Hougen HMD909, HMD909AUS Operator's Manual

®

CUTTERS

HMD909 & HMD909AUS

PORTABLE MAGNETIC DRILLS

2

®

®

stant innovation and development, Hougen is committed to provide you with hole-

years of effective hole drilling performance. Once again, thank you for selecting our

Tornado II Paint shaker for one (1) year and other products for ninety (90) days from date of purchase against defects

due to faulty material or workmanship and will repair or replace (at its option) without charge any items returned. This

warranty is void if the item has been damaged by accident or unreasonable use, neglect, improper service, or other

causes not arising out of defects in material or workmanship. No other expressed warranty is given or authorized.

the expressed warranty and shall not be liable for incidental or consequential damages. Some states do not allow

exclusions of incidental or consequential damages or limitation on how long an implied warranty lasts and, if the law of

such a state governs your purchase, the above exclusion and limitation may not apply to you. This warranty gives you

specifi c legal rights and you may also have other rights which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest Factory Authorized Repair Center

or to Hougen Manufacturing, Inc., 3001 Hougen Drive, Swartz Creek, Michigan 48473.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

© 2006 Hougen Manufacturing, Inc.

The products in this manual may be covered by one or more of the following U.S. patents, foreign patents, and pending

4632610 4952102 5145296

hardware packages.

2. Read and follow all Instructions before attempting

to operate your new Magnetic Drill.

3. Complete and mail the Product Registration Card

NOW. It is important that Hougen Manufacturing, Inc.

have a record of product ownership.

4. Open hardware package and check contents.

10565 1/8” Allen Wrench for Gib Adjustment

10569 Feed handles (3)

04532 Feed handle knobs (3)

10727 3/16” Allen Wrench for reversing feed handle.

10730 Safety Chain

10779 7/32” Allen Wrench for cutter installation

13013 5/32” Allen Wrench

5. Using the handle of the Magnetic Drill, lift unit out of

the shipping case.

6. Remove all packing and securing material from the

drill unit.

7. Screw the three Knobs (04532) onto the three feed

handles (10569) and then screw the handles into the

hub. Do not overtighten.

8. Your Magnetic Drill was factory adjusted prior to shipping.

Check to make sure that all gib adjustment screws, motor

mount screws, front support bracket screws, and

magnet mounting screws are snug and have not vibrated

loose in transit.

9. Your New Magnetic Drill comes complete with arbor

mounted. The 3/4” diameter arbor bore fi ts all 3/4” -

shank “12,000-Series” Hougen Cutters.

WELCOME TO HOUGEN 2

COMMERCIAL WARRANTY 2

UNPACKING YOUR DRILL 3

SAFETY INSTRUCTIONS 4 - 5

SAFETY SWITCH INDICATOR LIGHT 5

OPERATING INSTRUCTIONS 6

INSTALLING HOUGEN CUTTERS 7

FRONT SUPPORT BRACKET SETUP 7

COOLANT BOTTLE ASSEMBLY 8

DRILL MAINTENANCE 9

WIRING DIAGRAM 10

ELECTRICAL PANEL LAYOUT & PARTS 11

MOTOR LAYOUT AND COMPONENTS 12 - 13

EXPLODED VIEW 14

PARTS LISTING 15

WARRANTY SERVICE CENTERS 16

Always wear eye protection while

The slug is ejected

at the end of the cut. Do not aim

slug may hit someone around, or

Cutters are sharp.

Wear gloves when installing or

To prevent electric

shock, do not use power tools

tool may become wet.

Important Safety Instructions

2. Grounding Instructions

This tool should be grounded while in use to protect the

operator from electric shock. The tool is equipped with

a 3-conductor cord and a 3-prong grounding type plug

to fi t the proper grounding type receptacle. The green

(or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and

yellow) wire to a live terminal. (Refer to Plug Diagram)

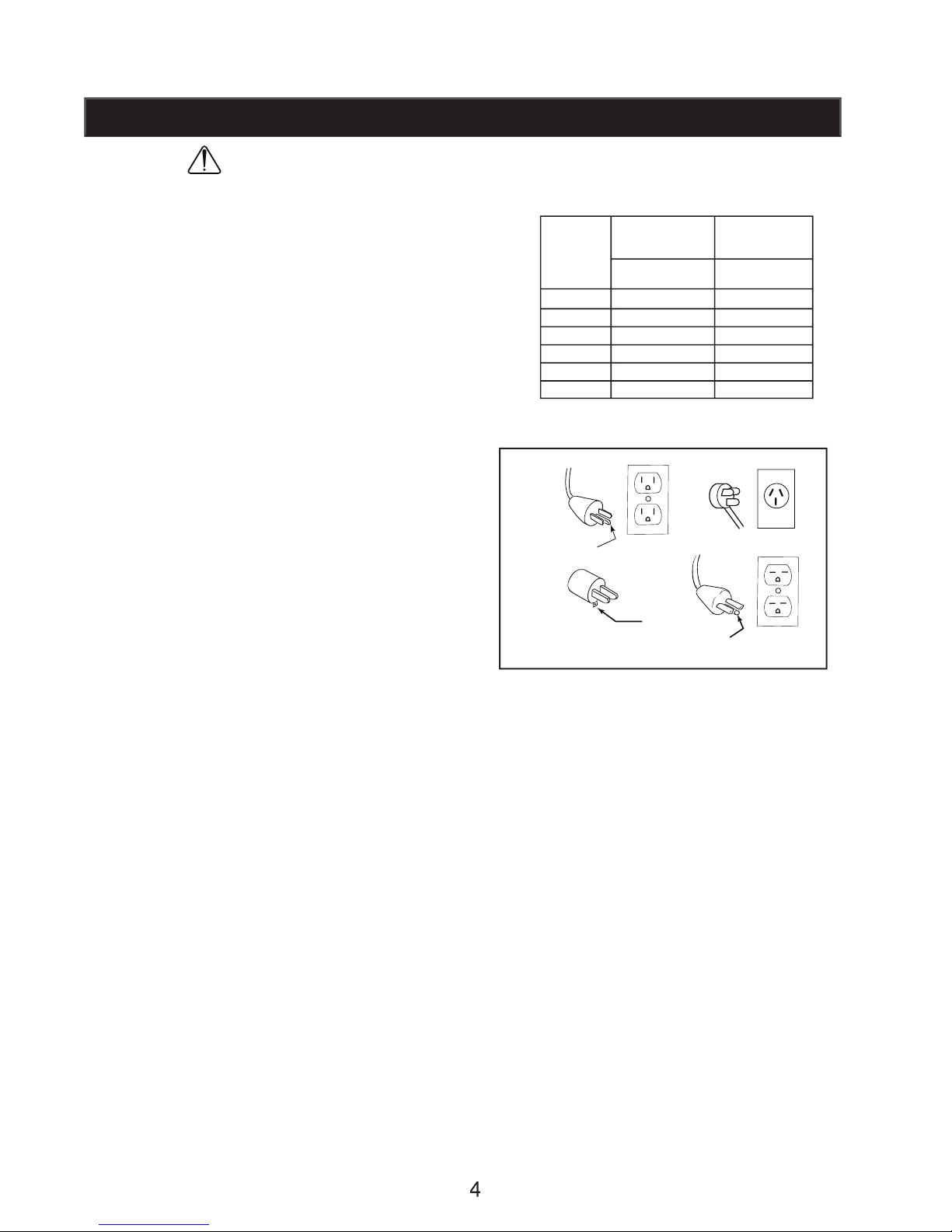

3. Safe Electrical Connection

Your Mag Drill is rated for use on 115VAC (Plug A) or

230V (Plug B) at 50-60Hz. Do not attempt to use drill on

power sources rated other than this. Wet electrical

connections are shock hazards. To prevent the cutting

fl uid from traveling along the cord and contacting the

plug or power outlet, tie a drip loop in the power cord.

Also elevate extension cords or gang box connections.

4. Extension Cords

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-pole receptacles that

accept the tool’s plug. Replace or repair damaged

cords. Make sure the conductor size is large enough

to prevent excessive voltage drop which will cause

loss of power and possible motor damage.

5. Do Not Force Tool

It will do the job better and faster at the rate for which

it was intended.

6. Keep Work Area Clean

Cluttered areas and benches invite injuries.

Keep dirt and chips from under the Cutter area.

7. Consider Work Area Environment

Do not expose tool to rain.

Do not use tool in damp or wet locations.

Keep work area well lit.

Do not use tool in presence of fl ammable liquids or

gases. Disconnect from power source when changing

cutters or maintaining drill.

8. Guard Against Electric Shock

Prevent body contact with grounded surfaces. For

example: pipes, radiators, ranges, refrigerator

enclosures.

9. Keep Children Away

Do not let visitors contact tool. All visitors should be

kept away from work area while in use.

When not in use, tools should be stored in a dry, and

high or locked-up place — out of reach of children.

Do not force small tool or attachment to do the job

of a heavy duty tool.

Do not use tool for purpose not intended — for

example — do not use a circular saw for cutting tree

limbs or logs.

Your Mag Drill is designed to use Hougen Cutters.

The use of drilling tools having different shank styles

is not recommended as they may not tighten securely

in the drill arbor with risk of accident or injury.

Use clamps or a vise to hold work. It is safer than

using your hand and it frees both hands to operate

tool.

Do not wear loose clothing or jewelry. They might

entangle with spinning chips or get caught in

moving parts. Rubber gloves and nonskid foot

wear are recommended when working outdoors.

Wear sturdy leather gloves when working indoors.

Wear protective hair covering to contain long hair.

Never carry drill unit by its cord or yank it to discon-

nect from receptacle.

Keep cord away from heat, oil, and sharp edges.

Keep proper footing and balance at all time.

HTGNEL

,DROCFO

TEEF

DEDNEMMOCER

ERIW

EGUAG

DEDNEMMOCER

ERIW

EGUAG

ROTOMV511

SPMA21-01

ROTOMV032

SPMA6-5

52OTPU 61 81

05-62 41 81

001-15 01 61

002-101 8 41

003-102 6 21

005-103 4 01

Grounding Pin

Grounding Pin

Grounding

Means

(C)

(A)

(B)

(D)

WARNING:

When using electric tools, basic safety precautions should always be followed

to reduce the risk of fi re, electric shock, and personal injury, including the following:

26. Circuit Breaker

Changing of the circuit breaker to a higher amp rated breaker, or

bypassing the circuit breaker is not recommended and will void

product warranty.

27. Circuit Breaker Operation

The circuit breaker is a thermal breaker. When it reaches the

higher temperature rating it will trip and cause the unit to shut

down. This is a protective device and can be reset after 5 to 10.

To reset the breaker, press the breaker button back in. If it does

not reset, let the unit cool a little longer until you can push the

button in ans it stays n position.

28. Safe Electrical Connection

Wet electrical connections are shock

hazards. To prevent the cutting fl uid

from traveling along the cord and

contacting the plug or power outlet,

tie a drip loop as shown. Also elevate

extension cords or gang box

connections.

29. Save these Instructions.

Important Safety Instructions - Continued

Keep tools sharp and clean for better and safer

performance.

dull or broken Hougen Cutters.

Follow instructions for lubricating and changing

accessories.Inspect tool cords periodically and, if

damaged, have repaired by authorized service facility.

Inspect extension cords periodically and, if damaged,

have repaired by authorized service facility. Keep handles

dry, clean, and free from oil and grease.

Disconnect when not in use, before servicing, and

when changing cutters or accessories.

20. Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and

wrenches are removed from tool before turning it

on.

21. Check Damaged Parts

Before further use of the drill, a part that is

damaged should be carefully checked to determine

that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A

part that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this operator

manual. Do not operate tool if switch does not turn

it on and off.

22. Stay Alert

Watch what you are doing and use common sense.

Do not operate tool when you are tired.

Have defective switches replaced by authorized

service center.

23. Outdoor Use Extension Cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

24. Additional Safety Precautions

Arbor and cutter should never be used as a hand-

hold. Keep hands and clothing away from all moving

parts. Do not use Hougen Cutters where ejected slug

might cause injury (slug ejected at end of cut).

Also, adhere to all operating instructions. Do not drill

through any surface that may contain live electrical

wiring. Drilling into a live wire could cause exposed

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock-

wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

25. Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

also result in personal injury to the operator.

The Safety Switch Indicator Light is a Standard Safety

A condition with the safety switch exists that needs to be

corrected.

Possible causes:

• Safety Switch is defective. Have drill serviced.

• Uneven work surface or material. Check work

surface for fl atness.

• Dirt or chips under magnet. Clean work surface.

• Too thin material. Make sure material is at least 3/8”

thick.

CONDITIONS ARE CORRECTED SO LIGHT TURNS

GREEN. THIS ALLOWS FOR THE UNIT TO BE

OPERATED IN A SAFE MANNER.

When light is Red the motor will still function, but “ON” switch

down to operate motor.)

Technical Service at (810) 635-7111.

SAFETY SWITCH

INDICATOR LIGHT

Loading...

Loading...