Rotary heat exchangers

for Heat Recovery in Ventilation Systems

Handbook for Design, Installation and Operation

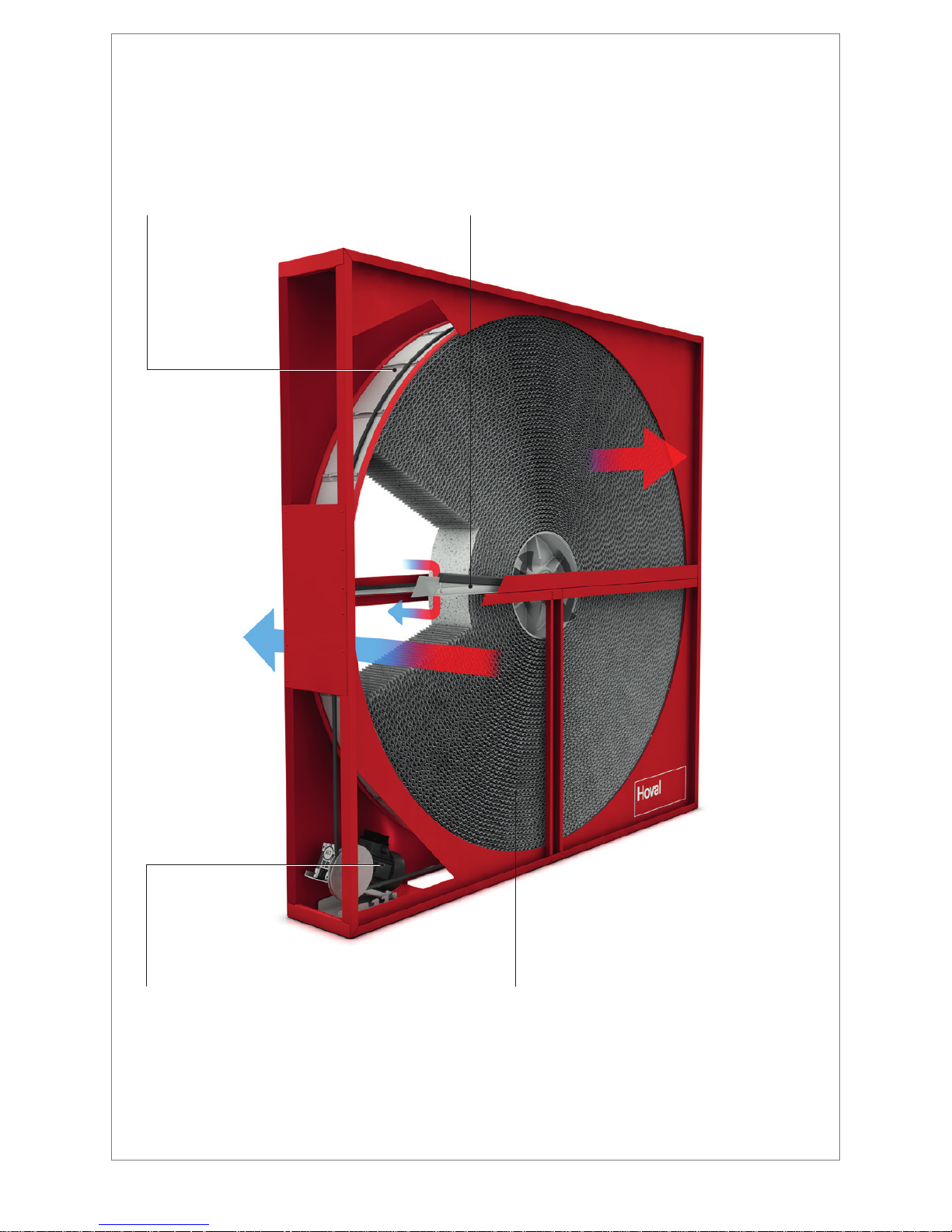

Drive motor

The 3-phase gear motor with belt pulley

and v-belt is installed on a rocker in

the corner of the casing. The speed

of rotation is innitely adjustable.

Peripheral slide seal

Constant-force springs permanently press

the abrasion-resistant ring seal against the

casing. The patented system permanently

minimises leakage and allows the unit

to be sized for smaller air ow rates.

Adjustable purge sector

The size of the purge sector can be adjusted

to suit requirements. The device (patent

pending) prevents contamination of the

supply air by the extract air and at the same

time minimises purge and energy loss.

Storage mass

Hoval supplies the storage mass in three types of

material: for condensation, enthalpy and sorption

wheels. The sorption coating guarantees a consist-

ently high degree of humidity efciency, even under

summer conditions.

1

1 Principle and Operation __________ 2

1.1 Heat transmission

1.2 Humidity transmission

1.3 Leakage of rotary heat exchangers

1.4 Frost limit

1.5 Temperature efciency

1.6 Pressure drop

1.7 Pressure difference

1.8 Hygiene

1.9 Reliable data

2 Performance control ____________ 7

3 Structure _____________________ 8

3.1 Wheel

3.2 Casing

3.3 Peripheral slide seal

3.4 Transverse seal

3.5 Drive

4 Options _____________________ 11

4.1 Drive

4.2 Control unit

4.3 Operating unit

4.4 Rotational speed monitoring

4.5 Inspection cover

4.6 Purge sector

4.7 Duct design

4.8 Coated casing

4.9 Offset wheel position

5 Dimensions of the exchangers ___ 15

6 Unit type reference ____________ 16

7 System design ________________ 18

7.1 Hoval CASER design program

7.2 Design data

7.3 Local conditions, installation position

7.4 Wheel type

7.5 Performance control

7.6 Using and setting the purge sector

7.7 Mixing of the air streams

7.8 Supply air humidication

7.9 Corrosion

7.10 Application limits

7.11 Danger or contamination

7.12 Condensation in the warm air stream

8 Transport and installation _______ 21

8.1 Transport

8.2 Mechanical installation

8.3 Installation of sensors

8.4 Electrical installation

8.5 Assembly of segmented rotary heat exchangers

8.6 Storage

9 Commissioning and maintenance _ 22

9.1 Commissioning

9.2 Maintenance

10 Specication texts ____________ 23

10.1 Condensation wheel

10.2 Enthalpy wheel

10.3 Sorption wheel

Content

2

1 Principle and Operation

Hoval rotary heat exchangers are regenerators with rotating

heat accumulators (category 3) in accordance with the guide-

lines for heat recovery (e.g. VDI 2071).

The heat-dissipating and heat-absorbing air ows heat

or cool the rotating, air-permeable storage accumulator.

Depending on the air conditions and the surface of the

accumulator material, humidity may also be transferred in the

process. Supply and exhaust air must therefore be brought

together and ow through the heat exchanger.

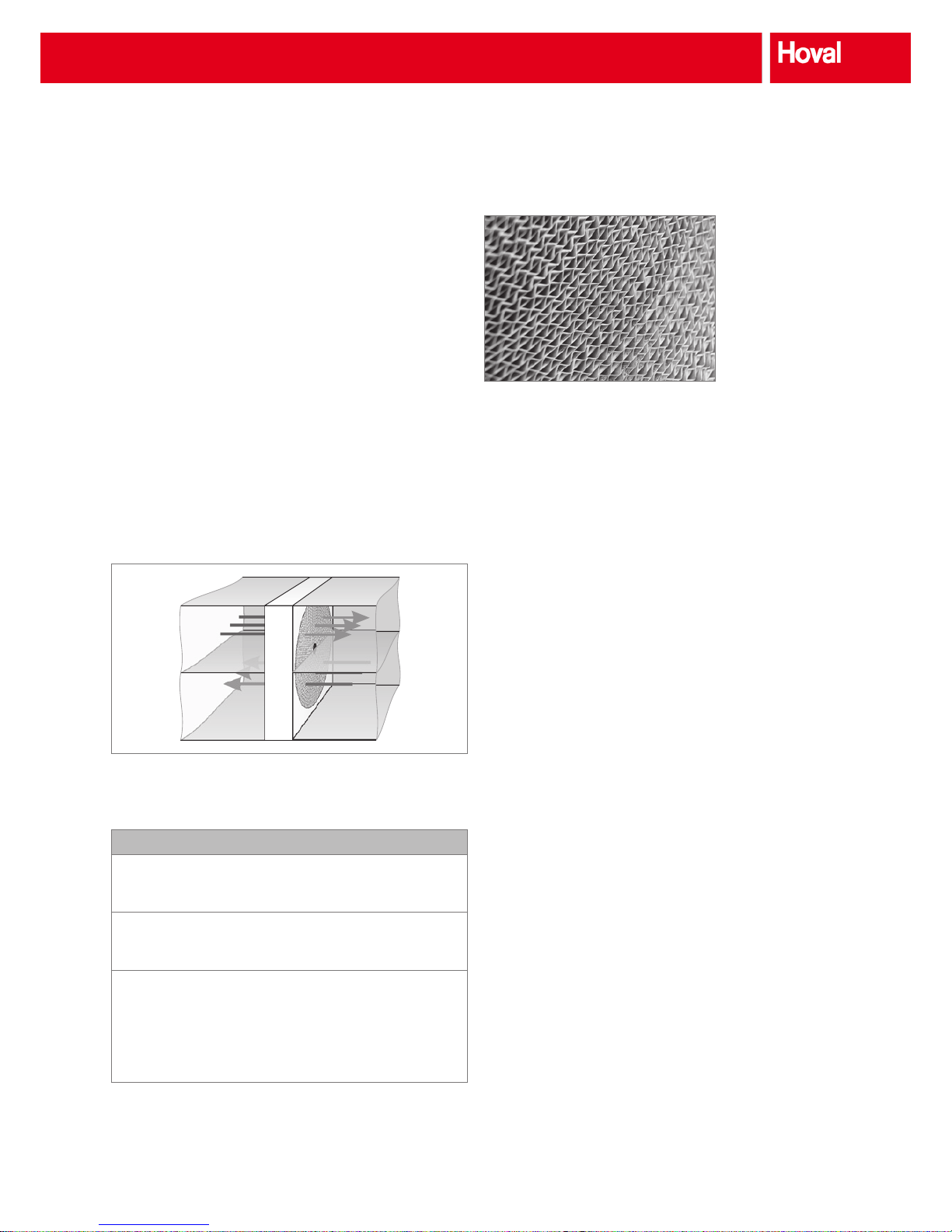

The storage mass consists of triangular, axially arranged

small ducts made of thin metal foil. The depth of the storage

mass (viewed in the direction air ow) is generally 200 mm;

the airway height is normally 1.4 – 1.9 mm, depending on the

application. With these dimensions the storage mass generates a laminar ow in the wheel ducts.

Fresh air

t

21

x

21

Supply air

t

22

x

22

Exhaust air

t

12

x

12

Extract air

t

11

x

11

Fig. 1: Function diagram and air conditions

Denition of key data according to Eurovent

Temperature efciency

t

22

- t

21

ηt =

t

11

- t

21

Humidity efciency

x

22

- x

21

ηx =

x

11

- x

21

Legend: t = Temperature [K; °C]

x = Absolute humidity [g/kg]

Index: …

11

Extract air

…

21

Fresh air

…

12

Exhaust air

…

22

Supply air

1.1 Heat transmission

The wheel with its axially arranged, smooth ducts acts as a

storage mass, half of which is heated by the warm air and

the other half of which is cooled by the counter-ow of cold

air. The temperature of the storage mass therefore depends

on the axis coordinates (wheel depth) and the angle of

rotation.

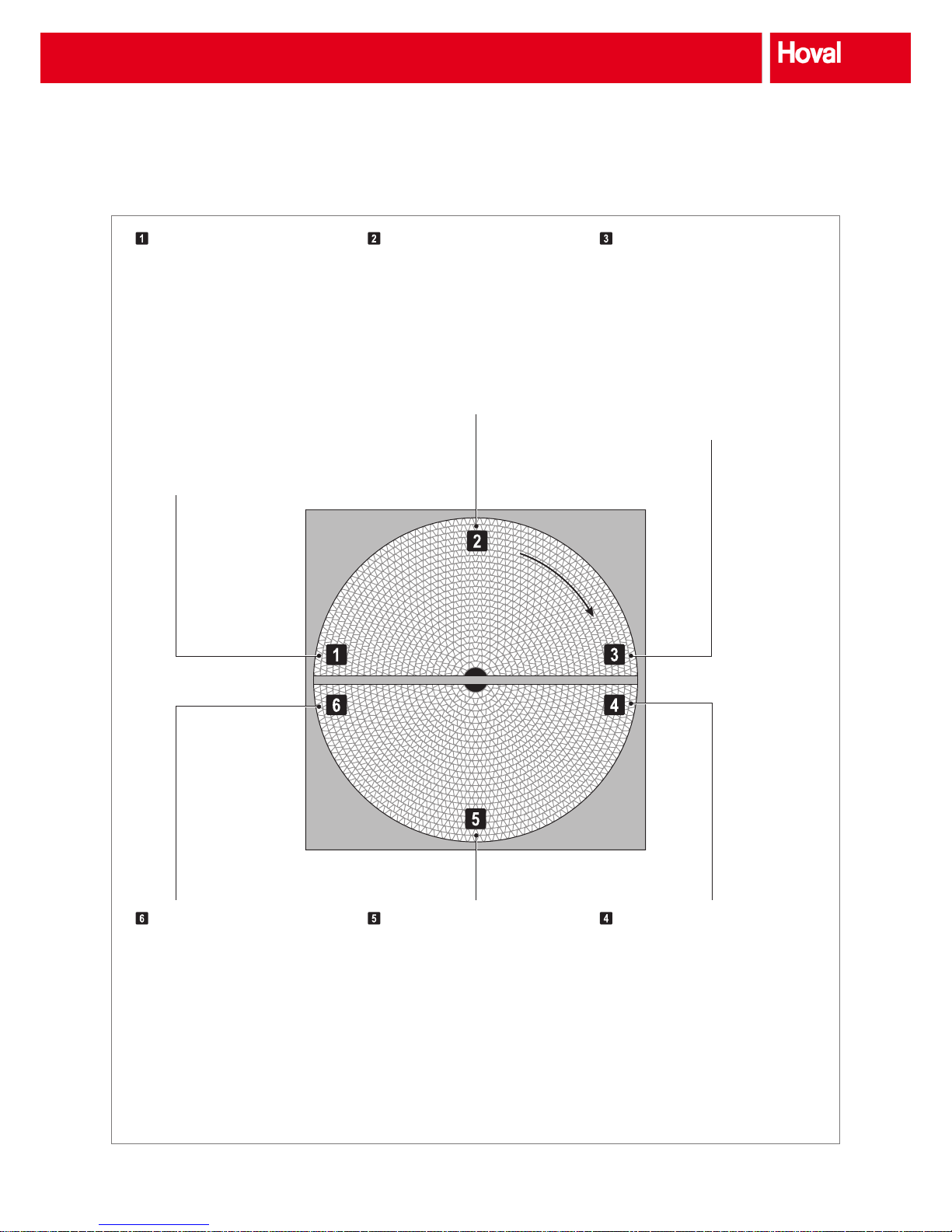

The function is easy to understand by following the status

of a wheel duct through one revolution (see Fig. 3). The

following can be recognised with reference to the heat

transfer from this process:

■ The air temperature after the exchanger varies; it depends

on the location on the wheel.

■ The heat recovery efciency can be varied by varying the

speed.

■ The heat recovery efciency can be changed with the

storage mass. This can be done with different cross-sections of the wheel ducts, different thickness of the storage

material or by changing the wheel depth. However, in all

cases this varies the pressure drop.

■ The specic heat output depends on the temperature

difference between warm air and cold air. The rotary heat

exchanger is therefore suitable for heat and cool recovery,

i.e. for winter and summer operation.

Fig. 2: Geometry of

storage mass

Fig. 3: States depending on the turning angle

Principle and Operation

3

Fig. 3: States depending on the turning angle

Warm air entry

The rotation of the storage mass has

moved the wheel duct from the cold air

to the warm air. The storage material is

cooled almost to the temperature of the

cold air. This applies particularly to the

entry side of the cold air (= exit side of the

warm air). The warm air now ows through

the duct with reference to the temperature

in the counter-ow and is cooled greatly.

The storage mass is therefore heated. The

local temperature efciency, i.e. directly

at the inlet to the warm air, is very high.

Condensation can also occur very easily.

Mid warm air

The wheel duct now has passed half of

its time in the warm air. The storage mass

has been heated by the owing warm air;

therefore, the warm air is not cooled down

as much as in entry inlet zone. The wall

temperature at the entry and exit is approximately the same. Condensation occurs only

with large humidity differences.

Warm air exit

The wheel duct is now shortly before entry

to the cold air. It has virtually reached the

temperature of the extract air at the entry

side. The transferred performance is still

only low.

The dwell time in the warm air and in the

cold air, i.e. the speed of rotation, is decisive for the performance of the rotary heat

exchanger. It depends on the storage mass

(thickness, geometry), the heat transfer and

the air velocity.

Cold air exit

The wheel duct has passed through the

cold-air section. The storage mass has

greatly cooled, almost down to the cold-air

temperature in the entry section. After

crossover to the warm air side, the cycle

starts anew.

Mid cold air

Half of the dwell time in the cold air is past.

The storage mass has already cooled

signicantly. The temperatures at the entry

and exit are approximately equal.

Cold air entry

After the transition from the warm air to the

cold air, the wheel duct now has cold air

owing through in the opposite direction

(referring to the temperature). With the

high temperature difference the transferred

performance is very high, i.e. the cold air is

very strongly heated; in reverse the storage

mass is strongly cooled. Any condensate formed on the exchanger surface is

(partially) absorbed by the heated cold air.

W

A

R

M

A

I

R

C

O

L

D

A

I

R

Principle and Operation

4

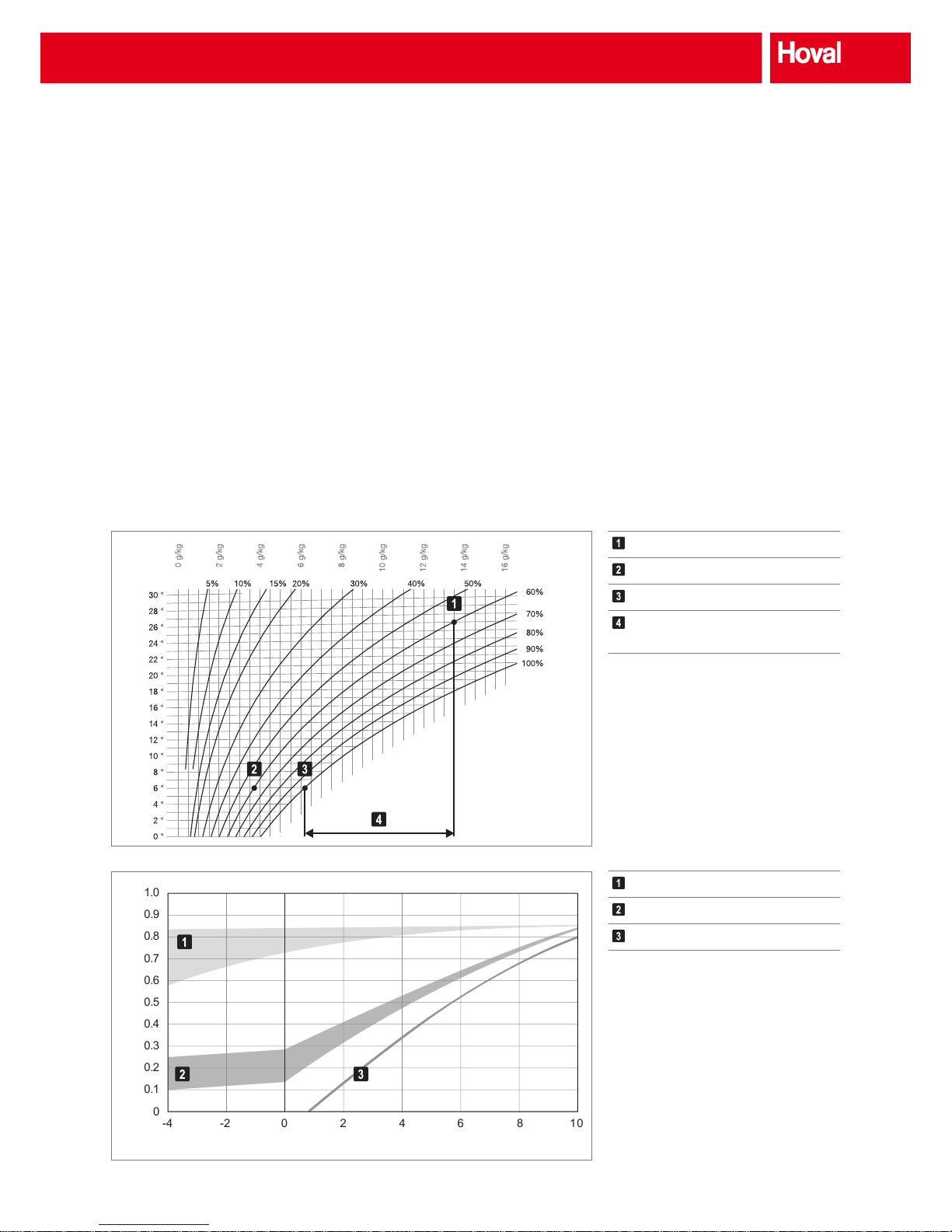

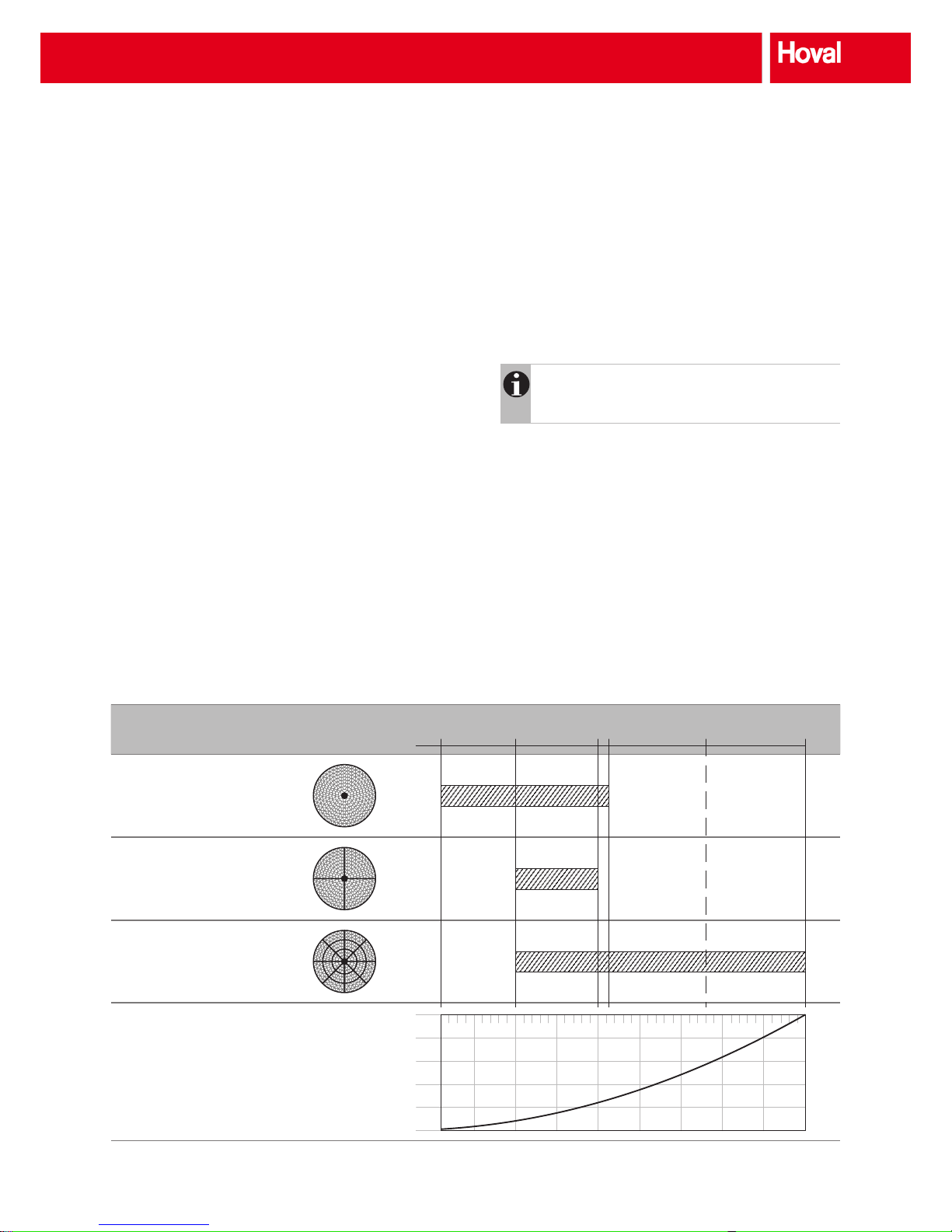

1.2 Humidity transmission

In addition to heat, humidity can also be transported with

rotary heat exchangers. The decisive factor here is the mate-

rial and/or the surface of the storage mass. Characteristic

features for different designs have been developed with

detailed measurements of wheels from different manufac-

turers by the building technology test centre of the University

of Lucerne. The reference factor for the humidity efciency

is the condensation potential; that is the humidity difference

between warm-air humidity and the saturation humidity of the

cold air (see Fig. 4).

Fig. 4: Denition of condensation potential κ

Sorption wheel

Enthalpy wheel

Condensation wheel

Warm air entry

Cold air entry

Saturated cold air

Condensation potential of

warm air κ

Humidity efciency η

x

0

0.2

0.4

0.6

0.8

0.9

1.0

0.7

0.5

0.3

0.1

-4 -2 0 2 4 6 8 10

Condensation potential κ [g/kg]

The following must be noted:

■ The greater the condensation potential the greater the

volume of condensate that can be expected at the warm

air side.

■ If the condensation potential is zero or negative, no

condensation can take place. Humidity transmission is

therefore only possible by sorption.

■ The derived characteristics reect typical values of 1 : 1

for the mass-ow ratio and the pressure drop of approx.

130 Pa at an airway height of 1.9 mm.

■ The area of application of reference magnitude κ, i.e. the

condensation potential, is restricted to the standard condi-

tions of ventilation technology. The temperature efciency

must be at least 70 %. The humidity transmission must

not be restricted by the saturation curve (e.g. with very

low outside temperatures).

Fig. 5: Typical course of humidity efciencies of various

wheels depending on the condensation potential

Temperature

WaterRelative humidity

Principle and Operation

5

There are 3 different designs:

Condensation wheel

The storage mass consists of smooth, untreated aluminium,

which only transmits humidity if condensation occurs on the

warm-air side and it is picked up by the cold air (partially).

Humidity efciency rates greater than 80 % can be reached if

the temperature difference is high.

The use of condensation wheels for heat and humidity transmission is recommended primarily for ventilation systems

without mechanical cooling, i.e. for winter operation.

Enthalpy wheel (hygroscopic wheel)

The metallic storage mass has been treated to form a capillary surface structure. The humidity is transmitted by sorption

and condensation, with the sorption component being very

low. Humidity transmission in summer operation (κ < 0) is

also very low.

Sorption wheel

The storage mass in this case has a surface that transmits

humidity by pure sorption (i.e. without condensation). The

humidity efciency is therefore virtually independent of the

condensation potential. The low decrease can be explained

with the simultaneous reduction of the temperature difference.

Sorption wheels are recommended particularly in systems

with mechanical cooling. The high humidity efciency, even

under summer conditions, dries the fresh air. This requires

less cooling capacity and reduces energy costs for cooling

up to 50%.

1.3 Leakage of rotary heat exchangers

Rotary heat exchangers transfer heat and humidity via a

rotating storage mass that alternates between the exhaust

air and supply air ows. This functional principle delivers

extremely efcient energy recovery, but it does also entail a

certain leakage: the exhaust air and supply air ows cannot

be completely separated from one another. The seals are

not able to withstand the existing differential pressure with

100 percent effectiveness. The rotating storage mass trans-

fers a small quantity of air from one air ow to the other on

every rotation (carryover).

The effects of the leakage must be taken into account during

planning and conguration of air handling systems. The draft

standard EN 13779:2014 consequently denes the calculation method for the leakage. It describes the following two

values:

■ Exhaust air transfer ratio EATR

This is the quantity of exhaust air that enters the supply

air due to carryover and seal leakage.

■ Outdoor air correction factor OACF

This is the ratio between the quantity of the fresh air and

supply air ows.

These two values are calculated using the design program

for a differential pressure to be specied between the supply

air and extract air (Δp

22 -11

). From April 2015, this calcula-

tion will be mandatory for Eurovent-certied rotary heat

exchangers.

Based on the calculated leakage values, it is possible to take

suitable measures according to the application. The following

must be noted:

■ The transfer from exhaust air to supply air can be signif-

icantly reduced or even completely eliminated by taking

the following measures:

– Using a purge sector

– Suitable arrangement of fans (supply air pushes,

exhaust air sucks)

■ The OACF value is decisive for setting the dimensions of

the fans:

– An OACF value greater than 1 means that fresh air

gets to the exhaust air side (due to seal leakage and/

or purge air). The size of the supply air fan will have to

be increased accordingly to ensure that the required

air volume is supplied to the building. This means more

energy is required for pumping the air.

– An OACF value less than 1 means air is moving in the

opposite direction, i.e. there is a proportion of recirculated air in the supply air.

Denition of leakage according to EN 13779:2014 (draft)

Exhaust air transfer ratio:

a

22

– a

21

EATR =

a

11

(Exhaust Air Transfer Ratio)

a

22

....... Concentration in supply air

a

21

....... Concentration in fresh air

a

11

....... Concentration in extract air

Outdoor air correction factor:

q

m 21

OACF =

q

m 22

(Outdoor Air Correction Factor)

q

m 21

..... Mass ow of fresh air

q

m 22

..... Mass ow of supply air

Principle and Operation

6

1.4 Frost limit

If the warm extract air stream is very strongly cooled condensate can be formed and it may even freeze. The fresh air

temperature at which this starts is referred to as the frost

limit.

■ Condensation wheel, enthalpy wheel: The condensate

generated by cooling the extract air may freeze at low

outside temperatures. There is a frost hazard at equiva-

lent mass ows for exhaust air and fresh air if the average

inlet temperature of the two air streams is less than 5 °C.

t

m

=

t11 + t

21

2

< 5 °C

■ Sorption wheel: The gaseous humidity transmission by

sorption generally prevents condensation; the frost hazard

is reduced.

1.5 Temperature efficiency

Appropriate design and serial layout allows virtually any

temperature efciency to be reached. The 'correct' temperature efciency depends on the applicable regulations and

the economy calculations, i.e. the operating data such as

energy price, service life, operation time, temperatures,

maintenance requirements, interest etc. Even minor changes

(a few percent lower temperature efciency, a few pascals

more pressure drop) can mean signicantly poorer results for

capital value and amortisation period.

1.6 Pressure drop

Heat recovery units cause pressure drop on the extract

and supply air sides and as a result operating costs. With

current general conditions the economical values for wheels

are between 80 Pa and 130 Pa. However, to reduce costs,

more and more heat recovery units whose pressure drops

are above these economically reasonable values are being

installed. This affects the feasibility of the system.

1.7 Pressure difference

A distinction is made between internal pressure difference

(between exhaust air and supply air) and external pressure

difference (between the exchanger and the environment).

Internal pressure difference:

The internal leakage between the two air streams depends

greatly on the pressure difference. Hoval rotary heat

exchangers with high tightness seal compared with other

designs are certainly very leak-proof, but the following information should be taken into account in the design:

■ The pressure difference in the rotary heat exchanger

should be as low as possible.

■ In applications that involve the danger of odours the pres-

sure gradients and therefore possible leakage from the

fresh air to the exhaust air must be considered.

However, the internal pressure difference may also cause

deformation of the casing; a pressure difference of more than

2000 Pa is not permitted.

Notice

The pressure difference depends on the layout of the

fans. Overpressure on one side and underpressure

on the other side add up.

External pressure difference:

This is a major factor for the external leakage of the heat

exchanger. If a duct system is correctly and carefully

installed, this effect can be ignored.

1.8 Hygiene

Hoval rotary heat exchangers with high tightness seal have

been tested for conformity with hygiene requirements at the

Institute for Air Hygiene in Berlin. The test criteria were the

requirements relevant to hygiene for applications in general

building ventilation and in hospital applications. All hygiene

requirements were met.

Notice

Hoval rotary heat exchangers are tested and certi-

ed for operation in hospitals in accordance with

DIN 1946-4. Install rotary heat exchangers with the

'coated casing' option for such applications.

Fig. 6: Certicate of

hygiene conformity test

(valid for Hoval rotary

heat exchangers with high

tightness seal)

Principle and Operation

7

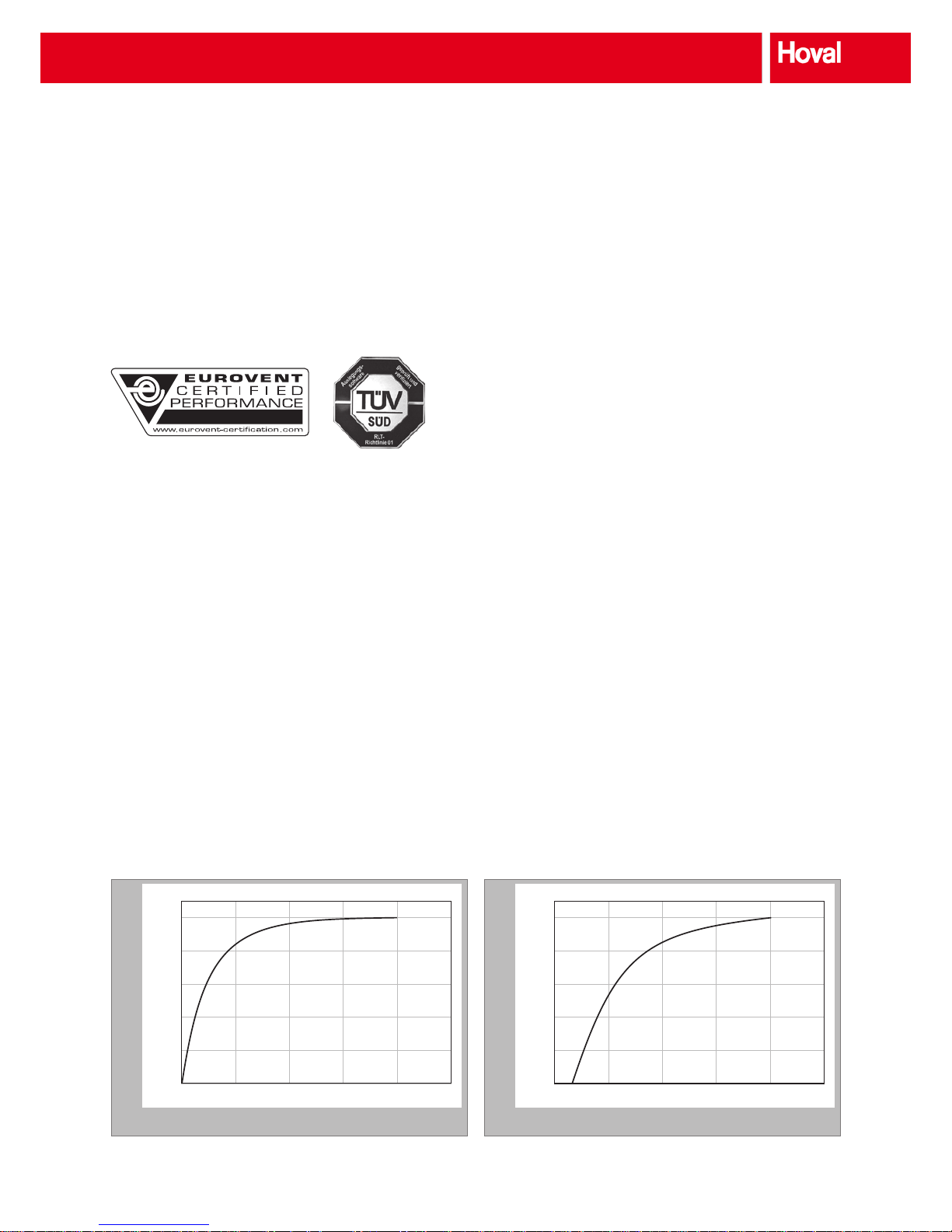

1.9 Reliable data

Hoval rotary heat exchangers are always tested by independent test organisations (e.g. at the building technology

testing laboratory of the University of Lucerne). All technical

data are based on these measurements. This means that

they are reliable data for planners, installers and operators.

Relative humidity efciency

0

5

10 15 20 25

0 %

20 %

40 %

60 %

80 %

100 %

Speed of rotation [rpm]

Fig. 8: Dependency of the humidity efciency on the rotational speed

Relative temperature efciency

0

5

10 15 20 25

0 %

20 %

40 %

60 %

80 %

100 %

Speed of rotation [rpm]

Fig. 7: Dependency of the temperature efciency on the rotational speed

2 Performance control

The Hoval rotary heat exchanger always operates as a

temperature rectier between the two air streams. The

ow direction of the heat is irrelevant in this context, i.e.

depending on the temperature gradients between extract

air and fresh air either heat or cold is harvested. Therefore,

regulation of the output of the Hoval rotary heat exchanger

is not necessary if the extract air temperature is identical to

the setpoint temperature. In this case, the fresh air is always

either heated or cooled in the direction of the set temperature

by the heat exchanger.

However, in most cases there are heat sources in the

ventilated rooms (people, machines, lighting, solar radiation,

processing systems) that increase the room temperature,

i.e. the extract air temperature is higher than the setpoint

temperature. In this case, check the outside temperature

from which the system is heated at full performance of the

rotary heat exchanger and – if this cannot be tolerated – the

performance of the heat exchanger must be controlled.

It is very simple and economical to reduce the performance

of the rotary heat exchanger for heating and also for humidity

transmission by reducing the speed of rotation. All Hoval

rotary heat exchangers can therefore be supplied with

speed-controlled drives.

There is also the option of diverting one or both air streams

past the wheel by a bypass. The method – used primarily in

process technology and at various air ow rates – must be

installed by the customer.

Performance control

8

3 Structure

A functional rotary heat exchanger consists of the wheel, the

casing and the drive.

3.1 Wheel

Storage mass

A corrugated and a smooth metal foil are wound together

as the storage mass. This forms triangular, axial ducts. The

material is 60 µm thick.

The surface treatment also depends on the use; there are

3 series:

■ Series A: condensation wheel, consisting of high-quality

aluminium.

■ Series E: enthalpy wheel, consisting of aluminium with

enthalpic coating.

■ Series S: sorption wheel, consisting of an aluminium

substrate foil coated with a sorption substance (e.g. silica

gel) for humidity transmission. This transmits humidity in

the form of a gas without condensation.

Fig. 9: A corrugated and a

smooth metal foil are wound

around each other.

Fig. 10: Production on stateof-the-art machines ensures

consistently high quality.

Fig. 11: Large wheels are cut

into several segments.

Design

The depth of the wheel is 200 mm. The wheel is stabilised by

double spokes, screwed (and welded) to the hub and welded

to the wheel mantle (see Fig. 12). This guarantees a long

service life.

For stability and performance large-diameter wheels must be

made in a segmented design. The diameter of the wheel can

be freely selected in 10-mm steps.

The outside of the wheel is held together by an aluminium

jacket plate (welded). This guarantees uninterrupted radial

runout and enables maximum usage of the wheel surface.

Hub with inner bearing

The hub, whose size depends on the wheel diameter, is

xed to the axle with 2 internal ball bearings. It is fastened

to the crossbars of the casing. This design has the following

advantages:

■ The internal bearings are protected against contamination

and require little space.

■ The axial lock with circlips makes installation and removal

quick and simple.

■ Both bearings are integrated into the hub, i.e. in the

same component. This ensures that they mesh together

perfectly (in contrast to external bearings). This does not

reduce the service life of the bearings.

■ The position of the axle, hub and wheel is precisely xed

by the fastening of the internal ball bearings by the hub

and the circlips.

■ The xed axles connects the two crossbars of the casing.

This greatly increases its stability.

Fig. 12: The wheel is permanently stabilised by internal welded double spokes.

Fig. 13: Hub with long-life, permanently

lubricated inner bearing

Structure

9

3.2 Casing

There are different casing designs, depending on the wheel

diameter and whether the wheel is 1-piece or segmented.

Sheet-metal casing

Self-supporting aluzinc sheet steel casing are standard for

1-piece wheels with diameters up to 2620 mm. The sheet-

metal casing is strengthened with galvanised steel proles

from wheel diameters of 1800 mm.

Prole casing

A prole design of aluminium is used for wheels above

1500 mm diameter. The casing is extremely stable and the

dimensions are exible. The plate covers can be removed

and replaced quickly and easily, a factor which is important

for installation of segmented wheels.

The height and width of the prole casing is limited to 4.2 m.

Larger casings (welded construction, galvanised) are available customised for specic systems.

The casings are designed for installation in a ventilation unit.

Therefore, the sides are open; this allows inspection and

maintenance as required.

Wheel diameter (in mm)

Wheel 1-piece

Sheet-metal casing

(Delivery assembled)

Wheel 4-piece

Prole casing

(Delivery in parts)

Wheel 8-piece

Prole casing

(Delivery in parts)

Required torque

500 Nm

400 Nm

300 Nm

200 Nm

100 Nm

0 Nm

Table 1: Overview of designs and wheel dimensions (for standard casing)

600

1500

2500

2620

3800

5000

Casing types

Different types of casing are also available for adaptation to

different installation situations (see also Section 4 'Options'):

■ Special size:

Height and width of the casing can be selected as

required (for example for adjustment to the internal

cross-section of a ventilation unit). The hub can also be

placed away from centre.

Notice

The casing design may be different for special

sizes compared to Table 1.

■ Duct design:

The side walls of the casing are closed (for the duct

connection).

Structure

10

3.3 Peripheral slide seal

High tightness seal

■ In rotary heat exchangers with sheet-metal casing auto-

matically adjustable constant-force springs are mounted

on the wheel mantle; they press the abrasion-resistant

slide seal against the casing. The patented system permanently minimises leakage and allows the unit to be sized

for smaller air ow rates.

■ In the prole casing a ring seal with externally accessible

double springs is used. They press the seal to the casing

and to the wheel.

Basic tightness seal

■ In rotary heat exchangers with sheet-metal casing, sealing

strips are mounted on the wheel mantle (e.g. brushes).

These guarantee the minimal sealing effect for the air

ows that is usual for devices on the market.

Fig. 14:

High tightness seal

Fig. 15: Peripheral slide

seal in prole casing

Fig. 16:

Basic tightness seal

3.4 Transverse seal

The transverse seal between the two air streams consists of

adjustable aluzinc sheet steel with a triple rubber-lip seal.

3.5 Drive

The wheel is driven by an electric motor and belt. The motor

is generally fastened on the left or right on a rocker in the

casing. Because manufacturers of ventilation units and

installers sometimes install their own drive, Hoval offers this

component as an option.

2 versions are available:

Constant rotational speed

The motor is switched on and off by a single switch or

contact. Output regulation (i.e. changing the temperature

efciency or humidity efciency) is not possible.

Controllable rotational speed

The drive motor is controlled by a control unit. A frequency

converter (FU) is generally used. Common additional func-

tions are speed monitoring (by inductive sensors) and inter-

mittent operation. If heat recovery is not required, the wheel

is moved slightly at intervals to prevent dirt build-up.

The control unit and as a result the wheel are normally actuated by the room temperature controller, for which the rotary

heat exchanger is perceived as an energy resource for both

heating and cooling, which forms part of the cascade control

concept.

Structure

11

4 Options

4.1 Drive

The wheels are driven by a worm gear or a spur-gear drive

motor using a v-belt; the type and size of the motor depends

on the wheel diameter:

■ Drive Y

for direct drive by mains power. On/Off operation at

constant speed only.

■ Drive A

The motor speed and therefore the performance of the

rotary heat exchanger can be controlled. A control unit

(option R) is required.

Motor designation A 60 A 250 A 370 A 750

Motor power kW 0.06 0.25 0.37 0.75

Output shaft mm 18 x 34 20 x 55 20 x 65 25 x 60

Current Y (direct operation by mains power) A 0.25 0.83 1.09 1.92

Current Δ (with control unit) A 0.30 1.44 1.90 3.40

Protection rating Drive Y – IP 44 IP 55 IP 55 IP 55

Drive A – IP 54 IP 55 IP 55 IP 55

Motor nominal speed n

1

min

-1

1600 1320 1380 1400

Output speed n

2

at 50 Hz min

-1

100 132 138 140

Motor nominal torque m

1

Nm 0.5 1.81 2.60 5.10

Output torque m

2

Nm 6.1 14 21 45

Rotor diameter mm up to 1300 up to 1800 up to 2620 up to 3800

Control unit Type R / 370 R / 370 R / 370 R / 750

Table 2: Data sheet for rotary drives

Options

12

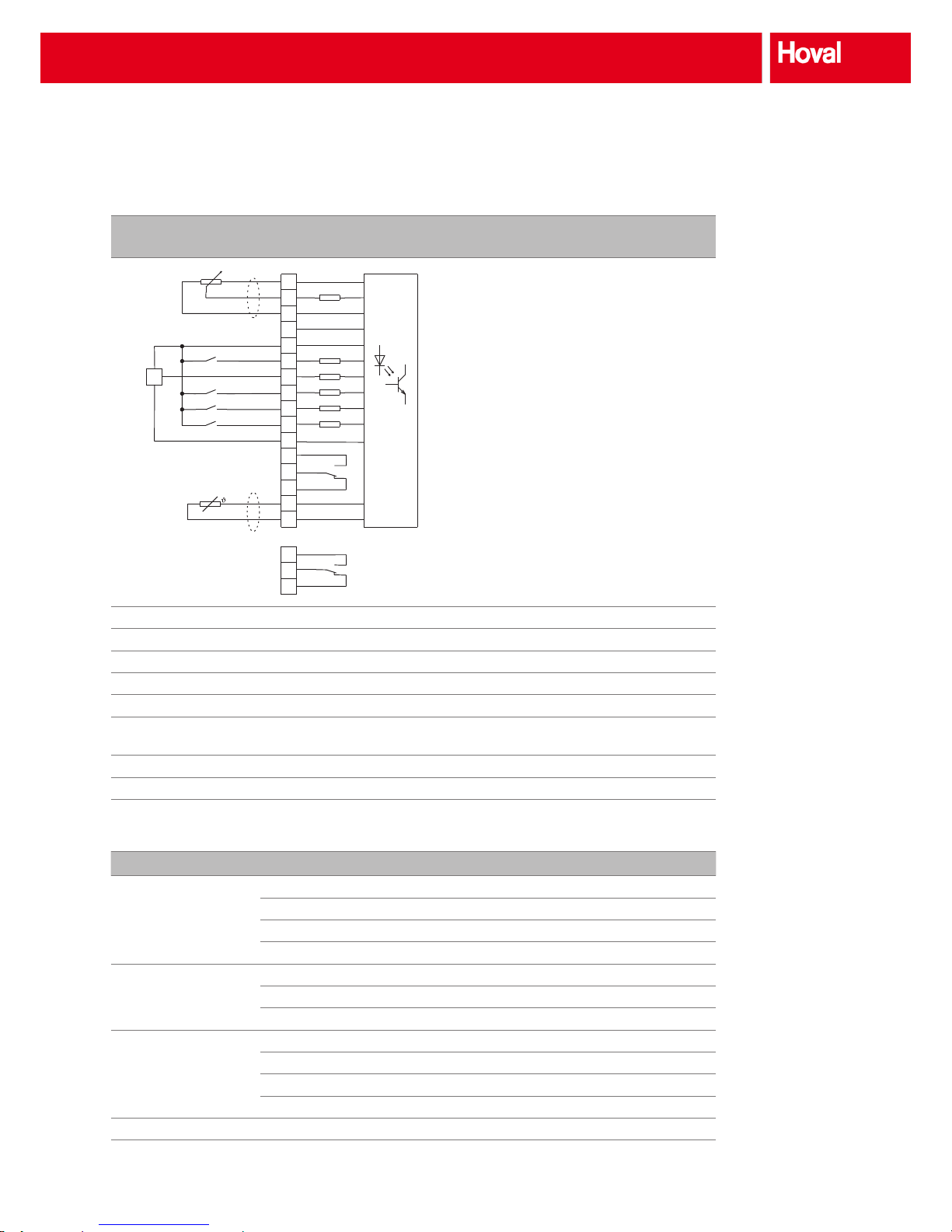

4.2 Control unit

Structure

A frequency converter with a modular design is used as the

control unit; it can adjust the speed of three-phase motors

innitely. Protection rating IP 54 is required for installation in

the ventilation unit. The power unit is protected from undervoltage, overvoltage or non-approved converter temperature.

The aluminium casing and the standard input and output

lters increase the immunity to interference. Error messages

can be read out directly at a ashing LED.

The control unit is delivered ready for operation with the

factory-set parameters. Various settings can be changed with

an optionally available operating unit.

Function

■ The control unit can be used for condensation, enthalpy

and sorption wheels that require speed control. All

standard control signals are accepted.

■ A quadratic (standard) or linear implementation of the

setpoint into the rotary eld frequency based on the

maximum frequency of the selected parameter set is

used.

■ As soon as the input signal is below the dened threshold

value, the wheel stops rotating. After an adjustable holding

time intermittent operation is started and the wheel rotates

at the dened speed for a few seconds.

■ An inductive sensor can be connected for speed moni-

toring (option D).

■ Readiness for operation and any fault messages can be

output via a relay.

System design

■ The control unit is not designed for outside installation.

■ The control unit is normally installed in the side wall of the

casing.

■ The normal installation position is vertical. Sufcient venti-

lation for heat dissipation is essential.

Fig. 17: Control unit R

Installation

Caution

All work for transport, installation and commissioning

as well as maintenance is conducted by qualied

technicians (note IEC 364 and VENELEC HD 384 or

DIN VDE 0100 and IEC Report 664 or DIN VDE 0110

and national occupational health and safety regulations or VGB 4).

Qualied technicians as dened by the basic safety instructions are persons who are familiar with the setup, installation,

commissioning and operation of the product and are appro-

priately qualied for their activities (dened in IEC 364 or DIN

VDE 0105).

Commissioning

■ Before commissioning the control unit the rotary heat

exchanger must be operating correctly.

■ The direction of rotation of the wheel can be changed by

reversing 2 phases of the motor.

■ A green LED lights when the unit is operating without

faults.

■ Causes of faults are displayed on the control unit.

Options

13

R/370 (Type: F-D 370-WT VECTOR IP54)

R/750 (Type: F-D 750-WT VECTOR IP54)

7

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

B1

10k

+10 V reference voltage

Analogue setpoint input

GND (analogue)

Analogue output

+15 V (max. 100 mA)

Start clockwise

External sensor

Priority speed

Parameter set switching

Release

GND (digital)

Relay output 1 (normally open contact)

Relay output 1 (changeover contact)

Relay output 1 (normally closed contact)

PTC motor temperature monitoring

PTC motor temperature monitoring

Relay output 2 (normally open contact)

Relay output 2 (changeover contact)

Relay output 2 (normally closed contact)

Terminals 1, 2, 3 Connection of control signal

Terminals 5, 7, 11 Connection of inductive sensor for speed monitoring

Terminal 6 Start of wheel (terminal 10 must be under power)

Terminal 9 not under power Sorption wheel operating mode

Terminal 9 under power Condensation/enthalpy wheel operating mode

Terminal 10 Reset-function by short-term voltage cut-off,

acknowledgements of faults

Terminals 15, 16 Connection of thermal contact from motor

Terminals 17, 18, 19 Potential-free output for output of faults via relay

Table 3: Circuit diagram of control inputs for control units

R/370 R/750

Output motor-side Max. motor power kW 0.37 0.75

Nominal output current A 2.2 4.0

Max. output voltage V 3 x 230 3 x 230

Output frequency Hz 0..500 0..500

Mains input Rated voltage V 230 230

Mains frequency Hz 50/60 50/60

Fuses A T 6 8

General data Protection rating IP 54 IP 54

Ambient temperature °C 0..40 0..40

Air humidity % 20..90 20..90

Power dissipation W 35 45

Dimensions H x W x D mm 282 x 112 x 70 282 x 112 x 70

Table 4: Technical data for the control units

Options

14

4.3 Operating unit

The control unit settings can be customised with the oper-

ating unit. Parameters can be congured quickly and easily

with the LCD graphical display, the menu structure in

German or English and the parameters displayed in plain

text.

Fig. 18: Operating unit

4.4 Rotational speed monitoring

The speed of rotation of the wheel can be monitored with an

inductive sensor. Stoppages, e.g. caused by a broken v-belt,

can be detected quickly and the cause can be corrected.

4.5 Inspection cover

The motor and the v-belt can be inspected through inspection covers on both sides. This is recommended if inspection

from the side is not possible.

Notice

Inspection covers cannot always be installed in small

casing dimensions. If applicable, this is shown in the

Hoval CASER design program. Detailed information

can be obtained from Hoval's application consulting

service.

4.6 Purge sector

When correctly laid out, the purge sector reduces the

transmission of extract air to the supply air. The size can be

congured individually to reduce the purge and energy loss

to a minimum.

Instructions for the optimum settings can be found in

Section '7.6 Using and setting the purge sector'.

Factory setting: 3°

Fresh air

Exhaust air

Fig. 19: Purge sector

4.7 Duct design

The side walls of the casings in Hoval rotary heat

exchangers with ducts are enclosed. This makes them suitable for the duct connection.

4.8 Coated casing

Hoval rotary heat exchangers with coated casings are available for applications with very high hygiene requirements

(e.g. hospitals): powder-coated red (RAL 3000).

4.9 Offset wheel position

The hub can be offset for optimum adjustment to the installation situation (such as installation in a ventilation unit).

Options

15

5 Dimensions of the exchangers

The minimum size of the casing depends on the wheel diam-

eter. The external dimensions can be individually adjusted.

A

B

290

70

30

60

Casing dimensions min. max.

Dimension A Ø + 80 1350

Dimension B Ø + 80 1350

Table 5: Dimensional drawing for small sheet-metal casing (dimensions in mm)

A

B

320

100

45

80

Casing dimensions min. max.

Dimension A Ø + 80 2850

Dimension B Ø + 80 2700

Table 6: Dimensional drawing for large sheet-metal casing, wheel diameter up to

1800 mm (dimensions in mm)

A

B

430

70

70

70

Casing dimensions min. max.

Dimension A Ø + 200 4200

Dimension B Ø + 200 4200

Table 7: Dimensional drawing for prole casing (dimensions in mm)

A

B

320

40

45

40

Casing dimensions min. max.

Dimension A Ø + 80 2850

Dimension B Ø + 80 2700

Table 8: Dimensional drawing for large sheet-metal casing, wheel diameter from

1800 mm (dimensions in mm)

Dimensions of the exchangers

16

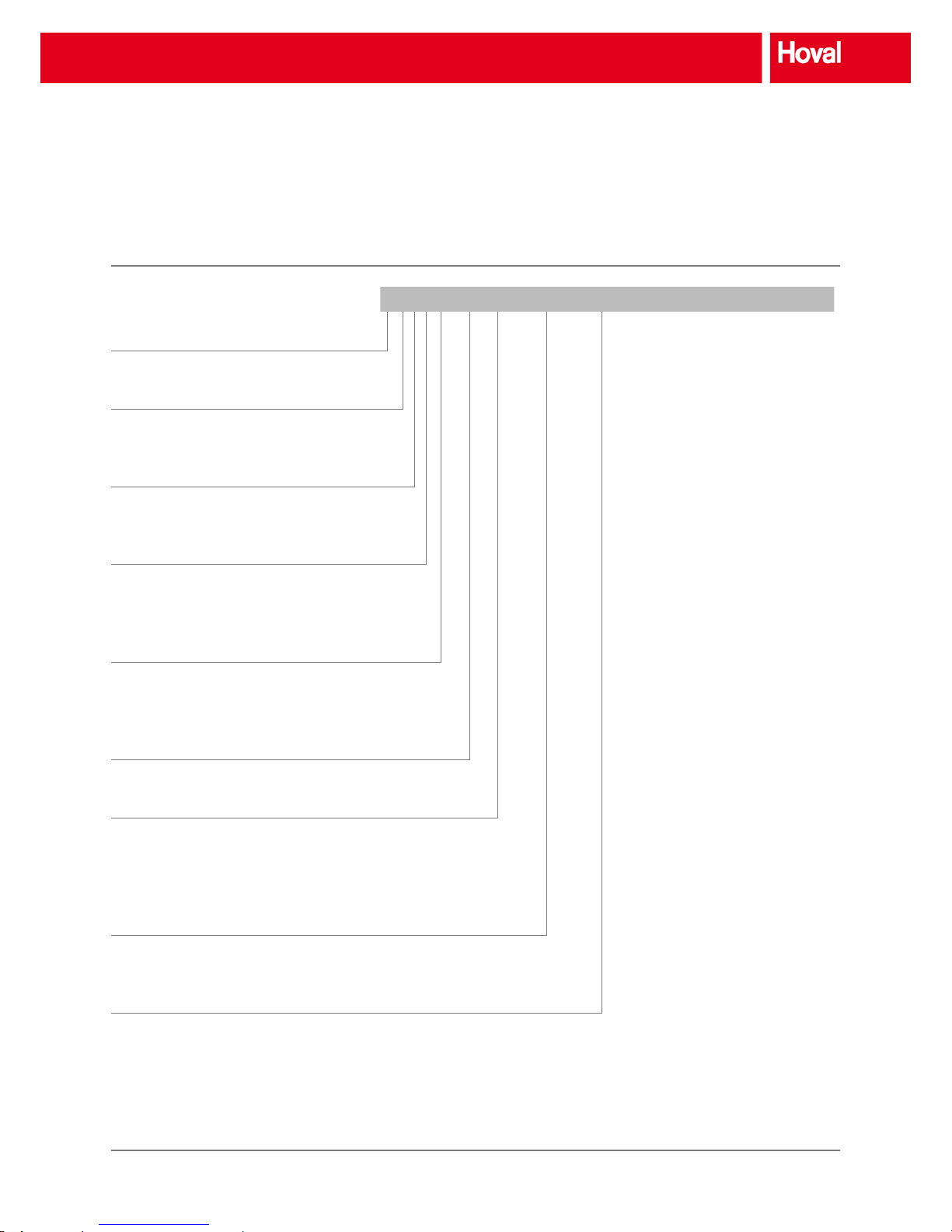

6 Unit type reference

A V - A 1 - 0600 / 1.4 / A0680B0680 / S001 / A1 ,RN , B , D ,SR , I3, K , AX1234BX1234

Air ow

Case A, B, C or D

Installation position

V Vertical to 20% inclination

H Horizontal

Peripheral slide seal

- High tightness seal

B Basic tightness seal

Rotor model

A Condensation wheel of aluminium

E Enthalpy wheel with enthalpy coating

S Sorption wheel with sorption coating

Wheel construction and casing design

1 Wheel 1-piece, sheet-metal casing, supplied assembled

4 Wheel 4-piece, prole casing, supplied unassembled

8 Wheel 8-piece, prole casing, supplied unassembled

Wheel diameter (in mm)

Any required size in steps of 10 mm

Airway height

1.4 mm

1.6 mm

1.9 mm

2.9 mm

Casing size in mm

Dimension A x dimension B

Any required size in steps of 1 mm

Special code

---- Standard

Unit type reference

17

A V - A 1 - 0600 / 1.4 / A0680B0680 / S001 / A1 ,RN , B , D ,SR , I3, K , AX1234BX1234

Drive

-- Without drive

A Drive controllable

Y Drive for constant speed of rotation (direct drive from mains power)

1…3 Species the position

Control unit

-- Without control unit

RN Control unit, supplied uninstalled

Operating unit

- Without operating unit

B Operating unit in German

O Operating unit in English

Rotational speed monitoring

- Without rotational speed monitoring

D Rotational speed monitoring

Purge sector

-- Without purge sector

SR Purge sector, mounted in position for clockwise direction of rotation

SL Purge sector, mounted in position for anticlockwise direction of rotation

SN Purge sector, supplied uninstalled

Inspection cover

-- Without inspection cover

I Inspection cover

1…3 Species the position

Casing model

- Standard

K Duct design

C Coated casing

Offset

------------ Standard

AX Distance of casing edge to wheel axle in dimension A

BX Distance of casing edge to wheel axle in dimension B

Unit type reference

18

7 System design

7.1 Hoval CASER design program

The Hoval CASER design program is available for fast

and accurate design of Hoval rotary heat exchangers

(= Computer Aided Selection of Energy Recovery). It runs

under Microsoft

®

Windows and offers the following applica-

tions:

■ Secure planning with Eurovent and TÜV-certied data

■ Accurate calculation of a specic Hoval rotary heat

exchanger

■ Calculation of all applicable rotary heat exchangers for a

specic project

■ Calculation of the efciency class in accordance with

EN 13053

■ Calculation of leakage in accordance with Eurovent

■ Price calculation for the selected rotary heat exchangers

Notice

You can download the Hoval CASER design program

free of charge from our home page (hrs.hoval.com).

The program is also available as a Windows DLL le and can

therefore be integrated into other spreadsheet programs (on

request).

Hoval CASER

7.2 Design data

As with all design, achieving the setpoint values depends

on the correct starting data. This often causes problems,

particularly in ventilation applications. The reason is the

dependence of the temperature of the specic density and

the specic heat. Water vapour in the air is also very impor-

tant for the design. This is why the data available on entry to

the exchanger are essential for accurate calculation of a heat

exchanger.

Exhaust air

stream

Extract air owrate V11[m3/s]

Extract air temperature t

11

[°C]

Extract air rel. humidity RH

11

[%]

Supply air

stream

Fresh air owrate V

21

[m3/s]

Fresh air temperature t

21

[°C]

Fresh air rel. humidity RH

21

[%]

Table 9: Design data

The following errors must be avoided with data recording:

■ Volume ow is not equal to mass ow. The mass ows

of supply air and exhaust air must be known for correct

design.

■ The humidity in the extract air is generally estimated too

high, particularly for winter operation. (Where does the

humidity come from?)

■ Are the temperatures (fresh air, extract air) really as stated

in practice (or are they wishful thinking)?

7.3 Local conditions, installation position

■ Where should the heat recovery unit be installed?

■ Which is the optimum air path?

■ What dimensions are approved?

Notice

Please note that the wheel must be accessible for

maintenance and cleaning. Hoval therefore recommends to provide 600 mm free space in front of and

behind the wheel (= width of an inspection door).

7.4 Wheel type

The wheel type must be selected depending on the application. The following are recommended:

■ The condensation or enthalpy wheel is suitable for venti-

lation systems without mechanical cooling and without

humidity control.

■ Sorption wheels are recommended for ventilation systems

with mechanical cooling. The high humidity efciency,

even under summer conditions, dries the fresh air. This

requires less cooling capacity and reduces energy costs

for cooling up to 50%.

System design

19

7.5 Performance control

Check which internal heat sources are available in the hall.

If the extract air temperature is expected to be signicantly

higher than the set value, speed control should be planned.

7.6 Using and setting the purge sector

The purge sector reduces transmission of extract air to

supply air. It virtually bypasses the fresh air through the

wheel to the exhaust air. To avoid deterioration of the temper-

ature efciency the purge sector must not be too large.

The size of the purge sector in Hoval rotary heat exchangers

can be individually adjusted to reduce the energy loss to a

minimum. The optimum size of the purge sector depends on:

■ the wheel type,

■ the existing purge pressure,

■ the airway height of the storage mass.

Optimum setting of the purge sector [°]

0

1

2

3

4

5

0 100 200 300 400 500 600 700 800

Existing purge pressure [Pa]

Condensation/enthalpy wheel airway height 1.9 mm

Condensation/enthalpy wheel airway height 1.6 mm

Condensation/enthalpy wheel airway height 1.4 mm

Sorption wheel airway height 1.9 mm

Sorption wheel airway height 1.6 mm

Sorption wheel airway height 1.4 mm

Diagram 1: Purge sector conguration diagram

The required purge pressure Δpp depends on the layout of

the fans:

Δpp = p

supply air

– p

exhaust air

Δpp = p

fresh air

– p

extract air

Both fans suction side:

A minimum purge pressure of 100 Pa is required.

Supply air Fresh air Fresh air Supply air

Extract air Exhaust air Exhaust air Extract air

Exhaust air suction side, fresh air pressure side

Keep the purge pressure as low as possible to minimise the

air ow rate through the purge sector and thus the energy

loss. A purge pressure > 800 Pa must be avoided.

Supply air Fresh air Fresh air Supply air

Extract air Exhaust air Exhaust air Extract air

Both fans pressure side:

A minimum purge pressure of 100 Pa is required.

Supply air Fresh air Fresh air Supply air

Extract air Exhaust air Exhaust air Extract air

Extract air pressure side, supply air suction side:

The purge sector cannot be used with this layout.

Supply air Fresh air Fresh air Supply air

Extract air Exhaust air Exhaust air Extract air

System design

20

7.7 Mixing of the air streams

Generally a mixing of the air streams must be expected

with wheels. Without special precautions VDI 6022 must be

observed: 'Regenerators with wheels are to be used only

if for hygienic reasons recirculation could also be used.'

Causes for mixing of the air streams include:

■ Carryover

A specic volume of air (depending on the speed of

rotation, air velocity and wheel geometry) is rotated in the

other direction by an air stream.

■ Leakage

Leakage through the radial and transverse seals

according to the pressure gradients and the seal quality.

■ Extract air transmission

Because the storage mass is alternately in both air

streams, they each inuence the other. For example,

odours can be transmitted with the smallest particles (e.g.

cigarette smoke).

■ Substance transmission

Wheels also transmit gaseous substances. The amount

transmitted depends on the wheel type and the substance

itself. Unfortunately, few measurements are available in

this eld, and on the other hand it is known in practice that

this is not a problem for standard VAC systems.

In rare cases odourants from the extract air may be

'collected' in the wheel and under extreme fresh-air condi-

tions (very high relative humidity) may be emitted again. This

can cause odour problems. In general, this problem can be

prevented by special adjustments of the cleaning mode or

with a minimum speed of rotation.

Notice

The high tightness seal in Hoval rotary exchangers

minimises leakage. They are even certied for operation in hospitals.

7.8 Supply air humidification

The humidication downstream from the wheel must be

dimensioned to ensure that the desired setpoint value is

reached even with minimum fresh-air humidity. Because the

wheel speed is generally controlled by the supply air temperature, the corresponding humidity content must be consid-

ered when dimensioning the humidier.

7.9 Corrosion

Hoval rotary heat exchangers have proven to be very

durable in VAC systems. The Hoval application consulting

service can provide information on what equipment to use for

applications where corrosion is potential danger, such as in

kitchens or specic industrial applications etc.

7.10 Application limits

Before selecting the rotary heat exchanger check that application limits are not exceeded during operation:

Temperature -40…70°C

Pressure difference max. 2000 Pa

Pressure difference to

outside

max. 2000 Pa

Pressure drop Recommended 80 Pa to 130 Pa

Table 10: Application limits

7.11 Danger or contamination

In 'normal' ventilation systems the air streams are generally

cleaned with coarse lters. This ensures that there is no

danger of dirt build-up on the rotary heat exchanger. If this is

a potential problem with specialised applications, this must

be considered in the design:

■ Install the exchanger so it can be cleaned in its installed

position.

■ Provide inspection openings before and after the rotary

heat exchanger.

■ If possible, clean the air stream by ltering to prevent dirt

built-up or the cleaning intervals are extended.

In practice it has been demonstrated that the danger of dirt

build-up is much less than expected. Clear statements can

only be made on the basis of experience. The Hoval application consulting service can also provide information.

7.12 Condensation in the warm air stream

If more water condenses from the warm air than the (heated)

cold air can absorb, condensate is formed. Because this

phenomenon primarily occurs in the rst third of the warm

wheel side primarily because of the thermodynamic function,

some of it is removed by the warm-air stream. This must

be considered for downstream components. In general,

condensate drip trays should be installed on the warm-air

and cold-air side. The following must also be checked or

implemented:

■ How is the condensate drained off?

■ Is there an icing hazard?

System design

21

8 Transport and installation

The following checks must be performed before installation:

■ Has the rotary heat exchanger been damaged during

transport (visual inspection of casing and wheel)?

■ Has the correct model been supplied (type, series, size,

options)?

■ How must the exchanger be mounted (purge sector)?

(Note labels!)

8.1 Transport

■ The wheel should always be vertical during transport.

■ The rotary heat exchanger should be attached to the

crossbars of the casing. The pulling direction should be

vertical to prevent damage.

■ The following general items are applicable: Do not lift the

exchanger at a single point but always suspend it by a

crane beam (Fig. 20).

8.2 Mechanical installation

■ The casing for duct connection can be bolted or riveted at

the face area up to 4 cm from the outer frame (Fig. 21).

Caution

The wheel casing cannot take any additional load

(e.g. ducts).

■ When installing the wheel in a ventilation unit, the casing

should be reasonably adapted to the unit size (Fig. 22).

■ If necessary, bafe plates can be installed to adapt the

casing to the unit cross-section.

Caution

Ensure that the wheel is not drilled or blocked and

the sealings are not damaged during installation.

■ Hoval rotary heat exchangers are designed for vertical

installation (max. tilt 20°).

Notice

Rotary heat exchangers for horizontal installation

are available on request. In this case the casing

must be supported at the bearings.

■ After installation check that the wheel runs smoothly.

8.3 Installation of sensors

If, for example, temperature sensors are installed, the function of the unit must not be affected.

Fig. 20: Recommended attachment

Fig. 21: Drill area

Fig. 22: Casing dimensions adjusted for unit

Transport and installation

22

8.4 Electrical installation

Constant drive

The drive motor is electrically connected at the factory (in

Y-circuit). The motor must be correctly fused. The direction of

rotation can be reversed by exchanging the phases.

Variable-speed drive

The control unit is supplied with the unit. The motor must

be wired to the control unit and the control unit must be

connected during installation.

8.5 Assembly of segmented rotary heat exchangers

The installation manual for segmented wheels can be

downloaded from the internet. To ensure correct function the

installation supervision by a Hoval technician or an authorised supplied is recommended.

8.6 Storage

■ Rotary heat exchangers with motors must be stored in a

dry, dust-free area which is free of vibrations.

■ Long periods of standstill can impair the function of gear

motors because after some time the bearings lose their

lubrication and the seals may become leaky. Too long

storage periods must therefore be avoided.

If a rotary heat exchanger is not installed and commissioned within 9 months from the date of delivery it must

be put into operation for minimum 5 minutes in order to

ensure the reliable operation of the motor.

9 Commissioning and maintenance

9.1 Commissioning

■ Check the correct direction of rotation of the wheel; it is

marked by arrows on the casing.

■ Check the function of the control unit.

■ Ensure that the air streams of the rotary heat exchanger

can ow through without obstacles.

■ Check that the installation is correct and whether applica-

tion limits (temperatures, differential pressure, material,

etc.) could be exceeded.

■ Check the tension of the drive belt and the fastening of

the motor.

■ Inspect the sealings on the wheel. When making adjust-

ments, ensure that the wheel rotates smoothly and is not

blocked. The drive torques listed in Table 1 must not be

exceeded.

9.2 Maintenance

Maintenance is restricted to regular visual inspections.

Inspections should be initially carried out about every

3 months and then after trouble-free operation can be

extended to 12 months. The following must be checked:

■ Tension of drive belt

■ Sealing of gear motor

■ Quality of bearings (assess by bearing noise)

■ Function of slide seal

■ Function of transverse seal

■ Condition of casing

■ Condition of wheel

Long experience shows that clogging of heat exchangers is

not expected in normal cooling and air-conditioning systems.

However, if deposits accumulate on the exchanger when

used for special applications, it can be cleaned as follows:

■ Remove dust and bres with a soft brush or vacuum

cleaner. Use caution when blowing dirt out with

compressed air to avoid damage to the wheel. Keep at a

distance!

■ Oils, solvents etc. can be removed with hot water (max.

70 °C) or grease-removing solvents or immersion.

Cleaning with pressure cleaners is possible if the following

is observed:

– a at 40° nozzle is used (type WEG40/04)

– max. water pressure 100 bar

Attention

Do not damage the exchanger mechanically or chemically during cleaning:

→ Select compatible cleansing agents.

→ Clean carefully. The thickness of the material is

less than 0.1 mm!

Commissioning and maintenance

23

10 Specification texts

10.1 Condensation wheel

Rotary heat exchanger for heat transmission consisting of

wheel and casing; suitable for optimum dimensioning in

accordance with VDI Directive 3803 Page 5.

Wheel

The storage mass consists of corrugated and smooth,

corrosion-resistant, blank aluminium foil. The result is small,

axially arranged, smooth ducts for laminar ow of air. The

outside of the storage mass is supported by the wheel

mantle; the hub is inside with the permanently lubricated,

maintenance-free roller bearings and the axle. The wheel is

permanently stabilised by internal spokes between the wheel

mantle and hub.

Casing

■ Sheet-metal casing (for one-piece wheels):

Self-supporting construction of aluzinc sheet steel, suit-

able for installation in ventilation units. The automatically

adjusted, abrasion-resistant slide seal with constant-

force springs (Hoval high tightness seal) reduces internal

leakage to a minimum. A lip seal is used as the transverse

seal. The motor for the wheel drive can be installed in the

casing.

■ Prole casing (for multi-component wheels):

Construction of aluminium extruded sections with aluzinc

sheet steel panels, suitable for installation in ventilation

units. The high-quality ring seal on both sides in the

double-acting support springs reduces internal leakage to

a minimum. A lip seal is used as the transverse seal. The

motor for the wheel drive can be installed in the casing.

Options

■ Drive: 3-phase gear motor with belt pulley and v-belt.

■ Control unit: for innite control of speed of rotation; insula-

tion class IP 54. The software includes the speed moni-

toring and intermittent operation for cleaning.

■ Operating unit: for modication of the control program and

manual operation (plugged into the control unit).

■ Speed monitoring: by sensor and an inductive sensor on

the rim of the wheel.

■ Purge sector: prevents rotation of the extract to the supply

air in the event of pressure gradients between supply air

and exhaust air, adjustable to minimise purge and energy

loss.

■ Inspection cover (on both sides): allows visual inspection

of motor and belt.

■ Duct design: casing with enclosed side walls for duct

connection.

■ Coated casing: for applications with very high hygiene

requirements (powder-coated red RAL 3000).

■ Offset wheel position: for optimum adjustment to the

installation situation.

10.2 Enthalpy wheel

Rotary heat exchanger for heat and humidity transmission

consisting of wheel and casing; suitable for optimum dimensioning in accordance with VDI Directive 3803 Page 5.

Wheel

The storage mass consists of corrugated and smooth corrosion-resistant aluminium foil with enthalpy coating for low

humidity transmission. The result is small, axially arranged,

smooth ducts for laminar ow of air. The outside of the

storage mass is supported by the wheel mantle; the hub is

inside with the permanently lubricated, maintenance-free

roller bearings and the axle. The wheel is permanently stabilised by internal spokes between the wheel mantle and hub.

Casing

■ Sheet-metal casing (for one-piece wheels):

Self-supporting construction of aluzinc sheet steel, suit-

able for installation in ventilation units. The automatically

adjusted, abrasion-resistant slide seal with constant-

force springs (Hoval high tightness seal) reduces internal

leakage to a minimum. A lip seal is used as the transverse

seal. The motor for the wheel drive can be installed in the

casing.

■ Prole casing (for multi-component wheels):

Construction of aluminium extruded sections with aluzinc

sheet steel panels, suitable for installation in ventilation

units. The high-quality ring seal on both sides in the

double-acting support springs reduces internal leakage to

a minimum. A lip seal is used as the transverse seal. The

motor for the wheel drive can be installed in the casing.

Options

■ Drive: 3-phase gear motor with belt pulley and v-belt.

■ Control unit: for innite control of speed of rotation; insula-

tion class IP 54. The software includes the speed moni-

toring and intermittent operation for cleaning.

■ Operating unit: for modication of the control program and

manual operation (plugged into the control unit).

■ Speed monitoring: by sensor and an inductive sensor on

the rim of the wheel.

■ Purge sector: prevents rotation of the extract to the supply

air in the event of pressure gradients between supply air

and exhaust air, adjustable to minimise purge and energy

loss.

■ Inspection cover (on both sides): allows visual inspection

of motor and belt.

■ Duct design: casing with enclosed side walls for duct

connection.

■ Coated casing: for applications with very high hygiene

requirements (powder-coated red RAL 3000).

■ Offset wheel position: for optimum adjustment to the

installation situation.

Specication texts

24

10.3 Sorption wheel

Rotary heat exchanger for heat and humidity transmission

consisting of wheel and casing; suitable for optimum dimensioning in accordance with VDI Directive 3803 Page 5.

Wheel

The storage mass consists of corrugated and smooth corrosion-resistant aluminium foil with highly effective sorption

coating for humidity transmission. Silica gel is used as

sorption material, ensuring ideal humidity transmission. The

result is small, axially arranged, smooth ducts for laminar

ow of air. The outside of the storage mass is supported by

the wheel mantle; the hub is inside with the permanently

lubricated, maintenance-free roller bearings and the axle.

The wheel is permanently stabilised by internal spokes

between the wheel mantle and hub.

Casing

■ Sheet-metal casing (for one-piece wheels):

Self-supporting construction of aluzinc sheet steel, suit-

able for installation in ventilation units. The automatically

adjusted, abrasion-resistant slide seal with constant-

force springs (Hoval high tightness seal) reduces internal

leakage to a minimum. A lip seal is used as the transverse

seal. The motor for the wheel drive can be installed in the

casing.

■ Prole casing (for multi-component wheels):

Construction of aluminium extruded sections with aluzinc

sheet steel panels, suitable for installation in ventilation

units. The high-quality ring seal on both sides in the

double-acting support springs reduces internal leakage to

a minimum. A lip seal is used as the transverse seal. The

motor for the wheel drive can be installed in the casing.

Options

■ Drive: 3-phase gear motor with belt pulley and v-belt.

■ Control unit: for innite control of speed of rotation; insula-

tion class IP 54. The software includes the speed moni-

toring and intermittent operation for cleaning.

■ Operating unit: for modication of the control program and

manual operation (plugged into the control unit).

■ Speed monitoring: by sensor and an inductive sensor on

the rim of the wheel.

■ Purge sector: prevents rotation of the extract to the supply

air in the event of pressure gradients between supply air

and exhaust air, adjustable to minimise purge and energy

loss.

■ Inspection cover (on both sides): allows visual inspection

of motor and belt.

■ Duct design: casing with enclosed side walls for duct

connection.

■ Coated casing: for applications with very high hygiene

requirements (powder-coated red RAL 3000).

■ Offset wheel position: for optimum adjustment to the

installation situation.

Specication texts

1

Hoval heating technology

As a full range supplier Hoval helps its customers to select

innovative system solutions for a wide range of energy sources,

such as heat pumps, biomass, solar energy, gas, oil and district

heating. Services range from small commercial to large-scale

industrial projects.

Responsibility for energy and environment

The Hoval brand is internationally known as one of the leading suppliers of indoor

climate control solutions. More than 65 years of experience have given us the nec-

essary capabilities and motivation to continuously develop exceptional solutions and

technically advanced equipment. Maximising energy ef ciency and thus protecting

the environment are both our commitment and our incentive. Hoval has established

itself as an expert provider of intelligent heating and ventilation systems that are

exported to over 50 countries worldwide.

Hoval comfort ventilation

Increased comfort and more ef cient use of energy from

private housing to business premises: our comfort ventilation

products provide fresh, clean air for living and working space.

Our innovative system for a healthy room climate uses heat and

moisture recovery, while at the same time protecting energy

resources and providing a healthier environment.

Hoval indoor climate systems

Indoor climate systems ensure top air quality and economical

usability. Hoval has been installing decentralised systems

for many years. The key is to use combinations of multiple

air-conditioning units, even those of different types, that can

be controlled separately or together as a single system. This

enables Hoval to respond exibly to a wide range of require-

ments for heating, cooling and ventilation.

Hoval heat recovery

Ef cient use of energy due to heat recovery. Hoval offers two

different solutions: plate heat exchangers as a recuperative

system and rotary heat exchangers as a regenerative system.

International

Hoval Aktiengesellschaft

Austrasse 70

9490 Vaduz, Liechtenstein

Tel. +423 399 24 00

Fax +423 399 27 31

info.klimatechnik@hoval.com

hrs.hoval.com

Hrvatska

Hoval d.o.o.

Nova ves 70

10000 Zagreb

Tel. +385 1 466 63 76

hoval.hr@hoval.com

hrs.hoval.hr

Hoval Rotary Heat Exchangers

Subject to technical changes.

Part. No. 4 213 602 – Edition 01 / 2015

© Hoval Aktiengesellschaft, Liechtenstein, 2011

Loading...

Loading...