Page 1

MODEL HMD150 SERIES

PORTABLE MAGNETIC DRILLS

OPERATOR’S MANUAL

COVERS DRILL PART NUMBERS 0150201, 0150301 & 0150401

FOR USE WITH ROTALOC PLUS™ CUTTERS

Page 2

HOUGEN

®

PORTABLE MAGNETIC DRILL

Welcome to Hougen

Congratulations on your purchase of the Hougen® Portable Magnetic Drill. Your model is designed to produce

superior holes quickly and efciently. Through constant innovation and development, Hougen is committed to

provide you with hole producing tools and products to help you be more productive.

Before attempting to operate your new Portable Magnetic Drill, please read all instructions rst. These include

the Operator’s Manual and Warning Label on the unit itself. With proper use, care, and maintenance, your

model will provide you with years of effective hole drilling performance. Once again, thank you for selecting

our product and welcome to Hougen.

Your new Hougen Magnet Base Drill now incorporates a Label for the Drill Part Number and Serial Number.

Below gives a explanation of the Part Number and the location of the Label is shown on the Drill Breakdown

Diagram.

Part No. Description

0150201

0150301

0150401

Specications

Cutter Type.......................RotaLoc Plus

Hole Capacity....................7/16" to 1-3/8" or 12mm to 35mm

Depth of Cut......................1" or 25mm

Motor.................................450 RPM, 4A, 240 volt

Net Weight.........................22.7 lbs. or 10.2 kg

HMD150 Low Prole, 230 volt

HMD150 Low Prole, 230 volt Type I Plug

HMD150 Low Prole, 230 volt, No Plug

Serial / Part Number Label

INDEX

Welcome to Hougen. 2 HMD150 Exploded View 8

Important Safty Instructions 3-4 Parts List 9

Safety Switch Indicator Light 4 Motor Diagram & Part List 10

Operating Instructions 5 Rotaloc Series of Cutters 11

Rotaloc Plus Cutter Installation 6 Limited Warranty Information 11

Control Panel Diagram 7 Factory Authorized Warranty Repair Centers 12

SAFETY FIRST

Always wear eye protection while

using cutting tools, or in the vicin-

ity of cutting.

CAUTION! The slug is ejected

at the end of the cut. Do not aim

cutter or arbor so that ejected

slug may hit someone around, or

below you.

CAUTION! Cutters are sharp.

Wear gloves when installing or

removing cutter from arbor. Do

not grab a rotating cutter.

CAUTION! To prevent electric

shock, do not use power tools

near wet areas, or where power

tool may become wet.

1180

2

Page 3

Important Safety Instructions

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

Work Area

Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to loose control.

Electrical Safety

Grounded tools must be plugged into an outlet properly installed and grounded in accordance with all codes and ordianaces. Never remove the ground prong or modify the plug in

any way. Do not us any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the tools should electrically malfunction or break-

down, grounding is provides a low resistance path to carry electricity

away from the user.

Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of eletric shock.

When operating a power tool outside, use an outdoor extension

cord marked “W-A” or “W”; These cords are rated for outdoor use

and reduce the risk of electrical shock.

Personal Safety

Stay alert, watch what you are doing and use common sense

when using a power tool. Do not use tool while tired or under

the influence of drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in serious personal

injury.

Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from moving

parts. Loose clothes, j

parts.

Avoid accidental starting. Be sure switchis off before plugging

in. Carrying tools with your finger on the switch or plugging in tools

that have the switch on invites accidents.

ewelry, or long hair can be caught in moving

Use safety equipment. Always wear eye production. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

Always use safety chain. Mounting can release.

Tool Use and Care

Use clamps or other practical way to secure and support

the work piece to a stable platform. Holding the work by

hand or against your body is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

Do not use tool if switch does not turn it on or off. Any

tool that cannot be controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the

tool. Such preventive safety measures reduce the risk of start-

ing the tool accidentally.

Store idle tools out of reach of childern and other

untrained persons. Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the

tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one tool, may become hazardous when used on another tool.

Service

Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section of

this manual. Use of unauthorized parts or failure to follow

Maitenance Instructions may create a risk of electric shock or

injury.

Remove adjusting keys or switches before turning the tool on. A

wrench or a key that is left attached to a rotating part of the tool may

result in personal injury.

Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in unexpected situations.

3

Page 4

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

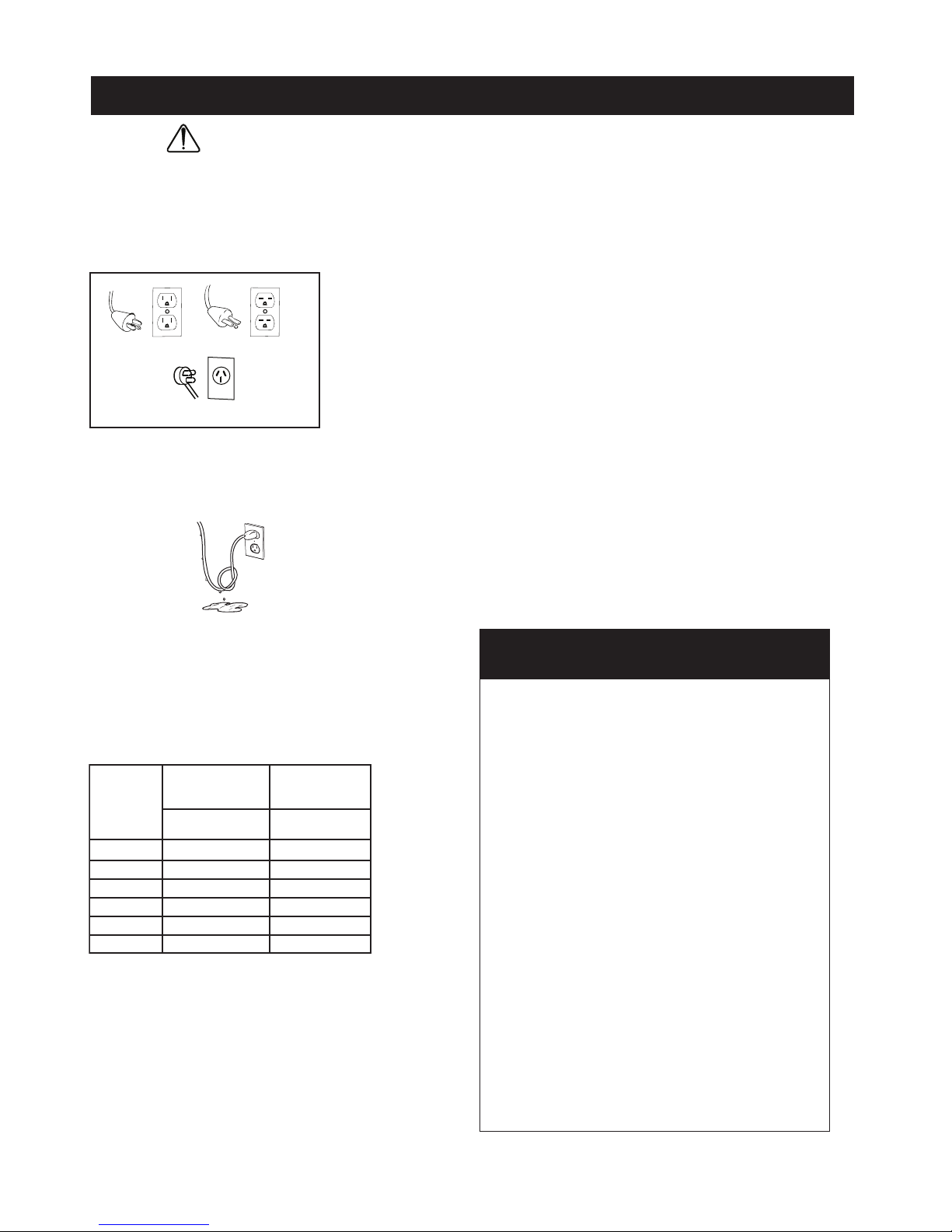

Extension Cord Table

Plugs and Receptacles

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

also result in personal injury to the operator.

Circuit Breaker (If Applicable)

Changing of the circuit breaker to a higher amp rated breaker, or

bypassing the circuit breaker is not recommended and will void

product warranty.

Circuit Breaker Operation (If Applicable)

The circuit breaker is a thermal breaker. When it reaches the

higher temperature rating it will trip and cause the unit to shut

down. This is a protective device and can be reset after 5 to 10.

To reset the breaker, press the breaker button back in. If it does

not reset, let the unit cool a little longer until you can push the

button in and it stays in position.

Save these Instructions.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

Wet electrical connections are shock hazards. To

prevent the cutting fluid from traveling along the cord

and contacting the plug or power outlet, tie a drip loop

as shown. Also elevate extension cords or gang

box connections.

Typical USA 120v

HTGNEL

TEEF

05-62 41 81

001-15 01 61

003-102 6 21

005-103 4 01

Typical USA 230v

I

230v Type Plug

DEDNEMMOCER

ERIW

,DROCFO

52OTPU 61 81

002-101 8 41

EGUAG

ROTOMV511

SPMA21-01

The Safety Switch Indicator Light is a Standard Safety Feature on

HMD150 magnetic drills. Its purpose is to inform the user that an

unsafe condition exists or the safety switch is defective.

SAFETY SWITCH

INDICATOR LIGHT

If light is Green:

In normal operation the safety switch light will be green.

DEDNEMMOCER

ERIW

EGUAG

ROTOMV032

SPMA6-5

Motor "On" and "Off" Switches function normally.

If light is Red:

A condition with the safety switch exists that needs to be corrected.

Possible causes:

• Safety Switch is defective. Have drill serviced.

• Uneven work surface or material. Check work

surface for

atness.

• Dirt or chips under magnet. Clean work surface.

Make sure material is at least 3/8" thick. Material thinner than

3/8" will cause a "weak" magnet condition.

HOUGEN MANUFACTURING RECOMMENDS THAT

CONDITIONS ARE CORRECTED SO LIGHT TURNS

GREEN. THIS ALLOWS FOR THE UNIT TO BE

OPERATED IN A SAFE MANNER.

For any questions please contact Hougen Manufacturing’s

Technical Service at (810) 635-7111.

4

Page 5

OPERATING INSTRUCTIONS

1. Place drill on material (at least 3/8" thick) and

locate for drilling hole.

2. Press magnet switch to "ON"

3. Thread safety strap through opening between

motor and drill housing. Ensure that strap

does not interfere with operation of feed handles.

Insert tab of strap into buckle. Cinch strap tight to

material and drill housing. Check for slack and

adjust as needed.

6. Feed Cutter slowly into workpiece. Only after cutting

path is established to a depth of about 1/16" can

additional force be applied to feed handles.

Ease up on feed pressure as cutter starts

breaking through

CAUTION: Do not over-feed cutter. Excessive feed

pressure may cause the magnet to break free from

material.

DRILLING MULTIPLE LAYER MATERIALS:

**Special Cutter Geometry Required!

Second layer penetration may be difficult. Slight

additional feed pressure may be required (avoid overfeed as noted above).

If unable to penetrate second layer, withdraw cutter

from material ejecting slug and clean away any

remaining chips. Feed cutter in hole and continue cut.

• Turn motor off when cut is nished.

• Fully retract cutter from material, ejecting the slug.

• Remove safety strap.

7. Turn magnet switch to "OFF" position.

CAUTION: Retain firm hold on drill to prevent

dropping.

CAUTION:

• Keep strap clear of cutting area, chips, and

rough edges on material.

• Inspect strap periodically for fraying and

damage. Do not use a damaged safety strap.

4. Apply liberal amount of cutting fluid or stick lubricant

to cutter. Additional lubrication may be required to

finish cut.

5. Make certain that cutter is clear of workpiece and

turn motor ON by pressing the motor START button.

Cutter Inside Diameter may collect chips, restricting

depth of cut. Cutter should be frequently inspected

and any chips or debris removed.

OPTIONAL FEED METHODS:

• 5/8" Box Wrench

• Ratchet with 5/8" Socket

• NO PLIERS OR OPEN END WRENCH (They will

damage threaded feed handle mounting holes)

5

Page 6

SAFETY SWITCH

NOTE: The Safety Switch located in the base of the unit

shuts off the motor when the unit lifts. The magnet will stay

engaged until you turn off the magnet. It is important to

keep this area clean and free from chips. Periodically check

this switch for proper function and if for some reason it is not

working properly, send the unit to an authorized repair center

for service.

ROTALOC PLUS™ CUTTER INSTALLATION

1. Disconnect machine from power source.

2. Insert pilot into cutter.

3. Align flat on shank with pin in spindle.

4. Insert cutter into spindle.

5. Give cutter 1/4 turn in opposite direction of utes.

6

Page 7

CONTROL PANEL / HOOKUP DIAGRAM

White Wire To Bend

On Anode

MAGNET MOTOR

5

2,4

6,3

14

1

13

7

10

8

9

05917 Control Panel Assembly - 230v, 0150201 &

0150401(includes the 05912 Faceplate Assy.and 05827

Circuit Board) (Note 2)

05918 Control Panel Assembly - 230v Type I Plug,

0150301(includes the 05913 Faceplate Assy. and 05827

Circuit Board)

05912 Faceplate Assembly 0150201 & 0150401 (includes

items 1-14 for a HMD150 230v) (Note 2)

05913 Faceplate Assembly 0150301 (includes items 1-14 for

a HMD150 230v Type I Plug)

Item Part # Description Qty

1 01226 Switch Guard 1

2 01228 Red Switch Cover 1

3 01334 Motor ON Switch 1

4 01335 Motor OFF Switch 1

Rocker Switch 230v

(Note 1)

Power Cord Assembly

230v 0150201 & 0150401

(Note 2)

Power Cord Assembly 230v

Type I Plug

not a lighted switch.

U.S.A 230v plug installed.

Pwr Black Wire

5 04437

6 02409 Green Switch Cover 1

7 04877 Wire Harness 1

8 04878 Spacer 1

9 04879 Clear Lens 1

10 04881 Bulb 1

11 05208 Green Ground Wire Assy. 1

13 05828 Faceplate 1

14 17640

04771

15 07522 Fuses 2

Note 1 - An alternative 04437 maybe used that is

Note 2 - Replacement part will have a standard

1

1

1

Safety Switch

Magnet Wires

(J2)

(J4)

(J1)

Pwr Green Wire

Green

Ground Wire

Route Magnet & Safety Switch

Wires thru the slot in the Circuit

Board

ON

OFF

J3

J9

J6

P5

J1 J2 J4 J5

(J8)

(J7)

P4

P3

P2

P1

J7

Pwr White Wire

L.E.D Wiring

Harness

(P4)

(P3)

Route Wires

Behind Circuit Board

Fuses

(P1)

(P2)

Blue

Brown

(P4)

(P3)

Motor

Black Wire

Motor

White Wire

1178

7

Page 8

1

2

3

4

5

6

7

8

9

10

11

13

16

14

18

19

20

21

15

17

22

23

24

25

26

27

28

29

30

31

12a

12g

12f

12b

12

12h

12d

12c

12d

12e

10a.

10a.

10c.

10b.

36

37

32

33

34

35

38

39

40

42

43

45

46

DRILL PARTS BREAKDOWN

0150201 HMD150 230v,

0150301 HMD150 TYPE I 230v & 0150401 HMD150 230v No Plug

1188

8

Page 9

HMD150 PARTS LIST

Item # Part # Description Qty

1 07176 Motor Assy 230v 1

2 17502 Left Hand Miter Gear 1

3 17002 SHC #6-32 X 1/2 7

4 17510 Gear Cap Assembly 1

5 17277 Key 1/8 sq. X .53 lg. 1

6 17517

7 17516

8 17278 Right Hand Miter Gear 1

9 17270 Ball Bearing 32 X12 X 10mm 1

10 17279 Housing Assy 1

10a 17495 Bronze Bearing

10b 17298 Feed Gear 1

10c 40546 O-Ring 2

11 17280 Spline Shaft 1

12 17646 Quill / Arbor Assembly 1

Thrust Washers .312 ID X .750

OD

Thrust Bearing .312 ID X .750

OD

2

1

Item# Part # Description Qty

20 17285 Plunger Assembly 1

21 17476 BHC Torx Screw #6-32 X 1-1/4 2

22 90052 Lock Washer #6 ext. tooth 2

23 04885 Safety Switch Assembly 1

24 75096 SHC Screw M6 X 20 2

25 75094 SHC Screw M5 X 12 2

26 05827 Circuit Board 230v 1

27 17691 Electrical Box 1

28 02547 SCR- #4-40 X 5/16 lg 3

29 24081 SCR #10 X 3/8 self tap. 4

30 05912

05913

31 17492 Comp. Spring 1

32 04439 BHC Screw #10-32 X 3/16 1

33 17289 Bearing Retaining Washer 1

Faceplate Assy. 230v (0150201

& 0150401) note1

Faceplate Assy. 230v Type I plug

(0150301)

1

1

12a 17649 Arbor Assembly 1

12b 17647 Quill Assembly 1

12c 17546 Bronze Thrust Washer 1

12d 17547 Steel Thrust Washer 2

12e 04720 Retaining Ring 1

12f 17644 Thrust Washer 1

12g 17645 Thrust Needle Bearing 1

12h 17643 Thrust Waher Seal 1

13 17493

14 17282 Hub Assembly 1

15 17283 Feed Handle Assembly 1

16 10553 SHC Screw 1/4-20 X 7/8 4

17 40374 Hex Nut #6-32 2

18 17271 Tapered Spring 1

19 17651 Magnet Assembly 1

SCR-FHC Modied 1/4-28 X

1/2 lg

34 04718 Screw #4-40 X 3/8 3

35 17494 Plunger 1

36 17291 Thumb Screw 1

37 90027 1/4 Flat Washer 1

38 17293 Motor Seal 1

39 17274 Grommet 1

40 17475 Retaining Ring 12mm Shaft 1

41 05208 Green Ground Wire 1

1

42 05921 Handle 1

43 05920 Locking Nut 1

44 05372 Lubiplate Grease

45

46

47

Note 1 - Replacement part will have a standard U.S.A 230v plug

installed.

90218 Wire Terminal 2

07294 1" Lexan Protector 1

07343 230v Power Cord Label 1

.01

oz

1188

The 0150401 is assembled without a

plug on the power cord

The 0150301 is assembled with a

Type I plug.

9

Page 10

07176 230v MOTOR DIAGRAM and PARTS LIST

1

2

3

4

5

6

7

8

9

10

5

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

29

30 opposite side

28

Item Part # Description Qty

1 17621 Carbon Brush 2

2 17622 Brush Cap 2

3 17632 Paper Washer 2

4 17600 Field Case 1

5 17602 Ball Bearing 2

6 17606 Dust Seal 1

7 17629 Field 230 volt 1

8 17623 Pan Head Screw 2

9 17631 Armature 230 volt 1

10 17604 Ball Bearing 1

11 17617 Fan Guide 1

12 17601 Gear Housing 1

13 17618 Gasket 1

14 17613 Flat Washer 1

15 17610 Flat Washer 1

Item Part # Description Qty

16 17607 1st Inter. Gear Assy 1

17 17608 2nd Inter. Gear Assy 1

18 17603 Ball Bearing 1

19 17626 Retaining Ring 1

20 17609 Spur Gear 1

21 17611 Key 1

22 17616 Spindle 1

23 17615 Gear Housing (includes 24 & 25) 1

24 17605 Ball Bearing 1

25 17627 Retaining Ring 1

26 17625 Pan Head Screw Long 2

27 17624 Pan Head Screw Short 2

28 17612 Dowel Pin 1

29 17537 Label - Motor Safety 230v 1

30 07153 Label - Motor Specs 230v 1

10

Page 11

ROTALOC PLUS™ CUTTERS for the HMD150

The ROTALOC PLUS™ cutters are made specically for the HMD150. They are equipped with 5/8" tool-less Bayonet-style

twist and lock shank, the 1" depth of cut standard cutter. They are made of premium high speed steel and available in

diameters from 1/2" to 1-3/8" and 12mm to 35mm. Cutters are also available in 3/4 depth of cut, please refer to our

Hougen Catalog for those sizes.

Rotaloc Plus™ Cutters 1" D.O.C.

Use with Pilot Pin 17470 Use with Pilot Pin 17470

17214 7/16" 17400 12mm

17216 1/2" 17402 13mm

17218 9/16" 17404 14mm

17220 5/8" 17406 15mm

17222 11/16" 17408 16mm

17224 3/4" 17410 17mm

17226 13/16" 17412 18mm

17228 7/8' 17414 19mm

17230 15/16" 17416 20mm

17232 1" 17418 21mm

17234 1-1/16" 17420 22mm

17236 1-1/8" 17422 23mm

17238 1-3/16" 17424 24mm

17240 1-1/4" 17425 24.5mm

17240 1-5/16' 17426 25mm

17244 1-3/8" 17428 26mm

17430 27mm

17432 28mm

17434 29mm

17436 30mm

17438 31mm

17440 32mm

17442 33mm

17444 34mm

17446 35mm

Rotaloc Plus™ Cutter Kits 1" D.O.C.

Part # DescriptionTION

17800

17801

17804

Kit contains (3) Cutters, 1" D.O.C.

- 1/2", 5/8", 3/4" dia. plus (2) pilots

in a sturdy plastic case

Kit contains (3) Cutters, 1" D.O.C.

- 9/16", 11/16", 13/16" dia. plus (3)

Pilots in a plastic carrying case

Kit contain (3) cutters, 1" D.O.C 14mm, 16mm, 18mm dia. plus (3)

pilots in a plastic carrying case.

Hougen Manufacturing, Incorporated warrants its Portable Magnetic Drills for one (1) year and its Electro-hydraulic Hole Punchers and other products for ninety (90) days from

Commercial / Industrial Limited Warranty

date of purchase against defects due to faulty material or workmanship and will repair or replace (at its option) without charge any items returned. This warranty is void if the

item has been damaged by accident or unreasonable use, neglect, improper service, or other causes not arising out of defects in material or workmanship. No other expressed

warranty is given or authorized. Hougen Manufacturing, Inc. disclaims any implied warranty of MERCHANTABILITY or FITNESS for any period beyond the expressed warranty

and shall not be liable for incidental or consequential damages. Some states do not allow exclusions of incidental or consequential damages or limitation on how long an implied

warranty lasts and, if the law of such a state governs your purchase, the above exclusion and limitation may not apply to you. This warranty gives you specic legal rights and

you may also have other rights which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest Factory Authorized Repair Center or to Hougen Manufacturing, Inc., 3001 Hougen Drive,

Swartz Creek, Michigan 48473.

Hougen Drills (Rotabroach Cutters) are warranted against manufacturing defects only. Subject to Hougen Manufacturing inspection.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

The products in this manual may be covered by one or more of the following U.S. patents, foreign patents, and pending patents:

D445808 6280123

Photographs and Specications shown are accurate in detail at time of printing. Manufacturer reserves the right to make improvements and modications without prior notice.

Hougen, Hougen-Edge, Trak-Star, and Punch Pro are proprietary trademarks of Hougen Manufacturing Inc. Ogura and the Ogura logo are proprietary trademarks of Ogura & Co.,

Ltd. Vac-Pad is a propriety trademark of Drillmate PTY, Ltd.

1180

HOUGEN PATENT NOTICE

11

Loading...

Loading...