Hougen HMD934 120V, HMD934 230V, 0934102, HMD934 230V Type I, 0934302 Operator's Manual

...

OPERATOR’S MANUAL

HMD934 SERIES PORTABLE MAGNETIC DRILL

Covers Drill

Covers Drill

Part Numbers:

Part Numbers:

0934102

0934302

OM9340717EF Printed in U.S.A.

0934202

HOUGEN

WARNING

IMPORTANT SAFETY INSTRUCTIONS

1. Work Area Safety

a) Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2. Electrical Safety

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodifiedplugs

and matching outlets will reduce risk of electrical shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Don’t expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying or unplugging the power tool. Keep cord

away from heat, oil, sharp egdges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use an

outdoor extension cord suitable for outdoor use.

Use of cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal Safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

infl uence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

Important Safety Instructions

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

English

c) Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

fingerontheswitchorenergizingpowertoolsthat

have the switch on invites accidents.

d) Remove any adjusting keys or wrench before

turning the power tool on. A wrench or a key that

is left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dustcollectioncanreducedust-relatedhazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a second.

i) Always use safety chain. Mounting can release.

4. Power Tool Use and Care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it is designed.

b) Do not use the power tool if the switch does

not turn it on or off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any

adjustments, changing accessories or storing

power tools. Such preventative safety measures

reduce the risk of starting the tool accidently.

(Continued on page 4)

Save all warnings and instructions

for future reference.

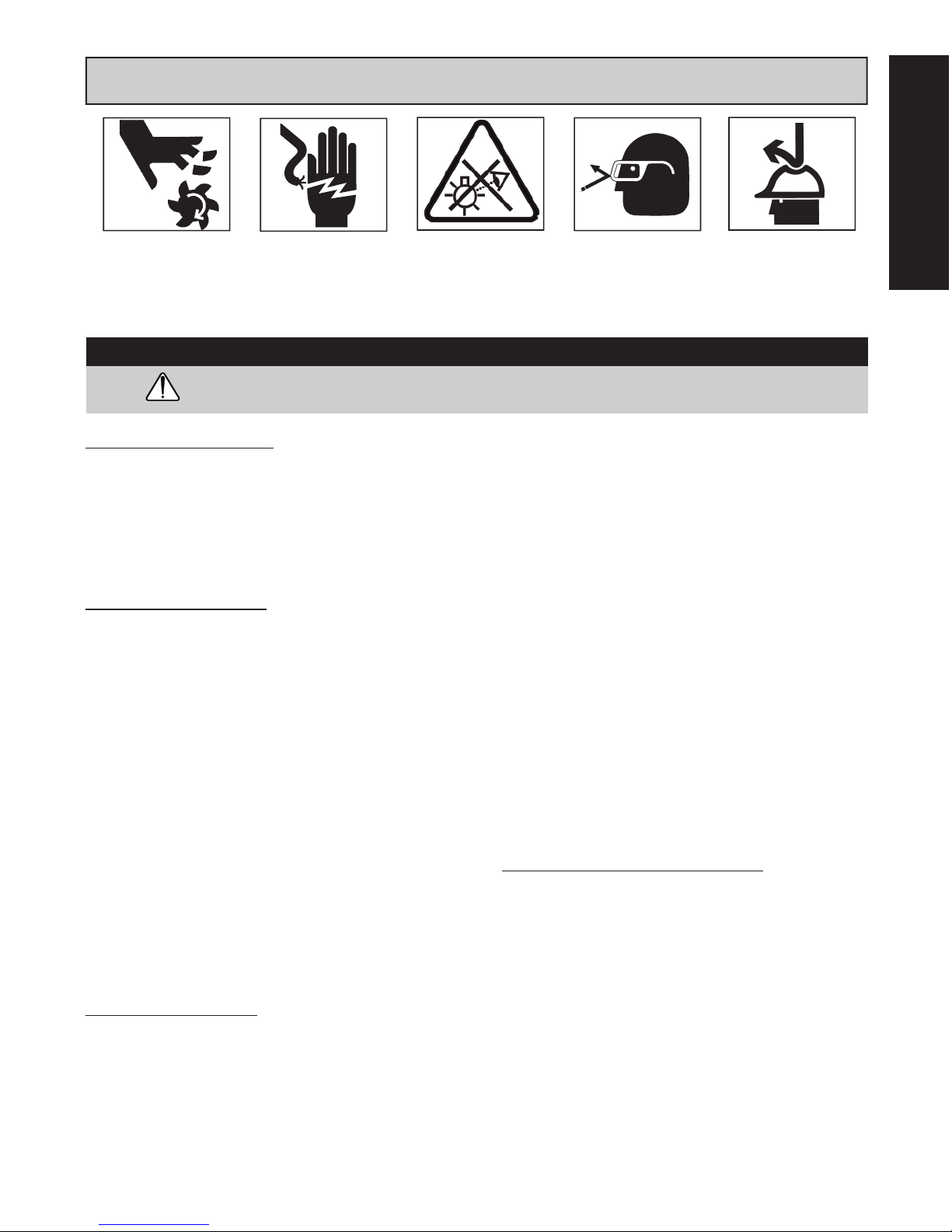

Always wear eye

protection while using

cutting tools, or in the

vicinity of cutting.

The slug is ejected at

the end of the cut. Do

not aim cutter or arbor

so that ejected slug

may hit someone

around, or below you.

To prevent electric

shock, do not use

power tools near wet

areas, or where power

tool may become wet.

Do not stare at

operating light.

Read all safety warnings, instructions, illustrations and speci cations provided with

this power tool.Failuretofollowallinstructionslistedbelowmayresultinelectricshock,fire

and/or serious injury.

WARNING:

Cutters are sharp. Wear

gloves when installing

or removing cutter from

arbor. Do not grab a

rotating cutter.

®

PORTABLE MAGNETIC DRILL

MODEL HMD934 SERIES

Welcome to Hougen

Congratulations on your purchase of the Hougen® Portable Magnetic Drill. Your model is designed to produce superior holes quickly

and ef ciently. Through constant innovation and development, Hougen is committed to provide you with hole producing tools and

products to help you be more productive.

Before attempting to operate your new Portable Magnetic Drill, please read all instructions rst. These include the Operator’s

Manual and Warning Label on the unit itself. With proper use, care, and maintenance, your model will provide you with years of

effective hole drilling performance. Once again, thank you for selecting our product and welcome to Hougen.

Specifi cations

Cutter Type....................... Hougen "12,000-Series"

Hole Capacity....................5/8" to 3-1/16" (16mm-77mm)

Depth of Cut......................4" (100mm)

Motor.................................70/120/200/332 RPM, 12.5A (115V), 6.25A (230V)

Net Weight........................ 72 lbs. (32.6kg)

Noise Specifi cations

Weighted Sound Pressure....................... LpA=88.9dB(A)

Weighted Sound Pressure Uncertainty.....KpA=3dB(A)

Weighted Sound Power............................LwA=101.9dB(A)

Weighted Sound Power Uncertainty.........KwA=101.9dB(A)

The HMD934 is offered in many versions. Refer to the Serial/Part number

Label on your housing to direct you to the correct breakdown.

Part Number

0934102 HMD934 120V

0934202 HMD934 230V

0934302 HMD934 230V Type I

Welcome to Hougen 2

Safety Instructions 3-4

Safety Chain Instructions 4

Operating Instructions 5

Feed & Glide Post Adjustment 6

Ejector Rod Adjustment 7

Gear Combinations 7

Installing Hougen Cutters 8

Hints for Smoother Operation 8

INDEX

Operation of Coolant Bottle 9

Optional Pressurized Coolant Bottle 9

Maintenance 9

Control Panel Breakdown 10

Motor Breakdown 11

HMD934 Exploded View 12-13

HMD934 Parts Breakdown 14-15

Commercial / Industrial Limited Warranty 16

Authorized Warranty Repair Centers 16

2

WARNING

appropriate conditions will reduce personal injuries.

Important Safety Instructions

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

English

c) Prevent unintentional starting. Ensure the switch

English

Cutters are sharp. Wear

gloves when installing

or removing cutter from

arbor. Do not grab a

rotating cutter.

To prevent electric

shock, do not use

power tools near wet

areas, or where power

tool may become wet.

Do not stare at

operating light.

IMPORTANT SAFETY INSTRUCTIONS

Read all safety warnings, instructions, illustrations and speci cations provided with

WARNING:

this power tool.Failuretofollowallinstructionslistedbelowmayresultinelectricshock,fire

and/or serious injury.

1. Work Area Safety

a) Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2. Electrical Safety

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodifiedplugs

and matching outlets will reduce risk of electrical shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Don’t expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying or unplugging the power tool. Keep cord

away from heat, oil, sharp egdges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use an

outdoor extension cord suitable for outdoor use.

Use of cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal Safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

infl uence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid shoes, hard hat or hearing protection used for

Always wear eye

protection while using

cutting tools, or in the

vicinity of cutting.

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

fingerontheswitchorenergizingpowertoolsthat

have the switch on invites accidents.

d) Remove any adjusting keys or wrench before

turning the power tool on. A wrench or a key that

is left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dustcollectioncanreducedust-relatedhazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a second.

i) Always use safety chain. Mounting can release.

The slug is ejected at

the end of the cut. Do

not aim cutter or arbor

so that ejected slug

may hit someone

around, or below you.

4. Power Tool Use and Care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it is designed.

b) Do not use the power tool if the switch does

not turn it on or off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any

adjustments, changing accessories or storing

power tools. Such preventative safety measures

reduce the risk of starting the tool accidently.

(Continued on page 4)

Save all warnings and instructions

for future reference.

3

IMPORTANT SAFETY INSTRUCTIONS

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock-

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

I

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

also result in personal injury to the operator.

Circuit Breaker (If Applicable)

Changing of the circuit breaker to a higher amp rated breaker, or

bypassing the circuit breaker is not recommended and will void

product warranty.

Circuit Breaker Operation (If Applicable)

The circuit breaker is a thermal breaker. When it reaches the

higher temperature rating it will trip and cause the unit to shut

down. This is a protective device and can be reset after 5 to 10.

To reset the breaker, press the breaker button back in. If it does

not reset, let the unit cool a little longer until you can push the

button in and it stays in position.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

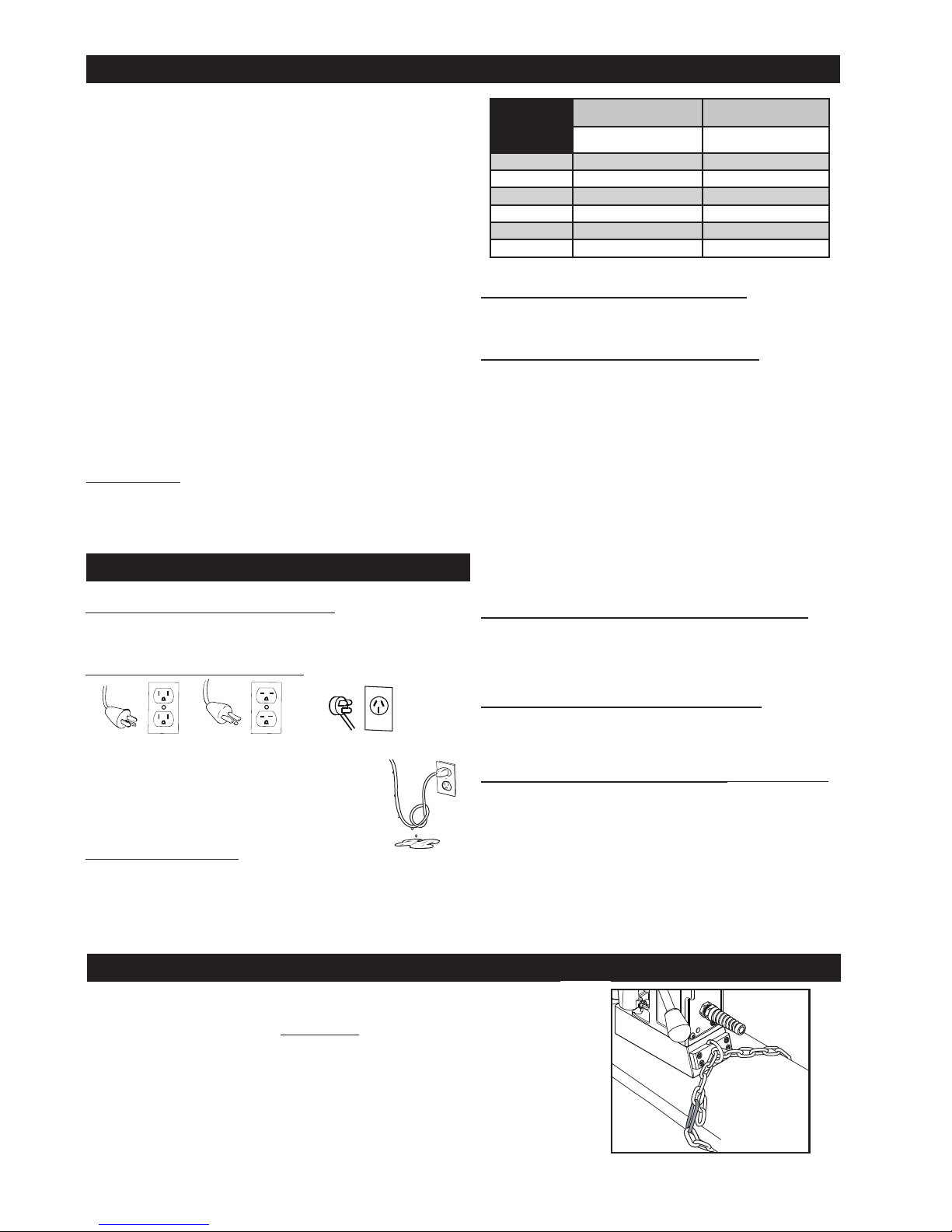

Typical USA 230v

230v Type Plug

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock-

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

I

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

product warranty.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

Typical USA 230v

230v Type Plug

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock-

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

Plugs and Receptacles

product warranty.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

d) Store idle power tools out of reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect

the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

LENGTH

OF CORD,

FEET

Up to 25 16 18

26 - 50 14 18

51 - 100 10 16

101 - 200 8 14

201 - 300 6 12

301 - 500 4 10

f) Keep cutting tools sharp and clean. Proper

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.

in accordance with the instructions, taking into

account the working conditions and the work to

be performed. Use of the power tiil for operations

differentfromthoseintendedcouldresultinahazard-

ous situation.

h) Keep handles and grasping surfaces, clean and

free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

5. Service

a) Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power tool

is maintained.

ADDITIONAL SAFETY INSTRUCTIONS

Safe Electrical Connection

Your Drill is rated for use on 115VAC or 230V at 50-60Hz. Do

not attempt to use drill on power sources rated other than this.

Plugs and Receptacles

.

Outdoor Extension Cord Use

When tool is used outdoors, use only extension cords

intended for use outdoors and so marked.

Additional Safety Precautions

Arbor and cutter should never be used as a handhold or

handle. Keep hands and clothing away from all moving parts.

Do not use Hougen Cutters where ejected slug might cause

injury (slug ejected at end of cut). Also, adhere to all

operating instructions. Do not drill through any surface that

may contain live electrical wiring. Drilling into a live wire

could cause exposed metal parts of the drill to be made live.

Remove chips wrapped around cutter and arbor after each

hole. With motor off and power disconnected, grasp chips

with leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in the

work, stop the unit immediately to prevent personal injury.

Disconnect the drill from the power supply and loosen

jammed cutter by turning the arbor counterclockwise. Never

attempt to free the jammed cutter by starting the motor.

Service at authorized repair center only.

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the unit,

particularly the power cord, could occur. This could also result

in personal injury to the operator.

Circuit Breaker (If Applicable)

Typical USA 120v

Typical USA 115V

Wet electrical connections are shock hazards.

To prevent the cutting uid from traveling along

the cord and contacting the plug or power outlet,

tie a drip loop as shown. Also elevate extension

cords or gang box connections.

Extension Cords

Use only 3-wire extension cords that have a 3-prong

grounding type plug and 3-pole receptacles that accept the tool’s

plug. Replace or repair damaged cords. Make sure the conductor

size is large enough to prevent excessive voltage drop which will

cause loss of power and possible motor damage.

A safety chain should ALWAYS be used

whenever

The safety chain prevents the drill unit from falling, in the event of a power

failure or if the magnet breaks loose from the work surface. The safety chain

attaches to the drill by running the chain thru the D-Ring on the back of the unit

and then continuing around the material and/or work surface. Adjust the chain

so it is tight and secure. Please refer to the diagram.

Typical USA 230v

Typical USA 230V

SAFETY CHAIN INSTRUCTIONS

operating the drill.

230V Type I Plug

Changing of the circuit breaker to a higher amp rated breaker,

or bypassing the circuit breaker is not recommended and will

void product warranty.

Circuit Breaker Operation (If Applicable)

The circuit breaker is a thermal breaker. When it reaches the

higher temperature rating it will trip and cause the unit to shut

down. This is a protective device and can be reset after 5 to

10 minutes. To reset the breaker, press the breaker button

back in. If it does not reset, let the unit cool a little longer until

you can push the button in and it stays in position.

Save all warnings and instructions

for future reference.

4

RECOMMENDED

WIRE GAUGE

115V MOTOR

10 - 12 AMPS

RECOMMENDED

WIRE GAUGE

230V MOTOR

5 - 6 AMPS

UNPACKING YOUR NEW MAGNETIC DRILL

1. Open shipping carton and remove the literature and

hardware packages.

2. Read and follow all instructions before attempting to

operate your new Magnetic Drill.

3. Complete and mail the Product Registration

Card NOW. It is important that Hougen Mfg., Inc. have

a record of product ownership.

4. Contents of Tool Box

10730 - Safety Chain

10569 - Feed Handles (3)

04532 - Knobs (3)

10565 - Hex Key 1/8" S.A.

13013 - Wrench Allen 5/32"

10779 - Wrench Allen 7/32"

01292 - Wrench Allen 1/4"

10727 - Wrench Allen 3/16"

10780 - Wrench Allen 5/16"

10781 - Wrench Allen 3/8"

OPERATING INSTRUCTIONS

40041 - Screw-Soc Set 5/8-11

40042 - Screw-Soc Set 3/4-10 (2)

40061 - Handle Assembly

05487 - Grease - Lubriplate GR-132

40126 - Coolant Btl. Assembly *

*(sometimes packed separately)

5. Lift the unit out of the shipping case.

6. Remove all packing and securing material from the

drill unit.

7. Screw the three knobs onto the three feed handles

and then screw the handles into the hub

8. Install coolant bottle on unit, utilizing screws that are

provided.

9. Your Magnetic Drill was factory adjusted prior to

shipping. Check to make sure that the feed rod

adjustment screws, motor mount screws, exterior bolts

and screws have not vibrated loose in transit.

10. Your New Magnetic Drill comes complete and ready

to go. This unit utilizes the Hougen "12,000-Series"

3/4" shank cutters.

English

Always remember that the magnet’s holding power is

directly related to the workpiece thickness and surface

condition. This drill is for use on 3/8" material or thicker.

Since magnetic attraction diminshes with thinner material

or rough surfaces, mechanical clamping of drill unit to the

workpiece should be used when cutting such material.

1. Make sure workpiece and bottom of magnet are free

chips, oil, etc.

2. Attach Safety Chain.

3. Position drill by sliding it so that point of the ejector

rod is above center of hole to be drilled.

4. Turn Magnet switch to ON position.

5. Set both impactors into the workpiece by striking

with hammer.

6. Open the Adjustment Needle to provide a generous

ow of cutting uid until a puddle approximately the

diameter of the cutter being used is developed on the

workpiece. Once this initial supply of cutting uid is

established on the workpiece, adjust the ow to a

steady drip.

8. Feed Hougen Cutter slowly into workpiece. Only

after cutting path is established to a depth of about

1/16" can full feed force be applied to feed handles.

On deep and large diameter holes,

clear chips from around cutter and arbor

9. Ease up on feed pressure as cutter starts breaking

through.

10. At conclusion of cut, turn Motor OFF. Turn feed handles

to raise Arbor, thereby ejecting the slug if it hasn’t

already fallen free.

11. Turn Magnet OFF.

12. Remove chips from both cutter and magnet.

Preferably while wearing leather work gloves.

13. Disconnect safety chain and you are ready to move

unit to new position.

after every inch of cutting depth.

SPECIAL INSTRUCTION FOR HORIZONTAL

OR OVERHEAD OPERATION

7. Make certain that cutter is clear of workpiece and turn

motor switch ON.

1. Always use Safety Chain and / or mechanical

clamping.

2. Use grease or animal fat base solid lubricant applied

liberally to cutter.

5

Loading...

Loading...