Hoval TopGas 35, TopGas 45, TopGas 60 Technical Information Installation Instructions

Subject to modi cations |

EN

Technical information

Installation instructions

4 213 893 / 01- 07/15

Hoval products may only be installed and commissioned by appropriately qualied experts. These instructions are intended exclusively for the specialist.

Electrical installations may only be carried out by a

qualied electrician.

Nominal output ranges at 40/30°C

and with natural gas:

41-TopGas

®

(35) 6,8 - 35,0 kW

41-TopGas® (45) 11,1 - 45,0 kW

41-TopGas® (60) 12,8 - 60,7 kW

Wall-mounted condensing gas boilers TopGas

®

(35,

45,60) in accordance with DIN 4702, DIN EN 483

und DIN EN 677 are designed and approved for use

as heat generators for hot water heating systems with

permissible ow temperatures of up to 85 °C. They are

designed for continuously controlled reduced operation

in heating systems.

TopGas® (35,45,60)

Wall-mounted condensing gas boilers

for natural and liquid gas

2

4 213 893 / 01

TABLE OF CONTENTS

1. Important Information ............................................................................................................................. 4

1.1 On delivery ...........................................................................................................................................................................4

1.2 Guarantee ............................................................................................................................................................................4

1.3 Instructions .........................................................................................................................................................................4

1.4 Regulations, official approvals ...........................................................................................................................................5

1.5 Transport and storage .........................................................................................................................................................5

2. Safety instructions .................................................................................................................................. 6

2.1 Warning levels .....................................................................................................................................................................6

2.2 Warning symbols .................................................................................................................................................................6

2.3 Information ..........................................................................................................................................................................6

3. Technical information ............................................................................................................................. 7

3.1 Technical Data .....................................................................................................................................................................7

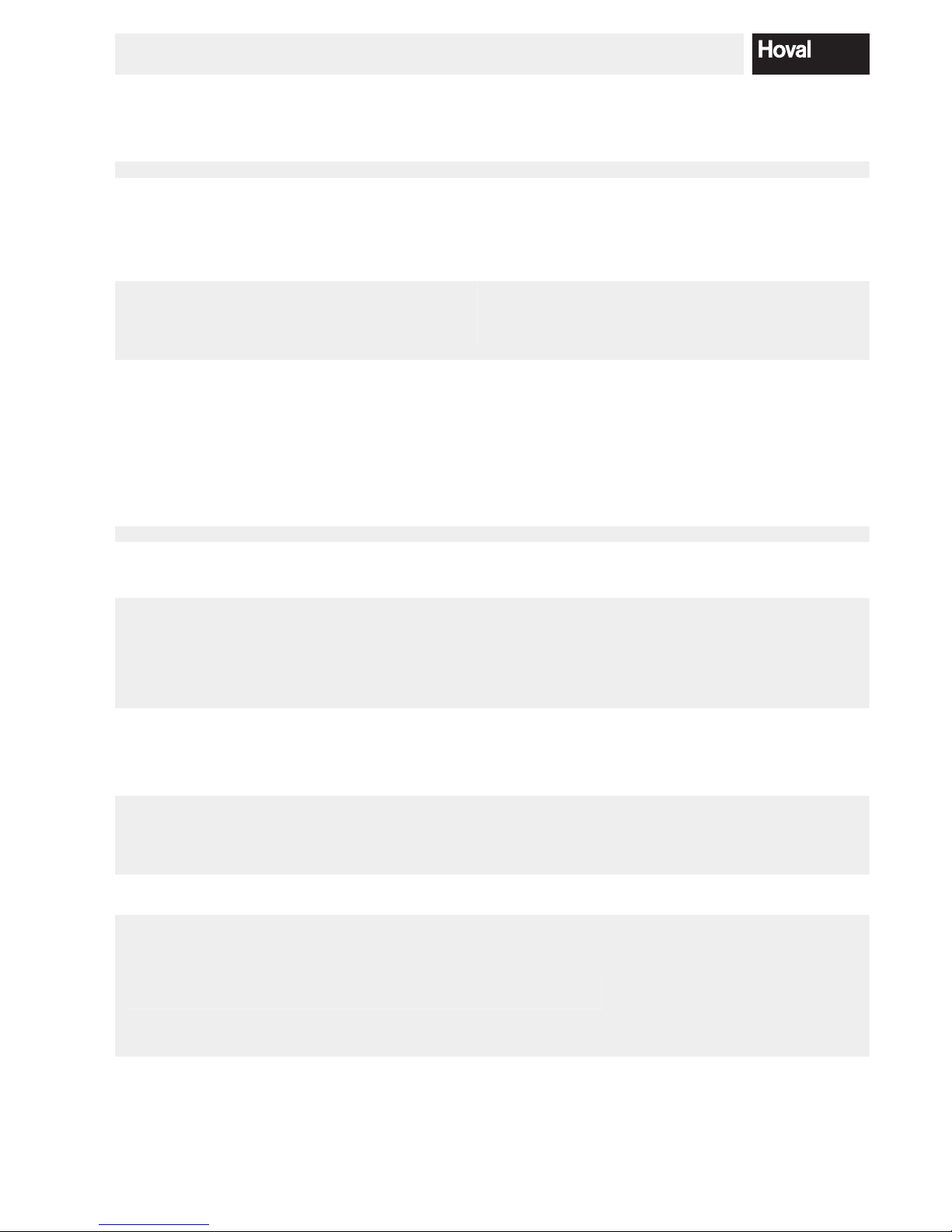

3.2 Boiler-flow resistance .........................................................................................................................................................8

3.3 Dimensions ..........................................................................................................................................................................9

3.4 Short description of the automatic firing unit BIC 335 ....................................................................................................10

3.5 Heating system control ..................................................................................................................................................... 11

3.6 Adjustable parameters ......................................................................................................................................................13

4. Installation ............................................................................................................................................. 15

4.1 Description of the Hoval TopGas® .....................................................................................................................................15

4.1.1 Diaphragm expansion tank ..............................................................................................................................................15

4.1.2 Boiler casing ...................................................................................................................................................................15

4.1.3 Gas fittings .....................................................................................................................................................................15

4.1.4 Automatic gas firing unit and heating controller ...............................................................................................................15

4.1.5 Heating circulation pump .................................................................................................................................................15

4.1.6 Hot water supply .............................................................................................................................................................15

4.1.7 Scope of supply ..............................................................................................................................................................15

4.1.8 TopGas® component designation .....................................................................................................................................16

4.2 Boiler installation room .....................................................................................................................................................17

4.3 Installing the boiler............................................................................................................................................................17

4.4 Hydraulic connection ........................................................................................................................................................17

4.4.1 Protection planning guidelines for the hy draulic connection .............................................................................................17

4.4.2 Boil-dry safeguard ...........................................................................................................................................................17

4.4.3 Gravity brake ..................................................................................................................................................................18

4.4.4 Minimum flow rate ...........................................................................................................................................................18

4.4.5 To be provided by customer ............................................................................................................................................18

4.4.6 Examples of hydraulic interconnection ............................................................................................................................18

4.5 Flue gas connection, chimney and condensate pipeline .................................................................................................20

4.5.1 Waste gas pipelines in compliance with building construction law ...................................................................................20

4.5.2 Project planning information for the TopGas® ..................................................................................................................20

4.5.3 Installation examples for room-air-dependent operation ..................................................................................................21

4.5.4 Exhaust gas system for room-air-independent operation .................................................................................................21

4.5.5 Roof heating centre concentric flue (vertical exhaust gas conduit installation) .................................................................22

4.5.6 Wall penetration (permitted only in Austria) ..................................................................................................................... 22

4.5.7 Connection of the pipes ..................................................................................................................................................23

4.5.8 Condensate draining and neutralisation ..........................................................................................................................23

4.5.9 Gas connection ...............................................................................................................................................................23

4.6 Electrical connection .........................................................................................................................................................23

4.6.1 Regulations for electrical connections .............................................................................................................................24

4.6.2 Electrical connection (mains) 230 V, 50 Hz ......................................................................................................................24

4.6.3 Boiler control / electrical connection diagram ..................................................................................................................24

4.6.4 Connection of the heating controller ................................................................................................................................24

4.6.4.1 TopTronic® RS-OT ..........................................................................................................................................................................24

4.6.4.2 TopTronic® E ................................................................................................................................................................................... 24

3

4 213 893 / 01

TABLE OF CONTENTS

5. Commissioning ..................................................................................................................................... 25

5.1 Setting the control .............................................................................................................................................................25

5.2 Water quality ......................................................................................................................................................................25

5.2.1 Heating water..................................................................................................................................................................25

5.3 Filling and replacement water:..........................................................................................................................................25

5.3.1 Filling up the system .......................................................................................................................................................26

5.4 Gas adjustment ..................................................................................................................................................................26

5.4.1 Bleeding the gas pipeline ................................................................................................................................................26

5.4.2 Commissioning ...............................................................................................................................................................26

5.4.3 Gas inlet pressure ...........................................................................................................................................................26

5.4.4 Gas fitting .......................................................................................................................................................................26

5.4.5 Setting the gas flow rate CO2 (O2) and measurement of NOx/CO content in the flue gas (flue gas measurement) ...........27

5.5 Changing to a different kind of gas ..................................................................................................................................28

5.6 Handing over to the user ...................................................................................................................................................28

5.6.1 Instruction the user .........................................................................................................................................................28

5.6.2 Checking the water level .................................................................................................................................................28

5.6.3 Maintenance ...................................................................................................................................................................28

6. Decommissioning ................................................................................................................................. 29

7. Maintenance .......................................................................................................................................... 29

7.1 Checking the water connections for leakage ...................................................................................................................29

7.2 Refilling ..............................................................................................................................................................................29

7.3 Maintenance includes ........................................................................................................................................................29

7.4 Cleaning the heat exchanger ............................................................................................................................................29

7.5 Function check ..................................................................................................................................................................30

7.6 Emission measurement .....................................................................................................................................................30

8. Faults ..................................................................................................................................................... 31

9. Automatic firing unit BIC 335-Parameter list ....................................................................................... 33

4

4 213 893 / 01

IMPORTANT INFORMATION

1. Important Information

BThe following points must be observed when performing

work on the TopGas®:

!

CAUTION

• If you smell ue gas or gas,

• avoid naked ames and

the occurrence of sparks,

• do not smoke,

• take the system out of operation,

• close the gas shut-off valve,

• open windows and doors

• The system may only be placed in operation if all the

relevant standards and safety regulations have been

complied with. However, for trial operation, the following are the minimum conditions requiring fullment:

- Safety valve installed (closed system)

- Control in operation

(connected to the mains current supply system)

- System lled with water

- Expansion tank connected

- Boiler connected to a ue gas conduit installed

in compliance with the relevant regulations

- Burner preset

• When performing maintenance and repairs:

- Allow the gas condensing boiler to cool down

- Switch off the gas condensing boiler

and disconnect it from the power supply

- Close the gas shut-off valve

- Close all cut-off valves on the unit

(cold water, heating ow and return)

- If work on the components of the gas condensing

boiler which carry water is not performed correctly,

the heating medium may escape and lead to scalding.

- After performing repair and maintenance work,

reattach all cover plates which were removed.

- Do not exceed the maximum operating pressure and

operating temperature (see type label) for the gas

condensing boiler.

- Open all cut-off valves on the unit

(cold water, heating ow and return)

- Open gas shut-off valve

WARNING

The heat generator can only be de-energised

by disconnection from the mains (e.g. allpole switch).

WARNING

All electric power supply circuits must be

switched off before accessing the terminals.

1.1 On delivery

Carry out a visual inspection immediately on receiving the

boiler. If any damage is found, take the necessary steps

as dened in the delivery contract. The respective risk

carrier bears the cost of repairs.

1.2 Guarantee

The warranty does not cover defects attributable to:

- Failure to comply with these instructions

- Failure to comply with the operating instructions

- Incorrect installation

- Impermissible modications

- Incorrect handling

- Contaminated operating materials

(gas, water, combustion air)

- Unsuitable chemical additives to the heating water

- Damage caused by the application of force

- Corrosion by halogen compounds

(e.g. paints, adhesives, solvents)

- Corrosion caused by not observing

the required water quality

1.3 Instructions

All instructions relevant to your system can be found in

the Hoval system manual! In exceptional cases, the instructions can be found with the components!

Further sources of information:

- Hoval catalogue

- Standards, regulations

5

4 213 893 / 01

IMPORTANT INFORMATION

1.4 Regulations, official approvals

The following regulations are to be complied with for

installation and operation, in addition to the recognised

rules of the art:

Germany

• DIN EN 12831 Heating systems in buildings

- Methods for calculating the design heat load

• DIN EN 13384 Flue gas systems

- Heat and ow calculation methods

• DIN EN 12828 Heating systems in buildings

- Planning of hot water heating systems.

• VDI 2035 Prevention of damage through corrosion

and scale formation in hot water heating systems.

• Firing regulation for the Federal regions

• DVGW-TRGI 86-96

• Technical regulations of gas supply enterprises

• VDE 0100 for electrical installations and the TAB

(technical connection conditions of

the responsible energy supplier)

• ATV data sheet M251

• Accident prevention regulations

- VBG 1 General regulations

- VBG 4 Electric systems and equipment

Austria

• OENORM 12831 Heating systems in buildings

- Methods for calculating the design heat load

• OENORM 13384 Flue gas systems

- Heat and ow calculation methods

• OENORM 12828 Heating systems in buildings

- Planning of hot water heating systems.

• OENORM H5152 Gas condensation

for furnace installations

• OENORM H5195-1 Prevention of damage

through corrosion

• M 7443, (Part 2,3,7) Gas appliances

with atmospheric burners

• M 7446, Heat output appliances for gaseous fuels

• M 7457, Heat output appliances with

mechanically supported premix batwing burners

• M 7444, Special gas boilers with burners without fan

• M 7459, Gas appliances with

gas-air compound controller

• ÖVGW TR- Gas (Austrian Gas and

Water Confederation - Technical Guidelines)

• Technical provisions of the gas suppliers

Switzerland

• SN EN 12831 Heating systems in buildings

- Methods for calculating the design heat load

• SN EN 13384 Flue gas systems

- Heat and ow calculation methods

• SN EN 12828 Heating systems in buildings

- Planning of hot water heating systems.

• Requirements of the VKF

Cantonal Fire Insurance Association

• Fire service regulations

• SVGW directives, gas guiding standard G1

• SNV271020 Aeration and ventilation

of the boiler installation room

• SWKI 88-4 Water treatment for heating,

steam and air conditioning systems

• SWKI 80-2 Technical safety regulations

for heating systems

• KRW Corrosion through halogen compounds

• Procal/FKR Plug-in electrical connections

on heating boiler and burner

• Technical tank regulations TTV 1990

• EKAS - Guideline for liquid gas part 2

and further regulations and standards prescribed by the

CEN, CEN ELEC, DIN, VDE, DVGW, TRD and by law.

The regulations of the local building authorities, insur-

ance companies and chimney inspectors must also be

taken into account. The regulations of the responsible

gas supply company are also to be complied with and

any necessary ofcial approval obtained if using gas.

Regulations governing the discharge and

treat ment of condensate are subject to the

spe cications of the local water authorities

and may deviate from waste water guideline

ATVM251. Please contact your water author

-

ity for details of the applicable local regula

-

tions.

1.5 Transport and storage

Please remove the packing materials and examine the

consignment for correctness, completeness and possible

transport damage.

The appliance is only to be transported and stored only in

its original packing. Interim storage of Hoval gas boilers is

only to take place in weather protected rooms and only in

the original packing. The ambient conditions for storage

must be within the following limits:

- Air temperature: -10 °C - +50 °C

- Air humidity: 50 - 85 % relative humidity

- no condensation

6

4 213 893 / 01

SAFETY

2. Safety instructions

2.1 Warning levels

!

DANGER

... indicates a situation of immediate danger

which will lead to serious or fatal injuries if

not avoided.

!

WARNING

... indicates a situation of possible danger

which can lead to serious or fatal injuries if

not avoided.

!

CAUTION

... indicates a situation of possible danger

which can lead to minor or slight injuries if

not avoided.

NOTICE

... indicates a situation of possible danger

which can lead to damage to property if not

avoided.

2.2 Warning symbols

!

General warning of a danger zone.

«Warning: dangerous electrical voltage» as a

warning for accident prevention.

Ensures that people do not come into contact

with electrical voltage. The danger sign with

the black lighting symbol warns against the

danger of electrical voltage.

2.3 Information

Information:

Provides important information.

7

4 213 893 / 01

TECHNICAL INFORMATION

3. Technical information

3.1 Technical Data

Type (35) (45) (60)

• Nominal heat output 80/60 °C with natural gas

1

kW 6,0-31,8 10,0-41,0 11,7-55,3

• Nominal heat output 40/30 °C with natural gas

1

kW 6,8-35,0 11,1-45,0 12,8-60,7

• Nominal heat output 80/60 °C propane gas

3

kW 6,6-31,9 10,8-41,0 13,1-54,9

• Nominal heat output 40/30 °C propane gas

3

kW 7,3-35,2 11,9-45,0 14,1-60,3

• Nominal load with natural gas

1

kW 6,4-33,0 10,6-42,5 12,2-57,3

• Nominal load with propane gas

3

kW 7,0-33,2 11,4-42,5 13,6-56,9

• Working pressure heating maximum/minimum. bar 3,0/1,0 3,0/1,0 3,0/1,0

• Working temperature maximum °C 85 85 85

• Boiler water content l 4,5 4,5 6,0

• Minimum water ow l/h 300 350 470

• Boiler weight (without water content, incl. body) kg 83 83 89

•

Boiler efciency at full load at 80/60 °C

(related to net/gross caloric value)

% 96,4/86,8 96,5/86,9 96,5/86,9

•

Boiler efciency at 30 % partial load (in acc. with EN 303)

(related to net/ gross caloric value)

% 107,1/96,5 106,9/96,3 106,9/96,3

• Normal degree of efciency (in accordance with DIN 4702 Part 8) 40/30 °C % 109,1/98,3 109,0/98,2 109,0/98,2

(related to net/gross caloric value) 75/60 °C % 106,1/95,6 106,0/95,5 106,0/95,5

• Standby losses at 70 °C Watt 95 95 120

• Norm emission factors Nitrogen oxide NOx mg/kWh 30,0 30,0 35,0

Carbon monoxide CO mg/kWh 9,0 11,0 13,0

• CO

2

content in ue gas max./min. output % 9,0/8,8 9,0/8,8 9,0/8,8

• Dimensions see table of dimensions

• Connections Flow/Return Inches Rp 1¼″ Rp 1¼″ Rp 1¼″

Gas Inches R ¾″ R ¾″ R ¾″

Air/ue gas Ø mm C80/125 C80/125 C80/125

• Gas ow pressure min./max.

Natural gas E/LL mbar 18-50 18-50 18-50

Liquid gas mbar 37-50 37-50 37-50

• Gas connection value at 0 °C/1013 mbar:

Natural gas E - (Wo = 15,0 kWh/m

3

) Hu = 9,97 kWh/m

3

m3/h 3,3 4,3 5,8

Natural gas LL- (Wo = 12,4 kWh/m

3

) Hu = 8,57 kWh/m

3

m3/h 3,9 5,0 6,7

Propane gas

3

(Hu = 25,9 kWh/m3) m3/h 1,27 1,64 2,21

• Operation voltage V/Hz 230/50 230/50 230/50

• Control voltage V/Hz 24/50 24/50 24/50

• Minimum/maximum electrical power consumption Watt 29/62 29/66 30/102

• Standby Watt 13 13 13

• Protection rating IP 40 40 40

• Sound power level

- Heating noise (EN 15036 part 1) (room air dependent) dB(A) 61 63 63

- Exhaust noise is radiated from the mouth

(DIN 45635 part 47) (room air dependent/room air independent

dB(A) 63 66 66

• Sound pressure level (depending on installation conditions)

2

dB(A) 49 51 51

• Condensate quantity (natural gas) at 40/30 °C l/h 3,1 4,0 5,4

• pH-value of the condensate ca. 4,2 ca. 4,2 ca. 4,2

• Flue gas system: requirements, values

Temperature class T120 T120 T120

Type of connection B23, C13(x), C33(x), C53(x), C63(x)

Flue gas mass ow kg/h 54,8 70,6 95,1

Flue gas temperature at nominal output and operation 80/60 °C °C 69 75 79

Flue gas temperature at nominal output and operation 40/30 °C °C 47 52 49

Volume ow rate combustion air Nm

3

/h 41,3 53,1 71,6

Feed pressure total at the combustion air/ue gas pipe Pa 95 115 140

Maximum draught/depression at ue gas outlet Pa - 50 - 50 - 50

1

Data related to Hu. The boiler series is tested for EE/H-settings. With a factory setting of the Wobbe coefcient of 15,0 kWh/m3 operation

at a Wobbe coefcient of 12,0 up to 15,7 kWh/m3 is possible without new settings.

2

See also notes at “Engineering”.

3

Data related to Hu. TopGas® is also suitable for propane/ butane (liquid gas) mixtures.

8

4 213 893 / 01

TECHNICAL INFORMATION

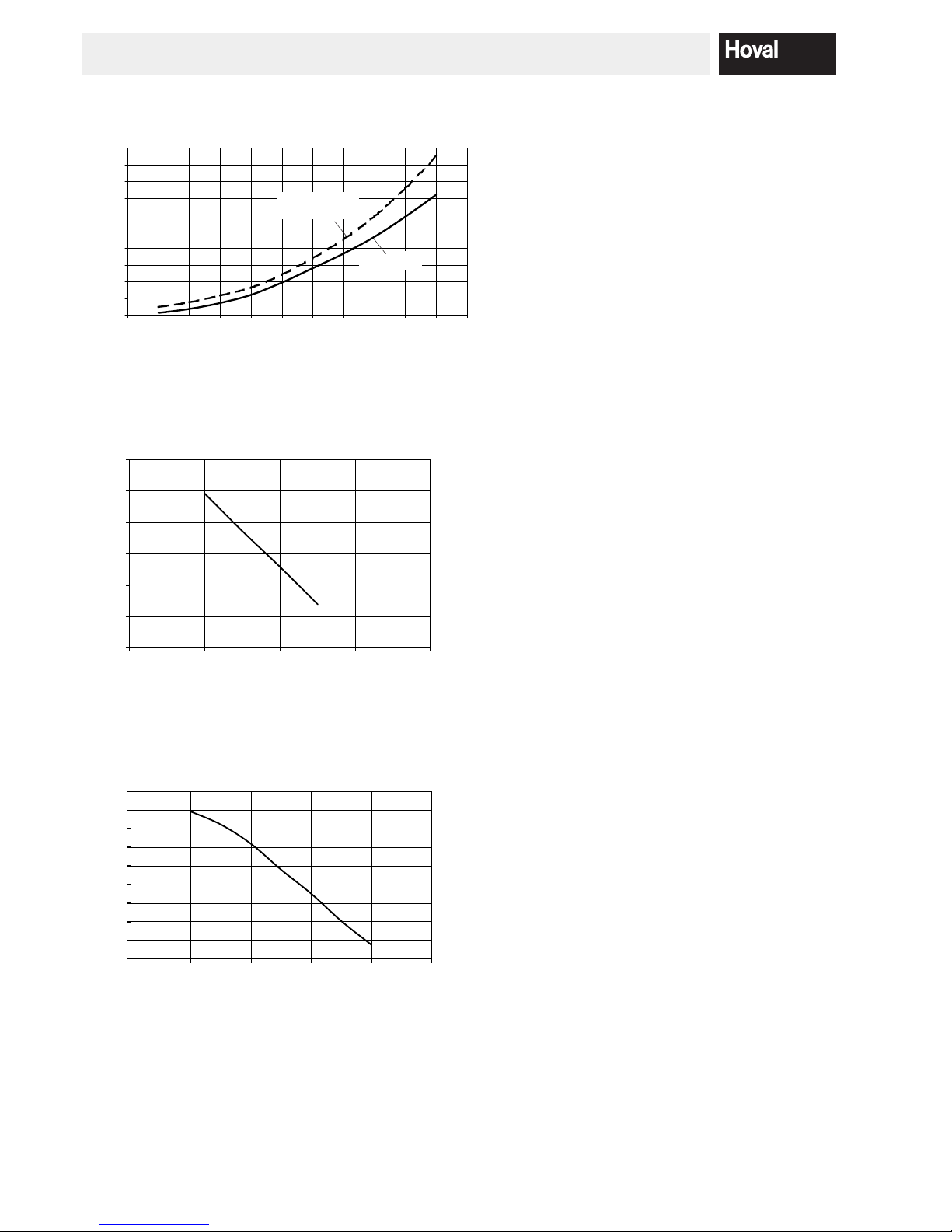

m3/h = Volume ow

mbar = Flow resistance

3.2 Boiler-flow resistance

Boiler incl.

connection set

(mbar)

Boiler only

500

450

400

350

300

250

200

150

100

50

0

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5 4,0 4,5 5,0 5,5 m

3

/h

Maximum residual overpressure TopGas® (35-60)

with connection set AS32-TG/UPM2 32-60

Maximum residual overpressure TopGas

®

(35-60)

with connection set AS32-TG/UPM GEO 32-85

0

100

200

300

400

500

600

700

800

900

0.0 1.0 2.0 3.0 4.0 5.0

mbar

m3/h

mbar

0

100

200

300

400

500

600

0.0 1.0 2.0 3.0 4.0

m3/h

9

4 213 893 / 01

TECHNICAL INFORMATION

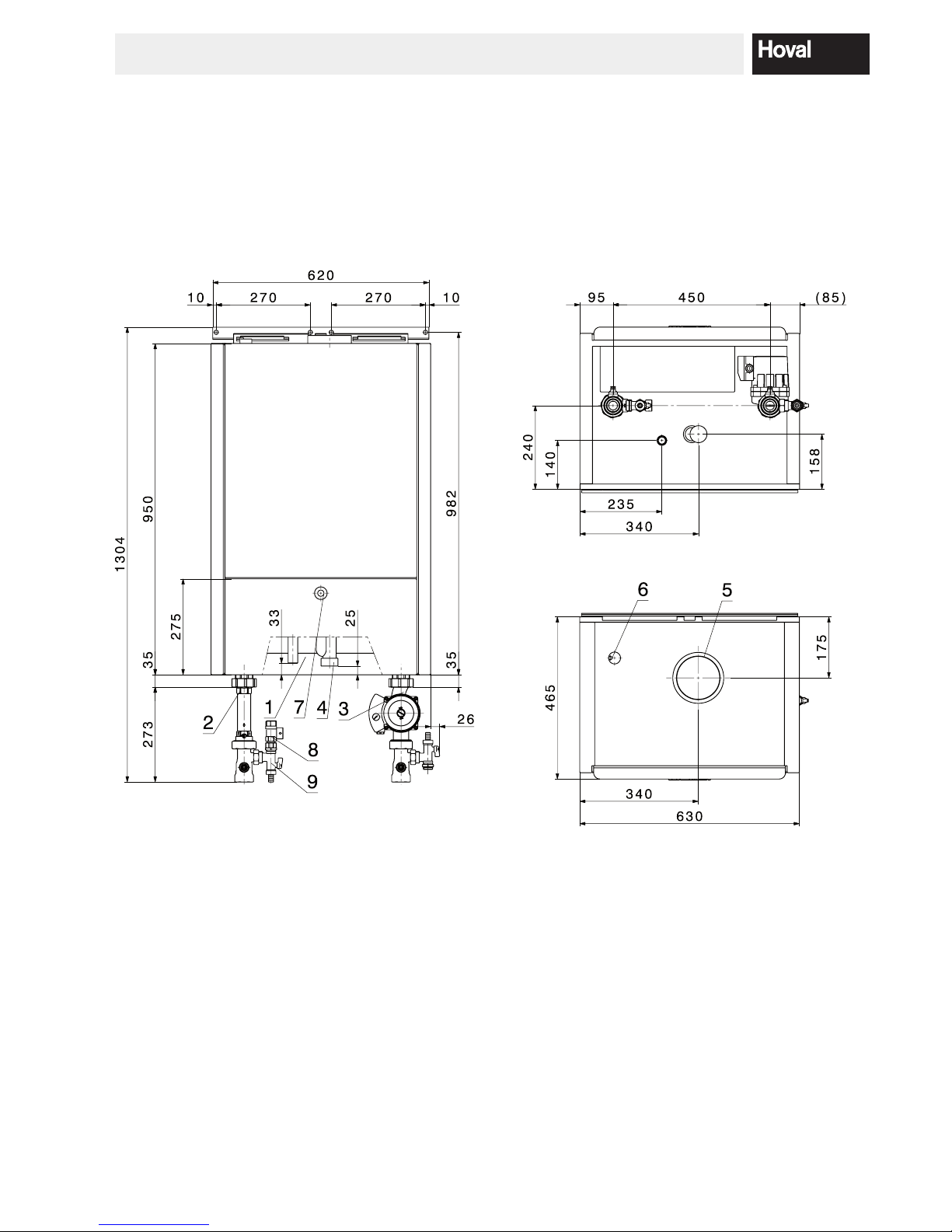

3.3 Dimensions

Minimum clearances

Dimensions in mm

• Lateral clearance 50 mm

• Distance from ceiling depending on exhaust ue system used

• Front 500 mm

Ansicht von oben

Ansicht von unten

View from bottom

View from top

Fig. 01

1 Gas connection R ¾″

2 Heating ow Rp 1¼″

3 Heating return Rp 1¼″

4 Condensate drain Ø 32

5 LAS ue gas/combustion air connection DN 80/125

6 Automatic deaeration

7 Boiler control cover

8 Safety valve

9 KFE ball valve

10

4 213 893 / 01

TECHNICAL INFORMATION

3.4 Short description of the automatic firing unit

BIC 335

- The automatic ring unit operates both without controller (TTE) and also without room station (RS-OT). The

automatic ring unit comprises the following functions

- PWM- fan (230V~)

- Modulating operation

- Inputs for Flow sensor

Return sensor

Flue gas sensor

Gas pressure deector

Air pressure deector:

(not used)

Water pressure deector

Safety temperature limiter:

(external ue gas thermostat)

HW-buffer sensor

Outdoor sensor

Locking entry:

(Burner blocking)

- Status exit „Failure“ (invertible by parameter setting)

- Three-way-valve control for heating/hot water or loading pump control (230V~exits); Exit for a three-wayvalve / HW loading pump is invertible by a parameter.

- Collective electrode for ignition and ame guide (Ionisa-

tion)

- Main gas valve (ev. LPG- valve) / heating room ventila-

tion accessable

- Interface to display

- OpenTherm- interface (RS-OT, TTE)

- RS 232- interface to PC

- Start attempts: 4

- Safety period: 5 sek

- Ignition period: 5 sek

- Pre-ventilation period: 20 sek

- After-run time main pump / heating pump

(230V ~): 10 min

- After-run time three-way valve / HW-loading pump: 2 min

- Restart locking after a heat demand: 2 min

- Restart locking after a temperature blocking: 2 min

Fuses

On the automatic ring unit theres is a mains fuse. The

breakdown of this fuse (2AT) is noticeable by an empty

display even the main deector is on.

Ionisation ow

The value of the ionisation ow is noted on the information level and appears as step 8. The access to the information level is explained in chapter 3.5.

11

4 213 893 / 01

TECHNICAL INFORMATION

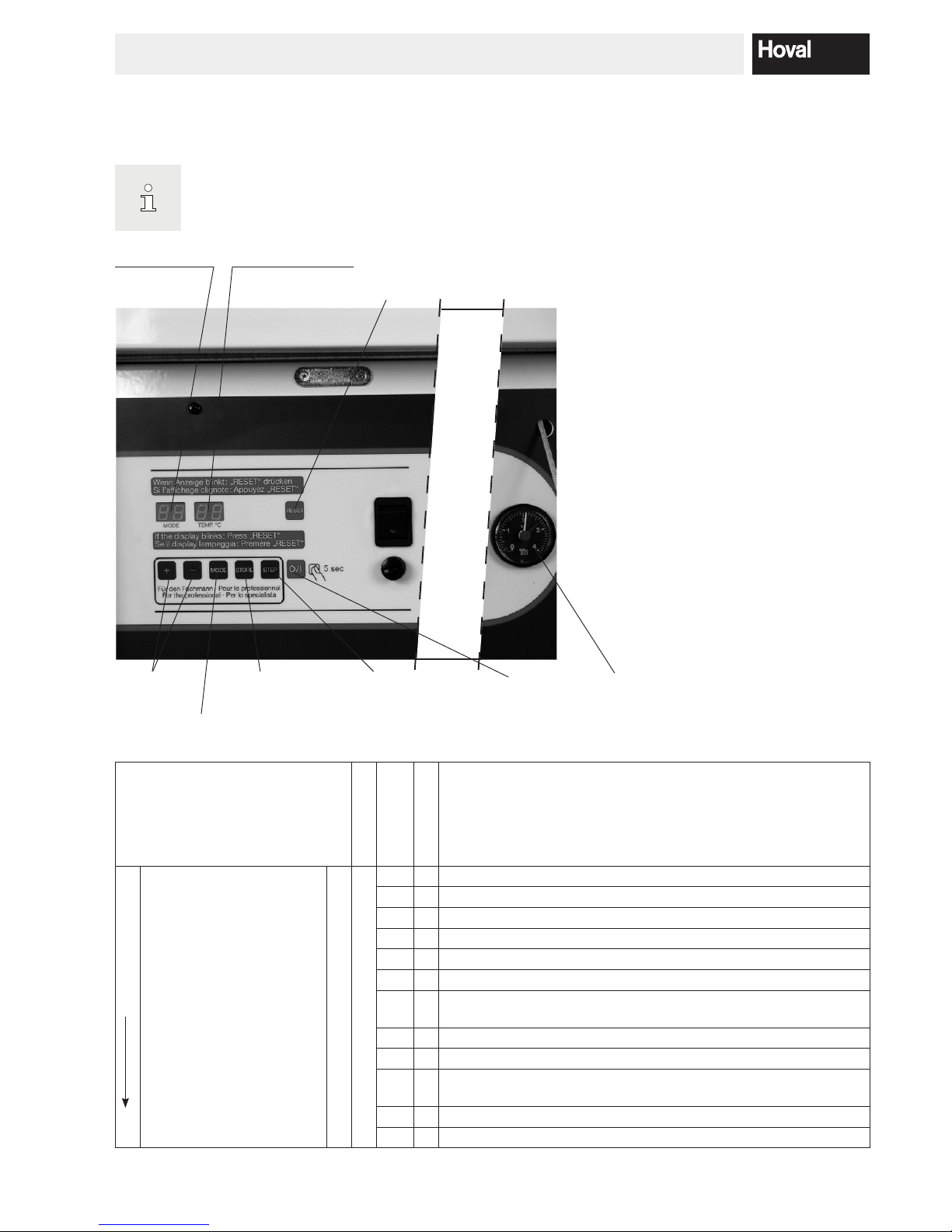

3.5 Heating system control

Boiler control

Normally, the user does not need to set the basic controller.

All settings have been made by the installer or the manufacturer.

Display: temperature

Changing of

the values

Display: Mode RESET

Fault-clearance (display is

blinking, if there is a failure)

Saving of

the settings

Options, to change settings

(Parmeter)

(p.ex. Calorier temperature)

ON/OFF Manometer

Function options

(stepwise display option)

Function

Mode indication

Parameter

Indication

Value indication

Meaning, Description

Standby-Mode

Normal position,

Start position

current ow temperature

no indication

0 = Standby, no heat demand, waiting time main gasvalve

1 = Rinsing

2 = Ignition

3 = Burner „on“ in heating operation

4 = Burner „on“ in hot water operation

5 = Air pressure deector defectiv (no air pressure deector in use)

6

= Burner „off“ in heating operation

(ow-Temp > ow-temp set point + blockage Offset ZH)

7 = Pump after-run time in heating operation

8 = Pump after-run time in hot water operation

9

= Burner „off“ on hot water operation

(ow-Temp > ow-temp. set point + Par.1 (2AB))

Fr = Frost protection is activated

Su = Summer short operation is activated

Loading...

Loading...