Hoval TopGas 80 Installation Instructions Manual

Technical Information

Installation Instructions

EN

4 207 803 / 01 - 11/09 Subject to modifications

Gas condensing boiler

TopGas® (80)

for natural and liquid gas

Wall-mounted gas boilers TopGas® (80) according to DIN 4702, DIN EN 483 and DIN EN 677

are suitable and approved as heat producers for

hot water heating systems with a permissible

flow temperature of up to 85°C). They are designed for a flexibly reduced operation in heating

systems according.

Hoval gas boilers are only to be installed and

placed in operation by technicians; these instructions are therefore intended for the specialist.

Electrical installation work is only to be carried

out by an electrician.

Rated output levels at 40/30°C and

natural gas

2-TopGas

®

(80) 17,3 - 80,0 kW

4 207 803 / 01

2

Contents

1. General Information ........................................................................................4

1.1 Symbols ........................................................................................................................ 4

1.2 Guarantee ..................................................................................................................... 4

1.3 Other instructions .......................................................................................................4

1.4 Safety instructions ...................................................................................................... 4

1.5 Regulations, official approvals ................................................................................... 5

1.6 Transport and storage ................................................................................................. 5

2. Technical Information .....................................................................................6

2.1 Technical Data ............................................................................................................. 6

2.2 Dimensions .................................................................................................................. 7

2.3 Boiler flow resistance .................................................................................................8

2.4 Short description of the automatic firing unit BIC 335 ............................................ 8

2.5 Control of the boiler .................................................................................................... 9

2.6 Adjustable parameters .............................................................................................. 11

3. Installation ..................................................................................................... 13

3.1 Description of the Hoval TopGas® ...........................................................................13

3.1.1 Diaphragm expansion tank .......................................................................................... 13

3.1.2 Boiler casing ................................................................................................................ 13

3.1.3 Gas fittings ................................................................................................................... 13

3.1.4 Automatic gas firing unit and heating controller ........................................................... 13

3.1.5 Heating circulation pump ............................................................................................. 13

3.1.6 Hot water supply .......................................................................................................... 13

3.1.7 Scope of supply ........................................................................................................... 13

3.1.8 TopGas

®

component designation ................................................................................ 14

3.2 Boiler installation room ............................................................................................15

3.3 Installing the boiler .................................................................................................... 15

3.4 Hydraulic connection ................................................................................................ 15

3.4.1 Protection planning guidelines for the hy drau-lic connection ....................................... 15

3.4.2 Boil-dry safeguard .......................................................................................................15

3.4.3 Gravity brake ............................................................................................................... 15

3.4.4 Minimum flow rate .......................................................................................................15

3.4.5 To be provided by customer......................................................................................... 16

3.4.6 Examples of hydraulic interconnection ........................................................................ 16

3.5 Flue gas connection, chimney and condensate pipeline ...................................... 17

3.5.1 Waste gas pipelines in compliance with building construction law .............................. 17

3.5.2 Project planning information for the TopGas

®

............................................................. 17

3.5.3 Natural ventilation flue example ................................................................................... 18

3.5.4 Flue gas system for room sealed operation.................................................................19

3.5.5 Roof heating centre concentric flue (room sealed) ......................................................19

3.5.6 Wall outlet .................................................................................................................... 20

3.5.7 Connection of pipelines ............................................................................................... 21

3.5.8 Condensate draining and neutralisation ...................................................................... 21

3.5.9 Gas connection ............................................................................................................ 21

3.6 Electrical connection ................................................................................................21

3.6.1 Electrical connection regulations ................................................................................. 21

3.6.2 Electrical connection (mains) 230 V, 50 Hz .................................................................22

3.6.3 Boiler control / electrical connection diagram .............................................................. 22

3.6.4 Connection of the heating controller ............................................................................ 22

3.6.4.1 TopTronic

®

RS-OT ........................................................................................................ 22

3.6.4.2 TopTronic

®

T/N ............................................................................................................. 22

4 207 803 / 01

3

Contents

4. Commissioning ............................................................................................. 22

4.1 Setting the control .....................................................................................................22

4.2 Water quality .............................................................................................................. 22

4.2.1 Heating water ..............................................................................................................23

4.2.2 Filling and replacement water ...................................................................................... 23

4.2.3 Filling up the system .................................................................................................... 24

4.3 Gas adjustment .......................................................................................................... 24

4.3.1 Bleeding the gas pipeline ............................................................................................24

4.3.2 Commissioning ............................................................................................................ 24

4.3.3 Gas inlet pressure .......................................................................................................24

4.3.4 Gas fitting ....................................................................................................................24

4.3.5 Setting the gas flow rate .............................................................................................. 25

4.3.6 Changing to a different kind of gas .............................................................................. 25

4.4 Handing over to the user .......................................................................................... 26

4.4.1 Instruction the user ...................................................................................................... 26

4.4.2 Checking the water level .............................................................................................. 26

4.4.3 Maintenance ................................................................................................................ 26

5. Decommissioning ......................................................................................... 27

6. System maintenance and cleaning .............................................................. 27

6.1 Water-side leak check ............................................................................................... 27

6.2 Refilling ......................................................................................................................27

6.3 Maintenance includes: ..............................................................................................27

6.4 Cleaning the heat exchanger .................................................................................... 27

6.5 Function check .......................................................................................................... 27

7. Faults .............................................................................................................. 29

8. Automatic firing unit BIC 335-Parameter list .............................................. 32

4 207 803 / 01

4

1. General Information

1.1 Symbols

Safety information

(Instructions for the safety and protec-

tion of persons)

Warning information

(Instructions for the protection of the

heating system)

Bold type = Important information

1.2 Guarantee

Important Note

Proper functioning is only guaranteed if the

operating instructions are observed and the

boiler is regularly maintained according to the

DVGW (German association of gas and water

management / ÖVGW (Austrian association

of gas and water management), respectively

SVGW (Switzerland association of gas and

water management) directives by an approved

specialist. Troubleshooting and damage repair

caused by contaminated operating media (gas,

water, combustion air), unsuitable chemical additives to the heating water, incorrect handling,

faulty installation, inadmissible modifications

and damage due to the exercising of force are

not covered by our warranty; the same applies

to corrosion through halogen compounds, e.g.

from spray cans, paints, adhesives, solvents

and cleaning agents.

Hoval gas boilers are only to be installed by

approved specialists. No modifications are to

be made to the boilers.

1.3 Other instructions

Depending on the model, any further instructions are

enclosed with the individually packed components.

- Adjustment

- Accessories

Further information sources

- Hoval catalogue

- Standards, regulations

1.4 Safety instructions

When working on the TopGas

®

the following points

need to be noted:

If you smell flue gas or gas:

- no open fire or sparks,

- do not smoke,

- deflector off the heating system,

- close the gas cock,

- open doors and windows

• The system may only be placed in operation when

all relevant standards and safety regulations have

been complied with. However, for a trial operation,

at least the following conditions must be satisfied:

- Safety valve installed (closed system)

- Control operative (connected to power supply)

- System filled with water

- Expansion tank connected

- Boiler is connected to the regulation type flue

gas pipeline

- Burner is preset.

• Withmaintenanceandrepair

- Allow the gas boiler to cool.

- Deflector off the gas boiler and disconnect from

the electrical supply.

- Shut off the gas cock.

- Close the shut-off cocks of the appliance (cold

water, heating flow and return).

- Inappropriate actions on water-carrying parts

of the gas boiler can result in an outflow of hot

water and cause severe burns.

- Replace all removed covers and cladding on

completion of the repair / maintenance work.

- Do not exceed the maximum operating pressure

and temperature of the gas boiler (see identification plate).

- Open the appliance cocks (cold water, heating

flow and return).

- Open the gas cock.

1. General Information

4 207 803 / 01

5

and further standards and regulations issued by

CEN, CEN ELEC, DIN, VDE, DVGW, TRD and by

the legislator.

Also to be complied with are the regulations of the

local building authorities, insurance companies and

chimney sweeping operations. When using gas as

a fuel, the regulations of the responsible gas supply

company are also to be complied with and any necessary official approval obtained.

The regulations concerning condensate pipelines and treatment are subject to the regulations of the local water authorities and can

differ from the provisions of the technical drainage directive ATVM251. Please obtain information on the relevant local regulations.

1.6 Transport and storage

Please remove the packing materials and examine

the consignment for correctness, completeness and

possible transport damage.

The appliance is only to be transported and stored

only in its original packing. Interim storage of Hoval

gas boilers is only to take place in weather protected

rooms and only in the original packing. The ambient

conditions for storage must be within the following

limits:

- Air temperature: -10°C - +50°C

- Air humidity: 50 - 85% relative humidity

- no condensation

1.5 Regulations, official approvals

The following regulations are to be complied with

for installation and operation, in addition to the

recognised rules of the art:

Germany

• DIN EN 12831 Heating systems in buildings Methods for calculating the design heat load

• DIN EN 13384 Flue gas systems - Heat and flow

calculation methods

• DIN EN 12828 Heating systems in buildings - Planning of hot water heating systems.

• VDI 2035 Prevention of damage through corrosion and scale formation in hot water heating

systems.

• Firing regulation for the Federal regions

• DVGW-TRGI 86-96

• Technical regulations of gas supply enterprises

• VDE 0100 for electrical installations and the TAB

(technical connection conditions of the responsible

energy supplier)

• ATV data sheet M251

• Accident prevention regulations

- VBG 1 General regulations

- VBG 4 Electric systems and equipment

Austria

• OENORM 12831 Heating systems in buildings

- Methods for calculating the design heat load

• OENORM 13384 Flue gas systems - Heat and

flow calculation methods

• OENORM 12828 Heating systems in buildings

- Planning of hot water heating systems.

• OENORM H5152 Brennwert

- Feuerungsanlagen

• OENORM H5195-1 Prevention of damage through

corrosion

• M 7443, (Part 2,3,7) Gas appliances with atmospheric burners

• M 7446, Heat output appliances for gaseous fuels

• M 7457, Heat output appliances with mechanically

supported premix bat-wing burners

• M 7444, Special gas boilers with burners without

fan

• M 7459, Gas appliances with gas-air compound

controller

• ÖVGW TR- Gas

• Technical provisions of the gas suppliers

1. General Information

Switzerland

• SN EN 12831 Heating systems in buildings - Methods for calculating the design heat load

• SN EN 13384 Flue gas systems - Heat and flow

calculation methods

• SN EN 12828 Heating systems in buildings - Planning of hot water heating systems.

• Requirements of the VKF Cantonal Fire Insurance

Association

• Fire service regulations

• SVGW directives, gas guiding standard G1

• SNV271020 Aeration and ventilation of the boiler

installation room

• SWKI 88-4 Water treatment for heating, steam and

air conditioning systems

• SWKI 80-2 Technical safety regulations for heating

systems

• KRW Corrosion through halogen compounds

• Procal/FKR Plug-in electrical connections on heat-

ing boiler and burner

• Technical tank regulations TTV 1990

• EKAS - Guideline for liquid gas part 2

4 207 803 / 01

6

2. Technical Information

2.1 Technical Data

2. Technical Information

Type (80)

• Nominaloutput80/60°Cwithnaturalgas1 kW 15,8 - 72,4

• Nominaloutput40/30°Cwithnaturalgas1 kW 17,3 - 80,0

• Nominaloutput80/60°Cwithpropanegas3 kW 19,5 - 72,4

• Nominaloutput40/30°Cwithpropanegas3 kW 21,6 - 80,0

• Nominalloadwithnaturalgas1 kW 16,5 - 75,0

• Nominalloadwithpropanegas3 kW 20,0 - 75,0

• Workingpressureheatingmaximum/minimum bar 4,0/1,5

• Workingtemperaturemaximum °C 85

• Boilerwatercontent l 10

• Minimumwaterow l/h 800

• Boilerweight(withoutwatercontent) kg 107

• Standardefciency(DIN4702,part8) 40/30°C % 109,4

• (relatedtonet/grosscaloricvalue) 75/60 °C % 106,1

• Stand-bylossat70°C Watt 95

• Standardemissionrate

Nitrogen oxides mg/kWh 18

Carbon monoxide mg/kWh 27

• ContentofCO2 in the exhaust gas maximum/minimum output % 9,0 / 8,8

• Dimensions: seetableofdimensions

• Connections

Flow/Return Inches Rp 1¼"

Gas Inches R ¾"

Flue gas/combustion air (concentrically) mm C100 / 150

• Gasowpressureminimum/maximum

Natural gas E/LL mbar 18 - 50

Propane gas mbar 37 - 50

• Gasconnectionvalueat0°C/1013mbar::

Natural gas E - (Wo = 15,0 kWh/m

3

) Hu = 9,97 kWh/m

3

m3/h 1,65 - 7,5

Propane gas 3 (Hu = 25,9 kWh/m3) m3/h 0,77 - 2,90

• Operationvoltage V/Hz 230/50

• Controlvoltage V/Hz 24/50

• Minimum/maximumelectricalpowerconsumption Watt 23/130

• Stand-by Watt 7

• IPrating(integralprotection) IP 20

• Soundpowerlevel dB(A) 63

• Soundpressurelevel(dependingoninstallationconditions)2 dB(A) 53

• Condensatequantity(naturalgas)at40/30°C l/h 7,1

• pHvalueofthecondensate ca.4,2

• Valueforchimneycalculation

Requirement flue gas system, temperature class T 120

Flue gas mass flow kg/h 124,5

Flue gas temperature at operation 80/60 °C °C 79

Flue gas temperature at operation 40/30 °C °C 49

Feed pressure total at the combustion air/flue gas pipe Pa 140

Maximum draught / depression at flue gas outlet Pa -50

1

Data related to Hu. The boiler series is tested for EE/H-settings. With a factory setting of the Wobbe coefficient of 15.0 kWH/m3 operation at a

Wobbe coefficient of 12.0 up to 15.7 kWh/m3 is possible without new settings.

2

See also notes at „Engineering“.

3

Data related to Hu.

4 207 803 / 01

7

2. Technical Information

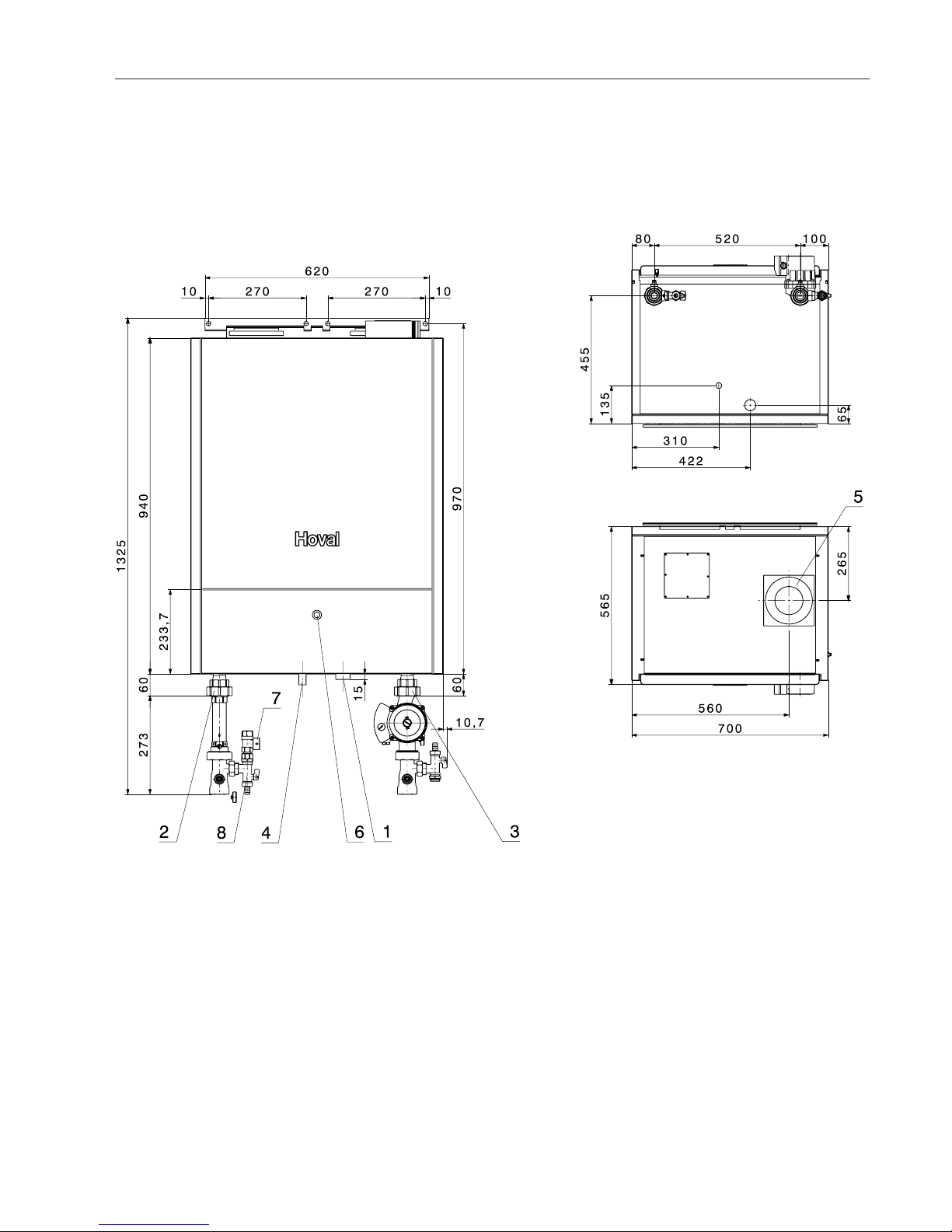

2.2 Dimensions

Measurements (mm)

• Distancefromtheside50mm

• Distancefromtheceilingdependenton

the utilised flue gas pipeline system

• Inthefront500mm

1 Gas connection Rp ¾"

2 Heating flow Rp 1¼"

3 Heating return Rp 1¼"

4 Condensate drain DN 40

5 LAS Flue gas-/combustion

air connection C 100/150

6 Cover control panel

7 Safety valve

8 Ball valve

View from bottom

View from top

4 207 803 / 01

8

0

50

100

150

200

250

300

0.0 1.0 2.0 3.0 4.0 5.0 6.0

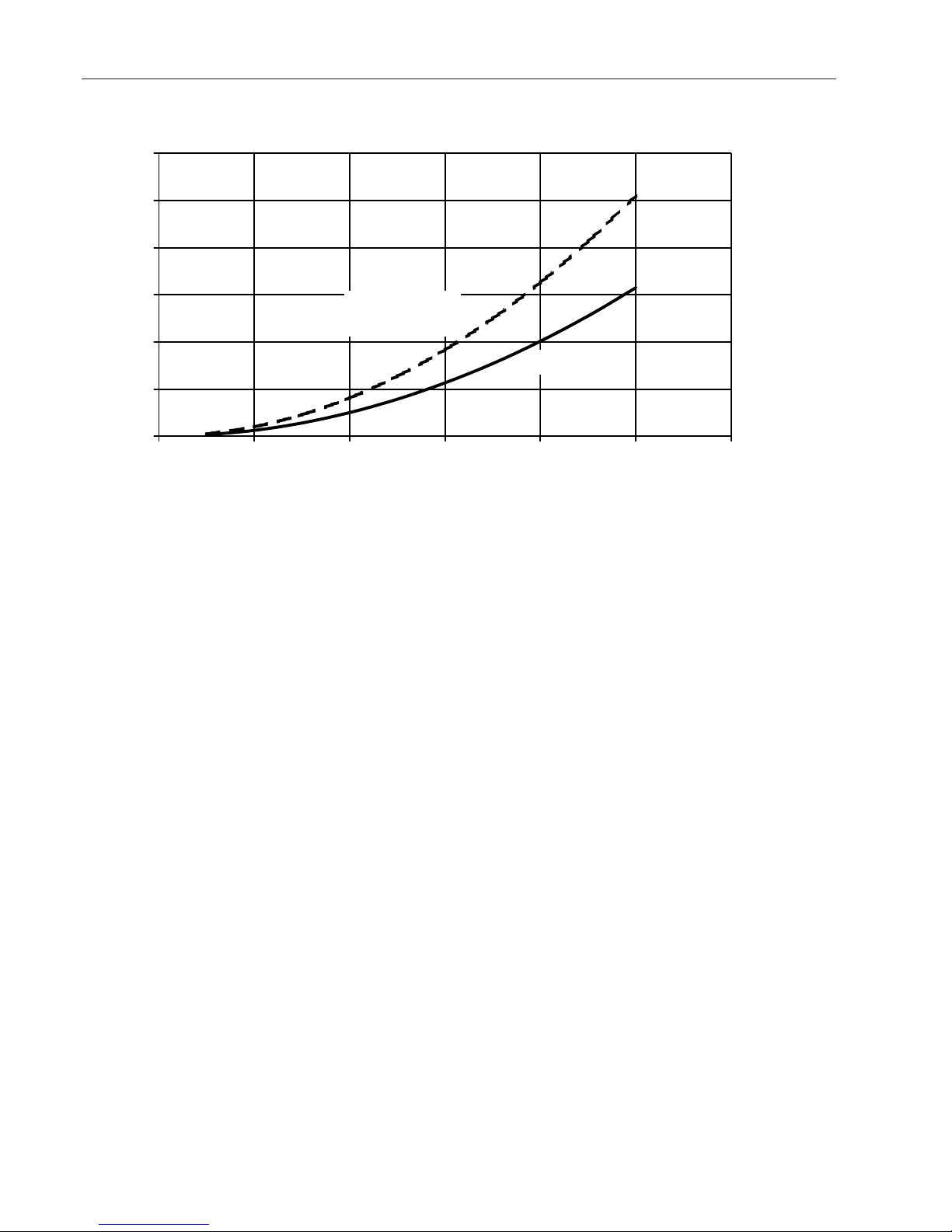

2.3 Boiler flow resistance

2. Technical Information

Water-side resistance [mbar]

Flow rate [m3/h]

2.4 Short description of the automatic firing

unit BIC 335

The automatic firing unit operates both without controller (TTT/N) and also without room station (RSOT). The automatic firing unit comprises the following functions

- PWM- fan (230V~)

- Modulating operation

- Inputs for Flow sensor

Return sensor

Flue gas sensor

Gas pressure deflector

Air pressure deflector:

(not used)

Water pressure deflector

Safety temperature limiter:

(external flue gas thermo stat)

HW-buffer sensor

Outdoor sensor

Locking entry:

(Burner blocking)

- Status exit „Failure“ (invertible by parameter set-

ting)

- Three-way-valve control for heating/hot water

or loading pump control (230V~exits); Exit for a

three-way-valve / HW loading pump is invertible

by a parameter.

- Collective electrode for ignition and flame guide

(Ionisation)

- Main gas valve (ev. LPG- valve) / heating room

ventilation accessable

Boiler incl. connection kit

Boiler only

Fuses

On the automatic firing unit theres is a mains fuse.

The breakdown of this fuse (2AT) is noticeable by an

empty display even the main deflector is on.

Ionisation flow

The value of the ionisation flow is noted on the information level and appears as step 8. The access to

the information level is explained in 2.5.

- Interface to display

- OpenTherm- interface (RS-OT, TTT/N)

- RS 232- interface to PC

- Start attempts: 4

- Safety period: 5 sek

- Ignition period: 5 sek

- Pre-ventilation period: 20 sek

- After-run time main pump / heating pump

(230V ~): 10 min

- After-run time three-way valve / HW-loading pump:

2 min

- Restart locking after a heat demand: 2 min

- Restart locking after a temperature blocking: 2

min

4 207 803 / 01

9

2. Technical Information

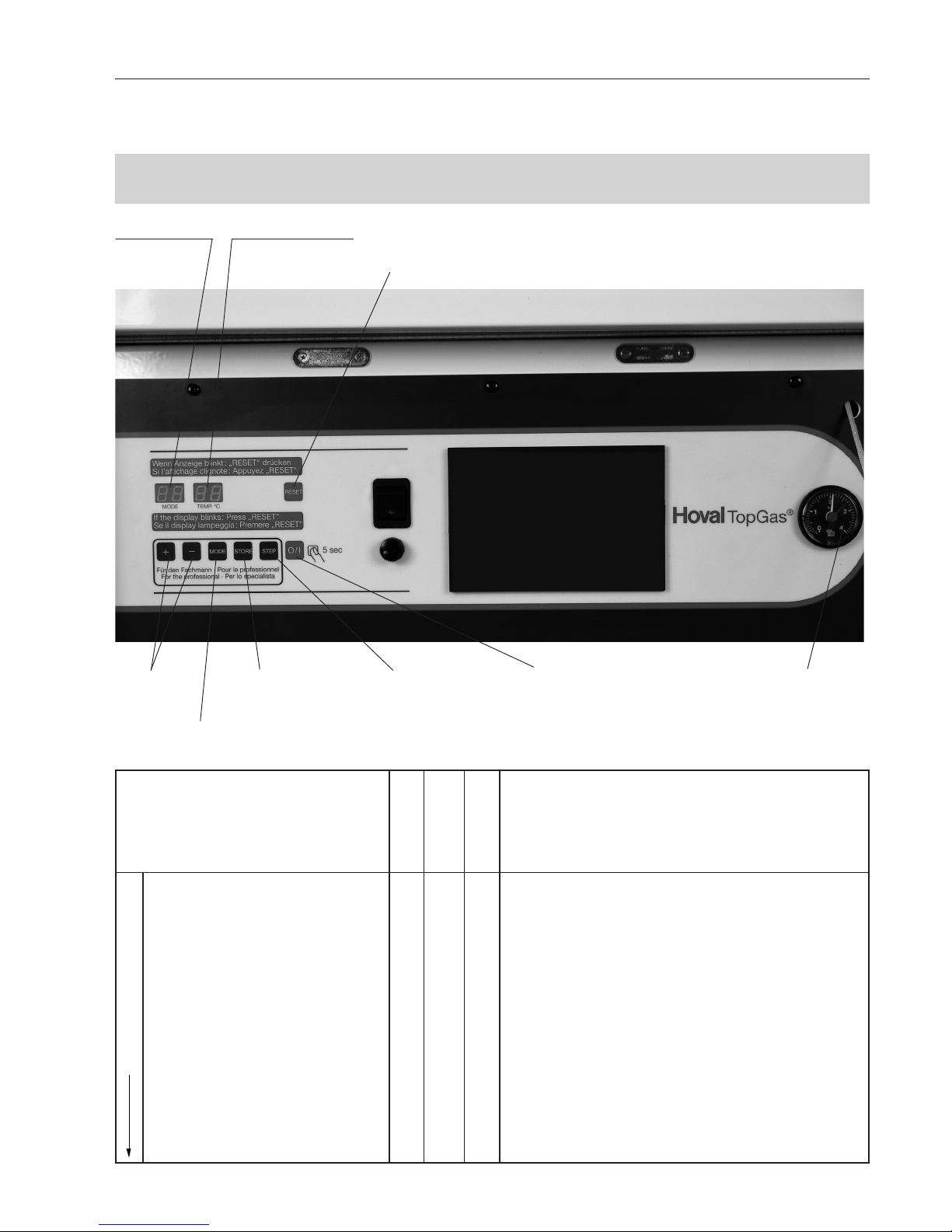

2.5 Control of the boiler

Control elements on the boiler control panel / Basic control N4.1

Usually, no settings of the basic control have to be made by the user. All settings have been made

by the installer or by the manufacturer.

Display: temperature

Changing of

the values

Display: Mode

RESET

Fault-clearance (display is blinking, if there is a failure)

Saving of the

settings

Options, to change settings

(Parmeter) (p.ex. Calorifier

temperature)

ON/OFF Manometer

Function

Standby-Mode

Normal position,

Start position

no indication

Value indication

current flow temperature

Mode indication

Function options (stepwise

display option)

Parameter

Indication

Meaning, Description

0 = Standby, no heat demand,

Waiting time main gasvalve

1 = Rinsing

2 = Ignition

3 = Burner „on“ in heating operation

4 = Burner „on“ in hot water operation

5 = Air pressure deflector defectiv (no air pressure deflector in

use)

6 = Burner „off“ in heating operation (flow-Temp > flow-temp

set point + blockage Offset ZH)

7 = Pump after-run time in heating operation

8 = Pump after-run time in hot water operation

9 = Burner „off“ on hot water operation (flow-Temp > flow temp. set point + Par.1 (2AB))

Fr = Frost protection is activated

Su = Summer short operation is activated

4 207 803 / 01

10

2. Technical Information

Meaning, DescriptionFunction

Value indica-

tion

Mode indication

Parameter

Indication

0 z.B. 45° Current flow temperature

(Heating water temperature)

1 z.B. 40° Current return temperature

2 z.B. 60° Current temperature in water heater

3 z.B. 3° Current outdoor temerature

4 z.B. 55° Current flue gas temperature

5 z.B. 50° Flow set value in the heating system

6 z.B. 70° Flow set value in hot water operation

7 z.B.23 RPM Fan speed in hundreds

8 z.B. 4 µ A Ionisation flow

It is possible to read monetary values

from here

Informations-Mode

Point is blinking

Point appears

Settings can be changed in this mode.

Procedure:

1. Select parameter Mode

(press Mode key 2 x)

Parameter (P.7) and setting appear

alternate

2. Select parameter to be changed (Step

key)

3. Change setting using + - keys

4. Save

(press Store key 1 x)

Automatic return to standby mode in 20

minutes or with Mode key.

Parameter-Mode

P.7 60 = Hot water set value

if threre is no TopTronic® attached.

P.18 80 = Max. Flow temperature during heating ope

ration

Par. 18

Setting of the service codes

For entering the code, press the keys „Mode“ und „Step“ simultaneously. The blinking numeral can be changed with the „+“ and „-“ –keys. To deflector between the numerals press the „Step“- key. To confirm and safe

the total code press the „Store“- key. After 20 minutes it will be changed into the indication level.

Parameter level (constant point)

The parameter level will be signalised by a constant point behind the second sign.

If none of both keys „+“/“-„ are pressed, “P“ + the parameter number will be shown alternating and then also

the coresponding parameter value. By pressing „+“ or „-“ the parameter value can be changed. To save the

changing press the „Store“- key, which will be confirmed by blinking twice (Wait for blinking before pessing

any further keys!). If the „Store“- key won‘t be pressed, the settings are not saved.

4 207 803 / 01

11

2. Technical Information

2.6 Adjustable parameters

Parameter 7 (2AH) – Set point DHW charging temperature –

Using this parameter the reference value for the DHW temperature can be set where there is no room control unit or other regulatory device installed. If a reference value is transmitted via an OT bus, the latter (value

via OT) will always override this parameter.

Parameter 8 (2AI) – Pump after-run time (DHW) –

During the time which can be set using this parameter the pump continues to run after a phase of hot water

demand. The after-run time occurs before a switchover to heating operation as well as before a switchover

to to stand-by mode (to be set at the RS-OT or control unit) or when the firing device is switched OFF. It

also occurs of course when the desired DHW value has been reached and further heating operation is not

required.

Parameter 9 (2AJ) – Legionella protection time –

The boiler is periodically heated to the temperature defined using parameter 2AF for the time period which

can be set using this parameter for protection against legionella infestation. If the parameter value is set to

0 the legionella protection function is deactivated.

Parameter 10 (2AK) – Maximum fan speed in DHW mode –

The parameter defines the maximum rpm value for the fan during DHW operation.

Parameter 18 (2BH) – Maximum heating temperature (when minimum outside temperature has been

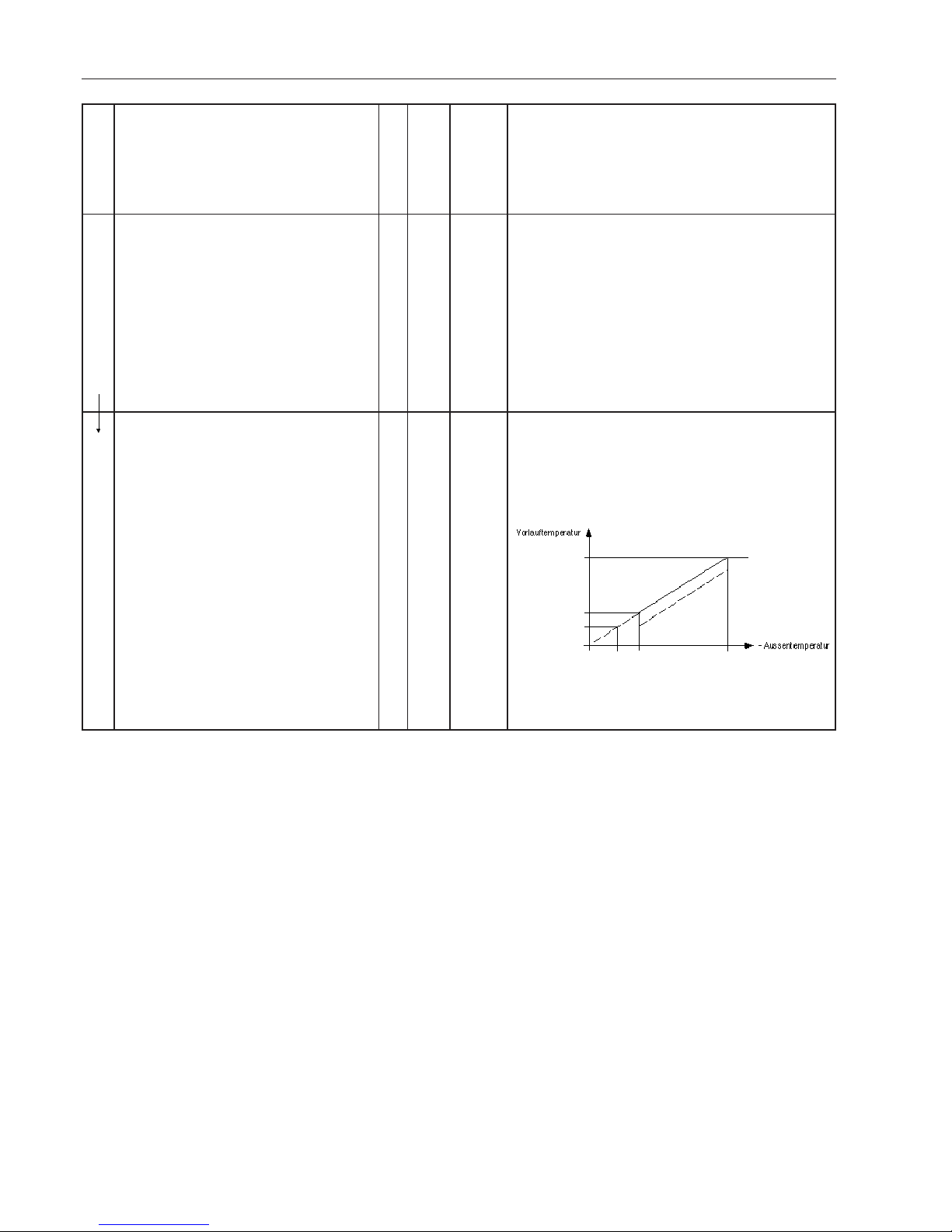

reached) –

The value which can be set here determines the flow temperature which is to be achieved when the outside temperature falls below the value set using parameter 19 (2BI) (minimum outside temperature). (see

diagram 2). If the OT bus sends a reference value to the firing device, this value is limited by the value set

using parameter 18.

Parameter 19 (2BI) - Minimum outside temperature - 19 (2BI) – Minimum outside temperature –

This parameter defines the minimum outside temperature which marks the limit where the flow temperature

target is to be set at the temperature given by parameter 18 (2BH).

Parameter 20 (2BJ) – Minimum heating temperature (when maximum outside temperature has been

reached) –

If the outside temperature sensor registers the value set using parameter 21 (2BK), then the system targets

the minimum heating temperature set using this parameter. If the outside temperature exceeds the parameter value, the heating demand is cancelled.

Parameter 21 (2BK) – Maximum outside temperature –

If the outside temperature exceeds the values set using this parameter, the heating demand is cancelled. At

the point where the parameter value is reached the system targets the minimum heating temperature which

has been set using parameter 20 (2BJ).

Parameter 22 (2BL) –Restart delay following temperature blocking in heating operation mode –

When the boiler is shut down on account of a temperature limit being exceeded, i.e. a set point plus offset,

the boiler restart is delayed for the period which can be set using this parameter – irrespective of whether

the hysteresis set for the next heating demand has expired or not.

Parameter 23 (2BM) – Restart delay following heating demand during heating operation –

Immediately following the end of a heating demand phase boiler restarts are delayed. That is to say, if the

boiler is shut down on account of a reference value trigger being sent from the OT bus to the firing device, a

restart (triggered by another reference value being reached) is delayed for at least the period of time which

can be set using this parameter.

Loading...

Loading...