HOUNO Visual Cooking I KP User Manual

Dear customer,

Congratulations on the purchase of your new HOUNÖ oven.

You are now the owner of one of the leading oven products on the market.

All HOUNÖ products are subjected to intensive product development, which ensures that the

products always offer the latest technology and the most up-to-date and energy-saving methods of

preparation.

Furthermore, the HOUNÖ products are entirely up-to-date with the latest developments/technology

in terms of

? ERGONOMICS AND SAFETY

? SIMPLE AND LOGICAL OPERATION

? ELEGANT AND FUNCTIONAL DESIGN

? RELIABILITY AND SERVICE

To ensure that our customers get an optimum and reliable product, all HOUNÖ units are passed

through an extensive test programme in which all functions are subjected to a continuous and

extreme load.

Before you start using the oven and its many automatic functions, we recommend that you study the

manual thoroughly so as to ensure optimum cooking results. The preset programs and a number of

special features such as ClimaOptima, Cook & Hold and Delta-T (optional extras on some models)

will ease the daily work in the kitchen. Furthermore, by going through the manual, you will obtain a

better understanding of the advanced technology and feel safer while using the oven. You will find

further information and useful tips on our website www.houno.com.

Terms of warranty

The oven cabinet and the technical parts of your new HOUNÖ oven are covered by a 12-month

factory warranty. However, the heating elements in the oven compartment and the steam generator

are guaranteed for 24 months. The period of warranty takes effect from the date of installation.

The warranty does not include....

We especially draw your attention to the fact that the factory warranty does not cover glass parts

such as oven door glass, lamp glass and incandescent lamps, nor does it cover sealing such as door

gaskets, gaskets for heating elements, etc.

Furthermore, the factory warranty does not apply in the case of

1. defects that are due to the fact that installation has not been carried out in accordance with the

HOUNÖ Installation & Service Manual at present in force (electricity, water/drain, exhaust).

2. defects and interruptions of operation that are the result of the oven not being handled/operated

as specified in the user's manual.

If you utilise all the technological facilities of this oven, you are guaranteed perfect results with a

minimum of resources.

Yours sincerely,

HOUNÖ A/S

KP – ver. 1.4x – Dec. 2005

2

Table of contents

3

5

7

8

10

12

13

15

18

19

21

23

24

31

32

33

35

36

39

40

For

further information

on

the

functions and user interface

of

the oven,

see Service &

Quick start

Setting of mode, temperature and time, and function keys for submenus 4

Setting of fan and exhaust

Setting of multipoint core temperature probe 6

Cleaning program

Steaming, forced steaming, low-temperature steaming

Combi steaming, 1-2-3 9

Regenerating/reheating and cooling

Proving and preheating 11

Time and date

Preset programs

Starting program 14

Entering and changing program

Selecting program or category 16

Entering/changing text in program 17

Selecting/changing category

Editing steps – adding, changing, deleting steps

Saving changes to program 20

Main menu and setting of timer start

Main menu, presetting values (time and temperature) 22

Main menu, changing set-up / locking functions with code

Cleaning

USB key - functions 26

Optional extras:

CombiClean, automatic cleaning system

ClimaOptima

Insufficient cleaning detergent and rinsing agent – replacing canisters 33

Energy counters

Descaling steam generator 34

HACCP library

HACCP diagram

CombiNet 37

Programs and other services

Indicative core temperatures

Roasting and recommended bactericidal holding times

Programs/recipes 41

Installation Manual.

KP – ver. 1.4x – Dec. 2005

3

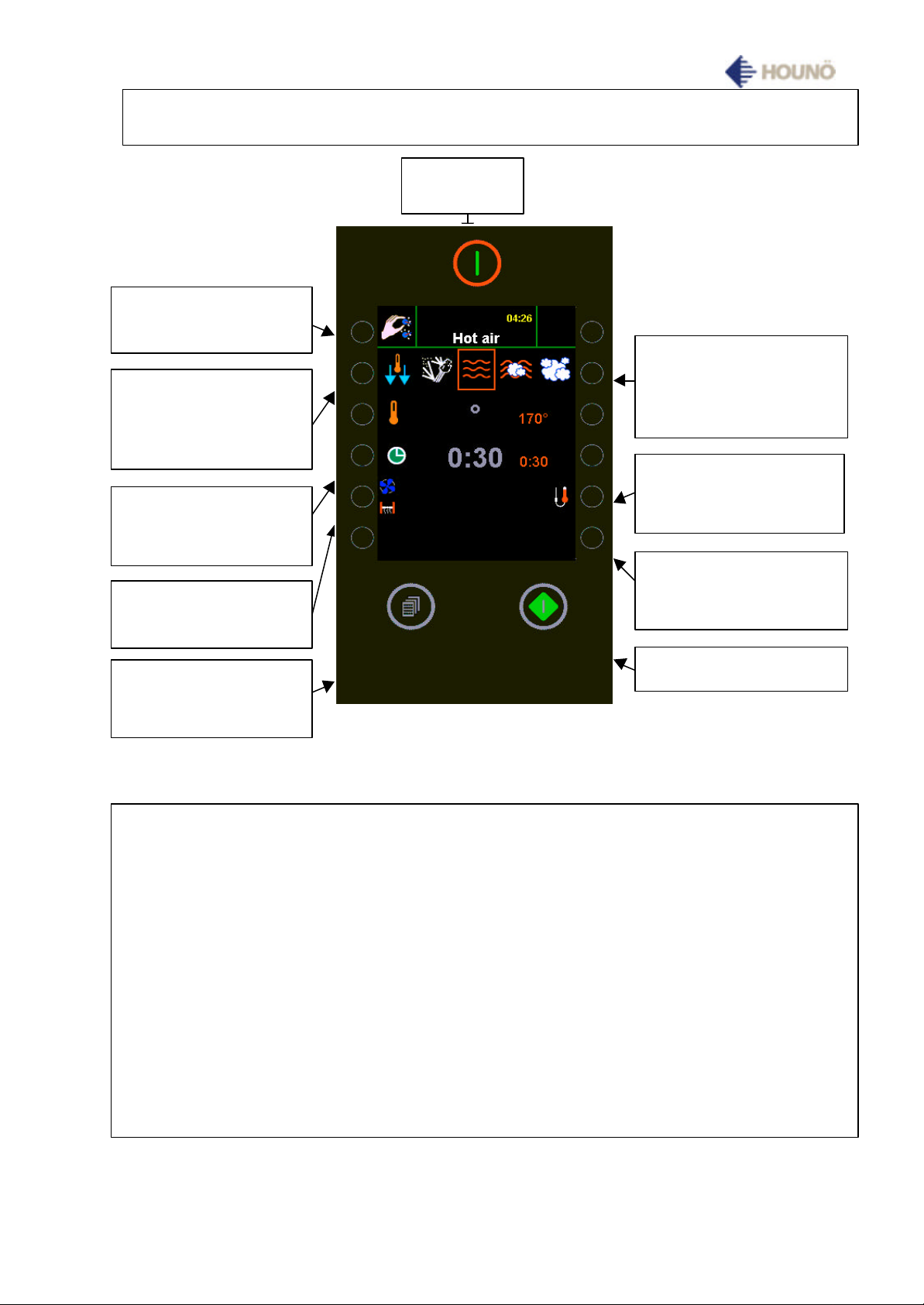

Quick Start

The operation panel is so designed that

the modes are activated by pressing the keys next to the

symbols or digits (6 keys on either side).

In the case of for instance time and temperature, the left as well as the right side next to the

mode are active. The right key increases time, temperature, etc. and the left key reduces time,

temperature, etc.

Some of the symbols are shown on one side only and will lead you to a submenu. When you

have made changes in the submenu, press OK at the upper right hand corner.

The read circle with the green line at the top of the panel is the main switch.

The green square with the white line at the lower right-hand corner is ON/OFF.

The white circle with the small symbol at the lower left-hand corner gives you access to the

program menu.

KP – ver. 1.4x – Dec. 2005

4

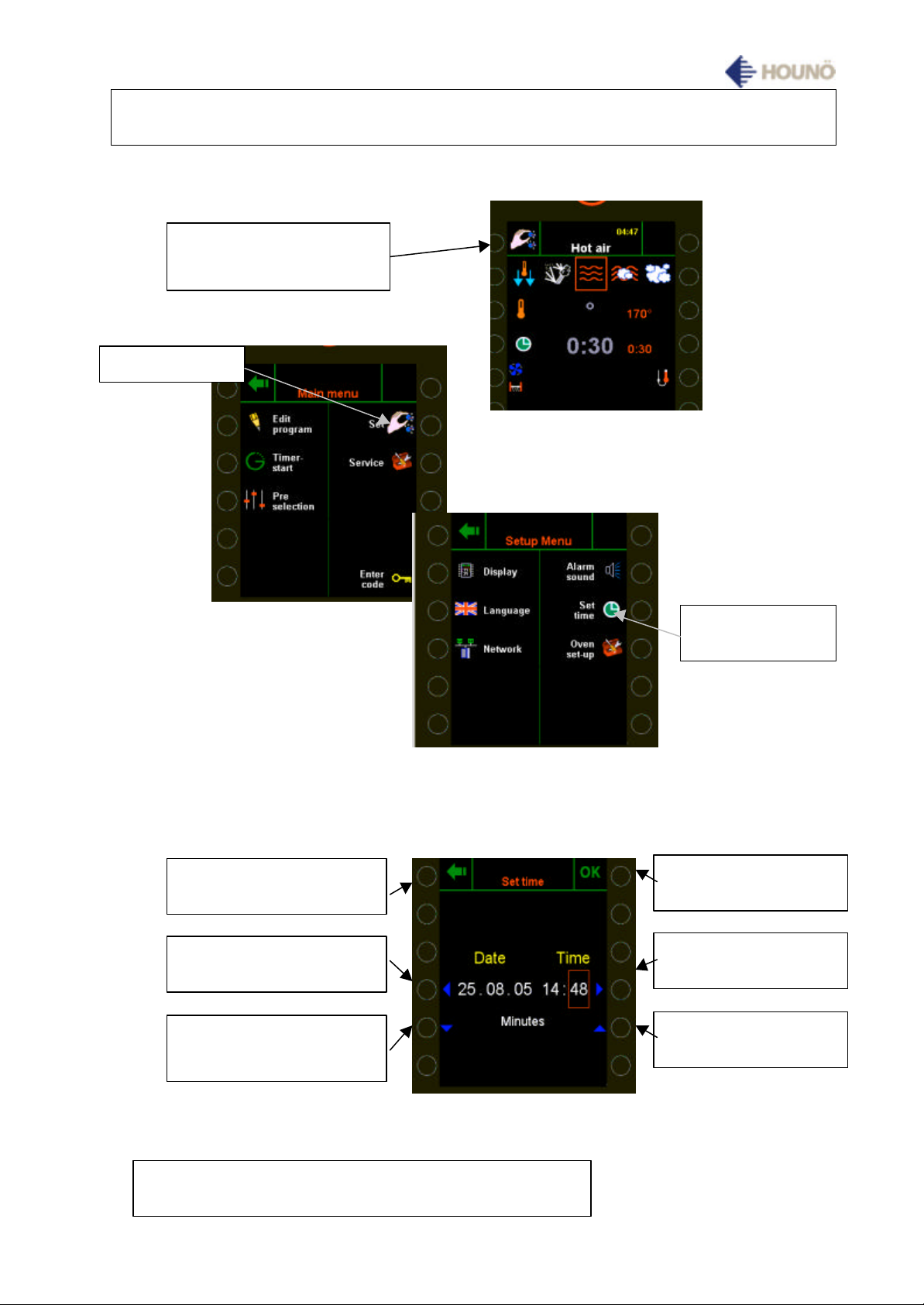

Access to main menu

Setting

of temperature

Setting

of time (

this

Access to fan and

Access to preset

Modes, temperature and time

Main switch

Selects next mode to

the left

side: time down, right

side: time up)*

exhaust

programs

The white digits next to the symbols for TEMPERATURE and TIME show the actual oven

temperature and the actual time remaining. When there is one minute left, the computer counts

down from 59 seconds. The alarm sounds when time is up.

(this side: temperature

up, left side: temperature

down)

Core temperature

Manual humidity

pulsing. Only active

when HOT AIR is on.

ON/OFF

KP – ver. 1.4x – Dec. 2005

When the oven is on (a program or a function has been activated – the square around the

function flashes), it is still possible to set TIME, TEMPERATURE, FAN and EXHAUST and

CORE TEMPERATURE.

Note that the fan wheel is reversible. This means that the wheel can run leftwards as well as

rightwards with a small interval when changing direction.

On the following pages, the above initial display image will be referred to as the “work screen”.

* For continuous operation, press the left key until the indication of time disappears.

5

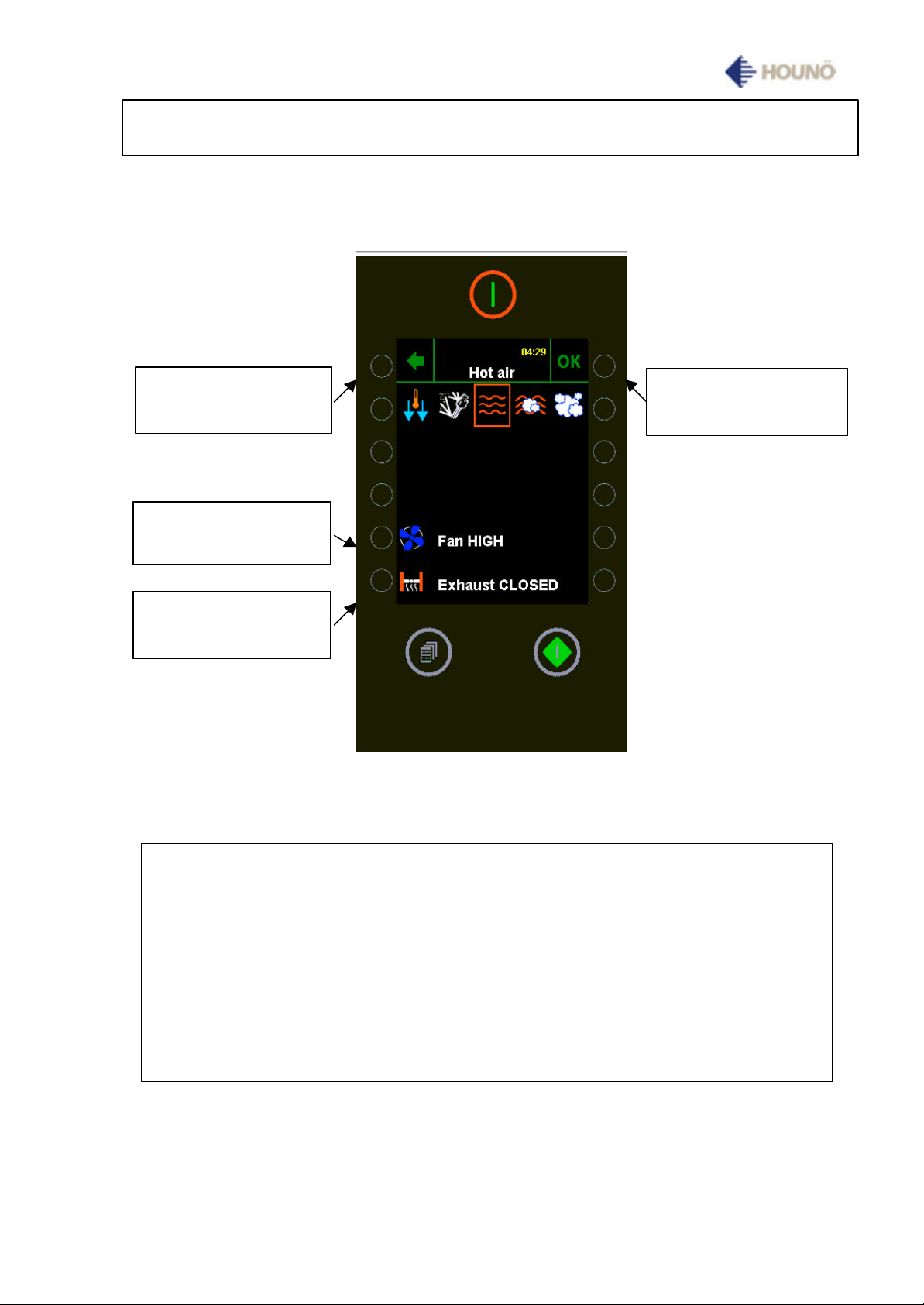

Fan and exhaust

b) OK for settings and

a) Return without

Choose between high

Choose between

Fan and exhaust can be activated before and after start.

saving

and low fan speed

exhaust open or closed

return

Low fan speed is recommended for puff pastry, Danish pastry, cakes, sweet biscuits, etc.

You may add 1 or 2 minutes’ baking time when using low fan speed.

Open exhaust is recommended for bread and pastry, roasting of pieces of meat and to

achieve a grill effect.

a) Return to work screen without storing settings of fan and exhaust, if any.

b) Accept settings of fan and exhaust and return to work screen.

KP – ver. 1.4x – Dec. 2005

6

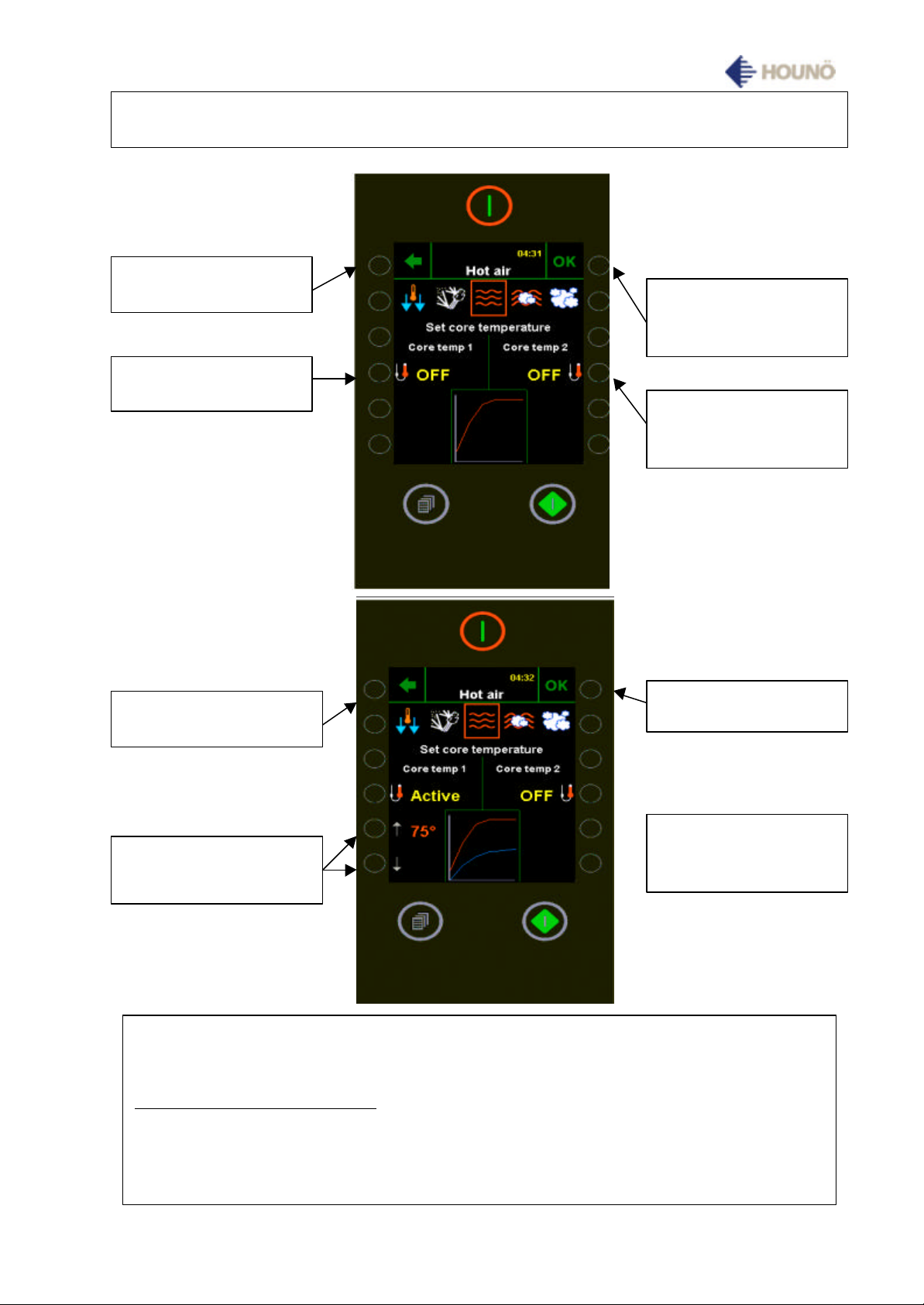

Multipoint core temperature probe

ON/OFF core

OK for settings and

return

Return without saving

OK for settings and

return

temperature probe 1

Return without saving

Setting of core

temperature

ON/OFF core

temperature probe 2

(optional extra)

Activate core

temperature probe 2

(optional extra)

KP – ver. 1.4x – Dec. 2005

The graph illustrates the difference between oven temperature and core temperature. The graph is fixed and

does not change when you set the core temperature. Core temperature probe 1 is red and core temperature

probe 2 (optional extra) is blue.

Cooking with core temperature probe 2

The temperature in the product determines which of the two probes first reaches the desired core temperature.

When one of the probes reaches the core temperature, an alarm sounds and a message appears in the display.

Take out the product and deactivate the probe (OFF). Close the door and the oven continues until the second

probe reaches the desired core temperature.

7

Cleaning program

Manual cleaning program lasting 30 minutes.

The alarm sounds when detergent should be added.

If the oven chamber is very soiled, apply combi steam 3 at 100°C for 30 minutes before

starting the program.

KP – ver. 1.4x – Dec. 2005

8

Steaming

To get the oven ready for production

water plant,

quickly and ensure a perfect start of the

steaming process, we recommend that

you cool down the oven chamber to 80°C.

If the oven chamber is too hot, it cools down automatically.

We recommend that you start the steaming process 8 minutes before you place the products in the oven chamber.

Low-temperature steaming at 65 - 90°C is recommended for delicate products such as fish.

Steaming at 80°C for 5 – 10 min. of fresh vegetables such as carrots, asparagus, potatoes and beans (diameter: 5 –

12 mm) produces end products that have kept their colour and crispness.

Ordinary steaming at 98 – 100°C is recommended for all kinds of root vegetables, pasta, rice and meat.

Forced steaming at 120°C can be used for vegetables that need further processing and for faster preparation of for

instance pasta, rice, hart root vegetables and frozen vegetables. Forced steaming should be used with care.

KP – ver. 1.4x – Dec. 2005

To achieve a perfect preparation every time, we

recommend the use of a core temperature probe in all

steaming modes.

If the oven is not connected to a soft

CombiClean cannot

function properly.

9

Recommendations for

combi steaming:

Combi steaming steps 1, 2 and 3

Combi steaming 1: Ordinary steaming of meat and poultry. The crust of the meat becomes as

brown as if HOT AIR was applied.

Combi steaming 2: For the braising of pieces meat, as the first step of a program. The pores of

the meat are rapidly closed, which keeps the meat juicy.

Combi steaming 3: Can be used as a steaming program at 100°C. The humidity content will be

almost 100% in the course of a few minutes, possibly a little longer if the

oven chamber is filled with e.g. meat and potatoes

If you need to change the humidity content in the steps, please contact your oven supplier.

KP – ver. 1.4x – Dec. 2005

10

Regenerating/reheating/cooling

Cooling is activated in either of the following ways:

Regenerating/reheating is a very gentle process (20 – 180°C). The program operates with low

fan speed and adds a carefully calculated amount of humidity which maintains the nice

appearance and taste of the products.

Use a core temperature probe to reach a perfect end temperature.

For the reheating of sous-vide products, etc., follow the recommendations of the supplier.

Recommended times and temperatures for optimum, gentle reheating:

8 – 12 minutes at 140°C for rice/meat and vegetables arranged on plates

40 – 60 minutes at 120 – 140°C for whole roasts, stews and sauces

20 – 30 minutes at 120°C for pasta, rice and the like

a) Oven door closed. Use water to speed up cooling process. Alarm sounds when the

temperature is reached.

b) Oven door open. Fan wheel draws in air to speed up cooling process. Program stops when

temperature is reached. No alarm.

It is recommended to set the cooling mode at 20°C below the required working temperature.

KP – ver. 1.4x – Dec. 2005

11

The computer is set to maintain a humidity level of 80% which is the optimum level for all

Proving/preheating

Note that the countdown does not

products that need to be proved before they are baked.

Recommended settings of temperature and time:

Loaves of 400 – 800 g: Low temperature and long proving time (32°C, 45 min.).

Rolls/baguettes of 60 – 200 g: High temperature and short proving time (36°C, 25 min.).

We call your attention to the preset ”semiautomatic bread program”, in which the bread is proved

and baked in the same process (models KPE, CPE and BPE).

Please note the distinction between prebaked (additional baking only) and preproved (thawing,

proving and baking).

PREHEATING can be set

for 0 – 15 minutes .

start until the selected oven

temperature is reached.

PREHEATING ensures that the oven chamber is thoroughly heated.

If the oven is cold, 2 - 5 minutes’ preheating is recommended (models 2.10 and 2.14 require 15

minutes’ preheating)

If the oven is hot, 0 – 2 minutes’ preheating is recommended.

Preheating at a temperature which is approx. 50°C higher than the desired working temperature

is recommended.

NOTE: When the oven door is opened for loading, the oven chamber loses 30-50% of the

heat.

KP – ver. 1.4x – Dec. 2005

12

Choose main menu

Return

without

making

Move red

square to

the

Reduce digit inside red

Accept

changes and

Move red

square to

Increase digit inside

Choose Set-up

Time and date

changes

left

square

Choose Set time

return (1)

the right

red square

(1) When you press OK, the oven restarts automatically.

KP – ver. 1.4x – Dec. 2005

13

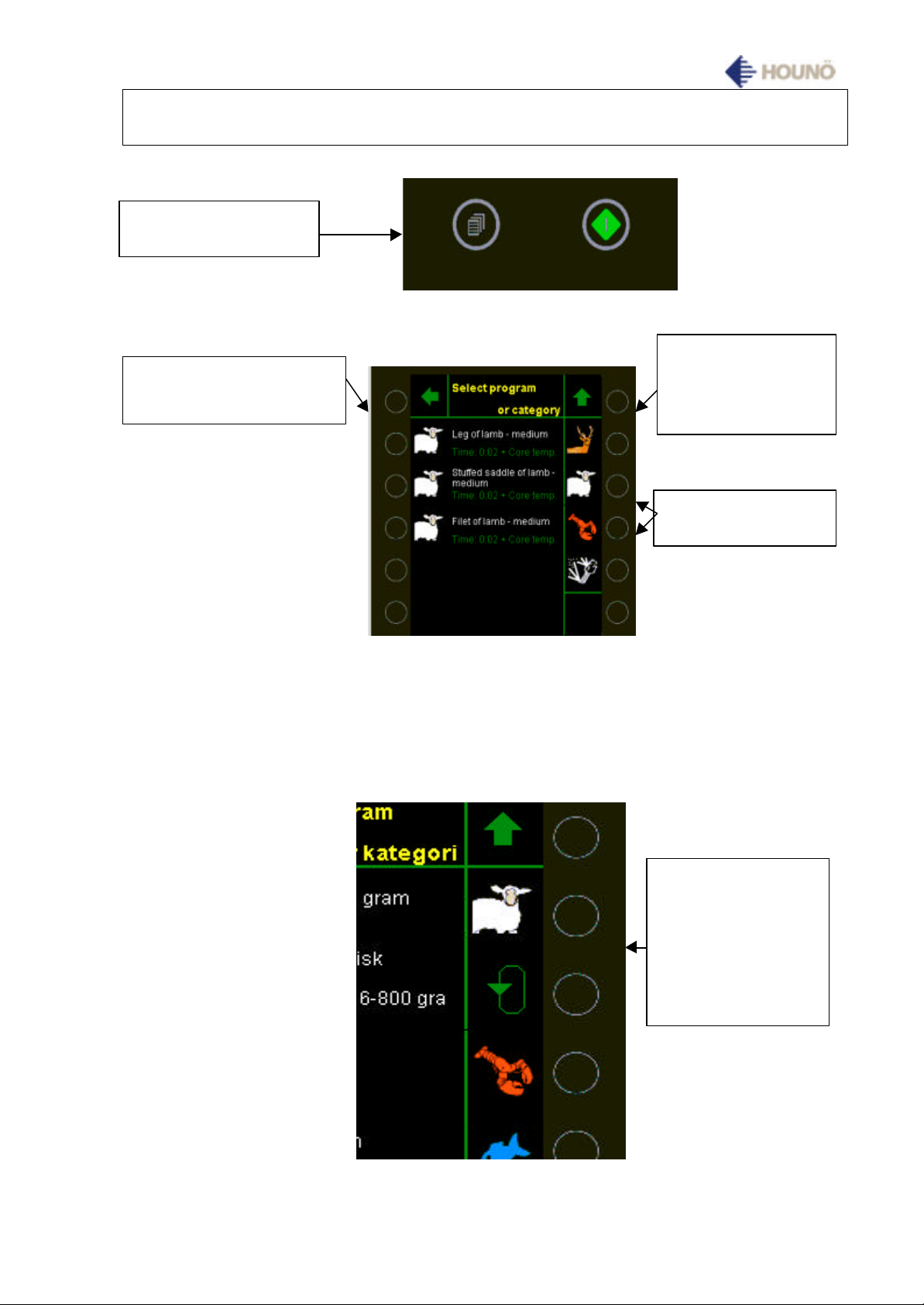

Press

again to scroll

Choose main

Press key to

the right

of

ON/OFF

Return

Preset programs

Arrow indicates that

there are more main

categories than

those shown.

category

KP – ver. 1.4x – Dec. 2005

through the

programs of the

category (there are

more categories than

the 5 listed to the

right)

14

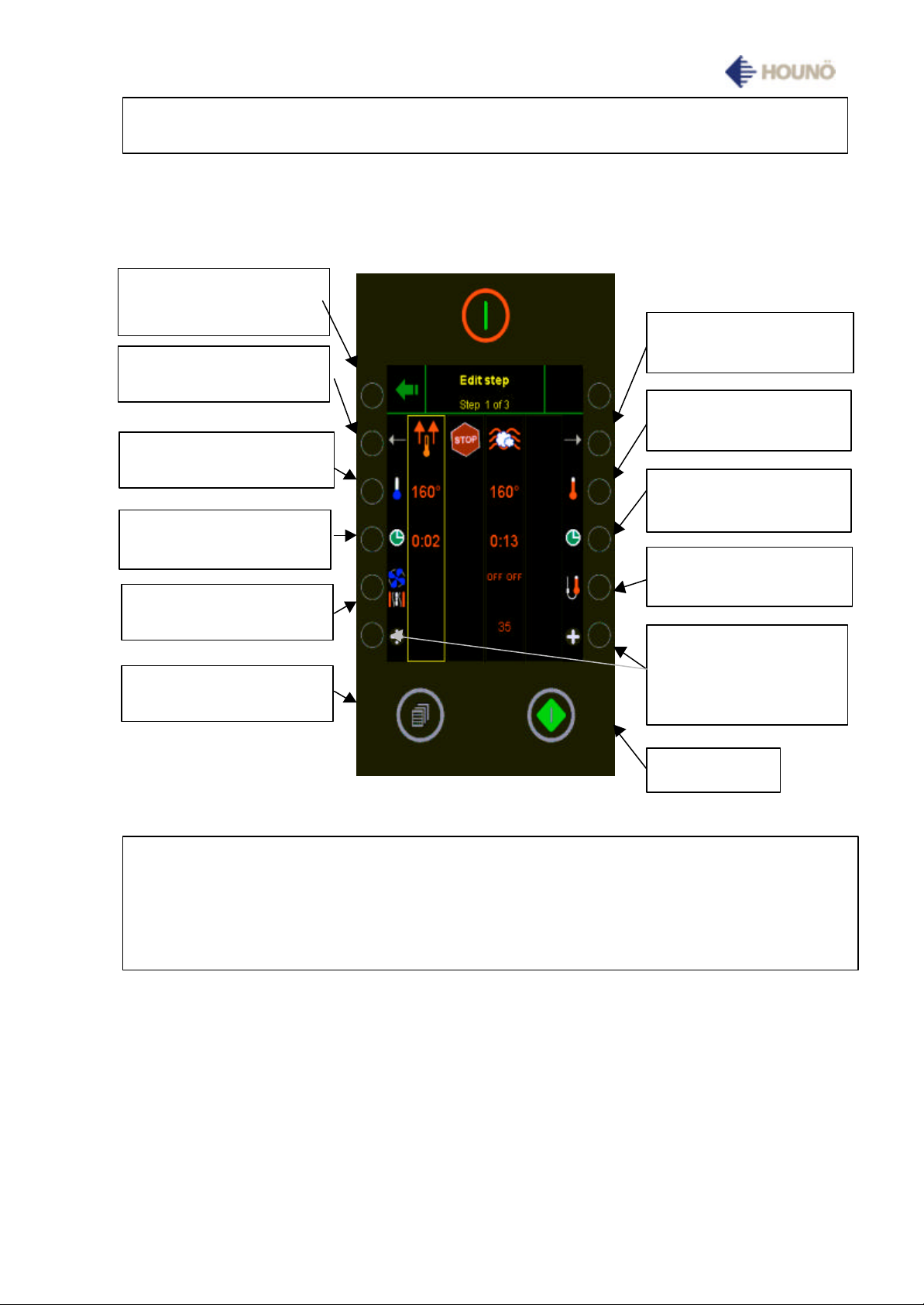

Return to previous

Temperature up in

Increase time in

current

Temperature

down in

(A) Note the location of the yellow square. Only that particular step in the program can now

be

Access to fan and

screen

Yellow frame moves to

the left (A)

current step

Reduce time in current

step

Starting program

Yellow frame moves to

the right (A)

current step

step

Access to core temperature in current step

exhaust in current step

Setting of humidity

content in Clima-

Return to work screen

edited in terms of time, temperature, fan/exhaust, core temperature and possibly humidity

content (ClimaOptima).

Any changes you may have made to the program are saved in the current run only.

Optima (if mode is

ClimaOptima)

Start program

KP – ver. 1.4x – Dec. 2005

15

Entering and changing program

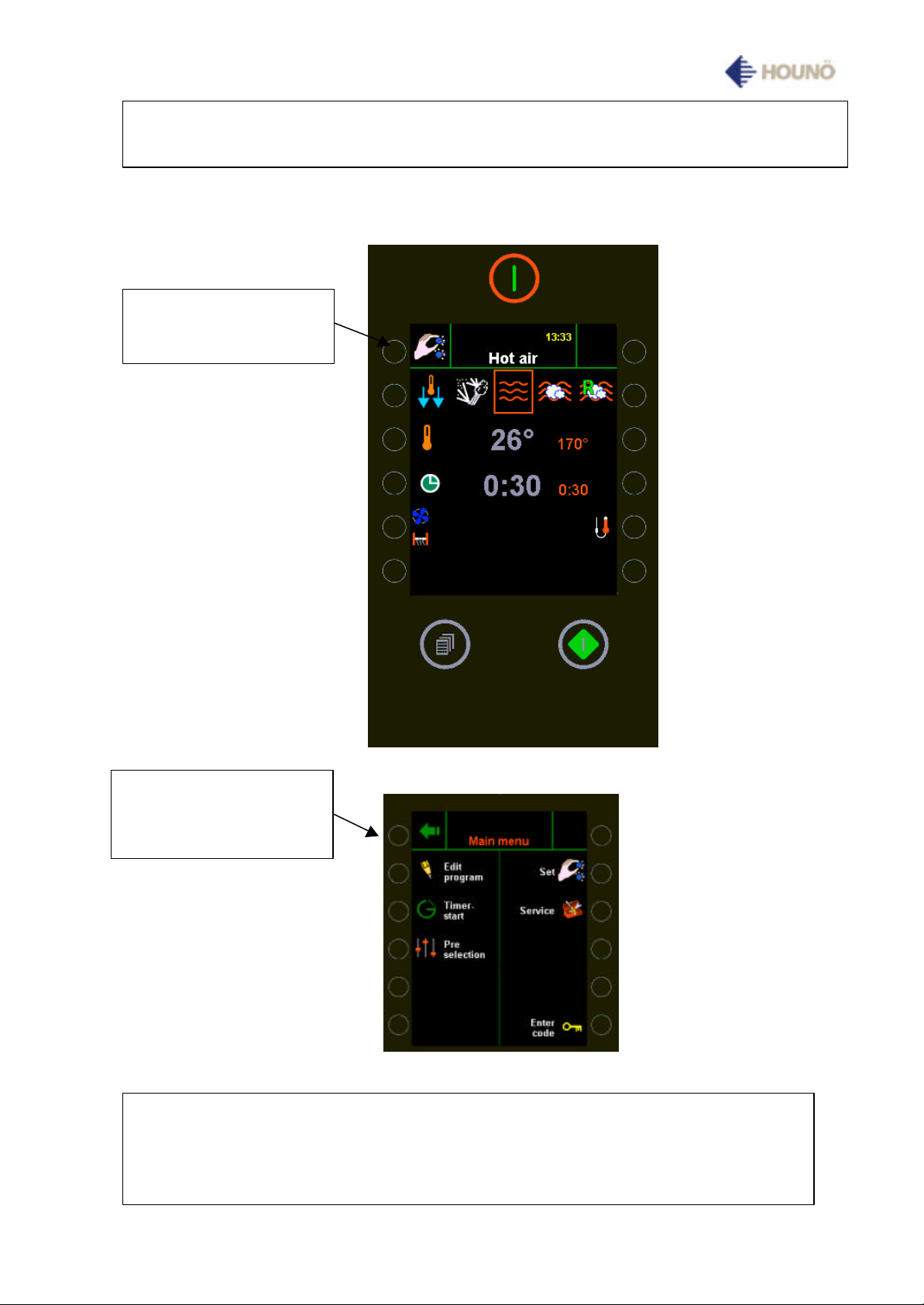

Press for access to main

menu

Press for access to making

new programs or

changing existing ones

If, when one of the functions in the main menu is activated, a screen appears asking for a

code, press 876412.

KP – ver. 1.4x – Dec. 2005

Loading...

Loading...