HOUNO CPE-gas User Manual

ENG

User Manual CPE

-

gas

2

Table of contents

Preface and warranty 3

Safety instructions 4

Quick start 5

Setting of operation modes, temperature and time 6

Fan and exhaust 7

Core temperature: 8-11

- Functions: Core temperature 8

- How to use the core temperature 9

- How to use Delta T 10

- How to use Cook & Hold 11

Operation modes: 12-16

- ClimaOptima

- Steaming 13

- Reheating 14

- Proving / Rising 15

- Preheating 15

- Cooling 15

- CombiWash® 16

Programmes: 17-24

- Preprogrammed recipes 17

- Starting programme / recipe 18

- Editing programme 19-24

Main menu: 25-28

- Setting clock 25

- Timer start 26

- Preset values 27

- Oven set-up 28

Counters for detergent and energy 29

Cleaning 30-31

USB key function 32-36

HACCP 37-38

CombiNet® 39-40

Error codes 41

Recommended core temperatures 42

Low-temperature and long-time roasting 43

Recommended programmes and the HOUNÖ recipe library 44-54

www.houno.com 54

For further information on the functions and user interface of the oven, see Service &

Installation Manual.

®

12

CPE/KPE – Ver. 1.54x – July 2009

3

Dear customer,

Congratulations on the purchase of your new HOUNÖ oven.

You are now the owner of one of the leading ovens on the market.

All HOUNÖ products are subjected to intensive product development, which ensures that the

products always offer the latest technology and the most up-to-date and energy-saving

methods of preparation. Moreover, the HOUNÖ products are entirely up-to-date with the latest

developments/technology in terms of

• ERGONOMICS AND SAFETY

• SIMPLE AND LOGICAL OPERATION

• ELEGANT AND FUNCTIONAL DESIGN

• RELIABILITY AND SERVICE

To ensure that our customers get an optimum and reliable product, all HOUNÖ units are

passed through an extensive test programme in which all functions are subjected to a

continuous and extreme load.

Before you start using the oven and its many automatic functions, we recommend that you

study the manual thoroughly so as to ensure optimum cooking results. By going through the

manual, you will obtain a better understanding of the advanced technology and feel safer while

using the oven in your daily work.

Furthermore, we call your attention to the wide variety of optional extras:

• Handshower

• Core temperature probe

• Additional cassette rack, trolley for rack, wall bracket

• Extraction hood and extraction hood with condenser

• Visit www.houno.com for further information on our wide range of

additional equipment

Terms of warranty

The oven cabinet and the technical parts of your new HOUNÖ oven are covered by a 12-month

factory warranty. However, the heating elements in the oven chamber are guaranteed for 24

months and the exterior door glass for 10 years. The period of warranty takes effect from the

date of delivery.

The warranty does not include....

We especially draw your attention to the fact that the factory warranty does not cover glass

parts such as interior door glass and halogen lamps, nor does it cover sealings. Furthermore,

the factory warranty does not apply in the case of

1. defects that are due to the fact that installation has not been carried out in accordance

with the HOUNÖ Installation & Service Manual at present in force (electricity,

water/drain, exhaust).

2. defects and interruptions of operation that are the result of the oven not being

handled/operated as specified in the user's manual.

If you utilise all the technological facilities of this oven, you are guaranteed perfect results with

only a minimum of resources.

Enjoy your new HOUNÖ oven.

Yours sincerely,

HOUNÖ A/S

CPE/KPE – Ver. 1.54x – July 2009

4

Safety Instructions

Ready to use….

When the oven is correctly installed, read this manual carefully before the oven comes into

service.

This manual should be kept handy to persons using the oven.

Always place trays filled with hot liquid in the bottom runners of the oven chamber to avoid

spilling the hot liquid on yourself when you take the tray out of the oven chamber.

Some areas on the outside of the oven may get as hot as 60°C or more, therefore, you should

only touch the front of the oven.

Do not open the oven during the automatic cleaning process.

Do not store flammable materials around or under the unit.

When using the roll-in or trolley system, be aware of hot racks sliding out of the oven. Use the

parking brakes on the wheels to prevent trolleys from rolling away on uneven floors.

Gas units only:

If your oven is installed under an extraction hood (recommended), the extraction hood should

be switched on when the oven is running.

If your oven is connected to a chimney, the flue duct must be cleaned in compliance with local

standards and regulations.

Do not block the exhaust pipes or the area around the oven.

The oven should only be used in calm conditions.

FAILURE TO COMPLY WITH THE ABOVE INSTRUCTIONS MAY INCREASE THE RISK OF

FIRE!

If you smell gas….

- Turn off the gas supply immediately.

- Do not use the control panel.

- Make sure there is ample ventilation near the oven.

- Avoid open fire and sparks.

- Call the gas supplier, using an external phone.

Maintenance and repair:

Maintenance and repair should only be carried out by trained technicians.

Only use cleaning detergent that matches the specifications from the factory.

CPE/KPE – Ver. 1.54x – July 2009

5

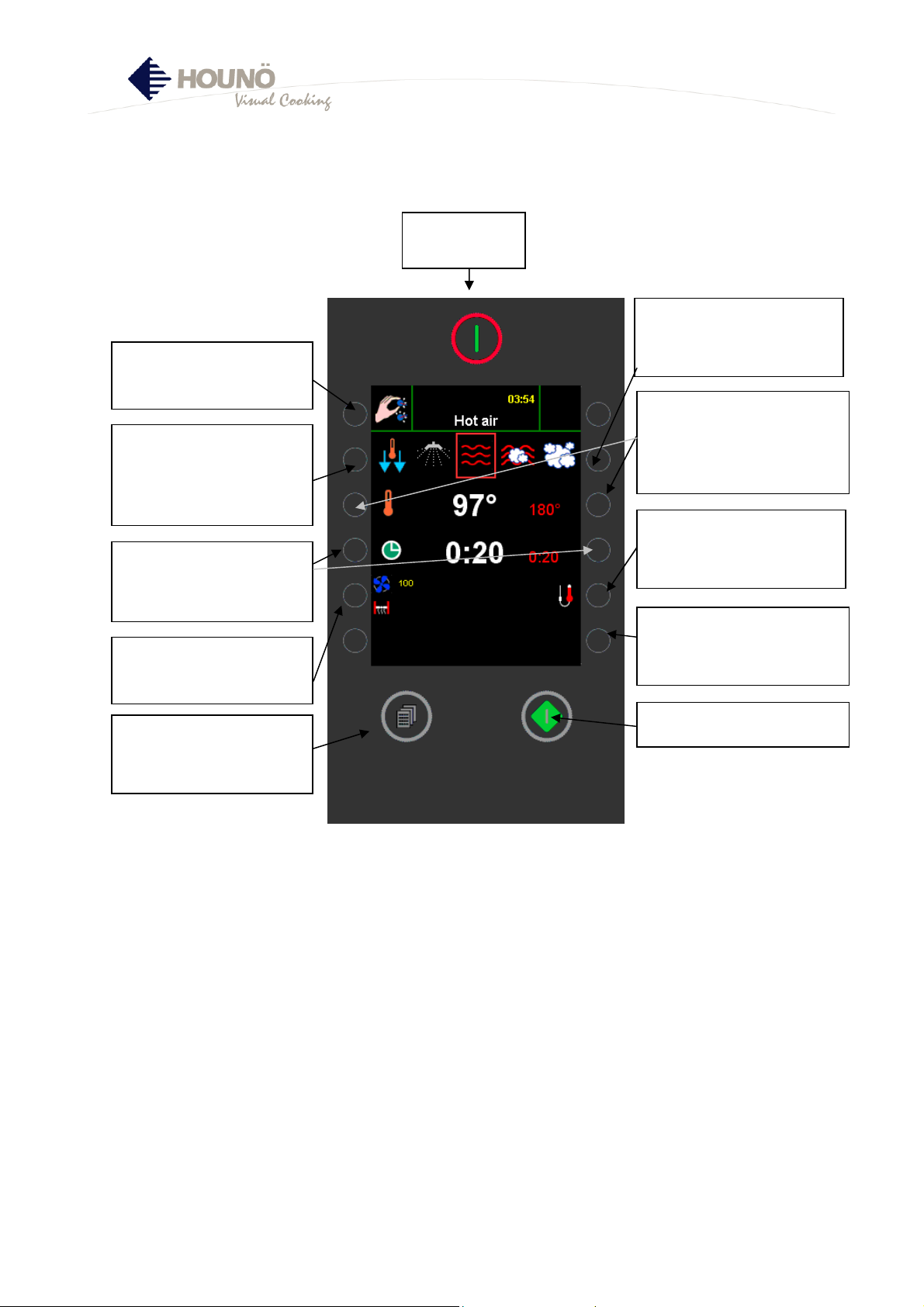

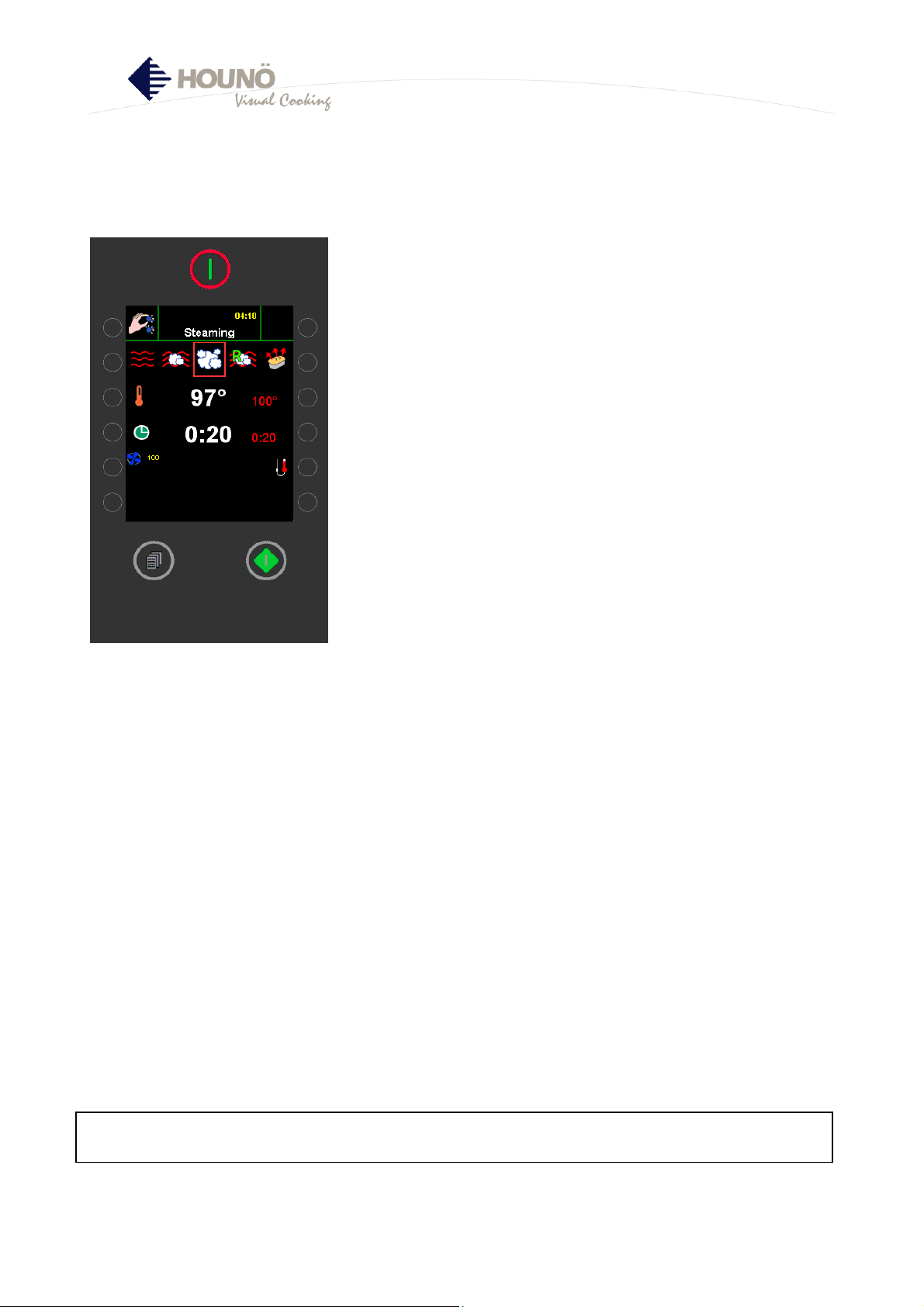

Quick start

The operation panel is so designed that the modes

are activated by pressing the keys next to the

symbols or digits (6 keys on either side).

In the case of for instance time and temperature,

the left as well as the right side next to the mode

are active. The right key increases time,

temperature, etc. and the left key reduces time,

temperature, etc.

Some of the symbols are shown on one side only

and will lead you to a submenu. When you have

made changes in the submenu, press OK at the

upper right hand corner.

The red circle with the green line at the top of the

panel is the main switch.

The green square with the white line at the lower

right-hand corner is ON/OFF.

The white circle with the small symbol at the

lower left-hand corner gives you access to the

programme menu.

CPE/KPE – Ver. 1.54x – July 2009

6

Access to main menu

Core temperature

ON/OFF

Main switch

Next mode to the right

Setting of mode, temperature and time

Selects next mode to

the left

Setting of time (this

side: time down, right

side: time up)*

Access to fan and

exhaust

Access to preset

programmes

The white digits next to the symbols for TEMPERATURE and TIME show the actual oven

temperature and the actual time remaining. When there is one minute left, the computer

counts down from 59 seconds. The alarm sounds when time is up. The red digits are the preset

time and temperature.

When the oven is on (a program or a function has been activated – the square around the

function flashes), it is still possible to set TIME, TEMPERATURE, FAN and EXHAUST.

Note that the fan wheel is reversible. This means that the wheel can run leftwards as well as

rightwards with a small interval when changing direction.

The core temperature should be set before the program is started.

On the following pages, the above initial display image will be referred to as the “work menu”.

* For continuous operation, press the left key until the indication of time disappears.

Setting of temperature

(this side: temperature

up, left side:

temperature down)

Manual humidity

pulsing. Only active

when HOT AIR is on.

CPE/KPE – Ver. 1.54x – July 2009

7

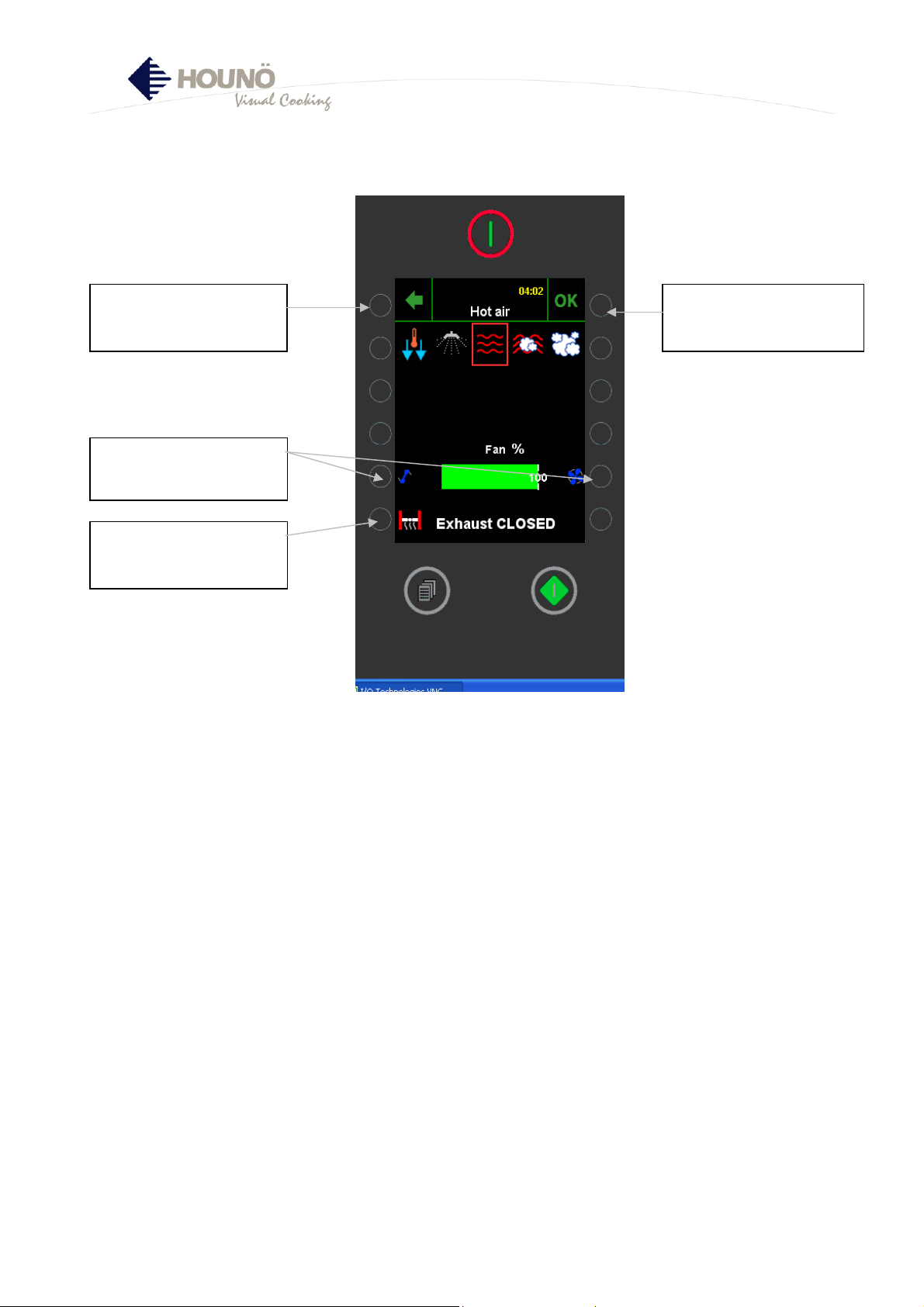

Setting of fan and exhaust

closed

a) Return without

saving

Choose fan speed

from 20% to 100%

Choose between

exhaust open or

Fan and exhaust can be activated before as well as after start-up.

A fan speed between 20 and 50% is recommended for the baking of puff pastry, Danish

pastry, cakes and small products as well as in the Delta-T and Cook-and-Hold modes. You may

add 1 – 2 minutes’ preparation time for each ½ hour when low fan speed is used.

Fan speeds below 50% cannot be used at temperatures above 200°C.

A fan speed between 50 and 90% are recommended if you want a particularly juicy end

product and can accept a longer cooking time.

Open exhaust is recommended for bread and pastry, roasting of pieces of meat and to achieve

a grill effect.

a) Return to work menu without saving settings of fan and exhaust, if any.

b) Accept settings of fan and exhaust and return to work menu.

It is only possible to set the exhaust function in the hot-air mode. In the other modes, the

exhaust function is controlled automatically by the oven.

The fan function is active in HOT AIR, STEAMING and REHEATING. In the other modes, the fan

is controlled automatically by the oven.

b) OK for settings and

return

CPE/KPE – Ver. 1.54x – July 2009

8

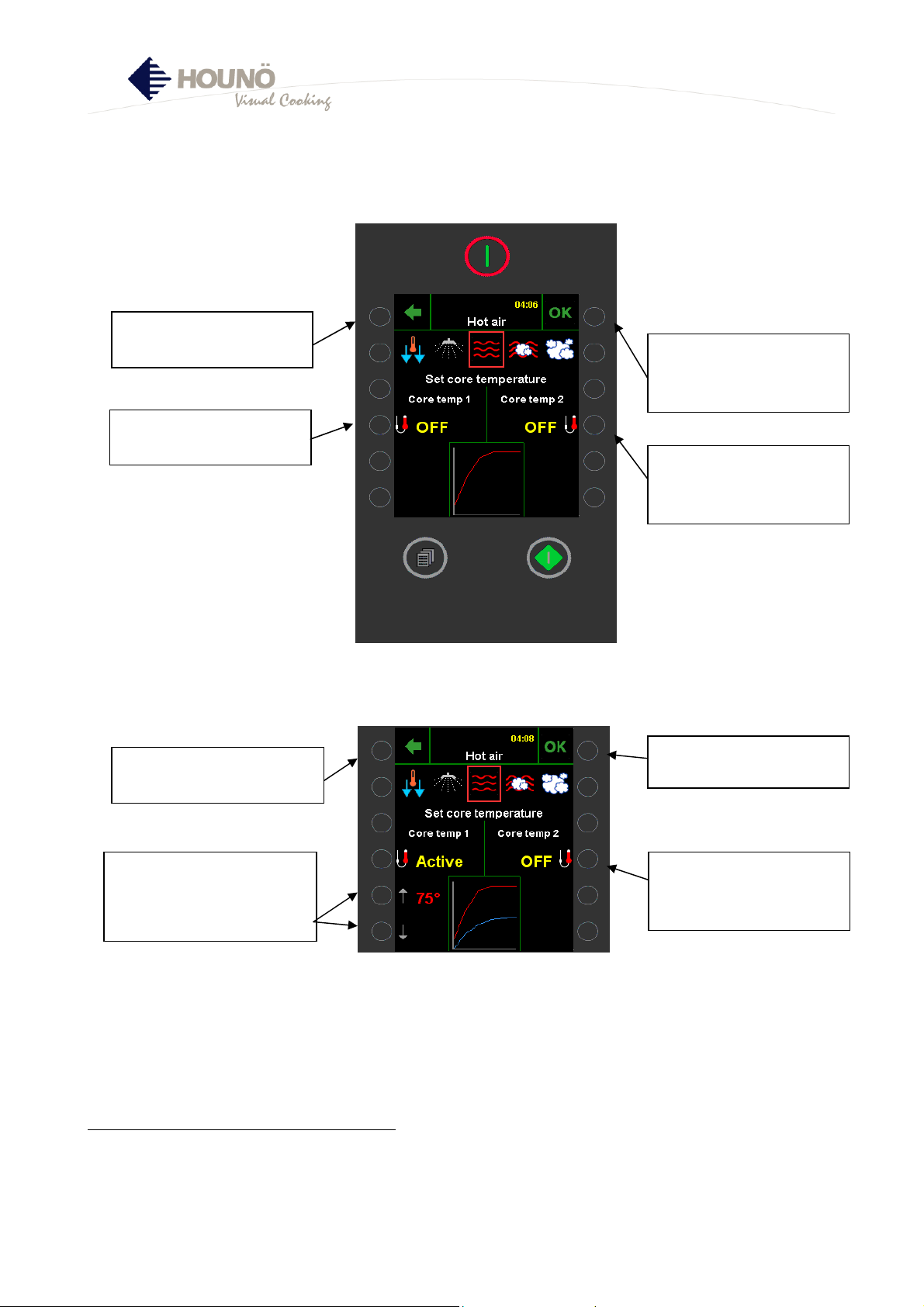

Core temperature

The core temperature sensor offers you the following modes:

Active: This is the mode in which you use the core temperature to determine when the

product is finished. In this mode, you set the oven temperature, the programme and, if actual,

the humidity content.

Delta-T: This is the mode in which you set the desired core temperature. You get the best

result starting with an oven temperature of 30 – 40°C. Subsequently, the oven automatically

controls the temperature in the oven chamber on the basis of the core temperature of the

product. The oven temperature is approx. 20°C higher than the current core temperature

rising gradually as the core temperature of the product rises. This mode offers you very gentle

preparation resulting in a tender and juicy end product and reducing shrinkage by up to 20%

compared to traditional modes of preparation.

Cook & Hold: Cook & Hold is an extension to the Delta-T mode. It starts like Delta-T but ends

up by evening out the temperature in the oven and the core temperature and thus acting as a

warming mode.

Cook & hold is suitable for roasting overnight when there is no staff around.

Start-up

You start core temperature sensor 1 (optional extra for CPE) by pressing the on/off key

once.

You start Delta-T by pressing once more next to the active core temperature sensor 1.

You start Cook & Hold by pressing once more next to the active Delta-T.

To switch off core temperature sensor 1, press the on/off key once more.

Remember always to confirm your setting by pressing OK on the key in the upper right-hand

corner.

You start core temperature sensor 2 (optional extra for KPE and CPE) by pressing the on/off

key once. Core temperature 2 only holds the mode “active”.

CPE/KPE – Ver. 1.54x – July 2009

9

Return without saving

Return without saving

Core temperature sensor

OK for settings and

return

ON/OFF core

temperature probe 1

ON/OFF core

temperature probe 2

(optional extra)

OK for settings and

return

Setting of core

temperature

30 – 150°C

Activate core

temperature probe 2

(optional extra)

The graph illustrates the difference between oven temperature and core temperature. The

graph is fixed and does not change when you set the core temperature. Core temperature

probe 1 is blue and core temperature probe 2 (optional extra) is green. The red line is the

oven temperature.

Cooking with core temperature probe 2

The temperature in the product determines which of the two probes first reaches the desired

core temperature. When one of the probes reaches the core temperature, an alarm sounds and

a message in yellow appears in the display. Take out the product. Close the door and the oven

continues until the second probe reaches the desired core

temperature.

CPE/KPE – Ver. 1.54x – July 2009

10

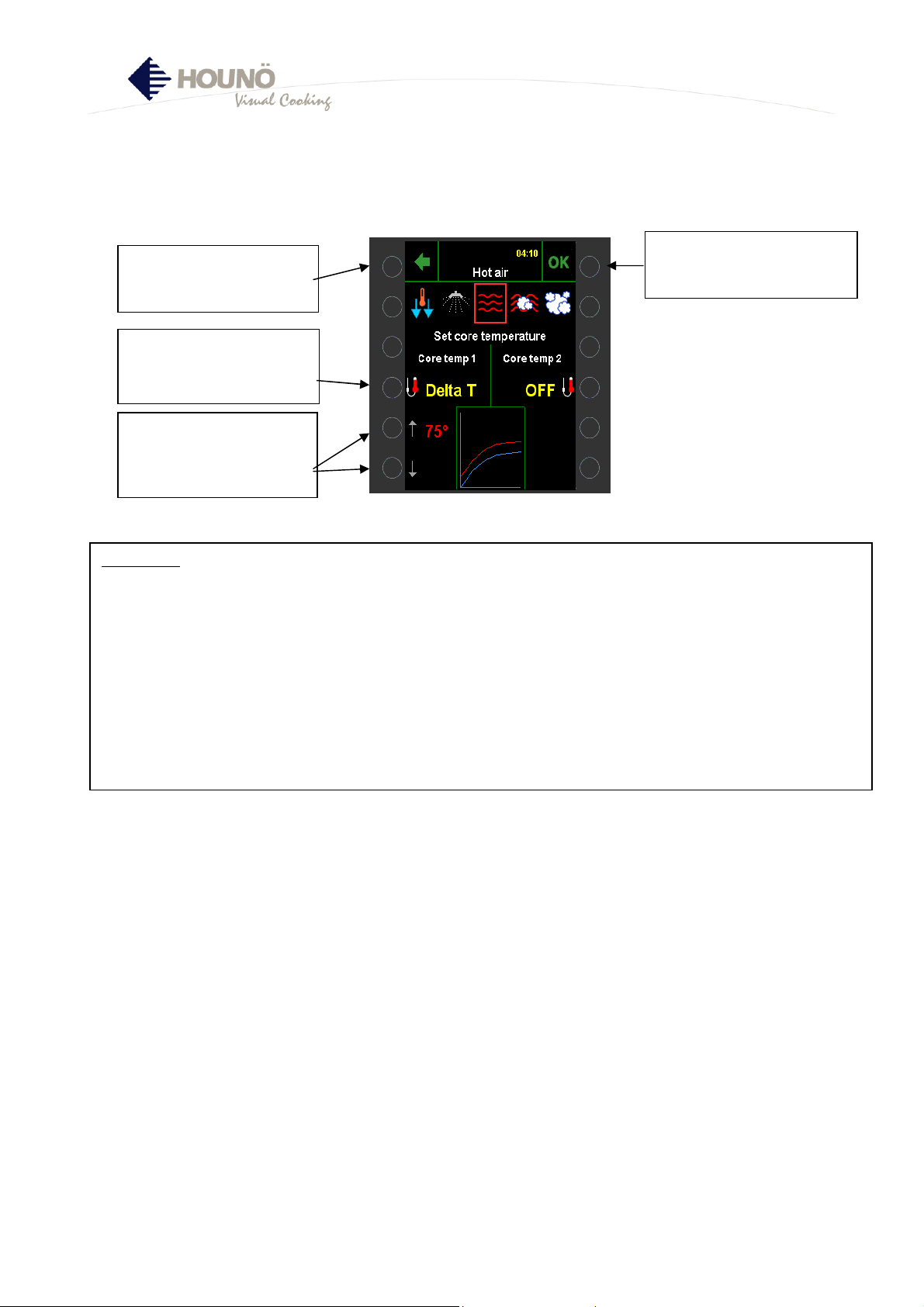

Return without saving

Delta-T

Delta-T has been

selected

Set core temperature

with arrows

Procedure

OK for settings and

return

1. Cool down the oven to 30 – 40°C

2. Select one of the following modes:

HOT AIR, recommended for very fatty and not too large roasts.

STEAMING, recommended for large hams with bones.

REHEATING, recommended for poultry and other lean pieces of meat.

CLIMAOPTIMA 50%-80%, recommended for all other products.

3. Insert the core temperature probe in the product with the largest diameter.

4. Activate Delta-T and set core temperature. Remember to confirm.

5. Press ON/OFF

Delta-T is particularly suitable for cuts of meat that contain a great deal of connective tissue,

for large roasts and for very lean cuts of meat. During this slow preparation process, the tough

connective tissue is gently broken down, which enhances the flavour and increases the

juiciness of the finished product.

The preparation time depends on the thickness of the meat and its contents of connective

tissue, bones and fat. The recommended preparation time is 60 – 75 minutes for each kg of

meet. This means that if the oven is loaded with pieces of meat, the largest of which weighs 3

kg, the preparation time will be 3 – 4 hours.

Note that the aromatic compounds in the meat only become volatile at temperatures above

120°C. This means that the meat does not give off flavour until it has been browned at a high

temperature for a few minutes. This is, however, of no importance if the meat is subsequently

to be cut out. It may be of importance if the meat is to be carved for a buffet.

Recommended core temperatures in Delta-T:

Rare : 52 - 57°C

Medium: 59 - 62°C

Well-done: 72 - 85°C

CPE/KPE – Ver. 1.54x – July 2009

11

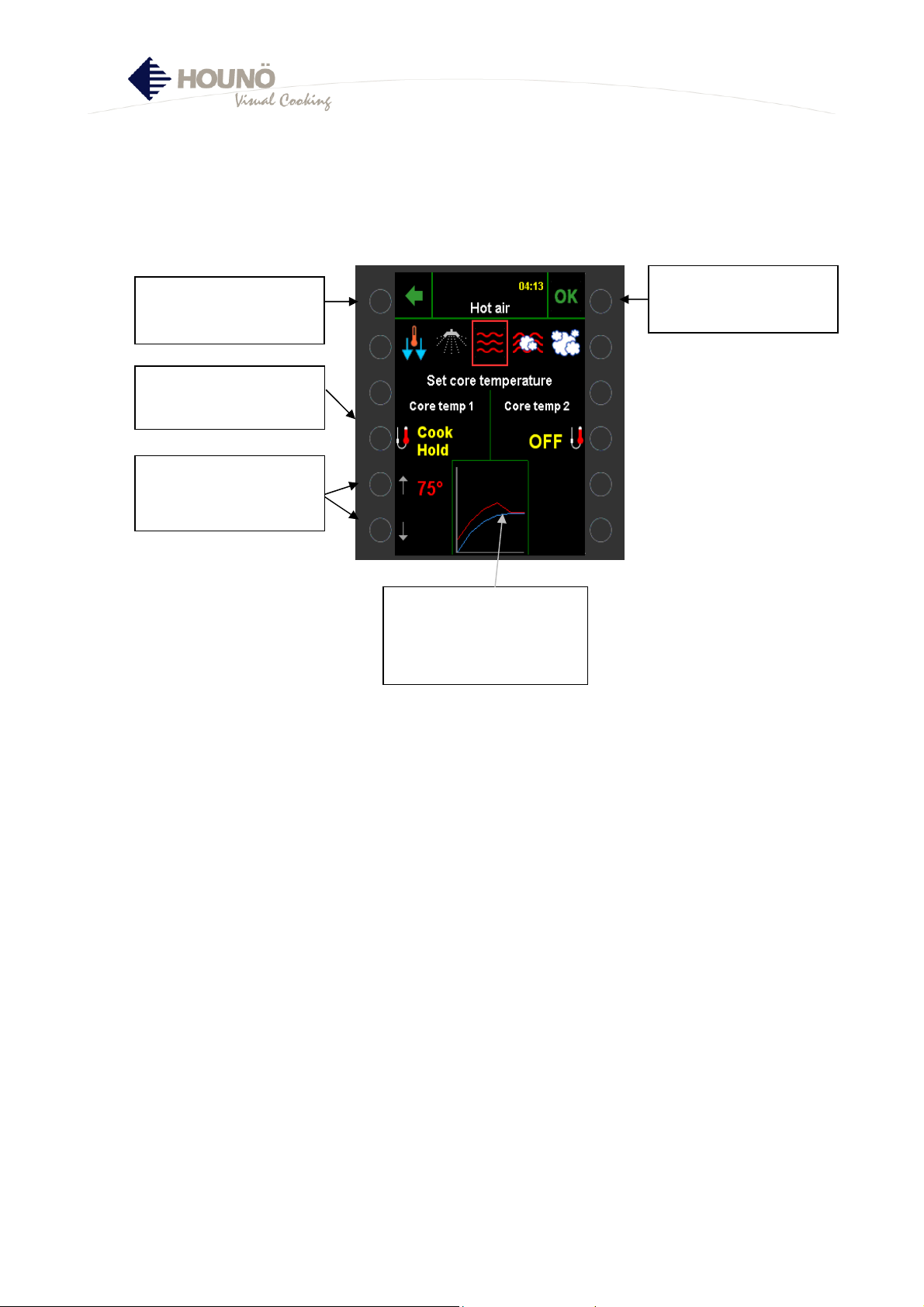

Cook & Hold

COOK & HOLD is a Delta-T mode which, in addition, keeps the food hot when it is done.

COOK & HOLD maintains the core temperature until the program is interrupted (by pressing

ON/OFF, by opening the oven door, or when the time has run out).

Cook & Hold can be activated in HOT AIR, STEAMING, REHEATING (recommended) and

CLIMAOPTIMA.

Recommended holding temperature is 60 – 65°C (at temperatures above 60°C, a gradual

dehydration of proteins takes place, the weight of the meat is reduced and the meat becomes

less juicy).

At the above temperature, the meat can be taken out immediately before carving.

After 5 – 6 hours’ preparation in COOK & HOLD, shrinkage increases.

Return without

changes

Cook & Hold has

been selected

Set core

temperature with

arrows

Fixed graph illustrating

the difference between

oven temperature and

core temperature

OK for setting and

return

CPE/KPE – Ver. 1.54x – July 2009

12

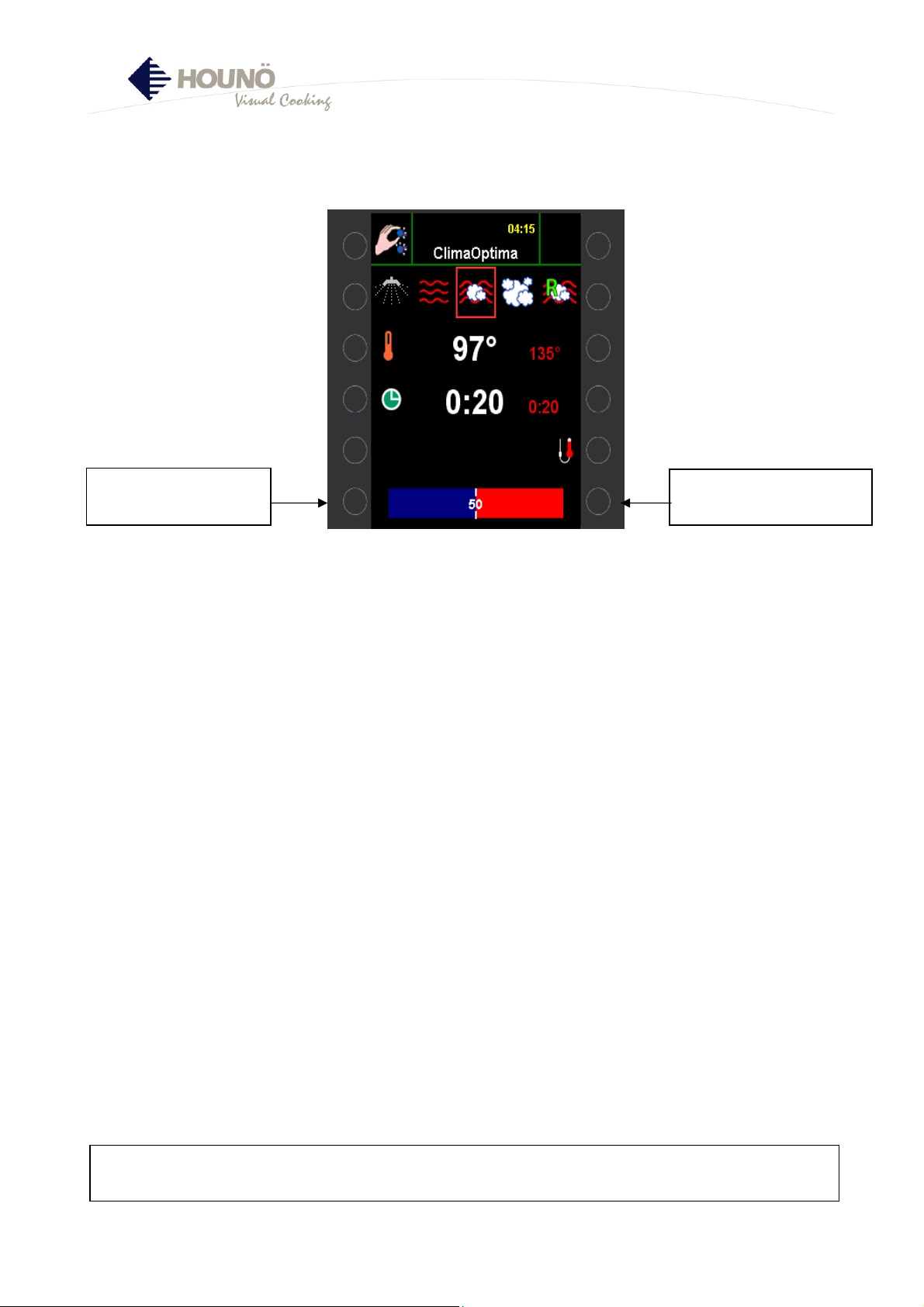

ClimaOptima®

Set humidity

content (lower)

When using ClimaOptima correctly, you minimise shrinkage and enhance the appearance and

taste of the products.

ClimaOptima offers you the possibility of adding up to 100% humidity to the oven chamber at

temperatures from 70 to 250°C). The computer automatically operates according to the

desired humidity content by adding or removing humidity.

Many products contain a rather large amount of water and therefore give off a great deal of

humidity during preparation. Therefore, the oven chamber often contains 15 – 50% natural

humidity.

Preheating for 5 minutes with the desired humidity content is recommended.

Depending on the amount of products in the oven and the setting of humidity and

temperature, the correct humidity content has been reached after 1 – 5 min.

Blue bar is the actual amount of humidity in oven chamber

White digits are the humidity set

If bar is all red, oven chamber contains 0% humidity.

If bar is all blue, oven chamber contains 100% humidity.

If you want dry air for grilling, for instance, apply 0% humidity at 200 – 250%C

To produce gravy when braising meat, apply 70 – 80% humidity at 145 – 165°C.

For poaching fish, poultry and crispy vegetables, apply 70 – 95% humidity at 70 – 120°C.

For steaming potatoes, rice, pasta, meat, etc., apply 100% humidity at 100°C.

Set humidity content

(higher)

For quick preparation, we recommend the following combination: 190°C – 70%

humidity.

Despite the short time of preparation, products such as herb-marinated cuts of meat, fresh

vegetables and bread are treated very gently.

If the oven is not connected to a soft water plant, ClimaOptima cannot function

properly.

CPE/KPE – Ver. 1.54x – July 2009

13

Steaming

To get the oven ready for production quickly and to

ensure a perfect start of the steaming process, we

recommend that you cool down the oven chamber to

80°C.

If the oven chamber is too hot, it cools down automatically. It is faster to use the cooling mode, as this

mode allows you to open the door while the mode is

active.

We recommend that you start the steaming process 8

minutes before you place the products in the oven

chamber.

For reasons of hygiene, the oven automatically checks

the water in the steam generator. If the water

temperature is below 65°C, the tank is emptied, refilled

and the water is heated.

Low-temperature steaming at 65 - 90°C is

recommended for delicate products such as fish.

Steaming at 80°C for 5 – 10 min. of small, fresh

vegetables such as carrots, asparagus, and beans

(diameter: 5 – 12 mm) produces end products that

keep their colour and crispness.

Traditional steaming at 98 – 100°C is recommended

for all kinds of root vegetables, potatoes, pasta, rice and

meat.

Forced steaming at 120°C can be used for vegetables

that need further processing and for faster preparation

of for instance pasta, rice, hard root vegetables and

frozen vegetables. Forced steaming should be used with

care.

To achieve a perfect result every time, we recommend

the use of the core temperature probe in all steaming

modes.

In a CPE model, you boil by means of injection steam.

Select ClimaOptima with 100% humidity at 100°C.

If the oven is not connected to a soft water plant, the steaming modes cannot

function properly.

CPE/KPE – Ver. 1.54x – July 2009

14

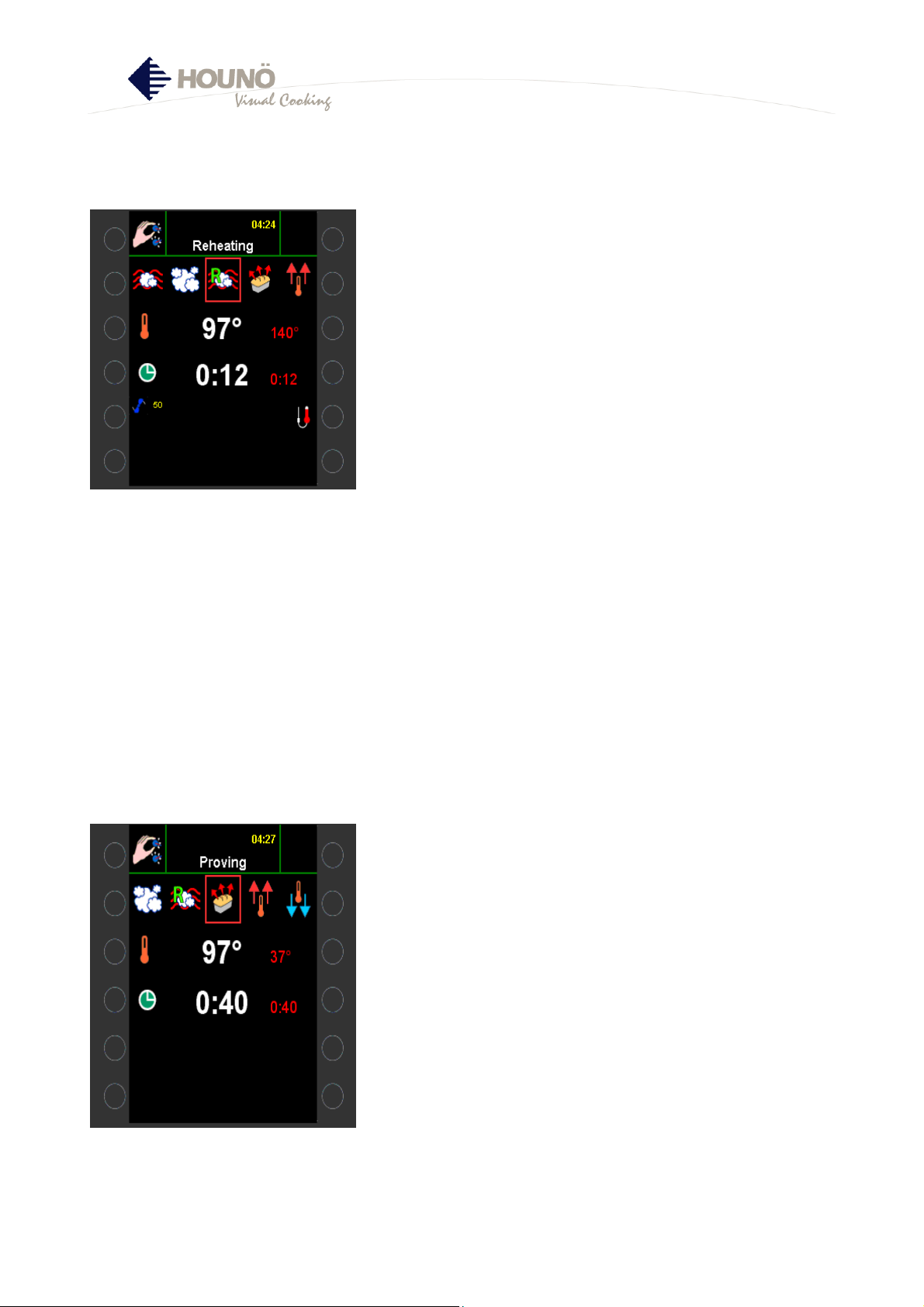

Cook & Regen

Cook & Regen is a very gentle process (20 – 180°C).

The program operates with low fan speed and adds a

carefully calculated amount of humidity which

maintains the nice appearance and taste of the

products.

To get the fastest regeneration, the products should not

be covered with a lid or the like.

Use a core temperature probe to reach a perfect end

temperature.

For the regeneration of sous-vide products, etc., follow

the recommendations of the supplier.

Recommended times and temperatures for fast reheating:

8 – 12 minutes at 140°C for rice/meat and vegetables arranged on plates

40 – 60 minutes at 120 – 140°C for whole roasts, stews and sauces

20 – 30 minutes at 120°C for pasta, rice and the like

Proving/Rising

The computer is set to maintain the perfect humidity for

all products that need to be proved before they are

baked.

Recommended settings of temperature and time:

Loaves of 400 – 800 g: Low temperature and long

proving time (32°C, 45 min.).

Rolls/baguettes of 60 – 200 g: High temperature and

short proving time (36°C, 25 min.).

We call your attention to the preset ”semiautomatic

bread program”, in which the bread is proved and baked

in the same process (models KPE, CPE and BPE).

Please note the distinction between prebaked (additional

baking only) and preproved (defrosting, proving and

baking).

CPE/KPE – Ver. 1.54x – July 2009

15

Preheating

PREHEATING ensures that the oven chamber is

thoroughly heated.

If the oven is cold, 2 - 5 minutes’ preheating is

recommended (models 2.10 and 2.14 require 15

minutes’ preheating)

If the oven is hot, 0 – 2 minutes’ preheating is

recommended.

Preheating at a temperature which is approx. 50°C

higher than the desired working temperature is

recommended.

NOTE: When the oven door is opened for loading, the

oven chamber loses 30-50% of the heat.

PREHEATING can be set at 0 – 15 minutes

.

Note that the countdown does not start until the

selected oven temperature is reached.

Cooling

Cooling is used if you need the oven chamber to be

cooler, for instance, when you switch from roasting to

steaming or if you are about to clean the oven.

Cooling is activated in either of the following ways:

a) Oven door closed. Water is used to speed up the

cooling process. Alarm sounds when the

temperature is reached.

b) Oven door open. Fan wheel draws in air to speed

up the cooling process. Programme stops when the

temperature is reached.

It is recommended to set the cooling mode at 20°C

below the desired working temperature.

CPE/KPE – Ver. 1.54x – July 2009

16

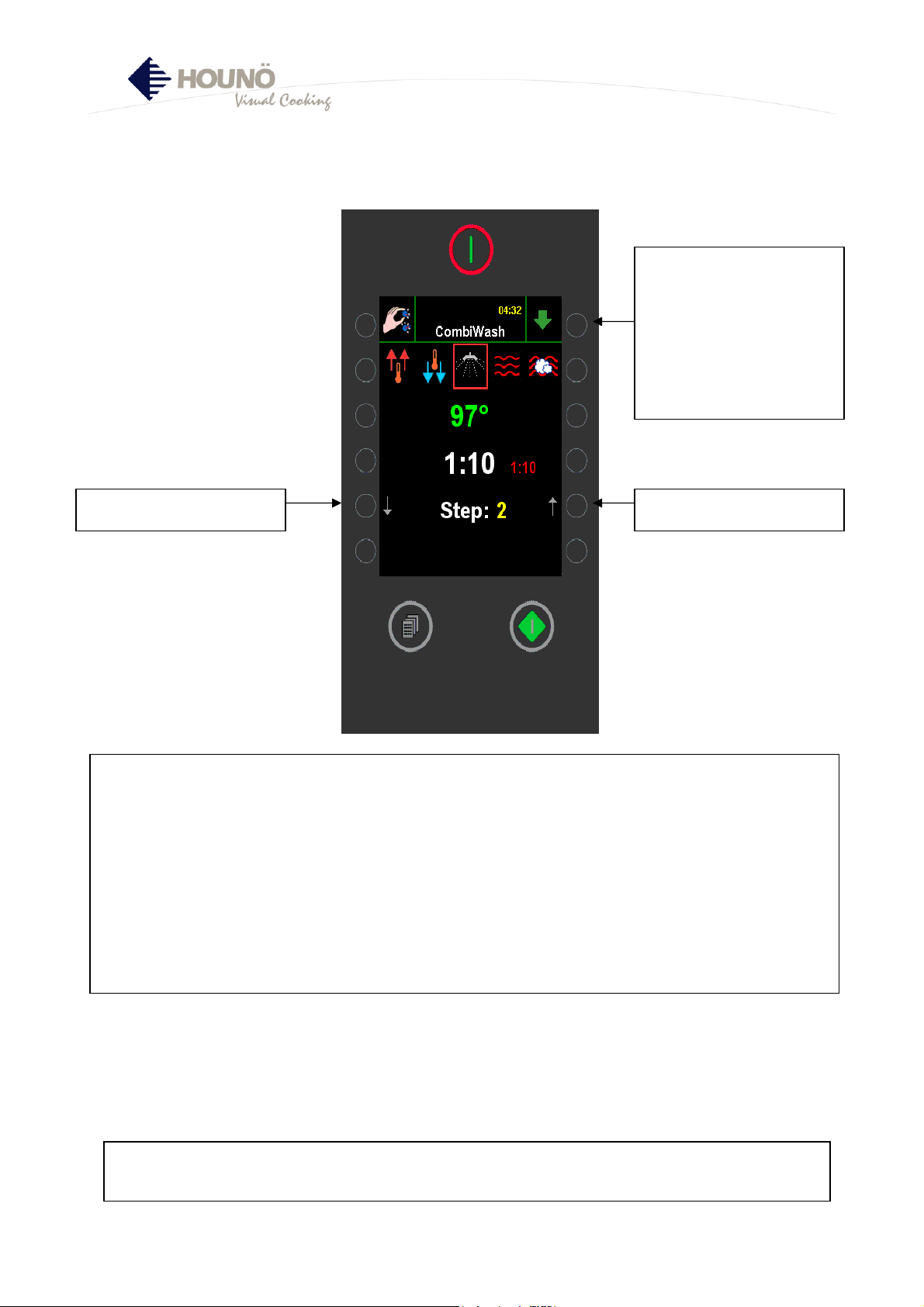

Step up

Step down

CombiWash®, Automatic Cleaning System

Press for indication of

level of detergent and

rinsing agent. Reading

and zero setting

(see page 29)*

How to do:

1. Check that the oven is not too hot (max. temperature: 80°C). If the oven is too hot,

use the cooling mode.

2. Check the level of detergent and rinse aid.

3. Select step

4. Close oven door and start programme by pressing the on/off key.

When the program is over, the oven automatically switches to an energy-saving standby

function.

Steps 1 and 2 are used after steaming/roasting at low temperatures.

Steps 3 and 4 are used after roasting at temperatures above 180ºC.

We recommend that CombiWash is used daily/after each production.

* Note that this mode is not active as standard.

If the oven is not connected to a soft water plant, CombiWash cannot function

properly.

CPE/KPE – Ver. 1.54x – July 2009

17

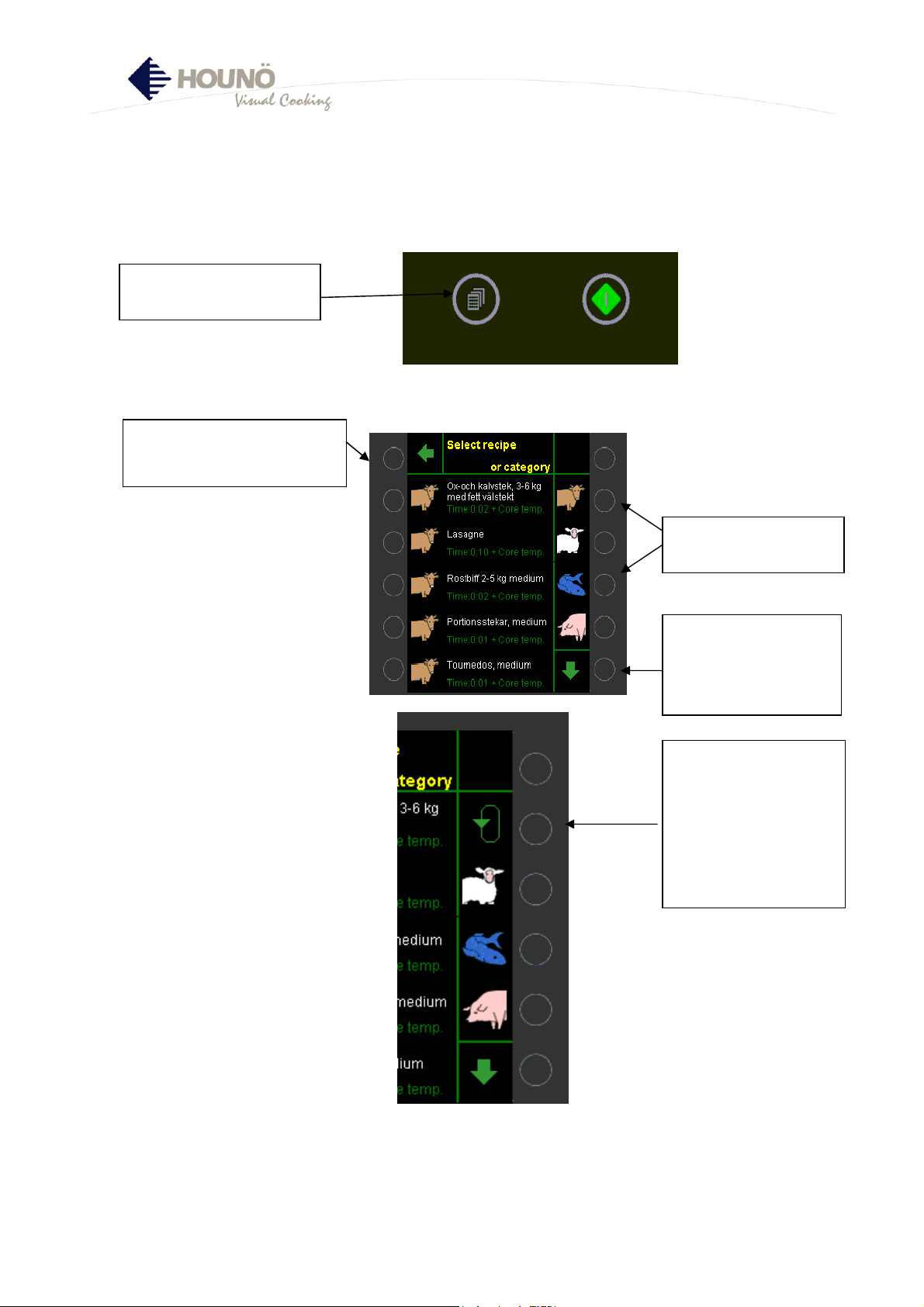

Return

Preset

P

rogrammes

Press key to the left of

ON/OFF

Select main

category

Arrow indicates

that there are more

main categories

than those shown.

Press again to scroll

through the programs of the

category (there are

more categories

than the 5 listed to

the right)

CPE/KPE – Ver. 1.54x – July 2009

Loading...

Loading...