HouseWarmer HW075DVN-1, HW075DVP-1, HW130DVN-1, HW130DVP-1, HW180DVN-1 Installation Instructions And Owner's Manual

...

INSTALLATION INSTRUCTIONS

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

AND OWNER’S MANUAL

GRAVITY TYPE DIRECT VENT

WALL FURNACE

MODELS

HW075DV(N,P)-1

HW130DV(N,P)-1

HW180DV(N,P)-1

EFFECTIVE DATE

JUNE 2006

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result, causing property damage, personal injury or loss of life.

Do not store or use any gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

This appliance may be installed in an aftermarket, permanently located, manufactured home

(USA only) or mobile home, where not prohibited

by state or local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

convertible for use with other gasses, unless a cer

tified kit is used.

WARNING: If not installed, operated and maintained in accordance with the manufacturer’s instructions, this product could expose you to substances in fuel or from fuel combustion which can

cause death or serious illness.

DO NOT RETURN THIS PRODUCT TO THE

STORE WHERE YOU PURCHASED IT. IF YOU

ARE MISSING PARTS, OR HAVE ANY PROBLEMS, CONTACT EMPIRE COMFORT SYSTEMS, INC. AT (877) 459-1583.

-

21091-0-0606 Page 1

TABLE OF CONTENTS

SECTION PAGE

Gas Specifications .......................................................................................................... 3

Specifications ..................................................................................................................

High Altitude Specifications ..........................................................................................

Unit Dimensions ............................................................................................................. 4

Important Safety Information ...................................................................................... 4

Introduction ....................................................................................................................

Requirements for Massachusetts ..................................................................................

Termination Clearances ................................................................................................

Installation and Assembly ........................................................................................

Installation Overview .................................................................................................8-9

Installation of HouseWarmer Product ..................................................................

Clearances to Combustibles .....................................................................................

Interior Preparation and Installation of the Back of the Unit ............................. 11-13

8-15

10-15

10

3

3

5

6

7

Exterior Installation of the Venting .....................................................................

Interior Installation of the Front of the Unit ............................................................

13-14

15

Before Operating the Appliance ............................................................................16-19

Operating Instructions ................................................................................................ 20

Lighting Instructions ................................................................................................... 21

To Turn Off Gas to the Appliance ...............................................................................

21

Parts List ....................................................................................................................... 22

Parts View .....................................................................................................................

23

Maintenance Instructions ............................................................................................ 24

Troubleshooting ............................................................................................................

How to Order Repair Parts .........................................................................................

HouseWarmer Heating Appliance Limited Warranty .............................................

25

26

26

Notes .............................................................................................................................. 27

Page 2 21091-0-0606

GAS SPECIFICATIONS

MODEL FUEL MAXIMUM INPUT

HW075DV

HW130DV 13,000 Btu/hr

HW180DV 18,000 Btu/hr

MANIFOLD PRESSURE

Gas Inlet 3/8"

SUPPLY

Natural Gas 5.0" W.C.P. 10.5" W.C.P.

LP Gas 11.0" W.C.P. 13.0" W.C.P.

Note: Appliance input ratings are based on sea level operation and need not be changed for operation up to 2,000 feet.

MINIMUM PRESSURE MAXIMUM PRESSURE

Propane/LP -- Natural gas

Natural gas: 3.5" water column pressure

Propane/LP gas: 10.0" water column pressure

7,500 Btu/hr

SPECIFICATIONS

MODELS HW075DV HW130DV HW180DV

COMBUSTION

STANDARD HEATING SPACE

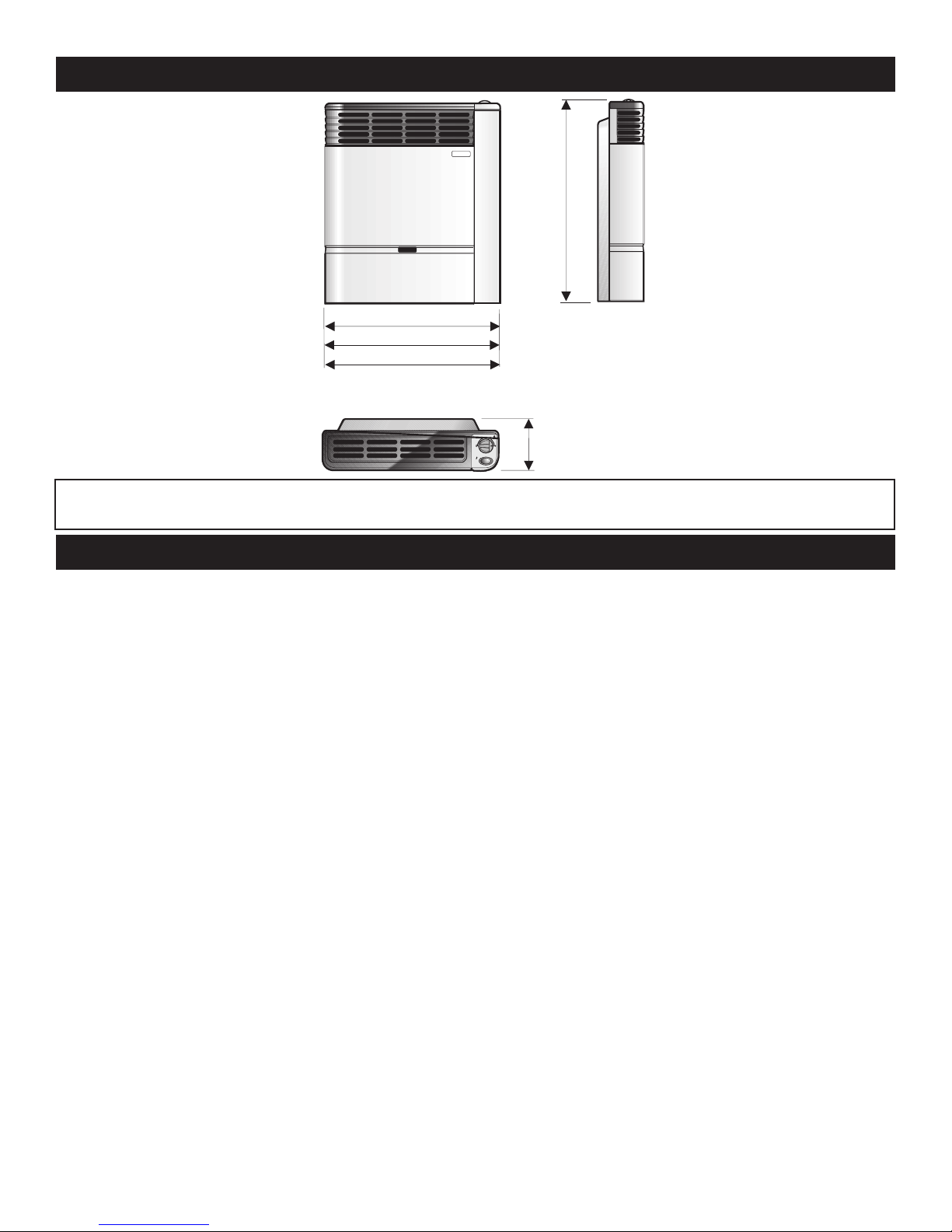

HEIGHT 24 5/64"

EXTERNAL DIMENSIONS INCHES

NET WEIGHT LBS.

MAX. GAS CONSUMPTION

TEST POINT PRESSURE

SAFETY DEVICES

Warning: This direct vent wall furnace is equipped for Natural or Propane gas. Field conversion is not permitted.

WIDTH 12 15/64" 19 39/64" 25 19/32"

DEPTH 5 1/32" 5 1/32" 7 1/32"

NATURAL GAS 3.5" W.C.

PROPANE/LP 10.0" W.C.

72 -225 Sq. Ft. 132 - 400 Sq. Ft. 169 - 529 Sq. Ft.

21.2 lbs. 35.5 lbs. 53.2 lbs

7,500 Btu/hr. 13,000 Btu/hr. 18,000 Btu/hr.

ATMOSPHERIC BURNER

Safety valve (thermocouple)

HIGH ALTITUDE SPECIFICATIONS

For altitudes/elevations above 2,000 feet (609.9m), input ratings should be reduced at the rate of 4 percent for each 1,000 feet (305m)

above sea level. Canadian High Altitudes for locations having an elevation above mean sea level between 2,000 feet (609.9m) and 4,500

feet (1,370m), use orifices as indicated in the following table:

0-2,000 feet (0-610m) 2,000-4,500 feet (610-1,370m)

Model

HW075 1.35mm/3.5" .85mm/10.0" 1.27mm/3.5" 0.83mm/10.0"

HW130 1.75mm/3.5" 1.10mm/10.0" 1.67mm/3.5" 1.03mm/10.0"

HW180 2.26mm/3.5" 1.30mm/10.0" 1.83mm/3.5" 1.27mm/10.0"

21091-0-0606 Page 3

Main Burner Orifice/Gas Pressure Main Burner Orifice/Gas Pressure

Natural Gas LP Gas Natural Gas LP Gas

HW075DV

HW130DV

HW180DV

24 5/64”

12

15/16”

19

39/64”

25 19/32”

5 1/32” (HW075DV

, HW130DV)

7 1/32” (HW180DV)

UNIT DIMENSIONS

MAKE SURE THAT APPLIANCE IS SUITABLE FOR THE GAS SUPPLY AVAILABLE: NATURAL GAS

OR PROPANE/LP.

IMPORTANT SAFETY INFORMATION

Children and adults should be alerted to the hazards of high surface temperatures and should stay away

to avoid burns or clothing ignition.

Any safety screen or guard removed for servicing must be replaced prior to operating the heater.

Do not use this heater if it has been under water. Immediately call a qualified service technician to inspect

the heater and to replace any part of the control system and any gas control which has been under water.

Young children should be carefully supervised when they are in the same room as the heater.

Installation and repair should be done by a qualified service person. Heater should be inspected before

use and at least annually by a qualified service person.

More frequent cleaning may be required due to excessive lint from carpeting, bedding material etc. It is

imperative that control compartments, burners, and circulating air passageways of the appliance be kept

clean.

Follow State and Local codes for installation.

DO NOT put anything around the furnace that will obstruct the flow of combustion and ventilation air.

DO keep the appliance area clear and free from combustible material, gasoline and other flammable va

pors and liquids.

DO examine venting system periodically and replace damaged parts.

DO make a periodic visual check of pilot and burners. Clean and replace damaged parts.

CAUTION: Pilot hole cover must be kept tightly closed during operation.

-

Vent cap hot while furnace is in operation.

Page 4 21091-0-0606

INTRODUCTION

Always consult your local Building Department regarding regulations, codes or ordinances which apply to the installation of a

direct vent wall furnace.

Instructions to Installer

1. Installer must leave instruction manual with owner after installation.

2. Installer must have owner fill out and mail warranty card supplied with furnace.

3. Installer should show owner how to start and operate furnace

and thermostat.

Warning:

Any change to this furnace or its control can be danger

ous. This is a heating appliance and any panel, door or

guard removed for servicing an appliance must be replaced prior to operating the appliance.

General Information

This furnace is design certified in accordance with American National Standard/CSA Standard Z21.86 and CSA 2.32 by the Canadian Standards Association as a direct vent wall furnace to be

installed according to these instructions.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not shown

on the rating plate is the responsibility of the person and com

pany making the change.

Notice: During initial firing of this unit, its paint will bake out and

smoke will occur. To prevent triggering of smoke alarms, ventilate the room in which the unit is installed.

Installation in Residential Garages

Gas utilization equipment in residential garages shall be installed

so that all burners and burner ignition devices are located not less

than 18" above the floor. Such equipment shall be located, or

protected, so it is not subject to physical damage by a moving

vehicle.

Qualified Installing Agency

Installation and replacement of gas piping, gas utilization equip

ment or accessories and repair and servicing of equipment shall

be performed by a qualified agency. The term “qualified agency”

means any individual, firm, corporation or company which either

in person or through a representative is engaged in and is responsible for (1) the installation or replacement of gas piping or (2) the

connection, installation, repair or servicing of equipment, who is

experienced in such work, familiar with all precautions required

and has complied with all the requirements of the authority having jurisdiction.

State of Massachusetts: The installation must be made by a

licensed plumber or gas fitter in the Commonwealth of Mas

sachusetts. The state of Massachusetts requires that a flexible

appliance connector cannot exceed three feet in length.

-

-

The installation must conform with local codes or, in the absence

of local codes, with the National Fuel Gas Code ANSI Z223.1/

NFPA 54* Natural Gas and Propane Installation Code, CSA

B149.1.

*Available from the American National Standards Institute, Inc., 11 West 42nd St.,

New York, N.Y. 10036.

The vent terminal of a direct vent appliance, with an input of

10,000 Btu per hour (3 kW) or less shall be located at least 6"

(150mm) from any air opening into a building, and such an appliance with an input over 10,000 Btu per hour (3 kW) but not

over 50,000 Btu per hour (14.7 kW) shall be installed with a 9"

(229mm) vent terminal clearance and the bottom of the vent terminal and the air intake shall be located at least 12" (305mm)

above grade.

WARNING: The nearest point of the vent cap should be

a minimum horizontal distance of six (6) feet (1.8m) from

any pressure regulator. In case of regulator malfunction,

the six (6) feet (1.8m) distance will reduce the chance of

gas entering the vent cap.

-

-

21091-0-0606 Page 5

REQUIREMENTS FOR MASSACHUSETTS

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those

owned or operated by the Commonwealth and where the

side wall exhaust vent termination is less than seven (7) feet

above finished grade in the area of the venting, including but

not limited to decks and porches, the following requirements

shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS. At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing

plumber or gasfitter shall observe that a hard wired

carbon monoxide detector with an alarm and battery

back-up is installed on the floor level where the gas

equipment is to be installed. In addition, the installing

plumber or gasfitter shall observe that a battery operated

or hard wired carbon monoxide detector with an alarm

is installed on each additional level of the dwelling,

building or structure served by the side wall horizontal

vented gas fueled equipment. It shall be the responsibility

of the property owner to secure the services of qualified

licensed professionals for the installation of hard wired

carbon monoxide detectors.

a. In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space or

an attic, the hard wired carbon monoxide detector

with alarm and battery back-up may be installed on

the next adjacent floor level.

b. In the event that the requirements of this subdivision

can not be met at the time of completion of

installation, the owner shall have a period of thirty

(30) days to comply with the above requirements;

provided, however, that during said thirty (30) day

period, a battery operated carbon monoxide detector

with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS.

Each carbon monoxide detector as required in accordance

with the above provisions shall comply with NFPA 720

and be ANSI/UL 2034 listed and IAS certified.

4. INSPECTION. The state or local gas inspector of the

side wall horizontally vented gas fueled equipment shall

not approve the installation unless, upon inspection,

the inspector observes carbon monoxide detectors and

signage installed in accordance with the provisions of

248 CMR 5.08(2) 1 through

EXEMPTIONS: The following equipment is exempt

from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the

most current edition of NFPA 54 as adopted by

the Board; and

2. Product Approved side wall horizontally

vented gas fueled equipment installed in a

room or structure separate from the dwelling,

building or structure used in whole or in part

for residential purposes.

MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM PROVIDED.

When the manufacturer of Product Approved side

wall horizontally vented gas equipment provides a

venting system design or venting system components

with the equipment, the instructions provided by the

manufacturer for installation of the equipment and the

venting system shall include:

1. Detailed instructions for the installation of the

venting system design or the venting system

components; and

2. A complete parts list for the venting system

design or venting system.

A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for venting

instructions, and/or all venting design instructions shall

remain with the appliance or equipment at the completion

of the installation.

3. SIGNAGE. A metal or plastic identification plate shall

be permanently mounted to the exterior of the building

at a minimum height of eight (8) feet above grade

directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or

equipment. The sign shall read, in print size no less than

one-half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

Page 6 21091-0-0606

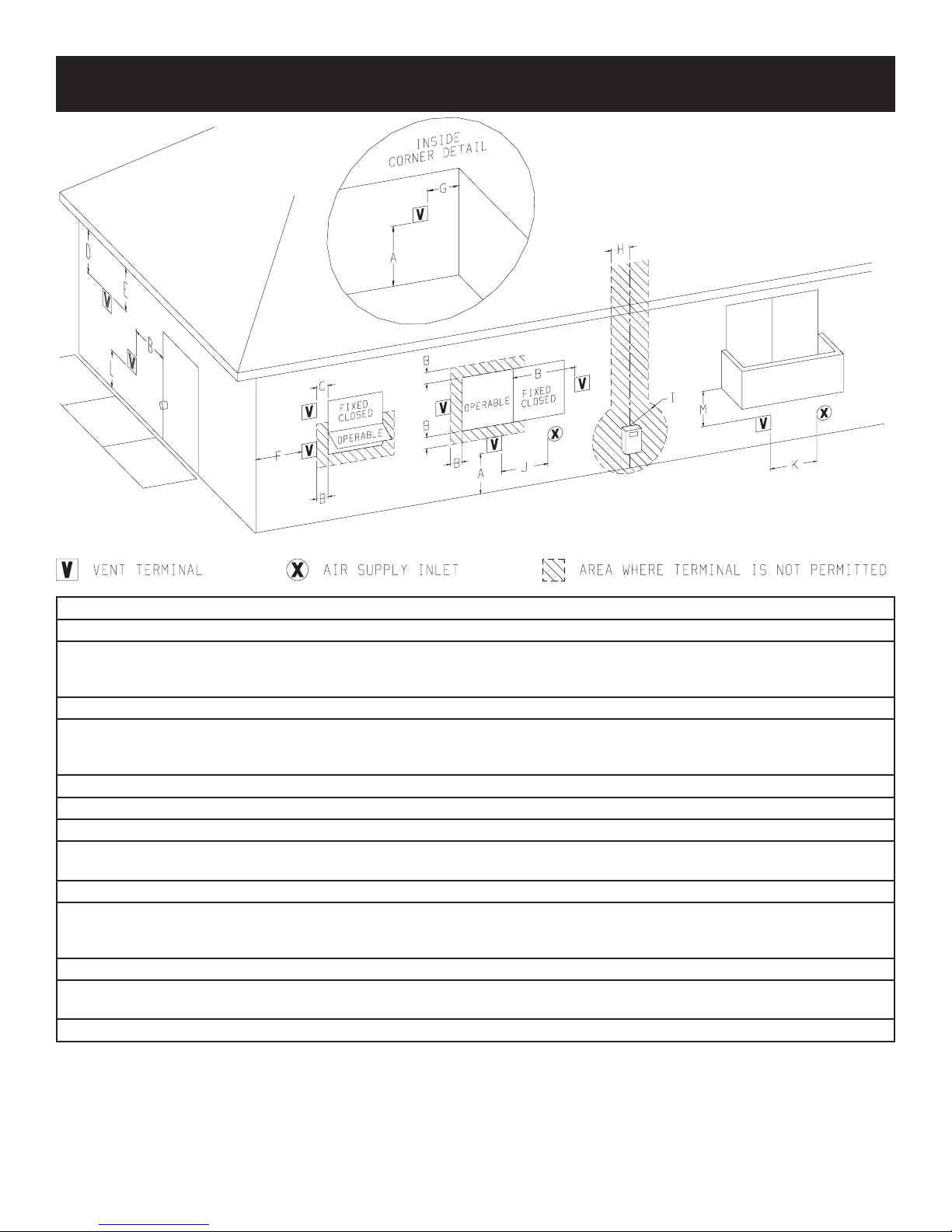

TERMINATION CLEARANCES

Description US Installations

A Clearance above grade, veranda, porch, deck, or balcony 12 inches (30 cm)

B Clearance to window or door that may be open 6 inches (15 cm) for appliance ≤ 10,000 Btuh (3 kW), 9 inches (23 cm)

for appliances > 10,000 Btuh (3 kW) and ≤ 50,000 Btuh (15 kW), 12

inches (30 cm) for appliances > 50,000 Btuh (15 kW)

C Clearance to permanently closed window *

D Vertical clearance to ventilated soffit located above the terminal

within a horizontal distance of 2 feet (61 cm) from the center line

of the terminal

E Clearance to unventilated soffit *

F Clearance to outside corner *

G Clearance to inside corner *

H Clearance to each side of center line extended above meter/regu-

lator assembly

I Clearance to service regulator vent outlet *

J Clearance to nonmechanical air supply inlet to building or the

combustion air inlet to any other appliance.

K Clearance to a mechanical air supply inlet 3 feet (91 cm) above if within 10 feet (3 m) horizontally

L Clearance above paved sidewalk or paved driveway located on

public property

M Clearance under veranda, porch, deck, or balcony. *

*

*

6 inches (15 cm) for appliance ≤ 10,000 Btuh (3 kW), 9 inches (23 cm)

for appliances > 10,000 Btuh (3 kW) and ≤ 50,000 Btuh (15 kW), 12

inches (30 cm) for appliances > 50,000 Btuh (15 kW)

*

1

The minimum distance from the center of the outside vent to the nearest inside and outside corner or obstruction or overhang is 18".

1

In accordance with current ANSI Z223.1/NFPA 54, National Fuel Gas Code

*

For clearances not specified in ANSI Z223.1/NFPA 54

a) A minimum clearance value determined by testing in accordance with section 2.19.6, or;

b) A reference to the following footnote:

“Clearance in accordance with local installation codes and the requirements of the gas supplier.”

or CSA B149.1, one of the following shall be indicated:

21091-0-0606 Page 7

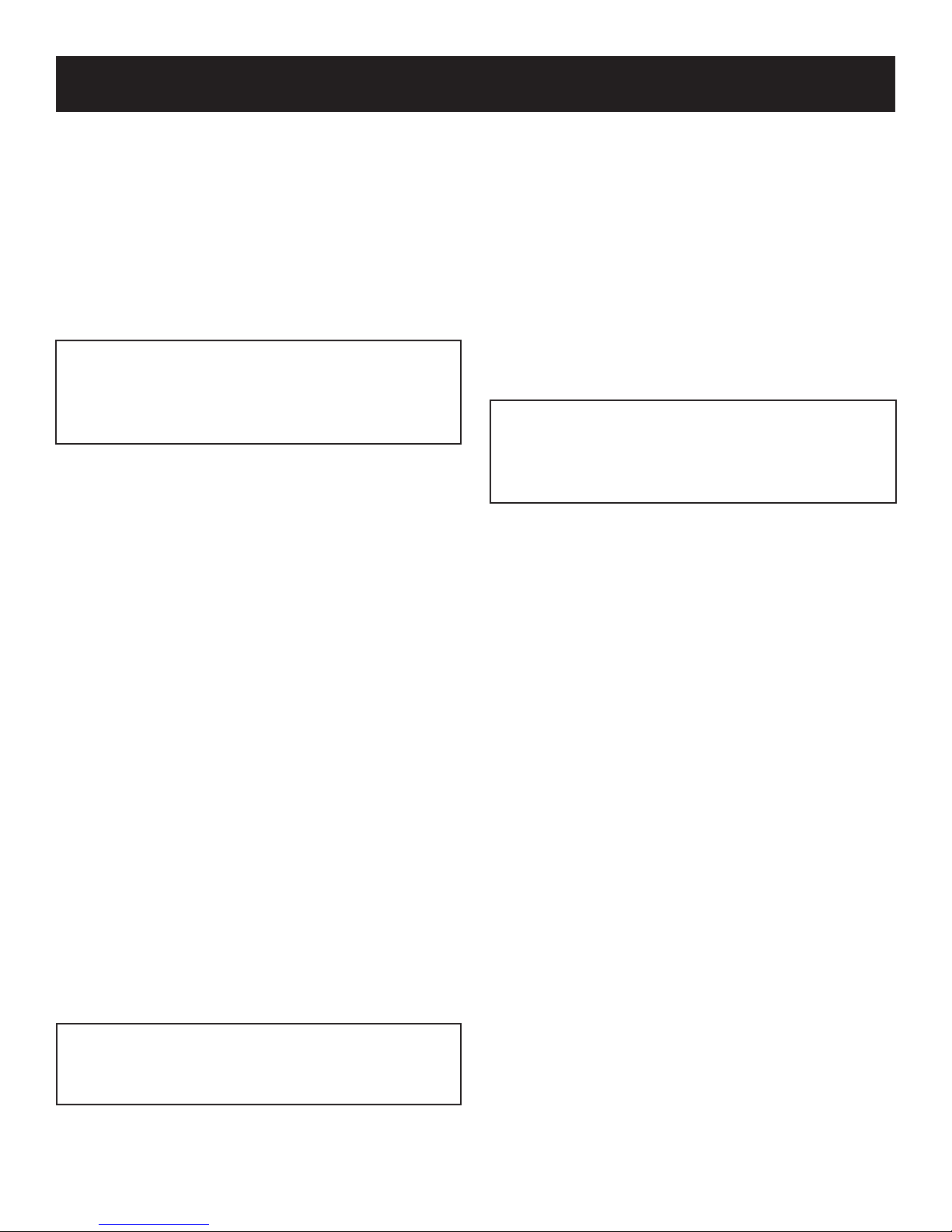

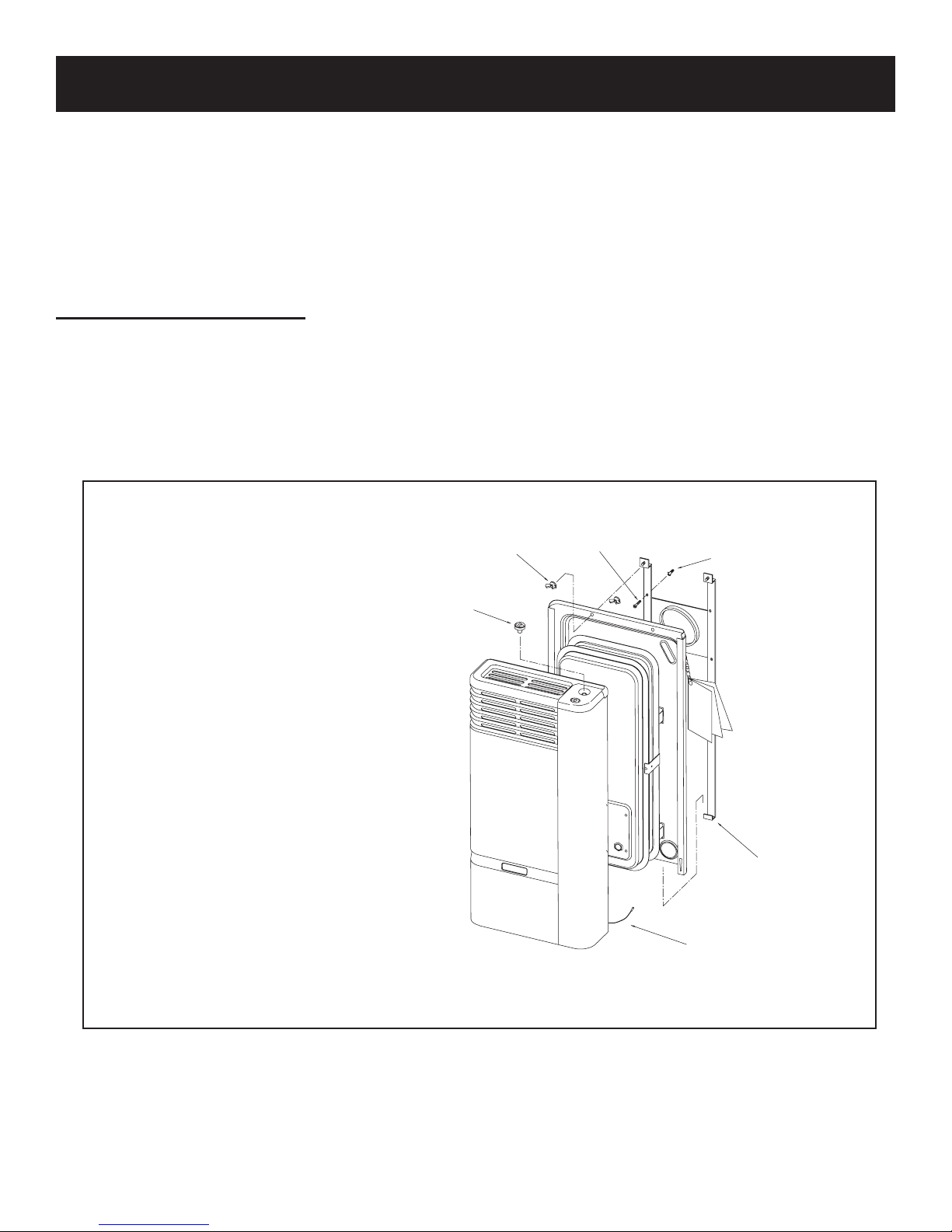

INSTALLATION AND ASSEMBLY

Control

Wing

Screw

Plastic wall anchor

Wall bracket

Piezo cable

WARNING: Any change to this heater or its control can be dangerous. Provide adequate clearances and

accessibility for purposes of servicing and proper operation.

A manufactured home (USA only) installation must conform with the Manufactured Home Construction and Safety Standard, Title 24

CFR, Part 3280 or, when such standard is not applicable, the Standard for Manufactured Home Installations, ANSI Z225.1.

Due to high surface temperature, keep children, clothing, and furniture away. Keep burner and control compartments clean. See instal

lation and operating instructions accompanying heater.

INSTALLATION OVERVIEW

WARNING: Improper installation, adjustments, alteration, service, or maintenance can cause property damage, personal injury

or loss of life.

Refer to the owner’s information manual provided with this appliance. Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

These wall furnace models are designed for direct venting through a wall. Only venting components approved for these furnaces may

be used.

Mark the venting system hole location (as indicated on page 8) and the four holes through

the wall bracket. Drill accordingly. Insert the

four wall anchors provided and tighten the wall

bracket firmly. Use special anchor fasteners if

the heater is to be installed on a wooden (hollow) wall. Pull out the control knob, slide the

front cabinet up and out from the rest of the

heater, and disconnect the sparker from the

piezoelectric igniter. Slide the rear panel lower

edge into the wall bracket fingers, and complete

by tightening the four wing nuts. Reconnect

the piezo cable, and complete the assembly.

The heater is now ready to receive the venting

system assembly from the opposite side of the

wall.

-

IMPORTANT: The venting system must be properly installed to insure proper and safe operation. The venting system

must also be properly re-installed and re-sealed to insure proper and safe operation.

Page 8 21091-0-0606

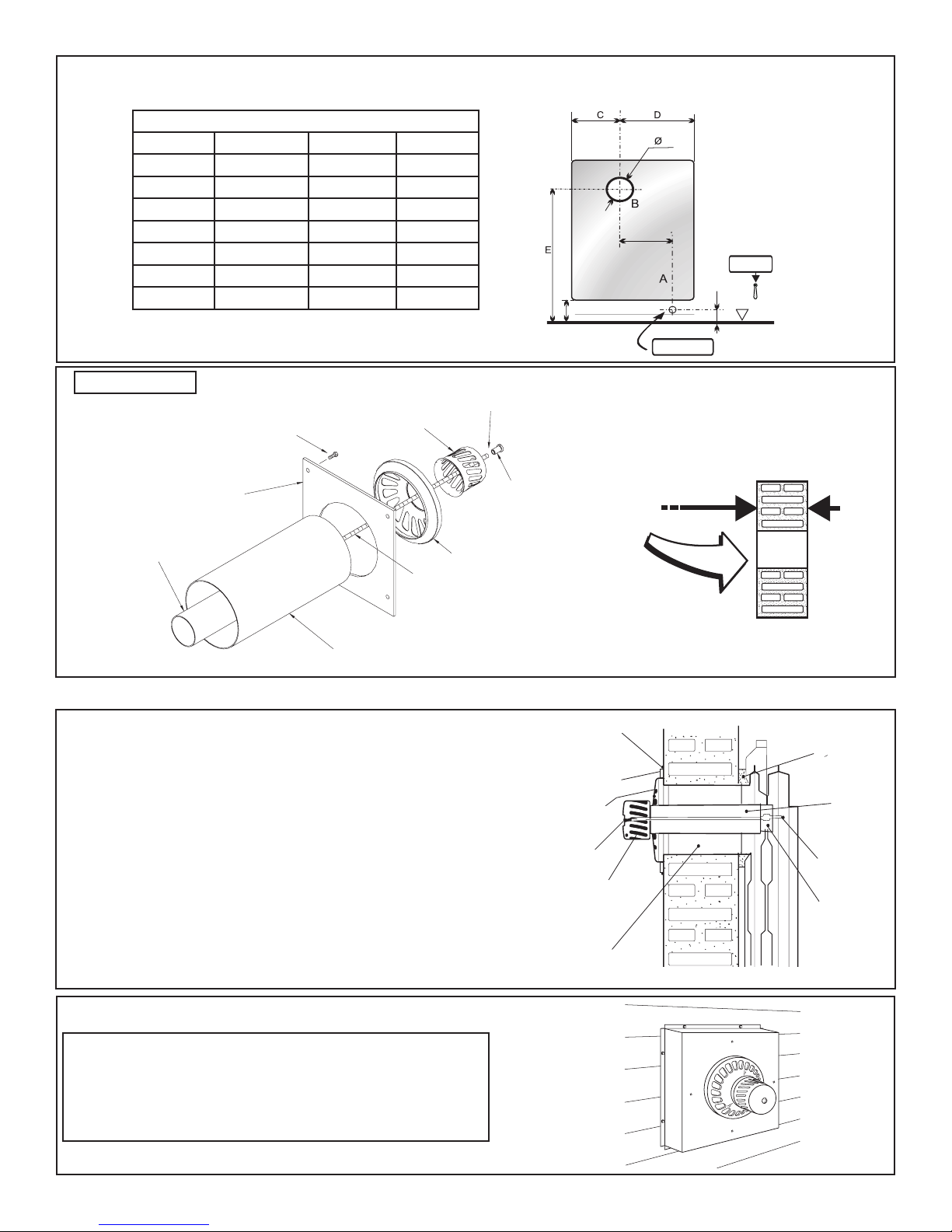

DIRECT VENTING HORIZONTAL INSTALLATION

Valve

Floor line

Gas Outlet

G

F

H

I

Washer not shown

Blind nut

Air inlet ring

Threaded rod

Air inlet pipe

Gases outlet pipe

Spacer

Screw (4x)

Cap

11.75”

Silicon-based

Sealant

Air Inlet

Ring

Spacer

Cup

Gasket

Gas

Outlet

Conduit

Air Inlet

Conduit

Threaded

Rod

Threaded

Support

Blind Nut

Once the place for the installation is selected, refer to the figure below for positioning the “B” hole. Be sure the skirtingboard does not get in the way.

MEASUREMENTS (inches)

Model HW180DV HW130DV HW075DV

C 12 9 5.5

D 13.75 10.5 6.75

E 21 21 22.5

F 11.5 8.75 5

G 5 5 5

H 3.5 3.5 3.5

I 8.25 8.25 6

TB Sub-assembly

This unit is to be installed on wall from 4" to

11.75" thick.

The cap has a hole to insert

the threaded rod easily

through the assembly.

IMPORTANT: The appliance’s venting system should be inspected at least once a year and immediately cleaned if necessary.

Insert the threaded rod (from the other side of the wall) through the

air inlet conduit, tightening it to the combustion chamber support.

Place the air inlet ring around the tube sealing it against the spacer.

Insert the cap through the rod and tighten firmly using the blind nut

and washer.

Failure to position these parts in accordance with diagram or

failure to use only parts specifically approved with these appli

-

ances may result in property damage or personal injury.

Note: Vinyl siding vent kit, HW822DV, is available from Empire

Comfort Systems, Inc. The depth is 3" (76mm), which enables the

vent cap to be extended away from vinyl siding or projections. The

wall depth plus the additional 3" (76mm) depth of the vinyl siding

vent cap extension should not exceed a total depth of 11.75" (330mm)

for HW130DV and HW180DV.

Warning: When vinyl siding vent kit, HW822DV is added to an

existing installation (furnace is installed) do not attempt to add

sections of pipe to the flue outlet tube or air inlet tube. An air tight

seal is required for both tubes. Refer to Parts List, page 22 to order

tubes.

21091-0-0606 Page 9

Loading...

Loading...