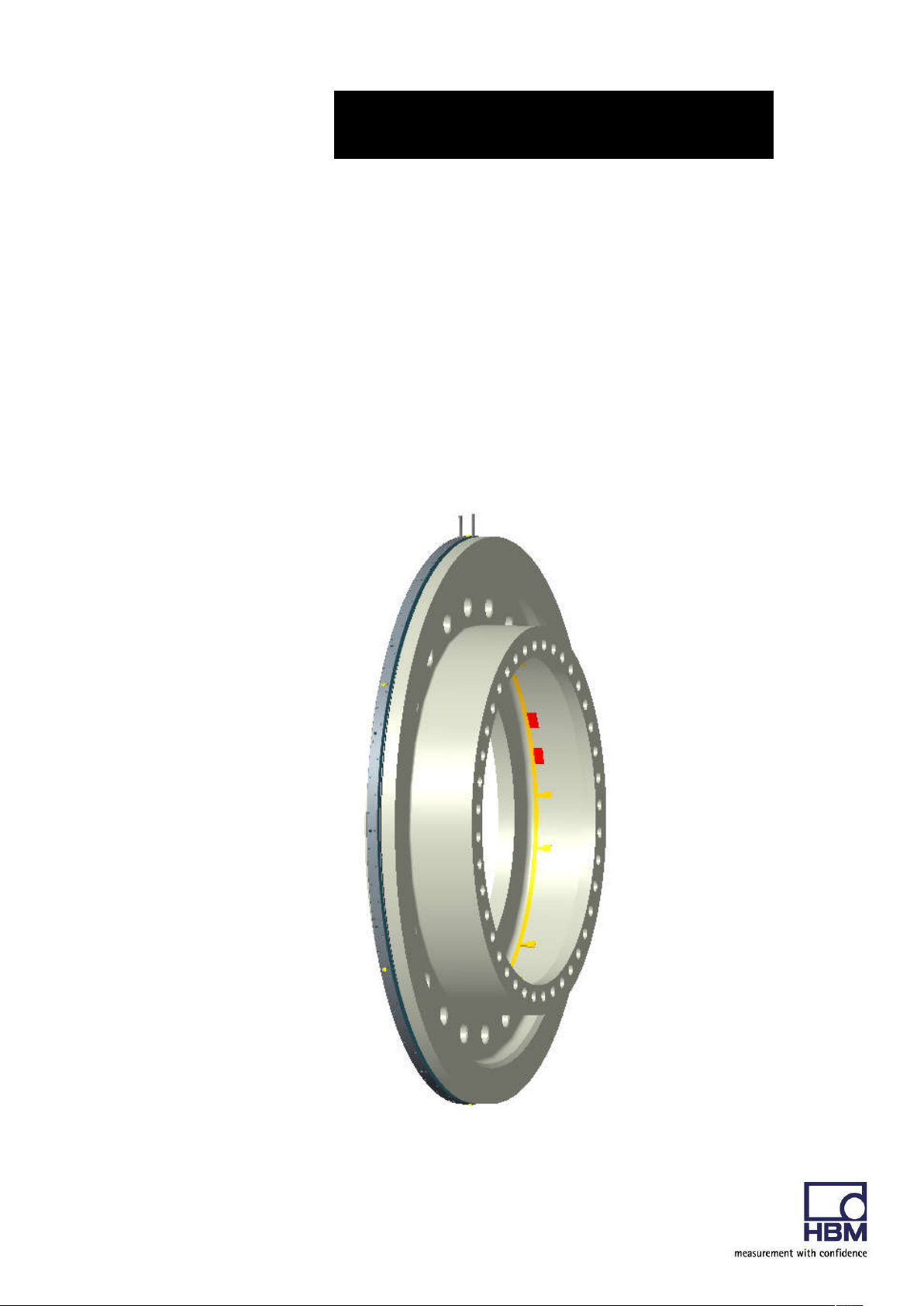

Hottinger Baldwin Messtechnik TJ1S9 User Manual

Mounting instructions

Installation of strain gages and

telemetry system on customer

diaphragm coupling project

9HA.02

TJ1-S9 (MPZ1701032)

HBM: Business Document

Directory

1 Safety Instructions ................................................................................................................................... 3

2 Markings used ......................................................................................................................................... 1

2.1 Symbols on the transducer ............................................................................................................. 1

2.2 The markings used in this document ............................................................................................. 2

3 Application ................................................................................................................................................ 2

4 Structure and mode of operation............................................................................................................ 3

5 Mechanical installation ............................................................................................................................ 5

5.1 Important precautions during installation

....................................................................................... 5

5.2 Conditions on site ............................................................................................................................ 6

5.3 Installation orientation...................................................................................................................... 6

5.4 Installation ........................................................................................................................................ 7

5.5 Preparing for the rotor mounting (exemplary)

............................................................................... 7

5.6 Mounting the rotor ............................................................................................................................ 9

5.7 Installing the telemetry system ........................................................................................................ 10

5.7.1 Measuring setup ......................................................................................................................... 11

5.7.2 Instruction for installation ........................................................................................................... 12

5.7.3 Calibration signal........................................................................................................................ 13

5.7.4 Stator antenna ............................................................................................................................ 13

5.7.5 Evaluation unit ............................................................................................................................ 14

6 Electrical connection ............................................................................................................................ 18

6.1 Connector pin assignment ............................................................................................................ 19

6.2 Supply voltage ................................................................................................................................ 19

7 Functional testing .................................................................................................................................. 20

8 Maintenance .......................................................................................................................................... 21

9 Dimensions of the stator antenna ........................................................................................................ 22

10

11

Dimensions of the rotor antenna

Declaration of conformity

.................................................................................................................. 24

...................................................................................................... 23

HBM: Business Document

1 Safety Instructions

FCC Compliance & Advisory Statement

Important

Any changes or modification not expressly approved in writing by the party

responsible for compliance could void the user’s authority to operate the device.

Where specified additional components or accessories elsewhere defined to be

used with the installation of the product, they must be used in order to ensure

compliance with FCC regulations.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

The FCC identifier or the unique identifier, as appropriate, must be displayed on

the device.

Model Measuring

FCC ID IC

range

TJ1-S9 1375kN·m 2ADAT-TJ1S9 n.a.

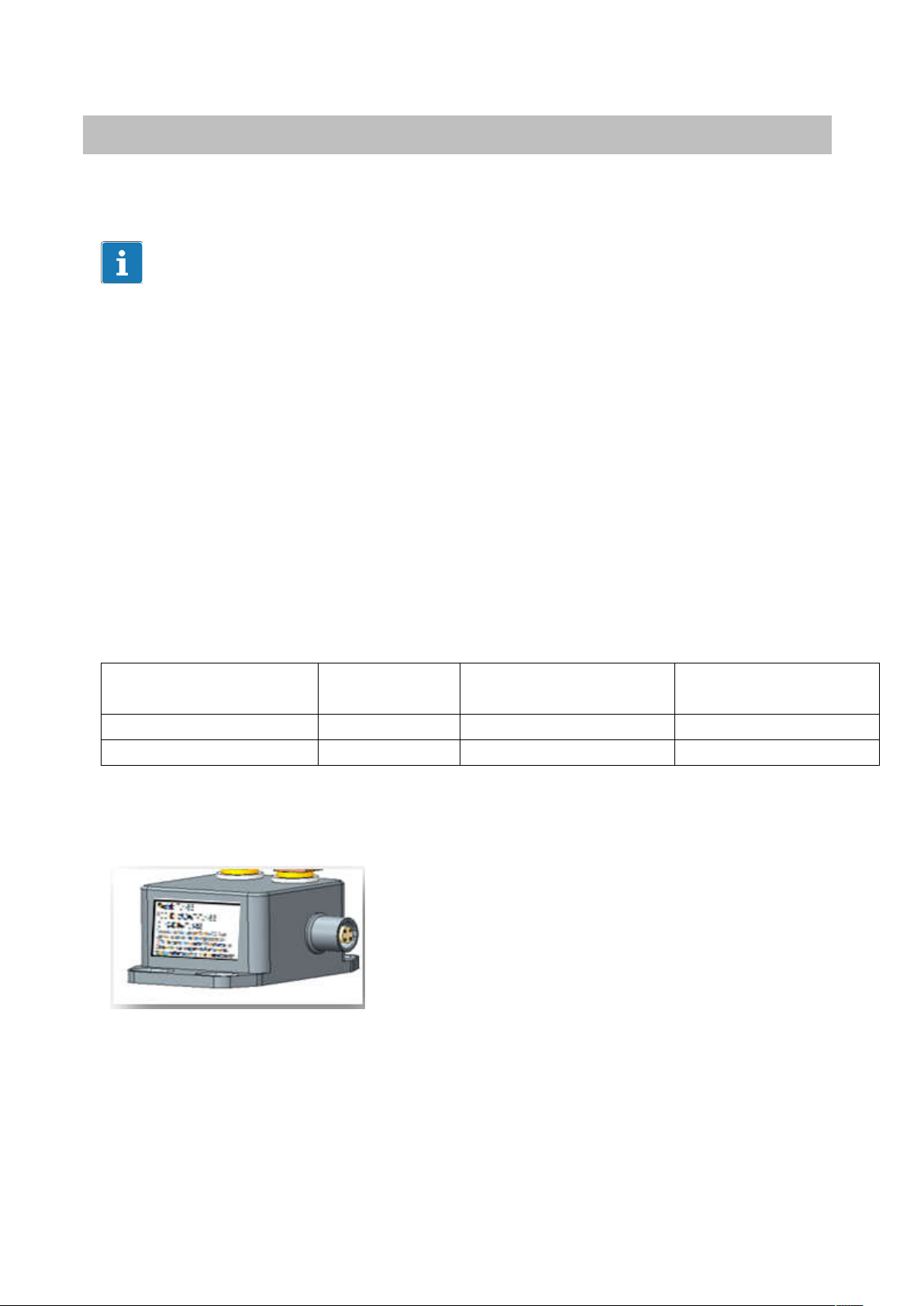

Label example with FCC ID.

Fig 1.1: Location of the label on the stator of the device

HBM: Business Document

Model: TJ1-S9

FCC ID: 2ADAT-TJ1S9

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

Fig. 1.2 Example of the label

Appropriate use

The torque transducer is used exclusively for torque, angle of rotation and

power measurement tasks within the load limits stipulated in the specifications. Any other use is not the designated use.

Stator operation is only permitted when the rotor and stator antenna are

coupled.

The torque flange may only be installed by qualified personnel in compliance

with the specifications and with the safety requirements and regulations of

these mounting instructions. It is also essential to observe the applicable legal

and safety regulations for the application concerned. The same applies to the

use of accessories.

The torque flange is not intended for use as a safety component. Please also

refer to the section: “Additional safety precautions". Proper and safe operation

requires proper transportation, correct storage, siting and mounting, and careful operation.

Loading capacity limits

The data in the technical data sheets must be complied with when using the

torque flange. In particular, the respective maximum loads specified must

never be exceeded. The values stated in the specifications‐must not be

exceeded, for example, for

limit torque,

longitudinal limit force, lateral limit force or limit bending moment,

torque oscillation width,

breaking torque,

temperature limits,

the limits of the electrical loading capacity.

HBM: Business Document

Use as a machine element

The torque flange can be used as a machine element. When used in this

manner, it must be noted that, to favor greater sensitivity, the transducer is not

designed with the safety factors usual in mechanical engineering. Please refer

here to the section “Loading capacity limits", and to the specifications.

Accident prevention

According to the prevailing accident prevention regulations, once the transducers have been mounted, a covering agent or cladding has to be fitted as

follows:

The covering agent or cladding must not be free to rotate.

The covering agent or cladding should prevent squeezing or shearing and

provide protection against parts that might come loose.

Covering agents and cladding must be positioned at a suitable distance or

be so arranged that there is no access to any moving parts within.

Covering agents and cladding must still be attached even if the moving

parts of the torque flange are installed outside people's movement and

working range.

The only permitted exceptions to the above requirements are if the torque

flange is already fully protected by the design of the machine or by existing

safety precautions.

Additional safety precautions

The torque flange cannot (as a passive transducer) implement any (safety‐rel

evant) cutoffs. This requires additional components and constructive measures for which the installer and operator of the plant is responsible. The layout

of the electronics conditioning the measurement signal should be such that

measurement signal failure does not cause damage.

The scope of supply and performance of the transducer covers only a small

area of torque measurement technology. In addition, equipment planners,

installers and operators should plan, implement and respond to safety engineering considerations in such a way as to minimize residual dangers. Pertinent national and local regulations must be complied with.

General dangers of failing to follow the safety instructions

The torque flange corresponds to the state of the art and is failsafe. Transducers can give rise to residual dangers if they are incorrectly operated or

inappropriately mounted, installed and operated by untrained personnel.

Every person involved with siting, starting‐up, operating or repairing a torque

flange must have read and understood the mounting instructions and in

particular the technical safety instructions. The transducers can be damaged or

destroyed by non-designated use of the transducer or by non-compliance with

the mounting and operating instructions, these safety instructions or any other

HBM: Business Document

applicable safety regulations (safety and accident prevention regulations),

when using the transducers. Transducers can break, particularly in the case of

overloading. The breakage of a transducer can also cause damage to property or injury to persons in the vicinity of the transducer.

If the torque flange is not used according to the designated use, or if the

safety instructions or specifications in the mounting and operating instructions

are ignored, it is also possible that the transducer may fail or malfunction, with

the result that persons or property may be adversely affected (due to the

torques acting on or being monitored by the torque flange).

Conversions and modifications

The transducer must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall

exclude all liability on our part for any damage resulting therefrom.

Selling on

If the torque flange is sold on, these mounting instructions must be included

with the torque flange.

Qualified personnel

Qualified personnel means persons entrusted with siting, mounting, starting

up and operating the product, who possess the appropriate qualifications for

their function.

This includes people who meet at least one of the three following requirements:

- Knowledge of the safety concepts of automation technology is a

requirement and as project personnel, you must be familiar with these

concepts.

- As automation plant operating personnel, you have been instructed how to

handle the machinery. You are familiar with the operation of the equipment

and technologies described in this documentation.

- As commissioning engineers or service engineers, you have successfully

completed the training to qualify you to repair the automation systems. You

are also authorized to activate, ground and label circuits and equipment in

accordance with safety engineering standards.

HBM: Business Document

2 Markings used

2.1 Symbols on the transducer

Label example

Label example with FCC ID number,

1

Location of the label on the stator unit.

HBM: Business Document

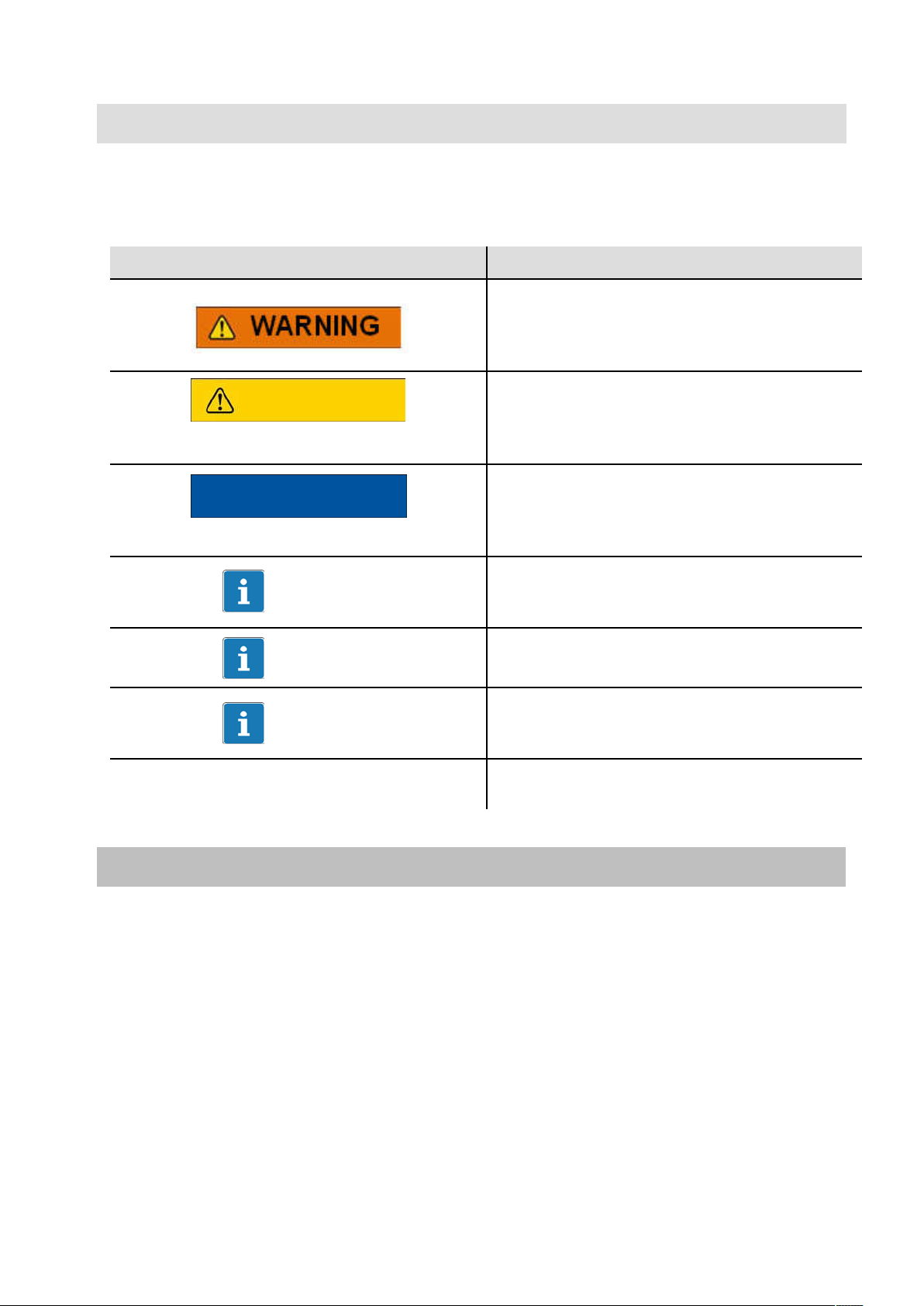

2.2 The markings used in this document

Important instructions for your safety are specifically identified. It is essential

to follow these instructions in order to prevent accidents and damage the

property.

Symbol Meaning

2

This marking warns of a potentially

dangerous situation in which failure to

comply with safety requirements can result

in death or serious physical injury.

This marking warns of a potentially

CAUTION

dangerous situation in which failure to

comply with safety requirements can result

in slight or moderate physical injury.

This marking draws your attention to a

NOTE

situation in which failure to comply with

safety requirements can lead to damage to

property.

This marking draws your attention to

important information about the product or

Important

about handling the product.

This marking indicates application tips or

Tip

other information that is useful to you.

This marking draws your attention to

information about the product or about

handling the product.

Emphasis

Italics are used to emphasize and highlight

texts.

3 Application

This transducer is designed only for the following machine:

GE Company – Gas Turbine Test Stand with coupling 9HA.02 according

request MPZ1701032

HBM: Business Document

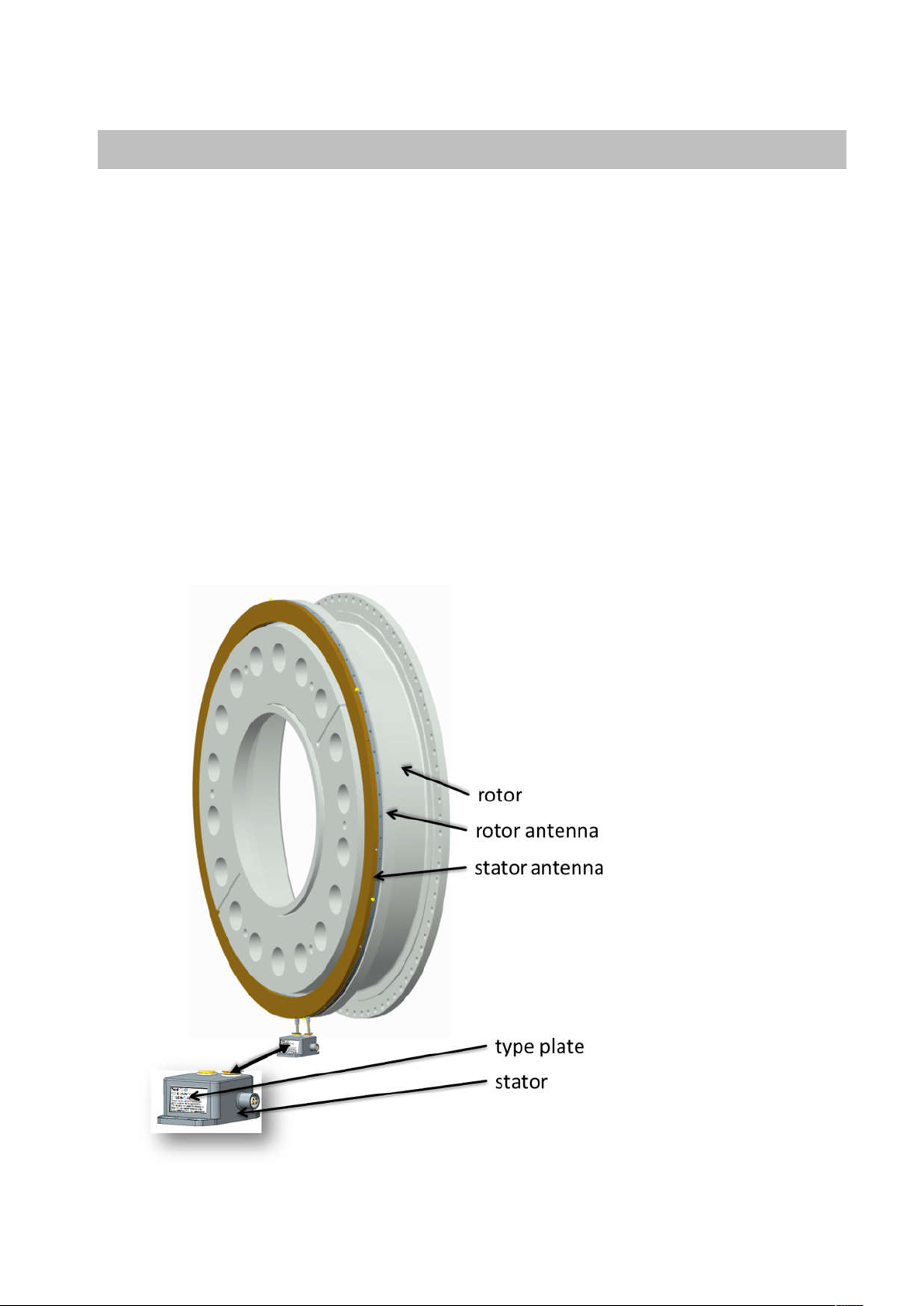

4 Structure and mode of operation

The torque flange consists of two separate parts: the rotor and the stator. The

rotor comprises the measuring body and the signal transmission elements.

Strain gauges (SGs) are installed on the measuring body. The rotor electronics for transmitting the bridge excitation voltage and the measurement signal

are located centrally in the flange. The transmitter coils for contactless transmission of excitation voltage and measurement signal are located on the

measuring body's outer circumference. The signals are sent and received by

a separable stator antenna. The antenna has to be mounted close to the rotor

antenna. The connection cable connects the stator antenna with the evaluation

unit which contains the electronics for voltage adaptation and the signal

conditioning.

Connector plugs for the torque signal and the voltage supply are located on

the evaluation unit. The stator antenna should be mounted tangential with

some gap to the rotor antenna (see chapter 5).

Fig 4.1: Mechanical construction in principle

3

HBM: Business Document

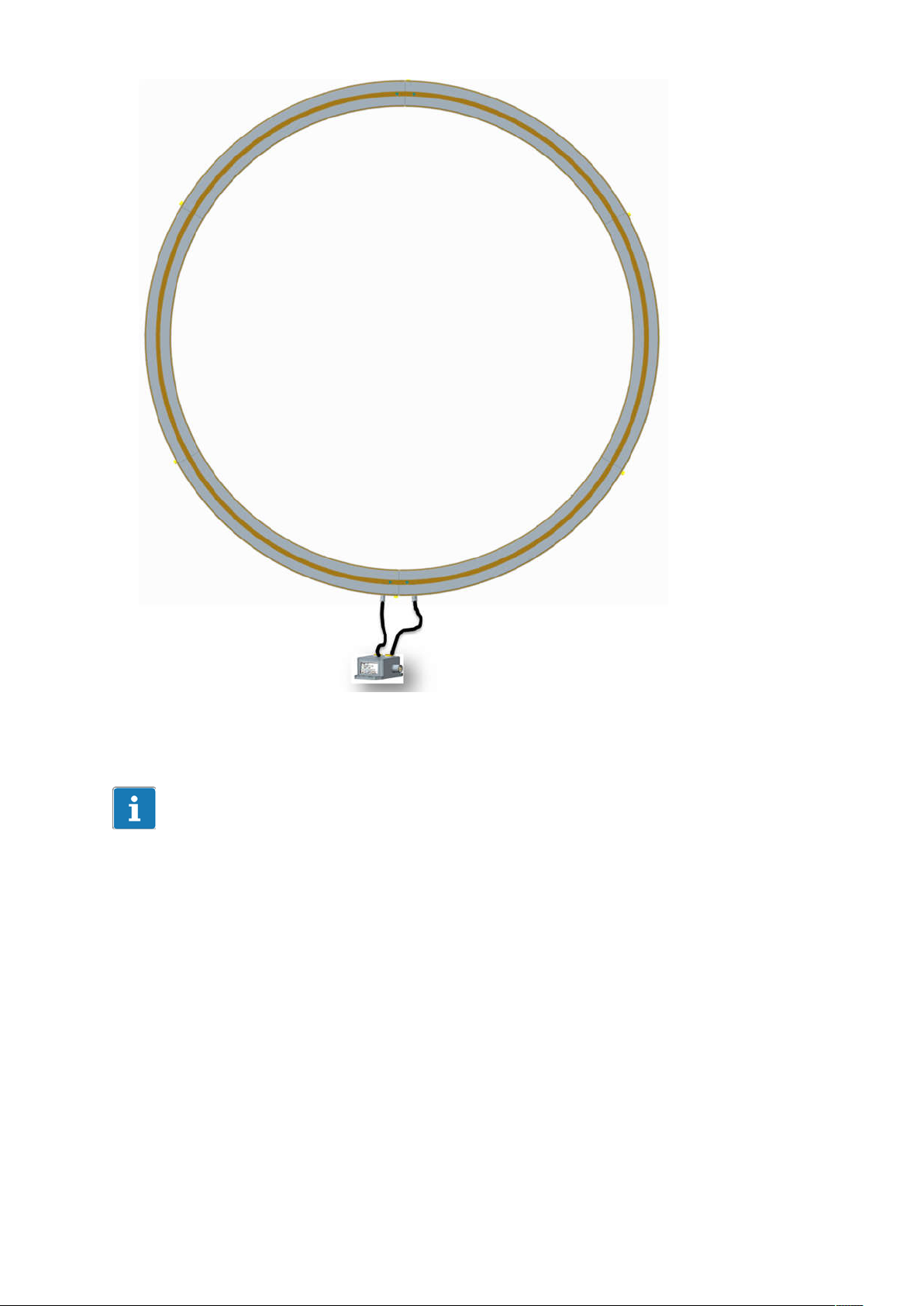

4

Fig 4.2: Mechanical construction of stator with mounted shielding

Important

The use of the shielding plates is important to ensure compliance with FCC

regulations. If the shielding plates has to be removed for any purpose (e.g.

installation or maintenance), they must be replaced in the original position

before the product is used.

HBM: Business Document

Loading...

Loading...