Page 1

PORTABLE MAGNETIC DRILLS

OPERATOR’S MANUAL

FOR USE WITH “12,000-SERIES” HOUGEN® CUTTERS

HMD908/HMD908AUS

Page 2

Hougen Manufacturing, Incorporated warrants its Portable Magnetic Drills, Electro-hydraulic Hole Punchers,and Torando II

Paint Shaker for one (1) year and its and other products for ninety (90) days from date of purchase against defects due to

faulty material or workmanship and will repair or replace (at its option) without charge any items returned. This warranty is void

if the item has been damaged by accident or unreasonable use, neglect, improper service, or other causes not arising out of

defects in material or workmanship. No other expressed warranty is given or authorized. Hougen Manufacturing, Inc.

disclaims any implied warranty of MERCHANTABILITY or FITNESS for any period beyond the expressed warranty and shall

not be liable for incidental or consequential damages. Some states do not allow exclusions of incidental or consequential

damages or limitation on how long an implied warranty lasts and, if the law of such a state governs your purchase, the above

exclusion and limitation may not apply to you. This warranty gives you specific legal rights and you may also have other rights

which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest Factory Authorized Warranty Repair

Center or to Hougen Manufacturing, Inc., 3001 Hougen Drive, Swartz Creek, Michigan 48473.

Hougen Drills are warranted against manufacturing defects only. Subject to Hougen Manufacturing inspection.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

© 2004 Hougen Manufacturing, Inc.

COM. / IND. LIMITED WARRANTY

INDEX

HOUGEN PATENT NOTICE

The products in this manual may be covered by one or more of the following U.S. patents, foreign patents, and pending patents:

5902076

Photographs and Specifications shown are accurate in detail at time of printing. Manufacturer reserves the right to make improvements and modifications without prior notice.

Hougen, Hougen-Edge, Trak-Star, and Punch-Pro are proprietary trademarks of Hougen Manufacturing, Inc.

Ogura and the Ogura logo are proprietary trademarks of Ogura & Co., Ltd. Vac-Pad is a proprietary trademarks of

Drillmate PTY, Ltd.

Page 2 Commercial/Industrial Limited Warranty

...Hougen Patent Notice

Page 3 Unpacking Your Magnetic Based Drill

...Safety Instructions

Page 4 Safety Instructions (Cont.)

Page 5 Table 1, Table 2

Page 6 ...Operation of Controls

Operating Instructions

Page 7 Installing a Hougen Cutter

...Operation of the Cutting Fluid Reservoir

... Adjustment of Gibs

... Arbor Adjustment

Page 8 Motor Parts Diagram

Page 9 Motor Parts List

Page 10 Control Panel Hook Up Diagram

Page 11 Control Panel Parts List

Page 12 Exploded Diagram

Page 13 Drill Parts List

Page 14 Maintenance

...Hints for Smoother Operation

...Remedies For Holemaking Problems

Page 15 “12,000-Series” Cutters

...HMD908 Accessories

2

Always wear eye protection

while using cutting tools, or in

the vicinity of cutting.

CAUTION! The slug is ejected

at the end of the cut. Do not aim

cutter or arbor so that ejected

slug may hit someone around,

or below you.

CAUTION! Cutters are sharp.

Wear gloves when installing or

removing cutter from arbor. Do

not grab a rotating cutter.

CAUTION! To prevent electric

shock, do not use power tools

near wet areas, or where power

tool may become wet.

SAFETY FIRST

Page 3

UNPACKING YOUR NEW MAGNETIC DRILL

1. Open shipping carton and remove the literature and

hardware packages.

2. Read and Follow All Instructions before attempting

to operate your new Magnetic Drill.

3. Complete and mail the Product Registration Card now.

It is important that Hougen Manufacturing, Inc. have a

record of product ownership.

4. Open hardware package and check contents.

10565 1/8" Hex wrench for Gib Adjustment

04558 Feed handles (3)

04532 Feed handle knobs (3)

10506 Set screw for cutter installation (2)

10730 Safety chain

02635 Hex wrench for cutter installation

13013 5/32" Hex wrench for safety switch adjustment

5. Using the handle of Magnetic Drill, lift unit out of the

shipping case.

6. Remove all packing and securing material from the drill

unit.

7. Screw the three Knobs (04532) into the three

Feed Handles (04558) and then screw Handles

into the Hub Assembly (40254).

8. Your Magnetic Drill was factory adjusted prior to

shipping. Check to make sure that all gib

adjustment screws, motor mount screws, front

support bracket screws, and magnet mounting

screws are snug and have not vibrated loose in

transit.

9. Your new Magnetic Drill comes complete with

arbor mounted. The 3/4" diameter arbor bore

fits all 3/4"-shank "12,000-Series" Hougen

Cutters. A 1/2"-diameter bore Arbor Adapter

(10851), for mounting 1/2"-shank "12,000-Series"

Hougen Cutters, is optional.

Reread Safety Warnings listed in the Operator's

Manual and on the drill unit to avoid injury. Follow

operating procedures.

3

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions should always be followed to reduce the risk of fire,

electric shock, and personal injury, including the following:

1. Read All Instructions

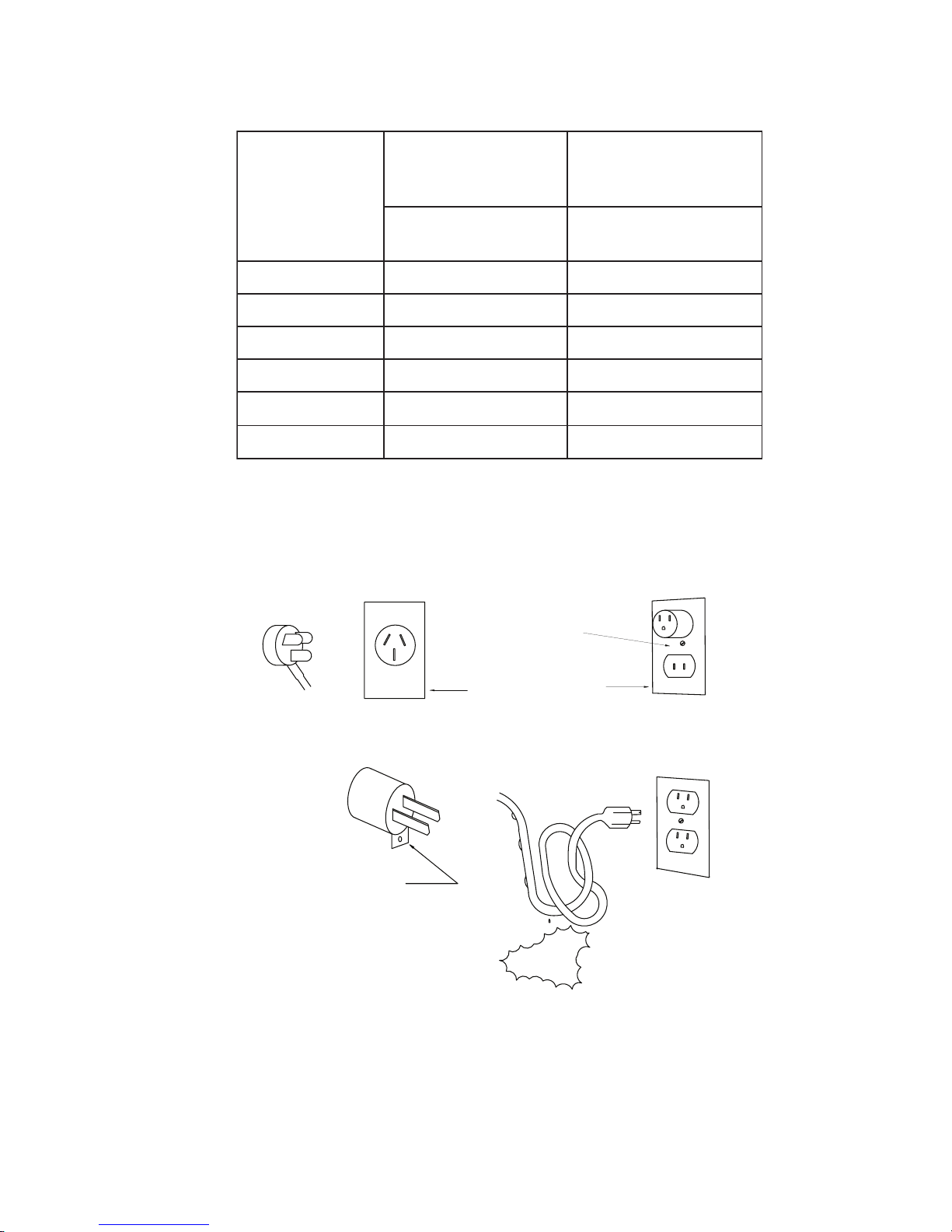

2. Grounding Instructions

This tool should be grounded while in use to protect the operator from electric shock. The tool is equipped

with a 3-conductor cord and a 3-prong grounding type lug to fit the proper grounding type receptacle. The

green (or green and yellow) conductor in the cord is the grounding wire. Never connect the green (or green and

yellow) wire to a live terminal. If your unit is for use on 230V, it has a plug that looks like that shown in

sketch (A). If it is for use on 115V, it has a plug that looks like that shown in sketch (D). An adapter, see

sketches (B) and (C), is available for connecting 115V type plugs to 2-prong receptacles. The green-colored

rigid ear, lug, or the like, extending from the adapter must be connected to a permanent ground, such as a

properly grounded outlet box. (See Table 2)

3. Extension Cords

Use only 3-wire extension cords that have 3-prong grounding type plugs and 3-pole receptacles that accept the

tool's plug. Replace or repair damaged cords. Make sure the conductor size is large enough to prevent

excessive voltage drop which will cause loss of power and possible motor damage. (See Table 1)

4. Consider Work Area Environment

Do not expose tool to rain. Do not use tool in damp or wet locations. Keep work area well lit. Do not use tool in

presence of flammable liquids or gases.

5. Guard Against Electric Shock

Prevent body contact with grounded surfaces. For example: pipes, radiators, ranges, refrigerator enclosures.

9. Secure Work

Use clamps or a vise to hold work. It is safer than using your hand and it frees both hands to operate tool.

6. Keep Children Away

Do not let visitors contact tool. All visitors should be kept away from work area.

7. Store Idle Tools

When not in use, tools should be stored in a dry, land high or locked-up place — out of reach of children.

8. Use Right Tool

Do not force small tool or attachment to do the job of a heavy duty tool. Do not use tool for purpose not intended

— for example — do not use a circular saw for cutting tree limbs or logs.

Page 4

4

10. Always Wear Safety Glasses or Goggles

11. Dress Properly

Do not wear loose clothing or jewelry. They might entangle with spinning chips or get caught in moving parts.

Rubber gloves and nonskid footwear are recommended when working outdoors. Wear sturdy leather gloves

when working indoors. Wear protective hair covering to contain long hair.

12. Do Not Abuse Cord

Never carry drill unit by its cord or yank it to disconnect from receptacle. Keep cord away from heat, oil, and

sharp edges.

13. Do Not Overreach

Keep proper footing and balance at all time.

17. Check Damaged Parts

Before further use of the drill, a part that is damaged should be carefully checked to determine that it will operate

properly and perform its intended function. Check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that may affect its operation. A part that is damaged

should be properly repaired or replaced by an authorized service center unless otherwise indicated elsewhere

in this operator manual. Do not operate tool if switch does not turn it on and off.

18. Stay Alert

Watch what you are doing. Use common sense. Do not operate tool when you are tired. Have defective

switches replaced by authorized service center.

19. Outdoor Use Extension Cords

When tool is used outdoors, use only extension cords intended for use outdoors and so marked. Refer to

Table 1 for recommended extension cord gauge.

20. Additional Safety Precautions

Arbor and cutter should never be used as a hand hold. Keep hands and clothing away from all moving parts.

Do not use Hougen Cutters where ejected slug might cause injury (slug ejected at end of cut). Be sure

that all safety devices are properly adjusted and in use. Also, adhere to all operating instructions. Do

not drill through any surface that may contain live electrical wiring. Drilling into a live wire could cause

exposed metal parts of the drill to be made live. Remove chips wrapped around Hougen Cutter and

arbor after each hole. With motor off and power disconnected, grasp chips with leather gloved hand or

pliers and pull while rotating counterclockwise. Should the cutter become jammed in the work, stop the unit

immediately to prevent personal injury. Disconnect the drill from the power supply and loosen jammed cutter

by turning the arbor counterclockwise. Never attempt to free the jammed cutter by starting the motor. If service

is required contact your nearest authorize service center.

21. Non-Conforming Cutting Tools

Your Magnetic Drill is designed to use Hougen Cutters. The use of drilling tools having different shank

styles is not recommended as they may not tighten securely in the drill arbor with risk of accident or

injury.

22. Operating Near Welding Equipment

When operating your Magnetic Drill near an arc welder, it is important that they are connected to the same

Earth Ground. If they are not, severe damage to the unit, particularly the power cord, could occur. This

could also result in personal injury to the operator.

23. Safe Electrical Connection

Wet electrical connections are shock hazards. To prevent the cutting fluid from traveling along the cord and

contacting the plug or power outlet, tie a drip loop as shown. Also elevate extension cords or gang box

connections.

24. Save These Instructions

IMPORTANT SAFETY INSTRUCTIONS (CONT)

14. Maintain Tools With Care

Keep tools sharp and clean for better and safer performance. Do not use dull or broken Hougen Cutters.

Follow instructions for lubricating and changing accessories. Inspect tool cords periodically and, if damaged,

have repaired by authorized service facility. Inspect extension cords periodically and, if damaged, have repaired

by authorized service facility. Keep handles dry, clean, and free from oil and grease. Keep handles dry, clean,

and free from oil and grease.

15. Disconnect Tools

When not in use, before servicing, and when changing Hougen Cutters or accessories.

16. Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and wrenches are removed from tool before turning it on.

Page 5

TABLE 1

5

(A)

(B)

Adapter

Grounding

Means

Cover of Grounded

Outlet Box

Metal Screw

(C)

(D)

TABLE 2

,droCfohtgneL

teeF

dednemmoceR

eguaGeriW

dednemmoceR

eguaGeriW

rotoMV511

spmA21-01

rotoMV032

spmA6-4

52otpU6181

05-624181

001-150161

002-1018 41

003-1026 21

005-1034 01

Page 6

OPERATING INSTRUCTIONS

Always remember that the magnet's holding power is directly related to the workpiece thickness and surface

condition. (Rating of 748 Kg pull is based on test using a 25mm thick ground surface.) Since magnetic

attraction diminishes with thinner material or rough surfaces, mechanical clamping of drill unit to the workpiece

should be used when cutting thin material (9.5mm or less) or material with uneven surfaces.

1. Make sure workpiece and bottom of magnet are free of chips, oil, etc.

2. Position drill by sliding it and gently feeding Arbor so that pilot point is touching center of hole to be drilled.

3. Secure unit to workpiece with safety chain.

4. Turn magnet ON by pressing the magnet ON button.

5. Turn Feed Handle, raising the cutter until the pilot is above the work surface.

6. Make certain that cutter is clear of workpiece and turn motor ON by pressing the motor START button.

7. Feed Hougen Cutter slowly into workpiece. Only after cutting path is established to a depth of about 1/16"

can full force be applied to feed handles.

8. Ease up on feed pressure as cutter starts breaking through.

9. At conclusion of cut, turn motor OFF by pressing motor STOP button. Turn Feed Handles to raise Arbor

thereby ejecting the slug if it hasn't already fallen free.

10. Turn magnet OFF by pressing the magnet OFF button. As the magnet de-energizes, the rear of the magnet

should lift up off the work surface.

11. Disconnect from power source.

12. If necessary, remove chips from cutter and magnet, preferably wearing leather work gloves and/or with pliers.

Disconnect safety chain and you are ready to move unit to new drilling position.

6

CHECK OUT OPERATION OF CONTROLS

BEFORE INSTALLING HOUGEN CUTTER

IMPORTANT: Before turning on the machine, it

is important that the operator understands the

interrelated functions of the SAFETY SWITCH,

MAGNET SWITCHES, AND MOTOR SWITCHES.

SAFETY SWITCH — Located in base of drill. Enables motor

operation only when magnet is properly seated on a clean and

flat work surface. Turns motor off if drill is lifted off work

surface.

MAGNET ON SWITCH — Energizes the magnetic base and

activates the safety switch. Motor can now be started by

pushing the motor START switch.

MAGNET OFF SWITCH — De-energizes the magnetic base

and deactivates motor START switch. (Note: Magnet OFF

switch will not function while motor is on.)

MOTOR START SWITCH — Starts the motor (will not

function unless the magnetic base is energized and the safety

switch is activated).

MOTOR STOP SWITCH — Deactivates motor. Magnetic

base remains energized and safety switch activated.

CONTROL PANEL SWITCH PLATE

FIGURE 2

1. Place Magnetic Drill on clean, flat steel plate that is at least 3/8" thick.

2. Plug unit into proper AC power source. DO NOT use with DC Power

3. Locate the Magnet ON and OFF switches and the motor STOP and START switches (Fig. 2).

4. NOTE: A loss of power will de-energize the magnetic base and deactivate the motor. When power is

restored, the magnet will reenergize, however, the motor START switch must be depressed before

the motor will start.

Page 7

7

INSTALLING HOUGEN CUTTER IN ARBOR

1. Disconnect from power source.

2. Lay drill on its side with feed handles up or be sure Arbor clears table if unit is in normal operating position.

3. Turn Feed Handles until cutter mounting set screws are exposed and completely remove the set screw.

4. Insert proper pilot in shank end of Hougen Cutter.

5. Insert Hougen Cutter until flat on cutter shank is aligned with set screw holes and is exactly perpendicular to

axis of set screw holes. If 1/2" diameter shank cutter is used, slip (10851) Arbor Adapter over the cutter shank

with adapter hole positioned exactly over flat on cutter shank prior to inserting into Arbor bore.

6. Insert set screws and tighten. When mounting 1/2" diameter shank cutter with adapter, use longer

set screw. (ordered separately) Check to be certain that cutter is secure.

ADJUSTMENT OF GIBS

1. Loosen all Gib Screws (40237).

2. Feed the drill in and out a few times and then, with top of motor slide flush with top of housing, tighten the Gib

Screws until you feel them touch the Steel Gib (02431).

3. Feed the drill in and out again.

4. Adjust Gib Screws so that there is uniform pressure from top to bottom. (Top of motor slide flush with top of

housing.)

5. Turn each Gib Screw in about 1/8 to 1/4 turn, depending upon your preference.

6. Gibs should be tight enough so that slide moves up and down smoothly with no wobble or shaking.

(Looseness will cause cutter breakage.)

NOTE: Gibs should be lubricated regularly.

OPERATION OF CUTTING FLUID RESERVOIR

1. With Magnetic Drill in operating position, turn the feed handles so that cutter and pilot are above the work surface.

2. With magnet turned ON and motor OFF, fill reservoir by introducing cutting fluid through slots in Arbor.

Cutting fluid should not leak out.

3. Test metering capabilities of Arbor/Cutter/Pilot assembly (magnet ON-motor OFF) by feeding the Arbor gently

toward work surface until pilot is pushed up into Cutter, thus allowing fluid to filter down onto work surface

through groove in pilot.

4. For proper lubrication, all cutting fluid in reservoir should empty onto work surface in no less than 15 seconds

and no longer than 30 seconds

ARBOR ADJUSTMENT

Adjust Gibs before adjusting front support bracket.

1. Loosen Arbor Support Bracket Bolts.

2. Be sure top of arbor is flush with the shoulder on motor output shaft. Also make certain arbor is securely

fastened.

3. Turn feed handle until motor and spindle are at the bottom of their travel.

4. Tighten Arbor Support Bolts.

5. Feed slide up and down a few times, checking for free and uniform movement.

NOTE: Check Arbor support bolts regularly to make certain they are tight. Tighten as required.

Page 8

MOTOR PARTS DIAGRAM

8

17617

17601

17618

17613

17608

17626

17609

17611

17616

17614

17605

17627

17625

Wires to Motor

Cord

17610

17603

17602

17607

17624

17623

17629

17606

17602

17632

17632

17621

17631

17604

17612

17600

Page 9

9

MOTOR PARTS LISTING

traP

.oN

noitpircseD

.ytQ

.d'qeR

traP

.oN

noitpircseD

.ytQ

.d'qeR

99440.yssA.calpeR,rotoM41671gnisuoHraeG1

00671esaCdleiF161671eldnipS1

10671revoCgnisuoHraeG171671ediuGnaF1

20671gniraeBllaB281671teksaG1

30671gniraeBllaB112671hsurBnobraC2

40671gniraeBllaB122671paChsurB2

50671gniraeBllaB132671)dleiF(wercSdaeHnaP2

60671laeStsuD142671)trohS(wercSdaeHnaP2

70671yssAraeGretnI.ts1152671)gnoL(wercSdaeHnaP2

80671yssAraeGretnI.dn2162671gniRgniniateR1

90671raeGrupS172671gniRgniniateR1

01671rehsaWtalF192671dleiF1

11671yeK113671erutamrA2

21671niPlewoD123671rehsaWrepaP2

31671rehsaWtalF1

Page 10

CONTROL PANEL HOOK UP DIAGRAM

10

J6

J5

Magnet Wires

(Yellow 22 ga.)

(Black 16 ga.)

J3

Safety Switch

J4

(White 16 ga.)

Safety Switch

J8

Motor Cord

(Black 18 ga.)

J7

Motor Cord

(White18 ga.)

Power Cord

(Black 22 ga.)

Power Cord

(White 22 ga.)

Page 11

CONTROL PANEL PARTS LIST

11

#TRAPNOITPIRCSED.YTQ

86520ETALPECAF1

14040.YSSADROCREWOP1

89440

.YSSADROCREWOP

)ylnOledoMsuA(

1

90420NEERGHCTIWSLAES1

62210DRAUGNOTTUBHSUP1

17640HCTIWSREKCOR1

82210DERHCTIWSLAES1

53310POTS/FFO.YSSAHCTIWS1

43310TRATS/NO.YSSAHCTIWS1

05520.YSSADRAOBTIUCRIC1

84520RECAPS3

7452004-4#WERCS3

7790102-4/1HB,WERCS1

04671

01228

02548

04041

04498 (Aus Only)

02568

10977

02547

02550

01334

01335

02409

01226

Page 12

MODEL HMD908 EXPLODED DIAGRAM

12

*03376 INCLUDES

THESE PARTS

** INCLUDES

THESE PARTS

04499

04907

04530 (2)

02551

04497 (Aus Only)

*01597

*10513

*01439

*10517

*01441

*40312

"12000 SERIES"

CUTTER

PILOT*

40234

04375

10506*

40234

02549

02429

**90052

**40214

10660

10679

02423

02422

04500

90077

10560

40038

02430

10972

10990

04909

10971

10983

04541

02431

40077

90028

40237

90028

02428

02447

75156

50035

40432

41044

10560

40229

40231

02413

01299

02411

90028

02461

02420

10560

41044

10538

11053

40231

04529

10977

40254

04558

04532

40398

04910

17271

Page 13

DRILL PARTS LIST

13

TRAP

.ON

NOITPIRCSED

.YTQ

.D'QER

99210TSURHT,REHSAW1

93410WERCSCHS2/1X82-4/11

14410RALLOCROTCEJE1

79510YDOBROBRA1

11420DROC.RTM-FEILERNIARTS1

31420YLBMESSADROCROTOM1

02420PMALCDROCROTOM2

22420TEKCARBDROCROTOM1

32420.ETORPXELFDROCROTOM1

82420RAEGKCAR1

92420THGIR-BIGSSARB1

03420TFEL-BIGSSARB1

13420BIGLEETS1

7442082-4/1DAEHXEH-TLOB2

16420WERCSCHB8/3X02-4/12

94520TIKTLOB"8/31

15520)809DMH(LENAPLORTNOC

67330YSSAROBRA1

7583004-4#DAEHXEH-WERCS61

57340.YSSA.TKRB.PPUSTNORF1

79440)YLNOSUA(LENAPLORTNOC1

99440.CALPERROTOMV0321

00540TNUOMROTOM,EDILS1

92540GATGNINRAW1

03540GATYTEFAS2

23540BONKELDNAHDEEF3

14540YLBMESSAGNISUOH1

85540ELDNAHDEEF3

70940TENGAM1

90940HCTIWSYTEFASTEKCARB1

01940YLBMESSAREGNULP1

60501WERCSSS503.X42-8/32

TRAP

.ON

NOITPIRCSED

.YTQ

.D'QER

31501GNIRPSROBRA1

71501GNIRGNINIATER2

83501REHSAWKCOL1

06501.TXE01#REHSAWKCOL11

06601WERCSCHS8/5X02-4/11

179012/1X02-4/1CHS,WERCS2

279018/7X23-6#CHB,WERCS2

779014/1X02-4/1CHB,WERCS1

97601REHSAWTALF"4/11

38901DLEIHSS/S1

09901YLBMESSAS/S1

3501123-8#CHB,WERCS1

17271GNIRPS1

830048/5X23-01#CHS,WERCS2

77004"1X02-4/1CHS,WERCS1

412042/1X23-6#CHS.WERCS1

92204RAEGDEEF1

13204GNIHSUBEZNORB2

43204REHSAWTSURHT2

73204WERCSBIG5

45204YLBMESSABUH1

21304DERETLANIPLLOR1

89304GNIRGNINIATER1

234048/3X82-4/1CHS,WERCS1

440148/3X23-01#CHB,WERCS6

53005TXE4/1REHSAWKCOL4

65157MM51X6MCHS,WERCS4

82009.ILEH4/1REHSAWKCOL5

25009.TXE6#REHSAWKCOL1

770092/1X23-01#CHBWERCS1

Page 14

14

MAINTENANCE

In order to minimize wear on moving parts and to insure smoother operation and longer life for your magnetic drill,

the following maintenance should be done periodically, based on use

1. Regularly tighten all fasteners and replace all worn parts.

2. Check motor brushes and replace if worn. (Break in period - 30 minutes at no load speed)

3. Check power cord and cord from panel to motor and, if cracked or frayed, return to an authorized repair center for

replacement.

4. Apply grease to the slide dovetails, brass gibs, and the feed gear rack. For best results use Shell Cyprina-RA or

equivalent.

5. Remove arbor and pack the bearing in the front support bracket with grease. Use Shell Cyprina-RA or equivalent.

HINTS FOR SMOOTHER OPERATION

1. Keep insides of Hougen Cutter clear of chips. Chips will interfere with cutting to maximum depth, may impede

the free oil flow and can cause cutter breakage.

2. Keep work, machine, arbor and Hougen Cutter free of chips and dirt.

3. Tighten all bolts and fasteners regularly.

4. We highly recommend using a light viscosity cutting fluid (preferably

Hougen Cutting Fluid)

5. Occasionally check metering of cutting fluid flow. Lack of cutting fluid

may cause Hougen Cutter to freeze in cut, slug to stick and may

result in poor cutter life.

6. Always start cut with light feed pressure and then increase suffi ciently to achieve maximum cutting rate.

7. Ease off on pressure as cutter begins to break through at the end of

the cut.

8. Keep slide dovetails, brass gibs and feed rack lubricated and free of

chips and dirt.

9. When slug hangs up in cutter, bring cutter down on a flat surface. This will normally straighten a cocked slug,

allowing it to be ejected.

10. When cutting large diameter or deep holes it may be necessary to stop in the middle of the cut to add cutting

fluid and remove the chips from around the arbor. (When doing this DO NOT raise the cutter out of the hole.

Doing so can allow chips to get under the teeth of the cutter and make it difficult to restart the cut.)

REMEDIES FOR HOLEMAKING PROBLEMS

1. Trouble: Magnetic base won’t hold effectively to work.

a. Cause: Chips or dirt under magnet.

Remedy: Clear area of chips and dirt.

b. Cause: Irregular surface on bottom of magnet

or on workpiece.

Remedy: Lightly surface grind the bottom of the

magnet flat and/or file imperfections

flat on the work surface as needed.

2. Trouble: Cutter tends to move across surface

of work.

a. Cause: Magnetic base not holding effectively.

Remedy: See causes and remedies under No. 1

above.

b. Cause: Too much feed pressure at start of cut.

Remedy: Light pressure until a groove is cut.

The groove then serves as a stabilizer.

c. Cause: Worn pilot.

Remedy: Replace pilot

3. Trouble: Out of round holes.

a. Cause: Worn arbor support bracket bearing

and or ejector collar.

Remedy: Replace: (only a few thousandths

wear permissible.)

b. Cause: Misaligned support bracket

Remedy: Realign support bracket

4. Trouble: Motor and slide won’t stay in set position

a. Cause: Gibs too loose

Remedy: Adjust gibs

5. Trouble: Erratic or intermittent feed.

a. Cause: Worn or pinion and/or rack.

Remedy: Replace worn parts.

6. Trouble: Motor doesn’t run when motor START

button is pushed.

a. Cause: Magnet is not turned on.

Remedy: Push magnet ON button.

b. Cause: Magnet on rough or dirty work surface

and safety switch not fully depressed.

Remedy: File work surface flat and clean all

chips and oil from under magnet.

c. Cause: No power.

Remedy: Check power source and extension

cords.

d. Cause: Worn motor brushes.

Remedy: Replace brushes.

e. Cause: Faulty motor START switch.

Remedy: Return unit to an authorized repair

center to have switch replaced.

NOTE: If you are unable to correct any malfunction

after trying the above, do not attempt to operate the

drill. Return the unit to the factory or authorized

Repair Center for service.

#1 cause of cutter

breakage and

prematurely dull

teeth is too little

feed pressure

Page 15

“12,000-SERIES”

15

HMD908

ACCESSORIES

retemaiD

)mm&nI(

lamiceD

tnelaviuqE

MM4.52-"1

COD

.ONTRAP

MM8.05-"2

COD

.ONTRAP

>>>STOLIP1350123501

61/75734.4112141221

MM214274.2132121421

>>STOLIP3350143501

2/10005.6112161221

61/95265.8112181221

8/50526.0212102221

61/115786.2212122221

MM318115.3132131421

MM412155.4132141421

MM516095.5132151421

MM619926.6132161421

MM713966.7132171421

MM817807.8132181421

>>STOLIP7250182501

MM910847.9132191421

4/30057.4212142221

MM024787.0232102421

61/315218.6212162221

MM128628.1232112421

MM221668.2232122421

8/70578.8212182221

MM325509.3232132421

61/515739.0312103221

MM429449.4232142421

MM523489.5232152421

10000.12312123221

MM627320.16232162421

61/1-15260.14312143221

MM720360.17232172421

MM820201.18232182421

8/1-10521.16312163221

MM927141.19232192421

MM032181.10332103421

61/3-15781.18312183221

MM135022.10412104221

4/1-10052.10412104221

MM238952.12332123421

MM333992.13332133421

61/5-15213.12412124221

MM436833.14332143421

8/3-10573.14412144221

MM539773.15332153421

MM633714.17332173421

61/7-15734.16412164221

MM737654.17332173421

MM831694.1---83421

2/1-10005.18412184221

.oNtraP noitpircseD

92810kcuhCsbocaJrofretpadA-eldnipS

94420evirDtehctaR

36420"2/1hguorht6#tiKgnippaT

46520tiKretpadAepiPtnuoMniahC

80620retpadAllirDtsiwT

54830

tiKretpadAllirDtsiwT

sknahsdettalfhtiwsllirDtsiwT5sedulcnI

00050daPcaVelbatroP

00101rednetxErobrA"1

00201rednetxErobrA"2

23701)92810seriuqeR(kcuhCsbocaJ"2/1

85921tiKkniSretnuoC

10021

tuCfohtpeD"1tiKrettuC

61/1-1,61/51,61/31,61/11,61/9seziS

20021

tuCfohtpeD"2tiKrettuC

61/1-1,61/51,61/31,61/11,61/9seziS

30021

tuCfOhtpeDmm52tiKrettuC

mm22,mm02,mm81,mm61,mm41seziS

40021

tuCfohtpeDmm05tiKrettuC

mm22,mm02,mm81,mm61,mm41seziS

Page 16

Hougen Manufacturing, Inc.

P.O. Box 2005 • Flint, MI 48501-2005

3001 Hougen Drive • Swartz Creek, MI 48473

Phone (810) 635-7111 • FAX (810) 635-8277

E-mail: www.hougen.com

Online: info@hougen.com

R

FACTORY AUTHORIZED WARRANTY REPAIR CENTERS

West

A.C.C. Machinery Co., Inc

747 Grand Avenue

Phoenix, AZ 85007

(602) 258-7330

ATS Repair Center

2400 West Directors Row

Salt Lake City, UT 84125

(801) 972-3182

Caltool Industrial Supply

470 Hester Street

San Leandro, CA 94577

(510) 729-0600

Kenbil Service Co.

2900 Adams St., B-14

Riverside, CA 92504

(909) 689-6633

Canada

Celtic Ind. Tool & Repair

5736-103 A Street

Edmonton, Alberta

Canada T6H 3J5

(780)) 431-0970

Edward H. Pope, Ltd.

10 Imperial Court

Brampton, Ontario

Canada L6T 4X4

(905) 458-4800

Outiltech Orleans, Inc.

4975 Rue Rideau Local 180

Quebec City, Quebec

Canada G2E 5H5

(418) 877-7776

Power Tool Clinic

#105 19835-56 Ave

Langley, B.C.

Canada V3A 3Y1

(604) 530-3550

Australia

Industrial Equipment Supplies

Factory 15-49/55 Garden Drive

Tullamarine, 3043

(03) 9330-2611

Southeast

Gardner Southeast Repair

807 Meroney Street

Chattanooga, TN 37405

(423) 756-4722

Mid-South Welding Supply

505 51st. Avenue

Meridian, MS 39307

(601) 483-9331

Strickland’s Tool & Repair

1906 Parliament Road

Cayce, SC 29033

(800) 867-1830

Northwest

American Equip. Services

22418 72nd. Ave South

Kent, WA 98032

(253) 395-9947

Idaho Tool & Equip.

452 Caldwell Blvd.

Nampa, ID 83651

(208) 465-7533

Pro Tool Repair

2238 James

Bellingham, WA 95225

(360) 733-7343

Quimby Welding Repair

1603 Northwest 14th. Ave

Portland, OR 97209

(503) 221-1100

Universal Repair

1611 Boylston

Seattle, WA 98122

(206) 322-2726

South

Allied Sales & Service Co.

1508 River Oaks Rd., West

Jefferson, LA 70123

(504) 734-9566

Wilbanks Repair Center

5532 S. 94th East Ave.

Tulsa, OK 74145

(918) 627-8445

Midwest

Ceekay Repair Center

5835 Manchester Ave.

St. Louis, MO 63110

(314) 644-3500

Cincinnati Electrical Repair

2023 Elm Street

Cincinnati, OH 45210

(513) 621-2183

DCT / Miller Industrial

Supply Co.

410 N. Jasper St.

Decatur, IL 62521

(217) 428-7787

Hougen Manufacturing, Inc.

3001 Hougen Drive

Swartz Creek, MI 48473

(810) 635-7111

Pennsylvania Tool Sales

and Service, Inc.

625 Bev Road

Youngstown, OH 44512

(330) 758-0845

Westbrook Engineering

23501 Mound Road

Warren, MI 48091

(586) 759-3100

Southwest

Arcmaster Repair Center

301 Woodrow Ave

Fort Worth, TX 76105

(817) 531-8101

Rex Supply Repair Center

3715 Harrisburg

Houston, TX 77003

(713) 222-2251

United States - East

A&A Industrial Supplies Inc.

251 Meacham Ave.

Elmont, NY 11003

(516) 437-0114

Arcet Equipment Co.

3416 Odd Fellows Road

Lynchburg, VA 24501

(804) 847-1234

Awisco NY Corp.

55-16 43rd Ave.

Maspeth, NY 11378

(718) 786-7788

Awisco NY Corp.

20C Gleam Street

West Babylon, NY 11704

(631) 643-1308

Boyer Machinery Co.

2280 Wyandotte Road

Willow Grove, PA 19090

(215) 657-2242

Colony Hardware Supply Co.

15 Stiles Street

New Haven, CT 06512

(203) 466-5252

Hanes Supply Repair Center

10 Cairn Street

Rochester, NY 14611

(716) 826-2636

N.H. Bragg & Sons

90 Perry Road

Bangor, ME 04401

(207) 947-8611

Jossam Tool Repair

Divison of Nefco

411 Burnham Street

East Hartford, CT 06108

(860) 290-9044

Weld Tooling Corp.

3001 W. Carson Street

Pittsburgh, PA 15204

(412) 331-1776

OM9080204

© 2004 Hougen Manufacturing, Inc.

Loading...

Loading...