Hoval BioLyt 8, BioLyt 23, BioLyt 25, BioLyt 31, BioLyt 13 Operating Instructions Manual

...

Operating Instructions

BioLyt (8-43)

Wood pellet boiler

United Kingdom

Hoval Ltd.

Northgate

Newark

Nottinghamshire NG24 1JN

Phone +44 1636 67 27 11

Fax +44 1636 67 35 32

Export

Hoval Aktiengesellschaft

Austrasse 70

LI-9490 Vaduz

Principality of Liechtenstein

Phone +423 399 24 00

Fax +423 399 24 11

Subject to modi cations |

4 214 153/ 00 - 03/16

EN

TABLE OF CONTENTS

1. Important notes ....................................................................................................................................... 4

1.1 Important addresses and telephone numbers....................................................................................................................5

1.2 System data .........................................................................................................................................................................5

1.3 Calculation basis .................................................................................................................................................................5

2. Safety ....................................................................................................................................................... 6

2.1 General safety instructions .................................................................................................................................................6

2.2 Intended use ........................................................................................................................................................................7

2.3 Explanation of the symbols ................................................................................................................................................7

2.3.1 Warnings ..........................................................................................................................................................................7

2.3.2 Icons .................................................................................................................................................................................8

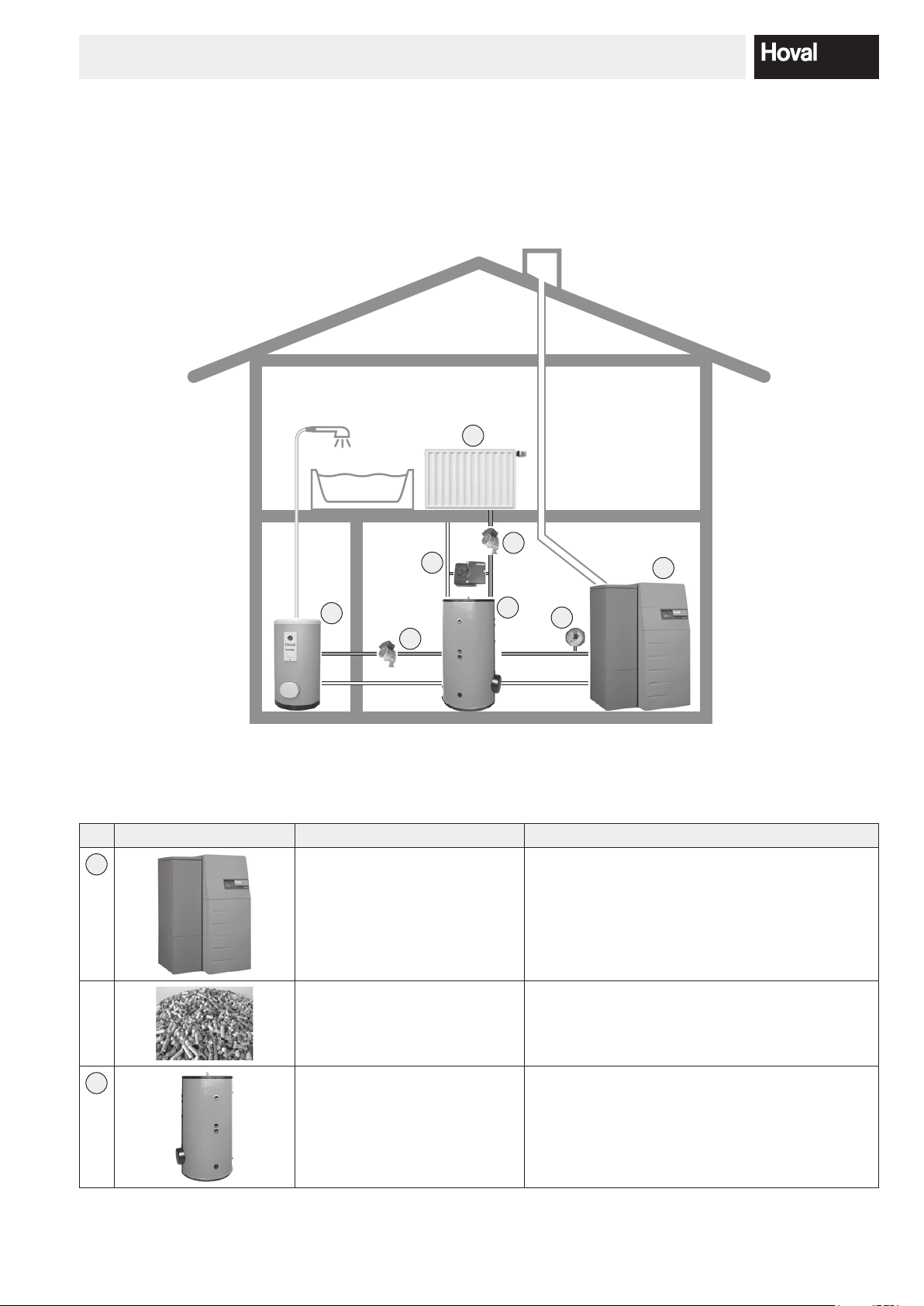

3. Functional principle of the heating system ........................................................................................... 9

3.1 Construction of the plant ....................................................................................................................................................9

3.2 What happens inside the BioLyt? ..................................................................................................................................... 11

3.3 How does the automatic pellet feed (option) from the pellet storage room work? ........................................................12

4. Control panel on heat generator .......................................................................................................... 13

4.1 Overview of control panel .................................................................................................................................................13

5. Heating system control ......................................................................................................................... 14

5.1 Function of the TopTronic® E control ...............................................................................................................................14

5.2 Operating and display elements .......................................................................................................................................14

5.3 What to do if... ...................................................................................................................................................................16

5.4 Efficient control of the system ..........................................................................................................................................17

5.5 Individual day and week programs ...................................................................................................................................18

5.6 Start screen .......................................................................................................................................................................19

5.6.1 Elements of the start screen heat generator and living area ............................................................................................20

5.6.2 Optional start screen .......................................................................................................................................................22

5.7 Main settings .....................................................................................................................................................................24

5.7.1 Changing the room temperature ......................................................................................................................................24

5.7.2 Adapt hot water temperature ...........................................................................................................................................25

5.7.3 Select heating circuit (if there are several) ......................................................................................................................26

5.7.4 Change the basic program (heating circuit) .....................................................................................................................26

5.7.5 Change active day program (heating circuit) ...................................................................................................................27

5.7.6 Change basic and day program (hot water) .....................................................................................................................28

5.7.7 Call up system information ..............................................................................................................................................30

5.7.8 Joint operating mode for heating and hot water circuits ...................................................................................................30

5.8 Basic programs .................................................................................................................................................................31

5.8.1 Functions of the various basic programs .........................................................................................................................31

5.8.2 “Holiday” – enter return date ........................................................................................................................................... 32

5.9 Week programs ..................................................................................................................................................................34

5.9.1 Week program default settings ........................................................................................................................................34

5.9.2 Notes on personal week programs ..................................................................................................................................35

5.9.3 Week program operating elements ..................................................................................................................................36

5.9.4 Adapt week program .......................................................................................................................................................37

5.9.5 Rename week program ...................................................................................................................................................39

5.9.6 Reset week program .......................................................................................................................................................41

5.10 Day programs / switching cycles ......................................................................................................................................43

5.10.1 Default settings for day programs / switching cycles ........................................................................................................ 43

5.10.2 Notes on personal day programs .....................................................................................................................................44

5.10.3 Party and absent ............................................................................................................................................................45

5.10.4 Day program / switching cycles operating elements ........................................................................................................47

5.10.5 Change room temperatures and switching cycles in the day program ..............................................................................48

5.10.6 Rename day program ......................................................................................................................................................50

5.10.7 Reset day program .........................................................................................................................................................52

5.11 Hot water ............................................................................................................................................................................54

5.11.1 Hot water operating elements..........................................................................................................................................54

5.11.2 Week programs – hot water ............................................................................................................................................55

5.11.3 Week program default settings – hot water ......................................................................................................................55

2 4 214 153 / 00

TABLE OF CONTENTS

5.11.4 Day programs / switching cycles for hot water .................................................................................................................56

5.11.5 Default settings for day programs / switching cycles – hot water .....................................................................................56

5.11.6 Legionella function ..........................................................................................................................................................57

5.11.7 Recharging hot water ......................................................................................................................................................58

5.11.8 Set hot water program to absent .....................................................................................................................................59

5.12 Other operating elements ..................................................................................................................................................61

5.12.1 Main menu view 1 ...........................................................................................................................................................61

5.12.2 Main menu view 2 ...........................................................................................................................................................62

5.12.3 Main menu view 3 ...........................................................................................................................................................63

5.12.4 Power station ..................................................................................................................................................................64

5.12.5 Power station ..................................................................................................................................................................65

5.12.6 Programs ........................................................................................................................................................................66

5.12.7 Heating circuit .................................................................................................................................................................67

5.12.8 Info .................................................................................................................................................................................68

5.12.9 Analysis ..........................................................................................................................................................................69

5.12.10 Emission - only for heating specialist ..............................................................................................................................70

5.12.11 Manual operation ............................................................................................................................................................71

5.12.12 Presentation 1.................................................................................................................................................................72

5.12.13 Presentation 2.................................................................................................................................................................73

5.12.14 Presentation 3.................................................................................................................................................................74

5.13 Further settings .................................................................................................................................................................75

5.13.1 Setting the language .......................................................................................................................................................75

5.13.2 Adapt start screen individually .........................................................................................................................................75

5.13.3 Rename heating circuit ...................................................................................................................................................75

5.14 Displaying the total pellet consumption ...........................................................................................................................76

5.15 Changing the off-periods for the pellet transfer system .................................................................................................76

6. Alarm messages .................................................................................................................................... 77

6.1 Display alarm message .....................................................................................................................................................77

6.2 Plant-related malfunctions ................................................................................................................................................78

6.3 Burner-related alarm messages ........................................................................................................................................79

7. Commissioning ..................................................................................................................................... 80

7.1 Checks prior to operation ................................................................................................................................................80

7.2 Switching on .....................................................................................................................................................................80

8. Maintenance (pellet boiler) ................................................................................................................... 80

8.1 Cleaning the ash box .........................................................................................................................................................80

8.1.1 Removing the ash box ....................................................................................................................................................80

8.1.2 Attaching the ash box .....................................................................................................................................................81

8.2 Annual maintenance (major maintenance) .......................................................................................................................81

8.2.1 Preparation .....................................................................................................................................................................81

8.2.2 Clean the flue gas collector .............................................................................................................................................81

8.2.3 Cleaning flue gas sensors ...............................................................................................................................................82

8.2.4 Clean and inspect the post-combustion ring and dust separator ......................................................................................82

8.2.5 Clean the combustion chamber, burner and ignition tube ................................................................................................83

8.2.6 Cleaning and checking the burner mechanism ................................................................................................................83

8.2.7 Cleaning and checking the pellet hopper and suction module (if present) ........................................................................ 83

8.2.8 Further information..........................................................................................................................................................84

8.3 Cleaning and checking pellet storage room .....................................................................................................................84

9. Maintenance and inspection (heating system) .................................................................................... 85

9.1 Checking the water pressure ............................................................................................................................................85

9.2 Top up with water ..............................................................................................................................................................85

10. Saving energy ....................................................................................................................................... 86

10.1 Specific steps for saving energy ......................................................................................................................................86

11. Waste disposal ...................................................................................................................................... 86

11.1 Disposal instructions ........................................................................................................................................................86

34 214 153 / 00

IMPORTANT NOTES

1. Important notes

Dear Customer,

With the Hoval Biolyt (8-43), you have acquired a stateof-the-art product manufactured to the highest quality

standards.

For the correct installation and operation of your Hoval

BioLyt (8-43), all applicable laws, regulations and standards must be complied with as well as the regulations

of the responsible energy supply company. If you have

any questions, please contact the installer of your heating system.

Assembly and installation of the boiler are only allowed

to be carried out by trained personnel from a licensed

specialist company. Before commissioning, an installation inspection and approval of the overall installation by

the heating specialist are required.

To guarantee safe and trouble-free operation, operate

your Hoval boiler in accordance with these operating instructions at all times.

Hoval Customer Service

If you have any doubts with regard to the operation of

your Hoval boiler, or if minor faults affect its correct functioning, please contact Hoval Customer Service centre.

Our trained Customer Service staff will be pleased to help

you.

An optimally set heating system can not only save you a

lot of trouble, but also a lot of money. Take advantage of

the Hoval Customer Service offerings for regular maintenance, to prolong the service life and warranty period of

your Hoval heating system, and inquire about a service

agreement with extended warranty. Your Customer Service consultant will be pleased to advise you!

You will nd the addresses on the last page.

Please pay particular attention to the information in this

manual!

The boiler is only allowed to be used for its intended purpose and with fuels for which it was designed and which

have been approved by Hoval.

Do not carry out any modications to the system, otherwise all claims under the warranty will be waived. Conversion kits must be installed and the installation approved

by the heating specialist or by the Hoval Customer Service.

Reliable and safe functioning of a boiler, as well as the

achievement of optimum efciency and clean combustion are only possible and guaranteed if the system is

serviced and cleaned at least once every year. Please

pay particular attention to the instructions in this manual.

In the event of a fault or in the event of damage, please

contact the Hoval Customer Service to inquire about the

necessary repairs. In the meantime, shut down the unit to

avoid any damage.

With the acquisition of a Hoval unit, you also obtain comprehensive warranty cover, as indicated in the warranty

conditions on the warranty pass for your unit.

Provided it is used correctly, your Hoval boiler will ensure

you enjoy a well heated home for many years.

4 4 214 153 / 00

IMPORTANT NOTES

1.1 Important addresses and telephone numbers

Heating specialist

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plumber:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrician:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chimney sweep:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel supplier:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 System data

To be completed by the heating engineer!

Order no. / manufacturing no.:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boiler:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boiler output (kW):

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot water buffer storage tank size (if present):

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calorier:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heating circuit pump:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heating controller:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mixing valve:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of heating circuits:

1 2

3 . . .

Legionella function

activated:

Yes

No

1.3 Calculation basis

Lowest design outside temperature (°C):

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat energy demand (kW):

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max. ow temperature (°C):

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54 214 153 / 00

SAFETY

2. Safety

2.1 General safety instructions

Filling the pellet storage room

Switch off the heating system as instructed 15 min. before

lling the pellet storage room (press the blocking switch,

chapter 4.1 on page 13, no. 2).

Supply air openings

Air inlets and outlets must not be closed. It is important to

ensure that the combustion air required for correct operation of the boiler can ow unhindered and protect operating personnel from an oxygen-depleted atmosphere.

Entering the pellet storage room, storage tank

Under unfavourable circumstances, an increased concentration of harmful gases (such as carbon monoxide)

may occur in pellet storage rooms, possibly posing a risk

when accumulating over a longer period of time. Despite

the fact that under normal circumstances, there is no risk

at all, the possibility of such a scenario cannot be ruled

out.

• If work is being carried out in lled pellet storage rooms,

a second person must always be present outside the

room for security reasons.

• Before entering pellet storage rooms, they must always

be thoroughly aerated.

The storage room must be ventilated for at least 15

minutes. In the case of pellet storage rooms with a volume of more than 10 t, the duration of ventilation must

be extended or mechanical ventilation provided.

• No-one should enter the pellet storage room in the 4

weeks following lling. If it is necessary for persons to

enter the pellet storage room, the room must be ventilated for at least 2 hours before entering.

• It must be ensured that the storage room door remains

open while there are persons inside the pellet storage

room.

• Entering pellet storage rooms that have not been aerated (particularly underground tanks) must be avoided,

and only trained personnel is permitted to do so. Before entering the pellet storage rooms or pellet storage

tanks, the concentration of CO must be measured (the

concentration must be less than 30 ppm). If necessary,

thoroughly aerate the storage room or tank before entering it.

• If the storage is difcult to access or if it is accessible

only from above (such as underground tanks), the person entering the tank must be additionally secured.

• Keep away children from the pellet storage room!

• If there are moving parts (screw conveyors) in the pellet

storage room, turn off the mains switch of the heating

system before entering the storage room, as otherwise

there is a risk of injury.

• Smoking, naked ames and other possible sources of

ignition are prohibited inside the pellet storage room.

Keep the doors and pellet hopper closed

Do not operate the boiler with the doors or pellet hopper

open. There is a danger of burn-back, and any sparks

emitted could cause a re.

Leaks at doors and the pellet hopper

The doors and pellet hopper must be checked for leaks

on an annual basis. Smoke leaks should be avoided in

order to prevent any toxic low-temperature gases from

escaping into the boiler room.

Overpressure safety valve, burn-back protection and

thermal discharge safety device

Periodically, a heating engineer must check the proper

functioning of the safety equipment (overpressure safety

valve, burn-back protection on the burner, thermal discharge safety device).

Keep children away

Parents must keep their children away from the boiler

room; the heating system is not a toy!

Use suitable fuel

Only suitable fuel is allowed to be used. Use of unsuitable

fuels will invalidate all warranty claims.

The BioLyt (8-43) wood pellet boiler has been designed

for optimum combustion of wood pellets. The pellets must

meet the requirements of at least one of the standards

listed below

• ÖNORM M 7135

• DIN 51731 / HP5 (DINplus)

• SN 166000

• EN 14961-2 / A1 (ENplus/A1)

• EN ISO 17225-2

Hoval recommends ENplus (Class A1):

Pellet delivery

• Do not ll the pellet storage room until after initial commissioning of the boiler.

• Switch off the heating system as instructed 15 min. before lling the pellet storage room.

• The total pellet consumption of your plant can be seen

at any time on the control module. For further informa-

tion, see chapter 5.14 on page 76.

6 4 214 153 / 00

SAFETY

!

DANGER

... indicates a situation of immediate danger

which will lead to serious or fatal injuries if

!

WARNING

... indicates a situation of possible danger

which can lead to serious or fatal injuries if

!

CAUTION

... indicates a situation of possible danger

which can lead to minor or slight injuries if

NOTICE

... indicates a situation of possible danger

which can lead to damage to property if not

Do not carry out any modications to the unit

Do not carry out any modications to the system, otherwise all claims under the warranty will be invalidated, and

people may be placed at risk.

Checking the water pressure

Check the water pressure in the system at regular intervals, as described in chapter 8.1 on page 85.

Filling the heating system

The replacement water must be of the required quality.

The quality requirements are stated in the installation instructions in the “Water quality” chapter (Filling and replacement water).

Circulation pumps

During the periods when no heating is required, the circulation pumps should be operated for approx. 2 minutes at

least once every month. This will prevent the pumps from

seizing up.

Cleaning and inspection of the heating system

Periodic cleaning and inspection by the heating specialist

or Hoval customer service will not only extend the service life of the pellet boiler, but also increase its operat-

ing safety and ensure that a high combustion efciency

is maintained.

2.2 Intended use

The Hoval Biolyt boiler is exclusively intended for heating

the heating water. It is only permitted for fuels dened in

chapter 2.1 on page 6 to be used.

The heat produced must be carried away by the heating

water. All boiler openings must be closed during operation.

Only use the boiler if in perfect technical condition, as well

as according to the intended use, safely and with regard

to potential dangers!

The inspection and cleaning intervals stated in the documents must be complied with. Malfunctions that could im-

pair safety must be rectied immediately!

The manufacturer/supplier will not accept any liability for

any other use, or use beyond the scope of these denitions, and any resulting damage.

2.3 Explanation of the symbols

2.3.1 Warnings

not avoided.

Cleaning the pellet storage room

Pellet storage rooms must be cleaned regularly (approx.

every 2-3 years), and the sawdust which has accumulated must be disposed of!

Corrosion protection

Do not use sprays, solvents, chlorine-based cleansing agents, paint, adhesives etc. in the proximity of the

unit. Under certain circumstances, these substances can

cause corrosion inside the boiler and the ue gas system!

The heating installation must be inspected regularly according to local regulations.

not avoided.

not avoided.

avoided.

74 214 153 / 00

SAFETY

!

“Warning: dangerous electrical voltage” as a

Ensures that people do not come into contact

with electrical voltage. The danger sign with

the black lighting symbol warns against the

2.3.2 Icons

General warning of a danger zone.

warning for accident prevention.

danger of electrical voltage.

Information:

Provides important information.

ENERGY

Energy-saving tip:

Provides information about saving energy.

8 4 214 153 / 00

FUNCTIONAL PRINCIPLE OF THE HEATING SYSTEM

3. Functional principle of the heating system

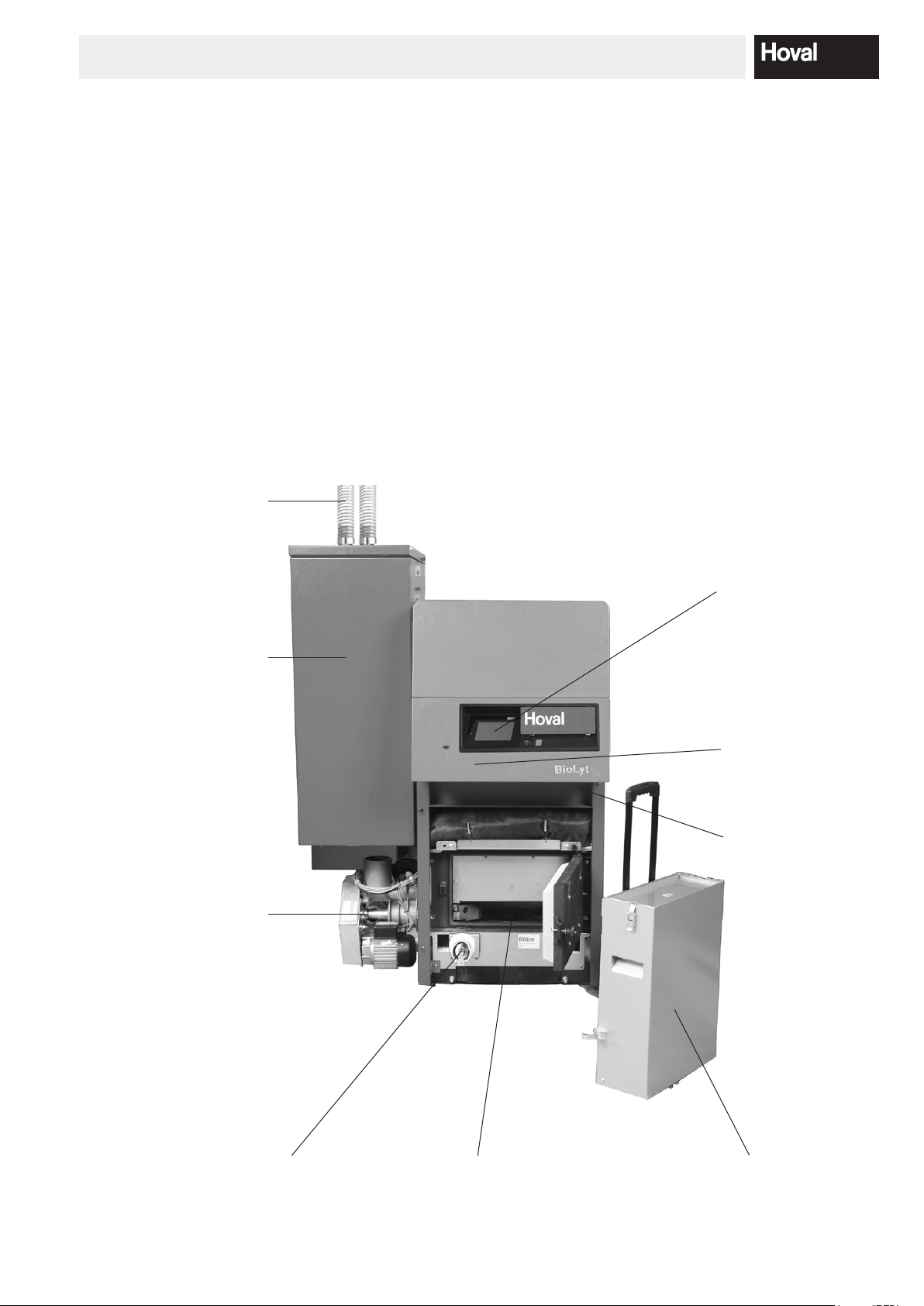

3.1 Construction of the plant

Depending on the type of heating system selected, some of the components might be different from the presentation

below. The heating specialist will explain the system to you.

4

5

6

3

5

2

7

1

The heating water heated by the boiler is supplied to the radiators or is used to heat up the hot water (calorier).

Figure Components Function / description

1

Pellet ow Burns the pellets safely and in an environmentally

friendly manner.

Extracts the heat from the gases produced during

combustion and transfers it to the heating water.

Pellets The process of combustion within the boiler con-

verts the energy contained in the pellets into heat.

2

Hot water buffer storage tank

(optional)

Is used for intermediate storage of hot heating

water (max. 80°C). It thus compensates for any

possible differences between heat generation and

demand.

94 214 153 / 00

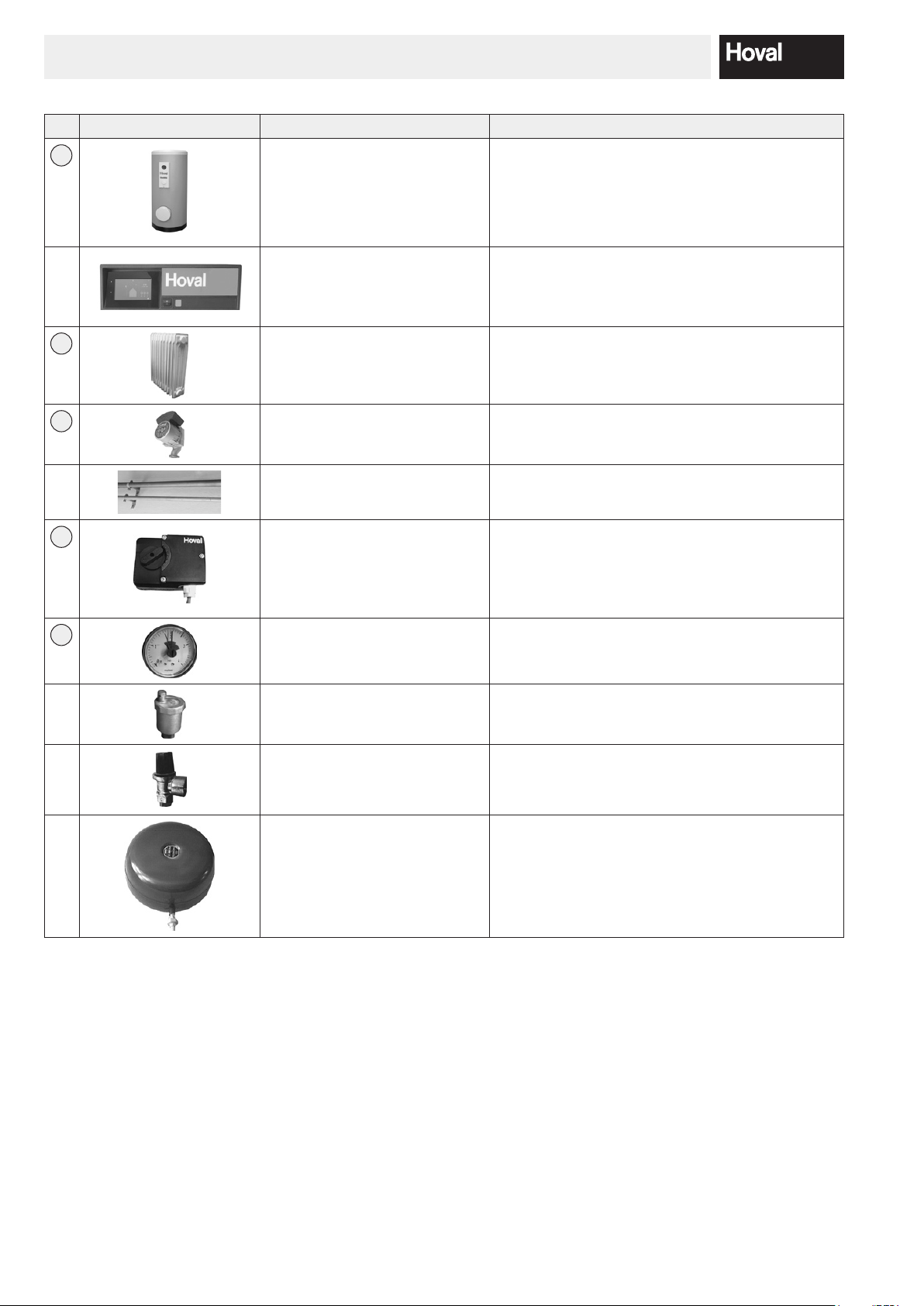

FUNCTIONAL PRINCIPLE OF THE HEATING SYSTEM

Figure Components Function / description

3

4

Calorier Holds a reserve of hot process water for house-

hold consumption (e.g. for showering).

Control panel / Control module Controls and monitors the operation of the boiler.

Maintains the desired room temperature optimal-

ly and fuel-efciently, independent of the outside

temperature.

Radiator, underoor heating Releases the heat of the heating water into the

room.

5

Heating pump Transports the heating water from the boiler to the

radiators and back into the boiler, where it is reheated.

Heating pipes Transport the heat which is generated (heating wa-

ter) from the boiler to the radiators.

6

Mixing valve Adjusts the heating ow temperature by mixing

in colder heating return water (water owing back

from the radiator) to maintain the desired room

temperature, independent of the outside temperature.

7

Pressure gauge Displays the water pressure in the heating system.

Air vent Ensures that the heating pipes contain only heat-

ing water and no air.

Safety valve Prevents overpressure in the system.

Diaphragm pressure expansion

tank

Maintains the pressure in the system at a constant

level and absorbs the expansion water.

10 4 214 153 / 00

FUNCTIONAL PRINCIPLE OF THE HEATING SYSTEM

3.2 What happens inside the BioLyt?

The BioLyt has been designed for the low-emission combustion of wood pellets in accordance with EN ISO 17225-2

and ENplus. The core element of the BioLyt is a rugged

horizontal burner tube, which provides a stable re bed

with its large, plate-shaped burner. The post-combustion

ring and dust separator above the burner plate give it a

distinct design. By combining these features, the burner

is able to keep dust emissions to a minimum. This is yet

another eco-friendly feature, since it burns with practically

no ash residues and provides for stable operation even

with variable pellet quality.

Pellet conveyor hose and return air hose for fully automated

lling of the pellet hopper

The BioLyt features a standard pellet hopper and an

optional fully-automated pellet feed system. When the

integrated pellet hopper is used exclusively, it needs to

be relled manually. When combined with the pellet feed

system, the pellet hopper is lled automatically from a

store. This feeder unit with control system and suction

turbine transports the pellets through a exible tube from

the storage room directly to the hopper. The hopper is

lled within minutes on a time-controlled and as-needed

basis, which is usually twice a day.

Large pellet hopper with integrated suction system for

problem-free operation and exible connection to a wide range of

pellet storage systems

Fully automated pellet feed

with rotary valve protects

against burn-back

TopTronic®T controller for

easy operation

Combustion regulation for

low emissions and the high-

est level of efciency

Safety temperature limiter

(STB) for automatic switch-off

at excessively high boiler temperature. Reset in the controller

box, bottom right.

Auger system for fully automated ash

discharge

Robust horizontal burner tube ensures stable operation even with variable pellet quality

Ash box mit extendible handle and

casters for simple, convenient handling

during emptying

114 214 153 / 00

FUNCTIONAL PRINCIPLE OF THE HEATING SYSTEM

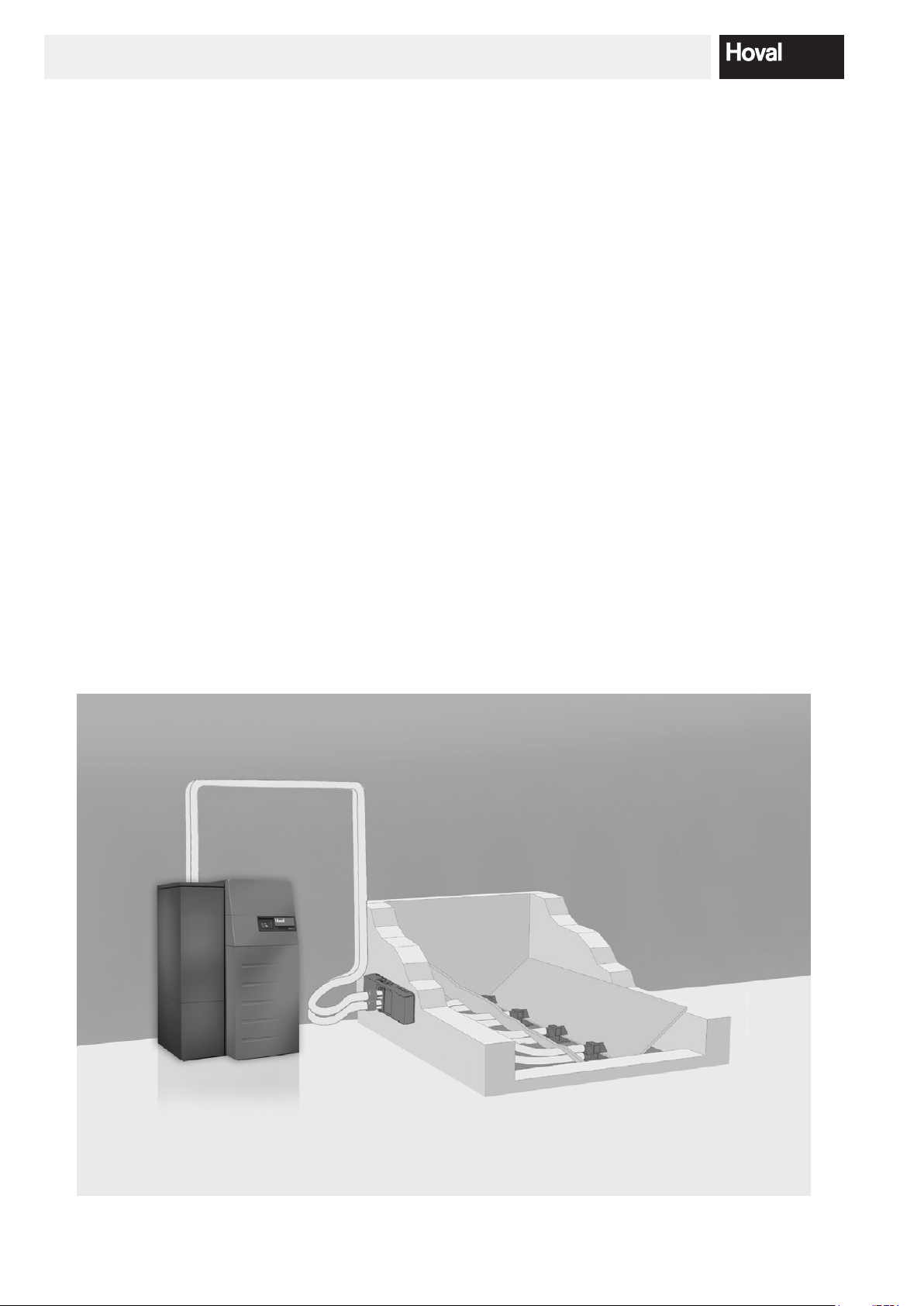

3.3 How does the automatic pellet feed (option) from the pellet storage room work?

The pellets are extracted from the pellet storage room

either directly via suction probes (Fig. 01), a mole system

or by means of a room discharge screw and then transported to the pellet hopper on the boiler by means of a

vacuum turbine.

The pellet hopper on the boiler includes two lling level

indicators:

• At the top in the pellet hopper for the "pellet hopper full"

signal

• At the bottom on the burner for the "pellet hopper emp-

ty“ signal

The pellet hopper can only be lled during the preset enable time in order to minimise the noise in the building.

The lling process is started every time the burner enters

burn-out mode or, at the latest, when the bottom lling

level indicator signals “empty.”

First, the suction turbine starts up.

Then, the mole (if tted) or the discharge screw starts

operating after a delay of approx. 15 secs.

Discharge is stopped as soon as the upper lling level

indicator sends the signal for "pellet hopper full." If a mole

or a discharge screw are tted, the suction turbine runs

on for a time in order to ush the hoses.

The Pellet transfer system can be disabled during two periods of time per day (e.g. to avoid unwelcome noise during the night). The factory settings are from 22.00 p.m. to

07.00 a.m. (see chapter 5.15 on Page 76). To ensure

that there is an adequate supply of pellets to span such

off-periods, forced burn-out with lling of the pellet hopper is carried out 30 min. before the beginning of every

off-period. Off-periods can be deactivated by setting the

beginning and end of the respective period to 00.00 (see

chapter 5.15 on Page 76)

Fig. 01

12 4 214 153 / 00

The reset button is allowed to be pressed once at most. If

failure indication lamp continues to be lit, please contact

CONTROL PANEL ON HEAT GENERATOR

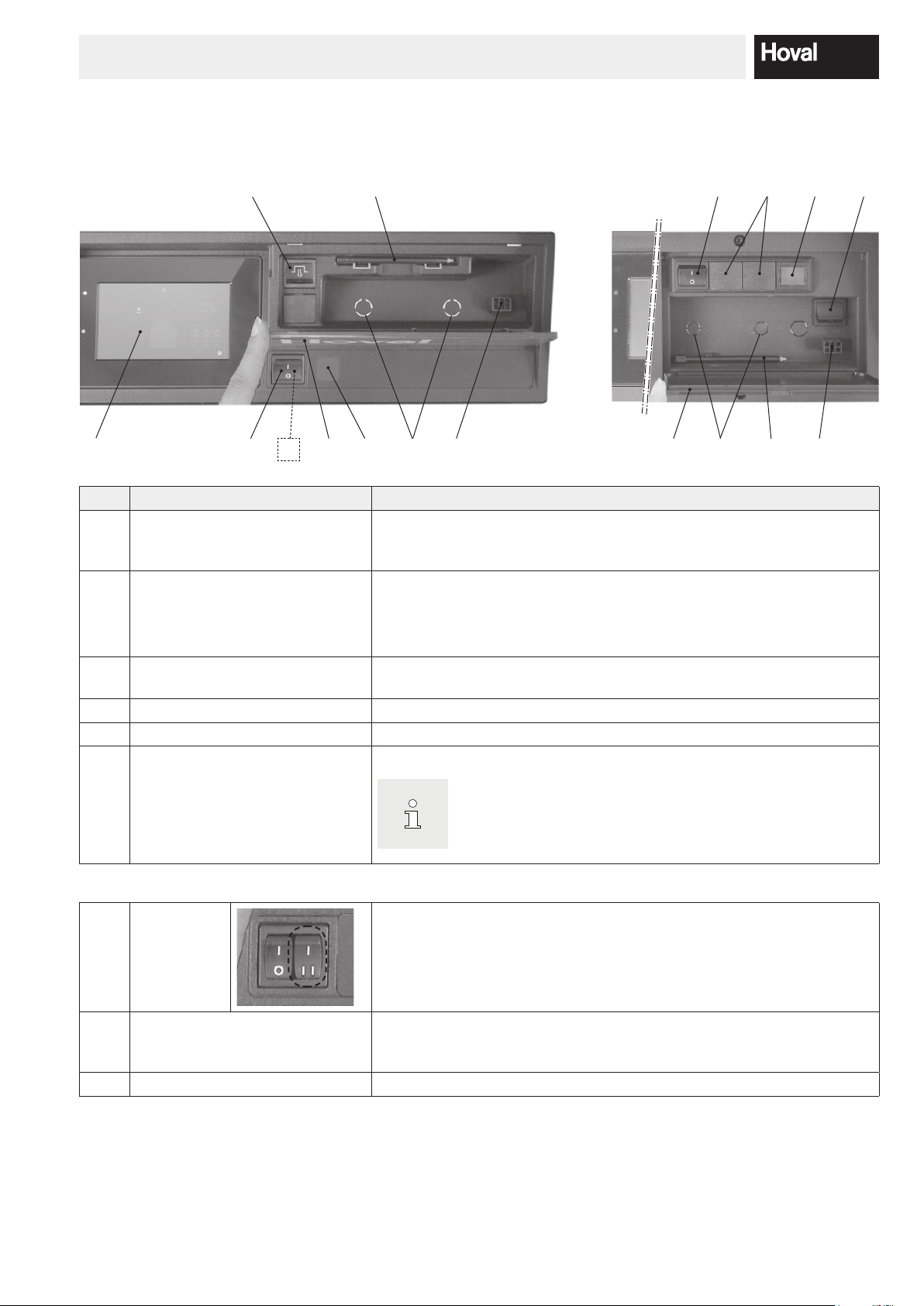

4. Control panel on heat generator

4.1 Overview of control panel

6

1 2

No. Designation Function

1 TopTronic

2 Blocking switch

®

E control module Used as operator terminal for the plant that can be operated by touching

3

7

8

5 9 98

with the nger or stylus (no. 4). For a detailed description of the elements,

see chapter 5.6.1 page 20.

1 = ON Heat generator in operation

0 = OFF Heat generator not in operation (plant live; no frost pro-

tection)

3 4

7

524

6

3 Flap To protect the folding compartment with stylus (no. 4), reset button (no. 6)

and service plug (no. 9). Safety temperature limiter optional (no. 8)

4 Stylus Stylus for operating the control module

5 Fault lamp Lights up if there is a heat generator fault.

6 Reset button Used for resetting if the failure indication lamp lights up.

the

Hoval Customer Service.

Optional:

7 Bivalent

switch

(optional)

8 Additional safety temperature

limiter

(optional)

9 Service plug Used exclusively by the service technician.

Used for switching priority in plants with several heat generators or for

other plant-specic switching functions.ww

Optional installation of an additional safety temperature limiter. Used for

interrupting the heat generator if a set temperature is exceeded.

134 214 153 / 00

HEATING SYSTEM CONTROL

NOTICE

or pointed objects for operation – risk of

E control module is in sleep

mode, it can be “woken up” by touching the

touchscreen. Sleep mode and the duration

until the mode starts can be adjusted (chapter

5. Heating system control

5.1 Function of the TopTronic® E control

5.2 Operating and display elements

The TopTronic® E control module is used for controlling

your heating system. Using the touch-sensitive screen

(referred to below as touchscreen), you can make vari-

ous settings on your system at the touch of a ngertip or

using the stylus.

The surface of the TopTronic® E control mod-

ule is not allowed to be touched with sharp

scratching.

The control module has the following functions:

• Maintaining the desired room temperature independent

of the outside temperature

• Heating the living space only when required

• Producing hot water only when required

• Displaying information about the system

Further functions:

• Making it possible to set the desired temperatures and

select a basic program (chapter 5.8 page 31)

• Turning the heat generator ON/OFF

• Monitoring temperatures

All the basic settings will have already been carried out by

Hoval, or the heating engineer, during commissioning of

the heating system. You can make further settings if you

go on a journey or if your home is too cold or too warm.

You can nd an overview of the most frequently asked

questions in chapter 5.3 page 16.

The graphical displays on the control module can be operating or display elements.

If the TopTronic

5.12.13 page 73, nos. 3 and 4).

Operating elements

Display elements

®

Operating elements are understood to be the buttons on the

control module that can be selected by touching in order to adjust

various settings. The operating

elements are shown in white on a

black background or in black on a

white background. Values that can

be changed with plus ( ) or minus

( ) can be touched directly. As

a result, a keypad appears on the

control module which helps you to

make the entry.

Display elements only provide information and cannot be selected.

They are shown in colour.

How to save energy!

For your benet and for the environment

Using energy more efciently by avoiding unnecessary

losses! With little effort, you can optimise the operation of

your heating system and save energy at the same time.

It is worth setting your personal day and week programs

You can save valuable energy and money by specically

adjusting the heating times with a personal day or week

program to take account of the times when you will be

present and absent. The TopTronic® E control makes it

very simple to set different switching cycles for individual

daily sequences (chapter 5.9 page 34).

14 4 214 153 / 00

HEATING SYSTEM CONTROL

Room temperature – coloured marking

The room temperature on the start

screen is shown in three different

colours. The colours have the following meaning:

Colour Meaning

Orange Heating

Heating operation active. The room is

heated to the desired room temperature.

Blue Cooling

Cooling operation active. The room is

cooled to the desired room temperature.

Grey Inactive

Heating/cooling operation inactive.

LED operating status

An LED indicator is additionally attached on the left of the

control module. This displays the operating status and

can light up in the following three colours:

LED indicator

Brightness sensor

Touchscreen

Colour Meaning

Green Correct operation

General information or warnings may

be displayed on the control module.

You as the customer do not need to

do anything, however! Heating operation is continued.

Orange Blocking

The heat generator has been temporarily blocked because of an error.

Contact Hoval customer service if the

blocking leads to inadvertent cooling

down of the heating system.

Red Locking

The heat generator sent a critical error and has been locked for safety

reasons. The heat generator cannot

continue to operate. Contact Hoval

customer service!

154 214 153 / 00

HEATING SYSTEM CONTROL

You can also access the function for setting

Main menu

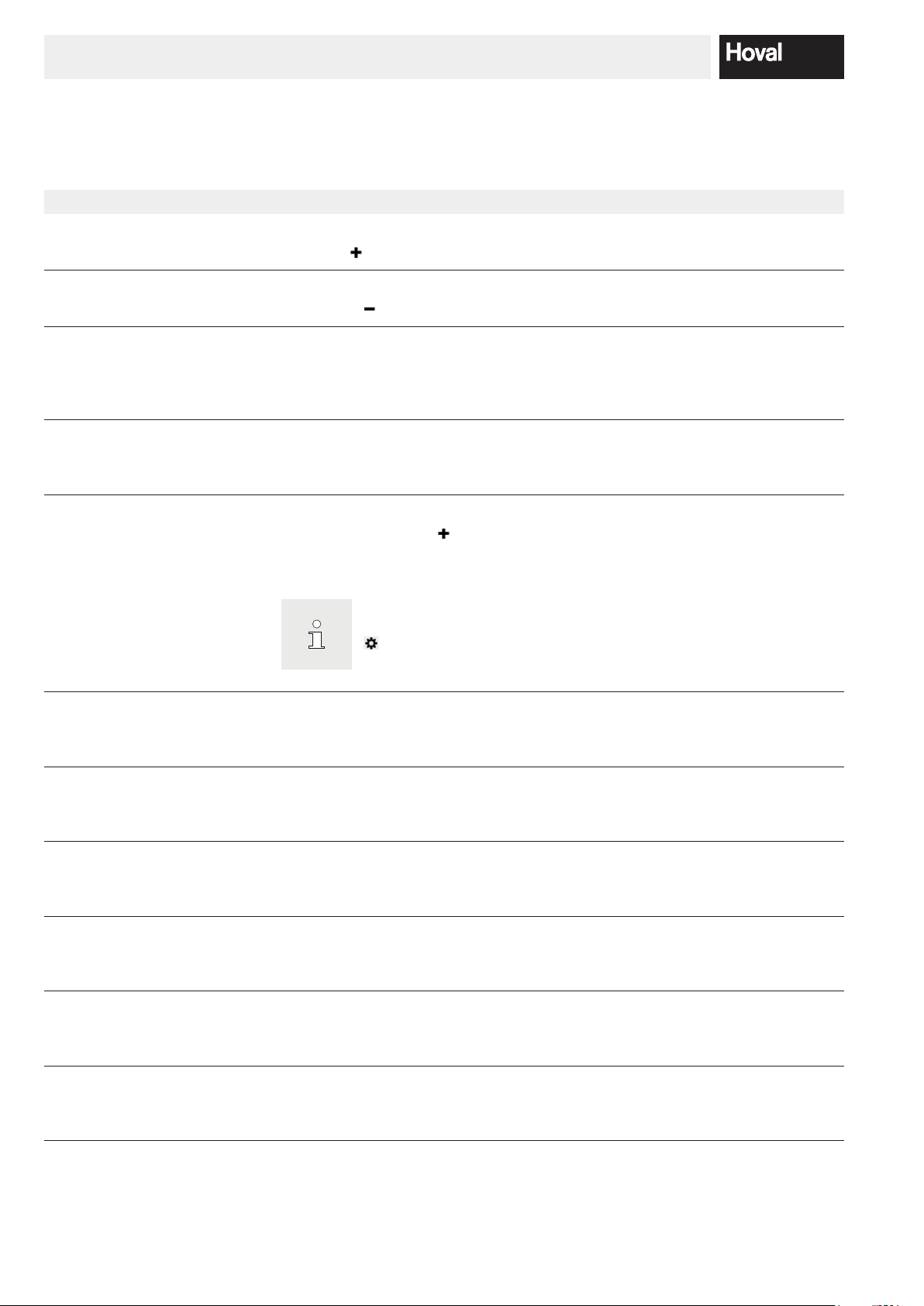

5.3 What to do if...

The following information can be used as a rst level support in frequently occurring situations.

Observation

It is too cold. Select Room temperature on the start screen and press

It is too warm. Select Room temperature on the start screen and press

From now on, equal day

and night temperatures

should be maintained continuously.

This evening, the heating should remain on for

longer.

A larger amount of hot water is required.

Remedy

the plus (

the minus (

Select Basic programs on the start screen and choose

the Constant basic program. Set the desired room

temperature.

Select Day programs on the start screen. Under “Select

day program”, set Party and enter the duration and room

temperature.

Select DHW temperature (tap icon) on the start screen

and press the plus (

temperature. If necessary, recharge domestic hot water

(“Recharging”).

) button to increase the room temperature.

) button to reduce the room temperature.

) button to increase the water

the water temperature using

( ) > Hot water.

Chapter / page

5.7.1 page 24

5.7.1 page 24

5.7.4 page 26

5.10.3 page 45

5.7.2 page 25 /

5.11.7 page 58

From now on, hot water but

no heating is required.

Suddenly, there is no heating or hot water; it is cold.

I will be absent for several

hours during the day today.

I am travelling for a certain

period of time (e.g. two

weeks).

I am going away for an in-

denite period of time.

In summer, it is too cold or

too warm.

Set Heating circ. to Standby basic program and Hot

water to the required basic program. Heating operation

OFF, hot water ON.

Check the control module for alarm messages and

consult a heating engineer, if necessary. Check if there is

still sufcient fuel/Electricity available, if necessary.

Select Day programs (e.g. all day) on the start screen.

Under “Select day program”, set another day program or

Absent (enter the duration and room temperature).

Select Basic programs on the start screen and choose

the Holiday basic program. Set the date of your return.

Select Basic programs on the start screen and choose

the Standby basic program. Change the basic program

when you return.

The basic program enables you to tell which operating

mode is active. Adapt the required basic program as

you need to.

5.7.4 page 26

Alarm messages

chapter

5.7.5 page 27 /

5.10.3 page 45

5.8.2 page 32

5.7.4 page 26

5.7.4 page 26

16 4 214 153 / 00

HEATING SYSTEM CONTROL

5.4 Efficient control of the system

You can save a lot of energy by efcient adjustment of

the heating operation. The TopTronic® E control module

provides basic programs (5.8 page 31) that help you

to control your system easily and specically when you

are present and absent over a fairly long period of time.

Basic programs Room temperature / day programs

For short-term changes to the heating times, you can use

various day programs in the Week 1 and Week 2 basic

programs (5.10 page 43). Furthermore, the living area

temperature can be increased or reduced effortlessly by

selecting the current room temperature.

See “Week programs” chapter

Heating circuit

Desired

room temperature

Active

day program

Active

day program

Switching cycle

Day program

selection

New active

basic program

Day program

“Party”

Day program

“Absent”

174 214 153 / 00

HEATING SYSTEM CONTROL

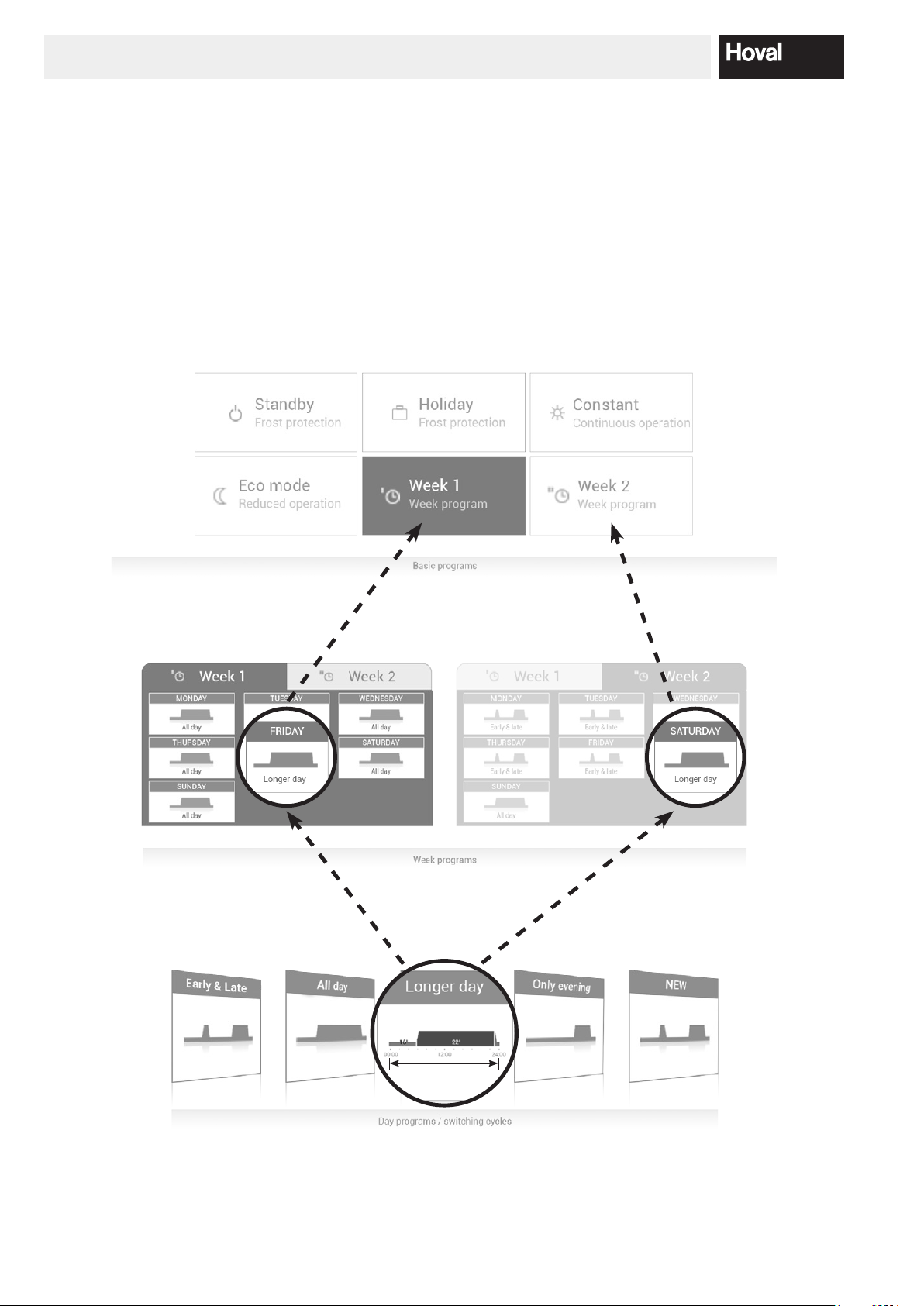

5.5 Individual day and week programs

To save you the trouble of selecting the required basic

program every day, the control module of the TopTronic®

E offers you the opportunity of using week programs. In

the two basic programs that can be selected, you can

plan your individual week sequences and assign day

programs (5.10 page 43) to adapt the heating times

to your presence and absence using switching cycles. In

the basic settings, the control module already contains

the two standard week programs, Week 1 and Week 2

(5.8 page 31). You can edit the two week programs

individually (5.9.4 page 37) and give them any name

(5.9.5 page 39).

Change

18 4 214 153 / 00

HEATING SYSTEM CONTROL

The display of the start screen is a standard view. The operating elements can be adapted by the user.

NOTICE

ule is not allowed to be touched with sharp

or pointed objects for operation – risk of

5.6 Start screen

The start screen of the control module is divided into

three vertical display elements. For a detailed list of the

various start screen functions, refer to 5.6.1 page 20.

The surface of the TopTronic® E control mod-

scratching.

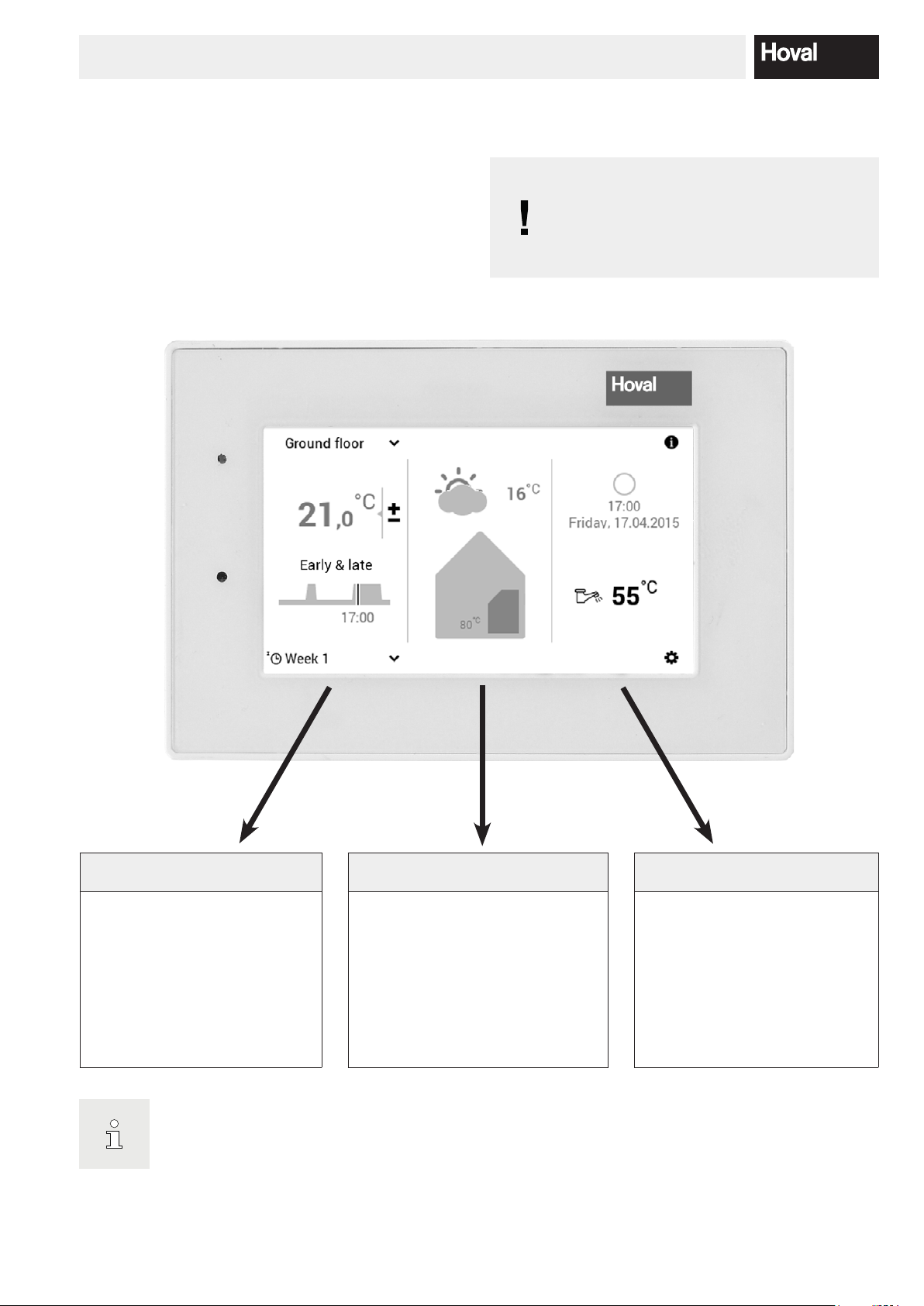

Information living area Information heat generator Information general

The left third of the start screen

contains information about the

living area. Here, you can make

settings for the heating circuit,

current room temperature, day

program and switching cycles as

well as basic program (chapter

5.4 page 17).

Please check the start screen settings in 5.13.2 page 75 if the display if different.

The middle third of the start screen

contains information about the heat

generator. This information area displays the error status, the outside

temperature as well as information

about the heating circuit. In addition,

the user level (referred to below

as authorisation level) can be displayed.

The right third of the start screen

contains general information.

Information about energy consumption, time/date as well as domestic hot water temperature. In

connection with the TopTronic® E

online, the weather forecast is displayed on the control module as

an option.

194 214 153 / 00

HEATING SYSTEM CONTROL

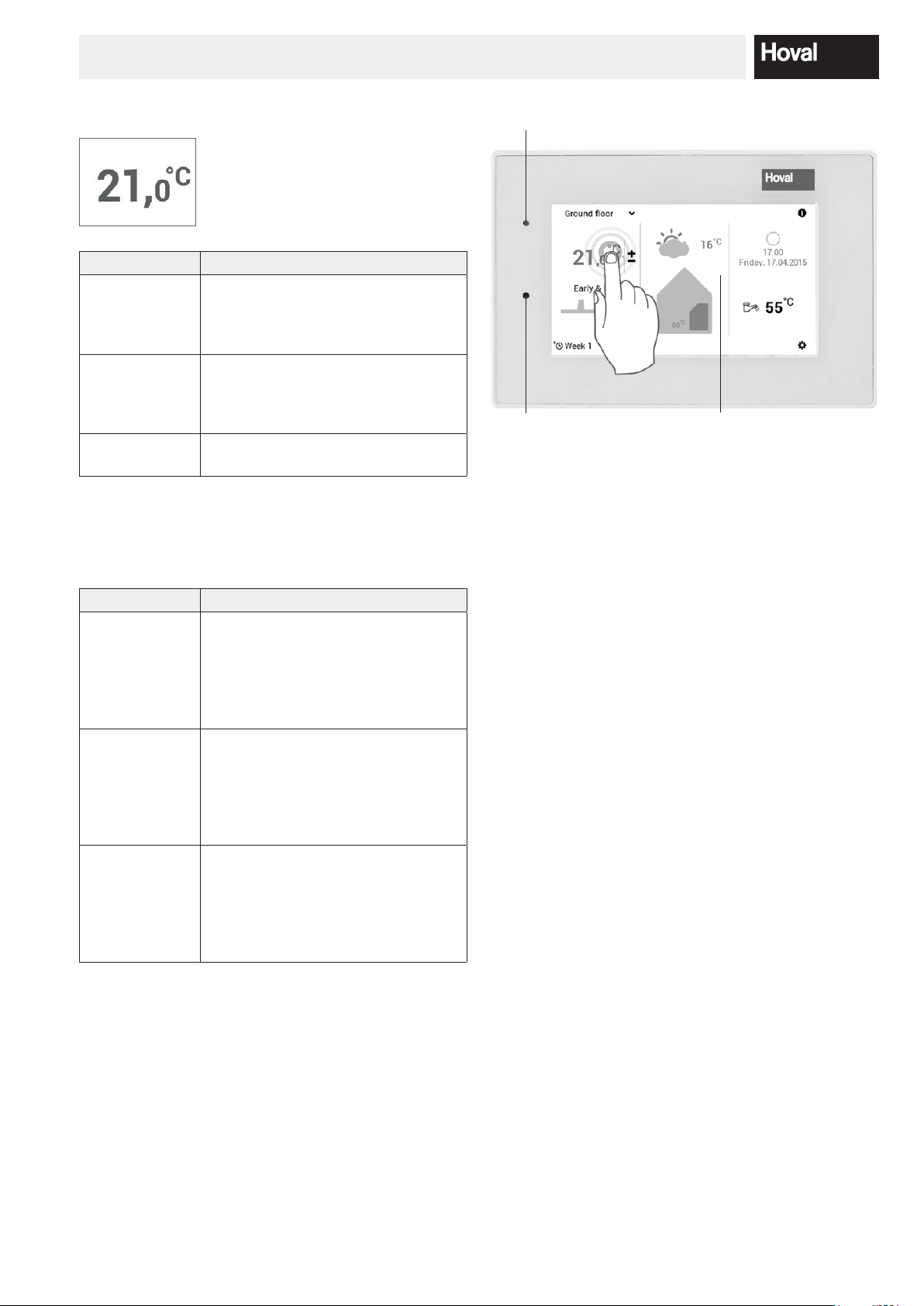

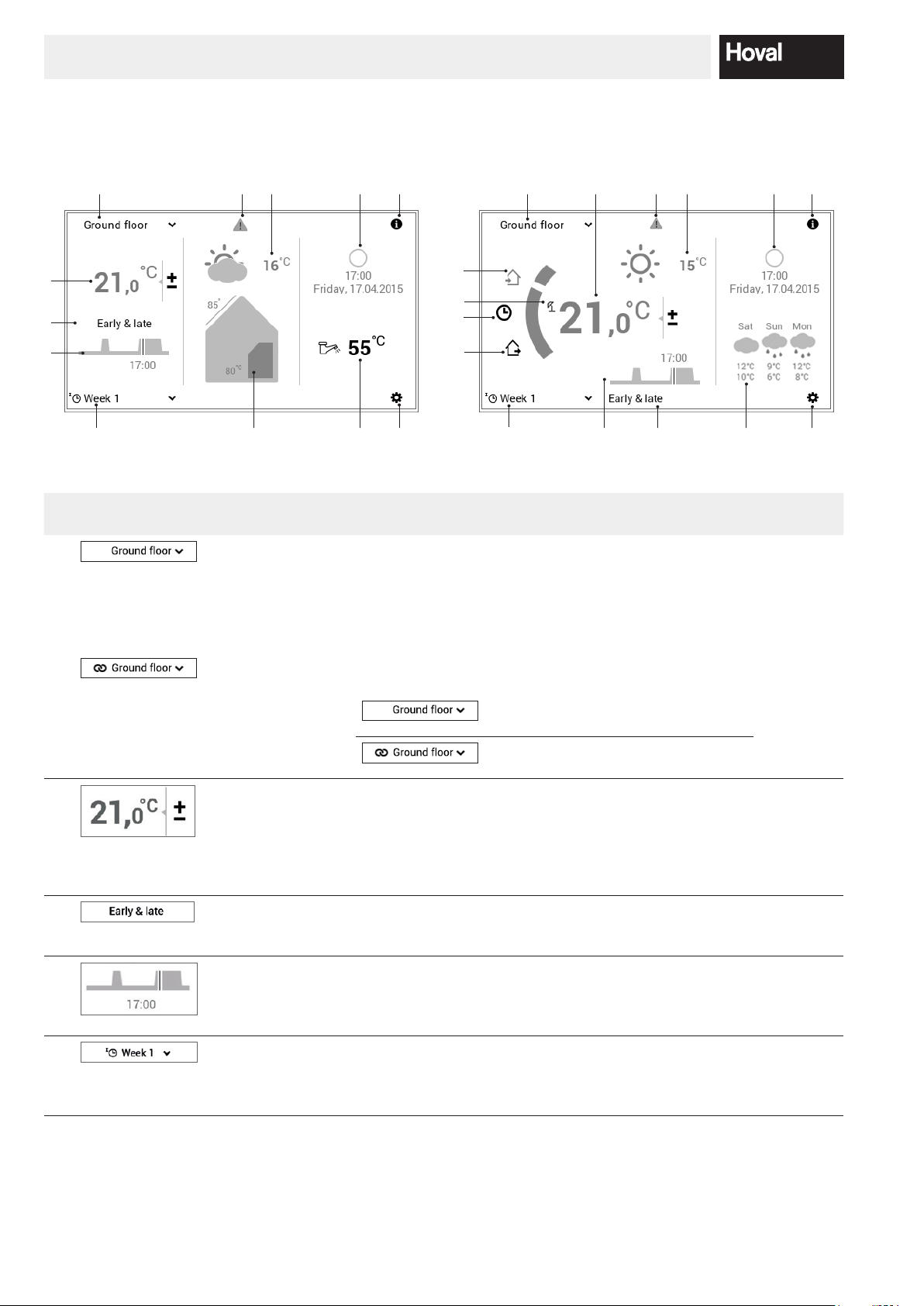

5.6.1 Elements of the start screen heat generator and living area

Heat generator Living area

7

6

1

7

2

10

9

1

13

2

6

10 9

16

3

4

5

Position / symbol Designation Function Chapter /

1

2

3

4

5

8 12

Heating circuit If a house is divided into individual heating areas, the

Operation

heating circuits

Room temperature Displaying the current room temperature – in room con-

Active

day program

Switching cycle The diagram shows the course of the day (room temper-

Basic program Assignment of the basic program for the particular situa-

11

heating circuit refers to each individually adjustable portion. Each heating circuit can have individual settings

assigned to it, such as basic program, day and week program as well as room temperature. If no name is shown,

then there is only one heating circuit.

Display of the joint or individual operation of all heating

and domestic hot water circuits.

trol modules and systems with room air sensor – in the

selected heating circuit. Adaptation of the temperature

by increasing or reducing the preset temperature (5.7.1

page 24). Display of the required room temperature in

systems without room air sensor.

Currently active day program. Only displayed if the basic programs Week 1 and Week 2 (5.8 page 31) are

selected.

ature vertical, time horizontal) of the active basic program

or the assigned day program. The vertical line represents

the current status.

tion (e.g. week programs, Constant, Holiday). The basic

program is used as the operating mode of the heating

circuit.

15

14

5 4 3 7 12

page

5.7.3 page

26

Individual operation of every individual heating circuit

Joint operation of all heating circuits

(temperature and programs identical)

5.7.1 page

24

5.7.5 page

27

5.10.5

page 48

5.7.4 page

26

20 4 214 153 / 00

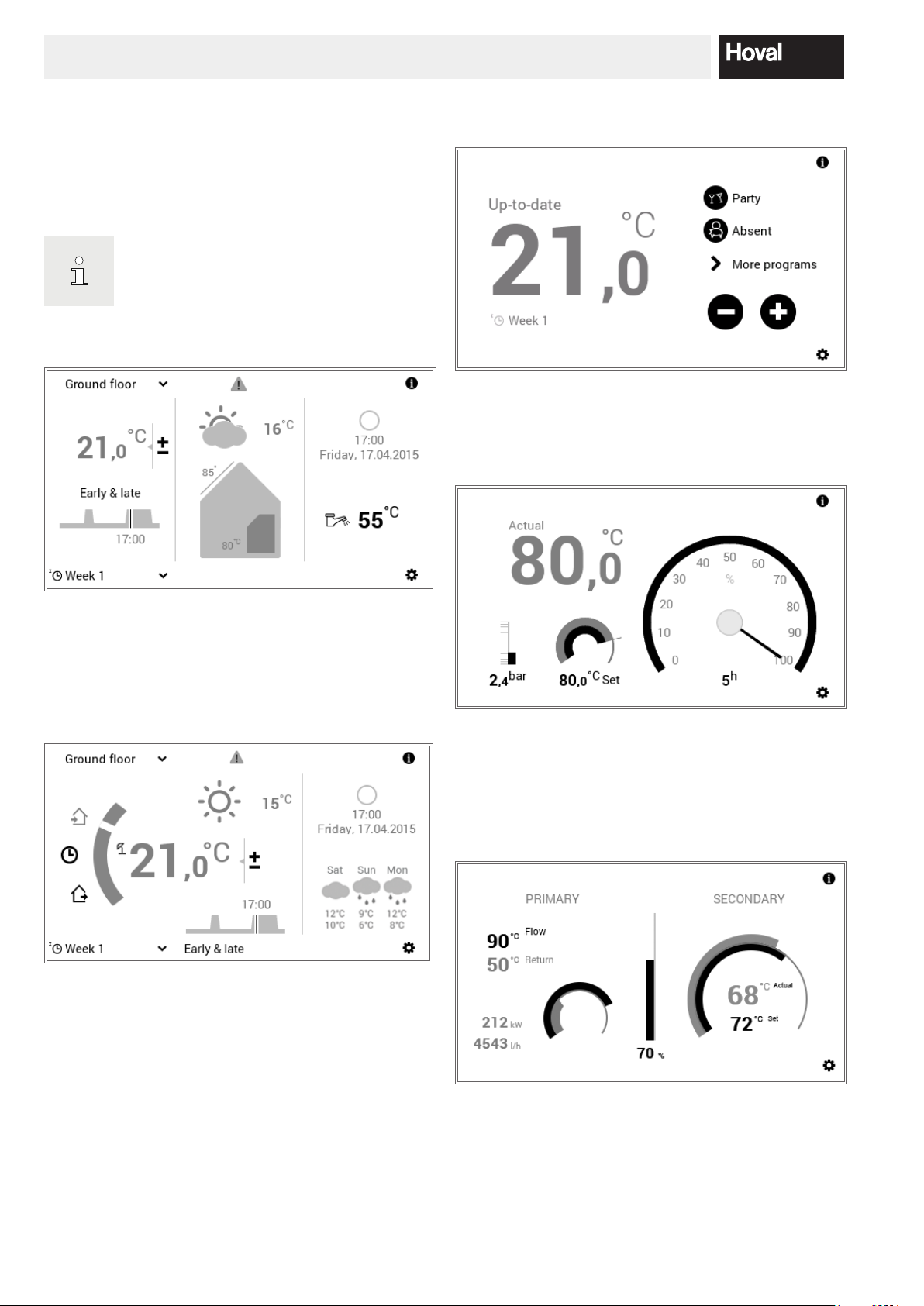

HEATING SYSTEM CONTROL

The display of the start screen is a standard view. The operating elements can be adapted by the user.

6 Operating status Currently active operating status 6.1 page

No display – correct operation

77

7

8

9

10

Alarm message

display

Outside

temperature

Information active

heat generator

Information Detailed information about the system 5.7.7 page

Phase of the

moon, time and

date

Display of the current outside temperature (only displayed if there is a outdoor temperature sensor). In addition, the phase of the moon is displayed at night.

In connection with the TopTronic® E online, the current

weather is displayed.

Displays the current temperature in the active heat generator. If a solar plant is installed, the collector temperature is also displayed. If the heat generator/solar plant

is currently active, this is indicated by an orange colour.

Display of the current time and date. In connection with

the TopTronic® E online, the current phase of the moon

is displayed.

Selection and display of alarm messages

Display authorisation level. If no level

is displayed, the control is in level 0 your operating level.

30

11

12

13

14

15

16

Hot water Shows the current domestic hot water temperature if

necessary.

Main menu This operating element accesses the main menu. 5.12.1

Day program Immediate heating starts, the day program is activated. 5.10 page

Present Immediate heating starts, the “All day” day program is

activated

Week program Back to the week program 5.7.4 page

Please check the start screen settings in 5.13.2 page 75 if the display if different.

Special symbols

= summer mode

= frost protection when pump on

= screed drying

5.11 page

54

page 61

43

5.10.3

page 45

26

214 214 153 / 00

HEATING SYSTEM CONTROL

-

ants described below can only be made by the

5.6.2 Optional start screen

The TopTronic® E control module includes ve different

displays of the start screen. Depending on the individu-

al requirement, the required start screen can be dened

during commissioning and set by the heating specialist.

A subsequent changeover to one of the vari

heating specialist.

Start screen Heat generator

Start screen Living easy (option)

Please refer to the separate operating instructions for the

room control module easy.

Start screen Industrial (option)

The heat generator screen shows detailed information

about the heat generator. In connection with the TopTronic® E online, the weather forecast and the current

phase of the moon are displayed.

Start screen Living comfort (option)

In contrast to the heat generator start screen, the “Living

comfort” start screen focuses on quickly switching over

between day programs (chapter 5.10 page 43) as well

as absence (chapter 5.10.3 page 45). The information about heat generators is shown with a smaller size.

In connection with the TopTronic® E online, the weather

forecast and the current phase of the moon can also be

displayed.

The start screen “Industrial” is usually used in large plants.

As a result, only the current heat generator temperature,

the water pressure (optional), the desired heat generator

temperature and the operating hours are displayed.

Start screen District heating (option)

The current power (%), the temperature deviation between desired and current temperature in the graph and,

optionally, the current absolute power are displayed.

22 4 214 153 / 00

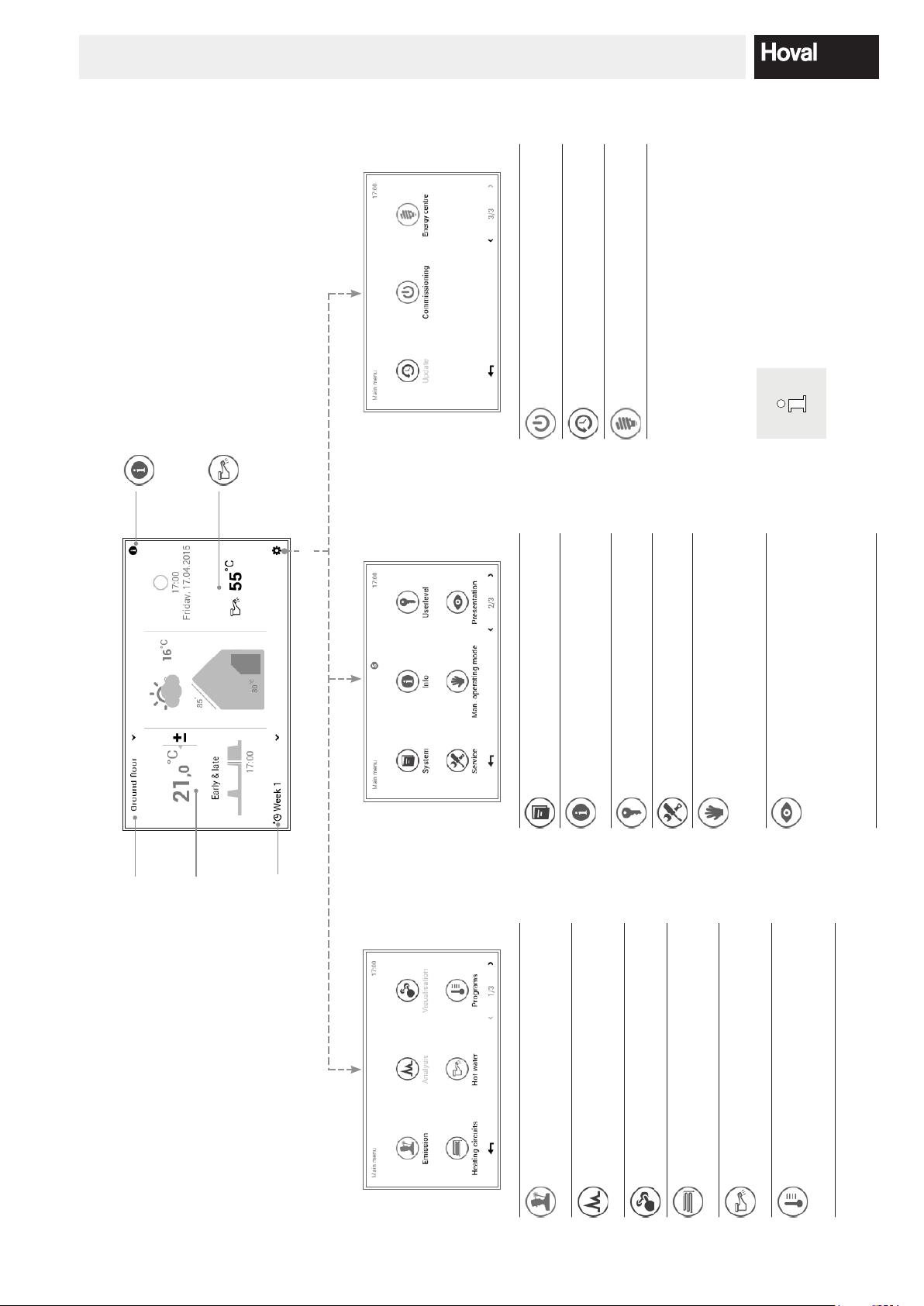

HEATING SYSTEM CONTROL

-

ble for selection, depending on

the version of your operating

ing circuit, hot water

- Information area selection

- Detailed selection heat generator, heat-

- Information area

- Desired HW temperature

- Basic program selection

- Day program selection

- Switching cycles hot water

Menu item only for heating specialist

Menu item only for heating specialist

Inuence of weather forecast on the

heating. The function is only active

with remote connection.

Commissioning

Update

Power station

Functions might not be availa

element.

Information

Hot water

Main menu

ing circuit, hot water, solar, etc.

- Information area selection

- Detailed selection heat generator, heat-

- Information area

Display of the next due maintenance/

cleaning/service

System

Info

- User level PIN entry

Menu item only for heating specialist

User level

Service

circuit

operation

- Selection heat generator/heating

- Detailed selection

- Cooling operation/OFF/heating

- Information

- Language

- Colour scheme

- Start screen

- Backlighting

- Duration until standby

Manual

mode

Presentation

- Display until standby

- Authorisation

- Conguration analysis

circuit

active heating

Room temperature/

- Selection heating circuit

- Selection joint operation

- Room temperature setting

Overview of control elements

day program

- Day program selection

- Display active switching cycles

Basic program

- Basic program selection

Page 1/3 Page 2/3 Page 3/3

- Selection heat generator

- Remaining run time

- Output limitation

- Information area

Emission

cuit, hot water

- Selection heat generator, heating cir-

- Selection duration

- Diagram display

Analysis

- For solar collector systems

- Desired room temperature

- Basic program selection

- Day program selection

- Switching cycles room temperature

- Desired HW temperature

Visualisation

Heating

circuits

Hot water

- Basic program selection

- Day program selection

hot water

- Switching cycles hot water

- Selection heating circuit/hot water

- Detailed selection heating circuit/

- Adapting week programs

- Adapting day programs

Programs

234 214 153 / 00

HEATING SYSTEM CONTROL

If there are several heating circuits, make sure that the correct

-

-

-

to store the change in the active day

5.7 Main settings

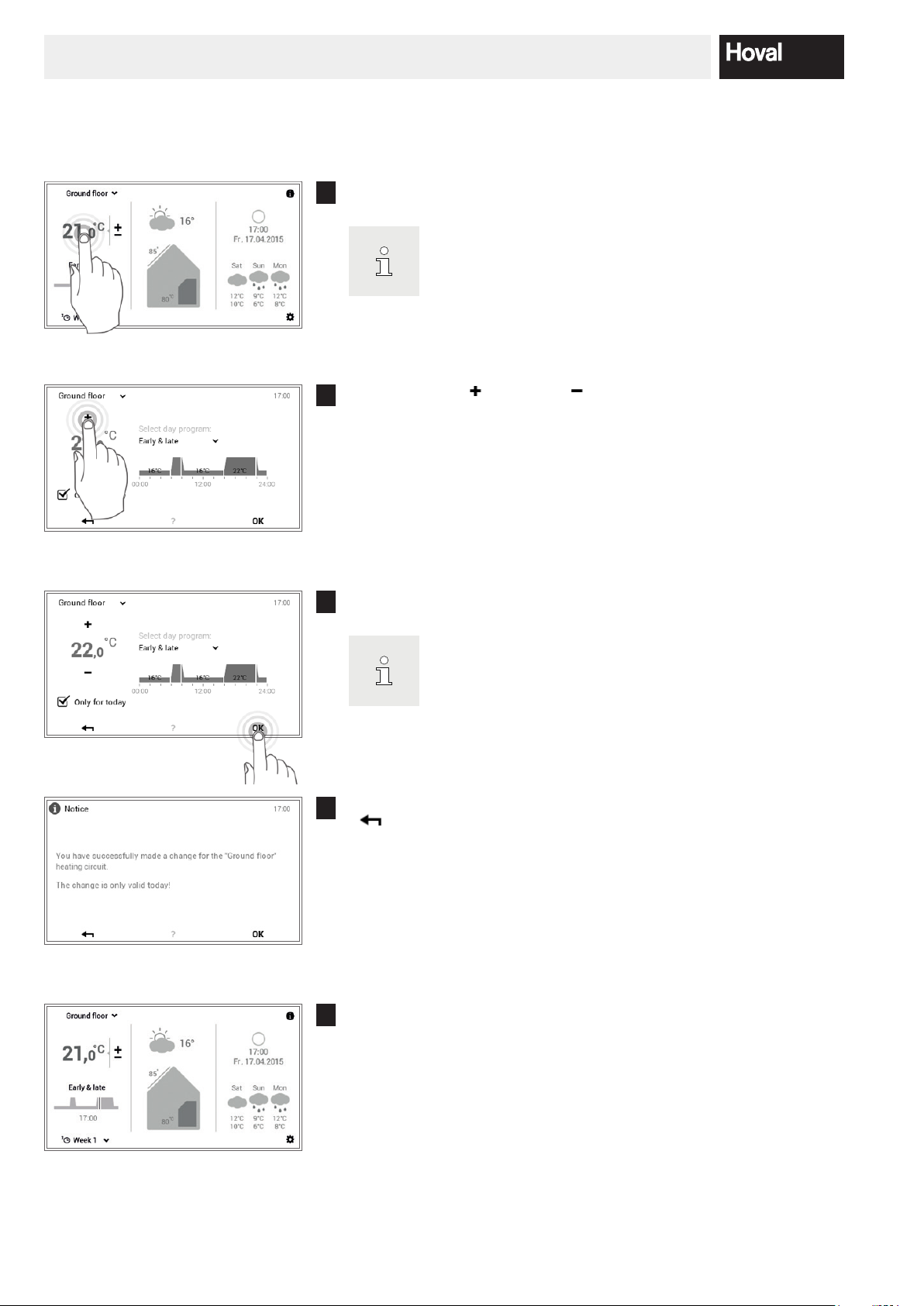

5.7.1 Changing the room temperature

Touch the displayed room temperature to select it.

1

heating circuit is displayed (example: ground oor). See “Se

lecting heating circuit” in chapter 5.7.3 page 26.

Touch the plus ( ) or minus ( ) button several times to set the re-

2

quired room temperature.

Accept the settings with OK.

3

The room temperature is only accepted in the active day pro

gram up to the end of the current cycle. Deactivate the check

box for “Only for today”

program.

A change message is displayed. Conrm this with OK. Touch the Back

4

( ) button if you want to edit the settings again.

The current room temperature is displayed on the start screen and goes

5

up or down until the desired room temperature is reached.

24 4 214 153 / 00

HEATING SYSTEM CONTROL

-

(5.12.1

When a day program is active, the hot water temperature is

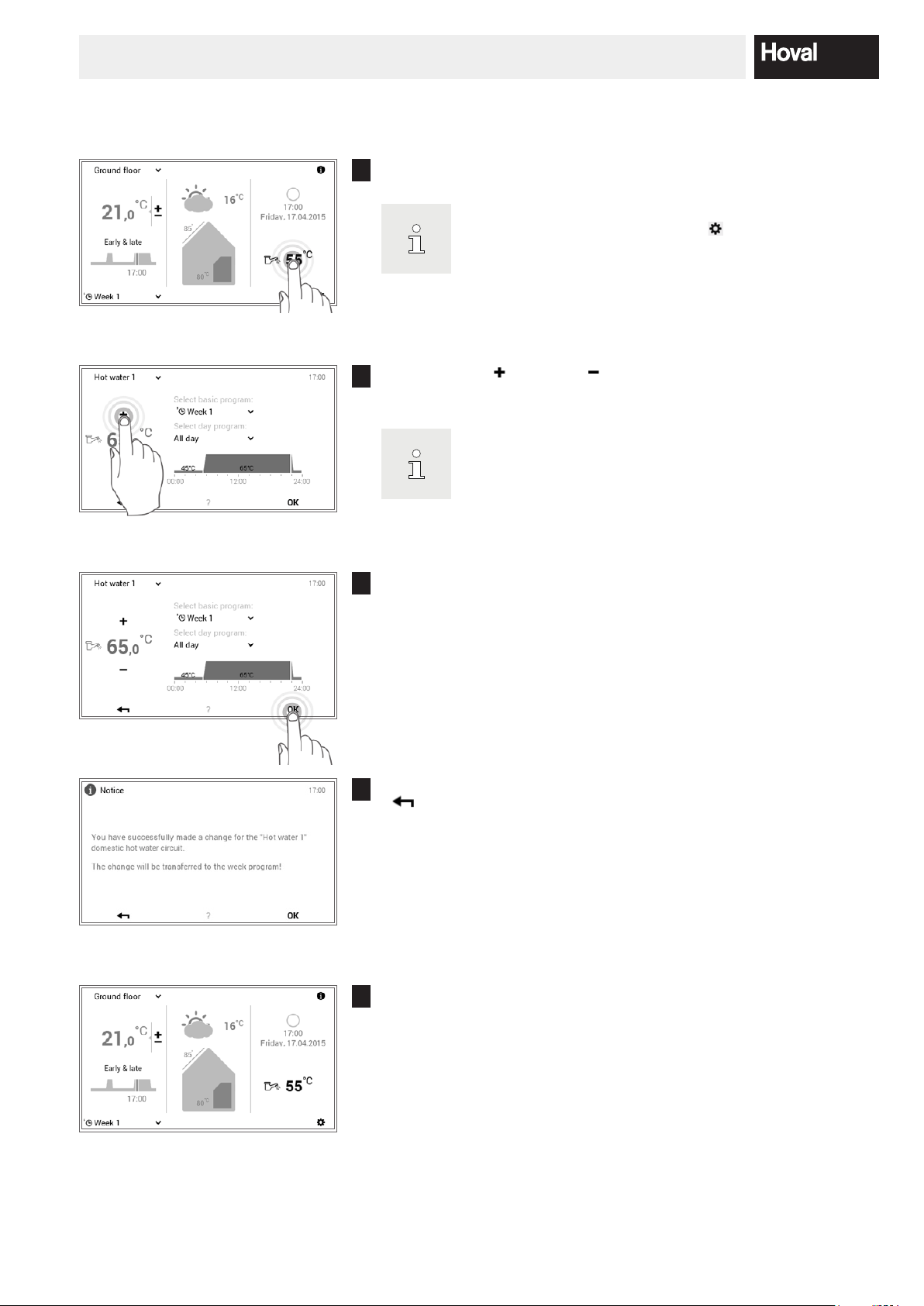

5.7.2 Adapt hot water temperature

Touch the displayed water temperature to select it.

1

You can also access the function for setting the required wa

ter temperature using Main menu ( ) > Hot water

page 61, no. 5).

Touch the plus ( ) or minus ( ) button several times to set the required

2

water temperature.

only accepted in the active switching cycle.

Accept the settings with OK.

3

A change message is displayed. Conrm this with OK. Touch the Back

4

( ) button if you want to edit the settings again.

The current hot water temperature is displayed on the start screen and

5

goes up or down until the desired water temperature is reached.

254 214 153 / 00

HEATING SYSTEM CONTROL

If your system only has one heating circuit, no heating circuit

-

checkbox (5.7.8 page 30)

allows all heating circuits to be controlled jointly. The room

temperature, the day program and the basic program are thus

-

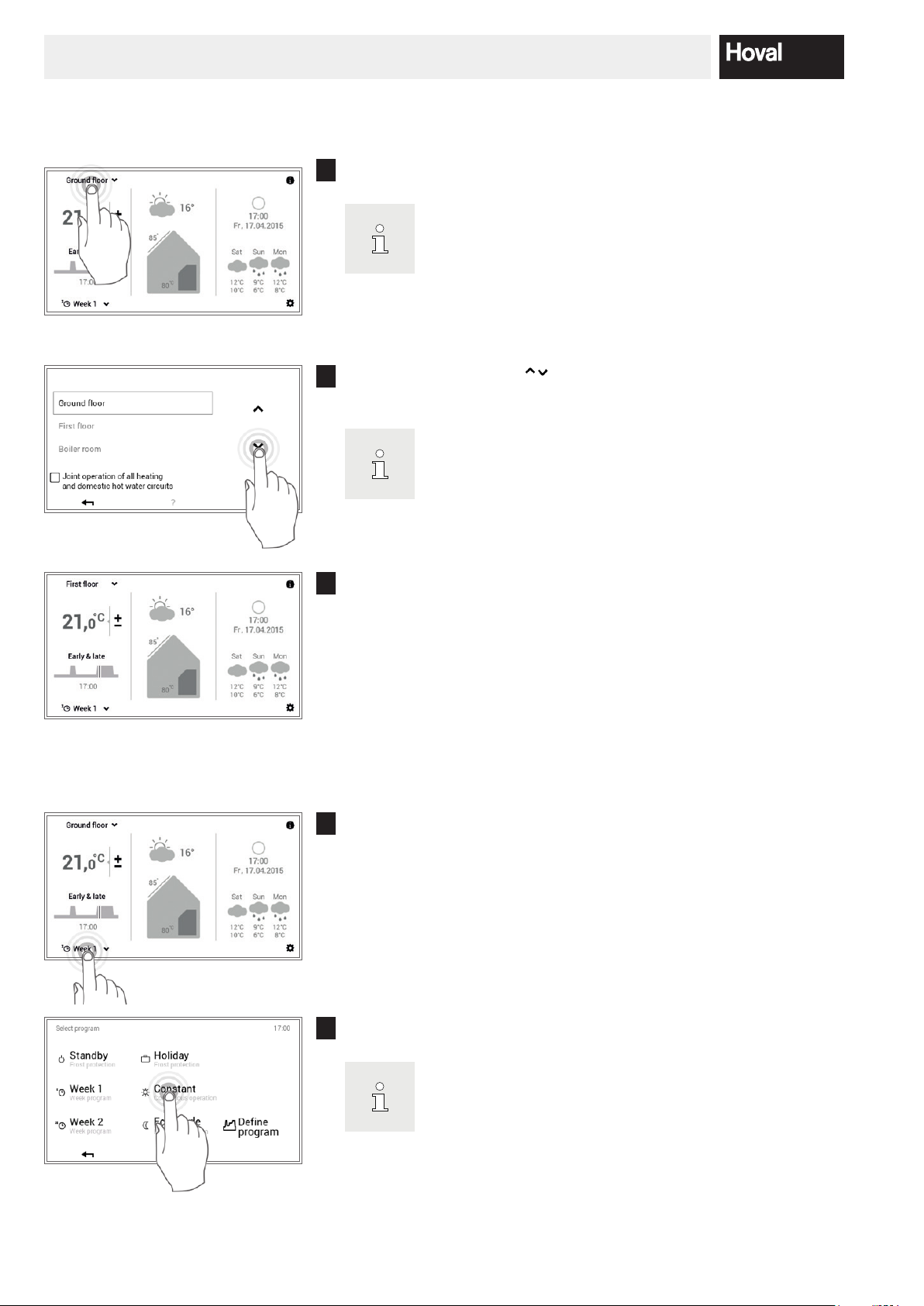

5.7.3 Select heating circuit (if there are several)

Touch the displayed heating circuit to select it (example: ground oor).

1

Use the vertical arrows ( ) to select the required heating circuit and

2

conrm with OK.

selection is displayed.

If there are several heating circuits (e.g. apartments), acti

vating the “Joint operation”

The selected heating circuit is displayed on the start screen. All settings

3

in the left area of the control module are now accepted for this heating

circuit.

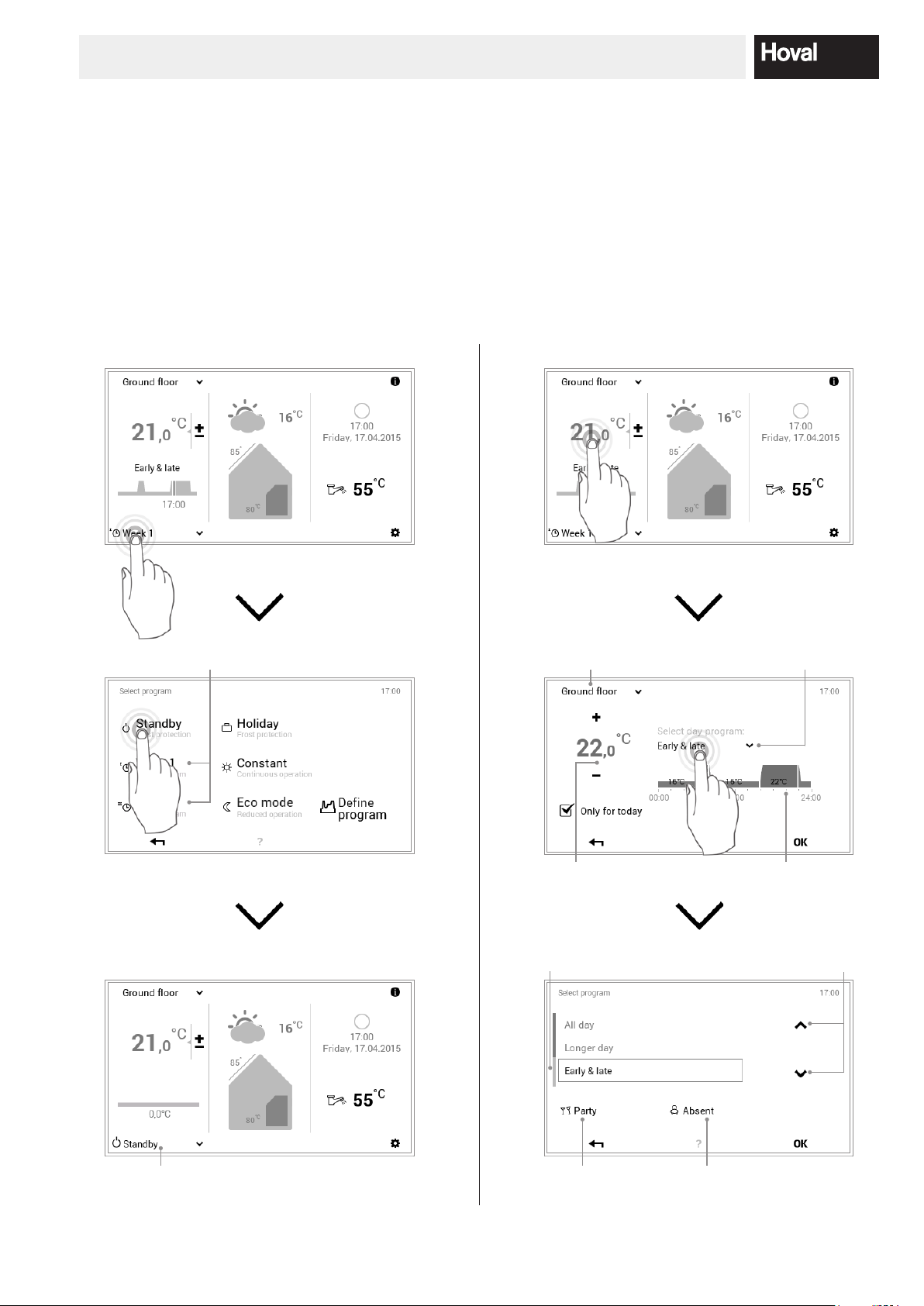

5.7.4 Change the basic program (heating circuit)

Touch the displayed basic program to select it (example: Week 1).

1

changed at the same time in all circuits.

Select the desired basic program.

2

Individual basic programs additionally require the room tem

perature or the return date to be entered (5.8.2 page 32).

26 4 214 153 / 00

HEATING SYSTEM CONTROL

-

-

to store the change in the week

A change message is displayed. Conrm this with OK.

3

The new active basic program is displayed on the start screen.

4

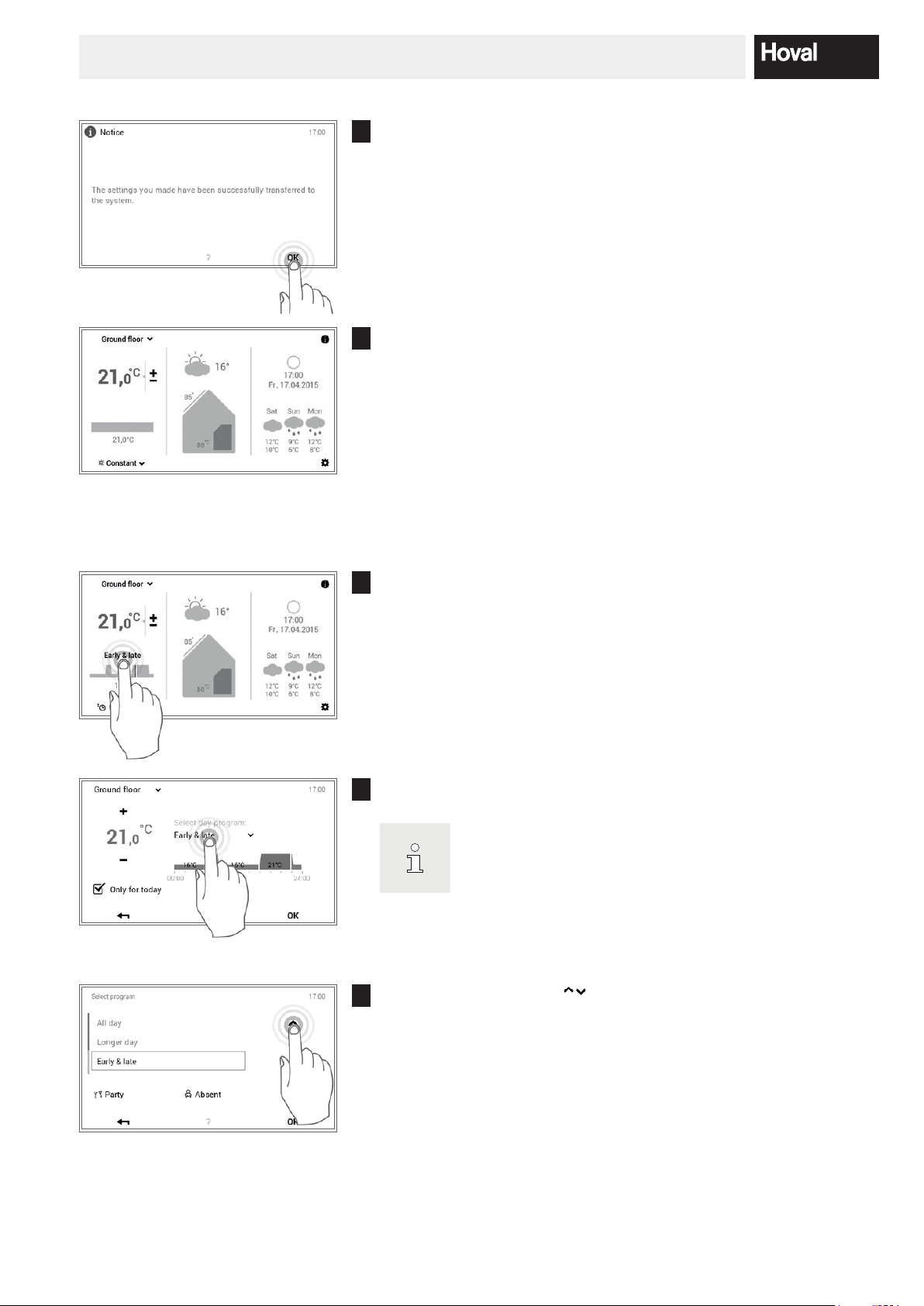

5.7.5 Change active day program (heating circuit)

Touch the displayed day program to select it (example: early & late).

1

Touch the active day program to select it.

2

The adaptation to the day program is only accepted in the ac

tive week program for the current day. Deactivate the check

box for “Only for today”

program.

Use the vertical arrows ( ) to select the required day program and

3

conrm with OK.

274 214 153 / 00

HEATING SYSTEM CONTROL

The room temperature can be adapted again after the new

-

cast is displayed on your start screen as an option. You can

-

Hot water basic and day programs are independent from the

heating circuit basic and day programs. The hot water basic

, for example, while the heating

The selected day program is now displayed with the associated switch-

4

ing cycles as well as the room temperature.

desired day program has been selected.

A change message is displayed. Conrm this with OK. Touch the Back

5

( ) button if you want to edit the settings again.

The new selected day program is displayed on the start screen.

6

5.7.6 Change basic and day program (hot water)

Touch the displayed hot water temperature to select it.

1

In connection with the TopTronic® E online, the weather fore

also access the function for adapting the required water tem

perature using Main menu > Hot water (5.12.1 page 61).

Touch the hot water basic program or hot water day program to select

2

it.

program can be set to Week 1

operation is heating with the Constant setting.

28 4 214 153 / 00

HEATING SYSTEM CONTROL

Select basic program:

3

Select the desired hot water basic program.

Select day program:

Use the vertical arrows ( ) to select the required hot water day pro-

gram and conrm with OK.

The selected basic or day program for water heating is displayed on the

4

menu. Press OK to return to the start screen.

A change message is displayed. Conrm this with OK.

5

The current hot water temperature is displayed on the start screen and

6

goes up or down until the water temperature of the selected basic or day

program is reached.

294 214 153 / 00

HEATING SYSTEM CONTROL

) > Info (page 2) to access the

synchronisation of the hot water temperature during

5.7.7 Call up system information

Touch the Info ( ) button to select it.

1

Also use the Main menu (

overview of the system information (5.12.2 page 62, no. 2).

The Info menu item is displayed. Information for each system area can

2

be called up here. To do this, use the horizontal arrows ( ) to select the

corresponding areas. Use the Back ( ) button to exit the menu item.

The start screen appears again.

5.7.8 Joint operating mode for heating and hot water circuits

If your system has several heating circuits (e.g. apartments), the TopTronic® E control module offers the “Joint

operation of all heating and domestic hot water circuits”

function. For the same operating mode to be set for all

heating and hot water circuits, it is necessary for the

“Joint operation of all heating and domestic hot water circuits” checkbox to be activated (5.7.3 page 26, no. 2).

The room temperature, the day program and the basic

program are thus changed at the same time in all circuits.

Programs are controlled as follows in joint operation:

Temperature Synchronisation exclusively in the heating circuits

There is no

the joint operating mode.

Basic programs Synchronisation in the heating and hot water circuits

Day programs Synchronisation exclusively in the heating circuits

“Special day programs”

(Party and Absent)

30 4 214 153 / 00

Synchronisation in the heating and hot water circuits

HEATING SYSTEM CONTROL

E automatically switches to

-

atures rise, thus saving energy. This function

-

5.8 Basic programs

Basic programs are referred to as the operating modes

of the TopTronic® E control and, in contrast to the day

programs (5.10 page 43), they are usually selected for

a lengthy period of time. You can thus achieve targeted

energy savings by deliberately selecting the right basic

program.

The basic programs Week 1 and Week 2 are available

for recurrent weekly rhythms. Here, you can plan your

individual week(s) by allocating day programs (5.10 page

43) and regulate the heating operation specically. In

addition, for example, you can activate the Standby basic program if you will be absent for a relatively long period of time. The heating system consequently switches

OFF and frost protection is activated. An overview of the

functions of the basic programs is presented below.

The TopTronic

®

summer disconnection as the outside temper

requires an outdoor sensor, however.

Refer to 5.7.4 page 26 for a detailed de

scription of selecting basic programs.

5.8.1 Functions of the various basic programs

Basic program Possible occasion and functions

Week 1

Day programs

Week 2

Day programs

You go to work during the day from Monday to Friday, and are at home on

Saturday and Sunday.

• Heating operation dened by individual day programs

• Hot water operation active in a separate basic program

• In the standard program mornings and evenings heating operation at 22 °C,

during the day and at night reduced heating operation (16 °C). On Saturdays

and Sundays, heating operation during the day at 22 °C and at night reduced

heating operation (16 °C).

• Mo – Fr = early & late / Sa and Su = all day

• For more information about “Week 1”, see chapter 5.9 page 34

You are at home all day, every day of the week.

• Heating operation dened by individual day programs

• Hot water operation active in a separate basic program

• In the standard program during the day continuous heating operation at 22 °C,

at night reduced heating operation (16 °C). On Saturdays and Sundays, heating operation during the day at 22 °C and at night reduced heating operation

(16 °C).

• Mo – Su = heating “all day”

• For more information about “Week 2”, see chapter 5.9 page 34

Eco mode

Reduced operation

You feel comfortable with a slightly lower temperature and you would like to

save energy.

• Continuously reduced 24 h operation

• Constant room temperature - optional

• Hot water operation active in a separate basic program

314 214 153 / 00

HEATING SYSTEM CONTROL

If joint operating mode is not active, the “Standby” basic program only

Constant

Continuous operation

Holiday

Frost protection

Standby

Frost protection

You would like to heat the rooms during the night, too.

• Room temperature is not reduced during the night

• Constant room temperature - optional

• Hot water operation active in a separate basic program

You are going on holiday for e.g. 1 week and you know the date of your return.

• Heating system OFF

• No hot water operation

• Frost protection activated

You are travelling for an indenite period of time in spring or in autumn. It does

not matter if the rooms are cold on your return. You do not need warm water

on your return.

• Heating system OFF

• Frost protection active

• No hot water operation

acts on the selected heating circuit!

5.8.2 “Holiday” – enter return date

Switching to the Holiday basic program additionally requires the return date to be entered for automatic resumption of heating operation. On the entered return date

Touch the displayed basic program to select it (example: Week 1).

1

Select the Holiday basic program.

2

(0:00 hours), the system switches back to the previously

active basic program.

32 4 214 153 / 00

HEATING SYSTEM CONTROL

-

Touch the plus ( ) button several times or select the current date to

3

select the required return date (end). Accept the settings with OK.

Start: the system is switched OFF at 0:00 hours (frost protec

tion activated).

A change message is displayed. Conrm this with OK.

7

The newly selected basic program is displayed on the start screen.

8

334 214 153 / 00

HEATING SYSTEM CONTROL

-

reset

-

-

5.9 Week programs

The Week 1 and Week 2 operating modes integrated in

the basic programs are referred to as week programs.

These enable you to plan your individual weekly rhythm

(example: working week, early shift, late shift, etc.). To

make the selection easier for you, it is possible to edit

the names of the week program individually. In this case,

each day of the week keeps its own day program with integrated switching cycles (5.10 page 43). You can also

adapt these to your personal requirements and assign

them to the week program.

5.9.1 Week program default settings

Refer to 5.9.4 page 37 for a detailed de

scription of editing the week programs.

The predened week programs (Week 1 and Week 2) are

used as default settings and can be activated using the

Resetting the week programs does not

the day programs they include!

Week 1 and Week 2 basic programs as operating mode.

They can be edited individually (5.9.4 page 37) and renamed (5.9.5 page 39). Changed week programs can

be reset to the default settings (see below) (5.9.6 page

41).

Week program default settings:

Week 1

Monday Tuesday Wednesday Thursday Friday Saturday Sunday

All day All day All day All day All day All day All day

Week 2

Monday Tuesday Wednesday Thursday Friday Saturday Sunday

Early & late Early & late Early & late Early & late Early & late All day All day

Attention: Each heating circuit has two week programs. These can be composed of ve different day pro

grams (5.10 page 43). These day programs only apply in the particular heating circuit and are independ

ent from the programs in other circuits!

34 4 214 153 / 00

HEATING SYSTEM CONTROL

-

cuits, please make a copy of the empty tables.

5.9.2 Notes on personal week programs

For a clear display of the week programs that you have

For heating systems with several heating cir

created, you will nd two empty tables below in which you

can record the day programs that you have stored.

Week program 1: __________________________

Monday Tuesday Wednesday Thursday Friday Saturday Sunday

Day program: Day program: Day program: Day program: Day program: Day program: Day program:

Week program 2: __________________________

Monday Tuesday Wednesday Thursday Friday Saturday Sunday

Day program: Day program: Day program: Day program: Day program: Day program: Day program:

354 214 153 / 00

HEATING SYSTEM CONTROL

The illustrated screen is the standard view.

-

5.9.3 Week program operating elements

1

4

2

3

5

6

10

No. Designation Function

1 Week program 1 Heating program with individual week cycle 1

2 Week program 2 Heating program with individual week cycle 2

3 Active week program

in heating circuit

4 For editing active

week program

5 Dened week cycle Day programs assigned to the week days. The seven assigned day programs

6 Rename Individual renaming of the selected week program (5.9.5 page 39)

7 Reset Reset the selected week program to the default settings (5.9.6 page 41)

8 Adapt Assignment of the day programs to the individual days of the week (5.9.4 page

9 OK Save (

10 Back Return (

11 Help Summarised information about the screen area shown above

Displays the active week program in the heating circuit. The message is not

displayed if neither of the two week programs is operating.

Marks the week program selected for editing (rename / reset / adapt).

thus make up the week cycle or the week program.

37)

) the changes in the selected week program and return to the pre-

vious screen

) to the previous screen. Changes made are not accepted/stored.

11

7

9

8

Various elements can be renamed and adapt

ed by the user in the menu.

36 4 214 153 / 00

HEATING SYSTEM CONTROL

“Adapt week program” is also possible using Basic program

The names of the week programs (Week 1 and Week 2) may

5.9.4 Adapt week program

Touch the Main menu ( ) button to select it.

1