Page 1

MODELS 10914(S), 10909(S), &

10909(S)AUS

PORTABLE MAGNETIC DRILLS

OPERATOR’S MANUAL

FOR USE WITH “12,000-SERIES” HOUGEN® CUTTERS

Page 2

HOUGEN

®

Portable Magnetic Drills

Models 10909, 10909S, 10914, 10914S

10909AUS

Welcome to Hougen

®

Congratulations on your purchase of the Hougen

model is designed to produce superior holes quickly and efficiently. Through

constant innovation and development, Hougen is committed to provide you with

hole-producing tools and products to help you be more productive.

Before attempting to operate your new Portable Magnetic Drill, please read all

instructions first. These include the Operator’s Manual and Warning Label on the

unit itself. With proper use, care, and maintenance, your model will provide you with

years of effective hole drilling performance. Once again, thank you for selecting our

product and welcome to Hougen.

Portable Magnetic Drill. Your

Commercial / Industrial Limited Warranty

Hougen Manufacturing, Incorporated warrants its Portable Magnetic Drills for one (1) year and its Electro-hydraulic

Hole Punchers and other products for 90 days from date of purchase against defects due to faulty material or

workmanship and will repair or replace (at its option) without charge any items returned. This warranty is void if the

item has been damaged by accident or unreasonable use, neglect, improper service, or other causes not arising out

of defects in material or workmanship. No other expressed warranty is given or authorized. Hougen Manufacturing,

Inc. disclaims any implied warranty of MERCHANTABILITY or FITNESS for any period beyond the expressed

warranty and shall not be liable for incidental or consequential damages. Some states do not allow exclusions of

incidental or consequential damages or limitation on how long an implied warranty lasts and, if the law of such a state

governs your purchase, the above exclusion and limitation may not apply to you. This warranty gives you specific

legal rights and you may also have other rights which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest Factory Authorized Repair

Center or to Hougen Manufacturing, Inc., 3001 Hougen Drive, Swartz Creek, Michigan 48473.

Hougen Drills (Hougen Cutters) are warranted against manufacturing defects only. Subject to Hougen

Manufacturing’s inspection.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

© 2003 Hougen Manufacturing, Inc.

Hougen Patent Notice

The products in this manual may be covered by one or more of the following U.S. patents, foreign patents, and pending

patents:

4632610 4952102 5145296

Photographs and Specifications shown are accurate in detail at time of printing. Manufacture reserves the

right to make improvements and modifications without prior notice.

Hougen, Hougen-Edge, and Punch Pro are proprietary trademarks of Hougen Manufacturing Inc. Ogura and

the Ogura logo are proprietary trademarks of Ogura & co., Ltd. Vac-Pad are propriety trademark of

Drillmate PTY, Ltd.

2

Page 3

INDEX

WELCOME TO HOUGEN 2

COMMERCIAL WARRANTY 2

UNPACKING YOUR DRILL 3

SAFETY INSTRUCTIONS 4 - 5

OPERATING INSTRUCTIONS 6

INSTALLING HOUGEN CUTTERS 7

FRONT SUPPORT BRACKET SETUP 7

COOLANT BOTTLE ASSEMBLY 8

WIRING DIAGRAM 9

ELECTRICAL PANEL LAYOUTS 10

PANEL COMPONENT LISTING 11

DRILL MAINTENANCE 11

MOTOR LAYOUT AND COMPONENTS 12 - 13

EXPLODED VIEW 14

PARTS LISTING 15

WARRANTY SERVICE CENTERS 16

Unpacking Your New Portable Magnetic Drill

1. Open shipping carton and remove the literature and

hardware packages.

2. Read and follow all Instructions before attempting

to operate your new Magnetic Drill.

3. Complete and mail the Product Registration Card

NOW. It is important that Hougen Manufacturing, Inc.

have a record of product ownership.

4. Open hardware package and check contents.

10565 1/8” Allen Wrench for Gib Adjustment

10569 Feed handles (3)

10570 Feed handle knobs (3)

10727 3/16” Allen Wrench for reversing feed handle.

10730 Safety Chain

10779 7/32” Allen Wrench for cutter installation

13013 5/32” Allen Wrench for arbor installation and

microswitch adjustment

5. Using the handle of the Magnetic Drill, lift unit out of

the shipping case.

SAFETY FIRST

Always wear eye protection while

using cutting tools, or in the

vicinity of cutting.

6. Remove all packing and securing material from the

drill unit.

7. Screw the three Knobs (10570) onto the three feed

handles (10569) and then screw the handles into the

hub. Do not overtighten.

8. Your Magnetic Drill was factory adjusted prior to shipping.

Check to make sure that all gib adjustment screws, motor

mount screws, front support bracket screws, and

magnet mounting screws are snug and have not vibrated

loose in transit.

9. Your New Magnetic Drill comes complete with arbor

mounted. The 3/4” diameter arbor bore fits all 3/4” shank “12,000-Series” Hougen Cutters. A 1/2”

diameter bore Arbor Adapter (10851), for mounting 1/2”

shank “12,000-Series” Hougen Cutters, is optional.

CAUTION! Cutters are sharp.

Wear gloves when installing or

removing cutter from arbor. Do

not grab a rotating cutter.

CAUTION! The slug is ejected at

the end of the cut. Do not aim

cutter or arbor so that ejected

slug may hit someone around, or

below you.

CAUTION! To prevent electric

shock, do not use power tools

near wet areas, or where power

tool may become wet.

3

Page 4

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions should always be followed

to reduce the risk of fire, electric shock, and personal injury, including the following:

1. Read All Instructions

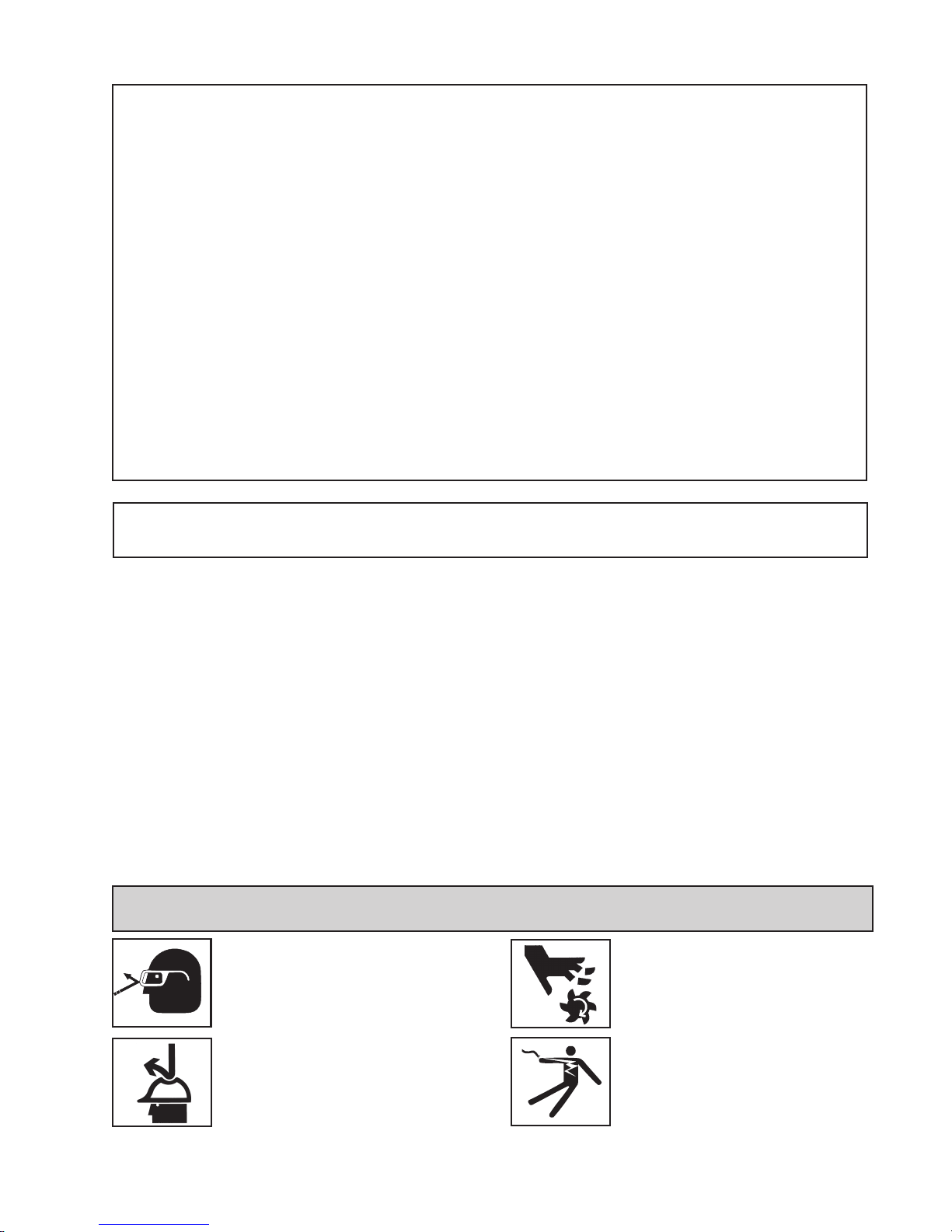

2. Grounding Instructions

This tool should be grounded while in use to protect the

operator from electric shock. The tool is equipped with

a 3-conductor cord and a 3-prong grounding type plug

to fit the proper grounding type receptacle. The green

(or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and

yellow) wire to a live terminal. (Refer to Plug Diagram)

Section A

3. Safe Electrical Connection

Your Mag Drill is rated for use on 115VAC (Plug A) or

230V (Plug B) at 50-60Hz. Do not attempt to use drill on

power sources rated other than this. Wet electrical

connections are shock hazards. To prevent the cutting

fluid from traveling along the cord and contacting the

plug or power outlet, tie a drip loop in the power cord.

Also elevate extension cords or gang box connections.

4. Extension Cords

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-pole receptacles that

accept the tool's plug. Replace or repair damaged

cords. Make sure the conductor size is large enough

to prevent excessive voltage drop which will cause

loss of power and possible motor damage.

5. Do Not Force Tool

It will do the job better and faster at the rate for which

it was intended.

HTGNEL

TEEF

52OTPU6181

05-624181

001-150161

002-101841

003-102621

005-103401

Grounding Pin

Extension Cord Table

DEDNEMMOCER

ERIW

,DROCFO

EGUAG

ROTOMV511

SPMA21-01

Plugs and Receptacles

(A)

Grounding

(C)

Means

Grounding Pin

DEDNEMMOCER

ERIW

EGUAG

ROTOMV032

SPMA6-5

(B)

(D)

6. Keep Work Area Clean

Cluttered areas and benches invite injuries.

Keep dirt and chips from under the Cutter area.

7. Consider Work Area Environment

Do not expose tool to rain.

Do not use tool in damp or wet locations.

Keep work area well lit.

Do not use tool in presence of flammable liquids or

gases. Disconnect from power source when changing

cutters or maintaining drill.

8. Guard Against Electric Shock

Prevent body contact with grounded surfaces. For

example: pipes, radiators, ranges, refrigerator

enclosures.

9. Keep Children Away

Do not let visitors contact tool. All visitors should be

kept away from work area while in use.

10. Store Idle Tools

When not in use, tools should be stored in a dry, and

high or locked-up place — out of reach of children.

11. Use Right Tool

Do not force small tool or attachment to do the job

of a heavy duty tool.

Do not use tool for purpose not intended — for

example — do not use a circular saw for cutting tree

limbs or logs.

12. Non-Conforming Cutting Tools

Your Mag Drill is designed to use Hougen Cutters.

The use of drilling tools having different shank styles

is not recommended as they may not tighten securely

in the drill arbor with risk of accident or injury.

13. Secure Work

Use clamps or a vise to hold work. It is safer than

using your hand and it frees both hands to operate

tool.

14. Always Wear Safety Glasses or Goggles

4

Page 5

Important Safety Instructions - Continued

15. Dress Properly

Do not wear loose clothing or jewelry. They might

entangle with spinning chips or get caught in

moving parts. Rubber gloves and nonskid foot

wear are recommended when working outdoors.

Wear sturdy leather gloves when working indoors.

Wear protective hair covering to contain long hair.

16. Do Not Abuse Cord

Never carry drill unit by its cord or yank it to discon-

nect from receptacle.

Keep cord away from heat, oil, and sharp edges.

17. Do Not Overreach

Keep proper footing and balance at all time.

18. Maintain Tools With Care

Keep tools sharp and clean for better and safer

performance.

Do not use dull or broken Hougen Cutters.

Follow instructions for lubricating and changing

accessories.

Inspect tool cords periodically and, if damaged,

have repaired by authorized service facility.

Inspect extension cords periodically and, if

damaged, have repaired by authorized service

facility.

Keep handles dry, clean, and free from oil and

grease.

19. Disconnect Tools

Disconnect when not in use, before servicing, and

when changing cutters or accessories.

20. Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and

wrenches are removed from tool before turning it

on.

21. Check Damaged Parts

Before further use of the drill, a part that is

damaged should be carefully checked to determine

that it will operate properly and perform its intended

function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A

part that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this operator

manual. Do not operate tool if switch does not turn

it on and off.

22. Stay Alert

Watch what you are doing.

Use common sense.

Do not operate tool when you are tired.

Have defective switches replaced by authorized

service center.

23. Outdoor Use Extension Cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

24. Additional Safety Precautions

Arbor and cutter should never be used as a hand hold. Keep hands and clothing away from all moving

parts. Do not use Hougen Cutters where ejected slug

might cause injury (slug ejected at end of cut).

Also, adhere to all operating instructions. Do not drill

through any surface that may contain live electrical

wiring. Drilling into a live wire could cause exposed metal

parts of the drill to be made live. Remove chips wrapped

around Cutter and arbor after each hole. With motor off

and power disconnected, grasp chips with leather gloved

hand or pliers and pull while rotating counterclockwise.

Should the cutter become jammed in the work, stop the

unit immediately to prevent personal injury. Disconnect the

drill from the power supply and loosen jammed cutter by

turning the arbor counterclockwise. Never attempt to free

the jammed cutter by starting the motor. Service at

authorized repair center only.

25. Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

also result in personal injury to the operator.

26. Circuit Breaker

Changing of the circuit breaker to a higher amp rated

breaker, or bypassing the circuit breaker is not

recommended and is cause for cancelation of the

product warranty.

27. Circuit Breaker Operation

The circuit breaker is a thermal circuit breaker. When it

reaches the higher temperature rating it will trip and cause

the unit to shut down. This is a protection device and can

be reset after 5 to 10 seconds of cool down period. To

reset the circuit breaker, press the breaker button back in.

If it does not reset, let the unit cool a little longer until you

can push the button in and it stays in position.

28. Safe Electrical Connection

Wet electrical connections are

shock hazards. To prevent the

cutting fluid from traveling along

the cord and contacting the plug

or power outlet, tie a drip loop as

shown. Also elevate extension

cords or gang box connections.

29. SAVE THESE INSTRUCTIONS.

5

Page 6

Operating Instructions

Adjustment of Gibs

Always remember that the magnet’s holding power is

directly related to the workpiece thickness and surface

condition. Since magnetic attraction diminishes with

thinner material or rough surfaces, mechanical clamping of

drill unit to workpiece should be used when cutting thin

material (3/8” or less) or material with uneven surfaces.

Note: Always form a loose knot in the power cord

close to the molded plug. This prevents cutting fluid

from running down the cord and into the power

receptacle. (Refer to the diagram within the Safety

Instructions in this manual)

1. Make sure workpiece and bottom of magnet are free

of chips, oil, etc.

2. Secure unit to workpiece with safety chain.

3. Position drill by sliding it and gently feeding Arbor so

that pilot point is touching center of hole to be drilled.

4. Turn magnet ON by pressing the magnet ON button.

5. Move Impactor Slide Hammer up and down several

times, rapping base sharply to insure Impactor Point

is seated in workpiece and magnet is flush with

workpiece.

6. Turn Feed Handle, raising the cutter until the pilot is

above the work surface.

7. Open the cutting fluid valve several full turns (Models

10909 and 10914 only)

8. Make certain that cutter is clear of workpiece and turn

motor On by pressing the motor START button.

9. Feed the cutter slowly into workpiece. Only

after cutting path is established to a depth of about

1/16” can full force be applied to feed handles.

10. Ease up on feed pressure as cutter starts breaking

through.

11. At conclusion of cut, turn motor OFF by pressing

motor STOP button. Turn feed handles to raise Arbor

thereby ejecting the slug if it hasn’t already fallen free.

12. Turn magnet OFF by pressing the magnet OFF

button. As the magnet de-energizes, the rear of the

magnet should lift up off the work surface.

13. Disconnect from power source.

14. If necessary, remove chips from cutter and magnet.,

preferably wearing leather work gloves and/or with

pliers.

15. Disconnect safety chain and you are ready to move

unit to new drilling position.

1. Loosen all Gib Screws (40237)

2. Feed the drill in and out a few times and then, with top of

motor slide flush with top of housing, tighten the Gib

Screws until you feel them touch the Steel Gib (40225)

3. Feed the drill in and out again.

4. Adjust Gib screws so that there is uniform pressure from

top to bottom. (Top of motor slide flush with top of

housing)

5. Turn each Gib Screw in about 1/8 to 1/4 turn, depending

upon your preference.

6. Gibs should be tight enough so that slide moves in and

out smoothly with no wobble or shaking. (looseness will

cause cutter breakage)

Safety Switch Adjustment

1. Unplug unit from power source and place it on a flat

sheet of steel that is at least 3/8” thick. Only magnet

portion should be on steel plate. Rear support block

(containing Glide Post and Impactor) should hang over

the edge of the steel plate.

2. Remove Access Hole Screw (10977) from back of

housing.

3. Insert 5/32” Allen Wrench into access hole and back off

(counterclockwise) Microswitch Adjusting Screw (10969)

about three full turns.

4. Plug unit into power source and turn magnet ON.

Depress and hold motor START switch ON while simulta neously turning Microswitch Adjusting Screw clockwise

until motor starts. Once the motor starts release the Motor

On Switch. Turn the adjusting screw 1-1/2 turns clock wise. This will set the Microswitch.

Testing of Microswitch

1. Plug unit into power source. Turn Magnet and motor

switches ON. Strike side of magnet at rear with a rubber

hammer. Motor should shut off before the magnet moves

1/2” in any direction. If the test was successful, replace

the Access Hole Screw (10969). If the unit failed the test,

recheck the Microswitch Adjustment.

NOTE: Safety switch adjustment should be checked

regularly following the procedures outlined above.

Special Instructions for horizontal or

Overhead Operation

1. Always Use Safety Chain.

2. Use grease or animal-fat base solid lubricant applied

liberally to cutter.

3. For horizontal use, apply cutting fluid to external parts

of cutter with plastic bottle or oiling can.

#1 cause of cutter

breakage and pre-

maturely dull teeth

is too little feed

pressure

6

Page 7

r

INSTALLING HOUGEN

CUTTER IN ARBOR

1. Disconnect power source.

2. Lay drill on its side with feed wheel up to be sure

arbor clears table if unit is in normal operating position.

3. Turn feed handles until cutter mounting set screws are

exposed and then completely remove the set screws.

4. Insert proper pilot into shank end of the cutter.

5. Insert the Cutter until flats on cutter shank are

aligned with set screw holes and is exactly perpendicular

to the axis of set screw hole.

6. Insert Set Screws and tighten.

NOTE: Arbor, Hougen part number #03736 and #40242

applies only to Models 10909 and 10914.

Arbor, Hougen part number #03737 applies ONLY to “S”

Models.

Adjusting Arbor Support Bracket for Depth

40451 Bolt

40391 Lock Washer

40392 Flat Washer

40299 Spacer

40222 Set

Screws go here

Pilot

"12000-Series"

Hougen Cutte

04375

Front Support Bracket

1" & 2" Depth of Cut

04375

Front Support Bracket

3" Depth of Cut

NOTE : Spacers must always be installed with short side toward arbor

7

40299 Spacer

Page 8

COOLANT BOTTLE ASSEMBLY - P/N: 40442

40433

51042

50035

40419

40417

40420

51042

40333

40338

Checking Operation of

Automatic Cutting

Fluid Inducer

Note: The automatic cutting fluid inducer system works

on a gravity flow basis. Therefore, it is only effective

when the drill is mounted on a horizontal or slightly

inclined work surface.

1. With Magnetic Drill in operation position, turn feed

handle so that the cutter and pilot are above the work

surface.

2. Fill cutting fluid bottle with cutting fluid.

3. To test automatic cutting fluid inducer (with the magnet

ON and motor OFF), feed the arbor gently toward the

work surface until the pilot is pushed up into the cutter.

Open the needle valve until fluid is visible filling the

plastic tube. Fluid should filter down onto the work

surface through the groove in the pilot.

4. To insure proper cutter lubrication, always make sure

that the slot in the pilot is kept clean from residual

buildup.

40429

40424

40326

40304

40422

Checking Operation of

Cutting Fluid Reservoir

(10909S & 10914S)

1. With magnetic drill in operating position, turn feed

handle so that cutter and pilot are above the work

surface.

2. With magnet turned ON and Motor OFF, fill reservoir by

introducing cutting fluid through slots in Arbor. Cutting

fluid should not leak out.

3. Test metering capabilities of Arbor/Cutter/ Pilot

assembly (magnet ON-motor OFF) by feeding the

Arbor gently toward work surface until pilot is pushed

up into Cutter, thus allowing fluid to filter down onto

work surface through groove in pilot.

4. For proper lubrication, all cutting fluid in reservoir

should empty onto work surface in no less than 15

seconds and no more than 30 seconds.

8

Page 9

GROUND WIRE/

FEED BACK IS

CAPPED OFF

DO NOT USE

Motor Black

Motor White

Yellow

From

Magnet

Power In

White

Power In

Black

Ground to

Housing

Safety

Switch

White

Safety

Switch

Black

MOTOR

ON

MOTOR

OFF

MAGNET

OFF

MAGNET

ON

86 42

1

0

14

12

8

4

13

14

13

9

5

1

MOV1

CR4

T1

C3

T2

CR3

R3

+

C2

D3

T5

T12

T4

T13

T6

T11

T10

T3

T8

J4

ZD1

J1

BR2

J2

CR1

QA1

+

C1

R2

J6

+

J3

J5

S.N.

BR1

CR2

T7

ZD2

MOTOR

WHITE

MOTOR

BLACK

AC WHITE

TO HOUSING

GROUND

SAFETY SWITCH

BLACK

AC BLACK

MAGNET

YELLOW

SAFETY SWITCH

WHITE

10909(S)

MODEL 10914(S) & 10909(S) HOOK UP DIAGRAM

9

10914(S)

Page 10

MODEL 10914 AND 10914S PANEL COMPONENTS

MOV1

CR4

T1

C3

T2

CR3

R3

+

C2

D3

T5

T12

T4

T13

T6

T11

T10

T3

T8

J4

ZD1

J1

BR2

J2

CR1

QA1

+

C1

R2

J6

+

J3

J5

S.N.

BR1

CR2

T7

ZD2

90571

40296

03868

90052

02409

04064

03884

01227

01226

01228

01334

01335

03880

04065

04064

40373

01185

03907

Panel Assembly

10914

P/N: 03930

10914S

P/N: 03908

MODEL 10909 AND 10909S PANEL COMPONENTS

Panel Assembly

P/N: 01086

Aus Panel Assembly

P/N: 01086AUS

04495AUS

(Aus Model)

01236

01465

40455

40288

01183

40373

10

10785

00998

10760

03665

01006

10757

02409

01226

01228

01237

10703

01005

90052

40374

10758

50037

50038

40296

Page 11

10909 & 10914 Panel Components

#traP noitpircseD .nauQ

8990090901etalpecaF1

50010)90901(V032cigoL-yaleR2

6001090901)V032(rewoP-yaleR1

38110)90901(V052gulP1

58110)41901(etalPecaF1

62210drauGhctiwS1

82210ffO/deRlaeShctiwS2

63210)90901(nOhctiwSnottuBhsuP2

73210)90901(ffOhctiwSnottuBhsuP2

60310)41901(23-6#swercSdaeHnaP4

43310)41901(hctiwSnOtengaM/rotoM2

53310)41901(hctiwSffOtengaM/rotoM2

56410)90901(tooBrekaerBtiucriC1

#traP noitpircseD .nauQ

70930)S41901(etalpecaF1

59930)41901(tnuoMnoitarbiV4

46040)41901(.yssArekaerBtiucriC1

56040)41901(.yssArepmuJeriW1

SUA59440)ledoMsuA(ylbmessAdroCrewoP1

30701)90901(.D.E.L1

75701)90901(geM1rotsiseR1

85701)90901(evawlluFreifitceR1

06701)90901(rosserpuSegruS1

58701)90901(rekaerBtiucriC1

88204)90901(3/61droC1

69204enerpoeN-laeS.TF2

37304feileRniartS1

90420neerGlaeShctiwS2

56630)90901(tiucriCrebbunS1

12730)41901(repmuJ1

08830)41901(.yssAssenraHpmaL/eniL1

48830)41901(draoBtiucriC1

47304)90901(23-6#tuNxeH6

55404)90901(feileRniartS1

73005)90901(23-01#tuNxeH1

83005)90901(rehsaWkcoL1

25009)41901(rehsaWkcoL4

17509)41901(.yssAdroCrewoP1

Drill Maintenance

In order to minimize wear on moving parts and insure

smoother operation and longer life, the following

maintenance should be done periodically, based on use.

1. At intervals of 500 holes or 10 hours of actual running

time, check all fasteners for tightness and retighten if

necessary. This is especially important for fasteners

required for smooth, efficient cutting action. These

include: Gib screws and nuts, motor hold down

screws, skid plate screws, bracket mounting screws

and nuts, housing bolts, clamp screw and front

support bracket bolts.

2. Coolant bottle must be attached to inducer under

pressure with shut-off valve open to lubricate inducer

o-rings whenever motor, is running.

3. Apply grease to slide dovetails, brass gibs, and the

feed gear rack. (For best results, use Shell Cyprina-RA

or equivalent.)

4. Remove front support bracket from arbor and pack

bearing with grease. (Shell Cyprina-RA or equivalent)

11

Page 12

40258

40445

40450

40441

40449

40284 (115V)

01088 (230V)

40260

40382

40384

40383

40286

40285

40261

01087

40262

40292

40262

40263

40290

40264

40269

40266

40265

40267

40267

40348

40268

40271

40270

40275

40276

40274

40279

40280

40281

40273

40298

40349

40289

40287

#242)

®

#271 to outside of Brush Holder

®

Motor Exploded View and Parts List

40287 Torque to 4 - 6 in/lb

40383 Torque to 15 - 25 in/lb (Use Loctite

40287 Loctite

12

Page 13

Motor Bolt Sequence

traP

.oN

noitpircseD

.oN

.d'qeR

08204llaB1

18204gulSrotoM1

48204V511ylbmessAdleiF1

58204gulPhsurB2

68204nobraC,hsurB2

78204redloHhsurB2

98204"4/1x23-01#wercS2

09204rehsaW1

29204gniRgniniateR1

89204"2/1-3x02-4/1wercS4

84304laeS1

94304gulP1

05304esaerGhcetnyS.zo8

28304elffaB1

3830423-01#wercS2

48304recapSelffaB2

14404paCdnE1

54404feileRniartS1

94404recapS2

05404"1x23-01#wercS2

42409pilCredloHhsurB2

1. Tighten bolts in the sequence shown

to 5 - 10 in/lb.

2. Retighten bolts in the same

sequence to 35 - 40 in/lb.

Motor Parts List

traP

.oN

78010V032ylbmessAerutamrA1

88010V032ylbmessAdleiF1

40240)eriw3(droCrotoM1

80340)eriw3(ylbmessAdleiF1

85204droCrotoM1

06204dnEhsurB,gnisuoH1

16204V511ylbmessAerutamrA1

26204gniraeB2

36204talF,gnirpS1

46204laeS1

56204talF,gnirpS1

66204rehsaW1

76204gniraeB2

86204raeG,gnisuoH1

96204retsulCraeG1

07204teksaG1

17204gnisuoHraeG,paC1

37204"4/1rehsaWkcoL4

47204gniraeB1

57204talF,gnirpS2

67204tuptuOraeG1

97204gniraeB1

noitpircseD

.oN

.d'qeR

13

3.

1.

2.

4.

Page 14

40253 (115V)

40650 (230V)

04462 (Aus Model)

MODELS 10909 AND 10914 EXPLODED VIEW

40309

40464

40465

90376

90027

10660

40390

90028

10661

SEE CONTROL

PANEL

DRAWING FOR

DETAILS

03930 (10914)

03908 (10914S)

01086 (10909)(S)

01086AUS (AUS MODEL)

40332

40242

40302

40301

40300

40295

40300

40301

40302

40256

Arbor

See Note 1

40398

40234

10513

40221

10517

40303

40222

10649

40299

90376

40452

90065

01149

10972

04375

10956

40230

40225

10973

10983

40388

40238

10971

10990

10968

10970

10967

10969

10979

10644

40229

04590

40255

03857

10966

10978

10962

10961

10567

40231

40254

10569

10570

40223

10725 - Carrying Case

Note 1:

03736 - 10909 & 10914

03737 - 10909S & 10914S

40242 for Coolant arbors only

40312

COOLANT BOTTLE SHOWN ON PAGE 8

Includes: 40222, 40256,10517, 10513

14

10993

{

{

10975

10618

10960

10638

10632

10974

Page 15

PARTS LIST

.oNtraP noitpircseD

68010V032lenaPlortnoC1

SUA68010)ledoMsuA(V032lenaPlortnoC1

6373041901&90901robrA1

73730S41901&S90901robrA1

03930V511lenaPlortnoC1

57340.yssA.tkrB.ppuSrobrA1

26440rotoMtnemecalpeRsuAV0321

09540lebaLgninraW1

31501gnirpSrobrA1

71501gniRgniniateR1

76501tuNbmaJ1

96501eldnaHdeeF3

07501bonKeldnaHdeeF3

81601gnirpShctiwSytefaS1

23601gniRgniniateR1

83601.yssA.grBhctiwSytefaS1

44601tsoPedilG1

9460123-01#CHSwercS3

066018/5x02-4/1CHSwercS1

1660142-01#CHBwercS2

52701esaCgniyrraC1

65901riaP-sbiGssarB1

06901ydoBregnulP1

16901remmaHedilS1

26901rotcapmI1

66901citsalP-paCtsuD1

76901gnirpS.tnuoMhctiwsorciM1

86901gnirpS.jdAhctiwsorciM1

96901wercStnuoMhctiwsorciM1

07901.tkrB.jdAhctiwSytefaS1

1790102-4/1CHSwercS2

2790123-6#CHBwercS2

37901tuNtresnInolyN23-6#2

47901regnulP,gniRgniniateR1

57901laeStnioPtoviP1

7790102-4/1HBwercS1

8790142-61/5HBwercS1

97901wercSkcoLtsoPedilG1

38901dleihS.snIhctiwsorciM1

09901.yssAhctiwsorciM1

39901.yssAtoviPhctiwSytefaS1

12204taeSgnirpS1

22204robrA-wercSteS2

32204ralloCrotcejE1

52204biGleetS1

92204raeGdeeF1

.oN

.d'qeR

.oNtraP noitpircseD

03204kcaRraeG1

13204eznorB-gnihsuB2

43204rehsaWtsurhT2

7320482-4/1wercSteS5

83204gnisuoH1

24204)tnalooc(rotceje/wyssArobrA1

45204.yssAbuH1

35204rotoMtnemecalpeRV5111

55204gaTgninraW1

6520481-61/5wercSteS1

49204edilSrotoM1

59204recudnI1

79204xeHdettolS-wercS4

99204)"4/3(.tkrBtroppuSrobrA1

00304gniR"O"2

10304rehsaWtsurhT2

20304gniRgniniateR2

30304gnittiFtnalooC1

40304.D.O"4/1gnibuT1

90304pmalCdroC1

21304deifidoM-niPlloR1

62304evlaVdiulFgnittuC1

23304.yssArecudnI1

33304tresnIssarB1

83304ebuT"4/1,elurreFnolyN1

77304ebuTknirhS1

88304V032/V511tengaM1

0930402-4/1HH-tloB3

89304gniR.teRralloCrotcejE1

71404elttoBtnalooC1

91404thgiR-tekcarBgniniateR1

02404tfeL-tekcarbgniniateR1

22404pmalCelttoBtnalooC1

42404regniFlanoitatoR-itnA1

92404gnikcoL-tuN1

33404paCelttoBtnalooC1

24404.yssAelttoBdiulFgnittuC1

25404tiKtloBrobrA1

46404partSdnuorG1

5640402-4/1HH-wercS1

05604rotoMtnemecalpeRV0321

53005htooTlanretnI"4/1rehsaW6

2401502-4/1CHSwercS2

72009talFrehsaW1

82009lacileH"4/1rehsaW3

25009wercSdnuorGrehsaW1

56009ratS"4/1rehsaW2

2530982-4/1CHSwercS4

67309lanretnI01#rehsaW3

.oN

.d'qeR

15

Loading...

Loading...