Page 1

®

®

PORTABLE MAGNETIC DRILLS

OPERATORS MANUAL

HMD100

FOR USE WITH “17,000-SERIES” ROTABROACH CUTTERS

Page 2

HOUGEN® ROTABROACH

®

Portable Magnetic Drill

Model HMD100

Welcome to Hougen

Congratulations on your purchase of the Hougen® Rotabroach

Portable Magnetic Drill. Your model is designed to produce

superior holes quickly and efficiently. Through constant innovation

and development, Hougen is committed to provide you with holeproducing tools and products to help you be more productive.

Before attempting to operate your new Portable Magnetic Drill,

please read all instructions first. These include the Operator's

Manual and Warning Label on the unit itself. With proper use,

care, and maintenance, your model will provide you with years of

effective hole drilling performance. Once again, thank you for

selecting our product and welcome to Hougen.

®

INDEX

Contents Checklist

Important Safety Instructions

Review of Controls

“17,000-Series” Cutter Installation

Operating Instructions

Control Panel Diagram

Hookup Diagram

Drill Parts Diagram

Parts List

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Other Hougen Products

Motor Diagram and Parts List

Limited Warranty

Factory Authorized Warranty Repair Centers. . . . .

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

CONTENTS CHECKLIST

Check the contents of the carrying

case to be sure the following items

are included with your new Magnetic

Drill.

Carrying Case 17052

Safety Strap 17059

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Finishing Plug

Stick Lubricant 11746

2

3

5

5

6

7

7

8

9

9

10

11

12

Cutting Fluid Pint 11741

Feed Handle/knob 17071 (2)

Operator’s Manual 17061 Warranty/Registration card*

* Please take the time NOW to fill out your Warranty/Registration card and return it to Hougen Mfg. within 10 days.

2

Page 3

Important Safety Instructions

1. Read All Instructions

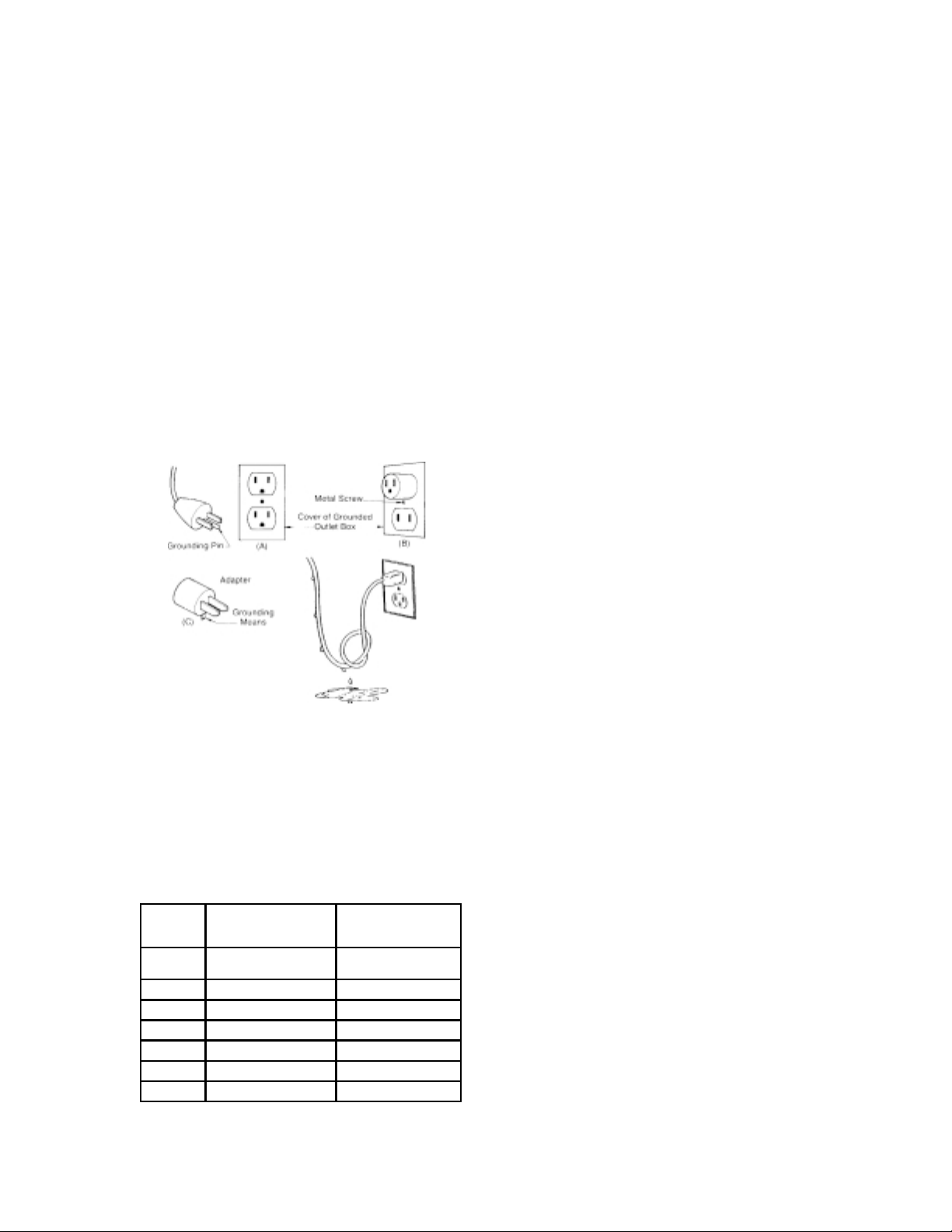

2. Grounding Instructions

This tool should be grounded while in use to protect the

operator from electric shock. The tool is equipped with

a 3-conductor cord and a 3-prong grounding type plug

to fit the proper grounding type receptacle. The green

(or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and

yellow) wire to a live terminal. Your unit is for use on

115V, and has a plug that looks like that shown in sketch

(A). An adapter, see sketches (B) and (C), is available

for connecting sketch (A) type plugs to 2-prong recep

tacles. The green-colored rigid ear, lug, or the like,

extending from the adapter must be connected to a

permanent ground, such as a properly grounded outlet

box.

Note: Use of a grounding adapter is prohibited in

Canada by Part I of the Canadian Electrical Code.

4. Extension Cords

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-pole receptacles that

accept the tool's plug. Replace or repair damaged

cords. Make sure the conductor size is large enough

to prevent excessive voltage drop which will cause

loss of power and possible motor damage.

5. Do Not Force Tool

It will do the job better and faster at the rate for which

it was intended.

6. Keep Work Area Clean

Cluttered areas and benches invite injuries.

Keep dirt and chips from under magnet and

Rotabroach Cutter area. Do not attach magnet to

surfaces where paint is thick or peeling.

7. Consider Work Area Environment

Do not expose tool to rain.

Do not use tool in damp or wet locations.

Keep work area well lit.

Do not use tool in presence of flammable liquids or

gases. Disconnect from power source when changing

cutters or maintaining drill.

8. Guard Against Electric Shock

Prevent body contact with grounded surfaces. For

example: pipes, radiators, ranges, refrigerator

enclosures.

3. Safe Electrical Connection

Your HMD100 is rated for use on 120VAC at 50-60Hz.

Do not attempt to use drill on power sources rated other

than this. Wet electrical connections are shock hazards.

To prevent the cutting fluid from traveling along the cord

and contacting the plug or power outlet, tie a drip loop

as shown above. Also elevate extension cords or gang

box connections.

Length

of Cord,

Feet

Up to 25 16 18

26-50 14 18

51 -100 10 16

101-2 00 8 14

201-3 00 6 12

301-5 00 4 10

Recommended Wire

Gauge

115V M o t or

10-12 Amps

Recommended

Wire Gauge

230V Motor

5-6 Am ps

9. Keep Children Away

Do not let visitors contact tool. All visitors should be

kept away from work area while in use.

10. Store Idle Tools

When not in use, tools should be stored in a dry, and

high or locked-up place — out of reach of children.

11. Use Right Tool

Do not force small tool or attachment to do the job

of a heavy duty tool.

Do not use tool for purpose not intended — for

example — do not use a circular saw for cutting tree

limbs or logs.

12. Secure Work

Use clamps or a vise to hold work. It is safer than

using your hand and it frees both hands to operate

tool.

13. Always Wear Safety Glasses or Goggles

14. Dress Properly

Do not wear loose clothing or jewelry. They might

entangle with spinning chips or get caught in moving

parts. Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear sturdy

leather gloves when working indoors.

Wear protective hair covering to contain long hair.

3

Page 4

Important Safety Instructions

(Continued)

15. Do Not Abuse Cord

Never carry drill unit by its cord or yank it to disconnect from receptacle.

Keep cord away from heat, oil, and sharp edges.

16. Do Not Overreach

Keep proper footing and balance at all time.

17. Maintain Tools With Care

Keep tools sharp and clean for better and safer

performance.

Do not use dull or broken Rotabroach Cutters.

Follow instructions for lubricating and changing

accessories.

Inspect tool cords periodically and, if damaged,

have repaired by authorized service facility.

Inspect extension cords periodically and, if

damaged, have repaired by authorized service

facility.

Keep handles dry, clean, and free from oil and

grease.

18. Disconnect Tools

Disconnect when not in use, before servicing, and

when changing Rotabroach Cutters or accessories.

19. Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and

wrenches are removed from tool before turning it

on.

20. Check Damaged Parts

Before further use of the drill, a part that is

damaged should be carefully checked to determine

that it willoperate properly and perform its intended

function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A

part that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this operator

manual. Do not operate tool if switch does not turn

it on and off.

21.Stay Alert

Watch what you are doing.

Use common sense.

Do not operate tool when you are tired.

Have defective switches replaced by authorized

service center.

22. Outdoor Use Extension Cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

23. Additional Safety Precautions

Arbor and cutter should never be used as a handhold. Keep hands and clothing away from all moving

parts. Do not use Rotabroach Cutters where ejected slug

might cause injury (slug ejected at end of cut).

Also, adhere to all operating instructions. Do not drill

through any surface that may contain live electrical

wiring. Drilling into a live wire could cause exposed metal

parts of the drill to be made live. Remove chips wrapped

around Rotabroach Cutter and arbor after each hole.

With motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

24. Non-Conforming Cutting Tools

Your Magnetic Drill is designed to use Hougen

Rotabroach Cutters. The use of drilling tools having

different shank styles is not recommended as they may

not tighten securely in the drill arbor with risk of accident or injury.

25. Operating Near Welding Equipment

When operating your Magnetic Drill near an arc welder,

it is important that they are connected to the same Earth

Ground. If they are not, severe damage to the unit,

particularly the power cord, could occur. This could

also result in personal injury to the operator.

26. Notice

This unit is an Industrial Portable tool and is not designed

for production. If this product is used as a production unit,

internal gear failure could occur and cause serious

damage.

27. Circuit Breaker

Changing of the circuit breaker to a higher amp rated

breaker, or by-passing the circuit breaker is not

recommended and is cause for cancelation of the

product warranty.

28. Circuit Breaker Operation

The circuit breaker is a thermal circuit breaker. When it

reaches the higher temperature rating it will trip and cause

the unit to shut down. This is a protection device and can

be reset after 5 to 10 seconds of cool down period. To

reset the circuit breaker, press the breaker button back in.

If it does not reset, let the unit cool a little longer until you

can push the button in and it stays in position.

4

Page 5

Review of Controls

Magnet On/Off

Feed Handle

Motor On/Off

Circuit Breaker

Feed Lock/Release

(pull & turn)

“17,000-Series” Cutter Installation

1. Disconnect machine from power source.

2. Insert pilot into cutter.

3. Align flat on shank with pin in spindle.

4. Insert cutter into spindle.

5. Give cutter 1/4 turn in opposite direction of flutes.

5

Page 6

Operating Instructions

Place drill on material and locate for drilling hole.

Press magnet switch to “ON”

CAUTION: Do not over-feed cutter. Excessive feed

pressure may cause the magnet to break free from

material.

Thread safety strap through opening between

motor and drill housing. Ensure that strap does not

interfere with operation of feed handles.

Insert tab of strap into buckle. Cinch strap tight to

material and drill housing. Check for slack and

adjust as needed.

17,000 FEATURES AND DESCRIPTION:

Second layer penetration may be difficult. Slight

additional feed pressure may be required (avoid

over-feed as note above).

If unable to penetrate second layer, withdraw cutter

from material ejecting slug and clean away any

remaining chips. Feed cutter in hole and continue

cut.

Release motor switch when cut is finished.

Fully retract cutter from material, ejecting the slug.

Engage feed lock/release.

Remove safety strap.

Turn magnet switch to “OFF” position.

CAUTION: Retain firm hold on drill to prevent

dropping.

Cutter I.D. may collect chips, restricting depth of cut.

Cutter should be frequently inspected and any chips

or debris removed.

CAUTION:

• Keep strap clear of cutting area, chips, and

rough edges on material.

• Inspect strap periodically for fraying and

damage. Do not use a damaged safety strap.

Apply liberal amount of cutting fluid or stick lubricant to cutter. Additional lubrication may be needed

to complete cut.

Disengage feed lock/release.

Press and hold motor switch. (Note: Switch must

be held in “ON” position while cutting)

Feed Rotabroach Cutter slowly into workpiece.

Only after cutting path is established to a depth of

about 1/16" can additional force be applied to

feed handles.

OPTIONAL FEED METHODS:

• 5/8” Box Wrench

• Ratchet with 5/8” Socket (shown below)

• NO PLIERS OR OPEN END WRENCH (will damage

threaded feed handle mounting holes)

Ease up on feed pressure as cutter starts breaking

through.

6

Page 7

Control Panel /Hookup Diagram

7

Page 8

HMD100 Drill Parts Diagram

8

Page 9

HMD100 Parts List

Part No. Description Qty.

01226 SWITCH GUARD 1

01833 ROCKER SWITCH 1

01989 1/4-28 X 3/4 SHCS 2

17002 SCR-SHC #6-32 X 1/2 SHCS 3

17003 LH SPIRAL MITER GEAR 1

17006 SPLINE SHAFT 1

17009 SCR-SHC #8-32 X 1/2 SHCS 3

17010 BALL BEARING 1

1 7 011 RETA INING RING 1

17013 HOUSING 1

17015 1/4-28 X 1/2 FHSCS 1

1 7 017 NYLON THRUS T WA SHE R 2

1 7 018 STEEL THRUS T WA SHER 2

1 7 019 RETA INING RING 2

17022 FEED GE AR 1

17023 SNAP RING 1

17027 MOTOR ASSEMBLY 1

17029 MAGNET ASSEMBLY 1

17030 3/32 X 3/32 X 5/8 KEY 1

17031 FACEPLATE 1

17032 SCREW 1

17034 POWER CORD ASSEMBLY 1

17035 SWITCH-MOMENTARY 1

17037 C ONTROL PANEL ASSE MBLY 1

17039 SPRING PLUNGER 1

17042 E LECTRICAL BOX 1

17045 FINISHING PLUG 1

17048 RECTIFIER ASSEMBLY 1

1 7 049 JUMPER- M O T O R SWITC H 1

17050 JUMPER-MAGNET SWITCH 1

17060 CIRCUIT BREAKER 1

17065 DOWEL PIN 1

17068 RH SPIRAL MITER GEAR ASSEMBLY 1

17069 QUILL ASSEMBLY 1

17070 ARBOR ASSEMBLY 1

17071 FEED HANDLE ASSEMBLY 2

17072 GEA R BOX CAP ASSEMBLY 1

40108 1/4-20 X 1-1/4 SHCS 4

40374 NUT 1

41042 8-32 X 3/8 BHCS 4

50035 1/4 LOCK WASHER 2

90077 1 0-32 X 1/2 BHCS 4

Hougen Holemaking Products

“17,000-Series” Rotabroach

Cutters for HMD100”

The “17,000-Series” Rotabroach

Annular cutters are made specifically

for the HMD100. They are equipped

with a tool-less quick release shank,

and can drill up to 3/4" deep in single or

stacked plate. They are made of

premium high speed steel and available

in diameters from 5/8" to 1-1/16".

*** NEW ***

“17,000” Series Cutter Kit Hougen part number 17001”

Kit includes all 10 cutters listed plus 2

pilots all in a handy case. Contact your

local distributor for pricing

Part No. Diameter

17116 1/2"

17118 9/ 16"

17120 5/8"

17122 11/16"

17124 3/4"

17126 13/16"

17128 7/8"

17130 15/16"

17132 1"

17134 1-1/16"

9

Page 10

Motor Diagram and Parts List

Item

Part No. Description Qty.

No.

1 BD -144266-00 Field Ca se 1 19 10995 B rush Assy. (pai r) 1

2 BD-445786-31 Armature 1 20 BD-376 Set Screw 2

3 BD-400322-71 Field 1 21 BD-40 0718 Nylon Ba ll 2

4 BD-12158 Screw & Washer 2 22 BD-46210 Brush Holder Plug 2

6 BD-133410 Fan 1 23 BD-61 208-03 Brush Holder 2

8 B D-51404-03 Gear Case Cover 1 24 BD-46212 Brush Lead Terminal 2

9 BD-143691-00 Gasket 1 25 BD-330003-04 Ball Bearing 1

10 BD-135937 Needle Bearing 1 26 BD-132332 Bearing Sleeve 1

11 BD-700964 Ball Bearing 2 28 BD-21235 Brush Cover 1

12 BD-212 46 Needle B eari ng 4 30 BD-5 1407 Fiber Washer 4

13 04370 Gear Case 1 31 BD-51405 1st. Inter Gear Assy. 1

14 BD-400147 Spindle Gear 1 32 BD-49082 1st.133410 Inter Gear 1

15 BD - 7027 Key 1 33 BD -51401 1st. Inter P ini o n 1

16 BD-133316-01 Spindle 1 34 BD-51406 2nd. Inter Gear Assy. 1

17 B D-990 2 2-02 Retain ing Ring 1 35 BD-21822 2nd. Inte r Gear 1

18 10992 Washer 1 36 BD-51402 2nd. Inter Pinion 1

Item

Part No. Description Qty.

No.

10

Page 11

Hougen Holemaking Products

Rotabroach Portable Magnetic Drills

Rotabroach®.. the Work Anywhere Portable Magnetic Drills. No matter what you do -fabricate, install, maintain, repair,

retrofit, or manufacture, Hougen Rotabroach Portable Magnetic Drills put superior holemaking capabilities in your

hands. On-site, at-the-work drilling that’s easier, faster, and safer, wherever electrical power is available.

A series of twelve models lets you custom match power and features to your specific application needs. You can choose

from economical light duty models for drilling holes up to 1-3/8" diameter and 2" depth of cut, while others have the

might to produce 3-1/16" holes thru 3" thick material. Some with power feed, some with multi-speed spindles. But all

have incomparable performance for fast drilling, maneuverability, and lightness, resulting in minimal operator fatigue,

fast setups, and improved productivity.

With Rotabroach Portable Magnetic Drills, you save time by no longer moving large, heavy structures to machines or

using hand-held drills that can be inaccurate and tiring.

Model Descriptio n

Max. Capacity

Dia. D epth

HMD100 Complete Drill w/Case 450 RPM Motor 115V 1-1/16" 3/4" "17,000"

Cutter

Series

*

10904 Complete Drill w/Case 450 RPM Motor 115V 1-3/8" 2"

HMD500 Complete Two-speed Drill w/Case 115V 2-3/8" 3"

10909 Complete Drill 350 RPM Motor 230V

10909S Complete Drill 350 RPM Motor 230V

"12,000"

10914 Complete Drill 350 RPM Motor 115V

2-1/16" 3"

10914S Complete Drill 350 RPM Motor 115V

10925 Power Feed 350 RPM Motor 115V

10926 Power Feed Drill 350 RP M Motor 230V

1 0915 Complet e Multi-speed Dr i ll 115 V

3-1/16" 3"

10916 Complete Multi-speed Drill 230V

* “17,000-Series” Rotabroach Cutters for use with HMD100 only.

"42,000" &

"43,000"

Commercial / Industrial Limited Warranty

Hougen Manufacturing, Incorporated warrants its Portable Magnetic Drills for one (1) year and its Electro-hydraulic

Hole Punchers and other products for ninety (90) days from date of purchase against defects due to faulty material

or workmanship and will repair or replace (at its option) without charge any items returned. This warranty is void if

the item has been damaged by accident or unreasonable use, neglect, improper service, or other causes not arising

out of defects in material or workmanship. No other expressed warranty is given or authorized. Hougen Manufacturing, Inc. disclaims any implied warranty of MERCHANTABILITY or FITNESS for any period beyond the expressed

warranty and shall not be liable for incidental or consequential damages. Some states do not allow exclusions of

incidental or consequential damages or limitation on how long an implied warranty lasts and, if the law of such a

state governs your purchase, the above exclusion and limitation may not apply to you. This warranty gives you

specific legal rights and you may also have other rights which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest Factory Authorized Repair

Center or to Hougen Manufacturing, Inc., 3001 Hougen Drive, Swartz Creek, Michigan 48473.

Hougen Drills (Rotabroach Cutters) are warranted against manufacturing defects only. Subject to Hougen Manufacturing inspection.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY

11

Page 12

Factory Authorized W arranty Repair Centers

United States - East

A&A Industrial Supplies Inc.

251 Meacham Ave.

Elmont, NY 11003

(516) 437-0114

Awisco Repair Center

55-16 43rd Ave.

Maspeth, NY 11378

(718) 786-7788

Boyer Machinery Co.

2280 Wyandotte Road

Willow Grove, PA 19090

(215) 657-2242

Colony Hardware Supply Co.

15 Stiles Street

New Haven, CT 06512

(203) 466-5252

Hanes Supply Repair Center

10 Cairn Street

Rochester, NY 14609

(716) 826-2636

N.H. Bragg & Sons

90 Perry Road

Bangor, ME 04401

(207) 947-8611

Pennsylvania Tool Sales

and Service, Inc.

625 Bev Road

Youngstown, OH 44512

(330) 758-0845

Weld Tooling Corp.

3001 W. Carson Street

Pittsburgh, PA 15204

(412) 331-1776

West

ATS Repair Center

2400 West Directors Row

Salt Lake City, UT 84125

(801) 972-3182

Caltool Industrial Supply

470 Hester Street

San Leandro, CA 94577

(510) 729-0600

Kenbil Service Co.

2900 Adams St., B-15

Riverside, CA 92504

(909) 689-6633

Quimby Welding Repair

1603 Northwest 14th Ave.

Portland, OR 97209

(503) 221-1100

A.C.C. Machinery Co., Inc.

747 Grand Ave.

Phoenix, AZ 85007

(602) 258-7330

Southeast

Gardner Southeast Repair

807 Meroney Street

Chattanooga, TN 37405

(423) 756-4722

Mid-South Welding Supply

505 51st. Avenue

Meridian, MS 39307

(601) 483-9331

South

Allied Sales & Service Co.

1508 River Oaks Rd., West

Jefferson, LA 70123

(504) 734-9566

Wilbanks Repair Center

5532 S. 94th East Ave.

Tulsa, OK 74145

(918) 627-8445

Midwest

Ceekay Repair Center

5835 Manchester Ave.

St. Louis, MO 63110

(314) 644-3500

Miller Industrial Supply Co.

1695 N. 21st

Decatur, IL 62525

(217) 428-7787

Hougen Manufacturing, Inc.

3001 Hougen Drive

Swartz Creek, MI 48473

(810) 635-7111

Westbrook Engineering

23501 Mound Road

Warren, MI 48091

(810) 759-3100

Southwest

Arcmaster Repair Center

301 Woodrow Ave

Fort Worth, TX 76105

(817) 531-8101

Rex Supply Repair Center

3715 Harrisburg

Houston, TX 77003

(713) 222-2251

Canada

OK Power Tool

14740 115 Avenue

Edmonton, Alberta

Canada T5M 3B9

(403) 454-5111

Outiltech Orleans, Inc.

5695 Rue Rideau

Quebec, Quebec

Canada G2E 5V9

(418) 877-7776

Edward H. Pope, Ltd.

10 Imperial Court

Brampton, Ontario

Canada L6T 4X4

(905) 458-4800

Power Tool Clinic

19835-56 Ave

Langley, B.C.

Canada V3A 3V1

(604) 530-3550

O.T.I. Repair Center Inc

195 Rue Henry Bessemer

Bois Des Filion

Quebec Canada J6Z 4S9

(450) 965-2224

®

Hougen Manufacturing, Inc.

P.O. Box 2005 • Flint, MI 48501-2005

3001 Hougen Drive • Swartz Creek, MI 48473

Phone (810) 635-7111 • FAX (810) 635-8277

Email: hougenco@tir.com

Online: www.hougen.com

Form 17061 7/2001 1M

.

Loading...

Loading...