Hougen HMD150, 0150201, 0150301, 0150401 Operator's Manual

MODEL HMD150 SERIES

PORTABLE MAGNETIC DRILLS

OPERATOR’S MANUAL

COVERS DRILL PART NUMBERS 0150201, 0150301 & 0150401

FOR USE WITH ROTALOC PLUS™ CUTTERS

HOUGEN

®

PORTABLE MAGNETIC DRILL

Welcome to Hougen

Congratulations on your purchase of the Hougen® Portable Magnetic Drill. Your model is designed to produce

superior holes quickly and efciently. Through constant innovation and development, Hougen is committed to

provide you with hole producing tools and products to help you be more productive.

Before attempting to operate your new Portable Magnetic Drill, please read all instructions rst. These include

the Operator’s Manual and Warning Label on the unit itself. With proper use, care, and maintenance, your

model will provide you with years of effective hole drilling performance. Once again, thank you for selecting

our product and welcome to Hougen.

Your new Hougen Magnet Base Drill now incorporates a Label for the Drill Part Number and Serial Number.

Below gives a explanation of the Part Number and the location of the Label is shown on the Drill Breakdown

Diagram.

Part No. Description

0150201

0150301

0150401

Specications

Cutter Type.......................RotaLoc Plus

Hole Capacity....................7/16" to 1-3/8" or 12mm to 35mm

Depth of Cut......................1" or 25mm

Motor.................................450 RPM, 4A, 240 volt

Net Weight.........................22.7 lbs. or 10.2 kg

HMD150 Low Prole, 230 volt

HMD150 Low Prole, 230 volt Type I Plug

HMD150 Low Prole, 230 volt, No Plug

Serial / Part Number Label

INDEX

Welcome to Hougen. 2 HMD150 Exploded View 8

Important Safty Instructions 3-4 Parts List 9

Safety Switch Indicator Light 4 Motor Diagram & Part List 10

Operating Instructions 5 Rotaloc Series of Cutters 11

Rotaloc Plus Cutter Installation 6 Limited Warranty Information 11

Control Panel Diagram 7 Factory Authorized Warranty Repair Centers 12

SAFETY FIRST

Always wear eye protection while

using cutting tools, or in the vicin-

ity of cutting.

CAUTION! The slug is ejected

at the end of the cut. Do not aim

cutter or arbor so that ejected

slug may hit someone around, or

below you.

CAUTION! Cutters are sharp.

Wear gloves when installing or

removing cutter from arbor. Do

not grab a rotating cutter.

CAUTION! To prevent electric

shock, do not use power tools

near wet areas, or where power

tool may become wet.

1180

2

Important Safety Instructions

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

Work Area

Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to loose control.

Electrical Safety

Grounded tools must be plugged into an outlet properly installed and grounded in accordance with all codes and ordianaces. Never remove the ground prong or modify the plug in

any way. Do not us any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly grounded. If the tools should electrically malfunction or break-

down, grounding is provides a low resistance path to carry electricity

away from the user.

Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of eletric shock.

When operating a power tool outside, use an outdoor extension

cord marked “W-A” or “W”; These cords are rated for outdoor use

and reduce the risk of electrical shock.

Personal Safety

Stay alert, watch what you are doing and use common sense

when using a power tool. Do not use tool while tired or under

the influence of drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in serious personal

injury.

Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from moving

parts. Loose clothes, j

parts.

Avoid accidental starting. Be sure switchis off before plugging

in. Carrying tools with your finger on the switch or plugging in tools

that have the switch on invites accidents.

ewelry, or long hair can be caught in moving

Use safety equipment. Always wear eye production. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

Always use safety chain. Mounting can release.

Tool Use and Care

Use clamps or other practical way to secure and support

the work piece to a stable platform. Holding the work by

hand or against your body is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

Do not use tool if switch does not turn it on or off. Any

tool that cannot be controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the

tool. Such preventive safety measures reduce the risk of start-

ing the tool accidentally.

Store idle tools out of reach of childern and other

untrained persons. Tools are dangerous in the hands of

untrained users.

Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the

tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one tool, may become hazardous when used on another tool.

Service

Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section of

this manual. Use of unauthorized parts or failure to follow

Maitenance Instructions may create a risk of electric shock or

injury.

Remove adjusting keys or switches before turning the tool on. A

wrench or a key that is left attached to a rotating part of the tool may

result in personal injury.

Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in unexpected situations.

3

metal parts of the drill to be made live. Remove chips

wrapped around Cutter and arbor after each hole. With

motor off and power disconnected, grasp chips with

leather gloved hand or pliers and pull while rotating

counterclockwise. Should the cutter become jammed in

the work, stop the unit immediately to prevent personal

injury. Disconnect the drill from the power supply and

loosen jammed cutter by turning the arbor counterclock wise. Never attempt to free the jammed cutter by starting

the motor. Service at authorized repair center only.

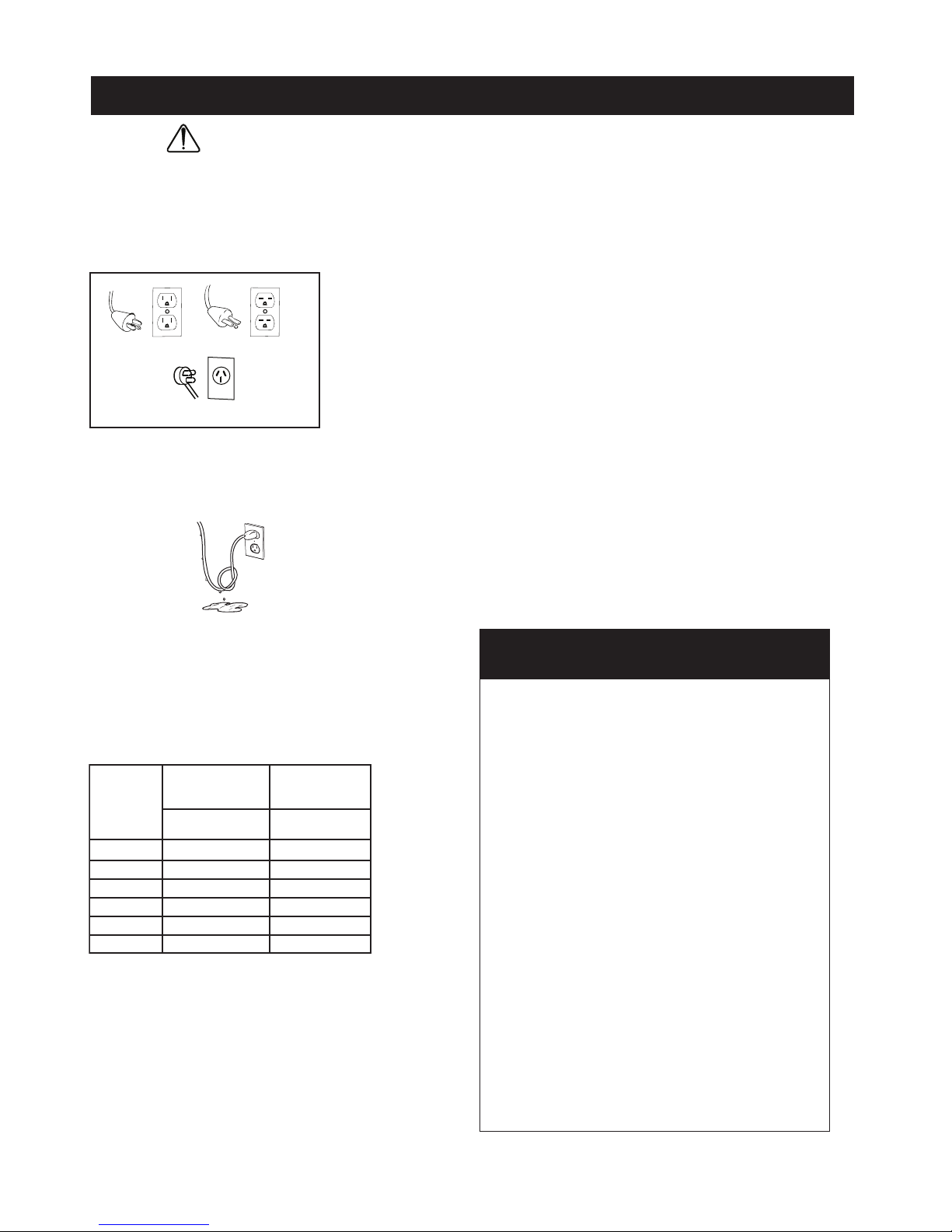

Extension Cord Table

Plugs and Receptacles

Operating Near Welding Equipment

DO NOT operate this unit on the same work surface that

welding is being performed on. Severe damage to the

unit, particularly the power cord, could occur. This could

also result in personal injury to the operator.

Circuit Breaker (If Applicable)

Changing of the circuit breaker to a higher amp rated breaker, or

bypassing the circuit breaker is not recommended and will void

product warranty.

Circuit Breaker Operation (If Applicable)

The circuit breaker is a thermal breaker. When it reaches the

higher temperature rating it will trip and cause the unit to shut

down. This is a protective device and can be reset after 5 to 10.

To reset the breaker, press the breaker button back in. If it does

not reset, let the unit cool a little longer until you can push the

button in and it stays in position.

Save these Instructions.

Important Safety Instructions - Continued

WARNING: Read and understand all instructions. Failure to follow all instructions listed below,

may result in electrical shock, fire and/or serious personal injury.

Wet electrical connections are shock hazards. To

prevent the cutting fluid from traveling along the cord

and contacting the plug or power outlet, tie a drip loop

as shown. Also elevate extension cords or gang

box connections.

Typical USA 120v

HTGNEL

TEEF

05-62 41 81

001-15 01 61

003-102 6 21

005-103 4 01

Typical USA 230v

I

230v Type Plug

DEDNEMMOCER

ERIW

,DROCFO

52OTPU 61 81

002-101 8 41

EGUAG

ROTOMV511

SPMA21-01

The Safety Switch Indicator Light is a Standard Safety Feature on

HMD150 magnetic drills. Its purpose is to inform the user that an

unsafe condition exists or the safety switch is defective.

SAFETY SWITCH

INDICATOR LIGHT

If light is Green:

In normal operation the safety switch light will be green.

DEDNEMMOCER

ERIW

EGUAG

ROTOMV032

SPMA6-5

Motor "On" and "Off" Switches function normally.

If light is Red:

A condition with the safety switch exists that needs to be corrected.

Possible causes:

• Safety Switch is defective. Have drill serviced.

• Uneven work surface or material. Check work

surface for

atness.

• Dirt or chips under magnet. Clean work surface.

Make sure material is at least 3/8" thick. Material thinner than

3/8" will cause a "weak" magnet condition.

HOUGEN MANUFACTURING RECOMMENDS THAT

CONDITIONS ARE CORRECTED SO LIGHT TURNS

GREEN. THIS ALLOWS FOR THE UNIT TO BE

OPERATED IN A SAFE MANNER.

For any questions please contact Hougen Manufacturing’s

Technical Service at (810) 635-7111.

4

Loading...

Loading...