Hoval BioLyt 50, BioLyt 70, BioLyt 75, BioLyt 110, BioLyt 150 Operating Instructions Manual

...

EN

Subject to modifi cations

Operating Instructions

Hoval United Kingdom

Hoval LTD

Northgate

Newark

Nottinghamshire NG24 1JN

Phone: +44 1636 67 27 11

Fax: +44 1636 67 35 32

Hoval Export

Hovalwerk AG

Austrasse 70

9490 Vaduz

Principality of Liechtenstein

Phone: +423 399 24 00

Fax: +423 399 26 18

Wood pellet heating boiler

BioLyt (50,70,75,110,150,160)

UK 4 204 793 / 04 - 05/10

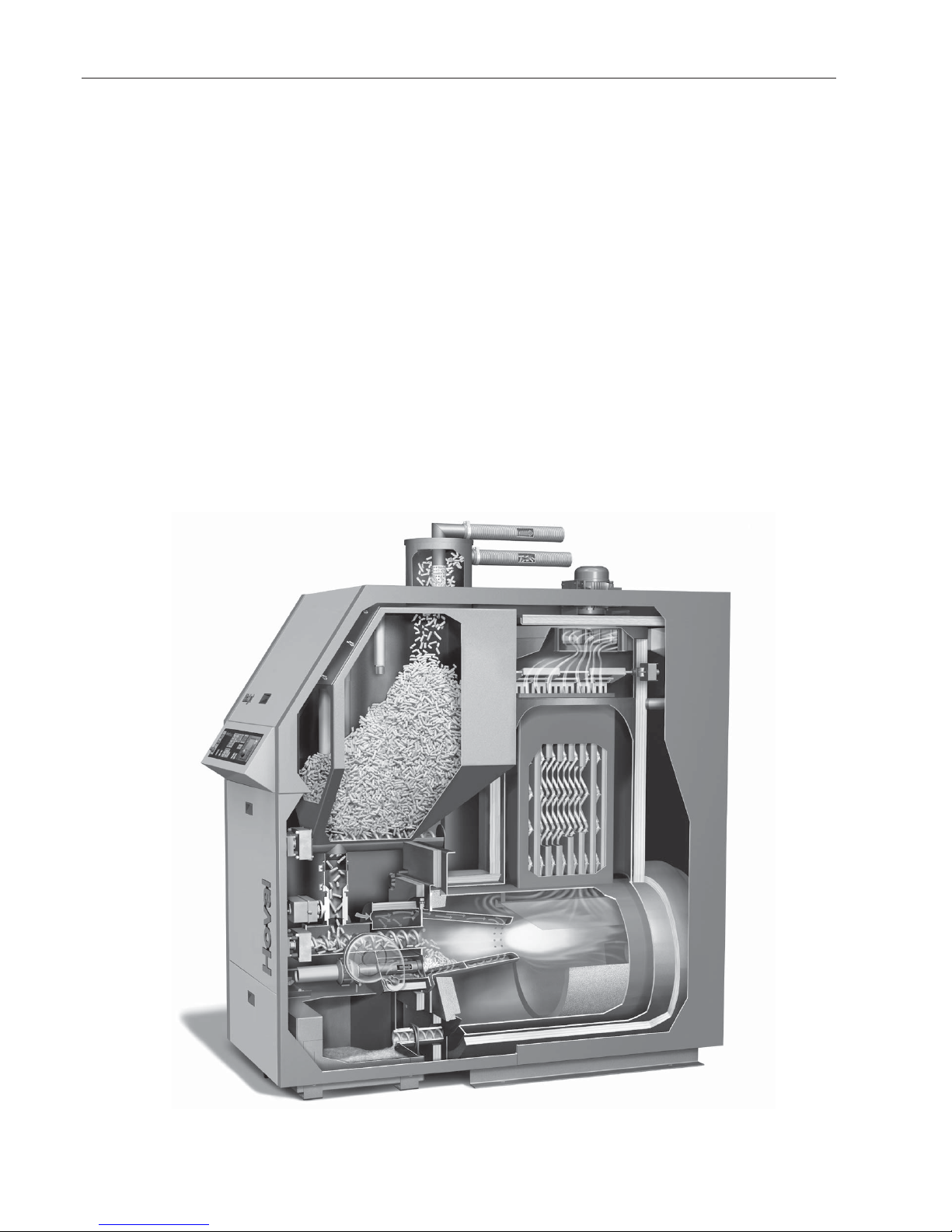

Figure type BioLyt (50-75)

2

UK 4 204 793 / 04Contents

Information about your heating system ..................................................................................... 3

Important notes ............................................................................................................................4

Safety information ....................................................................................................................................................... 4

Cautionary notes ......................................................................................................................................................... 5

Functional description ................................................................................................................. 6

Functional description of the heating system .......................................................................................................... 6

What happens inside the BioLyt? .............................................................................................................................. 8

How are the pellets extracted and conveyed from the storage room? ................................................................... 9

Boiler control .............................................................................................................................. 10

Control elements of the control panel ..................................................................................................................... 10

System start-up / Regular checks / Cleaning the heating boiler for BioLyt (50-75) ............. 15

System start-up (BioLyt 50-75) .................................................................................................................................15

Regular checks (BioLyt 50-75) ................................................................................................................................. 15

Cleaning the heating boiler (BioLyt 50-75) ..............................................................................................................15

System start-up / Regular checks / Cleaning the heating boiler for BioLyt (110-160) ......... 18

System start-up (BioLyt 110-160) .............................................................................................................................18

Regular checks (BioLyt 110-160) ............................................................................................................................. 18

Cleaning the heating boiler (BioLyt 110-160) ..........................................................................................................18

Errors and faults ......................................................................................................................... 21

How you can save energy .......................................................................................................... 23

3

UK 4 204 793 / 04 Information about your heating system

Typical Wood Pellet Fuel Specification

The pellets should be formed from CLEAN or

VIRGIN TIMBER and to the specification outlined in

wood pellet specification CEN/TS 14961.

The fuel MUST NOT contain halogenated organic

compounds or heavy metals as a result of

treatment with wood preservatives or coatings.

Typically the wood pellet fuel would have the

following As Received properties,

Calorifi c Value (min)

nCV basis (CV)

17,000 kJ/kg, or

4.72 kWh/kg

Mechanical Durability

(DU)

> 97.5%

Ash Content (A) < 1.0%

Moisture Content (M) < 10 %

Size Diameter (D)

Length

D 06, Diameter 6mm

20 – 30mm

Sulphur Content (S) <0.05%

Fines (- 3.15mm into

vehicle) (F)

< 1.0%

Bulk Density 650 kg/m

3

Hoval do not endorse any particular wood pellet

manufacturer, however it is recommended that

fuel is supplied against the specification indicated,

and the supplier operates well maintained vehicles

and fully trained delivery drivers to ensure that the

boiler and fuel transfer system are presented with

well sized wood pellets, which are free from any

contamination.

BioLyt (50-160)

pellet heating boiler

To be completed by the heating engineer:

Order No. / Manufacturing No.: _____________________

Boiler type: _____________________________________

Boiler power rating: ____________________________ kW

Hot water storage tank size (if present): ______________

Water heater size: _______________________________

Heating pump type: ______________________________

Heating controller type: ___________________________

Mixing valves type:_______________________________

Calculation basis for heating system

Lowest outside temperature: _____________________ °C

°C Required thermal output: _____________________ kW

kW Max. fl ow temperature: ______________________ °C

Intended use

The BioLyt (50-160) pellet heating boiler has

been designed for the optimal combustion of

wood pellets in accordance with ÖNORM M

7135 or DIN 51731, HP5 (DINplus) or SN 166000

(ø 6-8 mm).

Dear Heating System Owner,

With the purchase of this Hoval BioLyt (50-160) pellet

heating boiler, you have made an excellent choice.

This boiler offers you all the advantages of a modern

and effi cient heating system.

Please read these instructions carefully. They describe how the heating boiler works, how it is operated and how it is maintained.

Further information can be obtained from our Sales and

Service Centres (see back page for contact details).

Important addresses and telephone

numbers

Heating engineer _______________________________

______________________________________________

______________________________________________

Plumber _______________________________________

______________________________________________

______________________________________________

Electrician _____________________________________

______________________________________________

______________________________________________

Master chimney sweep ___________________________

______________________________________________

______________________________________________

4

UK 4 204 793 / 04Important notes

Safety information

(Information on personal protection)

• Attention

Duly switch off the heating system

15 min. before fi lling the stockroom

Press STOP key for 5 sec.

Don't switch off the main switch!

Danger of back fi re!

• Keep the air supply into the room

open:

Air inlets and outlets should not

be closed. It is important to ensure

that the combustion air required

for the correct operation of the

heating boiler can fl ow unhindered

and to protect the operating personnel from an oxygen depleted

atmosphere.

• Do not operate the boiler with the

cover of the pellet hopper open

(danger of backfi ring). In addition,

any sparks emitted from the boiler

could cause a fi re.

• The system must be cleaned regu-

larly, otherwise any possible warranty claims may be rejected.

• Parents must keep their children

away from the boiler room: the

heating system is not a toy!

• Do not burn any unsuitable fuel (see

page 3), otherwise any possible

warranty claims may be rejected.

• Do not conduct any modifi cations

on the system (possible danger

to persons; possible loss of warranty).

Under unfavourable circumstances, it may occur

that an increased concentration of harmful gases

(such as carbon monoxide) arises in pellet storage

rooms, possibly posing a risk when accumulating

over a longer period of time. Despite the fact that

under normal circumstances, there is no risk at all,

one cannot rule out the possibility of such a scenario

to occur.

• If work is being carried out in fi lled storage rooms,

a second person must always be present outside

the room for security reasons. Before entering the

pellet storage room, it must always be thoroughly

aerated.

• Entering fuel storage rooms that have not been

aerated (particularly underground tanks) must be

avoided, only trained personnel is permitted to

do so. Before entering the room or tank, the concentration of CO must be measured (the concentration must be less than 30 ppm). If necessary,

thoroughly aerate the storage room or tank before

entering it.

• It the storage is diffi cult to access or if it is accessible only from above (such as underground tanks),

the person entering the tank must be additionally

secured.

• Keep away children from the pellet storage place!

5

UK 4 204 793 / 04 Important notes

Cautionary notes

(Information on the protection of the heating

system)

Control of the water level

Control the water level in the system at regular intervals.

Circulation pumps

During the time periods when no heating is required,

the circulation pumps should be operated for approx. 2

minutes at least once every month. This will effectively

prevent the pumps from getting stuck.

Filling the heating system

The heating system can normally be fi lled and topped

up with mains water. No chemical additives should

be added to the water. The water quality can vary

strongly in different parts of the country (you can

obtain information about the water quality from your

local water company) and it might not always be suitable for fi lling the heating system (highly corrosive or

hard water). Please contact your heating engineer in

those cases (see also Technical Information).

Tightness / Backfi re protection

The doors and pellet hopper must be checked for leaks

on annual basis. Smoke leaks should be avoided in

order to prevent any poisonous sulphur gases from

escaping into the boiler room. Moreover, leaky doors,

or a faulty pellet hopper gasket, could cause the embers to burn back into the pellet burner.

Cleaning

Periodic cleaning and inspection by the heating engineer or Hoval customer service, not only extend the

useful life of the pellet boiler, but also increase its

operating safety and ensure that a high combustion

effi ciency is maintained.

Heating boiler care

Do not use any sprays, solvents, chlorine based cleaning products, paint, glue, etc. in the proximity of the

heating boiler. These substances can cause corrosion

within the heating boiler and the fl ue gas system.

Pressure relief valve, backfi re protection and thermal

safety valve

The correct functioning of the different safety devices

(pressure relief valve on the heating installation, burnback protection valve on the burner, pellet hopper seal,

thermal safety valve) need to be checked periodically

by the heating engineer.

6

UK 4 204 793 / 04Functional description

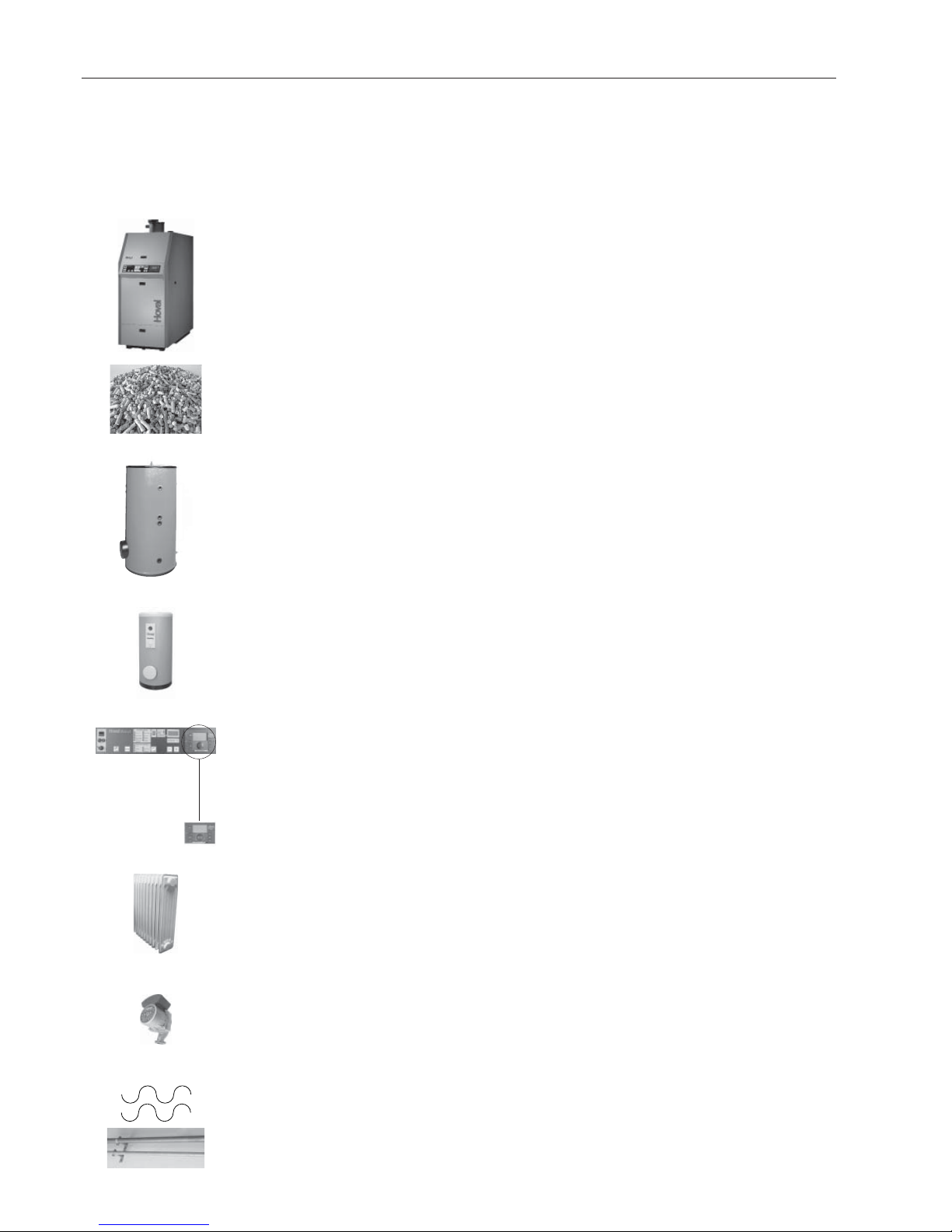

Functional description of the heating system

It is important for the perfectly coordinated individual components to function properly to ensure that your

home stays warm in winter.

FUNCTION:

Burns the pellets safely and environmentally friendly.

Extracts the heat from the combustion gases and

transfers it to the heating water.

The pellets are combusted within the heating boiler

to release and convert the natural energy contained

therein into heat.

It is used as an intermediate storage of hot heating

water (max. 90°C). It compensates for any differences between heat generation and demand.

It holds a reserve of hot water for consumption (e.g.

for showering).

Controls and monitors the operation of the heating

boiler.

Adjusts the room temperature optimally and fuel effi ciently, independently of the outside temperature.

Releases the heat of the heating water into the

room.

Transports the heating water from the heating boiler to the radiators and back into the heating boiler,

where it is reheated.

Transports the generated heat from the heating boiler to the radiators.

COMPONENTS

Wood pellet heating

boiler

Wood pellets

Hot water storage tank

(optional)

Storage tank water

heater

Boiler control

Heating controller

Radiator or fl oor heating

Heating pump

Heating water and heating pipes

7

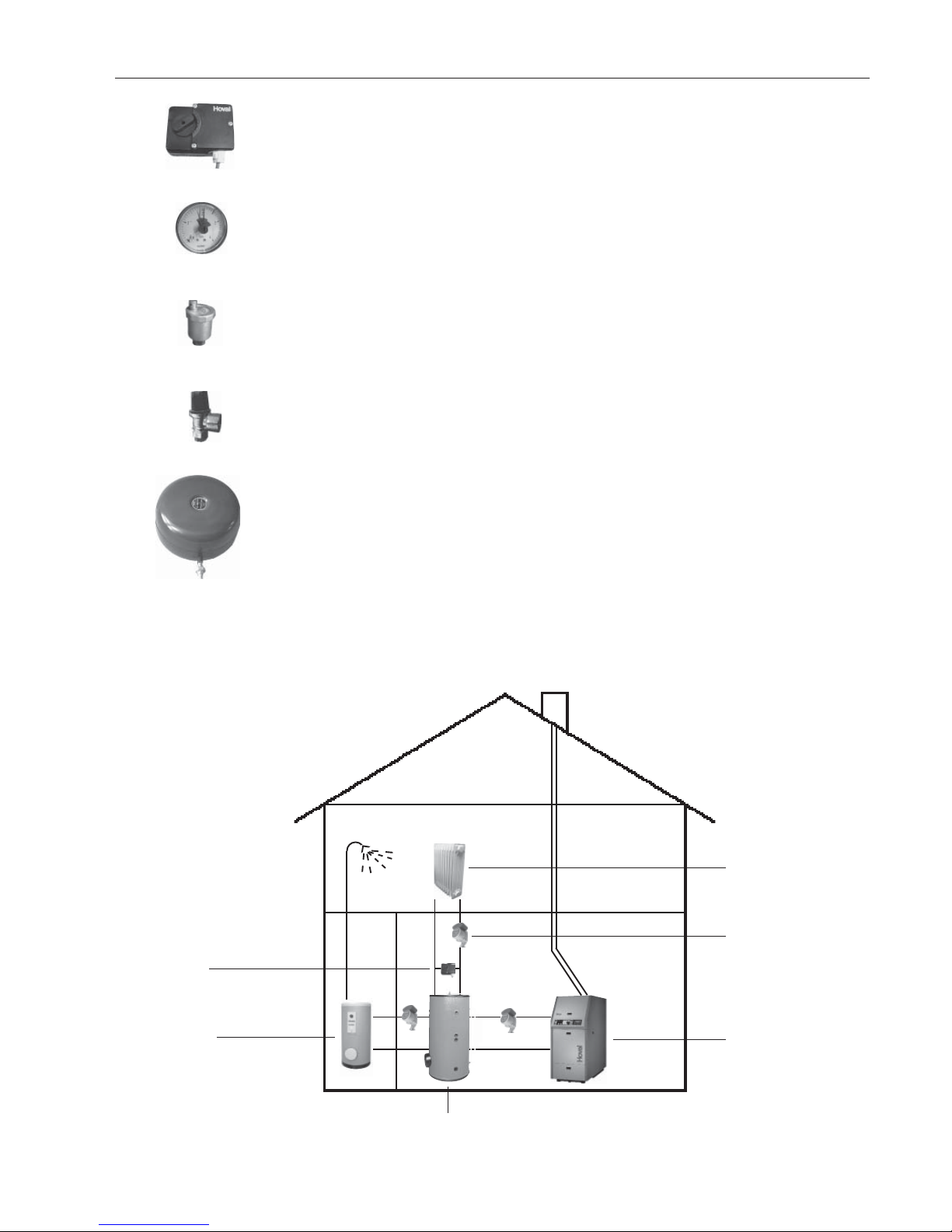

UK 4 204 793 / 04 Functional description

Adjusts the heating fl ow temperature to the radiator

to maintain the desired room temperature, independently of the outside temperature. This is achieved

by admixing colder return heating water.

Displays the water pressure in the heating system.

Eliminates any air from within the heating pipes.

Prevents an overpressure in the installation.

Maintains the pressure in the system constant and

accepts the expanding water.

Mixing valve

Manometer

Air bleeder

Safety valve

Diaphragm expansion tank

Water heater

Mixing valve

Radiator

or fl oor heating

Heating pump

Wood pellet

heating boiler

Hot water storage tank (optional)

Depending on the selected type of heating system, some of the components might be missing or some might

be added. The heating engineer will explain the system to you.

8

UK 4 204 793 / 04Functional description

What happens inside the BioLyt?

The Hoval BioLyt boiler has been designed for the

low emission combustion of wood pellets in accordance with ÖNORM M 7135 and DIN 51731, HP5

(DINplus) and SN 166000 (HP5). The dosing screw

conveys the wood pellets from the pellet hopper over

a drop chute to the feed screw. The dosing screw

adjusts the conveyed pellet amount as a function of

the power demand, while the continuously operating

feed screw feeds the pellets into the burner. Degassing of the pellets takes place in the rear section of

the burner into which primary air is supplied by the

high pressure fan. The combustible gas thus generated is thoroughly mixed with secondary air (supplied by the induced draught-fan) within the front

section of the tube, where it burns cleanly and completely with low emission levels.

The horizontal combustion results in a fl ame similar to that of an oil or gas burner. The combustion

system achieves an excellent pellet burnout rate.

Thanks to the large, mostly refractory lined combustion chamber, it is possible to attain a long residence

time of the hot gases, as well as suffi ciently high

combustion temperatures. These factors contribute to a further optimisation of the burnout quality.

The heat exchange between the hot gases and the

heating water takes place by means of the proven

thermolytic secondary heat exchange surface.

The ashes created as result of the combustion process are collected in the front part of the combustion

chamber and are periodically conveyed to the ash

container by the ash extraction screw.

Fig. 2

Loading...

Loading...