Hougen HMD934 120V, HMD934 230V, 0934102, HMD934 230V Type I, 0934302 Operator's Manual

...

OPERATOR’S MANUAL

HMD934 SERIES PORTABLE MAGNETIC DRILL

Covers Drill

Covers Drill

Part Numbers:

Part Numbers:

0934102

0934302

OM9340717EF Printed in U.S.A.

0934202

HOUGEN

WARNING

IMPORTANT SAFETY INSTRUCTIONS

1. Work Area Safety

a) Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2. Electrical Safety

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodifiedplugs

and matching outlets will reduce risk of electrical shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Don’t expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying or unplugging the power tool. Keep cord

away from heat, oil, sharp egdges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use an

outdoor extension cord suitable for outdoor use.

Use of cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal Safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

infl uence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

Important Safety Instructions

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

English

c) Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

fingerontheswitchorenergizingpowertoolsthat

have the switch on invites accidents.

d) Remove any adjusting keys or wrench before

turning the power tool on. A wrench or a key that

is left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dustcollectioncanreducedust-relatedhazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a second.

i) Always use safety chain. Mounting can release.

4. Power Tool Use and Care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it is designed.

b) Do not use the power tool if the switch does

not turn it on or off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any

adjustments, changing accessories or storing

power tools. Such preventative safety measures

reduce the risk of starting the tool accidently.

(Continued on page 4)

Save all warnings and instructions

for future reference.

Always wear eye

protection while using

cutting tools, or in the

vicinity of cutting.

The slug is ejected at

the end of the cut. Do

not aim cutter or arbor

so that ejected slug

may hit someone

around, or below you.

To prevent electric

shock, do not use

power tools near wet

areas, or where power

tool may become wet.

Do not stare at

operating light.

Read all safety warnings, instructions, illustrations and speci cations provided with

this power tool.Failuretofollowallinstructionslistedbelowmayresultinelectricshock,fire

and/or serious injury.

WARNING:

Cutters are sharp. Wear

gloves when installing

or removing cutter from

arbor. Do not grab a

rotating cutter.

®

PORTABLE MAGNETIC DRILL

MODEL HMD934 SERIES

Welcome to Hougen

Congratulations on your purchase of the Hougen® Portable Magnetic Drill. Your model is designed to produce superior holes quickly

and ef ciently. Through constant innovation and development, Hougen is committed to provide you with hole producing tools and

products to help you be more productive.

Before attempting to operate your new Portable Magnetic Drill, please read all instructions rst. These include the Operator’s

Manual and Warning Label on the unit itself. With proper use, care, and maintenance, your model will provide you with years of

effective hole drilling performance. Once again, thank you for selecting our product and welcome to Hougen.

Specifi cations

Cutter Type....................... Hougen "12,000-Series"

Hole Capacity....................5/8" to 3-1/16" (16mm-77mm)

Depth of Cut......................4" (100mm)

Motor.................................70/120/200/332 RPM, 12.5A (115V), 6.25A (230V)

Net Weight........................ 72 lbs. (32.6kg)

Noise Specifi cations

Weighted Sound Pressure....................... LpA=88.9dB(A)

Weighted Sound Pressure Uncertainty.....KpA=3dB(A)

Weighted Sound Power............................LwA=101.9dB(A)

Weighted Sound Power Uncertainty.........KwA=101.9dB(A)

The HMD934 is offered in many versions. Refer to the Serial/Part number

Label on your housing to direct you to the correct breakdown.

Part Number

0934102 HMD934 120V

0934202 HMD934 230V

0934302 HMD934 230V Type I

Welcome to Hougen 2

Safety Instructions 3-4

Safety Chain Instructions 4

Operating Instructions 5

Feed & Glide Post Adjustment 6

Ejector Rod Adjustment 7

Gear Combinations 7

Installing Hougen Cutters 8

Hints for Smoother Operation 8

INDEX

Operation of Coolant Bottle 9

Optional Pressurized Coolant Bottle 9

Maintenance 9

Control Panel Breakdown 10

Motor Breakdown 11

HMD934 Exploded View 12-13

HMD934 Parts Breakdown 14-15

Commercial / Industrial Limited Warranty 16

Authorized Warranty Repair Centers 16

2

WARNING

appropriate conditions will reduce personal injuries.

Important Safety Instructions

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

English

c) Prevent unintentional starting. Ensure the switch

English

Cutters are sharp. Wear

gloves when installing

or removing cutter from

arbor. Do not grab a

rotating cutter.

To prevent electric

shock, do not use

power tools near wet

areas, or where power

tool may become wet.

Do not stare at

operating light.

IMPORTANT SAFETY INSTRUCTIONS

Read all safety warnings, instructions, illustrations and speci cations provided with

WARNING:

this power tool.Failuretofollowallinstructionslistedbelowmayresultinelectricshock,fire

and/or serious injury.

1. Work Area Safety

a) Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2. Electrical Safety

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodifiedplugs

and matching outlets will reduce risk of electrical shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Don’t expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying or unplugging the power tool. Keep cord

away from heat, oil, sharp egdges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use an

outdoor extension cord suitable for outdoor use.

Use of cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

3. Personal Safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

infl uence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in

serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid shoes, hard hat or hearing protection used for

Always wear eye

protection while using

cutting tools, or in the

vicinity of cutting.

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

fingerontheswitchorenergizingpowertoolsthat

have the switch on invites accidents.

d) Remove any adjusting keys or wrench before

turning the power tool on. A wrench or a key that

is left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dustcollectioncanreducedust-relatedhazards.

h) Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a second.

i) Always use safety chain. Mounting can release.

The slug is ejected at

the end of the cut. Do

not aim cutter or arbor

so that ejected slug

may hit someone

around, or below you.

4. Power Tool Use and Care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it is designed.

b) Do not use the power tool if the switch does

not turn it on or off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any

adjustments, changing accessories or storing

power tools. Such preventative safety measures

reduce the risk of starting the tool accidently.

(Continued on page 4)

Save all warnings and instructions

for future reference.

3

IMPORTANT SAFETY INSTRUCTIONS

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock-

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

I

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

also result in personal injury to the operator.

Circuit Breaker (If Applicable)

Changing of the circuit breaker to a higher amp rated breaker, or

bypassing the circuit breaker is not recommended and will void

product warranty.

Circuit Breaker Operation (If Applicable)

The circuit breaker is a thermal breaker. When it reaches the

higher temperature rating it will trip and cause the unit to shut

down. This is a protective device and can be reset after 5 to 10.

To reset the breaker, press the breaker button back in. If it does

not reset, let the unit cool a little longer until you can push the

button in and it stays in position.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

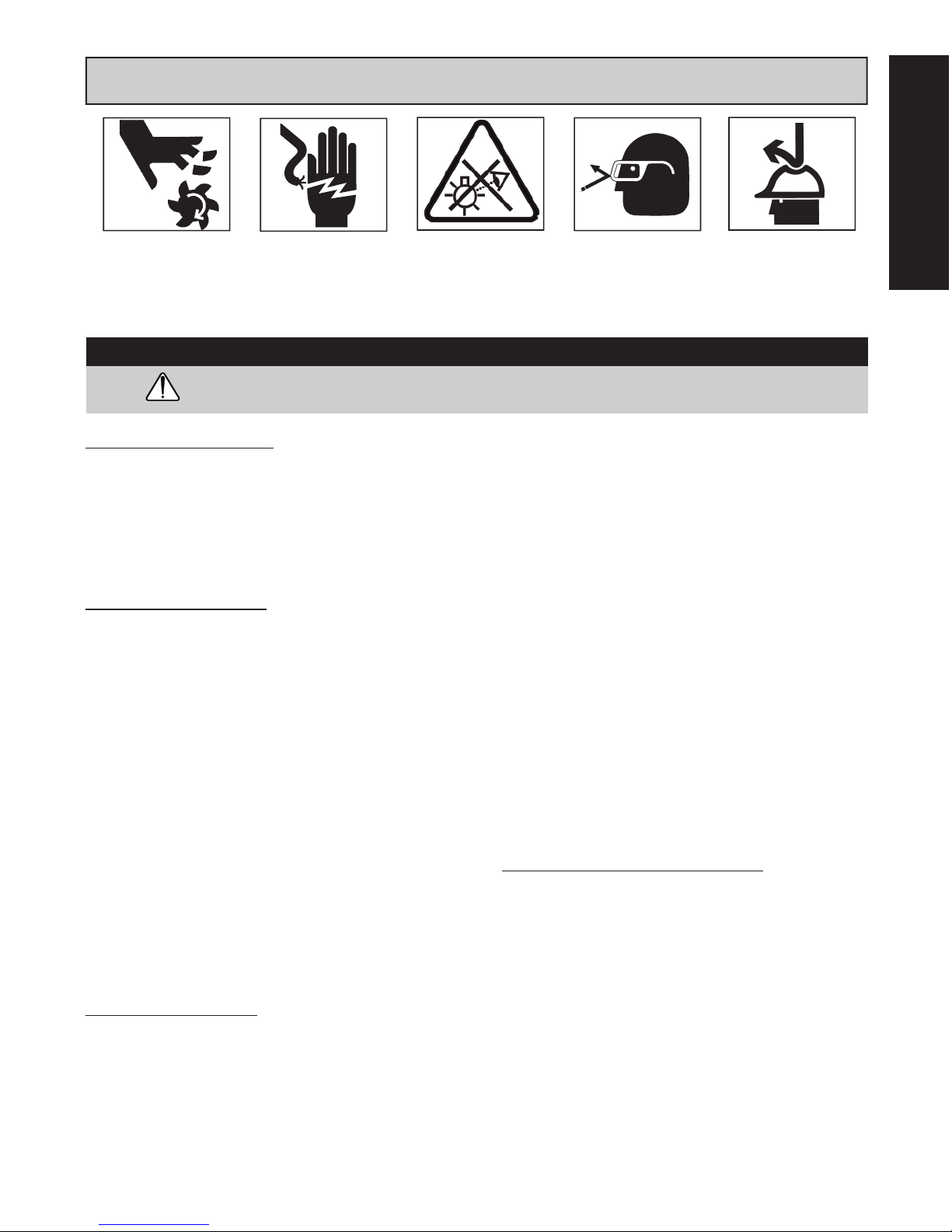

Typical USA 230v

230v Type Plug

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock-

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

I

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

product warranty.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

Typical USA 230v

230v Type Plug

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock-

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

Plugs and Receptacles

product warranty.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

d) Store idle power tools out of reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect

the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

LENGTH

OF CORD,

FEET

Up to 25 16 18

26 - 50 14 18

51 - 100 10 16

101 - 200 8 14

201 - 300 6 12

301 - 500 4 10

f) Keep cutting tools sharp and clean. Proper

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc.

in accordance with the instructions, taking into

account the working conditions and the work to

be performed. Use of the power tiil for operations

differentfromthoseintendedcouldresultinahazard-

ous situation.

h) Keep handles and grasping surfaces, clean and

free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

5. Service

a) Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power tool

is maintained.

ADDITIONAL SAFETY INSTRUCTIONS

Safe Electrical Connection

Your Drill is rated for use on 115VAC or 230V at 50-60Hz. Do

not attempt to use drill on power sources rated other than this.

Plugs and Receptacles

.

Outdoor Extension Cord Use

When tool is used outdoors, use only extension cords

intended for use outdoors and so marked.

Additional Safety Precautions

Arbor and cutter should never be used as a handhold or

handle. Keep hands and clothing away from all moving parts.

Do not use Hougen Cutters where ejected slug might cause

injury (slug ejected at end of cut). Also, adhere to all

operating instructions. Do not drill through any surface that

may contain live electrical wiring. Drilling into a live wire

could cause exposed metal parts of the drill to be made live.

Remove chips wrapped around cutter and arbor after each

hole. With motor off and power disconnected, grasp chips

with leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in the

work, stop the unit immediately to prevent personal injury.

Disconnect the drill from the power supply and loosen

jammed cutter by turning the arbor counterclockwise. Never

attempt to free the jammed cutter by starting the motor.

Service at authorized repair center only.

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the unit,

particularly the power cord, could occur. This could also result

in personal injury to the operator.

Circuit Breaker (If Applicable)

Typical USA 120v

Typical USA 115V

Wet electrical connections are shock hazards.

To prevent the cutting uid from traveling along

the cord and contacting the plug or power outlet,

tie a drip loop as shown. Also elevate extension

cords or gang box connections.

Extension Cords

Use only 3-wire extension cords that have a 3-prong

grounding type plug and 3-pole receptacles that accept the tool’s

plug. Replace or repair damaged cords. Make sure the conductor

size is large enough to prevent excessive voltage drop which will

cause loss of power and possible motor damage.

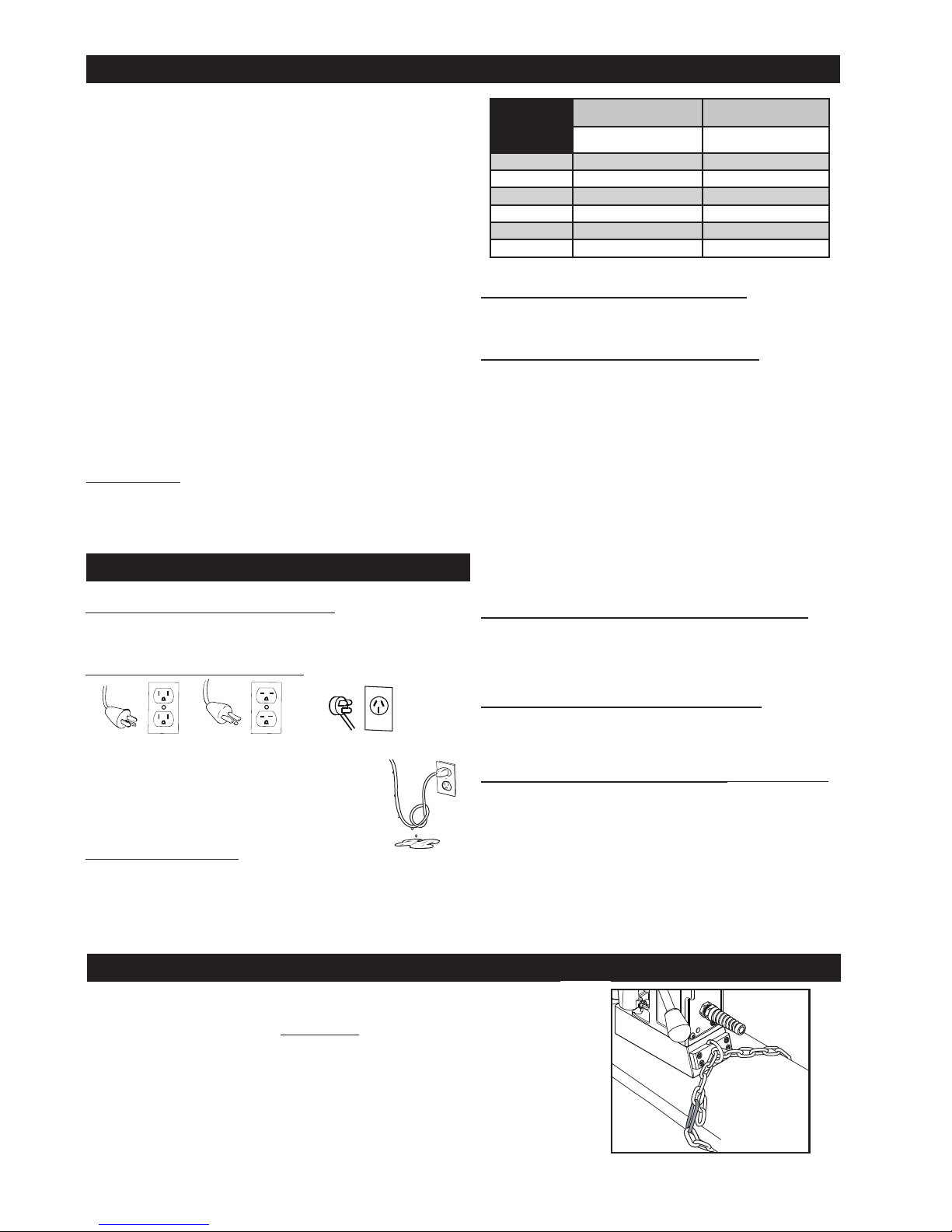

A safety chain should ALWAYS be used

whenever

The safety chain prevents the drill unit from falling, in the event of a power

failure or if the magnet breaks loose from the work surface. The safety chain

attaches to the drill by running the chain thru the D-Ring on the back of the unit

and then continuing around the material and/or work surface. Adjust the chain

so it is tight and secure. Please refer to the diagram.

Typical USA 230v

Typical USA 230V

SAFETY CHAIN INSTRUCTIONS

operating the drill.

230V Type I Plug

Changing of the circuit breaker to a higher amp rated breaker,

or bypassing the circuit breaker is not recommended and will

void product warranty.

Circuit Breaker Operation (If Applicable)

The circuit breaker is a thermal breaker. When it reaches the

higher temperature rating it will trip and cause the unit to shut

down. This is a protective device and can be reset after 5 to

10 minutes. To reset the breaker, press the breaker button

back in. If it does not reset, let the unit cool a little longer until

you can push the button in and it stays in position.

Save all warnings and instructions

for future reference.

4

RECOMMENDED

WIRE GAUGE

115V MOTOR

10 - 12 AMPS

RECOMMENDED

WIRE GAUGE

230V MOTOR

5 - 6 AMPS

UNPACKING YOUR NEW MAGNETIC DRILL

1. Open shipping carton and remove the literature and

hardware packages.

2. Read and follow all instructions before attempting to

operate your new Magnetic Drill.

3. Complete and mail the Product Registration

Card NOW. It is important that Hougen Mfg., Inc. have

a record of product ownership.

4. Contents of Tool Box

10730 - Safety Chain

10569 - Feed Handles (3)

04532 - Knobs (3)

10565 - Hex Key 1/8" S.A.

13013 - Wrench Allen 5/32"

10779 - Wrench Allen 7/32"

01292 - Wrench Allen 1/4"

10727 - Wrench Allen 3/16"

10780 - Wrench Allen 5/16"

10781 - Wrench Allen 3/8"

OPERATING INSTRUCTIONS

40041 - Screw-Soc Set 5/8-11

40042 - Screw-Soc Set 3/4-10 (2)

40061 - Handle Assembly

05487 - Grease - Lubriplate GR-132

40126 - Coolant Btl. Assembly *

*(sometimes packed separately)

5. Lift the unit out of the shipping case.

6. Remove all packing and securing material from the

drill unit.

7. Screw the three knobs onto the three feed handles

and then screw the handles into the hub

8. Install coolant bottle on unit, utilizing screws that are

provided.

9. Your Magnetic Drill was factory adjusted prior to

shipping. Check to make sure that the feed rod

adjustment screws, motor mount screws, exterior bolts

and screws have not vibrated loose in transit.

10. Your New Magnetic Drill comes complete and ready

to go. This unit utilizes the Hougen "12,000-Series"

3/4" shank cutters.

English

Always remember that the magnet’s holding power is

directly related to the workpiece thickness and surface

condition. This drill is for use on 3/8" material or thicker.

Since magnetic attraction diminshes with thinner material

or rough surfaces, mechanical clamping of drill unit to the

workpiece should be used when cutting such material.

1. Make sure workpiece and bottom of magnet are free

chips, oil, etc.

2. Attach Safety Chain.

3. Position drill by sliding it so that point of the ejector

rod is above center of hole to be drilled.

4. Turn Magnet switch to ON position.

5. Set both impactors into the workpiece by striking

with hammer.

6. Open the Adjustment Needle to provide a generous

ow of cutting uid until a puddle approximately the

diameter of the cutter being used is developed on the

workpiece. Once this initial supply of cutting uid is

established on the workpiece, adjust the ow to a

steady drip.

8. Feed Hougen Cutter slowly into workpiece. Only

after cutting path is established to a depth of about

1/16" can full feed force be applied to feed handles.

On deep and large diameter holes,

clear chips from around cutter and arbor

9. Ease up on feed pressure as cutter starts breaking

through.

10. At conclusion of cut, turn Motor OFF. Turn feed handles

to raise Arbor, thereby ejecting the slug if it hasn’t

already fallen free.

11. Turn Magnet OFF.

12. Remove chips from both cutter and magnet.

Preferably while wearing leather work gloves.

13. Disconnect safety chain and you are ready to move

unit to new position.

after every inch of cutting depth.

SPECIAL INSTRUCTION FOR HORIZONTAL

OR OVERHEAD OPERATION

7. Make certain that cutter is clear of workpiece and turn

motor switch ON.

1. Always use Safety Chain and / or mechanical

clamping.

2. Use grease or animal fat base solid lubricant applied

liberally to cutter.

5

FEED ADJUSTMENT

Drag Screw must be adjusted against the Feed Rod so that main

housing moves freely up and down the feed

rods when feed wheel is turned, so that main housing stays in

position on feed rod when wheel is released.

GLIDE POST ADJUSTMENT

1. Adjustment is made with magnet on and glide

posts over work surface.

2. Remove front glide post lock screw, and loosen

rear glide post lock screw.

Lock Screw

Drag Screw

3. Screw both glide posts up until the ends are

above the work surface.

4. Place a .040" shim under the front glide post and

a 0.125" shim under the rear glide post.

5. Screw glide posts down, compressing plungers,

until the body of the glide posts rest on the shims.

6. Replace the front lock screw and tighten both the

front and rear lock screws.

IMPACTOR ADJUSTMENT

1. Adjustment is made with Magnet ON and impactor

over the work surface.

2. Loosen Heads of Front and Rear Impactors

(Detail No. 25)

3. Screw Impactor Points (Detail No. 26) up (counter clockwise) until point just touches work surface.

Glide Post

Impactor

Head

4. Screw Impactors down (clockwise) until point just

touches work surface.

5. Screw Impactor Points 1/2 turn further toward

work surface. (It may be necessary to turn off

Magnet while advancing Impactor).

6. Tighten Heads.

Impactor

Point

6

Motor

Shaft

Spline Shaft

Cuttter Side of Drill

Gear

Altered Washer

Gear

B

A

B

Lower Bearing

Retainer

Cap

Lower Bearing

Retainer

Washer

EJECTOR ROD ADJUSTMENT

In addition to providing a positive method to insure that a

slug is not retracted with the cutter, the ejector rod serves

as a conduit for the cutting uid and as a centering guide for

positioning the Mag Drill on the workpiece. Under normal

conditions, the point of the ejector rod should be kept at

least 1/16" above the work surface.

It is important that the point of the ejector rod not be

allowed to rest on the work surface for two reasons:

A) The point will drag on the work surface when Mag Drill

is repositioned which may cause the ejector rod to

become bent.

B) The ejector rod may hold the front of the magnet off of

the work surface, deminishing its holding ability.

GEAR COMBINATIONS FOR VARIOUS RPMS

Gear

Case

Cover

To adjust the ejector rod:

1. Place the Mag Drill on a steel plate and turn the

magnet on.

2. Loosen the lock nut and rotate the knurled nut until the

point of the ejector rod is in the desired location.

3. When adjusted properly, the point should clear the

work surface (1/16" minimum) both when the magnet

is on and when it is off (Mag Drill riding on glide post).

4. When adjustment is complete, using a wrench,

retighten the lock nut against the underside of the tie

bar.

English

Remove

Screws

Drawings above show arrangement of gears. Be sure that upper and lower washers are replaced on Shafts A

and B when changing gears. If necessary, refer to exploded view when removing lower bearing retainer cap.

Cutter

RPM

120 18 30

332 30 18

70 18 30

200 30 18

No. of Teeth per Gear

Shaft A Shaft B

Motor High Speed

Motor Low Speed

Drill unit comes with 18-tooth gear on Shaft A and 30-tooth gear

on Shaft B to provide 120 RPM. For other RPM’s, use optional gears

with the following procedure.

1. Remove the Lower Bearing Retainer Cap by removing the ve

Cap screws.

2. Use two threaded holes to ease cover off. Remove gears from Shafts

A and B, being careful to save the two Altered Torrington Thrust

Washers and two lower Washers.

3. Be certain that the two Altered Torrington Thrust washers are

rst mounted on Shaft A and B.

4. Slide proper gears on Shafts A and B (refer to table on left).

5. Mount lower washers on both shafts.

6. Pack gears with liberal supply of grease.

7. Replace Lower Bearing Retainer Cap. Replace and tighten all

six cap screws.

7

INSTALLING HOUGEN CUTTER IN ARBOR

Pilot

1. Disconnect from power source and remove 1/4" Allen Wrench.

2. Lay drill on its side with feed handles up or be sure Arbor clears table if unit

is in normal operating position.

3. Turn Feed Handles until cutter mounting set screws are exposed and

completely remove the set screws.

4. Insert Hougen Cutter on ejector rod.

5. Insert Hougen Cutter until at on cutter shank is aligned with set screw holes

and is exactly perpendicular to axis of set screw holes.

6. Insert set screws and tighten. Check to be certain that cutter is secure.

Set Screws

go here

Pilot

"12000-Series"

Hougen Cutter

HINTS FOR SMOOTHER OPERATION

1. Keep the inside of Hougen Cutter clear of chips. Chips will interfere with cutting

to maximum depth, maybe impede the free oil ow and can cause cutter breakage.

2. Keep work, machine, arbor and Hougen Cutter free of chips and dirt.

3. Tighten all bolts and fasteners regularly.

4. We highly recommend using a light viscosity cutting uid (preferably

Hougen Cutting Fluid.

5. Occasionally check metering of cutting uid ow. Lack of cutting uid may

cause Hougen Cutter to freeze in cut, slug to stick and may result in poor

cutter life.

6. Always start cut with light feed pressure and then increase sufciently to

achieve maximum cutting rate.

7. Ease off on pressure as cutter begins to break through at the end of the cut.

8. Keep slide dovetails, brass gibs and feed rack lubricated and free of chips and dirt.

9. When slug hangs up in cutter, turn off motor and bring cutter down on a at surface. This will normally straighten a cocked slug,

allowing it to be ejected.

10. When cutting large diameter or deep holes it may be necessary to stop in the middle of the cut to add cutting uid and remove the

chips from around the arbor. (When doing this DO NOT raise the cutter out of the hole. Doing so can allow chips to get under the

teeth of the cutter. This will make it difcult to restart the cut.)

#1 cause of cutter

breakage and

prematurely dull

teeth is too little

feed pressure

"Babying" the cutter through the cut will only decrease tool life.

REMEDIES FOR HOLEMAKING PROBLEMS

1. Trouble: Magnetic base won’t hold effectively to work.

a. Cause: Chips or dirt under magnet.

Remedy: Clear area of chips and dirt.

b. Cause: Irregular surface on bottom of magnet

or on workpiece.

Remedy: Lightly surface grind the bottom of the magnet at

and/or le imperfections at on the work surface

as needed.

2. Trouble: Cutter tends to move across surface of work.

a. Cause: Magnetic base not holding effectively.

Remedy: See causes and remedies under No. 1 above.

b. Cause: Too much feed pressure at start of cut.

Remedy: Use light pressure until a groove is cut.

The groove then serves as a stabilizer.

c. Cause: Worn cutter.

Remedy: Replace or have cutter resharpened.

3. Trouble: Out of round holes.

a. Cause: Worn arbor support bracket bearing

and or ejector collar.

Remedy: Replace: (only a few thousandths wear permissible.)

b. Cause: Misaligned support bracket

Remedy: Realign support bracket

c. Cause: Misaligned or loose arbor set screw.

Remedy: Tighten set screw.

4. Trouble: Motor and slide won’t stay in set position

a. Cause: Drag Screw is loose

Remedy: Adjust Drag Screw

5. Trouble: Erratic or intermittent feed.

a. Cause: Worn or pinion and/or rack.

Remedy: Replace worn parts.

6. Trouble: Motor doesn’t run when motor START

button is pushed.

a. Cause: Magnet is not turned on

Remedy: Push magnet ON button.

b. Cause: Magnet on rough or dirty work surface

and safety switch not fully depressed.

Remedy: File work surface at and clean all

chips and oil from under magnet.

c. Cause: No power

Remedy: Check power source and extension cords.

e. Cause: Worn motor brushes

Remedy: Replace brushes

f. Cause: Faulty motor START switch

Remedy: Return unit to an authorized repair

center to have switch replaced.

NOTE: If you are unable to correct any malfunction after trying

the above, do not attempt to operate the drill. Return the unit to

the factory or authorized repair center for service.

8

OPERATION OF CUTTING FLUID RESERVOIR

When everything is ready to go (Magnet ON and Impactors seated), open the Adjustment Needle to provide a generous

ow of cutting uid until a puddle approximately the diameter of the cutter being used is developed on the workpiece.

Once this initial supply of cutting uid is established on the workpiece, adjust the ow to a steady drip.

OPTIONAL PRESSURIZED COOLANT BOTTLE

1

2

4

Reference Only

Existing Screws

#40108

3

Reference Only

#40062 Tie Bar

located on the

machine

English

4

08446 Pressurized Coolant Assembly

Item Part # Description Qty

1 08557 Pressurized Coolant Block 1

2 05646 Fitting-Qk Connect Male 1

3 04807 O-Ring 1

4 05630 Coolant Bottle Assembly 1

MAINTENANCE

In order to minimize wear on moving parts and to insure smoother operation and longer life for your magnetic drill, the following

maintenance should be done periodically, based on use.

1. Regularly tighten all fasteners and replace all worn parts.

2. Check motor brushes and replace if worn.

3. Check power cord and cord from panel to motor and, if cracked or frayed, return to an authorized repair center for replacement.

4. Apply grease to the slide rods, brass gibs, and the feed gear. For best results use Shell Cyprina-RA or equivalent.

5. The safety switch plunger should be clean and lubricated with penetrating oil periodically. As necessary remove the magnet

from drill and remove safety switch assembly from magnet. Push the plunger out of magnet. Clean out any debris from inside an

around plunger hole in magnet. Coat the plunger with anti-seize. Replace plunger and safety switch assembly and tighten down

screws. Replace magnet into drill housing.

9

CONTROL PANEL BREAKDOWN & WIRING

2 & 5

16

1

3 & 4

08577 Panel Assembly 120V

08585 Panel Assembly 230V

Item Part # Description Qty

1 07011 Faceplate 1

2 01335 Switch - Motor Off 1

3 01334 Switch - Motor On 1

4 02409 Seal - Green 1

5 01228 Seal - Red 1

6 01226 Guard Switch 1

7 04614 Magnet Switch 1

6

7

15

14

8

9

8 02548 Stand Off 3

9 08578 Plug - Dome 1

10 04879 Lens Clear L.E.D. 1

11 04878 Spacer L.E.D. 1

12 04881 Bulb L.E.D. 1

13 04877 Wire Harness L.E.D. 1

14 08646 Circuit Board 120V 1

08673 Circuit Board 230V 1

15 02547 SCR #4-40 x 5/16 LG 3

16 07522 Fuse 2

White

Wire

13

Red

Anode

11

12

Wire Harness

Green Ground

to Attach to Housing

10

Blue Wire

Brown Wire

Pilot Light

Safety Switch

J10

J4 J1 J2

Magnet

To

Power Cord

Black Wire

White Wire

Fuses

Motor

Black Wire

Motor

White Wire

10

MOTOR PARTS

21

English

18

15

19

20

18

13

28

19

35

34

33

32

31

16

13

12

11

10

5

6

7

2

1

9

17

14

8

4

3

26

22

2

24

23

25

29

27

08579 Motor Assembly 120V

08586 Motor Assembly 230V

Item Part # Description Qty Item Part # Description Qty

1 41048 SCR-SHC #10-32 x 1-1/2 4 20 07911 Assembly Gears #2 & #3 1

2 50038 Washer - Lock Helical #10 6 21 08278 Gear Box Cover 1

3 07860 Retaining Ring 1 22 24093 Washer - Spring 1

4 40274 Bearing 25mm x 47mm x 12mm 1 23 08276 Armature Assembly - 120V 1

5 08069 SCR-SHSLD 3/16 x 7/8 1 08277 Armature Assembly - 230V 1

6 07908 Switch 1 24 07895 SCR-SHC #10-32 x 3-1/2 LG 2

7 07910 Spring-Comp 1 25 07892 Bafe 1

8 07826 Gear Box Housing 1 26 07891 Field - 120V 1

9 08131 Spindle- Motor Drive 1 08040 Field - 230V 1

10 07904 Key 1 27 08280 Motor Brush Holder Assembly 1

11 07900 Gear Spur Removable 1 28 07876 Specs Label - 120V 1

12 24160 Retaining Ring 1 08038 Specs Label - 230V 1

13 24100 Ball Bearing 3 29 08558 Motor Label 1

14 07899 Gear Spur Removable 1 30 24044 Brush Holder Cap 2

15 07905 Key 1 31 24045 Carbon Brushes 2

16 07868 Shift Control Rod Arm 1 32 08339 Motor Cord 1

17 07914 Assembly, Change gear 1 33 07848 Cover, Brush Access 1

18 17610 Washer - Flat 8mm 2 34 02385 SCR-BHC #6-32 x 1/4 4

19 07903 Needle Bearing 2 35 10538 Washer - Lock 1

30

11

113

114

115

79

80

81

104

31

112

116

117

105

4*

3*

2*

1*

6

7

5a*

11

13

13

15

16

14

12

10

8*

9*

5*

6

7

71

72

73

61

75

66

67

68

69

70

64

62

62

61

61

17

63

94

62

61

51

69

70

68

67

76

* Included in

40126 Assembly

133

110

136

137

138

141

135

138

140

HMD934

Exploded View

12

130

131

118

119

120

133

125

126

128

127

123

122

133

26

41

52

81

88

89

90

101

100

99

95

97

96

95

84

98

91

90

89

88

78

80

82

82

83

85

98

30

32

39

37

19

7

28

28

27

33

29

30

48

25

132

49

42

45

31

59

35

6

40

24

21

18

19

12

56

55

139

22

23

20

18

18

19

19

18

19

English

13

HMD934

No. Part # Description Qty

40126 Bottle Assembly 1

1 40126 Cap (Must buy Bottle Assy) 1

2 40123 Hold Down Fitting 1

3 40058 Washer 1

4 40121 Bottle 1

5 40126 Block (Must buy Bottle Assy) 1

5a 40125 Drip Tube 1

6 40070 SHCS 1/2-13 x 1 3

7 40069 Washer 1/2 4

8 40126 Adjustment Needle 1

9 40124 O-Ring 1

10 90071 Screw 1/4-20 x 1/4 2

11 40062 Tie Bar 1

12 40108 SHCS 1/4-20 x 1-1/4 3

13 40067 Feed Rod 2

14 40052 Hex Nut 7/16-14 1

15 40105 Knurled Nut 7/16 1

16 40113 Ejector Rod 1

17 40114 Ejector Rod Point 1

18 40558 SHCS 5/16-18 x 3/4 4

19 40107 Lock Washer 5/16 4

20 40086 Strut Assy 1

21 40117 Grommet 1

22 75156 SCR-SHC M6 x 15mm 2

23 17687 Washer-Lock Helical 6mm 2

24 08193 Handle - Pull 1

25 40181 Head - Impactor 1

26 40182 Point - Impactor 1

27 40141 SCR-SOC Set 5/8-11 x 1/2 1

28 10644 Spring Plunger 2

29 40183 SCR-SHC 5/16-18 x 2-1/4 1

30 40143 SCR-SHC 5/16-18 x 1-1/2 4

31 08231 Strain Relief 3

32 10977 SCR-BHC 1/4-20 x 1/4 1

33 40074 Washer 5/16 Flat 1

35 40134 Impactor Block 1

37 40184 Nut 5/16-18 UNC 1

39 40110 Washer Lock 1/2 Hel 4

40 40111 SCR-SHC 1/2-13 x 1-1/2 1

41 10972 SCR-BHC #6-32 2

No. Part # Description Qty

42 40130 Safety Switch Assy 1

45 04909 Bracket-Safety Switch 1

48 10983 Shield-Safety Switch 1

49 10971 SCR-SHC 1/4-20 x 1/2 1

51 90497 SCR-SS 1/4-20 x 3/8 BR 2

52 08550 Magnet 115V 1

08583 Magnet 230V 1

55 17271 Spring 1

56 04961 Plunger Assy 1

59 40139 Base Plate 1

61 10626 Seal 7/8 5

62 40065 Bushing 7/8 4

63 40001 Main Housing 1

64 40071 SCR-SHC 1/4-28 x 7/8 4

66 40044 Retaining Ring 1

67 40032 Washer 9/6 x 1-3/8 2

68 40116 Gear Spur 16 teeth 2

69 40045 Key 2

70 40048 Bushing 9/16 1

71 40032 Bushing 7/16 1

72 40092 Retaining Ring 1

73 40112 Thrust Washer 2

75 40090 Bearing 7/8 1

76 40061 Handle Assy 1

78 40035 Bushing 1

79 40091 Washer 7/8 1

80 40026 Gear Spindle 36 Teeth 1

81 40118 Spacer - Spindle 1

82 40033 Bearing 3/4 1

83 40021 Gear Idler 32 Teeth 1

84 40012 Change Gear 18 Teeth 1

40016 Change Gear 30 Teeth 1

85 40018 Idler Shaft 1

88 40008 Bearing 3

89 40009 Bearing 3

90 40007 Seal 3/4 x 1 3

91 40006 Retaining Ring Lower 1

94 10681 Grease Fitting 2

95 40002 Washer Altered 2

96 40039 Shaft-Spline 1

14

HMD934 PARTS BREAKDOWN

No. Part # Description Qty

97 40010 Driven Gear 16 Teeth 1

98 40020 Thrust Washer 4

99 40038 SHCS 10-32 x 5/8 2

100 10560 Washer #10 2

101 40037 Upper Retaining Ring 1

104 08555 Electrical Box 1

105 08579 120V Motor 1

08586 230V Motor 1

106 10766 Circuit Breaker 15A - 120V 1

10785 Circuit Breaker 8A - 230V 1

107 10771 Grommet 1

108 40066 SCR-BHC 1/4-28 3

110 08577 Panel Assy - 120V 1

08585 Panel Assy - 230V 1

111 41042 SCR- #6-32 2

112 08222 Power Cord 120V 1

08226 Power Cord 230V 1

08223 Power Cord 230V Type I 1

113 90264 Hub - Feed Shaft Assy 1

114 10569 Feed Handle 3

115 04532 Feed Handle Knob 3

116 08569 Cord 1

117 40127 O-Ring 1

No. Part # Description Qty

118 40076 Dowel Pin 1/4 2

119 40003 Housing Spindle Bearing 1

120 40005 Lower Bearing Cap Assy 1

122 40078 SCR-SHC 1/4-20 x 1-1/2 3

123 40077 SCR-SHC 1/4-20 x 1 1

125 40129 SCR-SHC 1/4-20 x 2-1/4 2

126 40023 Retaining Ring 1

127 08547 Spindle 1

128 40025 Key 3/16 1

129 08554 SCR-SS 3/4-10 Alt 2

130 40636 Chip Guard 1

131 40635 Retaining Ring 1

132 10621 SCR-SS 1/4-20x1/4 BR Tip 1

133 04721 Washer 1/4 Lock Washer 12

134 40040 Adapter 1

135 08206 Tag - Gear Chart 1

136 41044 SCR BHC #10-32 x 3/8 LG 4

137 17537 Label - Safety Instructions 1

138 08148 Label - 120V 1

139 40022 Bearing 1

140 08144 Bottom Bracket Elect. Box 1

141 08560 Top Bracket Elect. Box 1

English

15

COMMERCIAL / INDUSTRIAL LIMITED WARRANTY

Hougen Manufacturing, Incorporated warrants its Portable Magnetic Drills and its Electro-hydraulic Hole Punchers for a

period of 1 year and other products for ninety (90) days from date of purchase against defects due to faulty material or

workmanship and will repair or replace (at its option) without charge any items returned. This warranty is void if the item

has been damaged by accident or unreasonable use, neglect, improper service, or other causes not arising out of defects

in material or workmanship. No other expressed warranty is given or authorized. Hougen Manufacturing, Inc. disclaims

any implied warranty of MERCHANTABILITY or FITNESS for any period beyond the expressed warranty and shall not be

liable for incidental or consequential damages. Some states do not allow exclusions of incidental or consequential

damages or limitation on how long an implied warranty lasts and, if the law of such a state governs your purchase, the

above exclusion and limitation may not apply to you. This warranty gives you specic legal rights and you may also have

other rights which vary from state to state.

To obtain warranty service: return the item(s), transportation prepaid, to your nearest Factory Authorized Warranty

Repair Center or to Hougen Manufacturing, Inc., 3001 Hougen Drive, Swartz Creek, Michigan 48473.

Hougen Drills are warranted against manufacturing defects only. Subject to Hougen Manufacturing inspection.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

© 2017 Hougen Manufacturing, Inc.

Photographs and Specications shown are accurate in detail at time of printing. Manufacturer reserves

the right to make improvements and modications without prior notice. Hougen, Rotabroach,

and Hougen-Edge are proprietary trademarks of Hougen Manufacturing Inc.

HOUGEN AUTHORIZED WARRANTY REPAIR CENTERS

Hougen Authorized Warranty Repair Centers have been factory trained to properly service and repair

Hougen Portable Magnetics Drills. To locate an Authorized Warranty Repair Centers near you, please visit:

www.hougen.com

Hougen Manufacturing, Inc.

P.O. Box 2005 • Flint, MI 48501-2005

3001 Hougen Drive • Swartz Creek, MI 48473

Phone (810) 635-7111 • Fax (810) 635-8277

www.hougen.com • info@hougen.com

© 2017 Hougen Manufacturing, Inc.

16

Loading...

Loading...