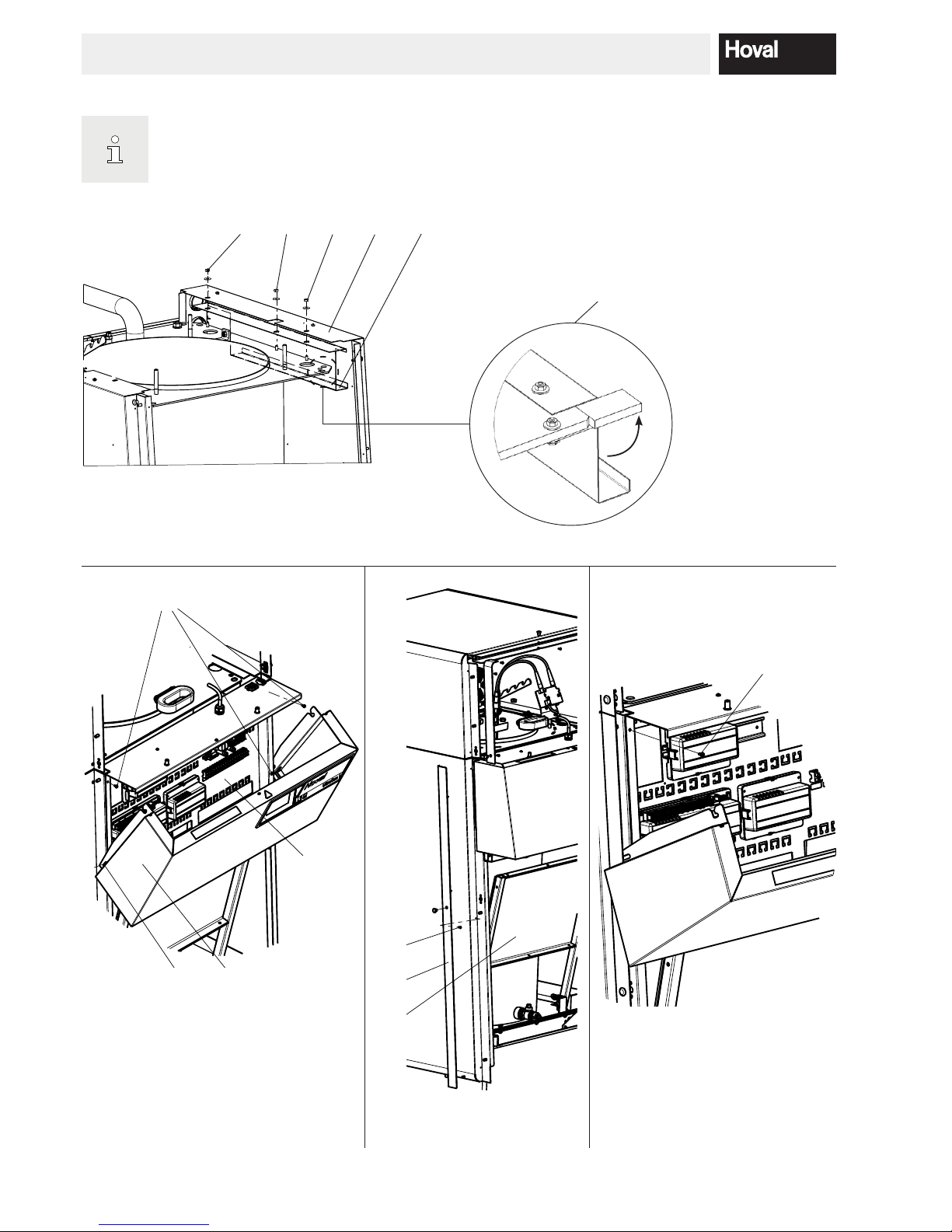

Procedure:

1. Remove the top two screw connections (1, Fig. 02) on the boiler foot (1a, Fig. 02).

2. Remove front wooden crossbeam.

3. Using a winch (3, Fig. 02) raise the front of the boiler.

4. Take out the side beam (4, Fig. 02) at the front to the side (see Fig. 02).

5. Push in the front feet and screw on.

6. Using a winch (3, Fig. 02, Fig. 02) raise the rear of the boiler.

7. Take out the side beam (4, Fig. 02) at the rear to the side (see Fig. 02).

8. Push in the rear feet and screw on.

9. Remove the step board protection (5, Fig. 02). Remove the securing pins (6, Fig. 02) and carefully fold the step

board down. In types (850, 1000) fold up 2nd and 3rd step board or remove ladder.

4 1a

1

3

Types (850, 1000) (H (720, 1000))

with six feet

6

5

Types (575-1000) (H (720, 1000))

Suspension possibilities for crane

1b

Fig. 02

Adjustable foot height is set after installation

of the neutralisation unit.

10

4 213 783 / 00

INSTALLATION

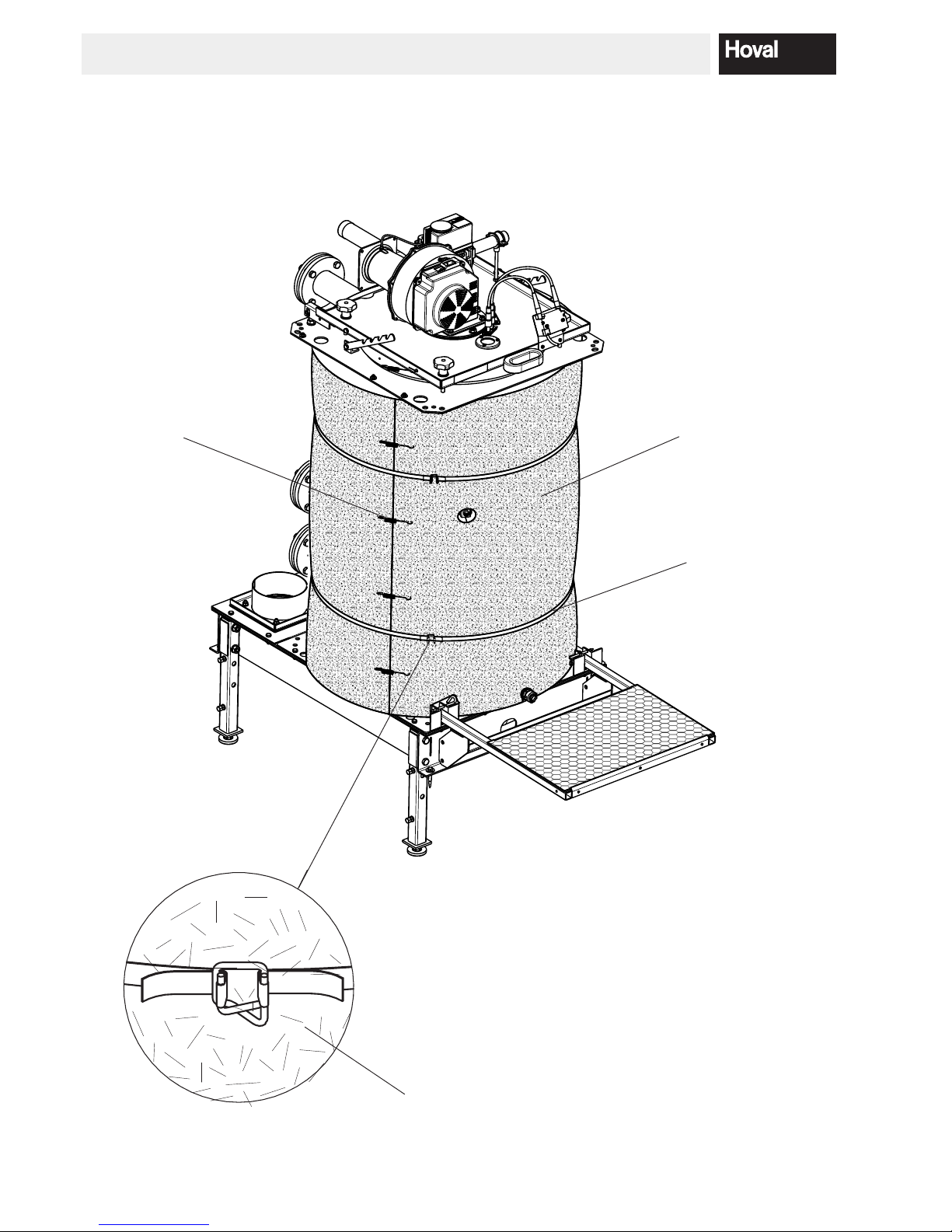

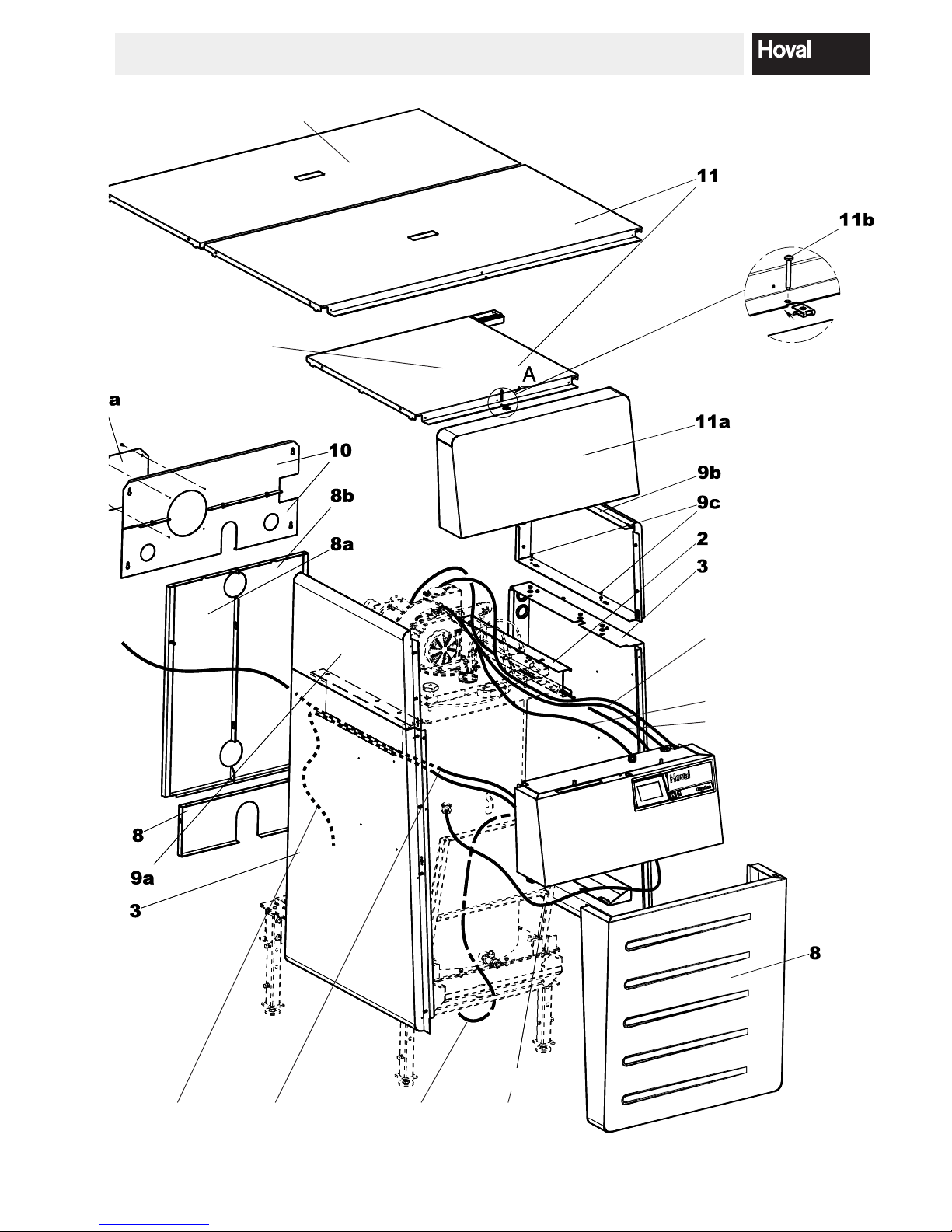

2.2 Fitting the thermal insulation

Place the insulation mat (1, Fig. 03) around the UltraGas® boiler and attach with plastic straps (1a, Fig. 03) and strap

fasteners (1b, Fig. 03).

- Tension springs (1c, Fig. 03) serve for additional xing

- Do not overtighten the straps (reduced insulating value).

1

1a

1b

Fig. 03

1c

11

4 213 783 / 00

INSTALLATION

2.3 Fitting the casing

1. Hook the cable duct (2, Fig. 04) into the pins on the

left and right and attach with the middle hexagon nuts

and washers (3a, Fig. 04) already mounted on the

boiler. If there is a side wall support (2b, Fig. 07), turn

outwards to the side.

2. Hook in the side walls (4, Fig. 04) on the boiler and

secure with those outer hexagon nuts and washers

(4a, Fig. 04) already mounted on the boiler. Hook in

the side wall at the bottom on the screw head on the

condensate drip tray. Align the side walls centrally,

set the clearance for the electrical box and rear wall.

Then tighten hexagon nuts (4a, Fig. 04).

3. Attach rear wall (terminal plate 5, Fig. 05) of the terminal box using 4 screws (4a, Fig. 04).

4. Remove the stud (6 Fig. 05) on the left or right. Hook

in the electrical box at the bottom on the side of the

stud. Hold the electrical box horizontal and tighten

with the second stud on the opposite side. Fold the

electrical box closed upwards and hook in.

5. Fit trim strips (7, Fig. 08)

- Open terminal box to t the top screw (7a, Fig. 06)

- Close terminal box again to t the bottom screw

(7b, Fig. 08)

6. Route the cable for the water pressure sensor (7,

Fig. 08) down out of the control and connect to the

boiler at the bottom (cable routing acc. to Fig. 09).

Route all other cables on the left or right of the boiler

and make the plug connections.

CAUTION

The cables must not touch any hot parts.

7. Hook the lower rear wall (8, Fig. 09) onto the side

walls. Hook in the rear walls (8a, 8b, Fig. 09) on the

opposite side and engage together on the side walls.

8. Mount the upper side walls (9a, 9b, Fig. 09). Place

the underside of the upper side walls (long slot) onto

the special screws of the lower side walls and push

in. Secure the upper side walls using 4 self-trapping

screws (9c, Fig. 09) ø 3.5 x 10.

9. Hook in the upper rear walls (10, Fig. 09) and t the

dummy cover (10a).

10. Put on cover plates (11, Fig. 09). Install the upper

front (11a, Fig. 09) and place the pins in slits, then

push back. Following that, secure with carriage bolt

(11b, Fig. 09). (When taking down, lift one side followed by the other.)

11. Hook the front cover (8, Fig. 09) in at the bottom (from

type 575 onwards with rail) and push closed upwards

(secure with carriage bolt on the side). In a cascade

> 3, no carriage bolts are tted on the middle boilers!

12. The remaining 3 casing walls (15, 15a, 16, Fig. 11)

are tted after mounting the condensate box.

12

4 213 783 / 00

INSTALLATION

Fig. 04

Fig. 05

3a 244a

21-UltraGas (850)

2b

4a

Fig. 07

7

7b

Fig. 08

7c

Illustration shown without burner

5a

6 6a

5

7a

Fig. 06

Secure the service pedestal (7c, Fig. 08) in

the folded-up status with pin (1b, Fig. 02)!

13

4 213 783 / 00

INSTALLATION

Burner wiring

Model (125-850);

2 plug connections

Model (1000);

3 plug connections

Mains cable

Ignition cable

Water pressure

sensor

Condensate box

(if tted)

Boiler temperature sensor

Models (850,1000) in two-piece design

Type (125,720)

in one-piece design

Fig. 09

Flue gas sensor

7

14

4 213 783 / 00

INSTALLATION

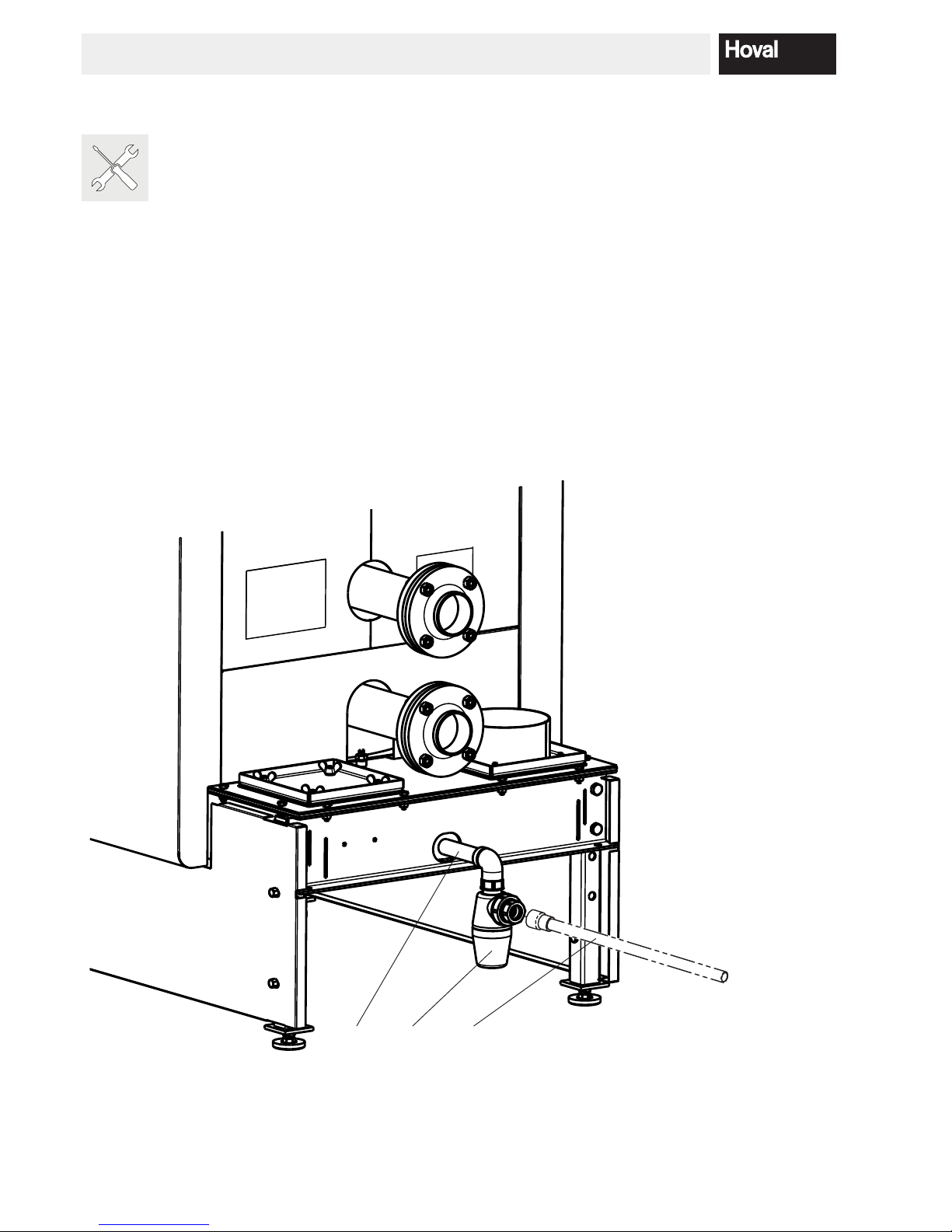

2.4 Fitting the pedestal casing

Attach the condensate trap (13, Fig. 10),

which is supplied loose, incl. double nipple

(13a, Fig. 10).

1. Place the condensate box (option) under the boiler

and establish the electrical connection. Make the

condensate drain or connection line according to separate instructions.

For UltraGas

®

(575,650,720,850,1000):

Fit condensate drain pipe (14, Fig. 10) (supplied with

the boiler)

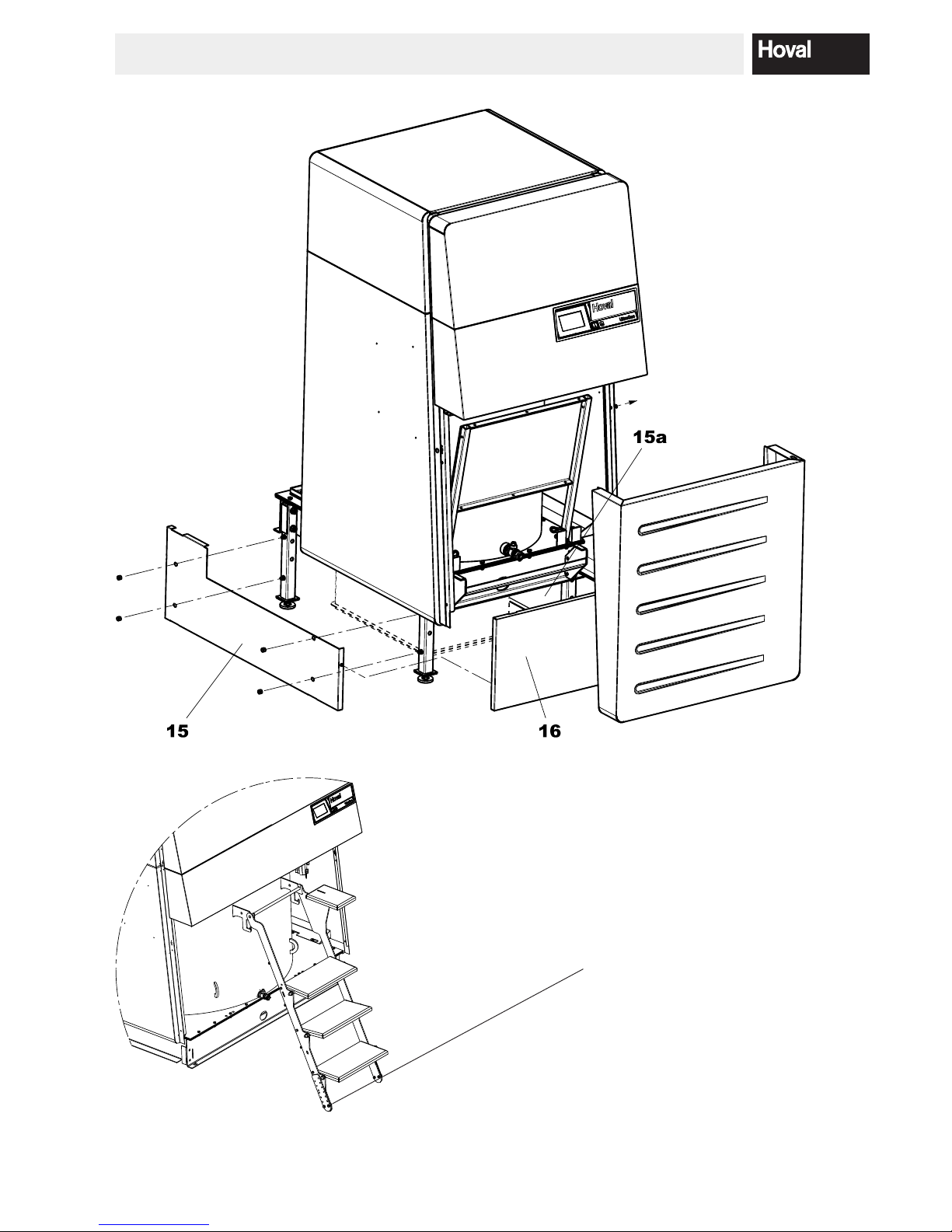

2. Screw the right and left side walls (15, 15a, Fig. 11)

using the cap nuts already mounted on the boiler foot.

3. Hook in the front (16, Fig. 11) on the side walls

(15, 15a, Fig. 11).

13a 13

14

Fig. 10

15

4 213 783 / 00

INSTALLATION

Fig. 11

Fig. 12

Only types UG (850,1000)

If you are using the variant with shortened boiler feet or you place the boiler

on a concrete pedestal, you will have to shorten the supplied conductors

(saw off at the watch) or extend them.

Loading...

Loading...