Hougen 75004A Operating Instructions Manual

PUNCH PRO

™

ELECTRO-HYDRAULIC HOLE PUNCHER

OPERATOR’S MANUAL

Model 75004A

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions should always be followed to reduce the

risk of fire, electric shock, and personal injury, including the following.

1. READ ALL INSTRUCTIONS

2. Grounding Instructions

2a. This tool should be grounded while in use to

protect the operator from electric shock. The

tool is equipped with a 3-conductor cord and

3-prong grounding type plug to fit the proper

grounding type receptacle. The green (or

green and yellow) conductor in the cord is the

grounding wire. Never connect the green or

green and yellow wire to a live terminal. If

your unit is for use on 115V, it has a plug that

looks like that shown in sketch (A). An adapter,

see sketches (B) and (C), is available for

connecting sketch (A) type plugs to 2-prong

receptacles. The green-colored rigid ear, lug, or

the like extending from the adapter must be

connected to a permanent ground, such as a

properly grounded outlet box.

NOTE: Use of a grounding adapter is pro-

hibited in Canada by Part 1 of the Canadian

Electrical Code.

5. Consider Work Area Environment

Do not expose tool to rain

Do not use tool in damp or wet

locations. Keep work area well lit.

Do not use tool in presence of flammable

liquids or gases.

6. Guard Against Electric Shock

Prevent body contact with grounded

sufaces. For example: pipes, radiators,

ranges, refrigerator enclosures.

7. Keep Children Away

Do not let visitors contact tool or extension

cord. All visitors should be kept away from

work area.

8. Store Idle Tools

When not in use, tools should be stored in a

dry high or locked-up place-out of reach of

children.

9. Do Not Force Tool

It will do the job better and safer at the rate for

which it was intended.

2b. Extension Cords

Use only 3-wire extension cords that have

3-prong grounding type plugs and 3-pole

receptacles that accept the tool’s plug.

Replace or repair damaged cords.

Make sure the conductor size is large enough

to prevent excessive voltage drop causing

loss of power and possible motor damage

3. FOR ALL DOUBLE-INSULATED TOOLS

When servicing use only identical replacement parts.

4. Keep Work Area Clean

Cluttered areas and benches invite injuries.

10. Use Right Tool

Do not force small tool or attachment to do the

job of a heavy-duty tool. Do not use tool for

purpose not intended.

11. Dress Properly

Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and

non skid footwear are recommended when

working outdoors. Wear protective hair covering

to contain long hair.

12. Always wear safety glasses or goggles.

13. Do Not Abuse Cord.

Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from

heat, oil and sharp edges.

TEEFNIDROCFOHTGNELTEEFNIDROCFOHTGNEL

TEEFNIDROCFOHTGNELTEEFNIDROCFOHTGNEL

TEEFNIDROCFOHTGNEL

V511

6-5 8161412101018

8-6 816121010186

01-8 81412101 886

21-01 614101 8866

41-21 612101 8666

61-41 612101 8664

.TF52.TF05.TF001.TF051.TF002.TF052.TF003

)spmA(

2

SAFETY FIRST

Always wear eye protection while

using punching tools, or in the

vicinity of punching.

CAUTION! The slug is ejected at

the end of the punch. Do not aim

the unit so that ejected slug may

hit someone around, or below

CAUTION! Risk of pinching or

crushing. Keep away from

moving parts when unit is in use.

CAUTION! To prevent electric

shock, do not use power tools

near wet areas, or where power

tool may become wet.

you.

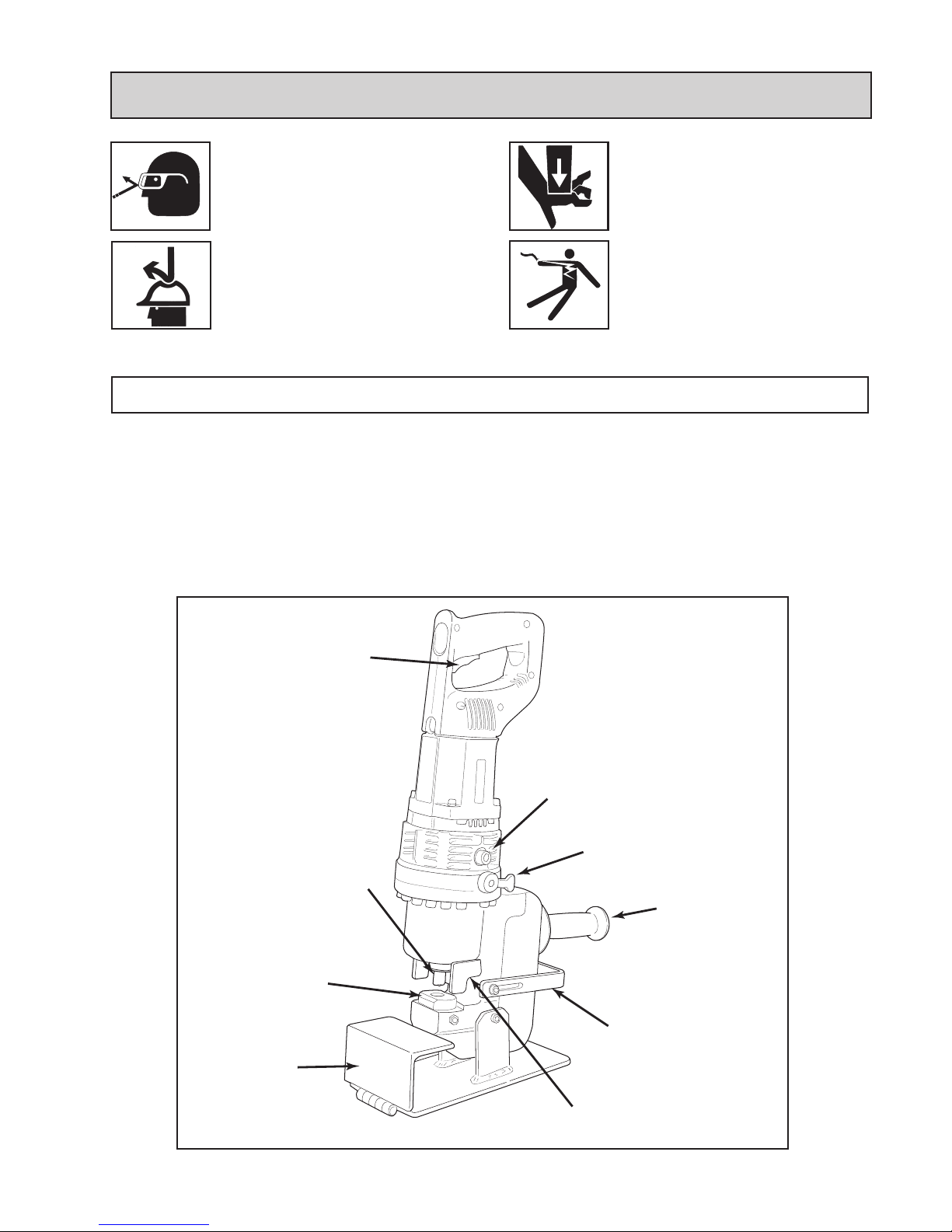

PRINCIPLES OF OPERATION

The Hougen-Ogura Electro-hydraulic Hole Puncher is an

integrated unit, containing the electric motor, hydraulic

pump, and “C”-frame punching unit. It uses hydraulic

power to force the punch through the workpiece, and a

strong spring to return the punch piston to its “home”

position. The patented design includes an automatic valve

that releases the hydraulic pressure when the punch

piston is at the bottom of its stroke. The automatic valve

remains open until the punch piston has fully returned to

the home position.

As a result of this design, the piston will not return to its

home position automatically unless the full stroke has

been completed. Also, the punch will not begin another

stroke unless the punch has fully returned to the home

position, resetting the automatic valve. To allow the punch

piston to be manually returned in the event that the punch

cycle is stopped prior to completion, a manual return

valve is provided.

Work Stand

Trigger

Oil Port

Manual Return

Valve

Punch

Handle

Die

Hole Locator

Gage

Stripper

3

OPERATING PROCEDURES

Read, understand and follow all safety instructions and

operating procedures. If you do not understand the

instructions or if conditions are not correct for proper

operation, do not operate the machine. Consult your

supervisor or other responsible person.

*Check that the trigger switch is not locked on.

*Check that the manual return valve is closed.

*Make sure that the proper punch and die are installed

correctly. See Die Selection and Proper Punches and

Dies in this Manual

*If you are using the hole locator gage, adjust it to the

proper distance. See Hole Locator Gage Adjustment in

this manual.

*Plug the power cord into the proper power supply.

INSTRUCTIONS -- FOOT SWITCH

Although the foot switch is guarded against inadvertent

operation, it is best to position the foot pedal away from

normal standing position. Place it in a position that

requires deliberate effort to reach and activate the switch.

*Position the puncher at the proper location on the

workpiece using the hole locator gage or by locating the

point on the end of the punch into a center punch mark on

the piece.

With everything in proper order, the switch can be activated

to start the electric motor. The punch piston will move out

and push the punch through the material. Keep the switch

on until the punch has reached the end of its stroke and

stops. Release the switch. The automatic return valve will

open at the end of the stroke allowing the punch piston to

retract to its home position. The punch piston must return

completely before another hole can be punched.

If the punch stops in the midst of its stroke or does not

come out of the material, open the manual return valve.

Once the punch piston has returned to its home position,

tighten the manual return valve.

The trigger switch should be locked on only when ready

to punch. Release the trigger switch immediately after

punching to prevent operation by inadvertent actuation of

the foot switch.

HOLE LOCATOR GAGE ADJUSTMENT

The Hole locator Gage can be set to hold the Hole

Punches at a constant distance from the edge of the

workpiece. The gage is held in place by one or two socket

head caps screws. Before making any adjustment,

USING THE WORK STAND

All models can be used with an accessory work stand for

bench or table mounting of the Hole Puncher. The stand

is standard with all models. To install the stand, first

unplug the power cord., then mount the unit to the stand

with the supplied hardware.

SELECTING PROPER DIES

Proper die selection is essential. Other than the obvious

necessity of matching shaped punches and dies, there are

two other basic selection factors that must be considered.

The first is die clearance. Different material types and

different material thicknesses require different clearances

between the punch and die. In order to maintain the best

possible hole while remaining within the tonnage

capacity of the machine, it is essential to choose the die

with the proper clearance. The second is the die angle.

Most structural shapes can be punched with the standard

first, unplug the power cord. To adjust the position of the

gage, loosen the cap screw(s), tap the gage into the

desired position and retighten the cap screw(s).

When using the stand, periodically check to make sure that

the punched material (slugs) are not stacking up between

the exit hole in the “C”-frame and the stand. Keep this area

clear of accumulated slugs.

flat dies, but “I” -beams and most channels which

have a 2-in-12 taper require the use of special

9-1/2 degree angled dies. Car and ship channel

flanges and other structural shapes with a 2 degree

taper can be punched with flat dies. Materials with

a flange taper of less than 5 degrees can also be

punched with the flat die, however, the hole will be

slightly angled. Refer to specific information and

tables within this manual for the proper punch and

die combination.

4

Loading...

Loading...