Hoval AgroLyt 20, AgroLyt 50 Operating Instructions Manual

Hoval LTD

Northgate

Newark

Nottinghamshire NG24 1JN

Phone: 01636 672 711

Fax: 01636 673 532

Hoval Export

Austrasse 70

9490 Vaduz

Principality of Liechtenstein

Phone: +423 399 2400

Fax: +423 399 2618

Export@hoval.com

ENG

Wood burning boiler

AgroLyt® (20-50)

Operating instructions

Subject to modifications 4 205 193 / 00 - 06/06

Overview of contents

Information about your heating system ............................................................ 3

Important notes ...................................................................................................

4

Function ............................................................................................................ 5-7

Heating system control ..................................................................................8-19

- N5.1 controller ............................................................................................................................... 10-13

- N5.2 TopTronic® lambda controller .............................................................................................. 14-19

Start-up (heat-up phase) ................................................................................... 20

Reloading (wood refilling) ................................................................................

21

Suitable and permitted fuels ............................................................................

22

Cleaning the heating boiler .........................................................................23-24

Maintenance and checks / Shutdown ..............................................................

25

Check list in case of faults ...............................................................................

26

Error message checklist for TopTronic

®

lambda controller ......................27-28

How you can save energy .................................................................................

29

Brief operating instructions ............................................................................. 31

2

4 205 193 / 00

Information about your heating system

AgroLyt® wood burning boiler

To be completed by the heating engineer:

Serial No.: __________________

Order No.: __________________

Boiler type: _____________________________

Boiler power rating: __________________ kW

Domestic hot water storage tank size:_________

Water heater size: ________________________

Heating controller type: ____________________

Heating pump type: _______________________

Mixing valves type: _______________________

Calculation basis for heating system

Lowest outdoor temperature: _____________ °C

Thermal output required: ________________ kW

Max. flow temperature: _________________ °C

Dear Heating System Owner,

With the purchase of this Hoval AgroLyt® wood burning

boiler, you have made an excellent choice. This boiler

- in conjunction with a domestic hot water storage

tank - offers you all the advantages of a modern and

efficient heating system.

Please read these instructions carefully. They describe

how the heating boiler works, how it is operated and

maintained.

Further information can be obtained from our Sales

and Service Centres (see last page for contact de

-

tails).

Important addresses and telephone

numbers

Heating installer ____________________

____________________

Plumbing installer ____________________

____________________

Electrical installer ____________________

____________________

Chimney sweep ____________________

__________________

__

INTENDED USE

The AgroLyt

®

wood burning boilers were designed for firing air-dried naturally seasoned

logs in the most optimal manner. The boiler may

not be used for burning waste, coated wood and

saw dust. It is also not intended to be utilised

for direct heating of the boiler room.

3

4 205 193 / 00

= Safety information:

(Information on personal protection)

• Keep open the air supply into the

room:

air supply and exhaust openings

may not be closed. This is important

to ensure that the combustion air

required for the correct operation of

the heating boiler can flow unhindered and to protect the operating

personnel from an oxygen depleted

atmosphere.

• Never operate the boiler with open

doors. Any sparks emitted from the

boiler could cause a fire and damage

the boiler.

• While the boiler is in operation, the

doors may only be opened during

start-up and for refilling purposes.

This should be done very slowly and

carefully. Sparks and tongues of flame

can emerge through the door.

• In case of power failure:

Do not open any door and do not refill

with wood.

• Daily and monthly cleaning of the sys

tem is necessary and must be carried

out; otherwise any possible warranty

claims may be rejected.

• If you have any doubts on the operation

of the boiler, call the heating engineer

or the Hoval customer service.

• Parents must keep their children away

from the boiler room (the heating sys

-

tem is not a toy).

• Do not burn unsuitable fuels (see page

22), otherwise any possible warranty

claims may be rejected.

• Do not make any modifications to the

system (possible danger to persons;

warranty claims may be rejected).

= Warning information:

(Information on the protection of the heating

system)

Controlling the water level

Control the water level in the system at regular inter

-

vals (page 25).

Flue gas temperature

If the flue gas temperature exceeds 230 ºC for a longer

period of time, it will be necessary to clean the boiler

or change the primary air setting (see page 12).

Circulation pumps

During the time periods when no heating is required,

the circulation pumps should be operated at least once

every month for approx. 2 minutes. This will effectively

prevent the pumps from getting stuck.

Gas tightness

Check the doors for gas tightness every month. Smoke leaks should be avoided in order to prevent any

poisonous smouldering gases from escaping into the

boiler room. The door hinges have to be readjusted

in case of leakage; see technical information / installation instructions.

Cleaning

Periodic cleaning and inspection by the heating engineer or the Hoval customer service not only extend

the useful life of the wood burning boiler, but also

increase its operating safety and ensure that high

combustion efficiency is maintained.

Protection of the boiler heating surfaces

Do not use any sprays, solvents, chlorine based cleaning products, paint, glue, etc. in the proximity of the

heating boiler. These substances can cause corrosion

within the boiler and the flue gas system.

Thermal safety valve, forced draught fan, draught

damper and safety valve

Correct functioning must be checked periodically by

the heating engineer.

Important notes

4

4 205 193 / 00

Function

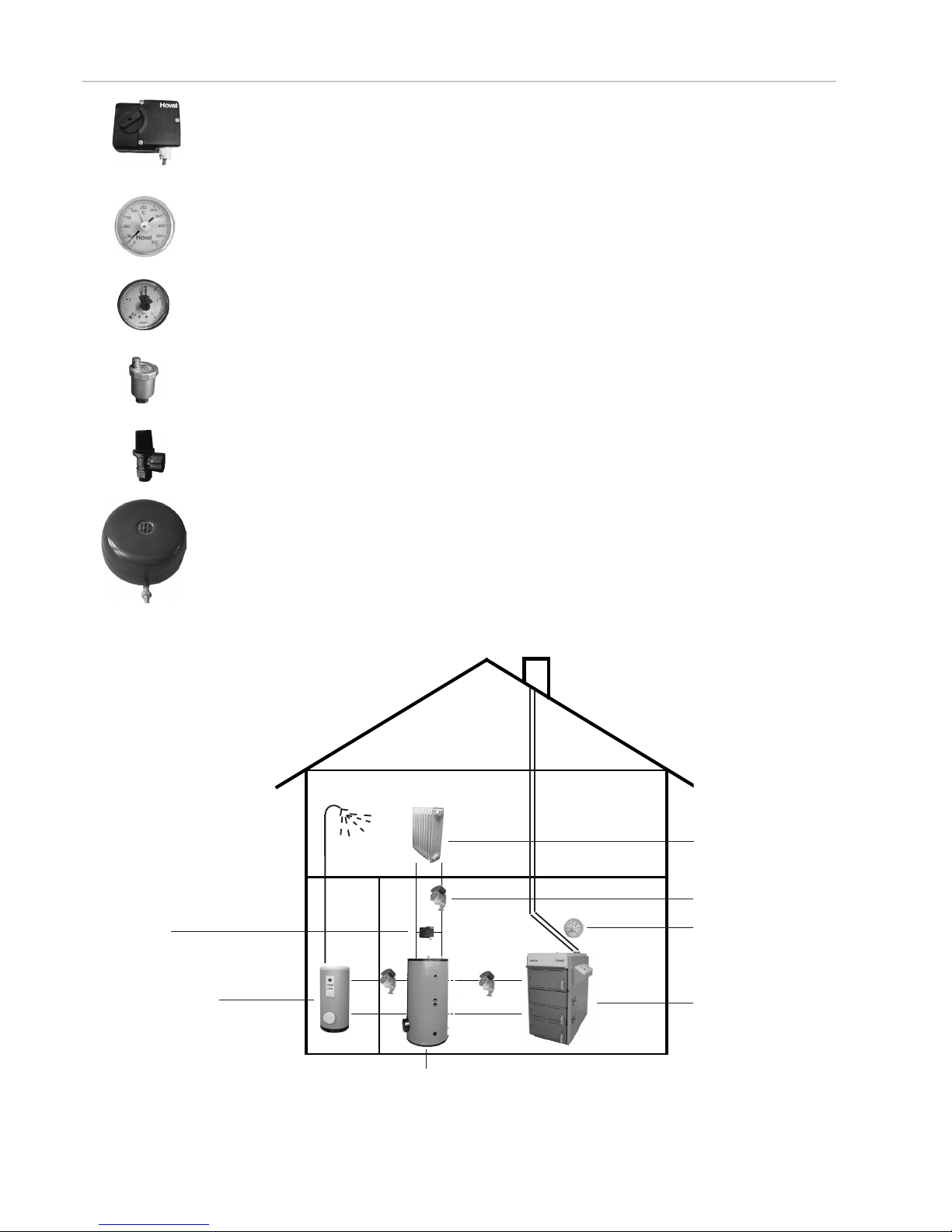

Functional description of the heating system

It is important that the perfectly coordinated individual components function properly at all times to ensure

that your home stays warm in winter.

FUNCTION:

Burns the wood safely and environmentally friendly.

Extracts the heat from the combustion gases and

transfers it to the heating water.

The wood is combusted within the heating boiler to

release and convert the natural energy contained

therein into heat.

It is used as an intermediate storage of hot heating

water (max. 90ºC). It compensates any differences

between heat generation and demand.

It holds a reserve of domestic hot water for consump

-

tion (e.g. for showering).

Controls and monitors the operation of the heating

boiler.

Adjusts the room temperature optimally and fuel effi

-

ciently, independently of the outdoor temperature.

Releases the heat of the heating water into the

room.

Transports the heating water from the heating boiler to

the radiators and back into the heating boiler, where

it is reheated.

Transport the generated heat from the heating boiler

to the radiators.

COMPONENTS

Wood burning boiler

Wood

Domestic hot water

storage tank

Storage tank water

heater

Boiler control unit

Heating controller

Radiator or underfloor

heating

Heating pump

Heating water and

heating pipes

5

4 205 193 / 00

Function

Adjusts the heating flow temperature to the radiator

to maintain the desired room temperature, independently of the outdoor temperature. This is achieved

by admixing colder return heating water.

Indicates the boiler flue gas temperature.

Displays the hydraulic pressure in the heating sys

-

tem.

Eliminates any air from within the heating pipes.

Prevents overpressure in the installation.

Maintains constant the pressure in the system and

accepts the expanding water.

Mixing valve

Flue gas thermometer

Pressure gauge

Air bleeder

Safety valve

Diaphragm expansion

tank

Water heater

Depending on the selected type of heating system, some of the components can be missing or some

might be added. The heating engineer will explain the system to you.

The heating water heated by the boiler is fed into the domestic hot water storage tank from where it is dis

-

tributed to heat the rooms (radiators) or for heating the domestic hot water (water heater).

Mixing valve

Radiator or floor

heating

Heating pump

Wood burning

boiler

Domestic hot water storage tank

Flue gas thermometer

6

4 205 193 / 00

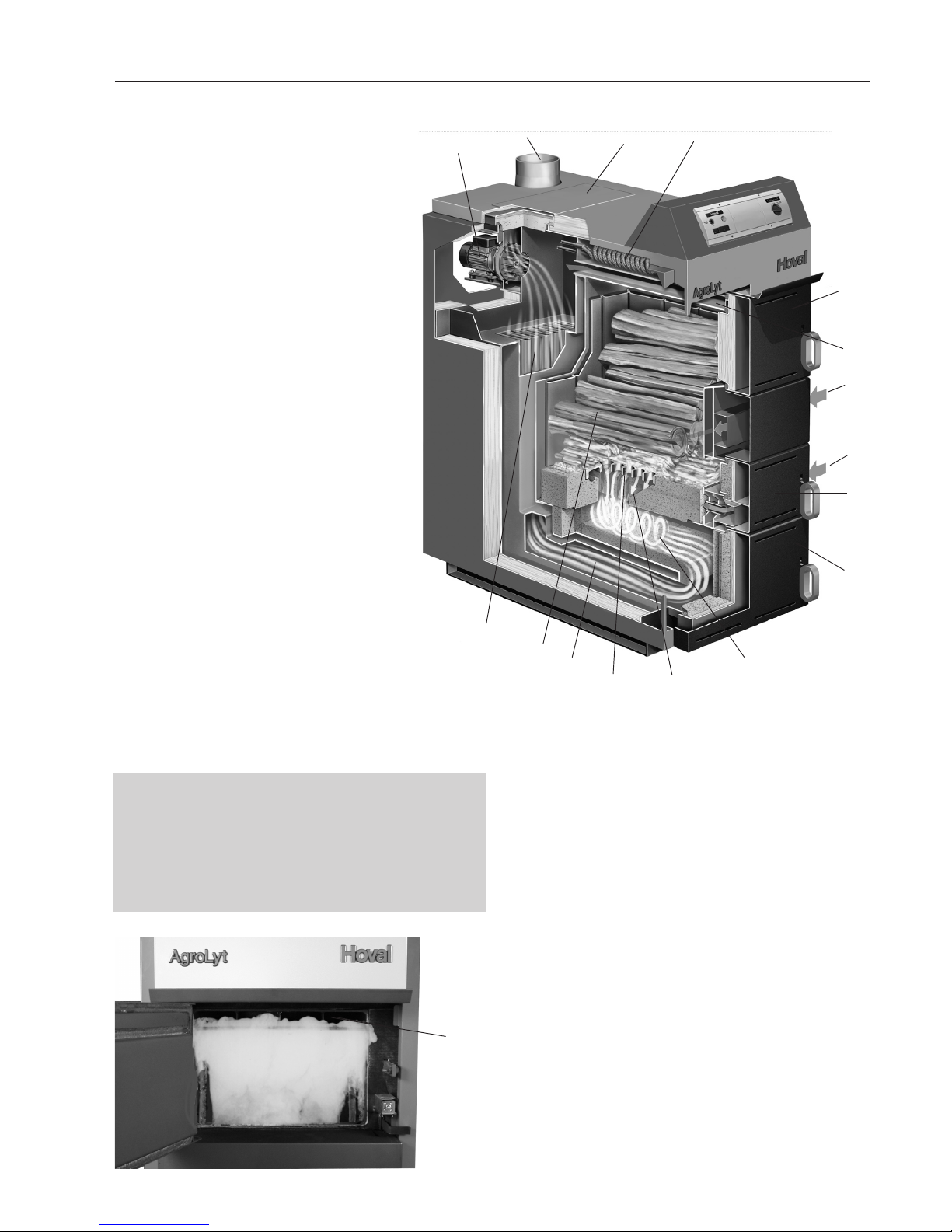

Function

What happens inside the

AgroLyt®?

The Hoval AgroLyt® is a state-of-theart, environmentally friendly wood

burning boiler that operates with 3stage combustion technology. The fuel

is introduced into the loading chamber

through the fuel loading door.

The AgroLyt

®

“bottom combustion

system” operates on the basis of three

combustion stages:

1. Primary air is supplied to the loading

chamber, drying the wood and causing its gasification.

2. The combustible gases flow through

the layer of embers into the combustion chamber cone.

3. The hot gases are mixed with the

secondary air in the adjacent re

fractory-lined vortex combustion

chamber, where they are completely

combusted.

The hot flue gases are subsequently

passed through and toward the back of

the vortex combustion chamber and, from

there, in upward direction through the

downstream heating surface, where they

transfer the heat to the heating water. From

there the flue gases pass through the flue

gas collector and are finally exhausted into

the flue by means of an extractor fan.

Figure 2

4

Extraction of smouldering gases:

The AgroLyt® is equipped with a smouldering

gas extractor which prevents any smouldering

gases from escaping while the fuel loading door

is open. The extractor operates while the fuel

loading door is open.

Figure 3

2

1

3

6

4

5

10

98

7

11

14

13

16

15

12

1 Fuel loading door

2 Combustion chamber and ash remov-

al door

3 Lighting and stoking door

4 Smouldering gas extraction

5 Primary air regulation

6 Secondary air regulation

7 Loading chamber

8 Grate and grate openings

9 Combustion chamber cone

10 Vortex combustion chamber

11 Ash chamber

12 Thermolytic downstream heating

surface

13 Fan

14 Cleaning aperture

15 Flue gas adapter pipe

16 Thermal safety valve

7

4 205 193 / 00

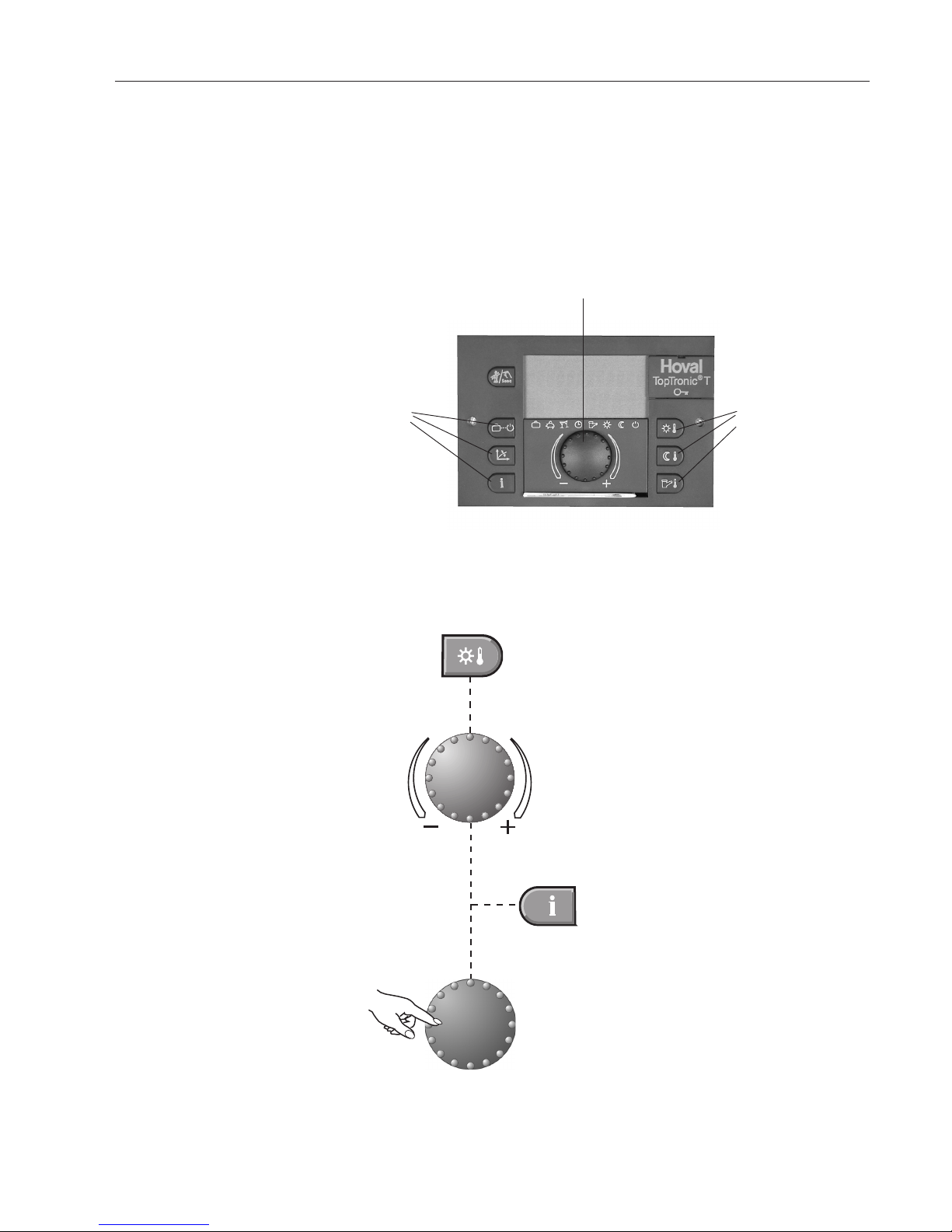

What is the function of the heating

controller TopTronic

®

T (optional)? The boiler control unit and the temperature sensor connected

to it represent, so to speak, the brain of the heating system.

The unit’s main functions are:

- maintaining the desired room temperature independently of

the outdoor temperature

- heating the living space when required

- producing domestic hot water (e.g. for showering) only when

required

- displaying information

Further functions:

- allows the input of the desired temperatures

- temperature monitoring

The correct settings for the heating system have already been

applied by Hoval or the installer during commissioning. Any

changes to those settings should only be carried out if you go

away on a trip or if your home is too cold or too warm.

An overview including a section with frequently asked questions/

answers is available in the operating manual of the TopTronic®T

heating controller.

Heating system control

Heating system control

8

4 205 193 / 00

Heating system control

Function of the TopTronic®T

operating elements (optional)

Rotary pushbutton:

Change and store

values

Basic procedure for changing

settings

An example

Select the desired function.

Turn the rotary pushbutton to select or

change the desired parameter (flashing

word or number).

Press the Info key at any time to go back

to the basic display without storing the

values set.

Press the rotary pushbutton to store

the set value.

It is also possible to store the value

using the selected function key.

Function keys

Function keys

The central rotary pushbutton and the labelled keys are

designed for easy and straightforward operation.

9

4 205 193 / 00

Operating elements of the heating boiler equipped with the N5.1/ZN2

TopTronic®T controller

2

341

10

Heating system control

Key Designation Function

1

Main switch

ON/OFF

0 = Heating boiler OFF; Heating boiler is shut down.

I = Heating boiler ON; Heating boiler is operational.

Note: The main switch should always be turned on

(also in summer when the boiler is not in operation).

This will prevent the pumps from getting stuck.

2

Electronic heating controller TopTronic®T (optional)

Maintains the desired room temperature indepen

dently of the outdoor temperature; regulates the output of the water heater.

Special brief operating instructions are provided with

the heating controller. Further information can be

obtained from the detailed operating instructions.

3

Daytime room temperature Set the daytime room temperature.

4

Reduced room temperature

Set the room temperature for reduced heating

.

5

DHW temperature Set the domestic hot water temperature. Manual DHW

reloading.

6

Rotary pushbutton Change the values by turning. Confirm the values by

pressing. Function selection by pressing and turning.

7

Information key

Show the operating data on the display or return to the

start page

.

5987 6

11

12

14 1315

16 1718

10

4 205 193 / 00

Key Designation Function

8

Heating curve set-up Set the heating curve

9

� ��

Operating mode selection

key

Operating mode selection

Holiday

Switch off the heating system during the holidays

(frost protection)

Absence

Temporarily switch off heating

Party

Extended heating

Automatic

Automatic heating programme according to the preset

heating times

Summer

Only domestic hot water; no heating

Constant heating

Continuous heating

Reduced heating

Continuous reduced heating

Standby

Frost protection activated

10

Manual mode / emission

measurement

For heating engineer only.

11

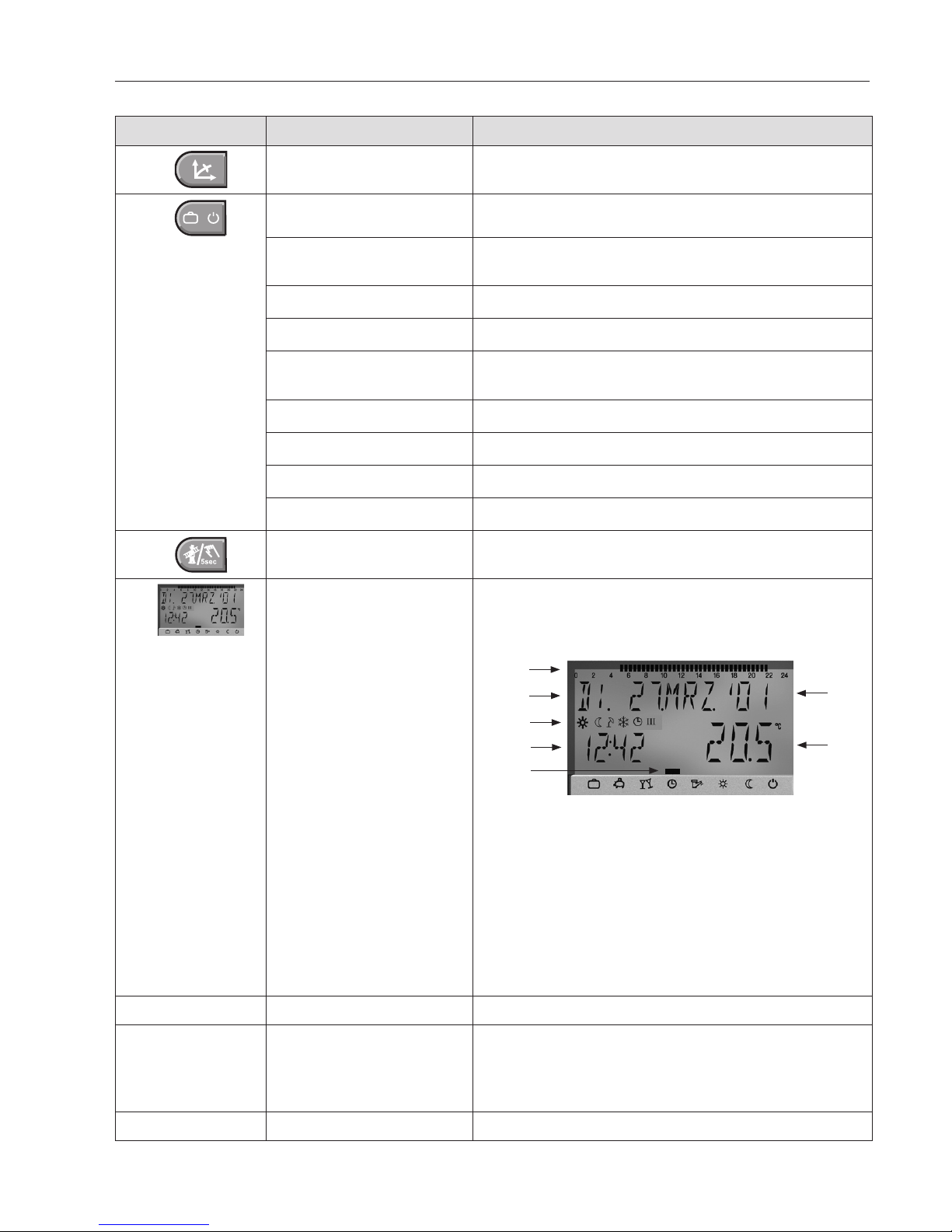

Display

The basic screen displays the day of the week, date

and time of the day, as well as the current boiler tem

-

perature and room temperature (room station).

2

1

3

4

6

7

5

Possible readouts:

1 Active heating time 24h

2 Weekday display

3 Display of the active operating mode and the clock

programme

4 Time of the day

5 Selected operating mode

6 Date / Day / Month / Year

7 Room temperature (when activated)

12

Brief operating instructions

Brief operating instructions for heating controller (2) only

13

Boiler temperature control

Use this function to set the required boiler water

temperature. Recommendation: Turn the control to +

to store as much heat as possible in the storage tank.

(Setting range 75 ºC - 85 ºC)

14

Boiler temperature indicator

The current boiler temperature is shown here.

Heating system control

11

4 205 193 / 00

Loading...

Loading...