HOUNO M ovens User Manual

1

Dear customer,

Congratulations on the purchase of your new HOUNÖ oven.

You are now the owner of one of the leading oven products on the market.

All HOUNÖ products are currently subjected to intensive product development, which ensures that

the products always contain the latest technology and the most up-to-date and energy-saving

methods of preparation.

Furthermore, the HOUNÖ products are entirely up-to-date with the latest developments/technology

in terms of

• ERGONOMICS AND SAFETY

• SIMPLE AND LOGICAL OPERATION

• USER FRIENDLY DESIGN

• RELIABILITY AND SERVICE

To ensure that our customers get an optimum and reliable product, all HOUNÖ units are passed

through an extensive test programme in which all functions are subjected to a continuous and

extreme load.

For optimum results – read your user’s manual

Before you start using the oven and in order for you to be able to fully utilise its many facilities and

advanced technology, it is important that you are familiar with its operating modes and range of

applications. We therefore recommend that you study the manual thoroughly, because if you do,

you are sure to achieve optimum cooking results through appropriate and safe operation. By going

through the manual, you will save time and avoid unnecessary problems1.

When you meet this warning triangle , you should be attentive as it indicates activities that

may cause injury to the user or damage to the oven.

Terms of warranty

The oven cabinet and the technical parts of your new HOUNÖ oven are covered by a 12-month

factory warranty. However, the heating elements in the oven compartment and the steam generator

are guaranteed for 24 months. The period of warranty takes effect from the date of installation.

The warranty does not include....

We especially draw your attention to the fact that the factory warranty does not cover glass parts

such as oven door glass, lamp glass and incandescent lamps, nor does it cover sealing such as door

gaskets, gaskets for heating elements, etc.

Furthermore, the factory warranty does not apply in the case of

1. defects that are due to the fact that installation has not been carried out in accordance with the

HOUNÖ Installation & Service Manual at present in force (electricity, water/drain, exhaust).

2. defects and interruptions of operation that are the result of the oven not being handled/operated

as specified in the user's manual.

We hope that you will be satisfied with your new oven.

Yours sincerely,

HOUNÖ A/S

1

We would also like to call your attention to our website www.houno.com from which you can download and print out further copies of our user

manuals or seek further information on the functions and characteristics of our ovens.

Please feel free to send us your comments regarding problems, suggestions for improvements, etc. on fax No. +45 87 11 47 10 or send us an e-mail on

houno@houno.com.

2

TABLE OF CONTENTS

Oven description ……………………………………………………………………………….. 3

Panel description ……………………………………………………………………………….. 4

Core temperature ………………………………………………………………………………. 10

Baking ………………………………………………………………………………………….. 13

Meat ……………………………………………………………………………………………. 14

Vegetables ……………………………………………………………………………………… 15

Poultry, fish and game …………………………………………………………………………. 16

Cleaning ………………………………………………………………………………………… 17

Auxiliary equipment …………………………………………………………………………… 20

Error codes …………………………………………………………………………………….. 23

How to achieve perfect baking and roasting results …………………………………………… 26

Rev. 3 / 01.08.03

3

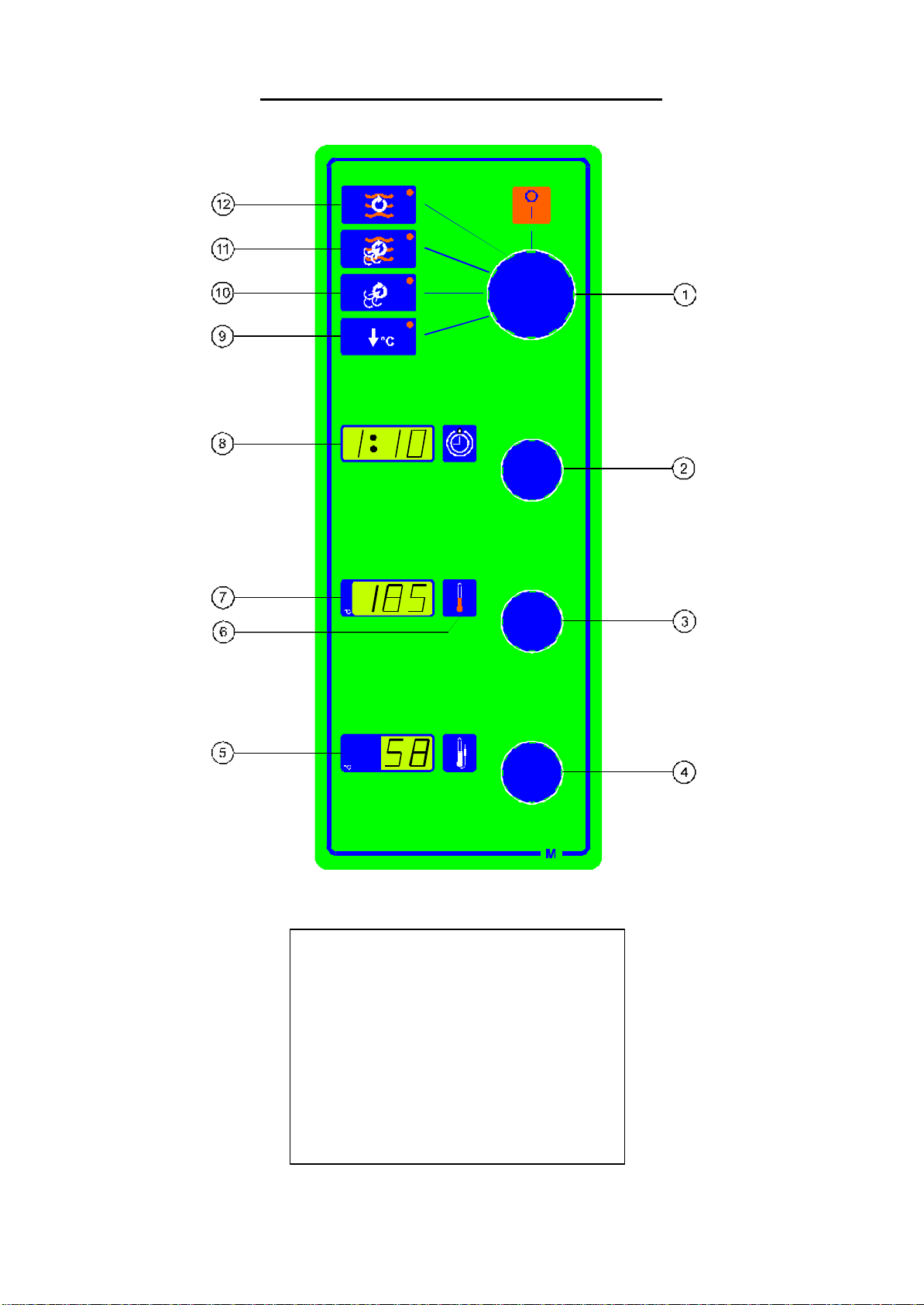

DESCRIPTION OF OPERATION PANEL

(1) Main switch

(2) FUNCTION SWITCH: Time

(3) FUNCTION SWITCH: Oven chamber temp.

(4) FUNCTION SWITCH: Core temperature

(5) Display for core temperature

(6) Indicator for heat

(7) Display for oven chamber temperature

(8) Display for time

(9) COOLING

(10) STEAMING

(11) COMBI STEAMING

(12) HOT AIR

4

(1) Main switch

Turn the main switch to the desired operating mode (9 – 12).

Set the time switch (2), the oven chamber temperature switch (3) or the core

temperature switch (4) and the steamer starts automatically

Before the steamer starts, all displays and control lamps light up for approx. 2 seconds to

indicate that all functions are being automatically tested.

(2) Time

The time can be set from 1 min. to 3 hours.

When the time has run out, the steamer automatically stops and an alarm sounds.

The pre-set time can also be changed while the program is running.

Continuous operation

Set the steamer at continuous operation by turning past 3 hours until --:-- appears.

If the core temperature is on at the same time, the steamer stops when the core temperature is

reached.

(3) Oven chamber temperature

The temperature range depends on the operating mode chosen:-

•HOT AIR 20 - 250°C

•COMBI STEAMING 20 - 250°C

•STEAMING 20 - 100°C

The temperature can be changed any time during the program.

(4) Core temperature

The core temperature range is 20 – 99°C.

(5) Display for core temperature

When the core temperature is activated, this is shown in the display. When the steamer is off,

the pre-set temperature is shown; when the steamer is on, the actual temperature is shown.

5

(6) Heat indicator

Lights while the heating elements are active.

(7) Display for oven chamber temperature

This display shows the pre-set temperature.

The steamer has an automatic checking function. The actual temperature shows briefly every 5

seconds.

The control lamp lights while the heating elements are active.

(8) Time display

While the program is running, the remaining time is displayed.

If any operational defects occur, an error code appears in the time display (see list of error

codes, page 22).

(9) COOLING

To achieve the optimum and most gentle preparation of the products, make sure that the

temperature in the oven chamber is correct.

By setting the program switch at COOLING, it is possible to cool the steamer to the right

working temperature.

We recommend that the oven is set at manual operation and the temperature approx. 20°C

below the subsequent working temperature.

After cooling, set the steamer at the desired operating mode and preheat as described in the

sections dealing specifically with each operating mode.

(10)STEAMING

Turn the switch (1) to STEAMING (10).

The steamer automatically starts at 98°C. As an optional extra, the steamer can be equipped

with LOW-TEMPERATURE STEAMING for steaming between 20 and 100°C.

Start the steamer by setting the time.

If the steam generator has not been preheated and is not ready to generate steam for the oven

chamber, the control light at the symbol STEAMING (10) flashes until the steam generator has

been heated.

Note! When a cold oven is preheated, water will automatically be drained from the oven.

Therefore, preheating for at least 8 – 10 min. is required.

6

Use

STEAMING can be used for:

•Steaming/boiling

•Low-temperature steaming

•Blanching

•Poaching

•Defrosting

•Heating

•Keeping warm

•Preservation

•Preparation of vacuum-packed products (sous-vide)

Advantages of STEAMING and LOW-TEMPERATURE STEAMING in general

•Shorter cooking time as compared to cooking in a pot.

•With steaming, the flavour, aroma and structure of the products are maintained to a

far greater extent than if they were prepared in a pot.

•The important vitamins and nutrients of the products are preserved and, consequently, the unique taste is retained.

•The consistency/structure of the products are preserved. Vegetables retain their

appetising and fresh colour.

•Different products can be prepared simultaneously, for instance fish and vegetables,

as flavour is not transferred from one product to the other.

•Fish should ALWAYS be steamed at a temperature below 80°C, to prevent the

albumen from coagulating and the fish from “shrinking”.

•Gentle steaming process during which even delicate products retain their consistency

and colour.

•Suitable for the preparation of fish and minced meat.

•Possibility of a more accurate temperature control as compared to cooking in a pot.

•Very little shrinkage, especially in fatty foods.

• In LOW-TEMPERATURE STEAMING, vegetables can be kept warm at approx.

70°C for a long time without turning into a mash.

Note! ‘Green’ vegetables should be steamed at at least 85°C, as, otherwise, they will

lose their colour.

•When possible, use perforated containers.

•Deep-frozen vegetables can be steamed directly from the freezer.

7

•For certain “delicate” products such as fish, shellfish, sausages, pâtés, poultry and

desserts, new variations of taste can be developed. Furthermore, good results are

achieved with diet food.

•Vegetables should only be steamed until they are almost done, as the steaming

process continues for a short while after they have come out of the oven.

Vacuum / sous-vide preparation

LOW-TEMPERATURE STEAMING is ideal for the preparation of sous-vide products. The

slightly prepared products are ‘welded’ into plastic bags and then further prepared at the

required gentle and low temperatures. Very rapid cooling down to approx. +2°C is necessary.

At the end of the preparation process, the vacuum-packed products are placed on grills and

“heated” by low-temperature steaming at 75 - 90°C depending on the type and size of the food

product.

(11)COMBI STEAMING

Activate the COMBI STEAMING operating mode by turning the switch (1) to COMBI

STEAMING (11).

Start the steamer by setting the time.

If the steam generator has not been preheated, it is not ready to generate steam for the oven

chamber, the control lamp at the combi-steaming symbol (11) flashes until the steam generator

is hot.

The control lamp will also flash, if the temperature in the oven chamber exceeds the pre-set

temperature. Before use, the oven chamber should be cooled down to approx. 20°C below the

desired working temperature.

Use

COMBI STEAMING is used for

•Roasting

•Steaming

•Baking

•Glazing

•Gratinating

•Reheating (for instance, ‘cook & chill’)

Which time and temperature to choose depends very much on the type, quality and level of

preparation of the product. The best results are achieved by trial and error. This allows you to

leave your own mark on the preparation.

For the most common tasks, for instance baking of liver paste and roasting of large roasts,

haunches, fillets and saddles, is unsurpassed.

8

Advantages of COMBI STEAMING

•If the roast is steamed with injection steam at the start, the pores will close

immediately preventing the meat juice from disappearing.

•In COMBI STEAMING, the shrinkage is reduced by up to 30 – 35%.

•Ideal for long-term roasting

•Deep-frozen, ready-prepared dishes can be reheated in COMBI STEAMING at

approx. 130°C using medium humidity/steam pulsing. This reduces the heating time

considerably as compared to reheating in the HOT AIR mode. No crust forms on the

products, as the preparation is done with steam.

(12)HOT AIR

Activate the HOT AIR operating mode by turning the switch (1) to HOT AIR (12).

Start the steamer by setting the time.

Use

The HOT AIR operating mode can be used for

•Roasting

•Grilling

•Baking

•Gratinating

•Roasting of breaded products

Advantages of circulating hot air:-

•Shorter roasting time

•Lower temperature

•Even temperature in the entire oven chamber

The circulating hot air gives a faster and more efficient supply of heat and reduces the

roasting/baking time considerably as compared to traditional roasting and baking ovens.

The larger the roast, the lower the temperature. ) If you apply these two rules of

The longer the cooking time, the lesser the shrinkage ) thumb, the roast becomes juicier.

In general, all individual products (pieces of chicken, steak, etc.) require preheating at a

higher temperature and roasting (baking) with the exhaust open.

- Direct exhaust

The direct exhaust removes surplus humidity from the oven chamber and gives crispier

products. Open the exhaust during the second half of the baking/roasting time.

Open and close the exhaust by pulling the lever located at the top of the RH side of the

steamer.

Loading...

Loading...